NISSAN ALMERA N15 1995 Service Manual

Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 401 of 1701

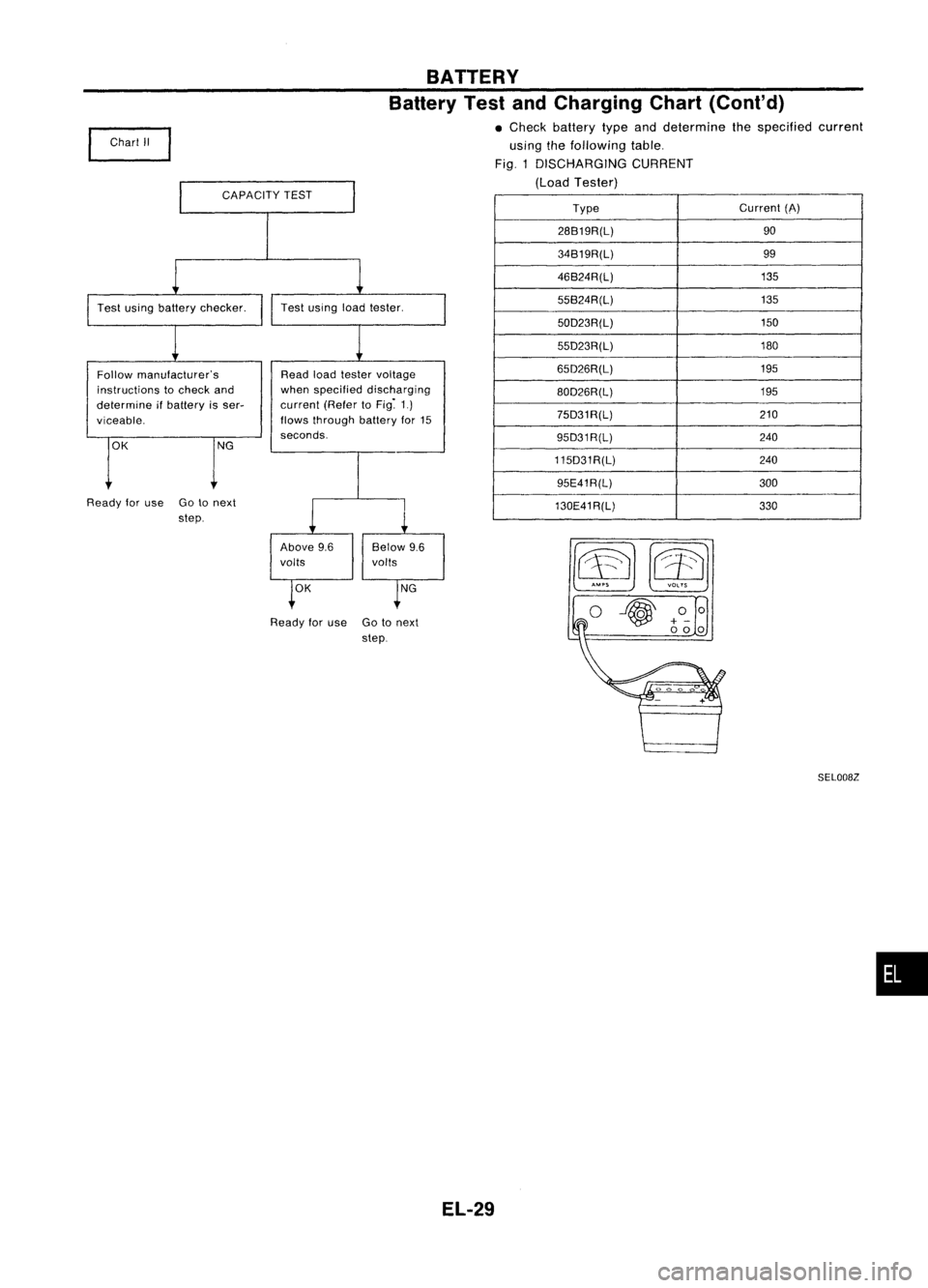

CAPACITYTEST BATTERY

Battery TestandCharging Chart(Cont'd)

• Check battery typeanddetermine thespecified current

using thefollowing table.

Fig. 1DISCHARGING CURRENT

(Load Tester)

~m o~

Type

Current

(A)

28B19R(L) 90

34B19R(L) 99

46B24R(L) 135

55B24R(L) 135

50D23R(L) 150

55D23R(L) 180

65D26R(L) 195

80D26R(L) 195

75D31R(L) 210

95D31R(L) 240

115D31R(L) 240

95E41R(L) 300

130E41R(L) 330

Test

using loadtester.

OK NG

Read

loadtester voltage

when specified discharging

current (RefertoFig~ 1.)

flows through batteryfor15

seconds.

Above 9.6 Below9.6

volts volts

Ready foruse Gotonext

step.

Chart

II

OK NG

Follow

manufacturer's

instructions tocheck and

determine ifbattery isser-

viceable,

Ready foruse Gotonext

step.

SEL008Z

•

EL-29

Page 402 of 1701

BATTERY

Battery TestandCharging Chart(Cont'd)

