engine NISSAN ALMERA N15 1995 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 1274 of 1701

![NISSAN ALMERA N15 1995 Service Manual CYLINDERHEAD

ill]

Assembly (Cont'd)

10. Install valvecomponent parts.

• Install valves withlarger diameter headonthe intake side.

•

Wide pitch

Narrow pitch

Paint mark

Cylinder headside

S NISSAN ALMERA N15 1995 Service Manual CYLINDERHEAD

ill]

Assembly (Cont'd)

10. Install valvecomponent parts.

• Install valves withlarger diameter headonthe intake side.

•

Wide pitch

Narrow pitch

Paint mark

Cylinder headside

S](/img/5/57349/w960_57349-1273.png)

CYLINDERHEAD

ill]

Assembly (Cont'd)

10. Install valvecomponent parts.

• Install valves withlarger diameter headonthe intake side.

•

Wide pitch

Narrow pitch

Paint mark

Cylinder headside

SEM085D•

Always usenew valve oilseal.

Refer toOIL SEAL REPLACEMENT.

• Before installing valveoilseal, install valvespring seat.

.' Install valvespring (uneven pitchtype) withitsnarrow

pitched sidetoward cylinder headside(paint mark).

• After installing valvecomponent parts,tapvalve stemtip

with plastic hammer toassure aproper fit.

11. Check hydraulic lashadjusters.

a. Push rocker armathydraulic lashadjuster location, andsee

if rocker armmoves. Ifitmoves atleast 1mm (0.04 in),it

indicates thatthere isair inthe high pressure chamber.

Noise willbeemitted fromhydraulic lashadjuster ifengine

is started without bleeding air.

b. Remove hydraulic lashadjuster anddipinacontainer filled

with engine oil.While pushing plungerasshown infigure,

lightly pushcheck ballusing athin rod. Airiscompletely

bled when plunger nolonger moves.

Air cannot bebled from thistype oflash adjuster byrunning the

engine.

SEM093D

• rEngine oil

- - , t-=1=i

Proper

rod

SEM772C

Rocker arm9UVide

Rock~rarm

Shim

Hydraulic

I

.,h

.dj"'"

i\\ j

12.

Install rocker arms,shims, rockerarmguides andhydrau-

lic lash adjusters.

CAUTION: Install allparts intheir original positions.

SEM202D EM-95

Page 1277 of 1701

ENGINEREMOVAL

SEM234F

[OJ

:

N'm (kg-m, ft-Ib)

I

0

~

@> ~

44•54 (4.5 •5.5, 33•40)

V

[OJ

44-54

(4.5 •5.5,

33 •40)

