engine NISSAN ALMERA N15 1995 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 1294 of 1701

COMPRESSIONPRESSURE

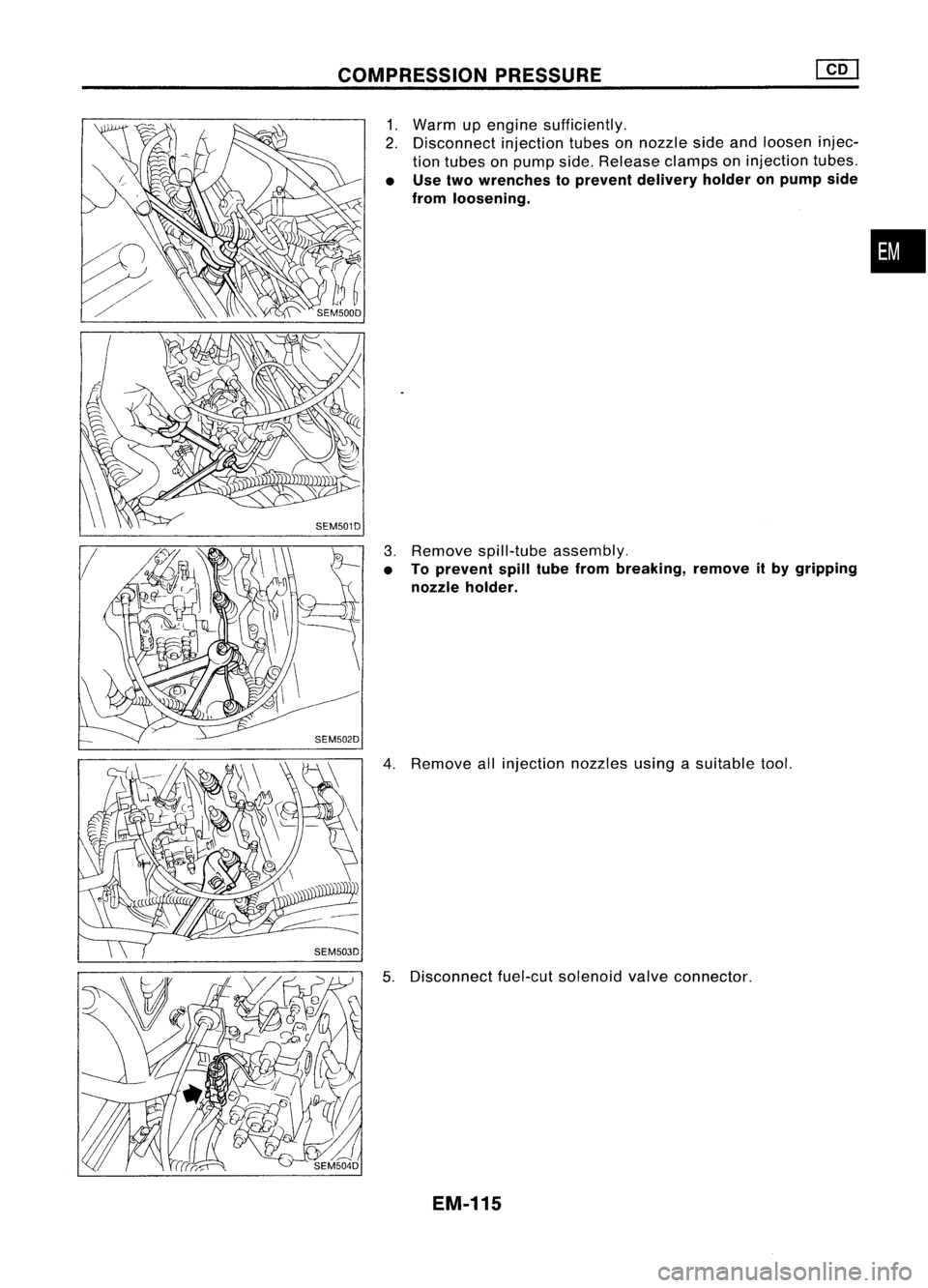

1. Warm upengine sufficiently.

2. Disconnect injectiontubesonnozzle sideandloosen injec-

tion tubes onpump side.Release clampsoninjection tubes.

