engine NISSAN ALMERA N15 1995 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 1316 of 1701

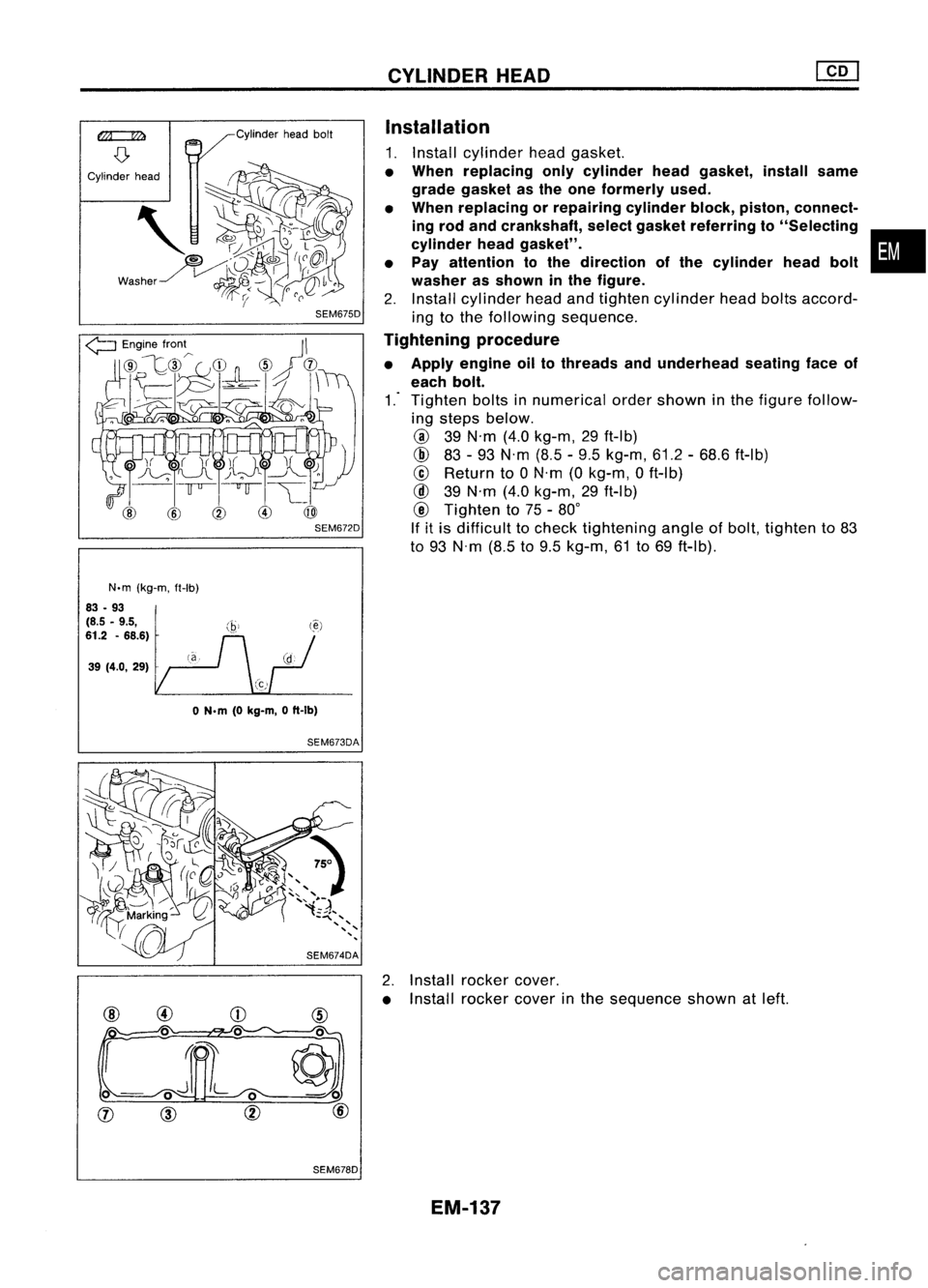

Cylinderheadbolt

N.m (kg-m, ft-Ib)

83 -93

(8.5 -9.5,

(Iii(~)

61.2 -68.6)

39 (4.0, 29)

o

N.m (0kg-m, 0ft-Ib)

SEM673DA

SEM678D CYLINDER

HEAD

Installation

1. Install cylinder headgasket.

• When replacing onlycylinder headgasket, installsame

grade gasket asthe one formerly used.

• When replacing orrepairing cylinderblock,piston, connect-

ing rod and crankshaft, selectgasket referring to"Selecting •

cylinder headgasket".

• Pay attention tothe direction ofthe cylinder headbolt

washer asshown inthe figure.

2. Install cylinder headandtighten cylinder headboltsaccord-

ing tothe following sequence.

Tightening procedure

• Apply engine oiltothreads andunderhead seatingfaceof

each bolt.

1.-

Tighten boltsinnumerical ordershown inthe figure follow-

ing steps below.

@

39N'm (4.0kg-m, 29ft-Ib)

@

83-93 N'm (8.5-9.5 kg-m, 61.2-68.6 ft-Ib)

@

Return to0N'm (0kg-m, 0ft-Ib)

@

39N'm (4.0kg-m, 29ft-Ib)

@

Tighten to75 -80°

If itis difficult tocheck tightening angleofbolt, tighten to83

to 93 N'm (8.5to9.5 kg-m, 61to69 ft-Ib).

2. Install rocker cover.

• Install rocker coverinthe sequence shownatleft.

EM-137

Page 1319 of 1701

SEC.112 ENGINE

REMOVAL

~~ 44.54(4.5.5.5,33 -40)

~44 .54 (4.5 .5.5, 33.40) ~~

~ 44•54 (4.5 .5.5, 33•40)"\ ~

-~1J.

~1

~~' ~64.74,

_' 2

(6.5.7.5, / \

~ 47.54),/'

rJ44. 54(4.5.5.5,33 -40) ~\

'" ~~~44.54 \....