~,

r1jl~

)

~~~

~~.

'/,

~",

~ 44-54 ~V/~ /\~"-

~v)~.

~l"J

22.29

(4.5 •5.") -

Y) .

(2.2•3.0, 16•22)

33.40) /' ,

\l"J

44."

~ ~(4.5•5,5, 33•40)

~ l"J

44." (4.5.5.5,33' 40) .~.

I~

22•29 (2.2 •3.0, 16.22)

>

[OJ

64. 74 ,~

(6.5 -7.5,

!

rf:{l"A

47 •54) .../ ,

~ /1.;'0-

/~ /[(1\ ~

~:5- _5~.5, 33-40) \

[OJ

74-91 "'~' .•~~ ~\

(8.0 -9.~~,,,

0

I

I'. ,

58 -67) /' \

[OJ

44_54 ~

[OJ

'64-74

~A1k

~Ol

(4.5-5.5, 33•40)

(6.5 -7.5, 47. 54) ~~ r~

[OJ

44-54

~I~,~

(4.5 -5.5, 33-40)

t?

I

!

"SR"

marked direction

~,"7 ~~

44•54 (4.5 •5.5,33.40)

Front

MIT models

[OJ

44•54

t

(4.5-5.5,

33 -40)

1~

ol~

Ill.~,

;~

;&6

[OJ

44-54 ~--W

(4.5 -5.5,

I

33 -40)

0

c~ ___

~

"

o

G)

Rear engine slinger

@

Front engine mounting

@

Mounting bracket

@

Rear insulator

@

Center member

@

Buffer

(J)

Front engine slinger

@

Rear engine mounting

@

Dynamic damper

EM-98

Page 1278 of 1701

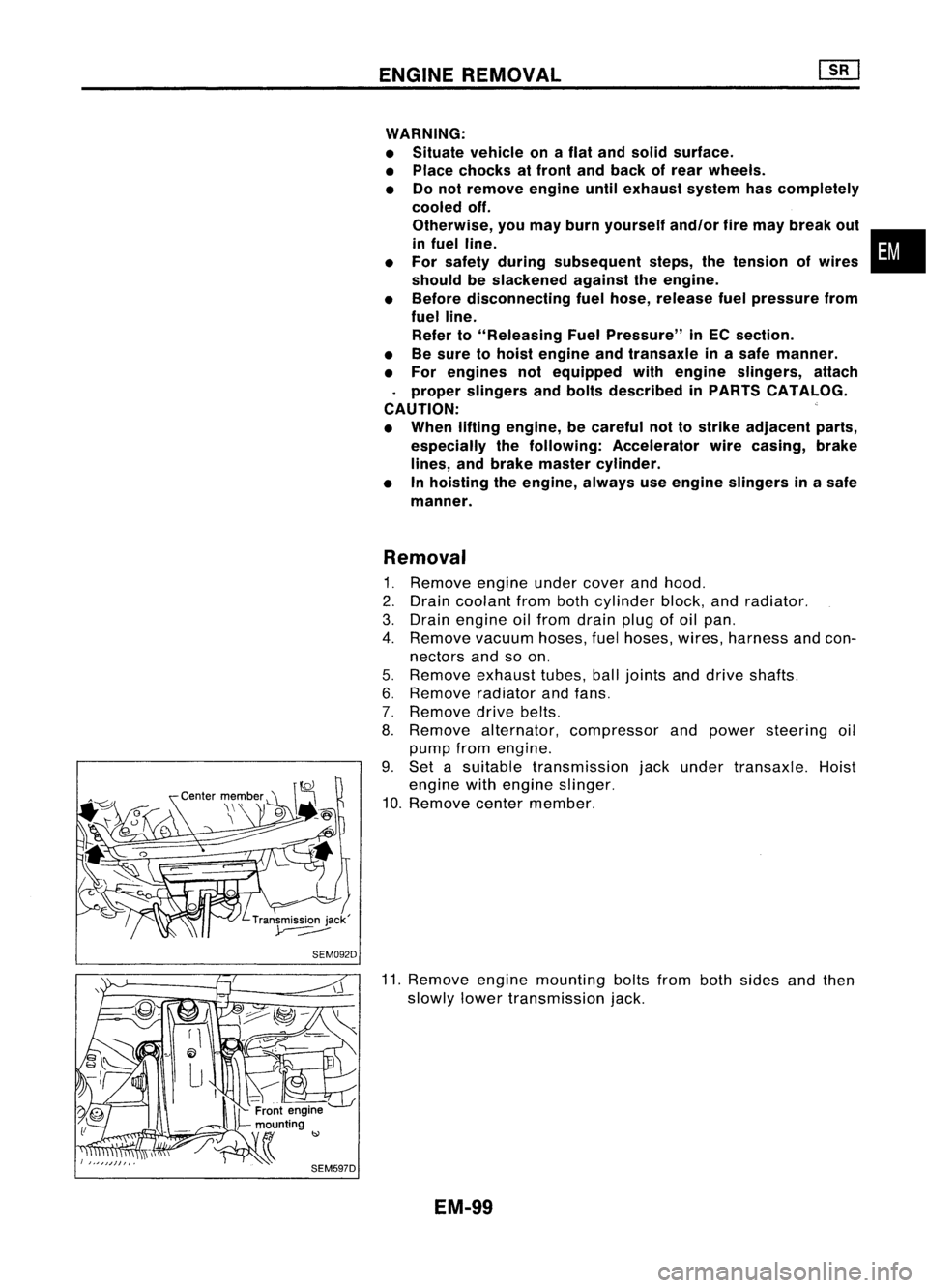

SEM092DENGINE

REMOVAL

WARNING:

• Situate vehicle onaflat and solid surface.

• Place chocks atfront andback ofrear wheels.

• Donot remove engineuntilexhaust systemhascompletely

cooled off.

Otherwise, youmay burn yourself and/orfiremay break out

in fuel line.

• For safety during subsequent steps,thetension ofwires

should beslackened againsttheengine.

• Before disconnecting fuelhose, release fuelpressure from

fuel line.

Refer to"Releasing FuelPressure" inEC section.

• Besure tohoist engine andtransaxle inasafe manner.

• For engines notequipped withengine slingers, attach

proper slingers andbolts described inPARTS CATALOG.

CAUTION:

• When liftingengine, becareful nottostrike adjacent parts,

especially thefollowing: Accelerator wirecasing, brake

