engine NISSAN ALMERA N15 1995 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 1391 of 1701

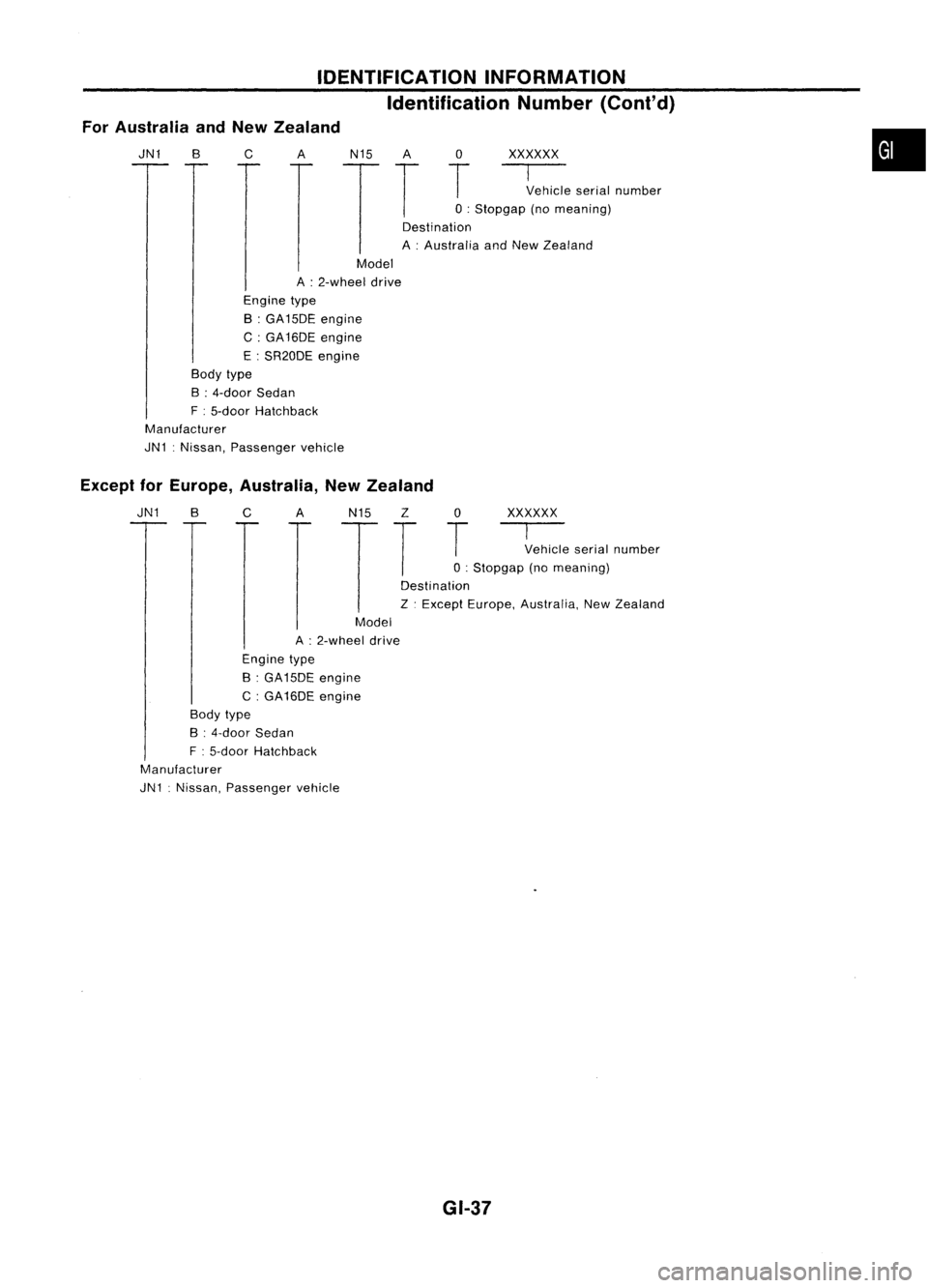

ForAustralia andNew Zealand IDENTIFICATION

INFORMATION

Identification Number(Cont'd)

JN1 B

c

A

N15A 0

xxxxxx

T

T

T

~ehicleserialnumber

o :

Stopgap (nomeaning)

Destination

A :Australia andNew Zealand

•

Model

A :2-wheel drive

Engine type

B :GA15DE engine

C: GA16DE engine

E :SR20DE engine

Body type

B :4-door Sedan

F :5-door Hatchback

Manufacturer

JN1 :Nissan, Passenger vehicle

Except forEurope, Australia, NewZealand

JN1 BC AN15Z 0

xxxxxx

T

T

T

~ehicleserialnumber

o :

Stopgap (nomeaning)

