engine NISSAN ALMERA N15 1995 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 1478 of 1701

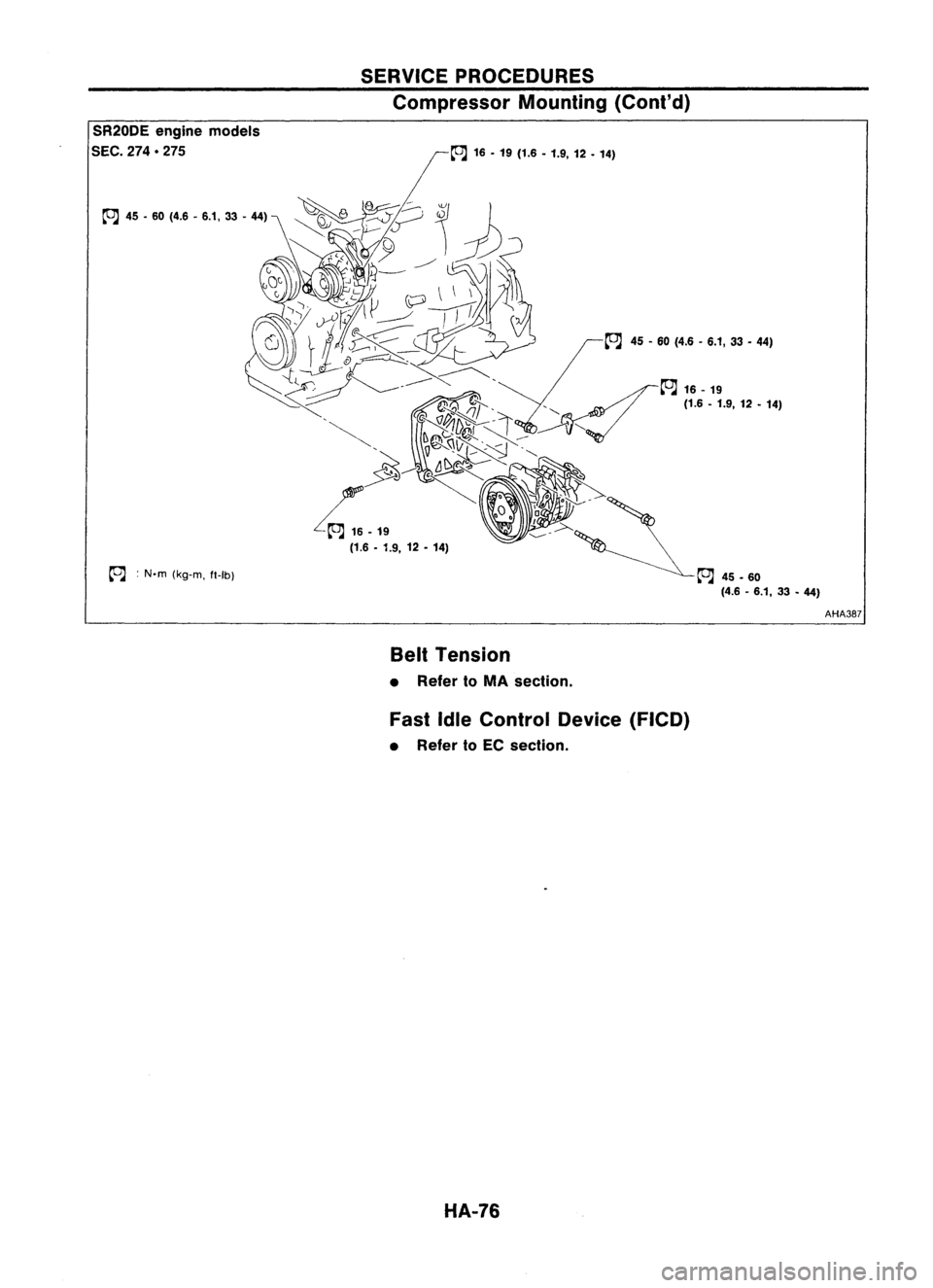

SR20DEenginemodels

SEC.

274.275

~ :N.m (kg-m, ft-Ib)

SERVICE

PROCEDURES

Compressor Mounting(Cont'd)

~ 16•19 (1.6 •1.9, 12•14)

~ 45-60 (4.6 -6.1, 33•44)

~45.60 (4.6-6.1, 33•44)

Belt Tension

• Refer toMA section.

Fast IdleControl Device(FICO)

• Refer toEC section.