lines, andbrake master cylinder.

• Inhoisting theengine, alwaysuseengine slingers inasafe

manner.

Removal

1. Remove engineundercoverandhood.

2. Drain coolant frombothcylinder block,andradiator.

3. Drain engine oilfrom drain plugofoil pan.

4. Remove vacuumhoses,fuelhoses, wires,harness andcon-

nectors andsoon.

5. Remove exhausttubes,balljoints anddrive shafts.

6. Remove radiatorandfans.

7. Remove drivebelts.

8. Remove alternator, compressor andpower steering oil

pump fromengine.

9. Set asuitable transmission jackunder transaxle. Hoist

engine withengine slinger.

10. Remove centermember.

11. Remove enginemounting boltsfrombothsides andthen

slowly lowertransmission jack.

EM-99

•

Page 1279 of 1701

SEM312DENGINE

REMOVAL

Removal (Cont'd)

12. Remove enginewithtransaxle asshown.

Installation

1. Install engine mounting bracketandfixing bolts.

Be sure thatinsulators arecorrectly positioned onthe brack-

ets.

2. Carefully lowertheengine ontoengine mounting insulators.

When installing theengine, adjusttheheight ofthe engine

mounting asshown. (ForM/T)

3. Installation isinthe reverse orderofremoval.

EM-100

Page 1280 of 1701

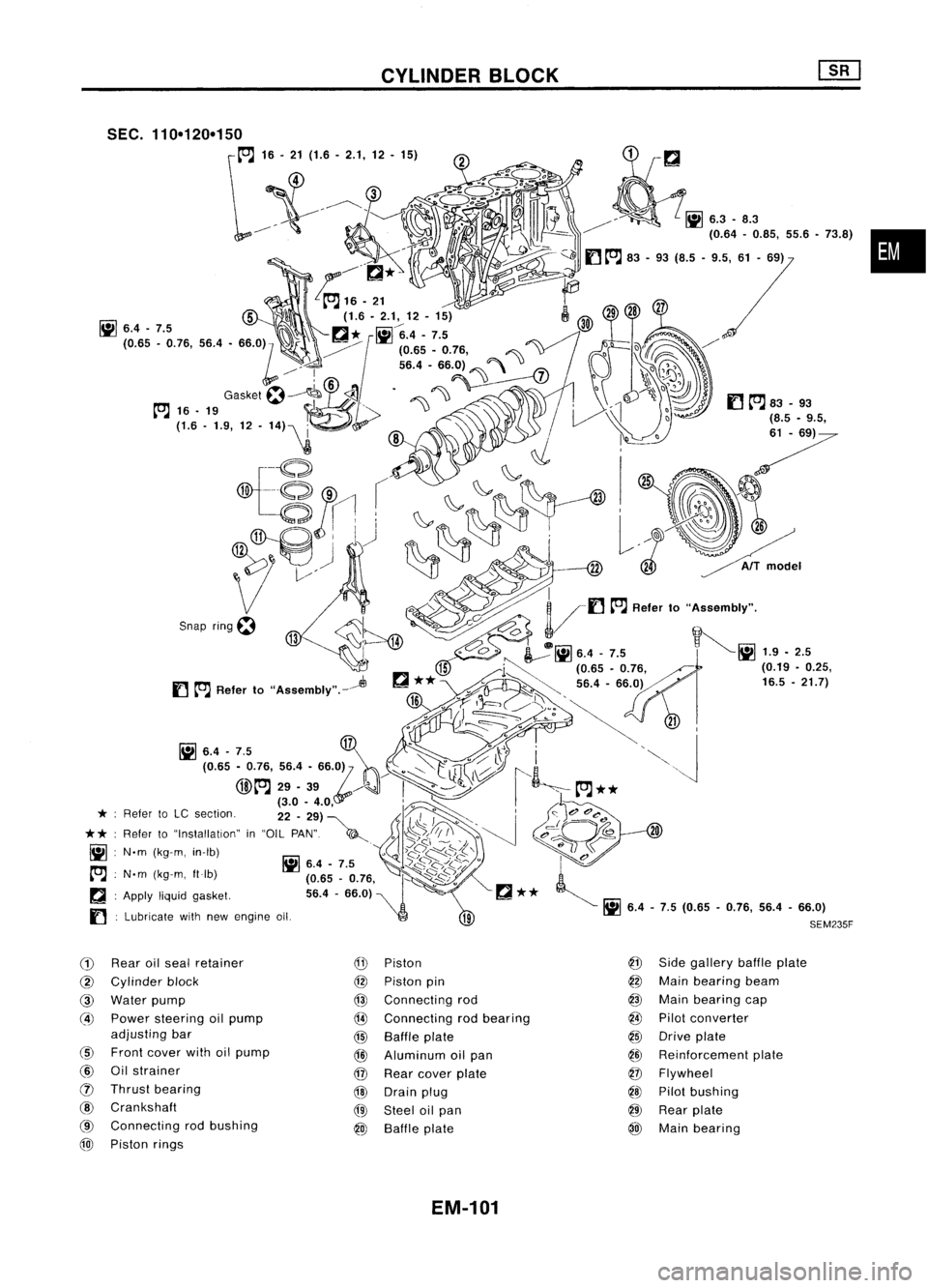

CYLINDERBLOCK

SEC.

Snapring~

f)

to:J

Refer to

"ASSembIY"'-~

: Apply liquidgasket.

Lubricate withnew engine

011

•

CD

Rear oilseal retainer

@

Cylinder block

@

Water pump

@

Power steering oilpump

adjusting bar

@

Front cover withoilpump

@

Oilstrainer

(J)

Thrust bearing

@

Crankshaft

@

Connecting rodbushing

@J

Piston rings

@

Piston

@

Piston pin

@

Connecting rod

@

Connecting rodbearing

@

Baffle plate

@

Aluminum oilpan

@

Rear cover plate

@

Drain plug

@J

Steel oilpan

@

Baffle plate

EM-101 @