Destination

Z .Except Europe, Australia, NewZealand

Model

A :2-wheel drive

Engine type

B :GA 15DE engine

C :GA16DE engine

Body type

B :4-door Sedan

F :5-door Hatchback

Manufacturer

JN1 :Nissan, Passenger vehicle

GI.37

Page 1392 of 1701

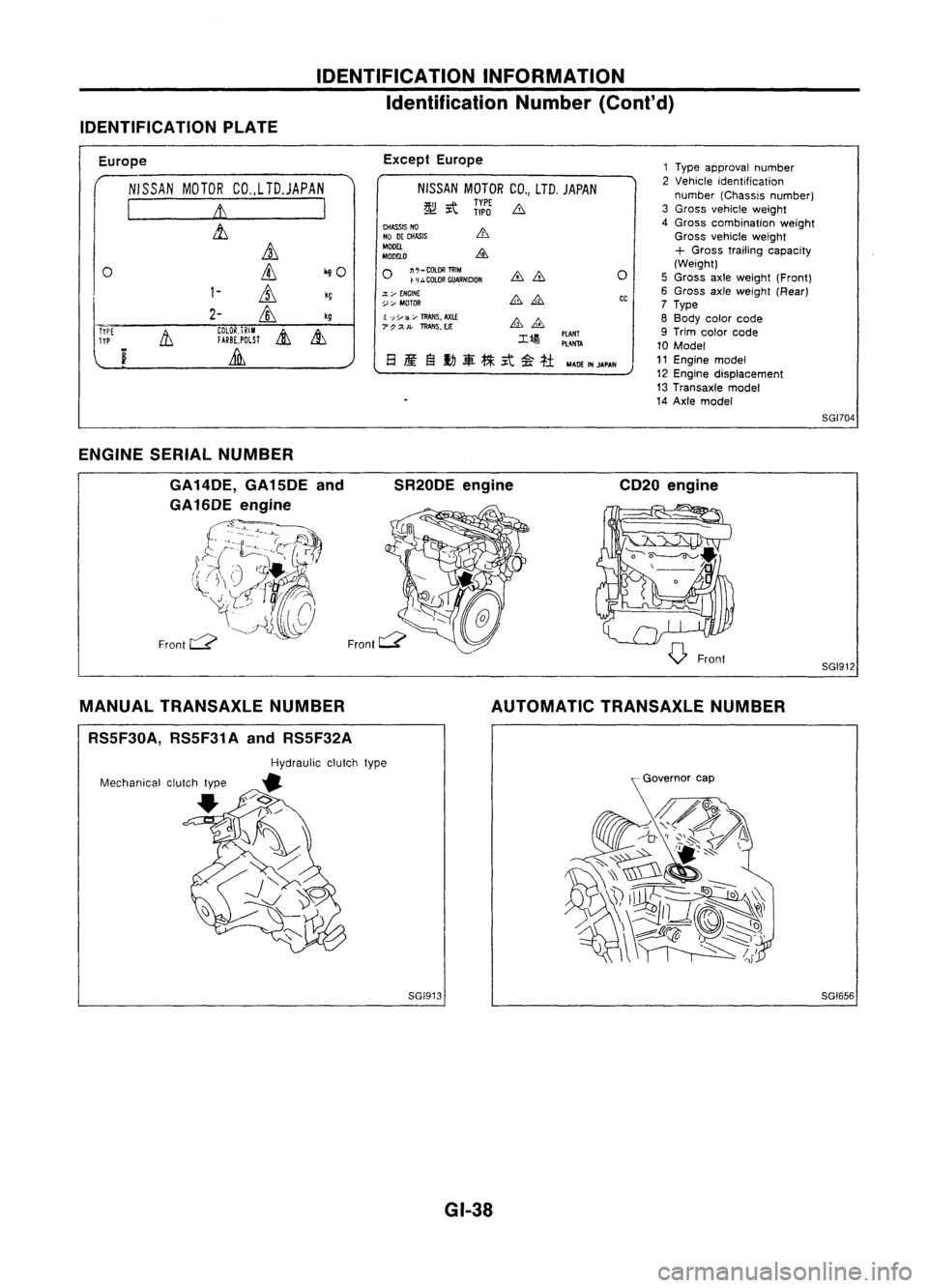

IDENTIFICATIONINFORMATION

Identification Number(Cont'd)

IDENTIFICATION PLATE

Europe

NISSAN MOTORCO.,LTD.JAPAN

I

It

I

&,

it

0

ill

iliO

1-

ill

kg

2-

&,

kg

Tri'[

11

COlOR.iRIM

&

&,

TYP

fARBE,POLSl

i

Lilli

Except

Europe

NISSAN MOTORCO.,LTD. JAPAN

~ it

ii:J

b

CHASS~ NO

NO DECHASIS

MODEL

MDDELO

o

~;::~:~~NlctDN

.:t;..-

ENGINE

~:,... MOTOR

~ ';;Y

3;..-

TRANS~

AXl.£

7P;;<'.

ll!AIIS.EJt:

M4DEINJAPAN

o

CC

1

Type approval number

2 Vehicle identification

number (Chassis number)

3 Gross vehicle weight

4 Gross combination weight

Gross vehicle weight

+

Gross trailing capacity

(Weight)

5 Gross axleweight (Front)

6 Gross axleweight (Rear)

7 Type

8 Body colorcode

9 Trim color code

10 Model

11 Engine model

12 Engine displacement

13 Transaxle model

14 Axle model

SGI704

ENGINE SERIALNUMBER

GA 14DE, GA15DE and

GA16DE engine

£~b-=~~rrf~)

(J~~~6

Front

c:::?