.- ,9

(4.5.5.5,

ttJJ 44-54 (4.5 •5.5, 33-40)

7

ttJJ64.75 ------~

@--."

('.5•7.5, 4~' \

y~

~~.~~ ~~f;fi\

~~~'~i':-l~"

k(j' --.

II!~o' ~

/'Oolk..,

ttJJ64.75 (6.5•7.5, 47•54) ~

~'o

@\

8,.'~

~- I

2

rJ64. 75(6.5 .7.5,47.54)..1"""-../

~2ft -."~

°

>

~44. 54

~@

ttJJ44.54(4.5 -5.5, 33. 40)

j~~~1 ~-/.~/

(4.5 -5.5, 33•40)

ti ~~

44•54

~'@

A

5~'

!-'~

~35'-4~.)5'~ ~/

,0

7

~ I~. '

.Vi

rJ44.54(4.5.5.5,33.40)

~ ~l

ttJJ44•54 (4.5 •5.5, 33•40)

~ 'l

o.o~

I...",;S'"

1.

..J'-;:7o

6

ttJJ44.54 (4.5 •5.5, 33•40)

~l \

'LrJ 44•54 (4.5 -5.5, 33•40)

ttJJ 44.54 (4.5 .5_5, 33.40)

rJ

N.m(kg-m. ft-Ibl

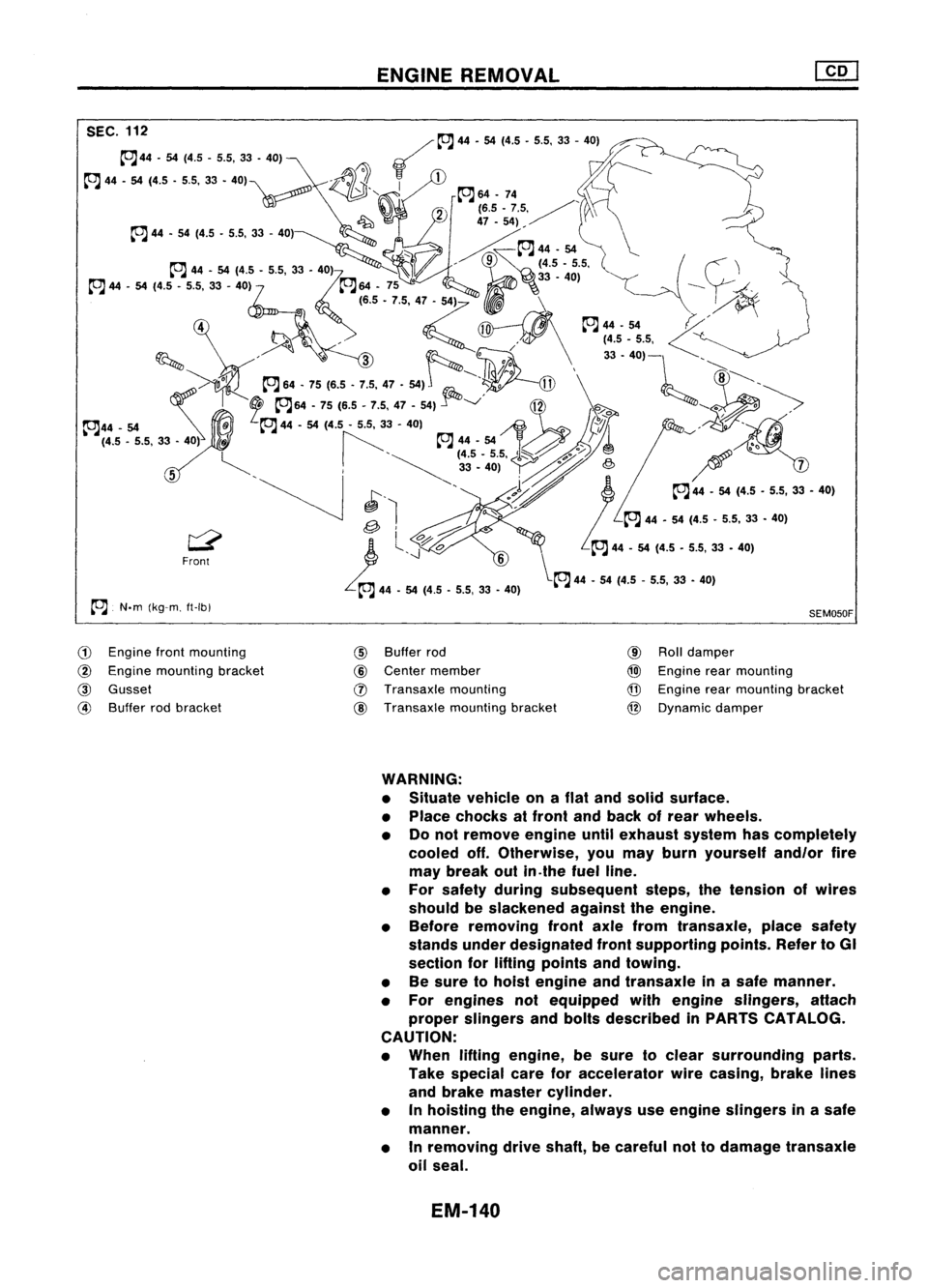

G)

Engine frontmounting

@

Engine mounting bracket

@

Gusset

@

Buffer rodbracket

@

Buffer rod

@

Center member

(J)

Transaxle mounting

@

Transaxle mountingbracket

SEM050F

@

Rolldamper

@)

Engine rearmounting

@

Engine rearmounting bracket

@

Dynamic damper

WARNING:

• Situate vehicle onaflat and solid surface.

• Place chocks atfront andback ofrear wheels.

• Donot remove engineuntilexhaust systemhascompletely

cooled off.Otherwise, youmay burn yourself and/orfire

may break outin.the fuel line.

• For safety during subsequent steps,thetension ofwires

should beslackened againsttheengine.

• Before removing frontaxlefrom transaxle, placesafety

stands underdesignated frontsupporting points.RefertoGI

section forlifting points andtowing.