• Use twowrenches toprevent delivery holderonpump side

from loosening.

3. Remove spill-tube assembly.

• Toprevent spilltube from breaking, removeitby gripping

nozzle holder.

4. Remove allinjection nozzlesusingasuitable tool.

5. Disconnect fuel-cutsolenoid valveconnector.

EM-115

•

Page 1295 of 1701

COMPRESSIONPRESSURE

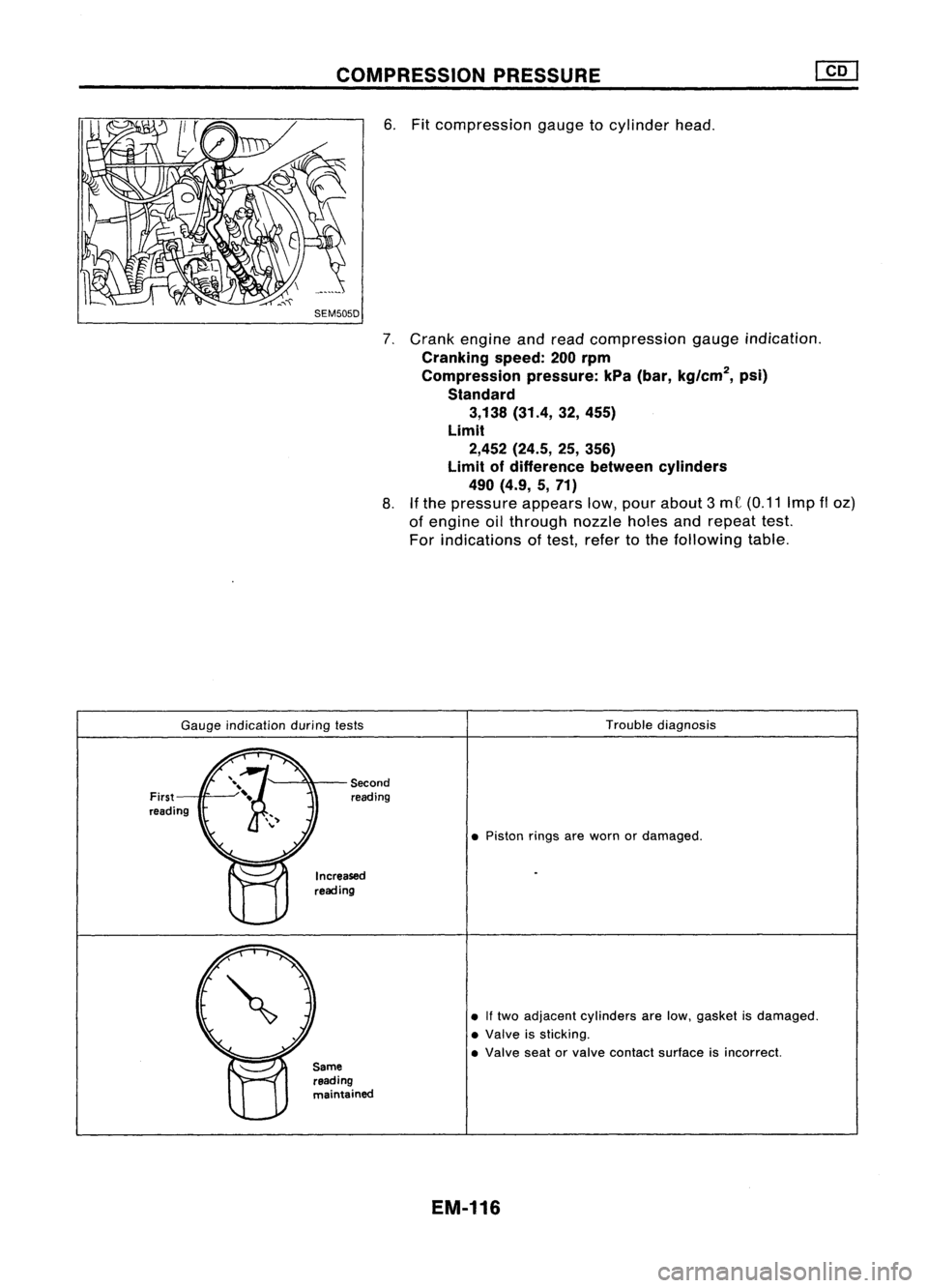

6. Fitcompression gaugetocylinder head.

SEM505D

7.Crank engine andread compression gaugeindication.