SR20DE

engine CD20engine

SGI912

MANUAL TRANSAXLE NUMBER

RS5F30A, RS5F31AandRS5F32A AUTOMATIC

TRANSAXLE NUMBER

SGI913 GI-38 SGI656

Page 1399 of 1701

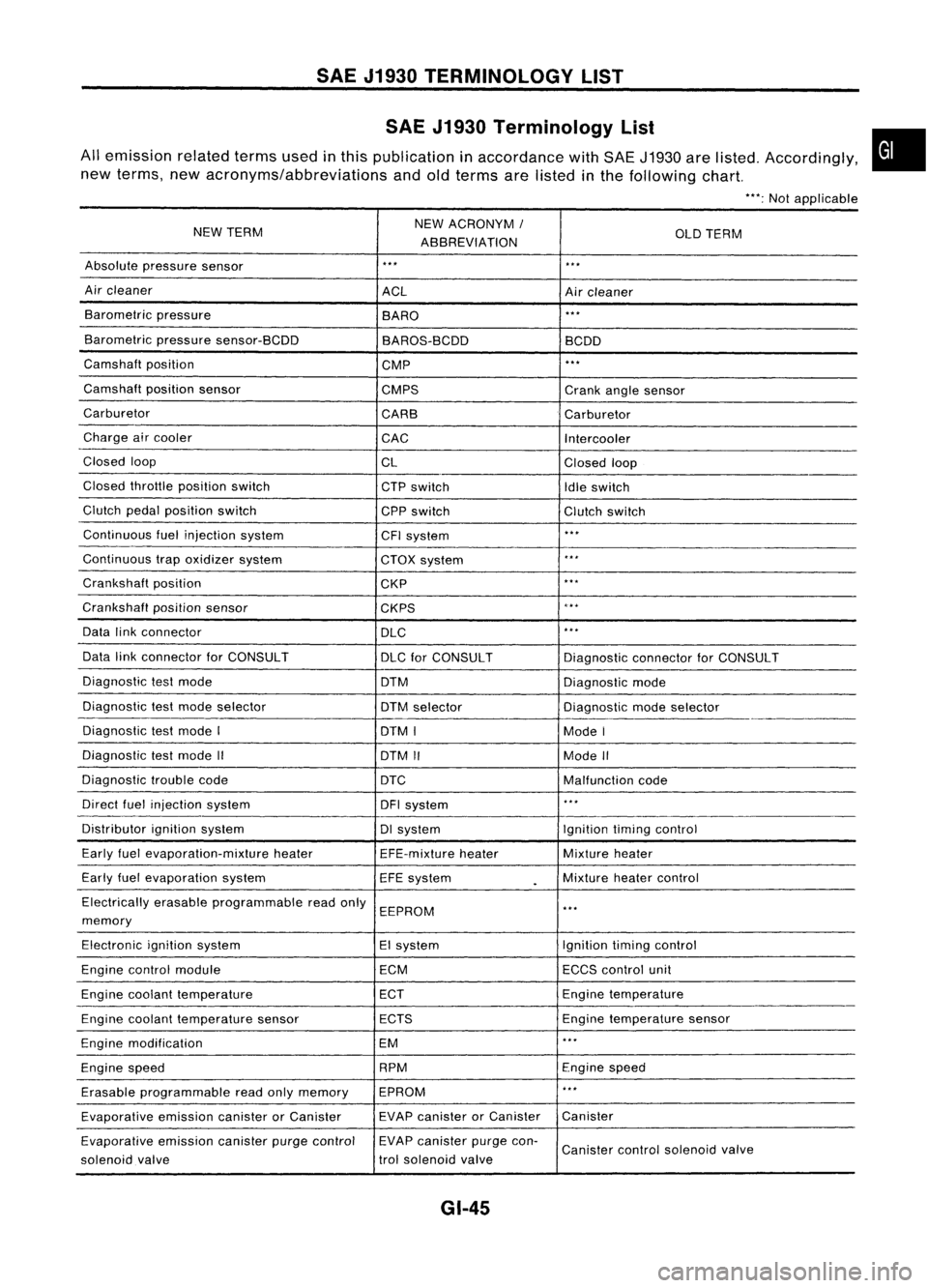

SAEJ1930 TERMINOLOGY LIST

SAE J1930 Terminology List

All emission relatedtermsusedinthis publication inaccordance withSAE J1930 arelisted. Accordingly,

new terms, newacronyms/abbreviations andoldterms arelisted inthe following chart.

"':Not applicable

NEW TERM NEW

ACRONYM /

ABBREVIATION OLD

TERM

Absolute pressure sensor

'" '"

Air cleaner

ACLAircleaner

Barometric pressure

BARO

."

Barometric pressuresensor-BCDD

BAROS-BCDD BCDD

Camshaft position

CMP

'"

Camshaft positionsensor

CMPS Crankanglesensor

Carburetor CARBCarburetor

Charge aircooler

CACIntercooler

Closed loop

CLClosedloop

Closed throttle position switch

CTPswitch

Idleswitch

Clutch pedalposition switch

CPPswitch Clutchswitch

Continuous fuelinjection system

CFIsystem

'"

Continuous trapoxidizer system

CTOXsystem

...

Crankshaft position

CKP

'"

Crankshaft positionsensor

CKPS

~.**

Data linkconnector

DLC

,

..

Data linkconnector forCONSULT

DLCforCONSULT DiagnosticconnectorforCONSULT

Diagnostic testmode

DTMDiagnosticmode

Diagnostic testmode selector

DTMselector Diagnosticmodeselector

Diagnostic testmode I

DTMI ModeI

Diagnostic testmode II

DTMII ModeII

Diagnostic troublecode

DTC Malfunctioncode

Direct fuelinjection system

DFIsystem

..

,

Distributor ignitionsystem DIsystem Ignitiontimingcontrol

Early fuelevaporation-mixture heater

EFE-mixtureheater Mixture

heater

Early fuelevaporation system

EFEsystem

.

Mixture

heatercontrol

Electrically erasableprogrammable readonly

EEPROM

'"

memory

Electronic ignitionsystem EIsystem Ignitiontimingcontrol

Engine control module ECMECCScontrol unit

Engine coolant temperature ECTEngine

temperature

Engine coolant temperature sensor ECTS Engine

temperature sensor

Engine modification EM

'"

Engine speed RPM

Enginespeed

Erasable programmable readonlymemory EPROM

'"