I

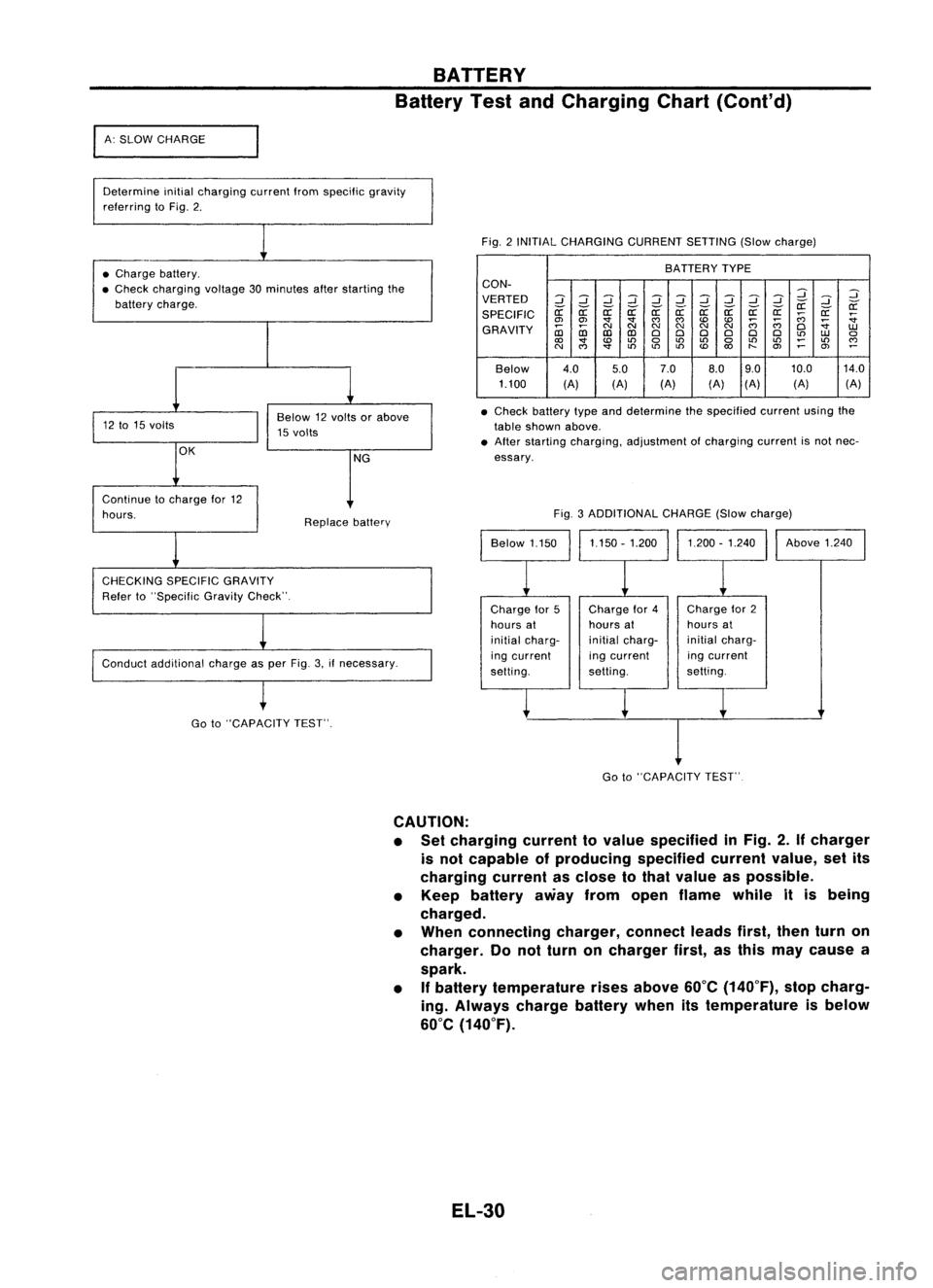

A: SLOW CHARGE

Determine initialcharging currentIromspecilic gravity

relerring toFig. 2.

Fig.2INITIAL CHARGING CURRENTSETTING(Slowcharge)

• Charge battery.

• Check charging voltage30minutes afterstarting the

battery charge. BATTERY

TYPE

CON-

VERTED

2

::J

2

::J

::J

2

::J

2

::J

::J

2

2

::J

if ifif if if

r:r:

if

SPECIFIC

r:r:

r:r: r:r:r:r:r:r:

;;;

r:r:

:;

en en

'

""""

;;;;;;

:;

GRAVITY

~

NNN

NN

N

0

1.U

CD CDCDCD

000 000

to

1.U

0

<0

'

0

to

LO

0

LOLO

~

LO

""

N

""

'

toto

LO

<0

"-

en

~

en

~

Below 4.0

5.07.0

8.09.0 10.0

14.0

1.100 (A)(A)(A) (A)(A)

(A) (A)

• Check battery typeanddetermine thespecified currentusingthe

table shown above.

• After starting charging, adjustment ofcharging currentisnot nec-

essary.

Conduct additional chargeasper Fig. 3.ifnecessary. Fig.

3ADDITIONAL CHARGE(Slowcharge)

Continue

tocharge lor12

hours.

CHECKING SPECIFICGRAVITY

Reier to"Specilic GravityCheck". Replace

battery

Chargefor5

hours at

initial charg-

ing current

selting. Charge

lor4

hours at

initial charg-

ing current

setting. Charge

lor2

hours at

initial charg-

ing current

setting. Above

1.240

Go to"CAPACITY TEST".

I

Go to"CAPACITY TEST"

CAUTION:

• Set charging currenttovalue specified inFig. 2.

If

charger

is not capable ofproducing specifiedcurrentvalue,setits

charging currentasclose tothat value aspossible.

• Keep battery awayfromopen flame whileitis being

charged.

• When connecting charger,connectleadsfirst,thenturnon

charger. Donot turn oncharger first,asthis may cause a

spark.

• If

battery temperature risesabove 60°C(140°F), stopcharg-

ing. Always chargebatterywhenitstemperature isbelow

60°C (140°F).