• Besure tohoist engine andtransaxle inasafe manner.

• For engines notequipped withengine slingers, attach

proper slingers andbolts described inPARTS CATALOG.

CAUTION:

• When liftingengine, besure toclear surrounding parts.

Take special careforaccelerator wirecasing, brakelines

and brake master cylinder.

• Inhoisting theengine, alwaysuseengine slingers inasafe

manner.

• Inremoving driveshaft, becareful nottodamage transaxle

oil seal.

EM-140

Page 1320 of 1701

Drainplug(Radiator)

SFA110A

SFA 1538

SEM534D ENGINE

REMOVAL

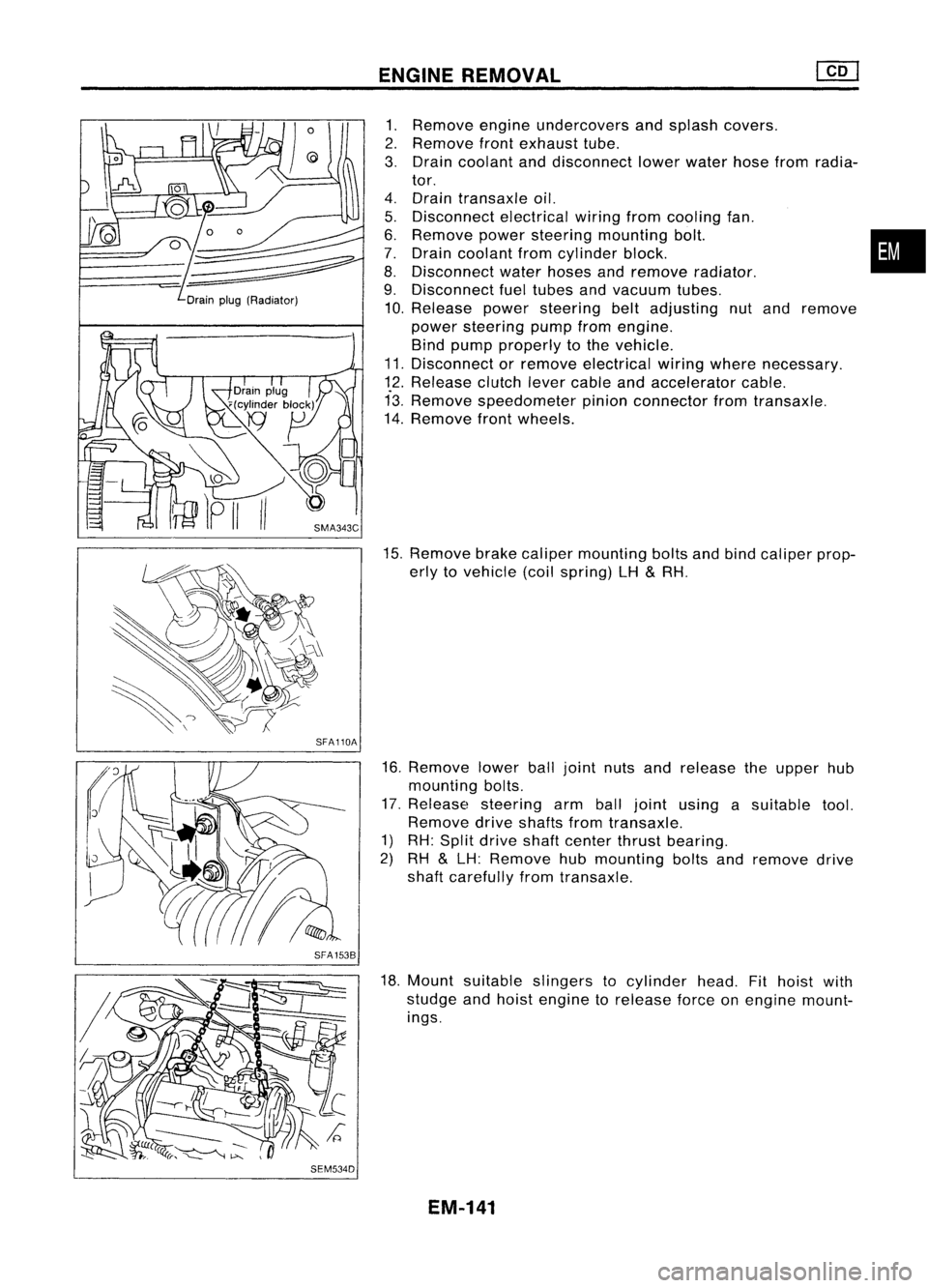

1. Remove engineundercovers andsplash covers.

2. Remove frontexhaust tube.

3. Drain coolant anddisconnect lowerwater hosefromradia-

tor.

4. Drain transaxle oil.

5. Disconnect electricalwiringfromcooling fan.

6. Remove powersteering mounting bolt. •

7. Drain coolant fromcylinder block.

8. Disconnect waterhoses andremove radiator.

9. Disconnect fueltubes andvacuum tubes.

10. Release powersteering beltadjusting nutand remove

power steering pumpfromengine.

Bind pump properly tothe vehicle.

11. Disconnect orremove electrical wiringwhere necessary.

12. Release clutchlevercable andaccelerator cable.

13. Remove speedometer pinionconnector fromtransaxle.

14. Remove frontwheels.

15. Remove brakecaliper mounting boltsandbind caliper prop-

erly tovehicle (coilspring) LH

&

RH.

16. Remove lowerballjoint nutsandrelease theupper hub

mounting bolts.