Side gallery baffleplate

@

Main bearing beam

@

Main bearing cap

@

Pilotconverter

@

Drive plate

@

Reinforcement plate

@

Flywheel

@

Pilotbushing

@

Rear plate

@

Main bearing

Page 1281 of 1701

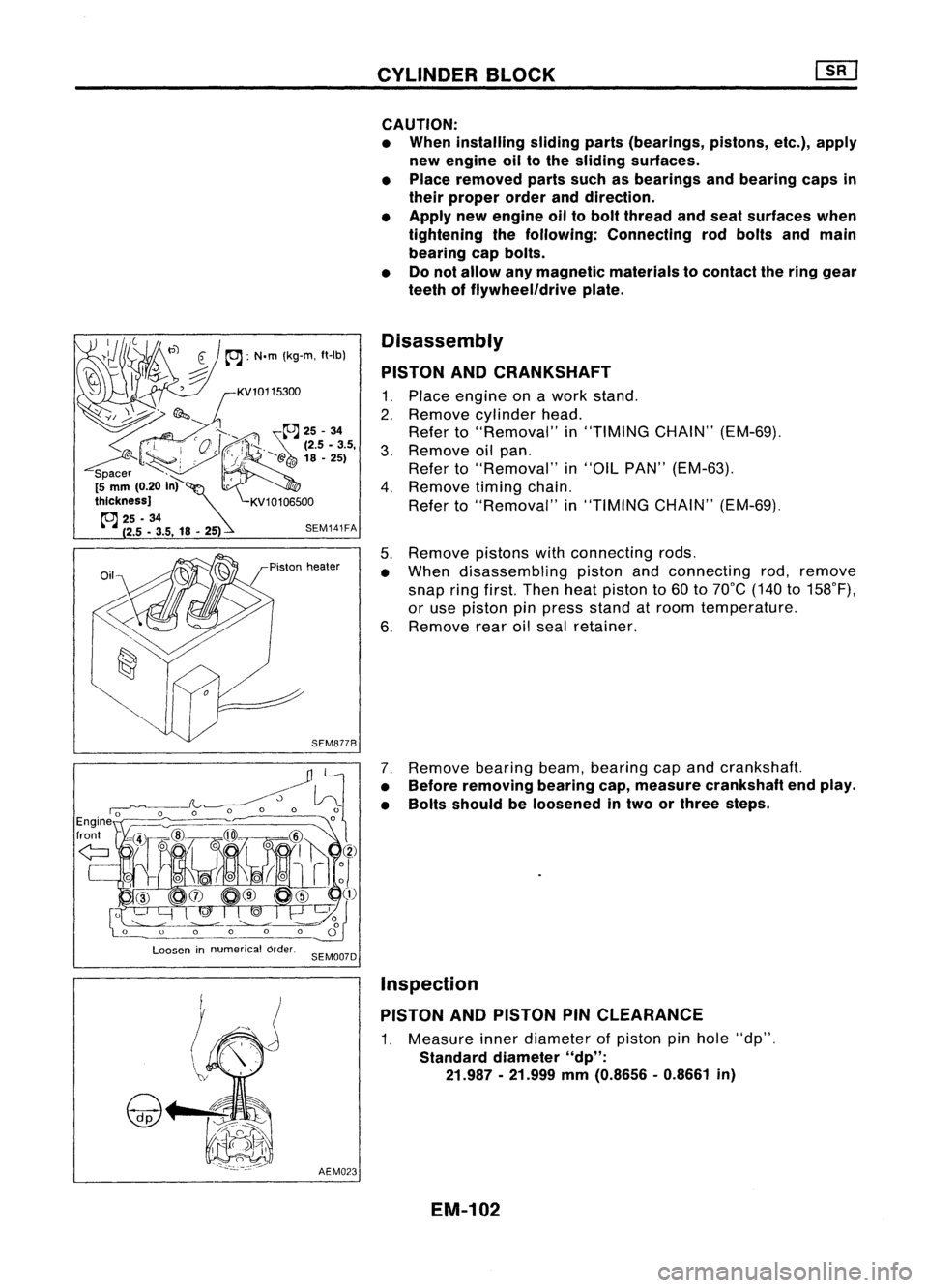

SEM141FA

jPiSIOn healer

SEM877S CYLINDER

BLOCK

CAUTION:

• When installing slidingparts(bearings, pistons,etc.),apply

new engine oiltothe sliding surfaces.

• Place removed partssuchasbearings andbearing capsin

their proper orderanddirection.

• Apply newengine oiltobolt thread andseat surfaces when

tightening thefollowing: Connecting rodbolts andmain

bearing capbolts.

• Donot allow anymagnetic materials tocontact thering gear

teeth offlywheel/drive plate.

Disassembly

PISTON ANDCRANKSHAFT

1. Place engine onawork stand.

2. Remove cylinder head.

Refer to"Removal" in"TIMING CHAIN"(EM-69).

3. Remove oilpan.

Refer to"Removal" in"OIL PAN" (EM-63).

4. Remove timingchain.

Refer to"Removal" in"TIMING CHAIN"(EM-69).

5. Remove pistonswithconnecting rods.

• When disassembling pistonandconnecting rod,remove

snap ringfirst. Then heatpiston to60 to70°C (140to158°F),

or use piston pinpress stand atroom temperature.

6. Remove rearoilseal retainer.

7. Remove bearingbeam,bearing capand crankshaft.

• Before removing bearingcap,measure crankshaft endplay.

• Bolts should beloosened intwo orthree steps.

Loosen innumerical order.

SEM007D

AEM023

Inspection

PISTON ANDPISTON PINCLEARANCE

1. Measure innerdiameter ofpiston pinhole "dp".

Standard diameter"dp":

21.987 -21.999

mm

(0.8656 -0.8661

in)

EM-102

Page 1283 of 1701

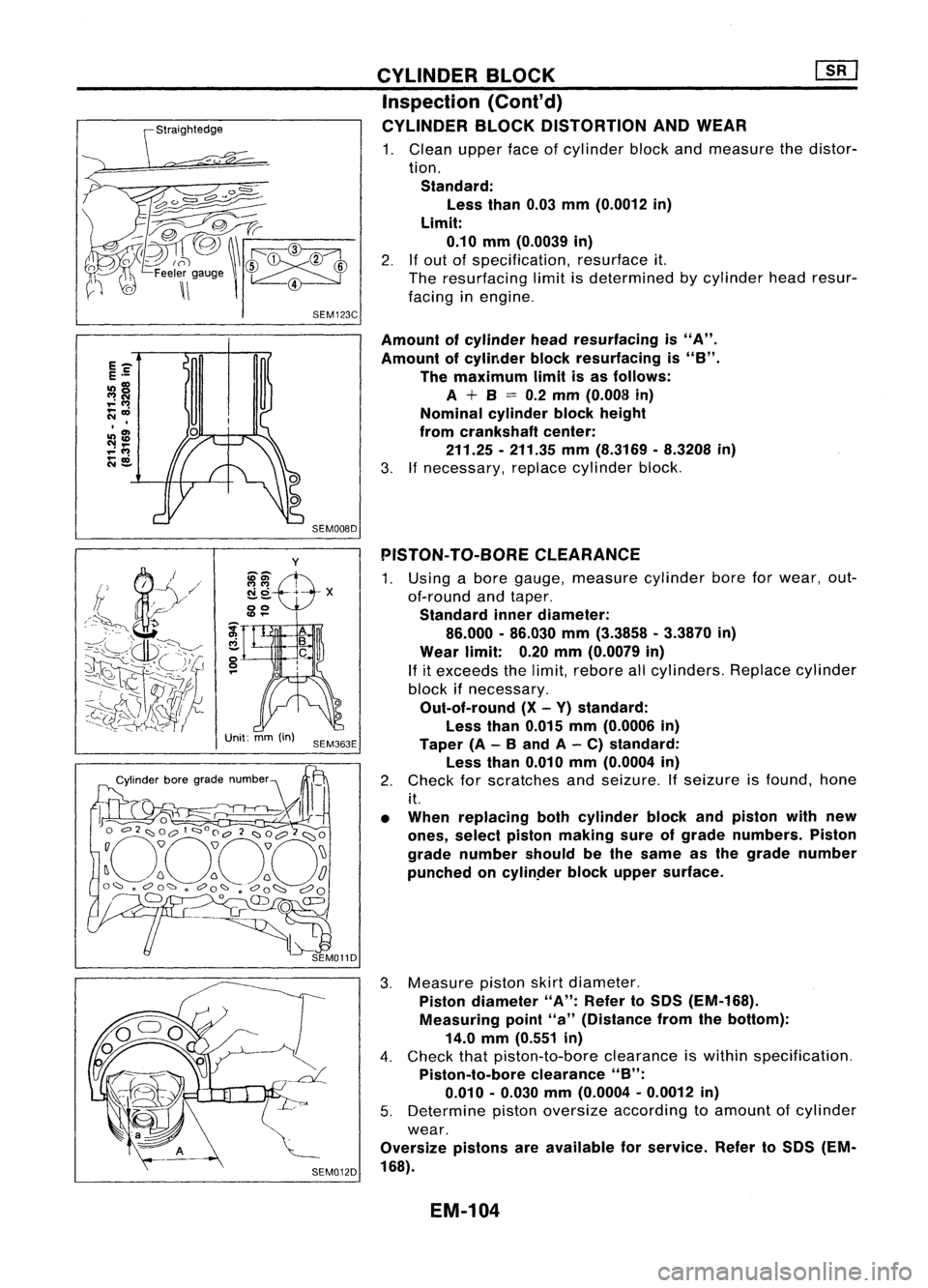

SEM123CCYLINDER

BLOCK ~

Inspection (Cont'd)

CYLINDER BLOCKDISTORTION ANDWEAR

1. Clean upperfaceofcylinder blockandmeasure thedistor-