EL-30

Page 403 of 1701

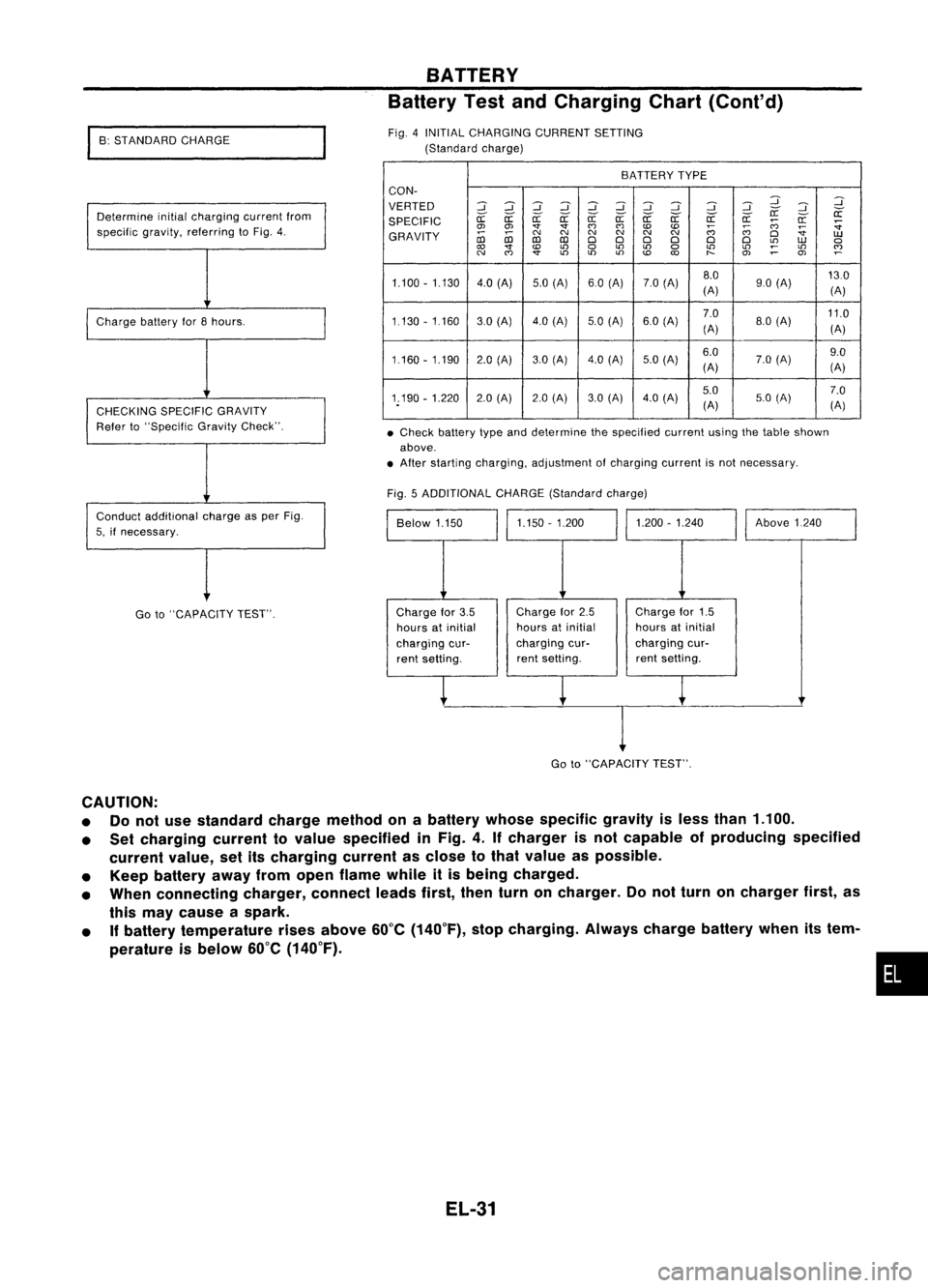

•Check battery typeanddetermine thespecified currentusingthetable shown

above .

• After starting charging, adjustment ofcharging currentisnot necessary.

BATTERY

Battery TestandCharging Chart(Cont'd)

BATTERY TYPE

CON-

VERTED

::J::J

~::J

::J

::J::J ::J ::J

::J

:J

:J

~

SPECIFIC

er:-

er:-

a:

er:-er:- er:-er:- er:- er:- er:-er:-

a:

;:;:;

a:

:;

0> 0> '1"'1"

(')

(')

to to

;:;:;

~

:;

GRAVITY

coco

C'J

C'J C'J

C'JC'J

C'J

(')

D

UJ

co co

DDD D D

D

L!)

UJ

a

to

L!)

a

L!)

L!)

a

L!)

L!)

~

L!)

~

C'J

(')

'1"

L!)

L!)L!)

to

O>

~

OJ

1.100 -1.130 4.0(A) 5.0(A) 60(A) 7.0(A) 8.0

130

(A) 90

(A)

(A)

1.130 -1160 30(Al 4.0(Al 5.0

(A) 6.0(A) 7.0

11.0

(A) 8.0

(A)

(A)

1.160 -1.190 2.0(A) 3.0(Al 4.0

(A)

5.0(Al 6.0

7.0(A) 9.0

(A) (A)

1.190 -1.220 2.0(A) 2.0(A) 3.0(A) 4.0

(A) 5.0

7.0

(A) 5.0

(A)

(A)

Fig. 5ADDITIONAL CHARGE(Standard charge)

Above1240

1.200 -1.240

1.150 -1.200

Below 1.150

Fig.

4INITIAL CHARGING CURRENTSETTING

(Standard charge)

Determine initialcharging currentfrom

specific gravity,referring toFig. 4.

Charge batteryfor8hours.

CHECKING SPECIFICGRAVITY

Refer to"Specific GravityCheck".

Conduct additional chargeasper Fig.

5, ifnecessary.

I

B: STANDARD CHARGE

Go to"CAPACITY TEST". Charge

for3.5

hours atinitial

charging cur-

rent setting. Charge

for2.5

hours atinitial

charging cur-

rent setting. Charge

for1.5

hours atinitial

charging cur-

rent setting.

I

Go to"CAPACITY TEST".

CAUTION:

• Donot use standard chargemethod onabattery whosespecific gravityisless than 1.100.

• Set charging currenttovalue specified inFig. 4.Ifcharger isnot capable ofproducing specified

current value,setitscharging currentasclose tothat value aspossible.

• Keep battery awayfromopen flame whileitis being charged.

• When connecting charger,connectleadsfirst,thenturnoncharger. Donot turn oncharger first,as

this may cause aspark.

• Ifbattery temperature risesabove 60°C(140°F), stopcharging. Alwayschargebatterywhenitstem-

perature isbelow 60°C(140°F).