Cranking speed:200rpm

Compression pressure:kPa(bar, kg/cm

2,

psi)

Standard

3,138 (31.4, 32,455)

Limit

2,452 (24.5, 25,356)

Limit ofdifference betweencylinders

490 (4.9, 5,71)

8. Ifthe pressure appearslow,pour about 3me (0.11 Impfloz)

of engine oilthrough nozzleholesandrepeat test.

For indications oftest, refer tothe following table.

Gauge indication duringtests Trouble

diagnosis

First

reading Second

reading

Increased

reading

Same reading

maintained

•

Piston ringsareworn ordamaged.

• Iftwo adjacent cylinders arelow, gasket isdamaged .

• Valve issticking .

• Valve seatorvalve contact surface isincorrect.

EM-116

Page 1298 of 1701

![NISSAN ALMERA N15 1995 Service Manual

~:Sealing point

SEM894BA

SEM369D OIL

PAN [][]

Installation (Cont'd)

3. Apply liquidgasket tooil pan front oilseal andrear oilseal.

4. Apply acontinuous beadofliquid gasket tomating surface

of o NISSAN ALMERA N15 1995 Service Manual

~:Sealing point

SEM894BA

SEM369D OIL

PAN [][]

Installation (Cont'd)

3. Apply liquidgasket tooil pan front oilseal andrear oilseal.

4. Apply acontinuous beadofliquid gasket tomating surface

of o](/img/5/57349/w960_57349-1297.png)

~:Sealing point

SEM894BA

SEM369D OIL

PAN [][]

Installation (Cont'd)

3. Apply liquidgasket tooil pan front oilseal andrear oilseal.

4. Apply acontinuous beadofliquid gasket tomating surface

of oil pan.

• Attaching shouldbedone within 5minutes aftercoating.

5. Install oilpan andtighten boltsinthe order shown inthe

figure.

Wait atleast 30minutes beforerefilling engineoil.

Oil pan bolts:

~: 7-

8 N"m (0.7-0.8 kg-m, 61-69 in-Ib)

EM-119

•

Page 1299 of 1701

TIMINGBELT

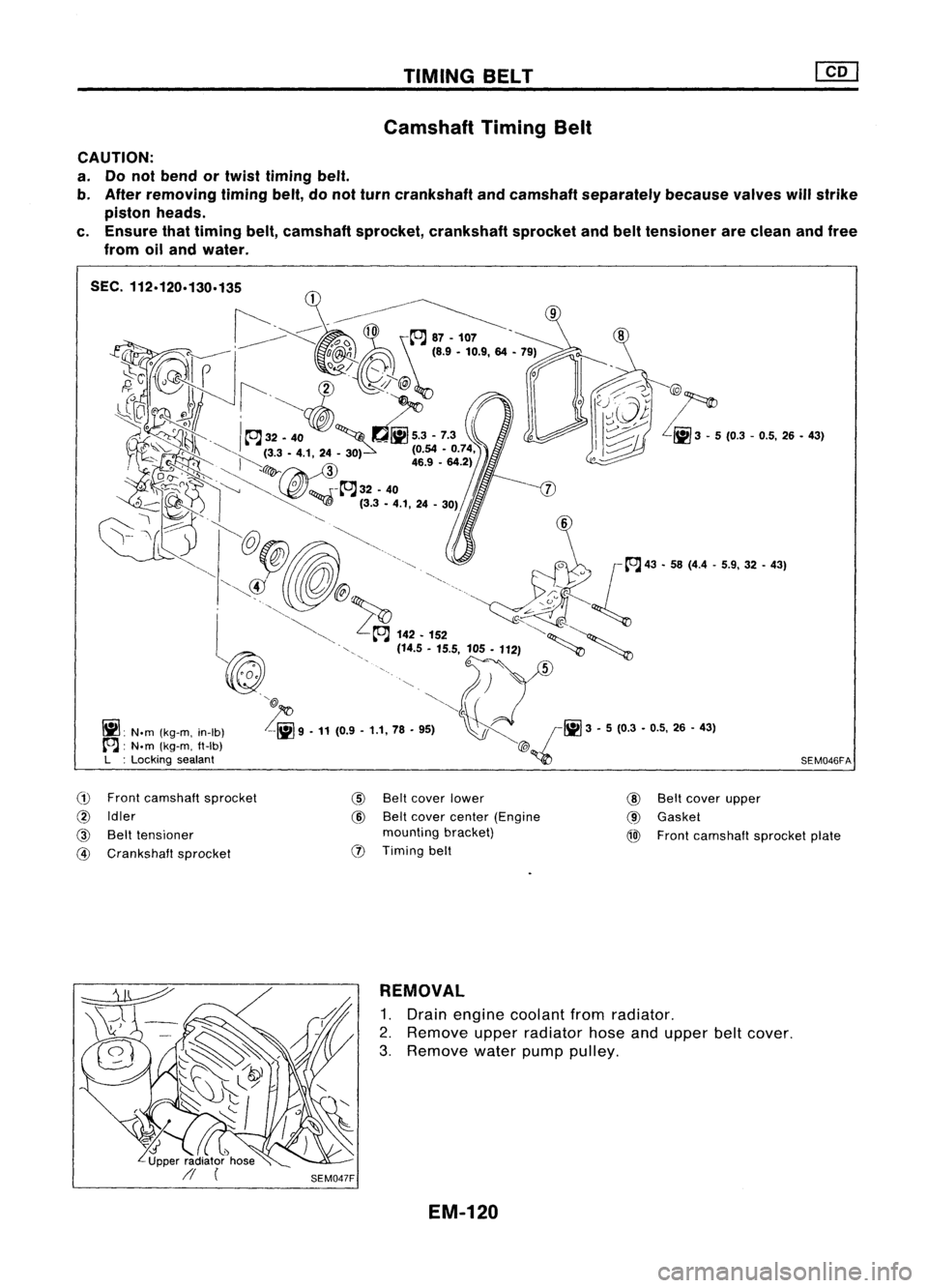

Camshaft TimingBelt

CAUTION:

a. Donot bend ortwist timing belt.

b. After removing timingbelt,donot turn crankshaft andcamshaft separately becausevalveswillstrike

piston heads.

c. Ensure thattiming belt,camshaft sprocket,crankshaft sprocketandbelttensioner areclean andfree

from oiland water.

~: N.m(kg-m, in-Ib)

A:

N.m(kg-m, ft-Ib)

L :Locking sealant

C"O

Front camshaft sprocket

@

Idler

@

Belttensioner

@

Crankshaft sprocket

@

Beltcover lower

@

Beltcover center (Engine

mounting bracket)

(1)

Timing belt

@)

~5 {O.'-0.5, "-

43'

SEM046FA

@

Beltcover upper

@

Gasket

@)

Front camshaft sprocketplate

REMOVAL

1. Drain engine coolant fromradiator.

2. Remove upperradiator hoseandupper beltcover.

3. Remove waterpumppulley.

EM-120

Page 1301 of 1701

TIMINGBELT

Camshaft TimingBelt(Cont'd)