Evaporative emissioncanisterorCanister EVAP

canister orCanister Canister

Evaporative emissioncanisterpurgecontrol EVAP

canister purgecon-

Canister controlsolenoid valve

solenoid valve trol

solenoid valve

GI-45

•

Page 1400 of 1701

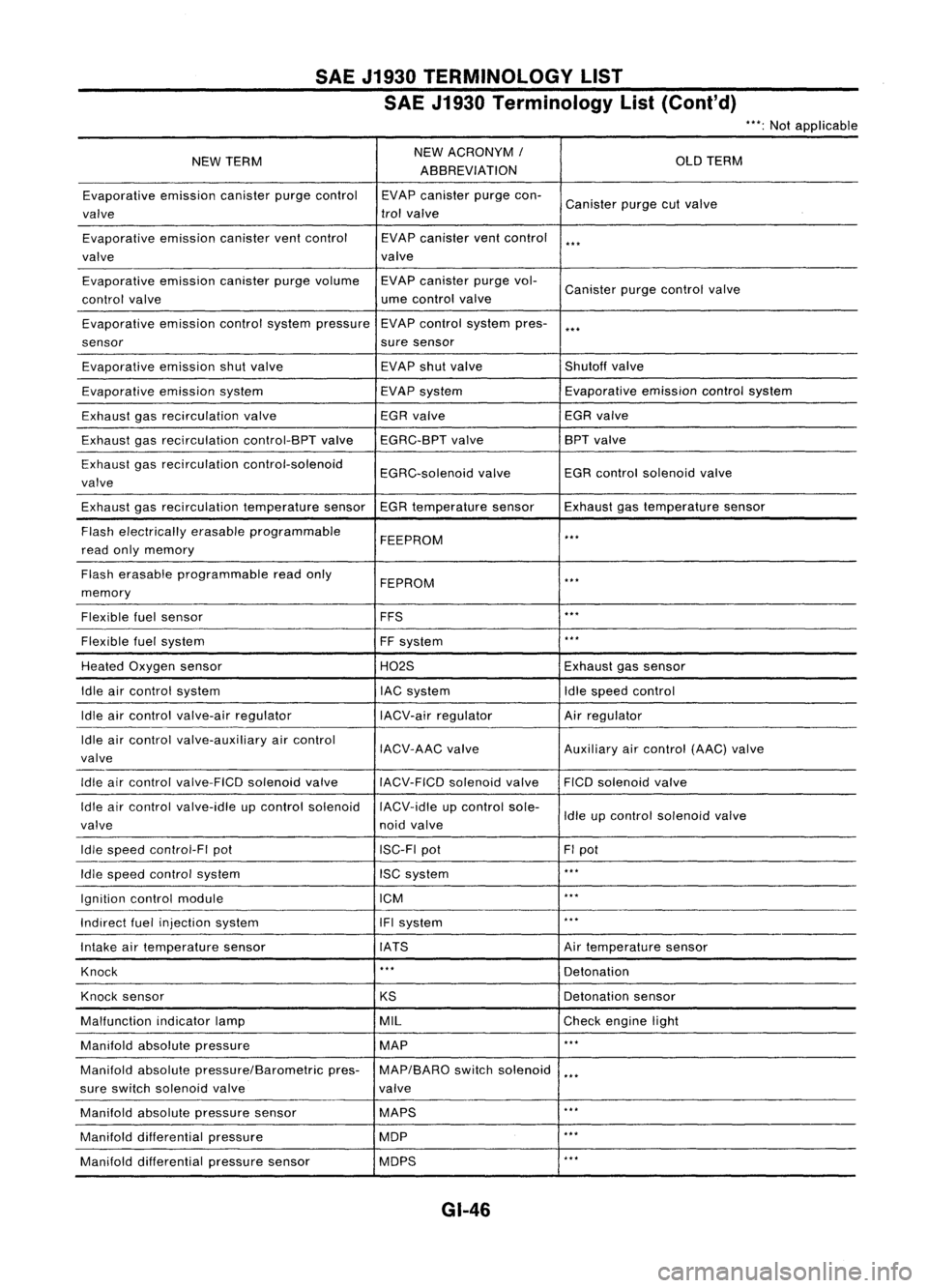

SAEJ1930 TERMINOLOGY LIST

SAE J1930 Terminology List(Cont'd)

***:

Not applicable

NEW TERM NEW

ACRONYM /

OLDTERM

ABBREVIATION

Evaporative emissioncanisterpurgecontrol EVAPcanister purgecon-

Canister purgecutvalve

valve trol

valve

Evaporative emissioncanisterventcontrol EVAPcanister ventcontrol

***

valve valve

Evaporative emissioncanisterpurgevolume EVAPcanister purgevol-

Canister purgecontrol valve

control valve ume

control valve

Evaporative emissioncontrolsystem pressure EVAP

control system pres-

***

sensor suresensor

Evaporative emissionshutvalve EVAP

shutvalve Shutoffvalve

Evaporative emissionsystem EVAPsystem Evaporative

emissioncontrolsystem

Exhaust gasrecirculation valve EGR

valve EGRvalve

Exhaust gasrecirculation control-BPTvalveEGRC-BPT valve BPT

valve

Exhaust gasrecirculation control-solenoid

EGRC-solenoidvalveEGR

control solenoid valve

valve

Exhaust gasrecirculation temperaturesensorEGRtemperature sensorExhaustgastemperature sensor

Flash electrically erasableprogrammable

FEEPROM

***

read onlymemory

Flash erasable programmable readonly

FEPROM

**.

memory

Flexible fuelsensor FFS

***

Flexible fuelsystem

FFsystem

***

Heated Oxygen sensor H02SExhaustgassensor

Idle aircontrol system lACsystem Idlespeed control

Idle aircontrol valve-air regulator IACV-airregulator Airregulator

Idle aircontrol valve-auxiliary aircontrol

IACV-AACvalve Auxiliaryaircontrol (AAC)valve

valve

Idle aircontrol valve-FICO solenoidvalve

IACV-FICDsolenoidvalve FICOsolenoid valve

Idle aircontrol valve-idle upcontrol solenoid IACV-idleupcontrol sole-

Idleupcontrol solenoid valve

valve noidvalve

Idle speed control-FI pot ISC-FIpot FIpot

Idle speed control system ISCsystem

***

Ignition controlmodule ICM

***

Indirect fuelinjection system IFIsystem

***

Intake airtemperature sensor IATS Airtemperature sensor

Knock

***

Detonation

Knock sensor

KSDetonation

sensor

Malfunction indicatorlamp MIL

Checkengine light

Manifold absolutepressure MAP

***

Manifold absolutepressure/Barometric pres-MAP/BARO switchsolenoid

***

sure switch solenoid valve valve

Manifold absolutepressure sensor MAPS

**.

Manifold differential pressure MOP

***

Manifold differential pressuresensor MOPS

***

GI-46

Page 1407 of 1701

PRECAUTIONSANDPREPARATION

Precautions forServicing Compressor

• Plug allopenings toprevent moisture andforeign matterfromentering.

• When thecompressor isremoved, storeitin the same position asitis when mounted onthe car.

• When replacing orrepairing compressor, follow"Maintenance ofLubricant QuantityinCompressor"

exactly. RefertoHA-68.

• Keep friction surfaces betweenclutchandpulley clean.

If

the surface iscontaminated, withlubricant,

wipe itoff byusing aclean waste clothmoistened withthinner.

• After compressor serviceoperation, turnthecompressor shaftbyhand more thanfiveturns inboth

directions. Thiswillequally distribute lubricantinsidethecompressor. Afterthecompressor is

installed, letthe engine idleandoperate thecompressor forone hour.

• After replacing thecompressor magnetclutch,applyvoltage tothe new oneandcheck fornormal

operation.