•

EL-31

Page 404 of 1701

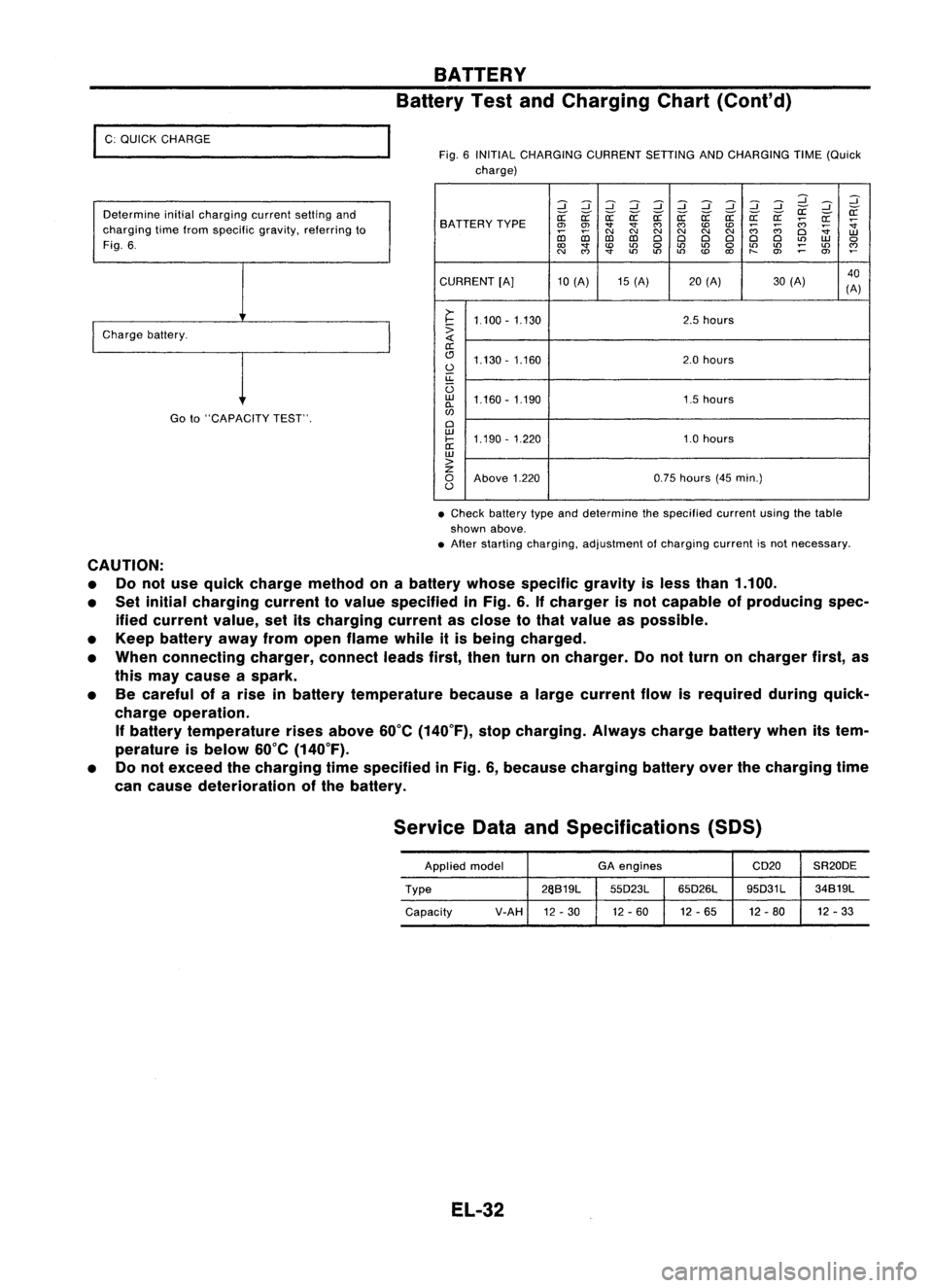

I

C: QUICK CHARGE

Determine initialcharging currentsettingand

charging timefrom specific gravity,referring to

Fig. 6.

I

Charge battery.

Goto"CAPACITY TEST".

BATTERY

Battery TestandCharging Chart(Cont'd)

Fig. 6INITIAL CHARGING CURRENTSETTINGANDCHARGING TIME(Quick

charge)

:::J:::J:::J:::J :::J:::J:::J

d dd

:::J

:::J :::J

~ ~

SA TTERY TYPE

~

~ ~~~~ ~a: a:a:

;;:;

~

~

0>

0>

""

""

C')

C')

CDCD

;;:;

;;:;

~

co co

C\I

N

C\I

N

C\I

N

Cl

W

D:l D:l

ClCl ClCl ClCl

L()

W

0

to

""

CD

L()

0

L()

L()

0

L()

L()

;:

L()

~

N

C')

""

L()

L()L()

CD

to

t-

O>

0>

CURRENT [A]10(A) 15(A) 20(A) 30(A) 40

(A)

>-

I-

1.100 -1.130 2.5

hours

:>

a:

(!J 1.130 -1.160 2.0

hours

0

u::

U

w

1.160 -1.190 1.5hours

0-

w

Cl

w

1.190 -1.220 1.0hours

I-

a:

w

>

z

0

Above 1.220 0.75

hours (45min.)

0

• Check battery typeanddetermine thespecified currentusingthetable

shown above.

• After starting charging, adjustment ofcharging currentisnot necessary.

CAUTION: • Donot use quick charge method onabattery whosespecific gravityisless than 1.100.

• Set initial charging currenttovalue specified inFig. 6.Ifcharger isnot capable ofproducing spec-

ified current value,setitscharging currentasclose tothat value aspossible.

• Keep battery awayfromopen flame whileitis being charged.

• When connecting charger,connectleadsfirst,thenturnoncharger. Donot turn oncharger first,as

this may cause aspark.

• Becareful ofarise inbattery temperature becausealarge current flowisrequired duringquick-

charge operation.

If

battery temperature risesabove 60°C(140°F), stopcharging. Alwayschargebatterywhenitstem-

perature isbelow 60°C(140°F).

• Donot exceed thecharging timespecified inFig. 6,because charging batteryoverthecharging time

can cause deterioration ofthe battery.