INSPECTION

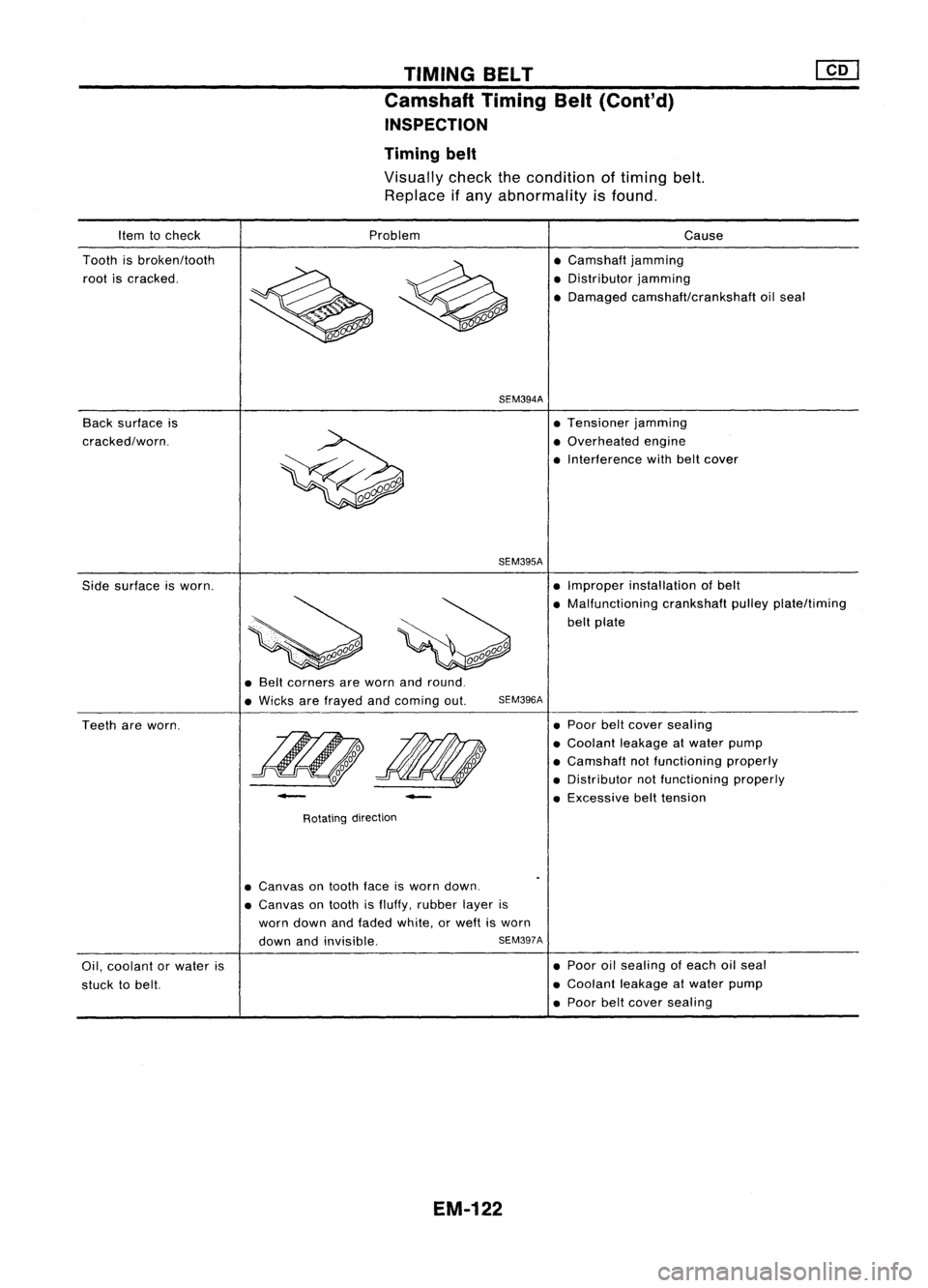

Timing belt

Visually checkthecondition oftiming belt.

Replace ifany abnormality isfound.

Item tocheck

Tooth isbroken/tooth

root iscracked.

Back surface is

cracked/worn. Problem

SEM394A

SEM395A

Cause

• Camshaft jamming

• Distributor jamming

• Damaged camshaft/crankshaft oilseal

• Tensioner jamming

• Overhe

ed

engine

• Interference withbeltcover

Side surface isworn. •

Improper installation ofbelt

• Malfunctioning crankshaftpulleyplate/timing

belt plate

• Belt corners areworn andround.

• Wicks arefrayed andcoming out.

SEM396A

Teeth areworn.

-

Rotating direction

-

•

Poor belt

cover

sealing

• Coolant leakageatwater pump

• Camshaft notfunctioning properly

• Distributor notfunctioning properly

• Excessive belttension

Oil, coolant orwater is

stuck tobelt.

•

Canvas

ontooth faceisworn down.

• Canvas

ontooth isfluffy, rubber layeris

worn down andfaded white, orweft isworn

down andinvisible.

SEM397A

EM-122

•

Poor oilsealing ofeach oilseal

• Coolant leakageatwater pump

• Poor belt

cover

sealing

Page 1305 of 1701

OILSEAL REPLACEMENT

Install newvalve oilseals forNo.1 andNO.4 cylinders as

illustrated. Reinstallvalvesprings. (narrowpitchside

toward cylinder head)

Install valvespring retainers onintake valves andvalve

rotators onexhaust valves,andremount valveassembly.

