NISSAN ALMERA N15 1995 Service Manual

Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 361 of 1701

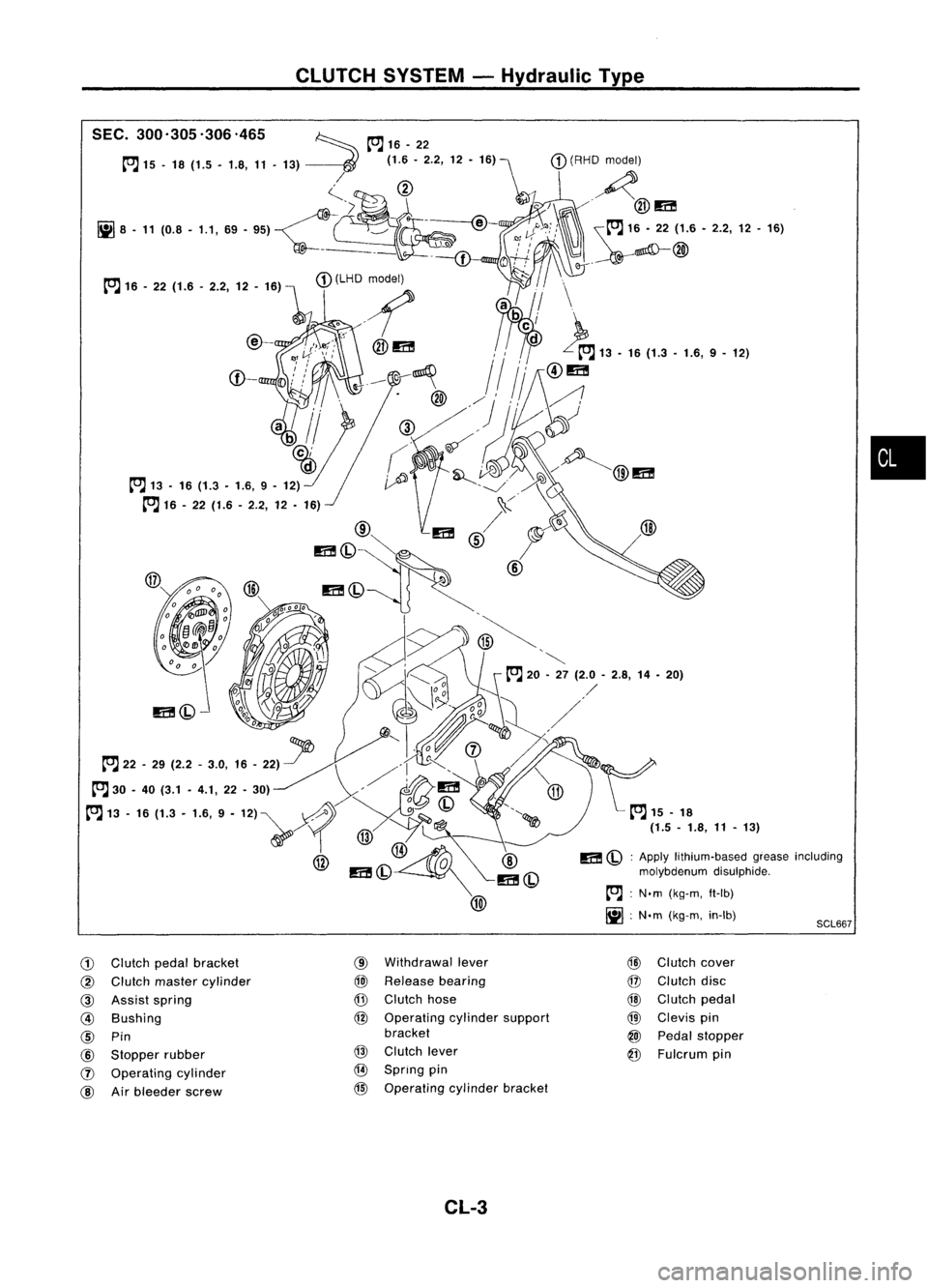

SCL667

CLUTCH

SYSTEM -Hydraulic Type

m

(bl:

Apply lithium-based greaseincluding

molybdenum disulphide.

~ :N.m (kg-m. ft-Ib)

~ :N.m (kg-m. in-Ib)

•

G)

Clutch pedalbracket

@

Clutch master cylinder

@

Assist spring

@

Bushing

@

Pin

@

Stopper rubber

(J)