Service DataandSpecifications (SOS)

Applied model GA

engines CD20SR20DE

Type 26S19L

55D23L65D26L 95D31L

34S19L

Capacity V-AH

12-30 12

-60 12-65 12-80 12

-33

EL-32

Page 405 of 1701

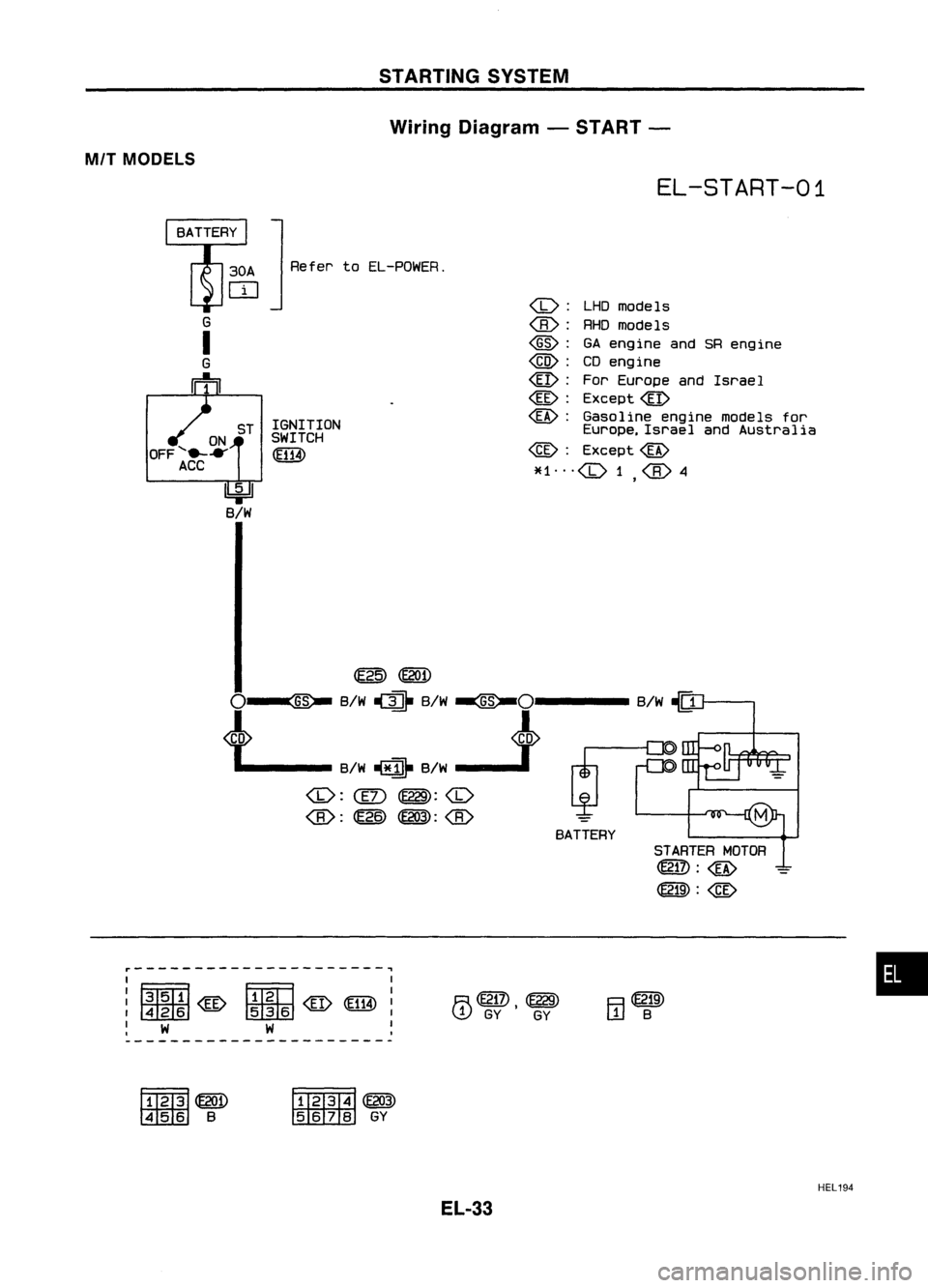

STARTINGSYSTEM

Wiring Diagram -START -

MIl MODELS

EL-START-01

U:i=ll

B/W

ON

OFF

'e- .....

ACC

:J

Refer to

EL-POWEA.

ST IGNITION

SWITCH

~

(1):

LHOmode 1s

@:

RHOmodels

@:

GAeng ine and SReng ine

@:

CDengine

@: ForEurope andIsrae 1

@:

Except@

~: Gasoline enginemodels for

Europe, IsraelandAustralia

@:

Except~

*1"'(1)1 @4

,

~~

O~ B/W~ B/W~Ol -B/W

-(Q

LB/W~B/W.J

~:

@: ~

~:@

BATTERY

STARTERMOTOR

@TI): ~

@lID:

@

~---------------------~

I I

: ~@

fTIN1@~:

,~mID

I

~ W W ~

R@TI)