Set NO.2 cylinder at

TOG.

Replace valveoilseals forNo.2 andNo.3 cylinders accord-

ing tosteps 2)and 3).

Install valvelifters inoriginal positions.

5.

Remove valveliftersandmark order No.oneach lifter.

6. Replace valveoilseal according tothe following procedure.

When replacing valveallseal, setthe corresponding pistonat

TOe. Failure todo socauses thevalve todrop intothecylin-

der.

1) Set NO.1 cylinder at

TOG.

2) Remove valvesprings andvalve oilseals forNO.1 andNo.

4 cylinders. Valvespring seatsshould notberemoved.

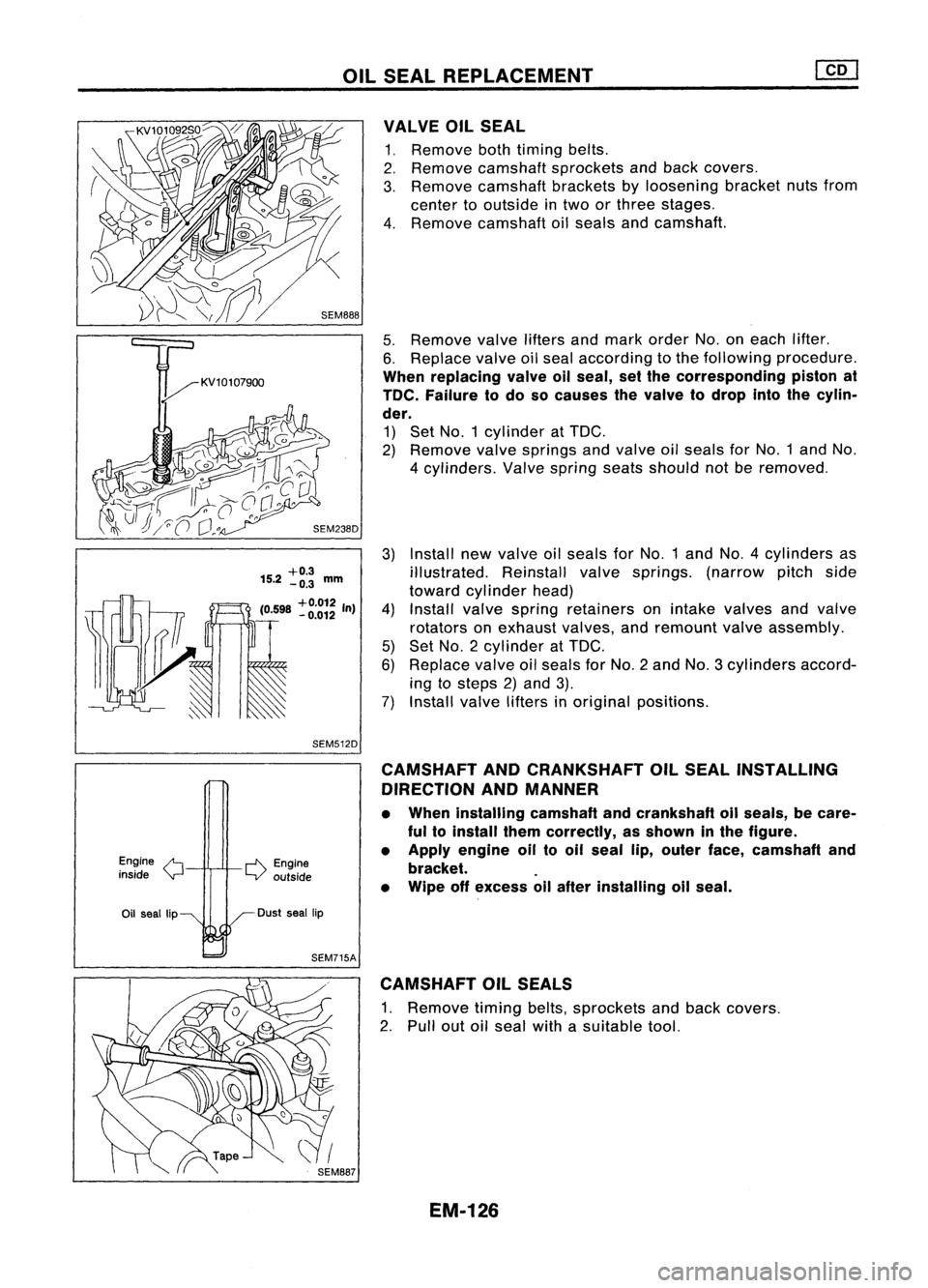

VALVE

OilSEAL

1. Remove bothtiming belts.

2. Remove camshaft sprockets andback covers.

3. Remove camshaft bracketsbyloosening bracketnutsfrom

center tooutside intwo orthree stages.

4. Remove camshaft oilseals andcamshaft.

3)

+0.3

15.2 -0.3

mm

(0598

+0.012

In)

4)

. -0.012

5)

6)

~ 7)

SEM512D

Engine

/'t

inside

Y

r-l'\.

Engine

LV outside CAMSHAFT

ANDCRANKSHAFT OilSEAL INSTALLING

DIRECTION ANDMANNER

• When installing camshaftandcrankshaft oilseals, becare-

ful toinstall themcorrectly, asshown inthe figure.

• Apply engine oiltooil seal lip,outer face,camshaft and

bracket. .

• Wipe offexcess allafter installing oilseal.