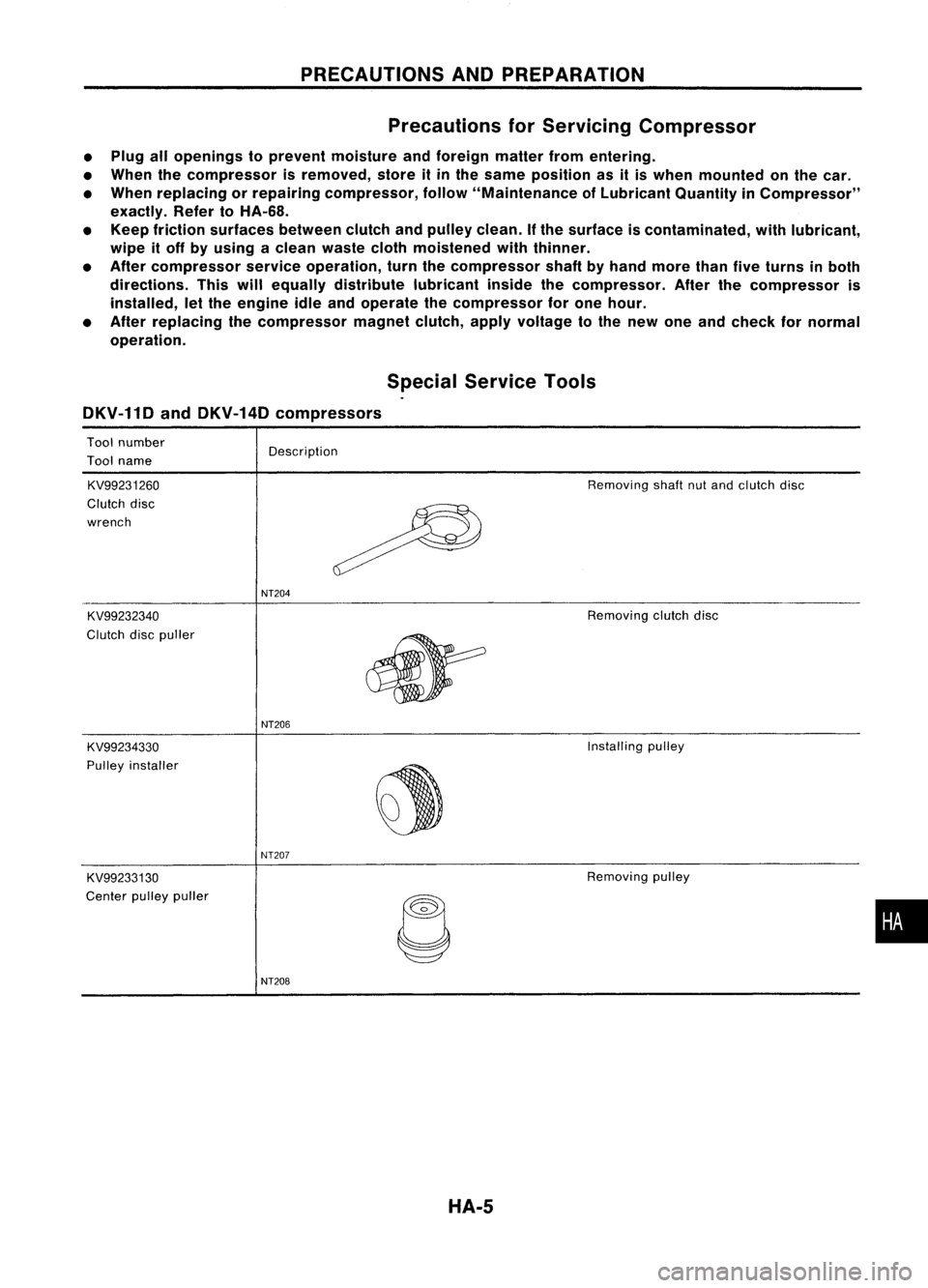

SpecialService Tools

DKV-11D andDKV-14D compressors

Tool number

Tool name

KV99231260

Clutch disc

wrench

KV99232340

Clutch discpuller Description

NT204

Removing

shaftnutand clutch disc

Removing clutchdisc

NT206

KV99234330

Installing

pulley

PUlley installer

~

NT207

KV99233130

Removing

pulley

Center pulleypuller

C

•

NT208

HA-5

Page 1415 of 1701

DESCRIPTION

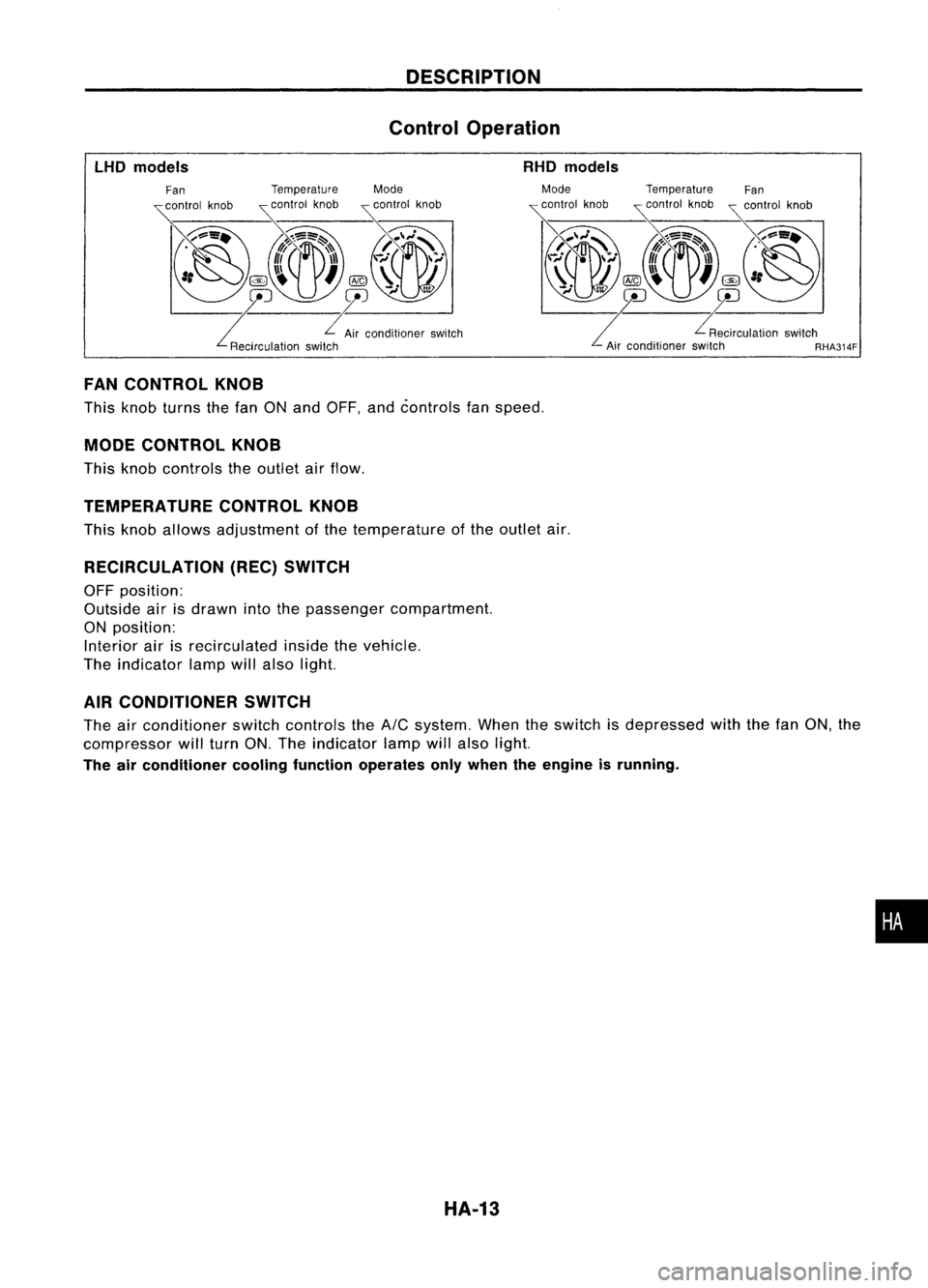

Control Operation

LHO models RHO

models

FAN CONTROL KNOB

This knob turns thefan ONand OFF, andcontrols fanspeed.