~

~ GY

I

GY

•

~~

@lID:ID

B ~oo

~GY

EL-33

HEL

194

Page 406 of 1701

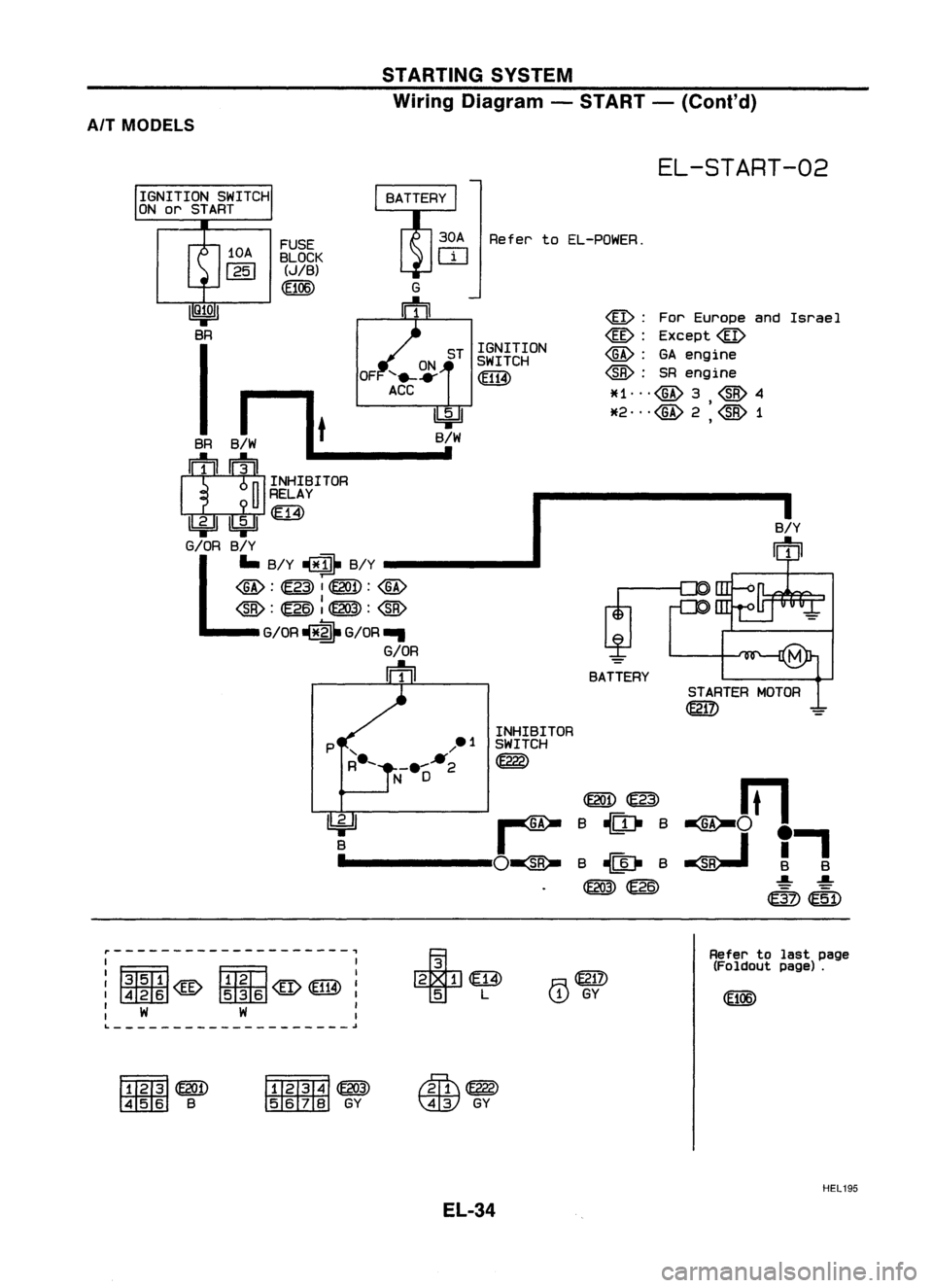

STARTINGSYSTEM

Wiring Diagram -START -(Conl'd)

AIT MODELS

EL-START-02

STARTER MOTOR

~

I

B/Y

m

@:

ForEurope andIsrael

@:

Except@

@:

SRengine

~H"'@3 @4

*2 ...

@

1

,

BATTERY

~~

B ~ B

B ~ B

~~

INHIBITOR

SWITCH

@g)

Refer

toEL-POWER.

ST IGNITION

SWITCH

*

I

FUSE

BLOCK

(JIB)

~B

•

IQ~OI

BR

I

OF

SA

J-.

-It

I

1111 --

n

INHIBITOR

u

RELAY

lkjJIlbjdlffi)

G/OR B/Y

lJ

B/Y~B/Y

@:~IOO:@

G/OR ~ G/OR...

G/OR

Iftn

r--------------------,

I I

I~

FmTl

I

: @@lID

@

tIDrnI

@

@W :

: W W :

L

~

~

T

L

R~

'.!J

GY

Refer

tolast page

(Foldout page).

~~

~B ~~

~GY

Iffi\m>

\AW

GY

HEL195

EL-34

Page 407 of 1701

STARTINGSYSTEM

Trouble Diagnoses

If any abnormality isfound, immediately disconnectbatterynegative terminal.

Starter doesnotstop.

Engine doesnotstart. Replace

magnetic switch.

Does engine turnbycranking? Doesengine turnnormally? Check

ignition/fuel system.

No No

(Turns slowly.)

Check battery asfollows:

OK

Repairstarter motor.

• Charging condition

• Terminal connections

• Terminal corrosion

NG

@

Does starter motorturn? Yes

Doesgearshaft turn? Checkpinionclutch.

No No

Check reduction gear,armature

and gear shaft.

Check fuseandfusible link. Replace.

OK

Check battery asfollows:

@

• Charging condition

• Terminal connections

NG

• Terminal corrosion •

Charge battery.

• Repair connections andcorro-

OK

sian

ofbattery terminals.

Check starting systemwiring.

Repair.

OK

Does magnetic switchoperation No

Replace magnetic switch

sound occur?

Yes

Check condition ofpinion and

OK

Doesstarter turnunder noload Yes

Replace magnetic switch.

ring gear mesh.

byconnecting wiresasfollows?

NG

•

• Adjust pinionmovement.

Repairstarter motor.

• Check pinionmoving mecha-

nism .

• Check ringgear.