tion. Standard: Less than0.03mm(0.0012 in)

Limit: 0.10 mm(0.0039 in)

2.

If

out ofspecification, resurfaceit.

The resurfacing limitisdetermined bycylinder headresur-

facing inengine.

SEM008D

Amount

ofcylinder headresurfacing is"A".

Amount ofcylinder blockresurfacing is

"8".

The maximum limitisas follows:

A

+

8

=

0.2 mm (0.008 in)

Nominal cylinderblockheight

from crankshaft center:

211.25 -211.35 mm(8.3169 -8.3208 in)

3. Ifnecessary, replacecylinder block.

y

ii-El)'

N 0+ -X

--

00

Unit: mm(in)

SEM363E PISTON-

TO-BORE CLEARANCE

1. Using abore gauge, measure cylinderboreforwear, out-

of-round andtaper.

Standard innerdiameter:

86.000 -86.030 mm(3.3858 -3.3870 in)

Wear limit: 0.20mm(0.0079 in)

If

itexceeds thelimit, rebore allcylinders. Replacecylinder

block ifnecessary.

Out-of-round (X-Y) standard:

Less than0.015 mm(0.0006 in)

Taper (A-

8

and A-C) standard:

Less than0.010 mm(0.0004 in)

2. Check forscratches andseizure. Ifseizure isfound. hone

it.

• When replacing bothcylinder blockandpiston withnew

ones, select piston making sureofgrade numbers. Piston

grade number shouldbethe same asthe grade number

punched oncylinper blockupper surface.

3. Measure pistonskirtdiameter.

Piston diameter "A":Refer toSDS (EM-168).

Measuring point"a"(Distance fromthebottom):

14.0 mm(0.551 in)

4. Check thatpiston-to-bore clearanceiswithin specification.

Piston-to-bore clearance"B":

0.010 -0.030 mm(0.0004 -0.0012 in)

5. Determine pistonoversize according toamount ofcylinder

wear.

Oversize pistonsareavailable forservice. RefertoSDS (EM-

168).

EM-104

Page 1285 of 1701

#5

#4 ~

~i1

hole #3~~ \)

#2 ~~,

#1~~~ ~~

12 ~~

Engine front~

SEM685D

SEM964

SEM313D CYLINDER