MODE CONTROL KNOB

This knob controls theoutlet airflow.

TEMPERATURE CONTROLKNOB

This knob allows adjustment ofthe temperature ofthe outlet air.

RECIRCULATION (REC)SWITCH

OFF position:

Outside airisdrawn intothepassenger compartment.

ON position:

Interior airisrecirculated insidethevehicle.

The indicator lampwillalso light.

AIR CONDITIONER SWITCH

The airconditioner switchcontrols the

Ale

system. Whentheswitch isdepressed withthefan ON, the

compressor willturn ON.The indicator lampwillalso light.

The airconditioner coolingfunction operates onlywhen theengine isrunning.

HA-13

•

Page 1416 of 1701

TROUBLEDIAGNOSES

Contents

How toPerform TroubleDiagnoses forQuick andAccurate Repair HA-15

Operational Check HA-16

Symptom Chart HA-18

Preliminary Check HA-20

PRELIMINARY CHECK1

(A/C

does notblow coldair.) HA-20

PRELIMINARY CHECK2

(Air outlet doesnotchange.) HA-21

PRELIMINARY CHECK3

(Noise) HA-22

PRELIMINARY CHECK4

(I nsufficient heating) HA-23

Performance TestDiagnoses HA-24

INSUFFICIENT COOLING HA-24

Performance Chart HA-26

TEST CONDITION HA-26

TEST READING HA-26

Trouble Diagnoses forAbnormal Pressure HA-27

Harness Layout. HA-31

Circuit Diagram -Air Conditioner HA-34

Wiring Diagram -HEATER - HA-36

Wiring Diagram -AIC - HA-38

Main Power Supply andGround CircuitCheck HA-49

Diagnostic Procedure1

(SYMPTOM: Blowermotordoesnotrotate.) HA-50

Diagnostic Procedure2

(SYMPTOM: Intake doordoes notchange.) HA-52

Diagnostic Procedure3

(SYMPTOM: Magnetclutchdoesnotoperate when

A/C

switch andfanswitch areON.)

- For GAand SRengines HA-54

- For CDengine HA-59

Electrical Components Inspection HA-62

Control Linkage Adjustment HA-64

System Description HA-65

HA-14

Page 1418 of 1701

TROUBLEDIAGNOSES

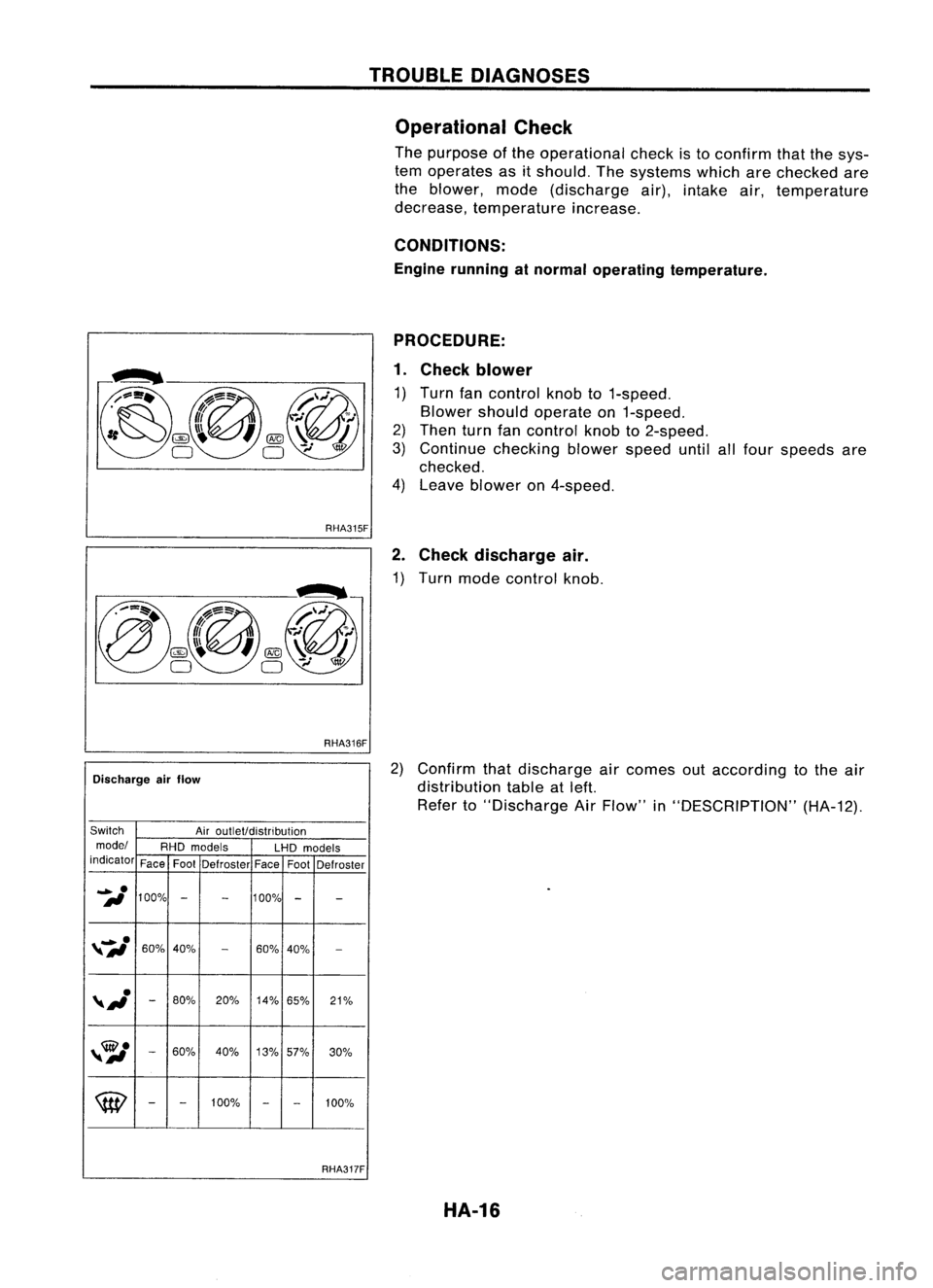

Operational Check

The purpose ofthe operational checkisto confirm thatthesys-

tem operates asitshould. Thesystems whicharechecked are

the blower, mode(discharge air),intake air,temperature

decrease, temperature increase.