HA-76 AHA387

Page 1486 of 1701

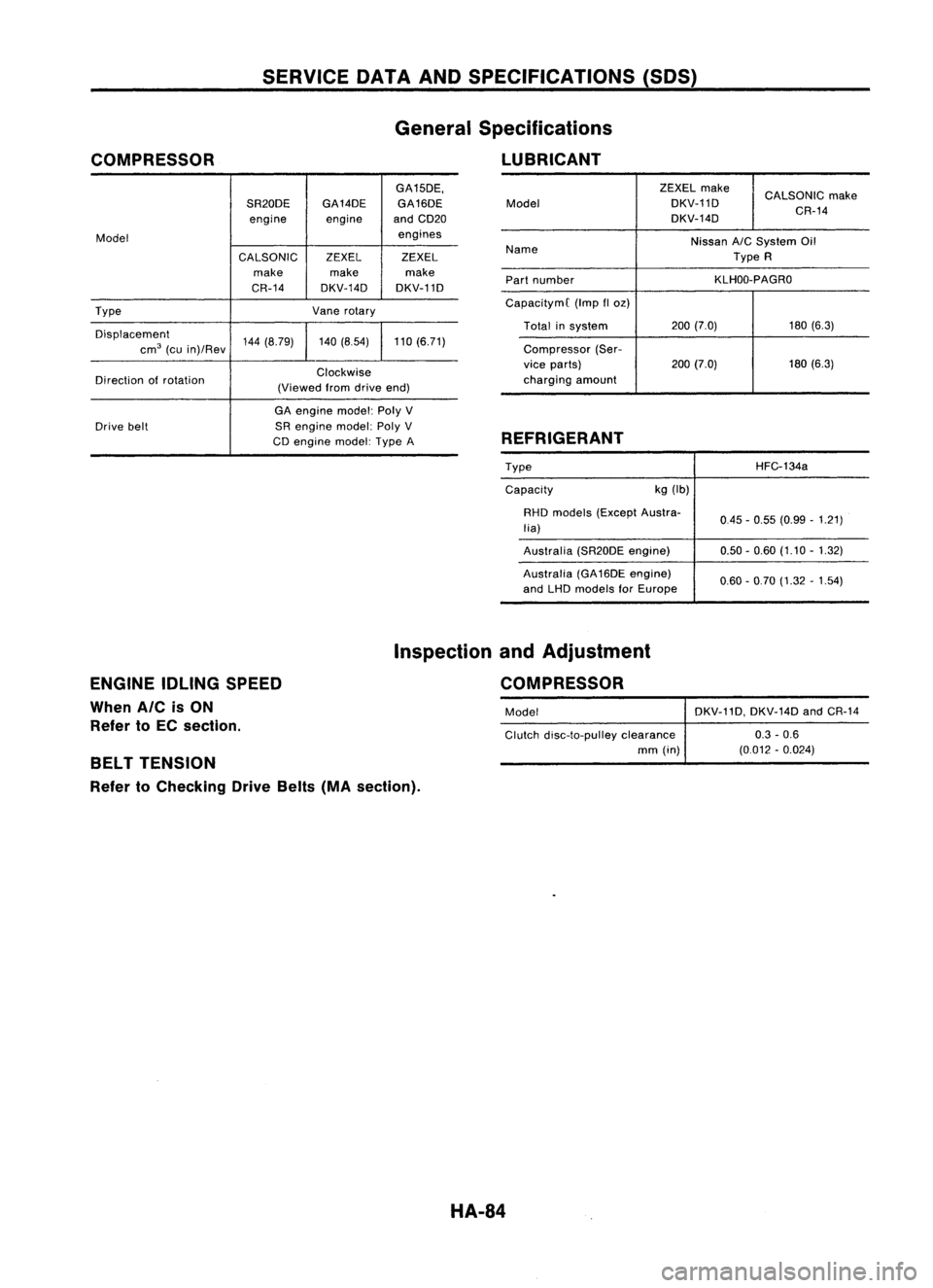

COMPRESSOR SERVICE

DATAANDSPECIFICATIONS (50S)

General Specifications

LUBRICANT

GA15DE,

SR20DE GA14DE

GA16DE

engine engineandCD20

Model engines

CALSONIC ZEXELZEXEL

make makemake

CR-14 DKV-14D DKV-11D

Type Vanerotary

Displacement 144(8.79) 140(8.54) 110(6.71)

cm

3

(cuin)/Rev

Direction ofrotation Clockwise

(Viewed fromdrive end)

GA engine model:PolyV

Drive belt SRengine model:PolyV

CD engine model:TypeA ZEXEL

make

CALSONIC make

Model DKV-11D

DKV-14D CR-14

Name Nissan

A/C

System Oil

Type R

Part number KLHOO-PAGRO

CapacitymC (Impfloz)

Total insystem 200

(7.0) 180(6.3)

Compressor (Ser-

vice parts) 200(7.0) 180

(6.3)

charging amount

REFRIGERANT

TypeCapacity kg

(Ib) HFC-134a

RHD models (Except Austra-

lia)

Australia (SR20DEengine)

Australia (GA16DE engine)

and LHD models forEurope 0.45

-0.55 (0.99 -1.21)

0.50 -0.60 (1.10 -1.32)

0.60 -0.70 (1.32 -1.54)

ENGINE IDLINGSPEED

When AICisON

Refer toEC section. Inspection

andAdjustment

COMPRESSOR

Model DKV-11D,DKV-14DandCR-14

Clutch disc-to-pulley clearance 0.3-0.6

mm (in) (0.012-0.024)

BELT TENSION

Refer toChecking DriveBelts(MAsection).