17. Release steering armballjoint using asuitable tool.

Remove driveshafts fromtransaxle.

1) RH: Split drive shaftcenter thrustbearing.

2) RH

&

LH: Remove hubmounting boltsandremove drive

shaft carefully fromtransaxle.

18. Mount suitable slingers tocylinder head.Fithoist with

studge andhoist engine torelease forceonengine mount-

ings.

EM-141

Page 1321 of 1701

SEM535D

SEM536D ENGINE

REMOVAL

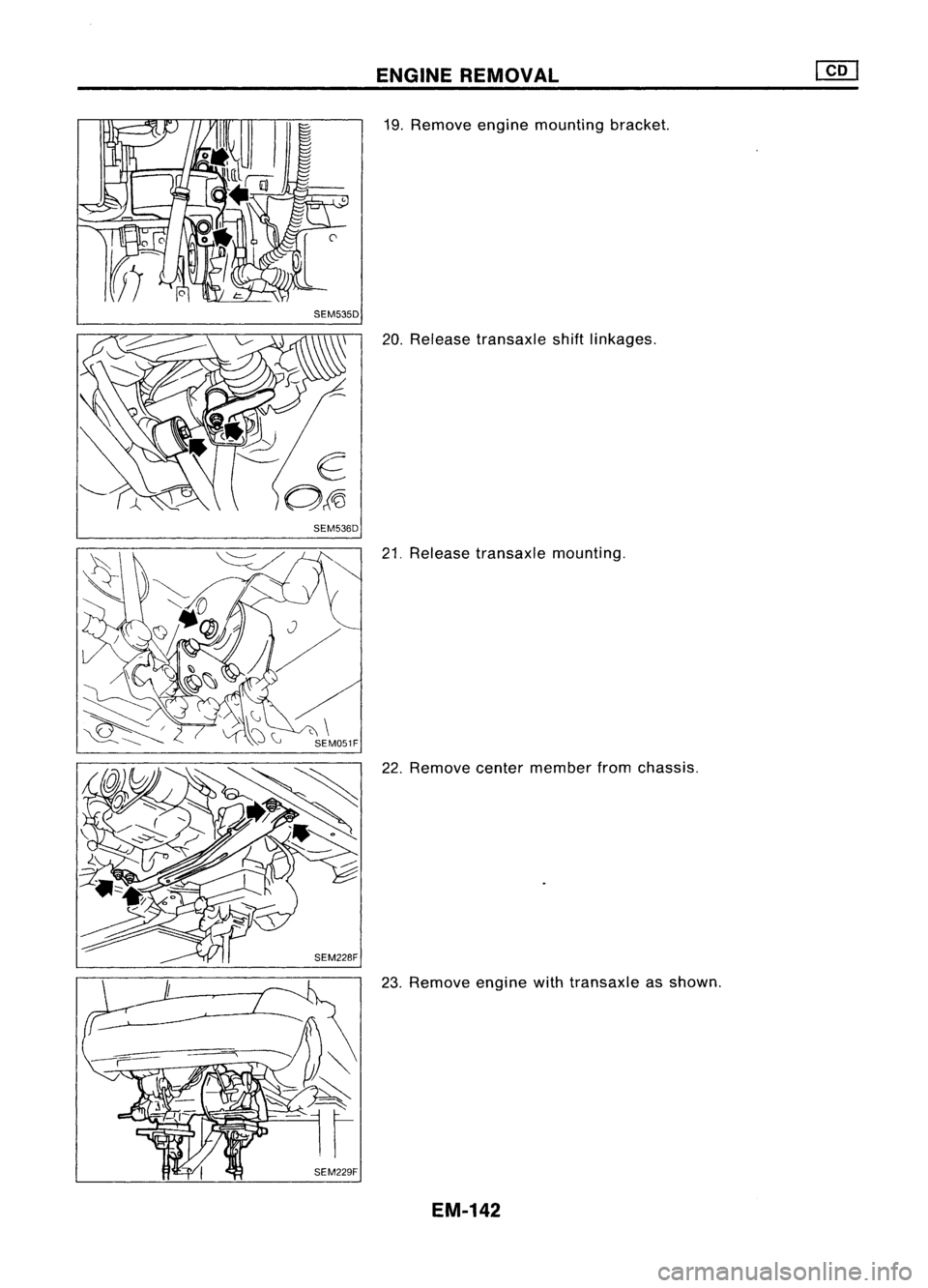

19. Remove enginemounting bracket.

20. Release transaxle shiftlinkages.

21. Release transaxle mounting.

22. Remove centermember fromchassis.

23. Remove enginewithtransaxle asshown.

EM-142

Page 1322 of 1701

![NISSAN ALMERA N15 1995 Service Manual CYLINDERBLOCK

•

l(]~

83-93

(8.5 -9.5

61 -

69)

~

~ :N.m (kg-m, ft-Ib)

f] :

Lubricate withnewengine oil.

(]

~76-78 (7.8 -8.0, 56-58)

@f]-

o

o

@~~ ~

! ~

l"J

R,t" I.

"A,~mbly& NISSAN ALMERA N15 1995 Service Manual CYLINDERBLOCK

•

l(]~

83-93

(8.5 -9.5

61 -

69)

~

~ :N.m (kg-m, ft-Ib)

f] :

Lubricate withnewengine oil.

(]

~76-78 (7.8 -8.0, 56-58)

@f]-

o

o

@~~ ~

! ~

l"J

R,t" I.

"A,~mbly&](/img/5/57349/w960_57349-1321.png)

CYLINDERBLOCK

•

l(]~

83-93

(8.5 -9.5

61 -

69)

~

~ :N.m (kg-m, ft-Ib)

f] :

Lubricate withnewengine oil.

(]

~76-78 (7.8 -8.0, 56-58)

@f]-

o

o

@~~ ~

! ~

l"J

R,t" I.

"A,~mbly".

SEC.

110-120

SEM227F

CD

Piston

ring

(J)

Rear

plate

@

Main

bearing