SELOO9Z

EL-35

Page 408 of 1701

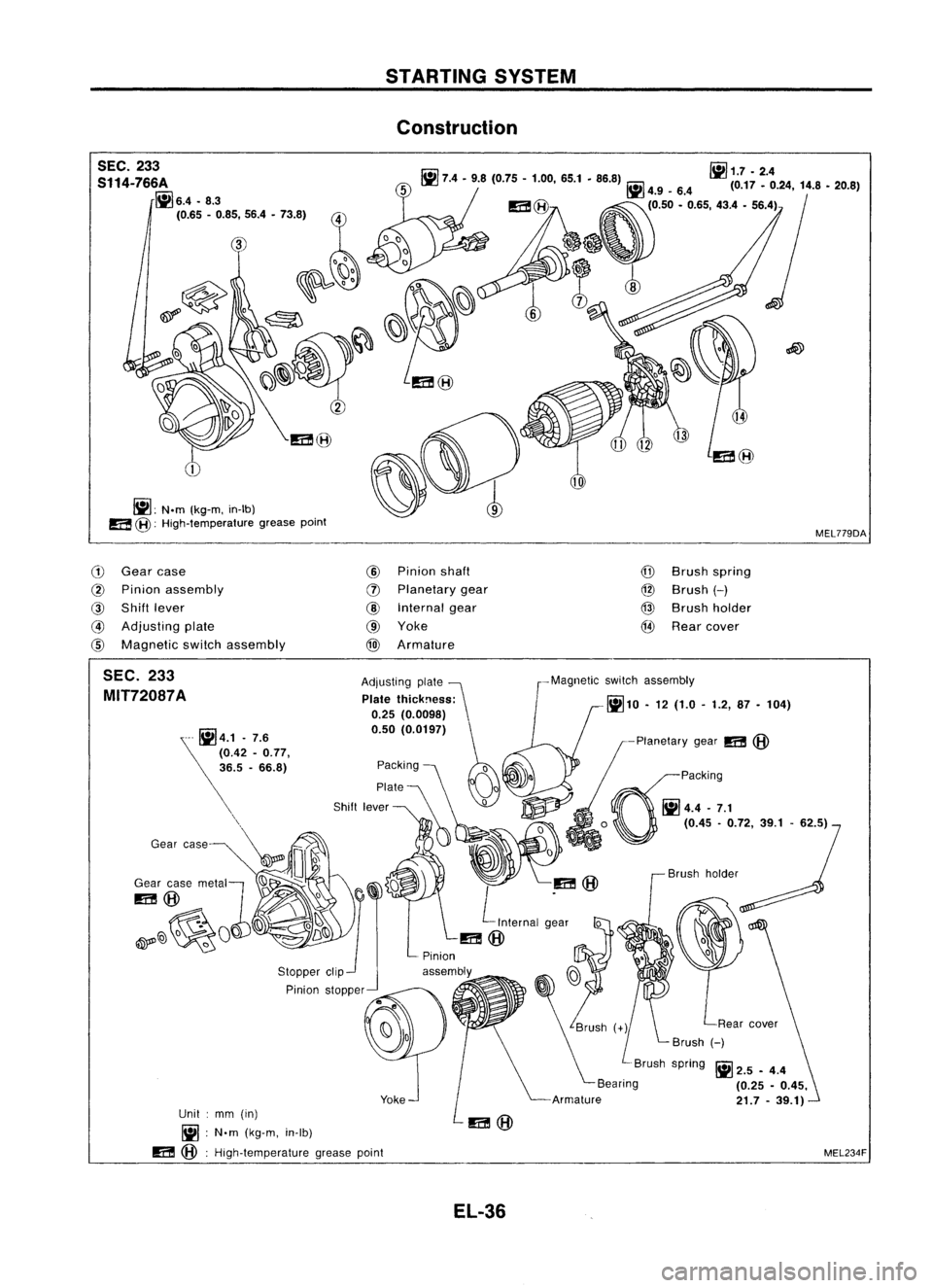

STARTINGSYSTEM

Construction

SEC. 233

S114-766A

~6.4.8.3

(0.65 -0.85, 56.4•73.8)

~: N.m(kg-m, in-Ib)

a

@:

High-temperature greasepoint

r.ii1

iii

1.7 •2.4

III 7.4-9.8 (0.75 -1.00, 65.1•86.8) ~4.9_6.4 (0.17_0.24, 14.8•20.8)

(0.50 -0.65, 43.4•56.4)

MEL779DA

G)

Gear case

@

Pinion assembly

@

Shift lever

@

Adjusting plate

@

Magnetic switchassembly

@

Pinion shaft

(J)

Planetary gear

@

Internal gear

@ Yoke

@

Armature

@

Brush spring

@

Brush

H

@

Brush holder

@

Rear cover

MEL234F

Ii!

2.5 -4.4

(0.25 -0.45,

21.7 -39.1)

Brush

holder

-Planetary

gear

m

@

~paCking

~4.4-7.1

o

(0.45-0.72, 39.1-62.5)

-Magnetic

switchassembly

~10 •12 (1.0 -1.2, 87-104)

Adjusting

plate~

Plate thickness:

0.25 (0.0098)

0.50 (0.0197)

Packing

0

Plate KJo

~

~m@

L

Internal g~ar

0

m@

Yoke

Pinion

stopper

Unit :mm (in)

Ii! :

N'm (kg-m, in-Ib)

m

@:

High-temperature greasepoint

SEC.