HA-84

Page 1487 of 1701

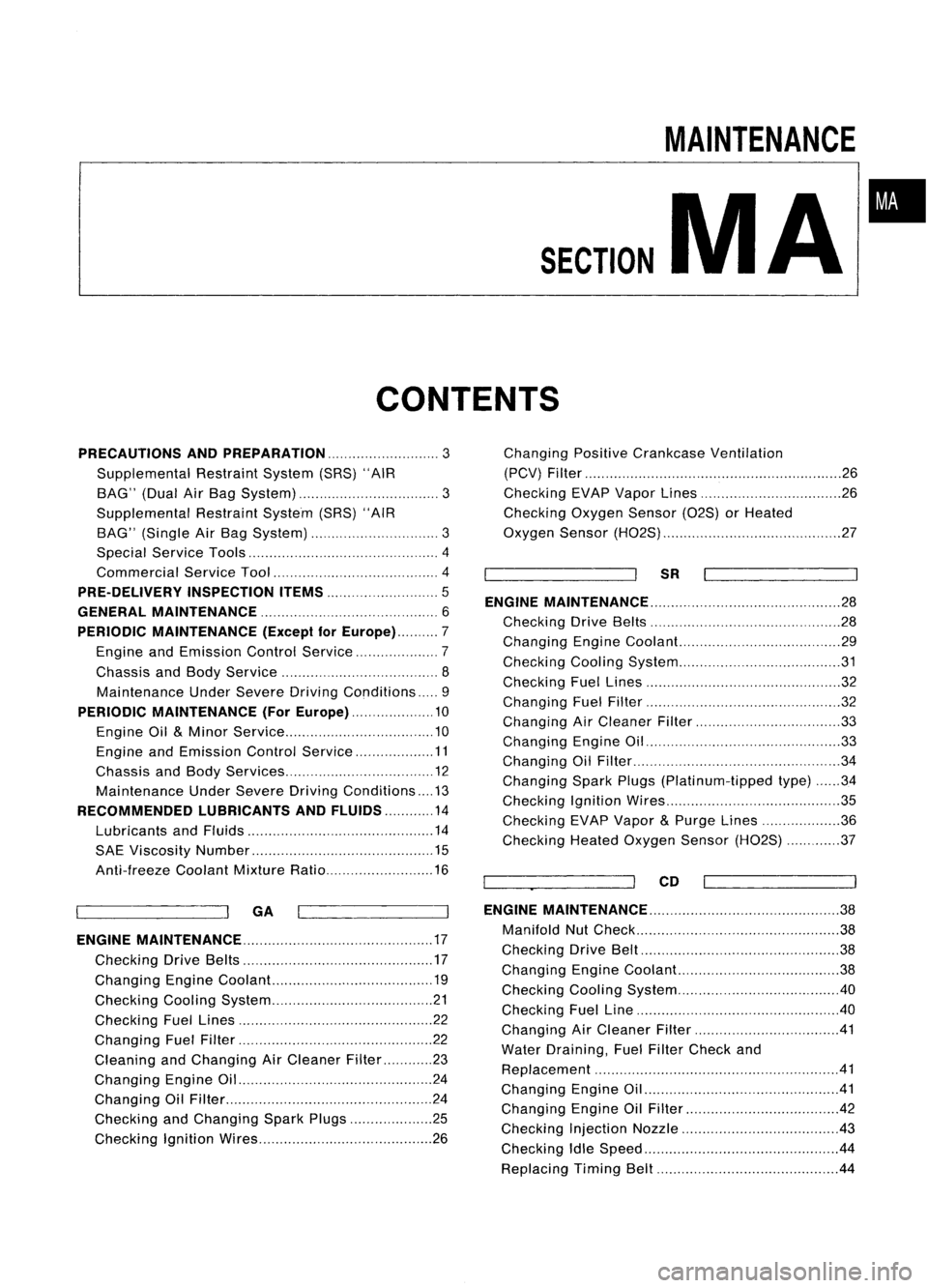

SECTION

CONTENTS

MAINTENANCE

MA

•

PRECAUTIONS ANDPREPARATION

3

Supplemental RestraintSystem(SRS)"AIR

BAG" (DualAirBag System) 3

Supplemental RestraintSystem(SRS)"AIR

BAG" (Single AirBag System) 3

Special Service Tools 4

Commercial ServiceTool 4

PRE-DELIVERY INSPECTIONITEMS

5

GENERAL MAINTENANCE 6

PERIODIC MAINTENANCE (Exceptfor

Europe) 7

Engine andEmission ControlService 7

Chassis andBody Service 8

Maintenance UnderSevere DrivingConditions 9

PERIODIC MAINTENANCE (ForEurope) 10

Engine Oil

&

Minor Service 10

Engine andEmission ControlService 11

Chassis andBody Services 12

Maintenance UnderSevere Driving Conditions 13

RECOMMENDED LUBRICANTSANDFLUIDS 14

Lubricants andFluids 14

SAE Viscosity Number 15

Anti-freeze CoolantMixtureRatio 16

~ --ll

GA

I I

ENGINE MAINTENANCE 17

Checking DriveBelts 17

Changing EngineCoolant... 19

Checking CoolingSystem 21

Checking FuelLines 22

Changing FuelFilter 22

Cleaning andChanging AirCleaner Filter 23

Changing EngineOil 24