@

Piston

@

Flywheel

@

Crankshaft

@

Piston

pin

@

Rear

oilseal

@

Main bearing

@

Connecting

rodbearing

@)

Rear oilseal retainer

@

Gusset

@

Connecting

rod

@

Gusset

@

Drain plug

@

Main

bearing cap

@

Cylinder block

@

Pilot bushing

EM-143

Page 1323 of 1701

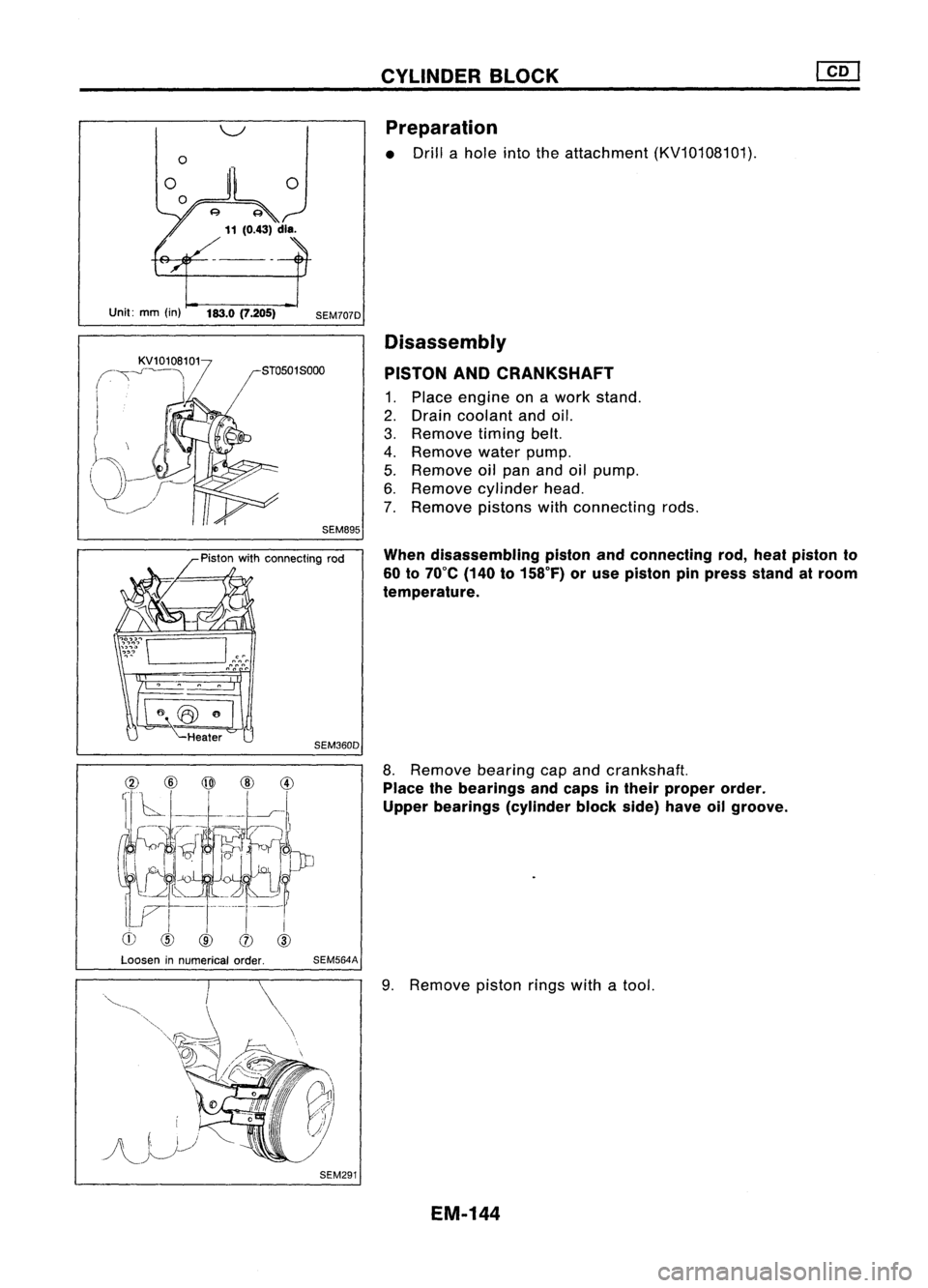

Unit:mm(in) 183.0(7.205)

SEM707DCYLINDER

BLOCK

Preparation

• Drill ahole intotheattachment (KV10108101).

Disassembly

PISTON ANDCRANKSHAFT

1. Place engine onawork stand.

2. Drain coolant andoil.

3. Remove timingbelt.

4. Remove waterpump.

5. Remove oilpan andoilpump.

6. Remove cylinder head.

7. Remove pistonswithconnecting rods.

When disassembling pistonandconnecting rod,heat piston to

60 to70°C (140to158°F) oruse piston pinpress standatroom

temperature.

Heater

SEM360D

8.Remove bearingcapand crankshaft.

Place thebearings andcaps intheir proper order.

Upper bearings (cylinderblockside)haveoilgroove.

Loosen innumerical order.

SEM564A

SEM291

9.

Remove pistonringswithatool.

EM-144

Page 1329 of 1701

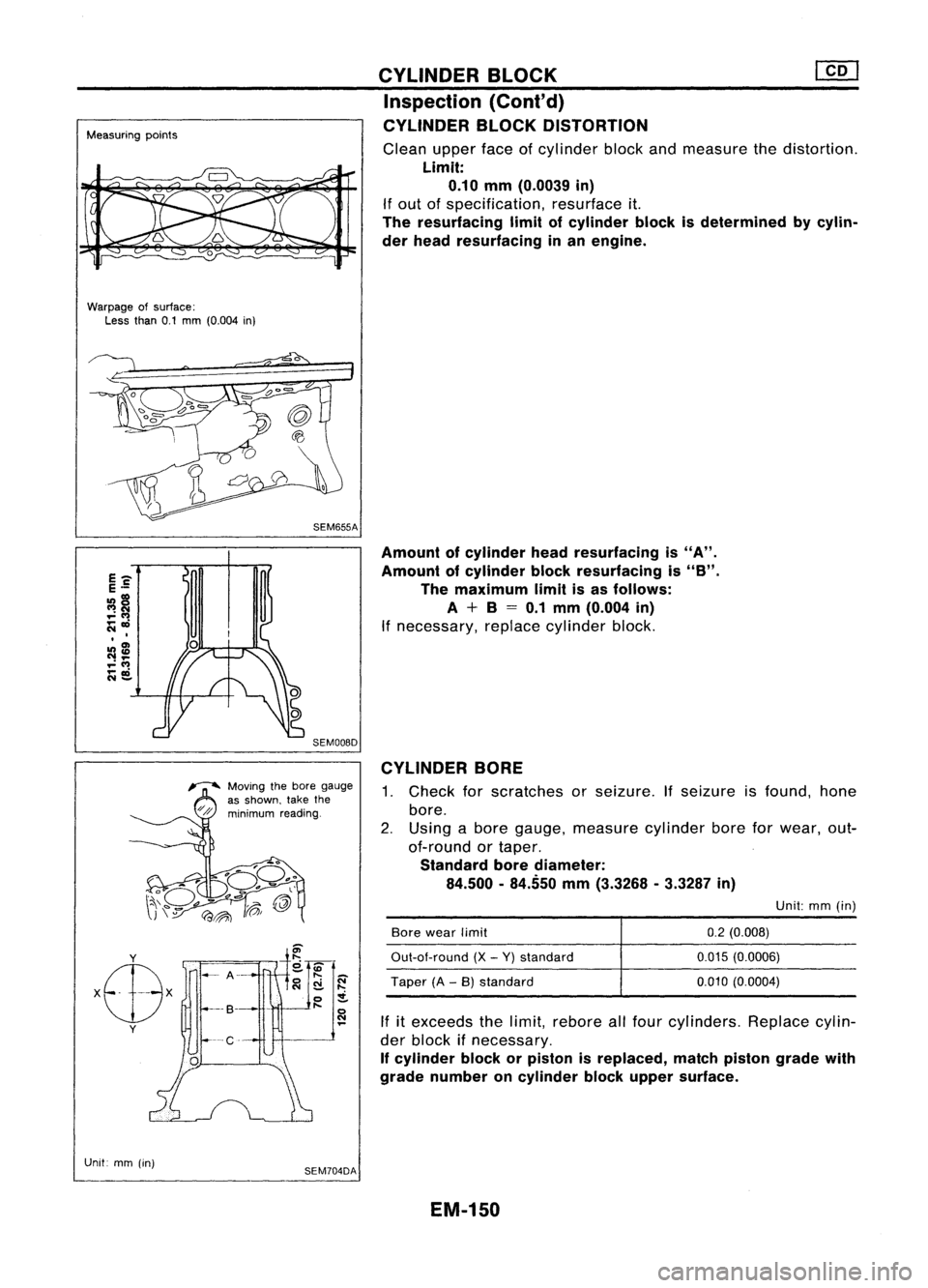

Measuringpoints

Warpage ofsurface:

Less than0.1mm (0.004 in)

SEM655ACYLINDER

BLOCK

Inspection (Cont'd)

CYLINDER BLOCKDISTORTION

Clean upperfaceofcylinder blockandmeasure thedistortion.

Limit:

0.10

mm

(0.0039

in)

If out ofspecification, resurfaceit.

The resurfacing limitofcylinder blockisdetermined bycylin-