Operating cylinder

@

Airbleeder screw

@

Withdrawal lever

@J

Release bearing

@

Clutch hose

@

Operating cylindersupport

bracket

@

Clutch lever

@

Spring pin

@ Operating cylinderbracket

CL-3 @

Clutch cover

@

Clutch disc

@

Clutch pedal

@

Clevis pin

@

Pedal stopper

@

Fulcrum pin

Page 362 of 1701

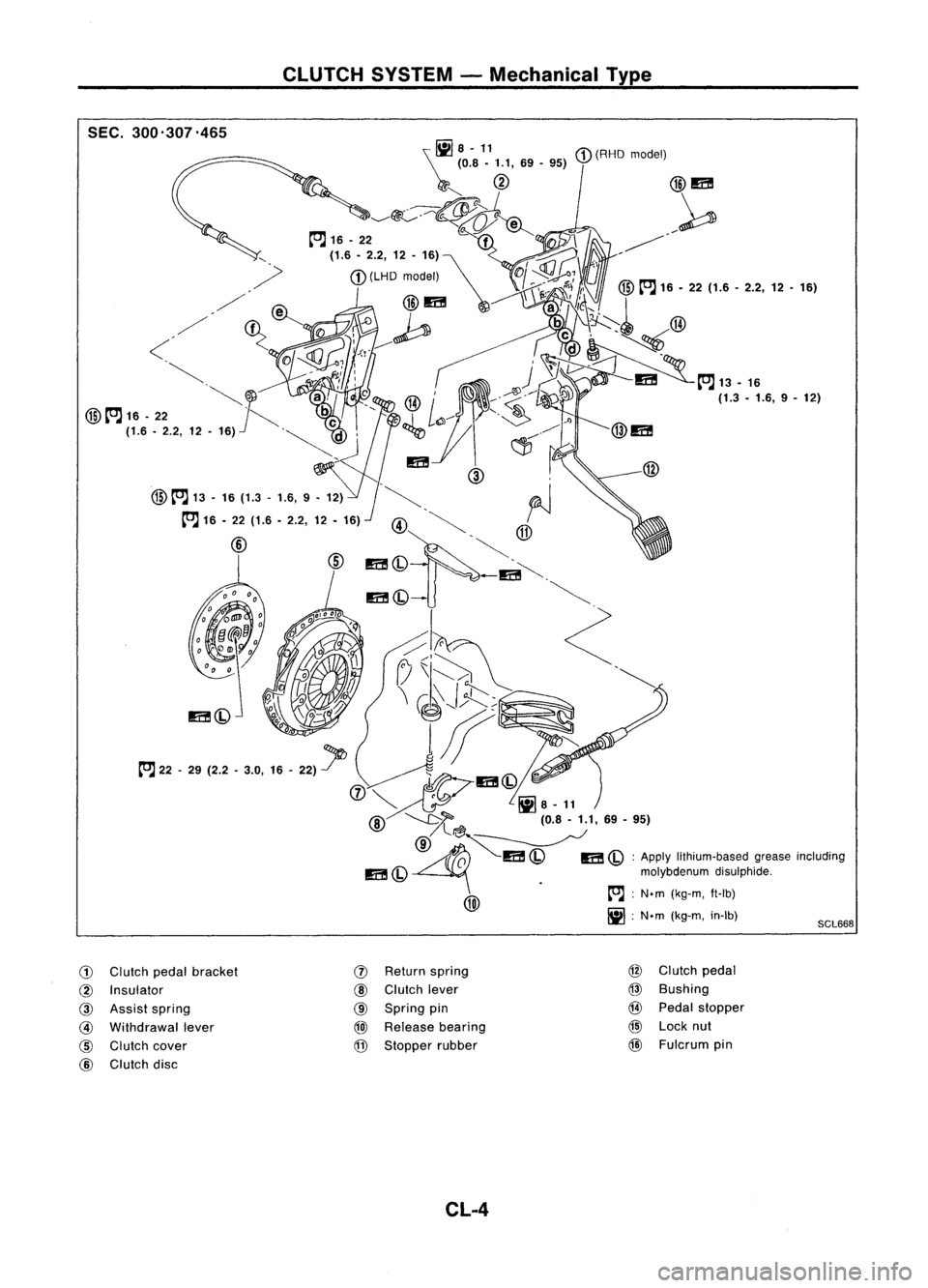

CLUTCHSYSTEM-Mechanical Type

SEC. 300'307.465

SCL668

\~

8-11

(0.8 -1.1, 69-95)

r""