Oil seal lip Dust

seallip

SEM715A CAMSHAFT OilSEALS

1. Remove timingbelts,sprockets andback covers.

2. Pull outoilseal withasuitable tool.

EM-126

Page 1306 of 1701

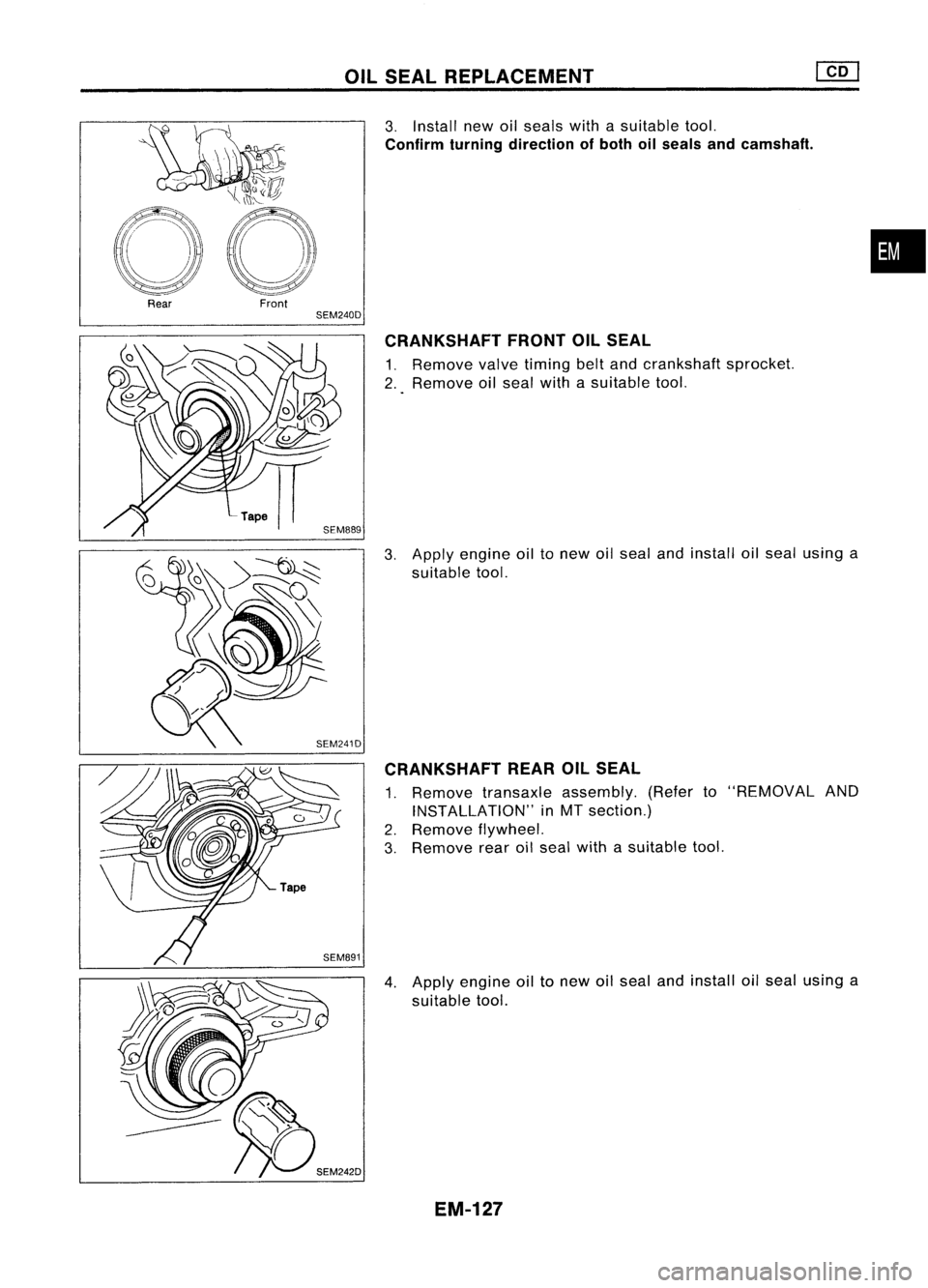

OILSEAL REPLACEMENT

3. Install newoilseals withasuitable tool.

Confirm turningdirection ofboth oilseals andcamshaft .

•

Rear

Front

SEM240D

CRANKSHAFT FRONTOILSEAL

1. Remove valvetiming beltandcrankshaft sprocket.

2. Remove oilseal withasuitable tool.

3. Apply engine oiltonew oilseal andinstall oilseal using a

suitable tool.

CRANKSHAFT REAROILSEAL

1. Remove transaxle assembly. (Referto"REMOVAL AND

INSTALLATION" in

MT

section.)

2. Remove flywheel.

3. Remove rearoilseal withasuitable tool.

4. Apply engine oiltonew oilseal andinstall oilseal using a

suitable tool.

EM-127

Page 1307 of 1701

![NISSAN ALMERA N15 1995 Service Manual CYLINDERHEAD

SEC. 111-130-135

[O.J

87-107 (8.9 -10.9, 64-79)

/ Swirl chamber

(Combustion chamber)

Valve seat

[O.J

87•107 (8.9 -10.9, 64-79)

~ :N.m (kg-m, in-Ib)

[O.J :

N. m (kg-m, ft-Ib)

f] NISSAN ALMERA N15 1995 Service Manual CYLINDERHEAD

SEC. 111-130-135

[O.J

87-107 (8.9 -10.9, 64-79)