CONDITIONS:

Engine running atnormal operating temperature.

RHA315F

RHA316F

Discharge airflow

Switch Airoutlet/distribution

model RHDmodels

LHDmodels

indicator FaceFootDefroster FaceFoot

Defroster

_e

100% 100%

II

-

- -

-

"#Ie

60%

40%

-

60%

40%

-

"J

-

80%

20%14%

65% 21%

,,

60% 40%

13%57%

30%

W

-

-

100%

-

-

100%

RHA317F PROCEDURE:

1. Check blower

1) Turn fancontrol knobto1-speed.

Blower shouldoperate on1-speed.

2) Then turnfancontrol knobto2-speed.

3) Continue checking blowerspeeduntilallfour speeds are

checked.

4) Leave blower on4-speed.

2. Check discharge air.

1) Turn mode control knob.

2) Confirm thatdischarge aircomes outaccording tothe air

distribution tableatleft.

Refer to"Discharge AirFlow" in"DESCRIPTION" (HA-12).

HA-16

Page 1422 of 1701

TROUBLEDIAGNOSES

Preliminary Check

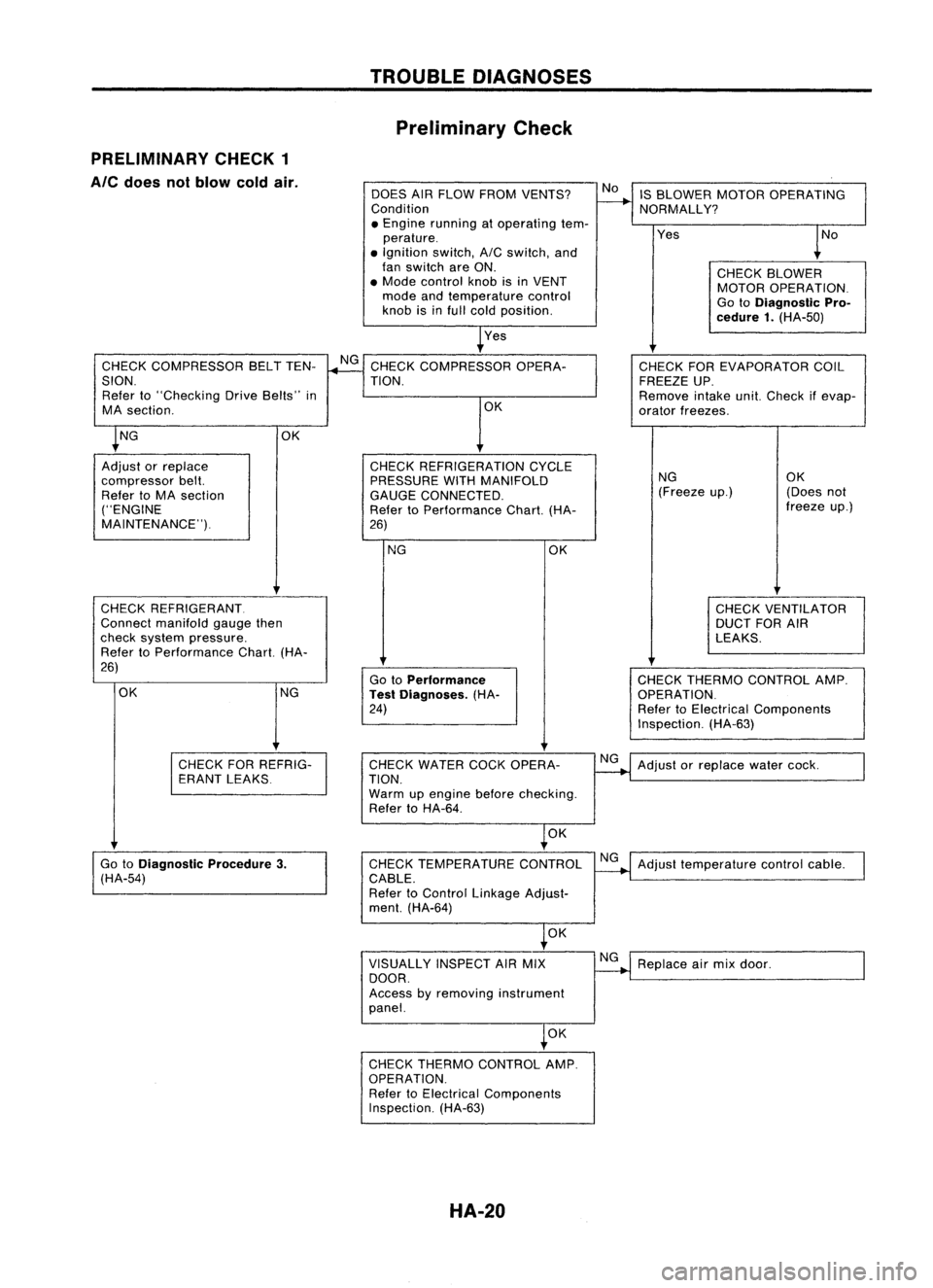

PRELIMINARY CHECK1

Ale

does notblow coldair.

DOESAIRFLOW FROM VENTS?

Condition

• Engine running atoperating tem-

perature .

• Ignition switch,AICswitch, and

fan switch areON.

• Mode control knobisin VENT

mode andtemperature control

knob isinfull cold position.

Yes IS

BLOWER MOTOROPERATING

NORMALLY?

Yes

CHECKBLOWER

MOTOR OPERATION.

Go toDiagnostic Pro-

cedure 1.(HA-50)

CHECK COMPRESSOR BELTTEN-

SION. Refer to"Checking DriveBelts" in

MA section.

CHECK REFRIGERANT.

Connect manifold gaugethen

check system pressure.

Refer toPerformance Chart.(HA-

26)

NG CHECK

THERMO CONTROL AMP.

OPERATION.

Refer toElectrical Components

Inspection. (HA-63)

CHECK

FOREVAPORATOR COIL

FREEZE UP.

Remove intakeunit.Check ifevap-

orator freezes.

NG OK

(Freeze up.) (Doesnot

freeze up.)

CHECK VENTILATOR

DUCT FORAIR

LEAKS.