@

@m

~~~ ~

/~

to.J 16-22

f

77'\

-j, ~'

, (1.6.2.2,12-16)~ ~

M-

.

Of~ ':,

,/ I

r';, ~~

I'

@

to.J 16•22 (1.6 -2.2, 12•16)

/ fA'l

@m~

a!',~~

I

,/' ~~ {l

,-0 ~

be\.\~':~ @

<

01Q'?0'J:l'e..------ ,

d~~

~;, 1

v,~

~, ~i,:

1r

J

~m

to.J13-16

c

I~..--.......

~JO

a,

',@/ :'~' ~ (1.3•1.6, 9-12)

@

to.J 16-22 ~

be c

_1

L~---- .~

.Jl

(1.6 -2.2, 12-16)

'~d' ~

C1J.~,

@m

'm (

@ ,

@

to.J 13-16 (1.3 •1.6, 9•12) .~. ~

I

to.J 16-22 (1.6 -2.2, 12-16)

@~ ~

@ ~~@

m(Q .

-m~.

m(Q ~

~h

<:

(7\I~ ~ .~

\ ~J;i::::;~

l"J" -

29 (2.2 -3.0,

1.-

22)1>

0~~

~ ¥:11)

@-..........t>'"l(0.8-1.1,69-95)

/l~~

~ ~I!C!

'001""00

m

(Q

molybdenumdisulphide.

Iiii\ .

[OJ;

N.m (kg-m, ft-lb)

~

IjJ;N'm (kg-m, in-Ib)

G)

Clutch pedalbracket

(1)

Return

spring @

Clutch pedal

@

Insulator

@

Clutch lever

@

Bushing

@

Assist spring

@

Spring pin

@

Pedal stopper

@

Withdrawal lever

@J

Release

bearing

@

Lock nut

@

Clutch cover

@

Stopper rubber

@

Fulcrum pin

@

Clutch disc

CL-4

Page 363 of 1701

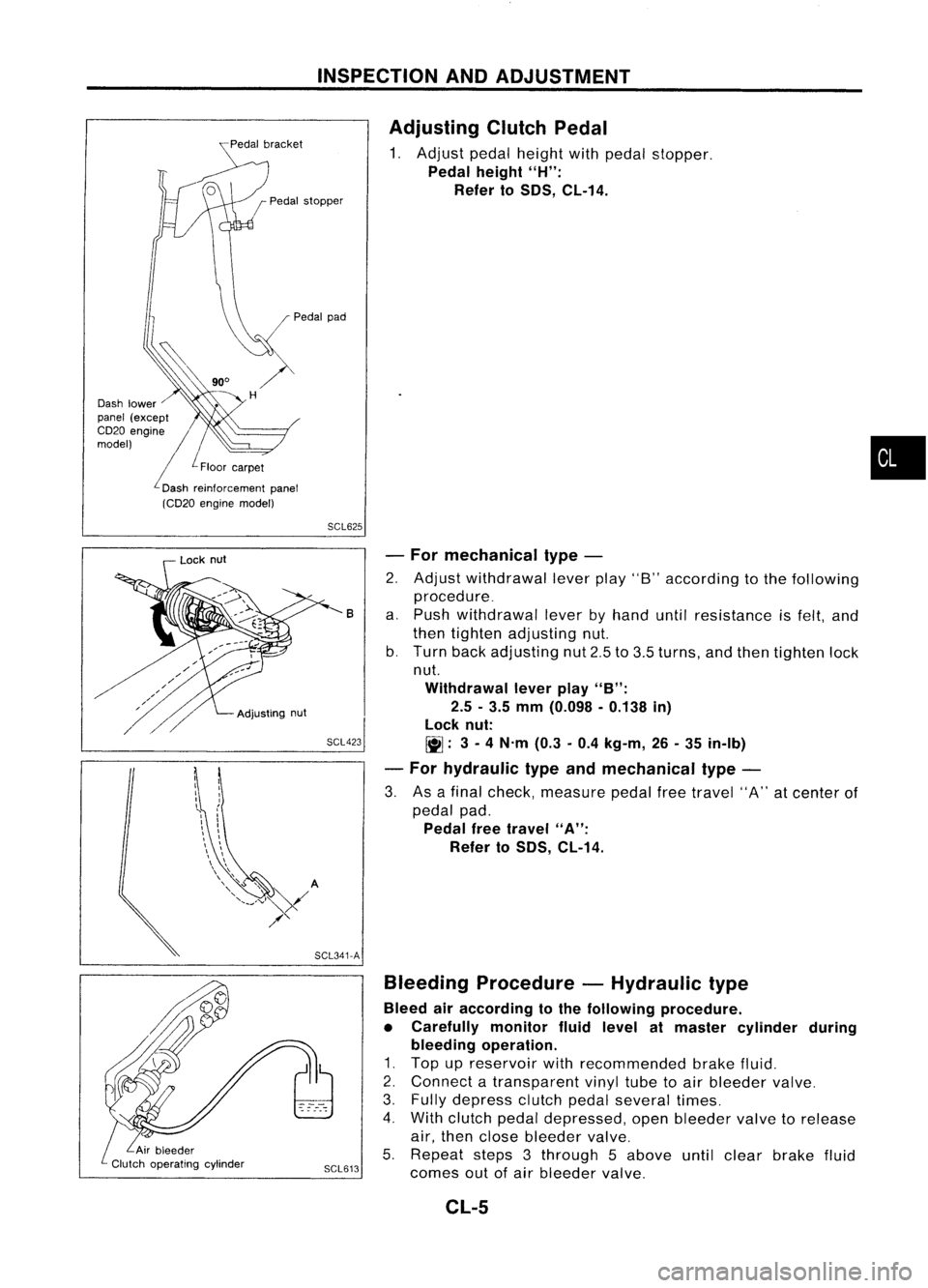

INSPECTIONANDADJUSTMENT

Pedal stopper

Dash lower

panel (except

CD20 engine //

model)

/L

Floor car-pet

L

Dash reinforcement panel

(CD20 engine model)

Adjusting

ClutchPedal

1. Adjust pedalheight withpedal stopper.

Pedal height

"H":

Refer to

50S,

CL-14.

•

SCL625

SCL423 -

For mechanical type-