Changing OilFilter 24

Checking andChanging SparkPlugs 25

Checking IgnitionWires 26Changing

PositiveCrankcase Ventilation

(PCV) Filter 26

Checking EVAPVapor Lines 26

Checking OxygenSensor(02S)orHeated

Oxygen Sensor(H02S) 27

~ --ll

SR

I I

ENGINE MAINTENANCE 28

Checking DriveBelts 28

Changing EngineCoolant... 29

Checking CoolingSystem 31

Checking FuelLines 32

Changing FuelFilter 32

Changing AirCleaner Filter 33

Changing EngineOil 33

Changing OilFilter 34

Changing SparkPlugs(Platinum-tipped type)34

Checking IgnitionWires 35

Checking EVAPVapor

&

Purge Lines 36

Checking HeatedOxygen Sensor(H02S) 37

~_~ ..-JI

CD

I I

ENGINE MAINTENANCE

38

Manifold NutCheck 38

Checking DriveBelt 38

Changing EngineCoolant. 38

Checking CoolingSystem .40

Checking FuelLine .40

Changing AirCleaner Filter 41

Water Draining, FuelFilter Check and

Replacement 41

Changing EngineOil .41

Changing EngineOilFilter 42

Checking InjectionNozzle 43

Checking IdleSpeed .44

Replacing TimingBelt 44

Page 1488 of 1701

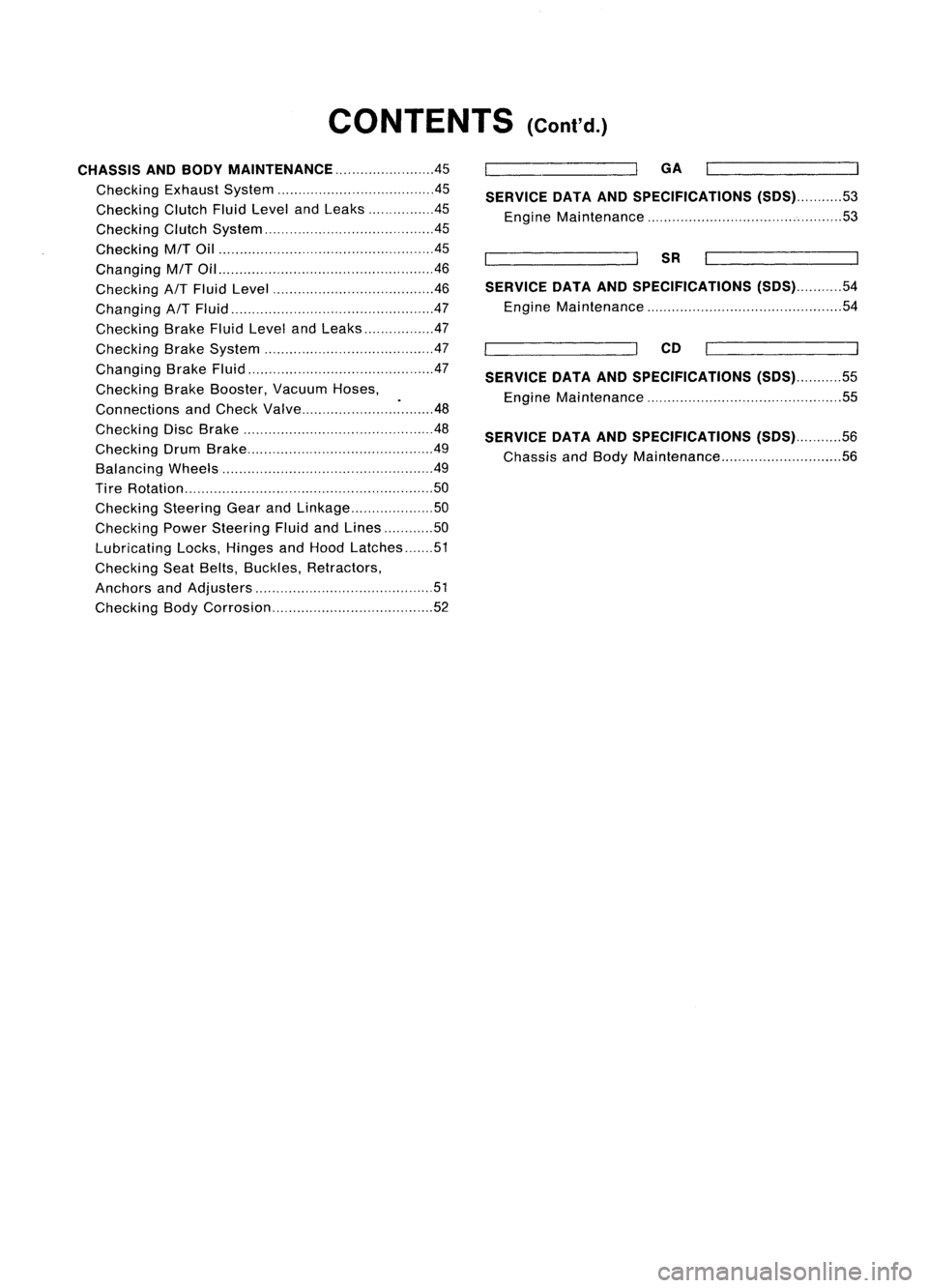

CONTENTS(Cont'd.)