OK

Go toPerformance

Test Diagnoses. (HA-

24)

NG

CHECK

REFRIGERATION CYCLE

PRESSURE WITHMANIFOLD

GAUGE CONNECTED.

Refer toPerformance Chart.(HA-

26) OK

CHECK

COMPRESSOR OPERA-

TION.

OK

OK NG

Adjust orreplace

compressor belt.

Refer toMA section

("ENGINE

MAINTENANCE").

CHECKFORREFRIG-

ERANT LEAKS CHECK

WATER COCKOPERA-

TION.

Warm upengine beforechecking.

Refer toHA-64.

NG

Adjust orreplace watercock.

OK

Go toDiagnostic Procedure3.

(HA-54) CHECK

TEMPERATURE CONTROL

CABLE.

Refer toControl Linkage Adjust-

ment. (HA-64) NG

Adjust temperature controlcable.

OK

VISUALLY INSPECTAIRMIX

DOOR.

Access byremoving instrument

panel. NG

Replace airmix door.

OK

CHECK THERMO CONTROL AMP.

OPERATION. Refer toElectrical Components

Inspection. (HA-63)

HA-20

Page 1424 of 1701

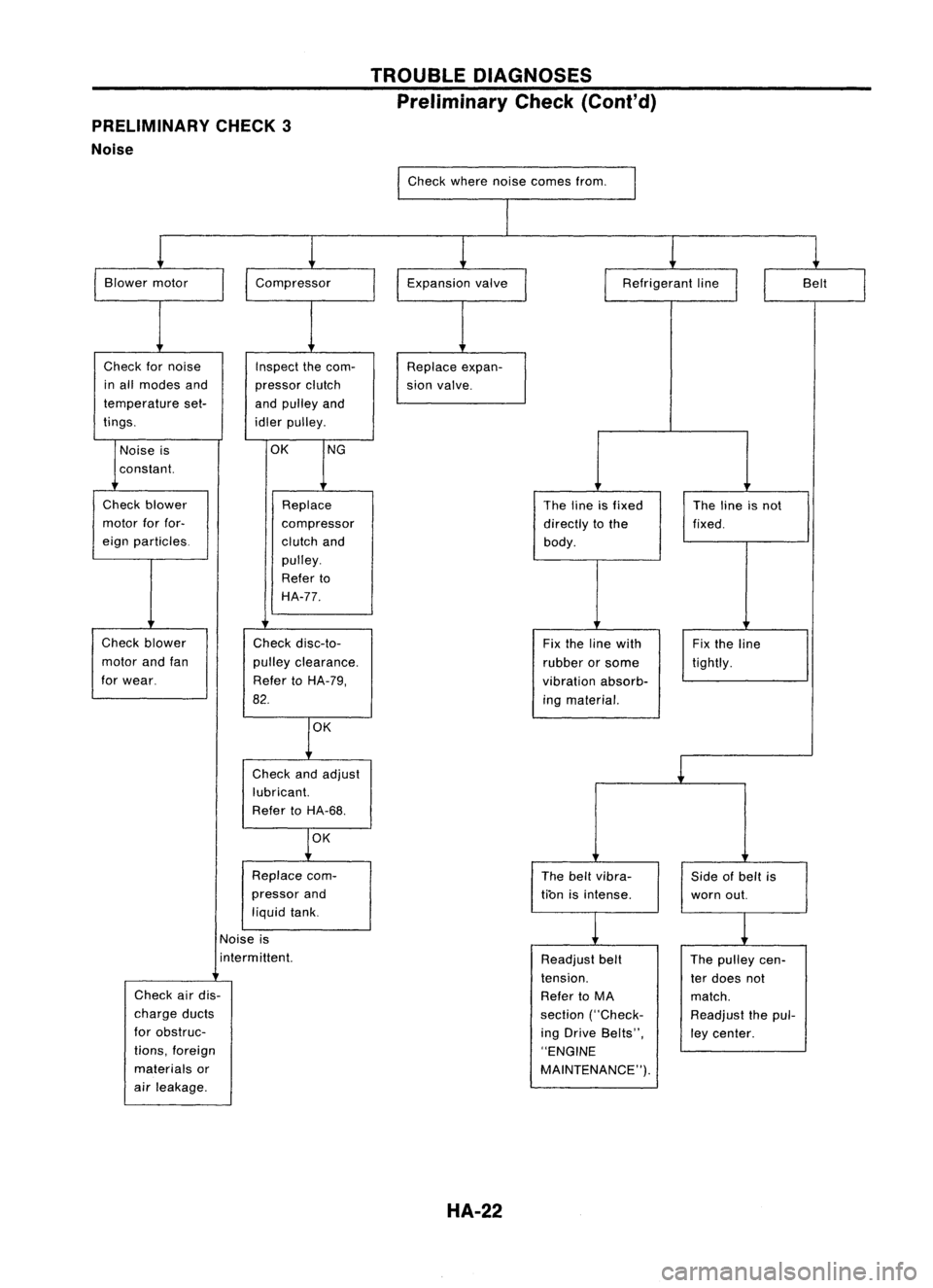

PRELIMINARY CHECK3

Noise TROUBLE

DIAGNOSES

Preliminary Check(Coni'd)

Check wherenoisecomes from.

I

I

Blower motor

Check fornoise

in all modes and

temperature set-

tings.

I

Compressor

Inspect thecom-

pressor clutch

and pulley and

idler pulley. Expansion

valve

Replace expan-

sion valve.

I

Refrigerant line

II

Belt

I

Noise is

constant.

OK

NG

Check blower

motor forfor-

eign particles.

Check blower

motor andfan

for wear. Replace

compressor

clutch and

pulley.

Refer to

HA-77.

Check disc-to-

pulley clearance.

Refer toHA-79,

82.

OK

Check andadjust

lubricant.

Refer toHA-68.

OK

Replace com-

pressor and

liquid tank. The

lineisfixed

directly tothe

body.

Fix the line with

rubber orsome

vibration absorb-

ing material.

The beltvibra-

tion isintense. The

lineisnot

fixed.

Fix the line

tightly.

Side ofbelt is

worn out.

Noise is

i nterm ittent.

Check airdis-

charge ducts

for obstruc-

tions, foreign

materials or

air leakage.

HA-22

Readjust

belt

tension.

Refer toMA

section ("Check-

ing Drive Belts",

"ENGINE

MAINTENANCE"). The

pulley cen-

ter does not

match.

Readjust thepul-

ley center.