2. Adjust withdrawal leverplay"8"according tothe following

procedure_

a. Push withdrawal leverbyhand untilresistance isfelt, and

then tighten adjusting nut.

b. Turn backadjusting nut2.5to3.5 turns, andthen tighten lock

nut.

Withdrawal leverplay

"B":

2.5 -3.5 mm (0.098 -0.138 in)

lock nut:

~: 3-

4 N'm (0.3-0.4 kg-m, 26-35 in-Ib)

- For hydraulic typeandmechanical type-

3. Asafinal check, measure pedalfreetravel "A"atcenter of

pedal pad.

Pedal freetravel

"A":

Refer to

50S,

CL-14.

B

Bleeding Procedure -Hydraulic type

Bleed airaccording tothe following procedure.

• Carefully monitorfluidlevel atmaster cylinder during

bleeding operation.

1. Top upreservoir withrecommended brakefluid.

2. Connect atransparent vinyltubetoair bleeder valve.

3. Fully depress clutchpedalseveral times.

4. With clutch pedaldepressed, openbleeder valvetorelease

air, then close bleeder valve.

5. Repeat steps3through 5above untilclear brake fluid

SCL613

comesoutofair bleeder valve.

SCL341-A

Adjusting

nut

Lock

nut

CL-5

Page 364 of 1701

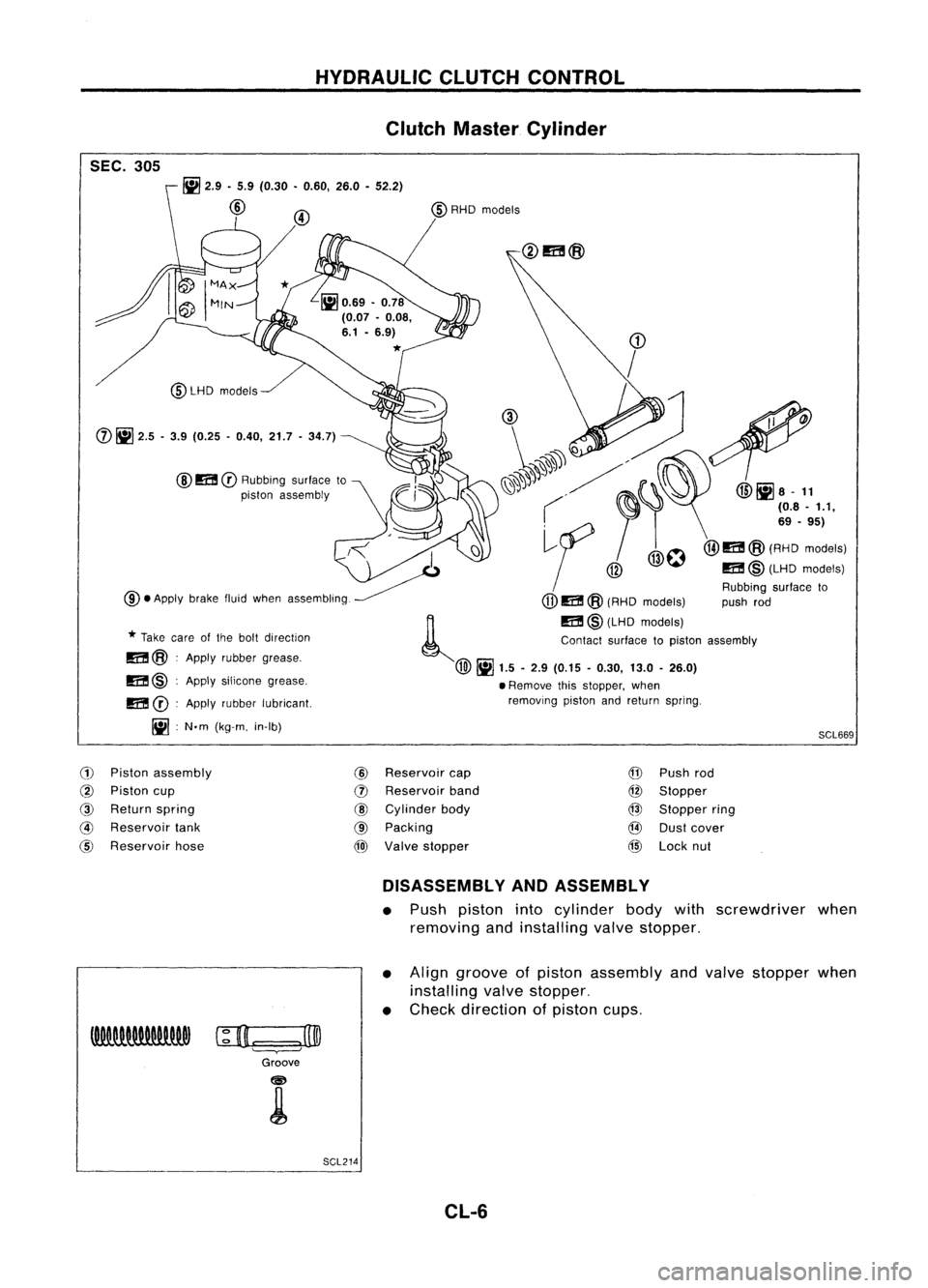

HYDRAULICCLUTCHCONTROL

Clutch Master Cylinder

SEC. 305

SCL669

~

2.9 •5.9 (0.30 •0.60, 26.0•52.2)

@

@

m

CD

Rubbing surfaceto

piston assembly

@LHD

models

m @:Apply silicone grease,

m

CD:

Apply rubber lubricant.

Iil :

N.m (kg-m. in-Ib)

CD

/

(1), ~

1'.

~'. ~". @liJa-

11

( ~I'

(08.'.1,

,<

I

~f

/@O@I1I!@(A':o'::"'1

~ @