233

MIT72087A

EL-36

Page 409 of 1701

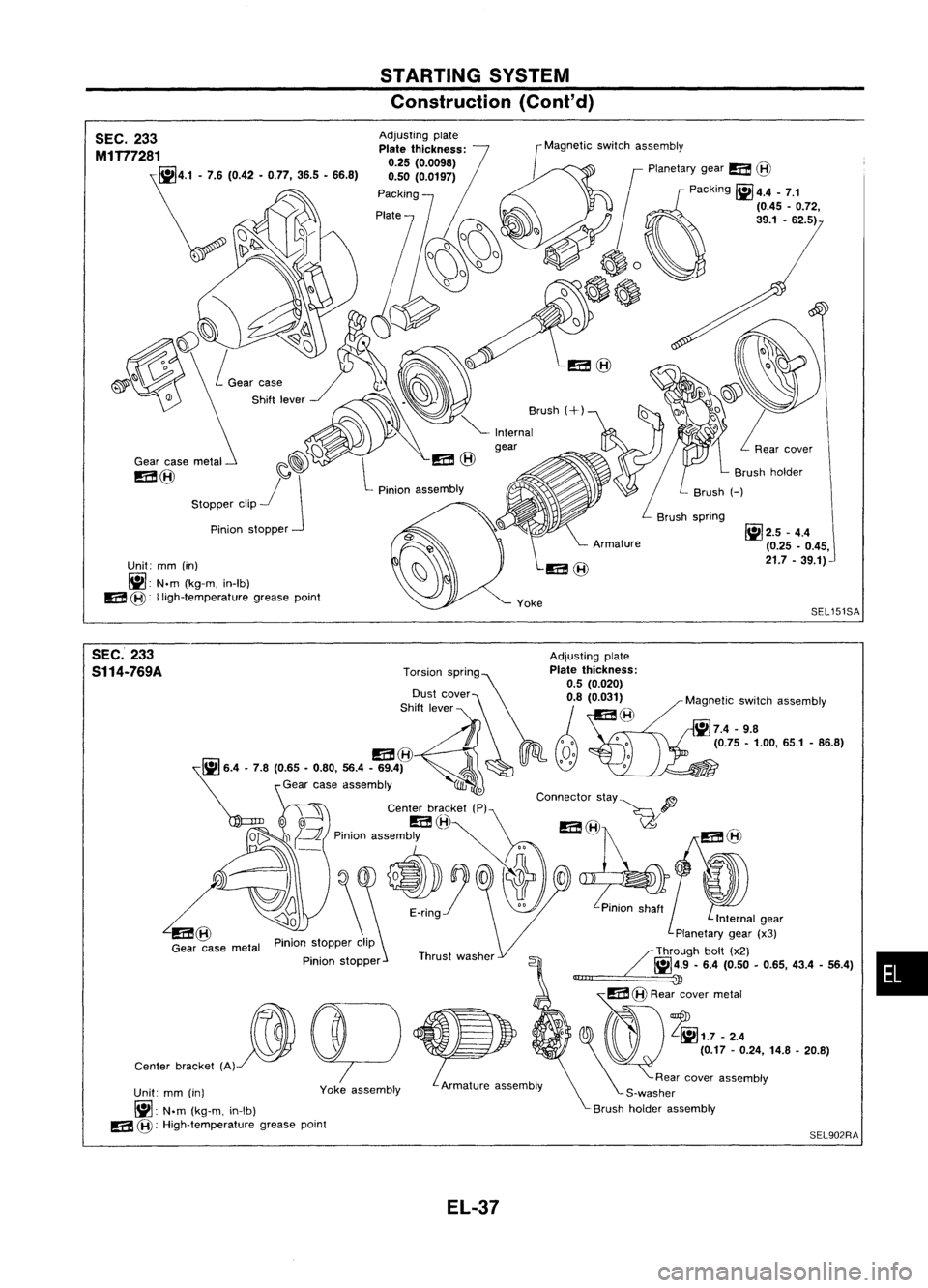

STARTINGSYSTEM

Construction (Cont'd)

SEC. 233

M1T77281

\:; ,o42•

0:

365•66.'}

Gear casemetal

m@

Unit: mm(in)

~: N.m

(kg-m, in-Ib)

m

@:

lligh-temperature greasepoint [Magnetic

SWitrChas:~::~ry gear

m@

~paCking ~4.4-7.1

(0.45 -0.72,

~ 39.1•62.5)

~

/'

~;:/ ~o

C)~G

Brushholder

Brush spring

~2.5-

4.4

(0.25 .0.45,

21.7 .39.1)

SEL151SA

SEC. 233

Adjustingplate

S114-769A

T::~~nc::~~g~p,a~~£~~~~~fr:Magneticswitchassembly

Shift lever ),~

m@

02,

Gear caseassembly

0

Connector stay

p

': Centerbr

o ~

I!E!

l~ \

I!E!@I\.' ~I!E!

(flJ

0" ;P

p;o;o~,,~ ~~~

7~0

I]

(J ,(

"';0'.5'..

P,",oo,.,. ~"""

Qo \

Planetarygear(x3)

Pinion stopper clip /_Through bolt(x2) •

1i'iI14.9 •6.4 (0.50 •0.65, 43.4.56.4)

Pinion

stopper _~

Ollll!

3J

~ cp

~m\@R"i'7m,::

~ l]J ~.

'0.17.0.24,14.'. 20.'}

Center bracket (A)

~oo

Rearcover assembly

Yoke assembly Armatureassembly S-washer

Unit: mm(in) Brushholder assembly

~: N.m

(kg-m, in-Ib) .

m

@:

High-temperature greasePOint SEL902RA

EL-37

Page 410 of 1701

![NISSAN ALMERA N15 1995 Service Manual STARTINGSYSTEM

Construction (Cont'd)

SEC. 233

S114.568A

S114-630

Unit: mm(in)

fj] :

N.m (kg-m, in-Ib)

m@ :

High-temperature greasepointDust

cover (Adjusting plate)

Plate

thickness:

0.5 (0.02 NISSAN ALMERA N15 1995 Service Manual STARTINGSYSTEM

Construction (Cont'd)

SEC. 233

S114.568A

S114-630

Unit: mm(in)

fj] :

N.m (kg-m, in-Ib)

m@ :

High-temperature greasepointDust

cover (Adjusting plate)

Plate

thickness:

0.5 (0.02](/img/5/57349/w960_57349-409.png)

STARTINGSYSTEM

Construction (Cont'd)

SEC. 233

S114.568A

S114-630

Unit: mm(in)

fj] :

N.m (kg-m, in-Ib)

m@ :

High-temperature greasepointDust

cover (Adjusting plate)

Plate

thickness:

0.5 (0.020)

0.8 (0.031)

Field coil

•

7.4.9.8 (0.75•1.00. 65.1.86.8)

• 4.9.6.4

(0.50 •0.65. 43.4•56.4)

E-ring

SEL249SC

SEC. 233

M3T37783

Gearcase

Gear casemetal

m

@

Adjusting

plate

Plate

thickness:

0.25 (0.0098)

0.50 (0.0197)

Armature

Unit: mm(in)

fj]:

N.m(kg-m. in-Ib)

m

@:

High-temperature greasepoint

EL-38

IiJ

2.5-4.4

r.ilI

(0.25-0.45.

~ 4.4•7.1 21.7•39.1)

(0.45 •0.72.

~

SEL464PA