CHASSIS ANDBODY MAINTENANCE 45

Checking ExhaustSystem .45

Checking ClutchFluidLevel andLeaks .45

Checking ClutchSystem .45

Checking MfTOil .45

Changing MfTOil 46

Checking

AfT

Fluid Level .46

Changing

AfT

Fluid .47

Checking BrakeFluidLevel andLeaks 47

Checking BrakeSystem .47

Changing BrakeFluid .47

Checking BrakeBooster, VacuumHoses,

Connections andCheck Valve ~48

Checking DiscBrake .48

Checking DrumBrake .49

Balancing Wheels 49

Ti re Rotation 50

Checking SteeringGearandLinkage 50

Checking PowerSteering FluidandLines 50

Lubricating Locks,Hinges andHood Latches 51

Checking SeatBelts, Buckles, Retractors,

Anchors andAdjusters 51

Checking BodyCorrosion 52

GA

SERVICE DATAANDSPECIFICATIONS

(505)53

Engine Maintenance 53

SR

SERVICE DATAANDSPECIFICATIONS

(505)54

Engine Maintenance 54

CD

SERVICE DATAANDSPECIFICATIONS

(505)55

Engine Maintenance 55

SERVICE DATAANDSPECIFICATIONS

(505)56

Chassis andBody Maintenance 56

Page 1490 of 1701

PRECAUTIONSANDPREPARATION

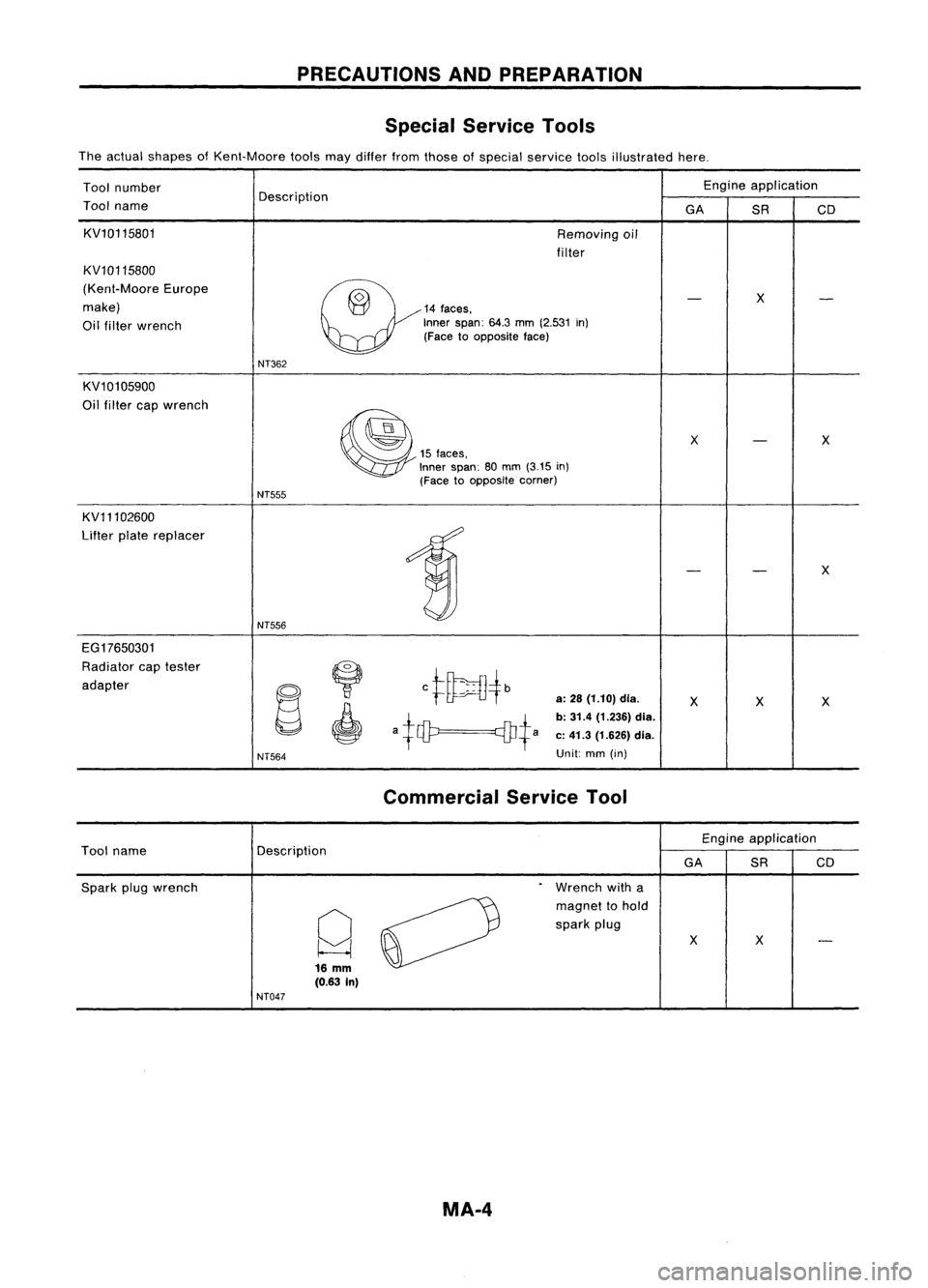

Special Service Tools

The actual shapes ofKent-Moore toolsmaydiffer fromthose ofspecial service toolsillustrated here.

Tool number Engine

application

Tool name Description

GASRCD

KV10115801 Removingoil

filter

KV10115800

(Kent-Moore Europe

~14"'"

-

X

-

make)

Oil filter wrench Inner

span:

64.3

mm

(2.531

in)

(Face toopposite face)

NT362

KV10105900

Oil filter capwrench

~

X

-

X

15

faces,

Inner span: 80mm

(3.15

in)

(Face toopposite corner)

NT555

KV11102600

Lifter platereplacer

1

-

-

X

NT556

EG17650301 Radiator captester

~

ct~4b

adapter

~

"

a:

28

(1.10) dia.

XX X

a+ciP q]J+a

b:

31.4 (1.236) dia.

c: 41.3 (1.626) dia.

I

NT564

Unit:

mm(in)

Commercial ServiceTool

Engineapplication

Tool name Description

GASRCD

Spark plugwrench

.