m@(LHDmodels)

Rubbing surfaceto

@.

Apply brakefluidwhen assembling.

(jJ)

m @(RHD models) pushrod

~ m@(LHD models)

*

Take careofthe bolt direction Contactsurfacetopiston assembly

m@ :Apply rubber grease.

@~

1.5-2.9 (0.15 -0.30, 13.0-26.0)

• Remove thisstopper, when

removing pistonandreturn spring.

(j)

~

2.5 -3.9 (0.25 -0.40, 21.7-34.7)

(1)

Piston assembly

@

Reservoir

cap

@

Piston cup

(])

Reservoir

band

@

Return spring

@

Cylinder body

@

Reservoir

tank

@

Packing

@

Reservoir hose

@)

Valve stopper

@

Push rod

@

Stopper

@

Stopper ring

@

Dustcover

@

Lock nut

DISASSEMBLY ANDASSEMBLY

• Push piston intocylinder bodywithscrewdriver when

removing andinstalling valvestopper.

• Align groove ofpiston assembly andvalve stopper when

installing valvestopper.

• Check direction ofpiston cups.

c;D.=:

=.J3@

Groove

SCL214 CL-6

Page 365 of 1701

HYDRAULICCLUTCHCONTROL

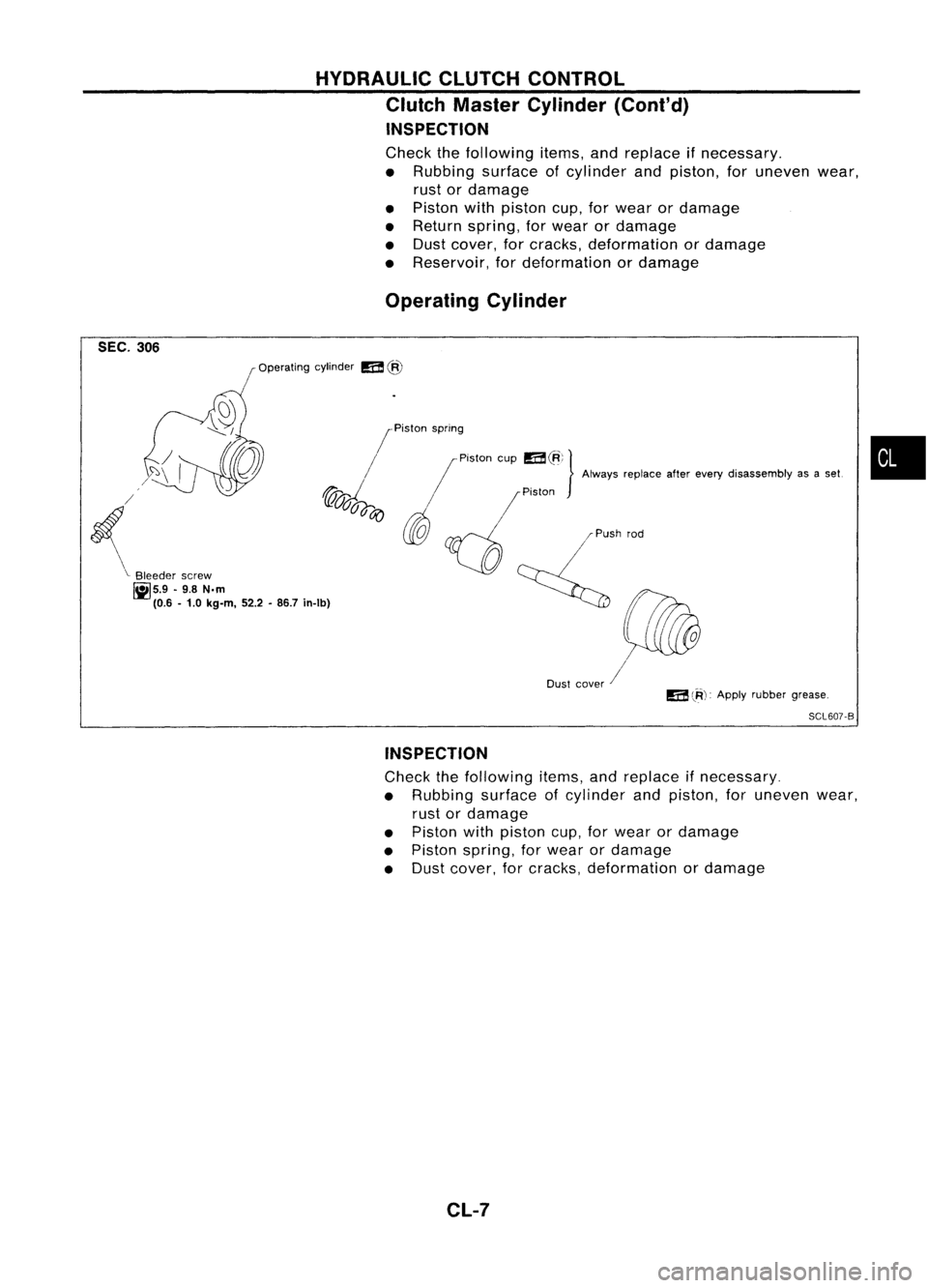

Clutch Master Cylinder (Cont'd)

INSPECTION

Check thefollowing items,andreplace ifnecessary.

• Rubbing surfaceofcylinder andpiston, foruneven wear,

rust ordamage

• Piston withpiston cup,forwear ordamage

• Return spring, forwear ordamage

• Dust cover, forcracks, deformation ordamage

• Reservoir, fordeformation ordamage

Operating Cylinder

SEC. 306

Operatingcylinder

m

@

•

/

Piston spring ,

/ I

Piston cup

m~;}

Alwaysreplace afterevery disassembly asaset.

~d /