BLOCK

Inspection (Cont'd)

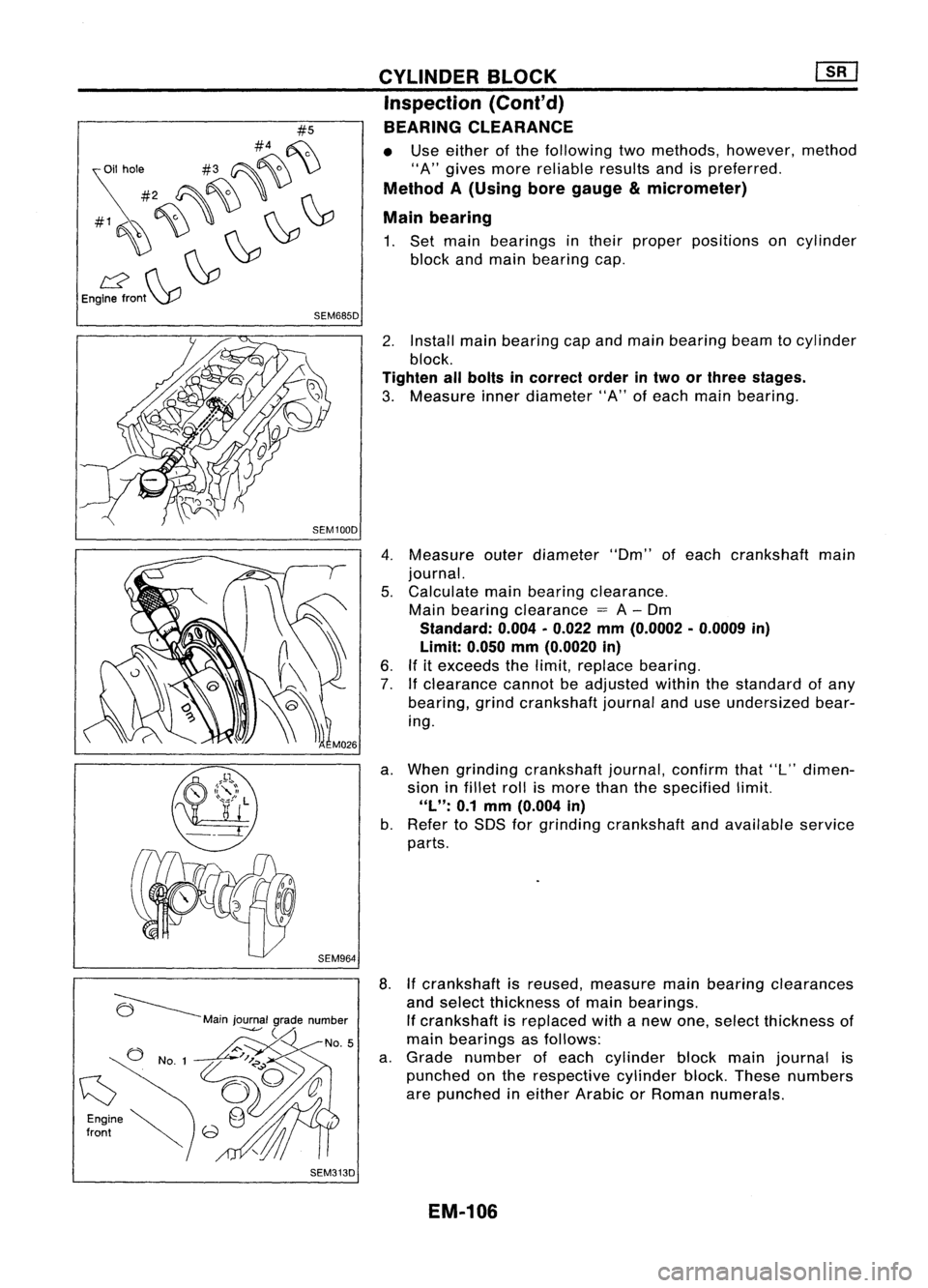

BEARING CLEARANCE

• Use either ofthe following twomethods, however, method

"A" gives morereliable resultsandispreferred.

Method A(Using boregauge

&

micrometer)

Main bearing

1. Set main bearings intheir proper positions oncylinder

block andmain bearing cap.

2. Install mainbearing capand main bearing beamtocylinder

block.

Tighten allbolts incorrect orderintwo orthree stages.

3. Measure innerdiameter "A"ofeach main bearing.

4. Measure outerdiameter "Om"ofeach crankshaft main

journal.

5. Calculate mainbearing clearance.

Main bearing clearance

=

A-Om

Standard: 0.004•0.022 mm(0.0002 •0.0009 in)

Limit: 0.050mm(0.0020 in)

6. Ifitexceeds thelimit, replace bearing.

7. Ifclearance cannotbeadjusted withinthestandard ofany

bearing, grindcrankshaft journalanduseundersized bear-

ing.

a. When grinding crankshaft journal,confirmthat"L"dimen-

sion infillet rollismore thanthespecified limit.

"L":

0.1mm (0.004 in)

b. Refer toSOS forgrinding crankshaft andavailable service

parts.

8. Ifcrankshaft isreused, measure mainbearing clearances

and select thickness ofmain bearings.

If crankshaft isreplaced withanew one, select thickness of

main bearings asfollows:

a. Grade number ofeach cylinder blockmainjournal is

punched onthe respective cylinderblock.These numbers

are punched ineither Arabic orRoman numerals.

EM-106

Page 1289 of 1701

![NISSAN ALMERA N15 1995 Service Manual Frontmark

Oil hole

Engine

front Piston

grade

number

Cylindernumber

SEM946C

Top

Oil

SEM199F CYLINDER

BLOCK []:[J

Assembly (Conl'd)

2. Heat piston to60 to70°C (140to158°F) andassemble piston,

p NISSAN ALMERA N15 1995 Service Manual Frontmark

Oil hole

Engine