der head resurfacing inan engine.

SEM008D

Amount

ofcylinder headresurfacing is"A".

Amount ofcylinder blockresurfacing is"B".

The maximum limitisas follows:

A + B=0.1

mm

(0.004

in)

If necessary, replacecylinder block.

~ Moving thebore gauge

as shown, takethe

//p'

minimum reading.

CYLINDER

BORE

1. Check forscratches orseizure. Ifseizure isfound, hone

bore.

2. Using abore gauge, measure cylinderboreforwear, out-

of-round ortaper.

Standard borediameter:

84.500 -84.550

mm

(3.3268 -3.3287

in)

Unit:mm(in)

If itexceeds thelimit, rebore allfour cylinders. Replacecylin-

der block ifnecessary.

If cylinder blockorpiston isreplaced, matchpiston gradewith

grade number oncylinder blockupper surface.

y

Unit mm(in)

SEM704DA

Bore

wear limit

Out-aI-round (X-Y) standard

Taper (A-B) standard

0.2

(0.008)

0.015 (0.0006)

0.010 (0.0004)

EM-150

Page 1331 of 1701

![NISSAN ALMERA N15 1995 Service Manual SEM550

SEM703D CYLINDER

BLOCK

@[]

Inspection (Cont'd)

Using feeler gauge

1. Set piston andfeeler gauge withspring scale.

2. Measure extracting forcewhile pulling upscale slowly.

Feeler gaugeuse NISSAN ALMERA N15 1995 Service Manual SEM550

SEM703D CYLINDER

BLOCK

@[]

Inspection (Cont'd)

Using feeler gauge

1. Set piston andfeeler gauge withspring scale.

2. Measure extracting forcewhile pulling upscale slowly.

Feeler gaugeuse](/img/5/57349/w960_57349-1330.png)

SEM550

SEM703D CYLINDER

BLOCK

@[]