/Piston

~ti)

d

~ Q

~,""d

(il@

Dust cover /

J

7:\

I

{

'c

Bleeder screw

IiIS.9 -9.8 N.m .

(0.6 -1.0 kg-m, 52.2-86.7 In-Ib)

m

lR):

Apply rubber grease.

SCL607-B

INSPECTION

Check thefollowing items,andreplace ifnecessary.

• Rubbing surfaceofcylinder andpiston, foruneven wear,

rust ordamage

• Piston withpiston cup,forwear ordamage

• Piston spring, forwear ordamage

• Dust cover, forcracks, deformation ordamage

CL-7

Page 366 of 1701

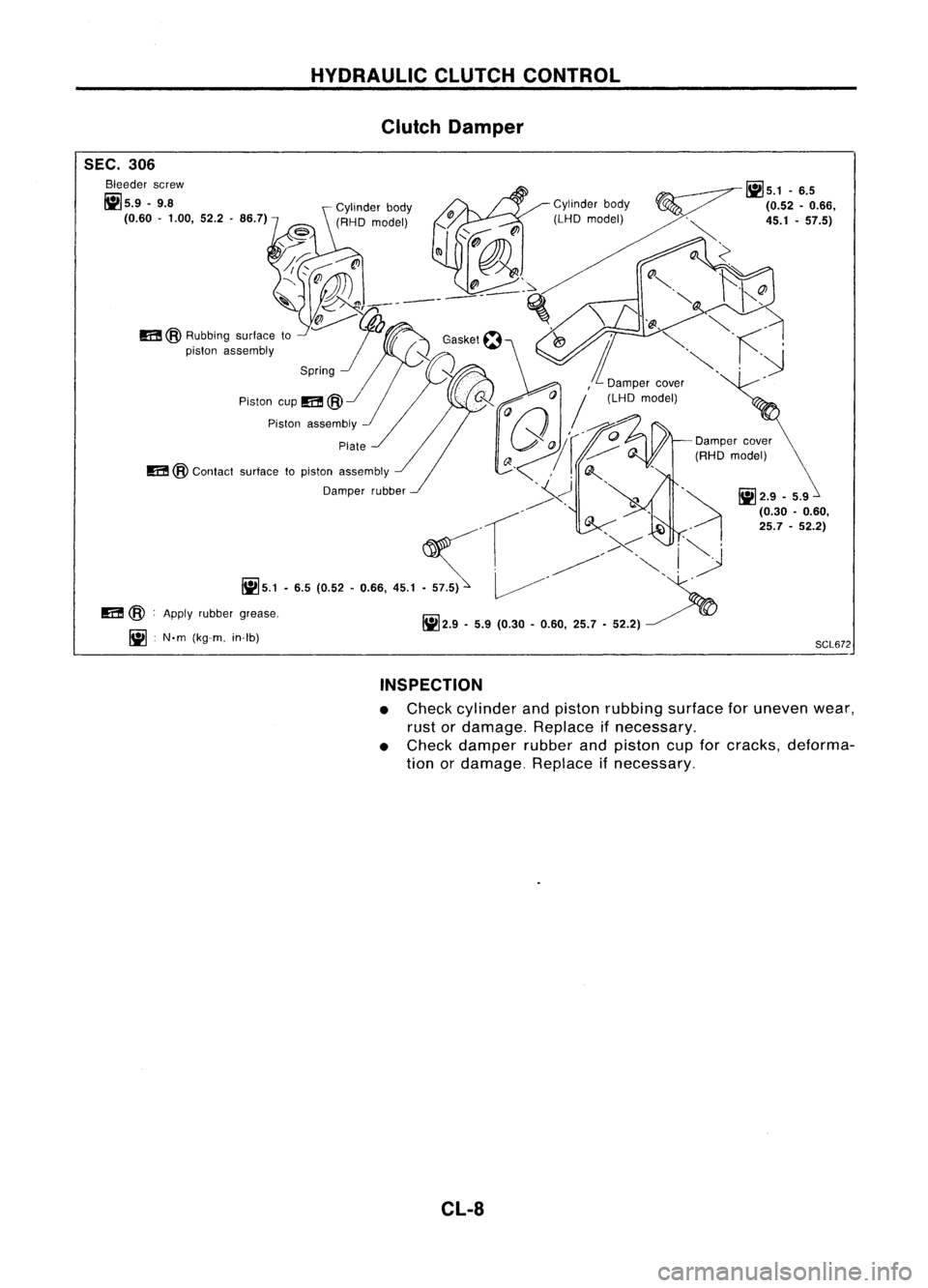

HYDRAULICCLUTCHCONTROL

Clutch Damper

SEC. 306

Bleeder screw

1i15.9 -9.8

(0.60 -1.00, 52.2.86.7)

m

@Rubbing surfaceto

piston assembly

Piston cup

m

@

J'

Piston assembly

m

@

Contact surfacetopiston assembly

Damper rubber~

m

@:Apply rubber grease.

II] :N'm (kg-m. in-Ib) Cylinder

body

(LHD model)

11]5.1

-6.5

(0.52 -0.66,

45.1 -57.5)

- Damper cover

(RHD model)

II]

2.9 -5.9

(0.30 -0.60,

25.7 -52.2)

SCL672

INSPECTION

• Check cylinder andpiston rubbing surfaceforuneven wear,

rust ordamage. Replaceifnecessary.

• Check damper rubberandpiston cupforcracks, deforma-

tion ordamage. Replaceifnecessary.

CL-8

Page 367 of 1701

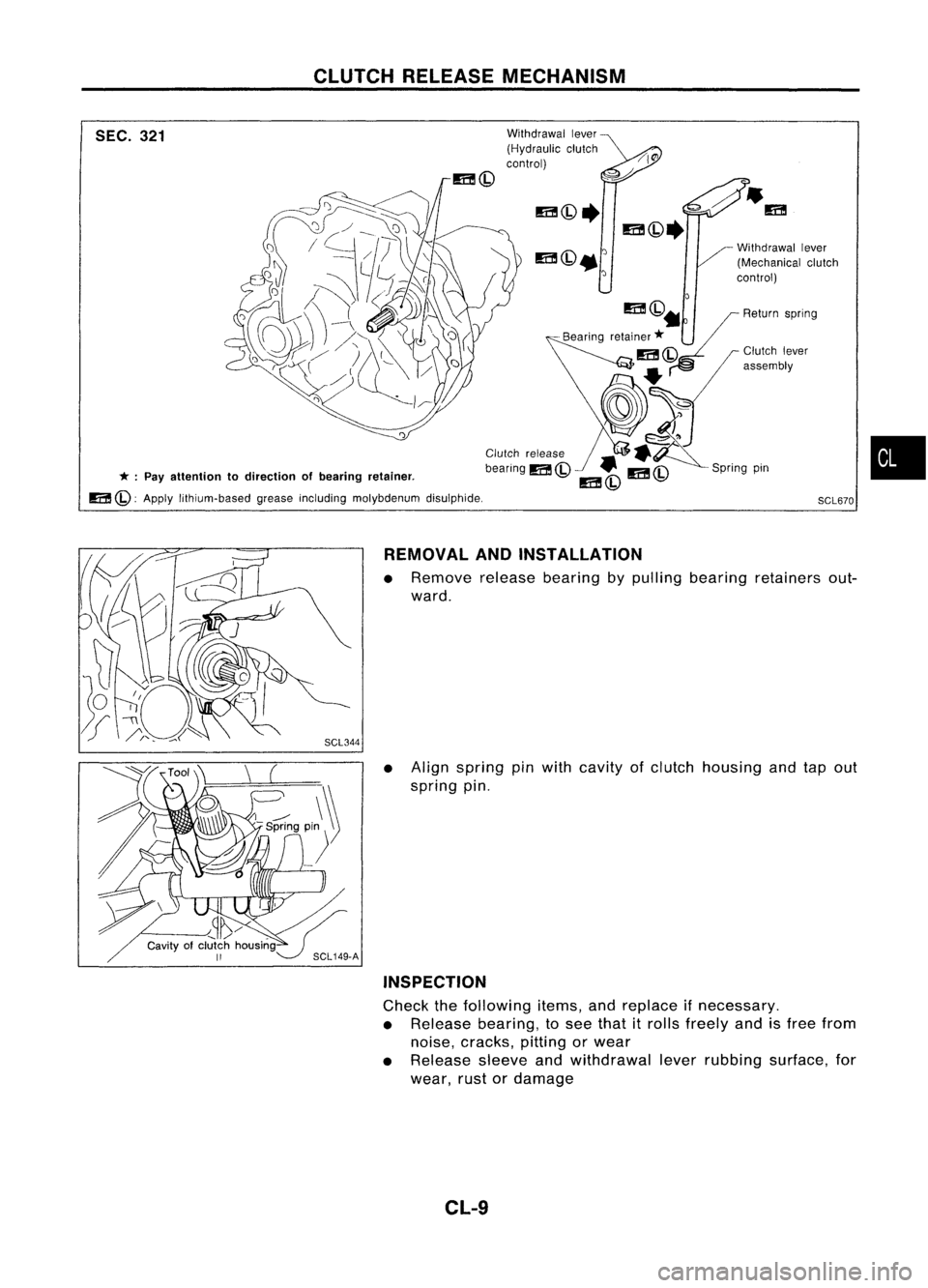

CLUTCHRELEASE MECHANISM

SEC. 321

* :

Pay attention todirection ofbearing retainer.

m

(Q: Apply lithium-based greaseincluding molybdenum disulphide. Withdrawal

lever

(Hydraulic clutch

control)

Springpin

SCL670

•