Wrench witha

Q

0

magnet

tohold

spark plug

XX

-

16

mm

(0.63 In)

NT047

MA.4

Page 1491 of 1701

PRE-DELIVERYINSPECTIONITEMS

Shown belowarePre-delivery InspectionItemsrequired forthe new vehicle. Itis recommended that

necessary itemsotherthanthose listedherebeadded, payingdueregard tothe conditions ineach

country.

Perform applicable itemsoneach model. Consult textofthis section forspecifications .

UNDER HOOD-engine off

o

Radiator coolantlevelandcoolant hosecon-

nections forleaks

o

Battery fluidlevel, specific gravityandcondi-

tions ofbattery terminals

o

Drive beltstension

D

Fuel filter forwater ordusts, andfuel lines

and connections forleaks

[] Engine oillevel andoilleaks

D

Clutch andbrake reservoir fluidlevel and

fluid lines forleaks

o

Windshield andrear window washerand

headlamp cleanerreservoir fluidlevel

D

Power steering reservoir fluidlevel andhose

connections forleaks

ON INSIDE ANDOUTSIDE

D

Remove frontspring/strut spacer(Ifapplica-

ble)

D

Operation ofall instruments, gauges,lights

and accessories

o

Operation ofhorn(s), wiperandwasher

[] Steering lockforoperation

[] Check airconditioner forgas leaks

o

Front andrear seats, andseat belts foroper-

ation

n

All moldings, trimsandfittings forfitand

alignment

[J

Allwindows foroperation andalignment

n

Hood, trunklid,door panels forfitand align-

ment

[1

Latches, keysandlocks foroperation

rl

Weatherstrips foradhesion andfit

[l

Headlamp aiming

I~ Tighten wheelnuts(Inc. inner nutsifapplica-

ble)

IJ Tire pressure (Inc.spare tire)

Il

Check frontwheels fortoe-in

IJ Install clock/voltmeter/room lampfuse(If

applicable)

~ Install deodorizing filtertoair purifier (If

applicable)

~ Remove wiperbladeprotectors (Ifapplicable)

UNDER

BODY

o

Manual transmission/transaxle, transferand

differential gearoillevel

D

Brake andfuel lines andoil/fluid reservoirs

for leaks

D

Tighten boltsandnuts ofsteering linkageand

gear box,suspension, propellershaftsand

drive shafts

~ Tighten rearbody boltsandnuts (Models with

wooden bedonly)

ROAD TEST

D

Clutch operation

D

Parking brakeoperation

[J

Service brakeoperation

D

Automatic transmission/transaxle shifttiming

and kickdown

[] Steering controlandreturnability

o

Engine performance

D

Squeaks andrattles

ENGINE OPERATING ANDHOT

D

Adjust idlemixture andspeed (andignition

timing*1)

n

Automatic transmission/transaxle fluidlevel

~ Engine idlingandstop knob operation (Diesel

only)

FINAL INSPECTION

n

Install necessary parts(outside mirror,wheel

covers, seatbelts, mat,carpet ormud flaps)

[1

Inspect forinterior andexterior metaland

paint damage

[] Check forspare tire,jack, tools (wheel

chock), andliterature

n

Wash, cleaninterior andexterior

"1: Not required onmodels withadirect ignition system

~ :Not appiicable tothis model.

•

MA-5

Page 1492 of 1701

GENERALMAINTENANCE

General maintenance includesthoseitemswhich should bechecked duringthenormal day-to-day

operation ofthe vehicle. Theyareessential ifthe vehicle isto continue operating properly.Theowners

can perform thechecks andinspections themselves orthey canhave theirNISSAN dealersdothem.

Item

OUTSIDE THEVEHICLE

The maintenance itemslistedhereshould beperformed fromtimetotime, unless oth-

erwise specified.

Tires

Check thepressure withagauge periodically whenataservice station, including

the spare, andadjust tothe specified pressureifnecessary. Checkcarefully fordamage,

cuts orexcessive wear.

Windshield wiperblades

Checkforcracks orwear ifthey donot wipe properly.

Doors andengine hood

Check thatalldoors, theengine hood,thetrunk lidand back

door operate properly. Alsoensure thatalllatches locksecurely. Lubricate hinges,

latches, rollersandlinks ifnecessary. Makesurethatthesecondary latchkeeps thehood

from opening whentheprimary latchisreleased.

When driving inareas usingroadsaltorother corrosive materials, checkforlubrication

frequently.

Tire rotation

Tiresshould berotated every

10,000

km

(6,000

miles).

INSIDE THEVEHICLE

The maintenance itemslistedhereshould bechecked onaregular basis,suchaswhen

performing periodicmaintenance, cleaningthevehicle, etc.

Lights

Makesurethattheheadlights, stoplights, taillights, turnsignal lights,andother

lights arealloperating properlyandinstalled securely. Alsocheck headlight aim.

Warning lightsandbuzzers/chimes

Makesurethatallwarning lightsandbuzzers/chimes

are operating properly.

Steering wheel

Check forchange inthe steering conditions, suchasexcessive freeplay,

hard steering orstrange noises.

Free play: Lessthan35mm (1.38 in)

Seat belts

Check thatallparts ofthe seat beltsystem (e.g.buckles, anchors, adjusters

and retractors) operateproperly andsmoothly, andareinstalled securely. Checkthebelt

webbing forcuts, fraying, wearordamage.

UNDER THEHOOD ANDVEHICLE

The maintenance itemslisted hereshould bechecked periodically e.g.each timeyou

check theengine oilorrefuel.

Windshield washerfluid

Check thatthere isadequate fluidinthe tank.