Inspection (Cont'd)

Using feeler gauge

1. Set piston andfeeler gauge withspring scale.

2. Measure extracting forcewhile pulling upscale slowly.

Feeler gaugeused:

0.05 -0.07 mm(0.0020 -0.0028 in)

Extracting force:

7.8 -14.7 N(0.8 -1.5 kg, 1.8-3.3 Ib)

Assembly

PISTON

• Numbers stampedonconnecting rodand capcorrespond to

each cylinder. Careshould betaken toavoid awrong com-

bination including bearingandconnecting roddirection.

KV101070S0

EM156

•

Install newsnap ringonone side ofpiston pinhole.

• When assembling pistonandconnecting rodwith piston pin,

heat piston tobetween 60and 80°C (140and176°F) and

install piston pinwith asuitable tool.

• Install newsnap ring.

• After assembling, ascertainthatpiston swings smoothly.

• Install

piston

ringswithasuitable tool.

Selective topring; When installing newtopring orreplacing

cylinder block,selecttopring toadjust ringgap.

Punch

marksideup

~r~~

~ Tetl~ntubesetposition

~ ,0

Ql

0

SEM251D

Top

ring grade No. Cylinder

boregrade

1,2,3

No mark 4,

5

S

SEM617

CRANKSHAFT

1. Set main bearings inthe proper position oncylinder block

and main bearing caps.

• Ifeither crankshaft, cylinderblockormain bearing isreused

again, itis necessary tomeasure mainbearing clearance.

• Upper bearings (cylinderblockside)haveoilgroove.

• Apply newengine oiltobearing surfaces.

EM-152

Page 1332 of 1701

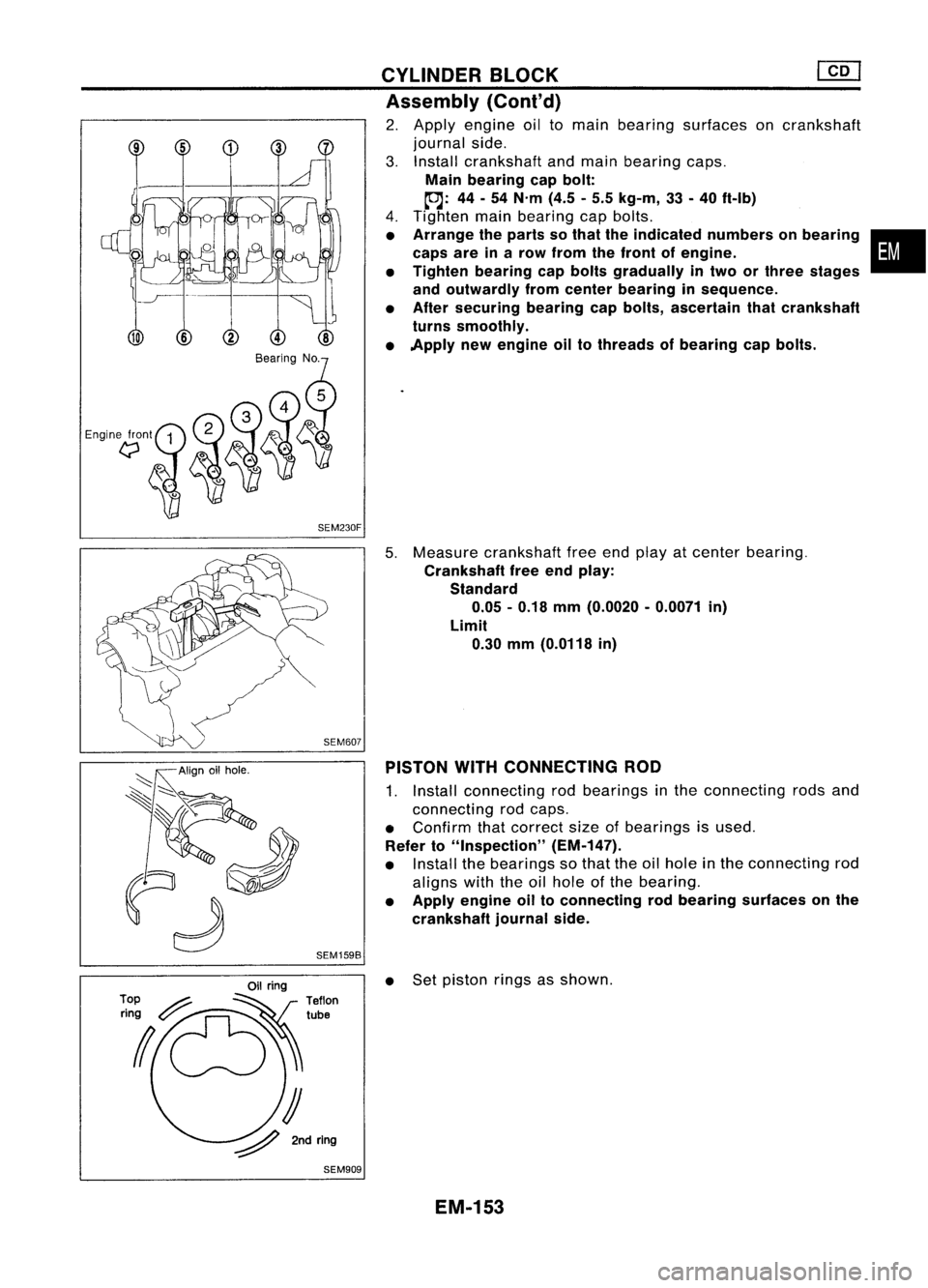

Enginefront1

t;J

SEM230F