REMOVAL ANDINSTAllATION

• Remove releasebearing bypulling bearing retainers out-

ward.

• Align spring pinwith cavity ofclutch housing andtapout

spring pin.

INSPECTION

Check thefollowing items,andreplace ifnecessary.

• Release bearing, tosee that itrolls freely andisfree from

noise, cracks, pittingorwear

• Release sleeveandwithdrawal leverrubbing surface, for

wear, rustordamage

CL-9

Page 368 of 1701

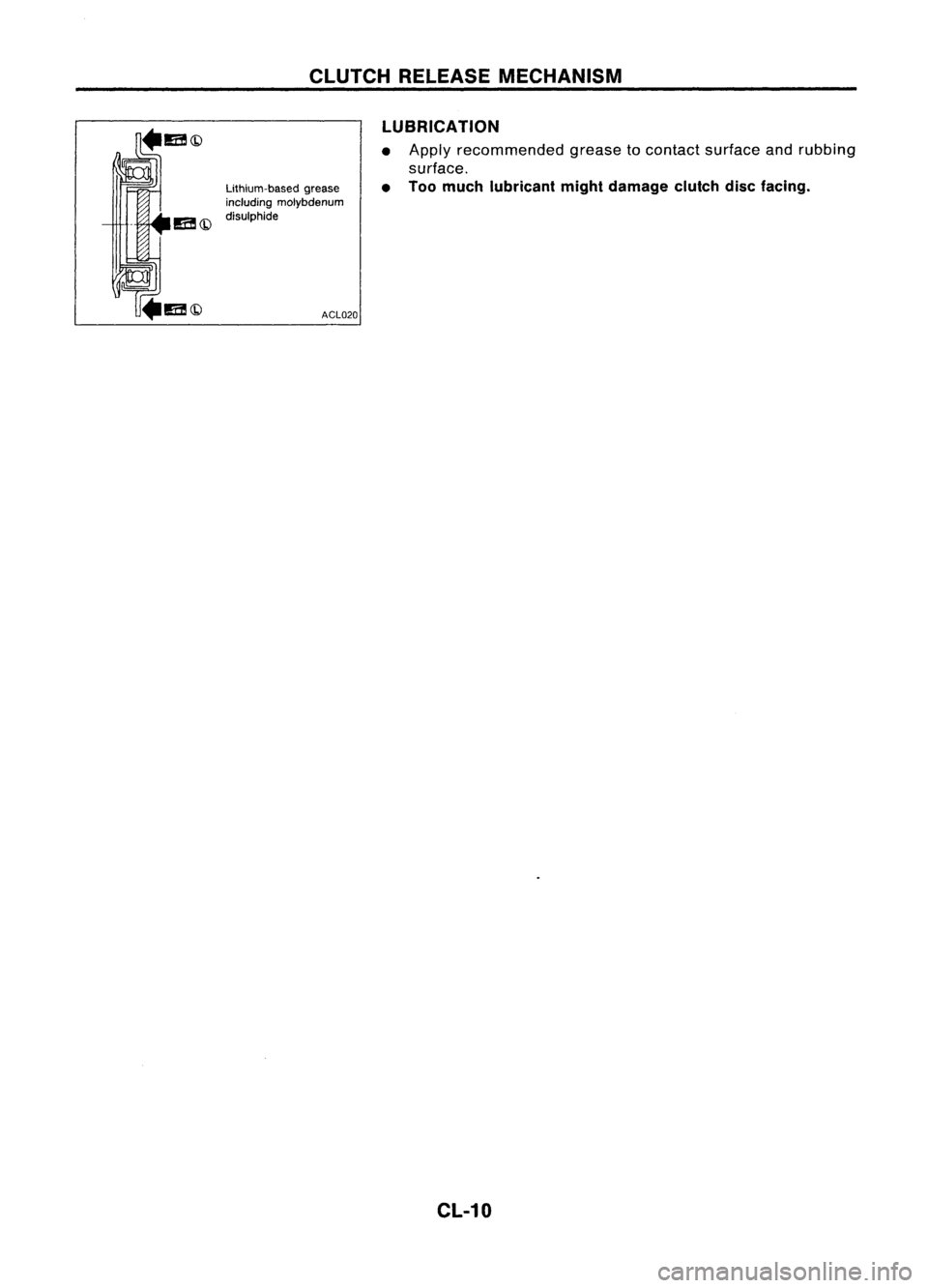

CLUTCHRELEASE MECHANISM

LUBRICATION

Lithium-based grease

including molybdenum

disulphide

ACL020•

•

Apply

recommended greasetocontact surface andrubbing

surface.

Too much lubricant mightdamage clutchdiscfacing.

CL-10

Page 369 of 1701

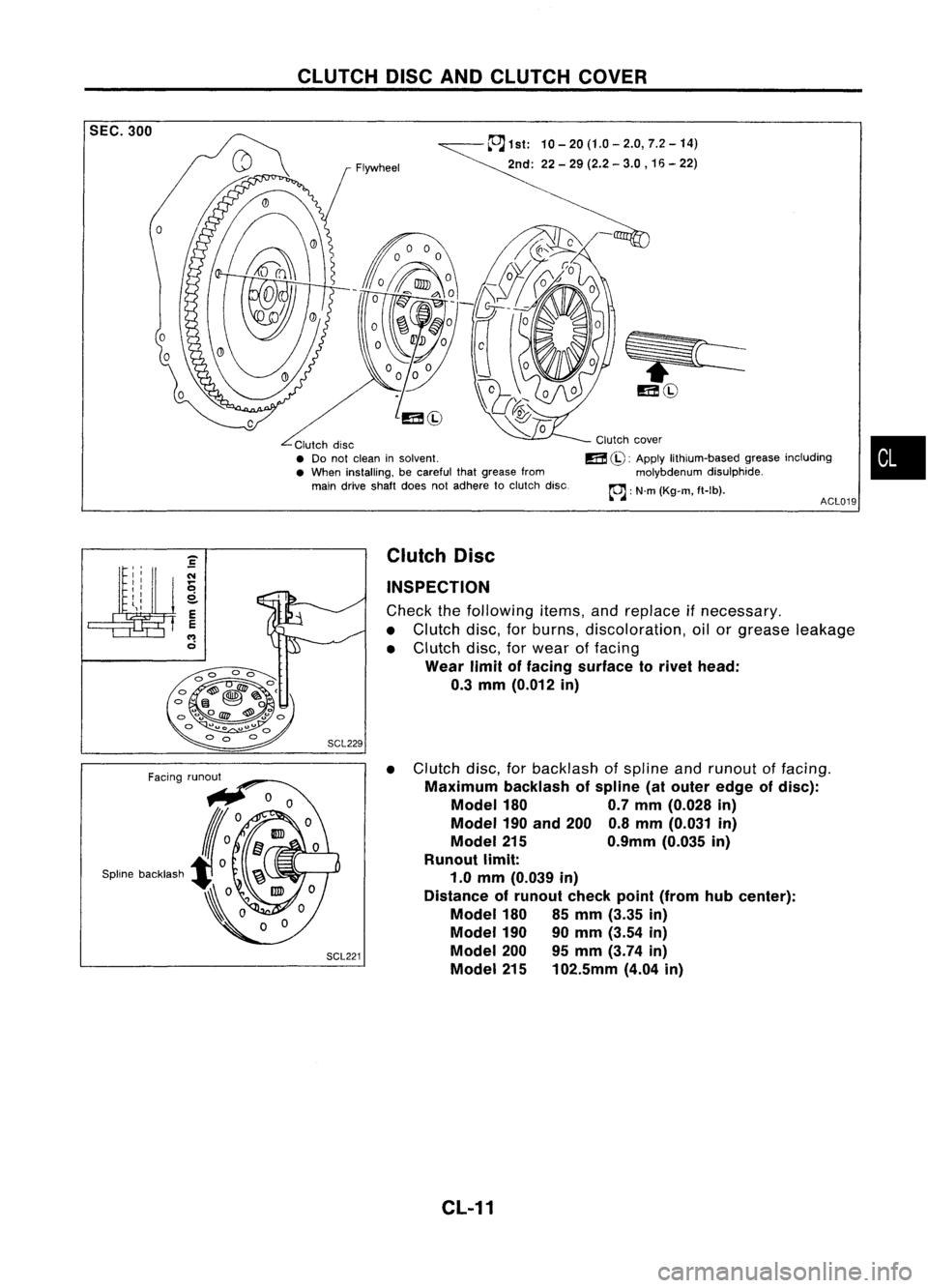

CLUTCHDISCANDCLUTCH COVER

~1st: 10-20(1.0-2.0,7.2-14)

2nd: 22-29 (2.2 -3.0 ,16 -22)

ACL019

SEC.

300

o

Clutchdisc

• Do not clean insolvent.

• When installing, becareful thatgrease from

main drive shaft doesnotadhere toclutch disc. Clutch

cover

m

(iJ:

Apply lithium-based greaseincluding

molybdenum disulphide.

~ :N'm (Kg-m, ft-Ib).

•

SCL221 Clutch

Disc

INSPECTION

Check thefollowing items,andreplace ifnecessary.

• Clutch disc,forburns, discoloration, oilorgrease leakage

• Clutch disc,forwear offacing

Wear limitoffacing surface torivet head:

0.3 mm (0.012 in)

• Clutch disc,forbacklash ofspline andrunout offacing.

Maximum backlashofspline (atouter edgeofdisc):