front Piston

grade

number

Cylindernumber

SEM946C

Top

Oil

SEM199F CYLINDER

BLOCK []:[J

Assembly (Conl'd)

2. Heat piston to60 to70°C (140to158°F) andassemble piston,

p](/img/5/57349/w960_57349-1288.png)

Frontmark

Oil hole

Engine

front Piston

grade

number

Cylindernumber

SEM946C

Top

Oil

SEM199F CYLINDER

BLOCK []:[J

Assembly (Conl'd)

2. Heat piston to60 to70°C (140to158°F) andassemble piston,

piston pin,connecting rodand new snap ring.

• Align thedirection ofpiston andconnecting rod.

• Numbers stampedonconnecting rodand capcorrespond to

each cylinder.

• After assembly, makesureconnecting rodswings

smoothly.

3. Set piston ringsasshown.

CAUTION:

• When piston ringsarenotreplaced, makesurethatpiston

rings aremounted intheir original positions.

• When replacing pistonrings,thosewithout punchmarks can

be mounted witheither sideup.

Oil ring

expander

*v

Engine!/

front

(:J

#5

#4 ~

~il hole #3~~ \)

#2 ~~ ,

#1~~~ ~~

12 ~~

Engine front~

SEM685DCRANKSHAFT

1. Set main bearings intheir proper positions oncylinder

block andmain bearing cap.

• Confirm thatcorrect mainbearings areused. Referto

"Inspection" ofthis section.

• Apply newengine oiltobearing surfaces.

EM-110

Page 1290 of 1701

![NISSAN ALMERA N15 1995 Service Manual Tighteninnumerical order.

'::::::-.... Alignoilhole.

~~

'~~-

SEM015D

SEM159B CYLINDER

BLOCK [][]

Assembly (Cont'd)

2. Install crankshaft andmain bearing capsandtighten bolts

to the spec NISSAN ALMERA N15 1995 Service Manual Tighteninnumerical order.

'::::::-.... Alignoilhole.

~~

'~~-

SEM015D

SEM159B CYLINDER

BLOCK [][]

Assembly (Cont'd)

2. Install crankshaft andmain bearing capsandtighten bolts

to the spec](/img/5/57349/w960_57349-1289.png)