~~~:::~"

IJ

~ 2ndring

SEM909 CYLINDER

BLOCK

[ill

Assembly (Cont'd)

2. Apply engine oiltomain bearing surfaces oncrankshaft

journal side.

3. Install crankshaft andmain bearing caps.

Main bearing capbolt:

~: 44-54 N'm (4.5-5.5 kg-m, 33-40 ft-Ib)

4. Tighten mainbearing capbolts.

• Arrange theparts sothat theindicated numbersonbearing •

caps areinarow from thefront ofengine.

• Tighten bearing capbolts gradually intwo orthree stages

and outwardly fromcenter bearing insequence.

• After securing bearingcapbolts, ascertain thatcrankshaft

turns smoothly.

• Apply newengine oiltothreads ofbearing capbolts.

5. Measure crankshaft freeendplay atcenter bearing.

Crankshaft freeendplay:

Standard 0.05 -0.18 mm(0.0020 -0.0071 in)

Limit 0.30 mm(0.0118 in)

PISTON WITHCONNECTING ROD

1. Install connecting rodbearings inthe connecting rodsand

connecting rodcaps.

• Confirm thatcorrect sizeofbearings isused.

Refer to"Inspection" (EM-147).

• Install thebearings sothat theoilhole inthe connecting rod

aligns withtheoilhole ofthe bearing.

• Apply engine oiltoconnecting rodbearing surfaces onthe

crankshaft journalside.

• Set piston ringsasshown.

EM-153

Page 1333 of 1701

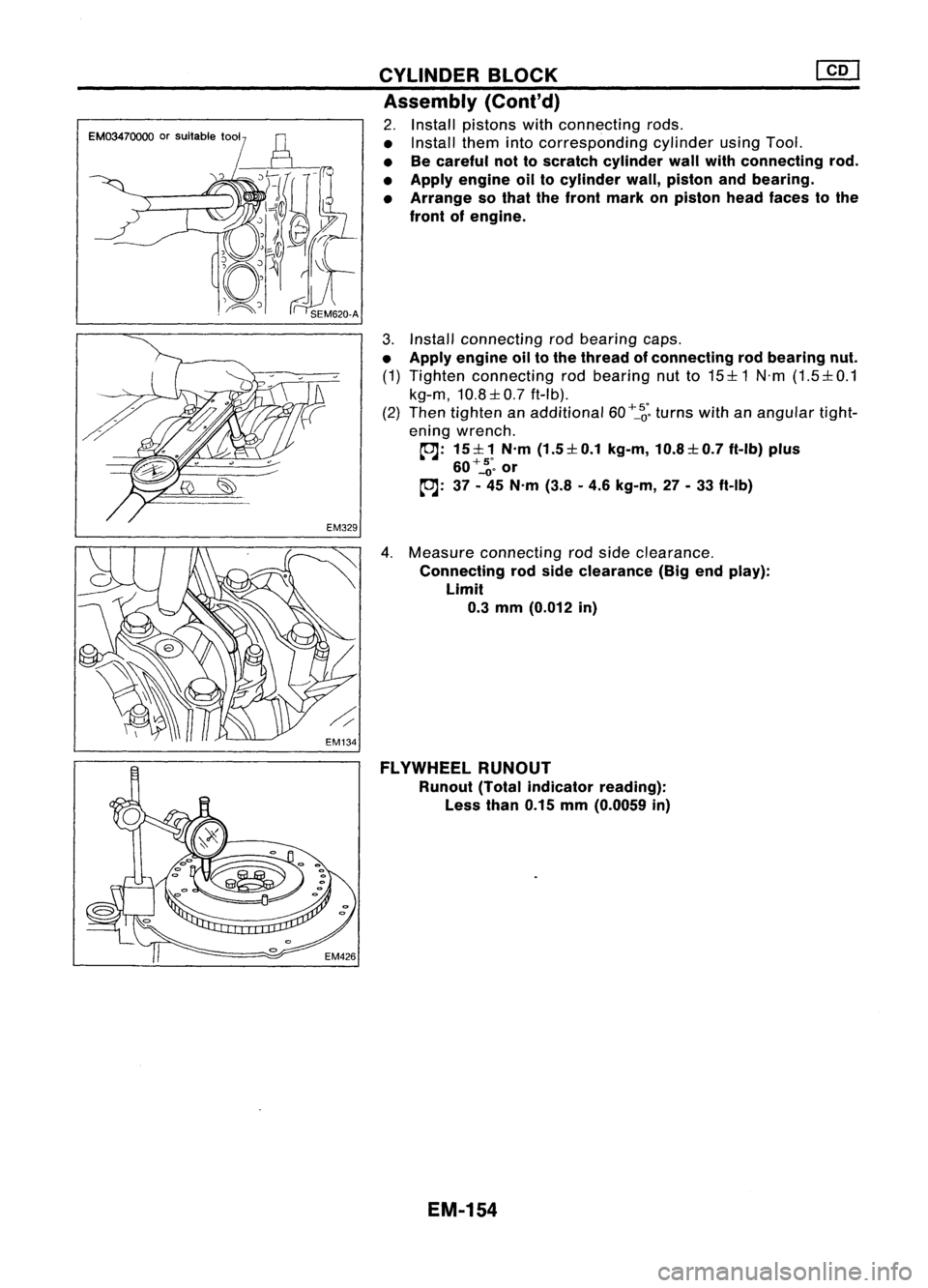

EM03470000orsuitable tool CYLINDER

BLOCK

lliJ

Assembly

(Conl'd)

2. Install pistons withconnecting rods.

• Install themintocorresponding cylinderusingTool.

• Becareful nottoscratch cylinder wallwithconnecting rod.

• Apply engine oiltocylinder wall,piston andbearing.

• Arrange sothat thefront mark onpiston headfaces tothe

front ofengine.

3. Install connecting rodbearing caps.

• Apply engine oiltothe thread ofconnecting rodbearing nut.

(1) Tighten connecting rodbearing nutto15:1:1 N'm(1.5:1:0.1

kg-m, 10.8:1:0.7ft-Ib).

(2) Then tighten anadditional 60

+_~'.

turns withanangular tight-

ening wrench.

~: 15:1:1 N'm(1.5:1:0.1 kg-m,10.8:1:0.7 ft-Ib)plus

60+'::;.

or

~: 37-45 N'm (3.8-4.6 kg-m, 27-33 ft-Ib)

4. Measure connecting rodside clearance.

Connecting rodside clearance (Bigendplay):

Limit

0.3

mm (0.012 in)

FLYWHEEL RUNOUT

Runout (Totalindicator reading):

Less than0.15mm(0.0059 in)

EM-154