Model 180 0.7mm (0.028 in)

Model 190

and 200 0.8mm (0.031 in)

Model 215 0.9mm(0.035in)

Runout limit:

1.0 mm (0.039 in)

Distance ofrunout checkpoint(from hubcenter):

Model 180

85mm (3.35 in)

Model 190

90mm (3.54 in)

Model 200

95mm (3.74 in)

Model 215102.5mm (4.04in)

CL-11

Page 370 of 1701

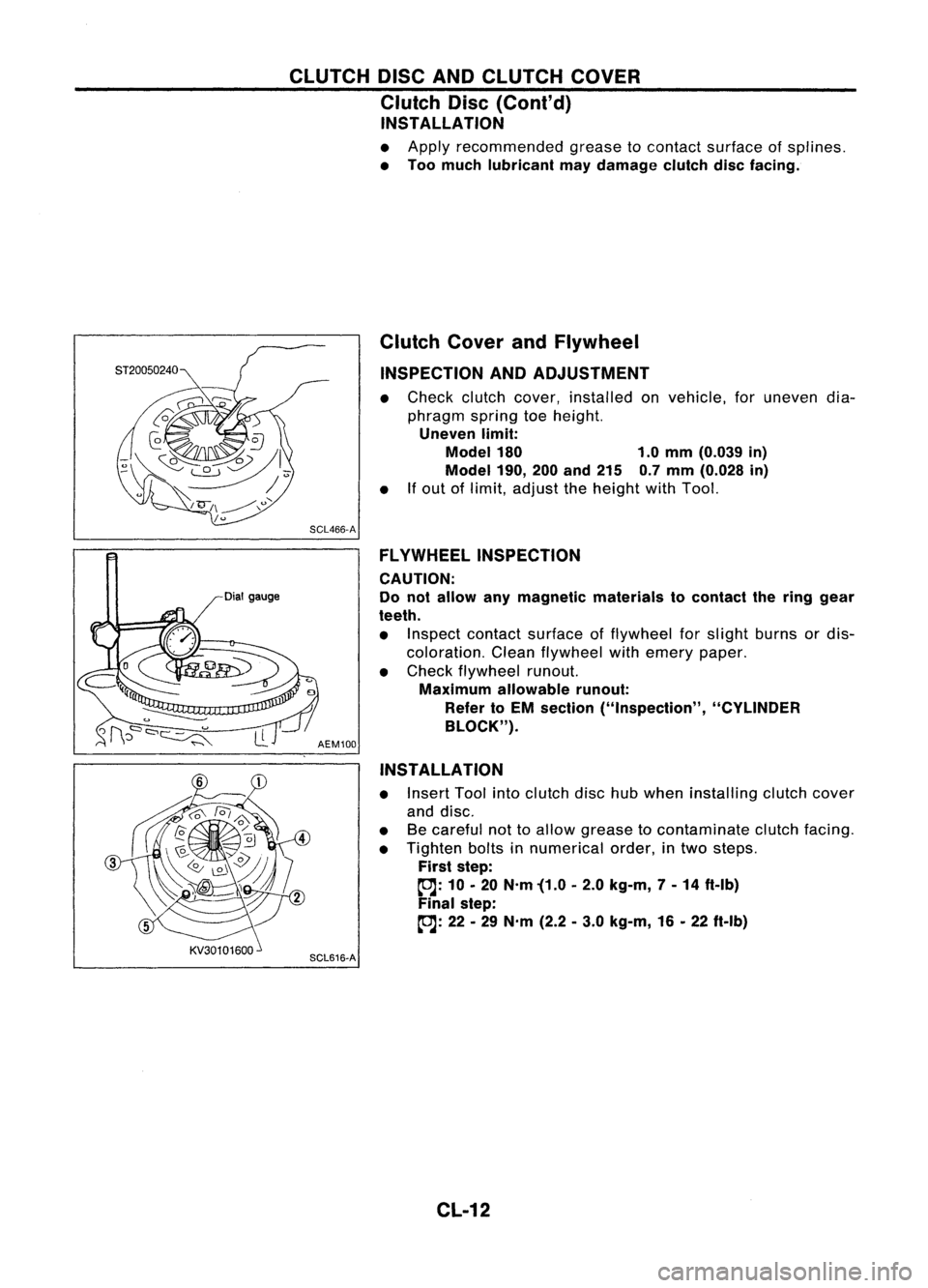

CLUTCHDISCANDCLUTCH COVER

Clutch Disc(Cont'd)

INSTALLATION

• Apply recommended greasetocontact surface ofsplines.

• Too much lubricant maydamage clutchdiscfacing.

Dial gauge Clutch

CoverandFlywheel

INSPECTION ANDADJUSTMENT

• Check clutchcover, installed onvehicle, foruneven dia-

phragm springtoeheight.

Uneven limit:

Model 180 1.0mm (0.039 in)

Model 190,

200and 215 0.7mm (0.028 in)

• Ifout oflimit, adjust theheight withTool.

SCL466-A FLYWHEEL INSPECTION

CAUTION:

Do not allow anymagnetic materials tocontact thering gear

teeth.

• Inspect contact surface offlywheel forslight burns ordis-

coloration. Cleanflywheel withemery paper.

• Check flywheel runout.

Maximum allowable runout:

Refer toEM section ("Inspection", "CYLINDER

BLOCK").

AEM100

INSTALLATION

• Insert Toolintoclutch dischubwhen installing clutchcover

and disc.

• Becareful nottoallow grease tocontaminate clutchfacing.

• Tighten boltsinnumerical order,intwo steps.

First step:

~: 10•20 N'm '(1.0 •2.0 kg-m, 7-14 ft-Ib)

Final step:

~: 22•29 N'm (2.2•3.0 kg-m, 16•22 ft-Ib)

SCL616-A

CL-12