Engine coolant level

Check thecoolant levelwhen theengine iscold.

Engine oillevel

Check thelevel afterparking thevehicle onalevel spotandturning off

the engine.

Brake andclutch fluidlevels

Makesurethatthebrake andclutch fluidlevels arebetween

the "MAX" and"MIN" linesonthe reservoir.

Battery

Checkthefluid level ineach cell.Itshould bebetween the"MAX" and"MIN"

lines.

MA-6

Reference

pages

MA-51

MA-50

MA-19,38

MA-24, 33,41

MA-45,47

Page 1493 of 1701

PERIODICMAINTENANCE (ExceptforEurope)

The following tablesshowthenormal maintenance schedule.Depending uponweather andatmospheric

conditions, varyingroadsurfaces, individual drivinghabitsandvehicle usage,additional ormore fre-

quent maintenance mayberequired.

Periodic maintenance beyondthelast period shown onthe tables requires similarmaintenance .

Engine andEmission ControlService

•

Abbreviations: I

=

Inspect andcorrect orreplace asnecessary. R

MAINTENANCE OPERATION

Perform eitheratnumber ofkilometers (miles)

or months, whichever comestirst. km

x1,000

(Miles x1,000)

Months

Replace.

A

=

Adjust, C

=

Clean.

MAINTENANCE INTERVAL

10 20 3040

506070

80

Reference page

(6) (12) (18)

(24)(30)(36)(42)(48)

6 12 18

24

3036

42 48

Underhood andunder vehicle GA

SR

Intake

&

exhaust valveclearance (GA15DE

&

GA16DE engines) SeeNOTE (1)

EM41

-

Drive belts

II

MA 17

24

Engine anti-Ireeze coolant(Ethylene glycolbase)(LLC) RRMA 1929

Engine coolant (Softwater) RRR

R

R R

R

RMA

1929

Cooling system

I

I

I

I

MA 2131

Fuel lines

I

I

MA

22

32

Air cleaner filter(Drypaper type)*

CC

C RC CC RMA 23

-

Air cleaner filter(Viscous papertype)* R

RMA

2333

Engine oil(Use APISE,SF.SGorSH oil)*

R

RRRR R

RR

MA 24

33

Engine oilfilter* R

R R

R

R RRRMA

2433

Fuel filter* R

RMA

22

32

Spark plugs(except Platinum-tipped type) R

RMA

25

-

Spark plugs(platinum-tipped type) Replaceevery100,000 km(60.000 miles). MA

-

34

Ignition wires

I

I

MA

2635

PCV filter* R

RMA

26

-

Vapor lines

I

I

MA

26

36

(Heated) OxygenSensor

I

I

MA 2737

NOTE: (1)

If

valve noiseincreases, checkvalveclearance.

*

Maintenance itemswith

"*"

should beperformed morefrequently accordingto"Maintenance undersevere driv-

ing conditions".