Tighteninnumerical order.

'::::::-.... Alignoilhole.

~~

'~~-

SEM015D

SEM159B CYLINDER

BLOCK [][]

Assembly (Cont'd)

2. Install crankshaft andmain bearing capsandtighten bolts

to the specified torque.

• Apply newengine oiltothread ofbearing capbolts.

• Prior totightening bearingcapbolts, shiftcrankshaft back

and forth toproperly seatthebearing cap.

• Tightening procedure

a. Tighten allbolts to26 to32 N'm (2.7to3.3 kg-m, 20to24 •

in-Ib).

b. Turn allbolts 75to80 degrees clockwise withTool orsuit-

able angle wrench.

c. Loosen allbolts completely.

d. Tighten allbolts to32 to38 N'm (3.3to3.9 kg-m, 24to28

ft-Ib).

e. Turn allbolts 45to50 degrees clockwise withTool orsuit-

able angle wrench.

• Ifan angle wrench isnot available, markallbearing cap

bolts onthe side facing engine rear.Then, turneach bolt

specified degreesclockwise. Confirmangleofdegrees with

a graduator, notbyeye-measurement.

• After securing bearingcapbolts, makesurecrankshaft

turns smoothly byhand.

3. Measure crankshaft endplay.

Crankshaft endplay:

Standard

0.10 -0.26 mm(0.0039 -0.0102 in)

Limit

0.30 mm(0.0118 in)

If beyond thelimit, replace thrustbearings withnewones.

4. Install connecting rodbearings inconnecting rodsandcon-

necting rodcaps.

• Confirm thatcorrect bearings areused. Referto

"I nspection" .

• Install bearings sothat oilhole inconnecting rodaligns with

oil hole ofbearing.

• Apply newengine oiltobolt threads andbearing surfaces.

5. Install pistons withconnecting rods.

a. Install themintocorresponding cylinderswithTool.

• Becareful nottoscratch cylinder wallbyconnecting rod.

• Arrange sothat front mark onpiston headfaces toward

front ofengine.

• Apply newengine oiltopiston ringsandsliding surface of

piston.

EM-111