MA-7

Page 1495 of 1701

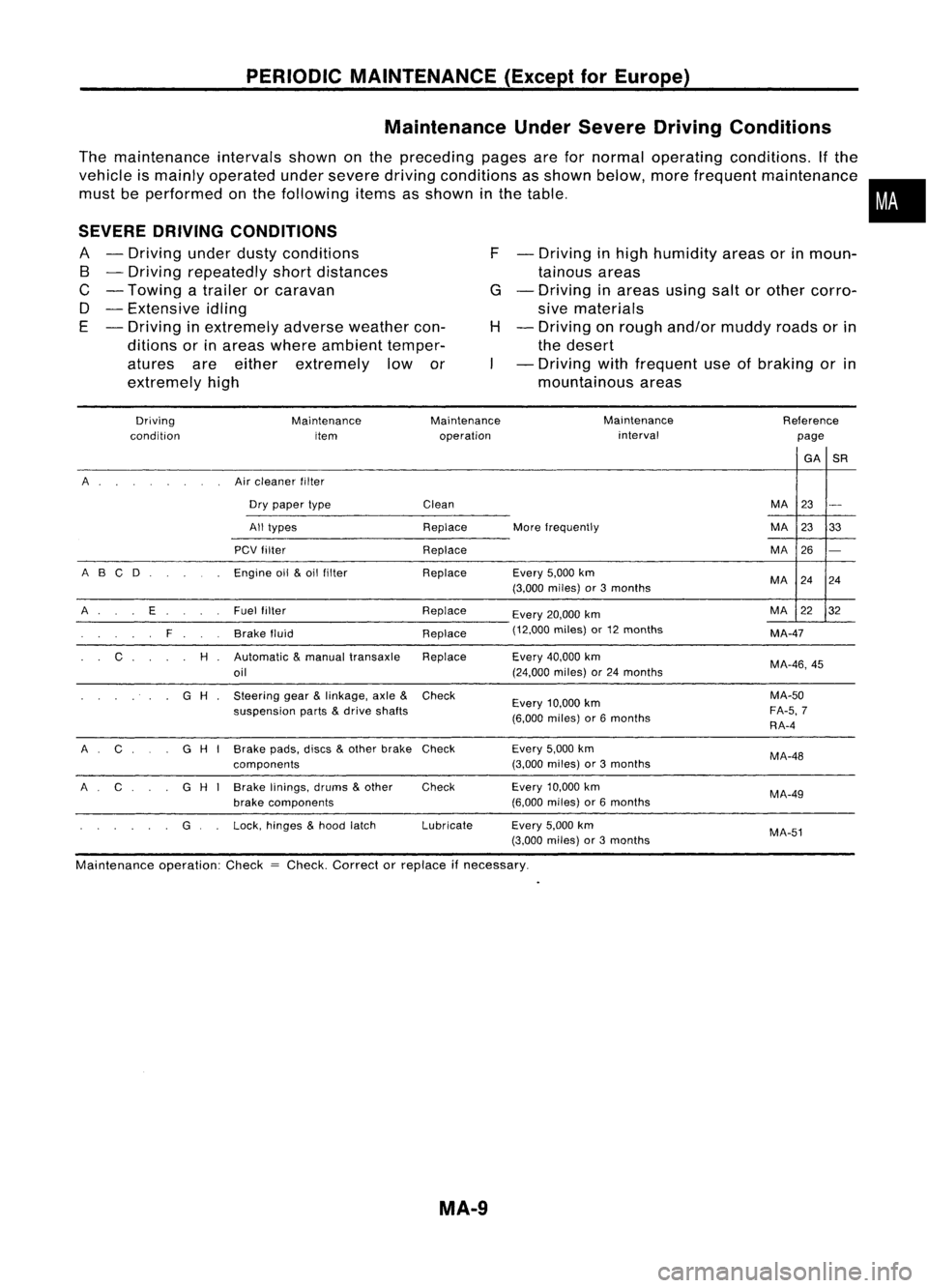

PERIODICMAINTENANCE (ExceptforEurope)

Maintenance UnderSevere DrivingConditions

The maintenance intervalsshownonthe preceding pagesarefornormal operating conditions. Ifthe

vehicle ismainly operated undersevere drivingconditions asshown below, morefrequent maintenance •

must beperformed onthe following itemsasshown inthe table. •

SEVERE DRIVING CONDITIONS

A -Driving underdustyconditions

B -Driving repeatedly shortdistances

C -Towing atrailer orcaravan

D -Extensive idling

E -Driving inextremely adverseweather con-

ditions orinareas where ambient temper-

atures areeither extremely lowor

extremely high F

-Driving inhigh humidity areasorinmoun-

tainous areas

G -Driving inareas usingsaltorother corro-

sive materials

H -Driving onrough and/or muddy roadsorin

the desert

- Driving withfrequent useofbraking orin

mountainous areas

Driving

condition Maintenance

item Maintenance

operation Maintenance

interval Reference

page

GA

SR

A Aircleaner filter

Dry paper type

Clean MA

23

-

All types ReplaceMorefrequently MA

2333

PCV filter Replace MA26

-

A BC D

Engineoil

&

oil filter ReplaceEvery

5,000km

MA2424

(3,000 miles) or3months

A E Fuel

filter Replace

Every20,000 km MA

2232

F Brakefluid Replace(12,000

miles)or12 months

MA-47

C

H

Automatic

&

manual transaxle Replace Every40,000 km

MA-46,45

oil (24,000

miles)or24 months

G

H

Steering

gear

&

linkage, axle

&

Check

Every10,000 km MA-50

suspension parts

&

drive shafts

(6,000miles) or6months FA-5,

7

RA-4

A C G

H

I

Brake pads,discs

&

other brake Check Every

5,000km

MA-48

components (3,000

miles) or3months

A C

G

H

1

Brake

linings, drums

&

other

Check Every

10,000 km

MA-49

brake components (6,000

miles) or6months

G Lock,

hinges

&

hood latch Lubricate

Every5,000km

MA-51

(3,000 miles) or3months

Maintenance operation:Check

=

Check. Correct orreplace

if

necessary.

MA-9

Page 1496 of 1701

PERIODICMAINTENANCE (ForEurope)

The following tablesshowthenormal maintenance schedule.Depending uponweather andatmospheric

conditions, varyingroadsurfaces, individual drivinghabitsandvehicle usage,additional ormore fre-

quent maintenance mayberequired.

Periodic maintenance beyondthelast period shown onthe tables requires similarmaintenance.

Engine Oil

&

Minor Service

GASOLINE ENGINE

Abbreviation: R

=

Replace.

MAINTENANCE OPERATION

Perform eitheratnumber ofkilometers (miles)or

months, whichever comesfirst. km

x1,000

(Miles x1,000)

Months MAINTENANCE

INTERVAL

15 30 45

60 75

90105

120

Reference

(9) (18) (27) (36)(45)(54) (63)(72) page

12 24 3648 6072 84

96

Underhood andunder vehicle

Engine

011

(API SGorSH

011)*

Engine oilfiller*

DIESEL ENGINE

R

R R

R R

R

R

R

R

R

R

R

R

R

R

R

MA-24

MA-24

Abbreviations: R

=

Replace, IInspect

andcorrect orreplace asnecessary

MAINTENANCE OPERATION

Perform eitheratnumber ofkilometers (miles)or kmx1,000 10

20 30

40

5060 70

80

Reference

months, whichever comesfirst.

(30)(36) page

(Miles x1,000) (6)(12) (18) (24)

(42)

(48)

Months 612

1824

3036 42

48

Underhood andunder vehicle

Engine oil(Use APiCDoil)* R

RRR

RR R

R MA-41

Engine oilfilter* R

RRR RR RR MA-41

Drive belts MA-38

Idle speed MA-44

NOTE:

*

Maintenance itemswith

"*"

should beperformed morefrequently accordingto"Maintenance UnderSevere Driv-

ing Conditions".

MA-10