/ Swirl chamber

(Combustion chamber)

Valve seat

[O.J

87•107 (8.9 -10.9, 64-79)

~ :N.m (kg-m, in-Ib)

[O.J :

N. m (kg-m, ft-Ib)

f]](/img/5/57349/w960_57349-1306.png)

CYLINDERHEAD

SEC. 111-130-135

[O.J

87-107 (8.9 -10.9, 64-79)

/ Swirl chamber

(Combustion chamber)

Valve seat

[O.J

87•107 (8.9 -10.9, 64-79)

~ :N.m (kg-m, in-Ib)

[O.J :

N. m (kg-m, ft-Ib)

f] :

Lubricate withnewengine oil.

SEM226F

G)

Camshaft

@

Front oilseal

@

Collar

@

Grommet

@

Front backcover

@ Front camshaft sprocketplate

(J)

Front camshaft sprocket

@

Spring

@

Selective cylinderheadgasket

@)

Valve

@

Spring seat

@

Valve spring

@ Valve oilseal

@ Spring retainer (INT)/Valve

rotator (EXH)

@

Valve cotter

@

Hydraulic valvelifter

@ Rear backcover

@

Rear camshaft sprocket

@

Grommet

@)

Collar

@ Rocker covergasket

@

Cam bracket

@ Rear oilseal

For hydraulic valvelifter

• Before starting engine,makesurethatvalve doesnothitpiston whenrotating crankshaft byhand.

• When bleeding airout from hydraulic valvelifter,runengine atmore than2,400 rpmfor20minutes

or more.

EM-128

Page 1308 of 1701

SEM373D

SEM682D SEM864

CYLINDER

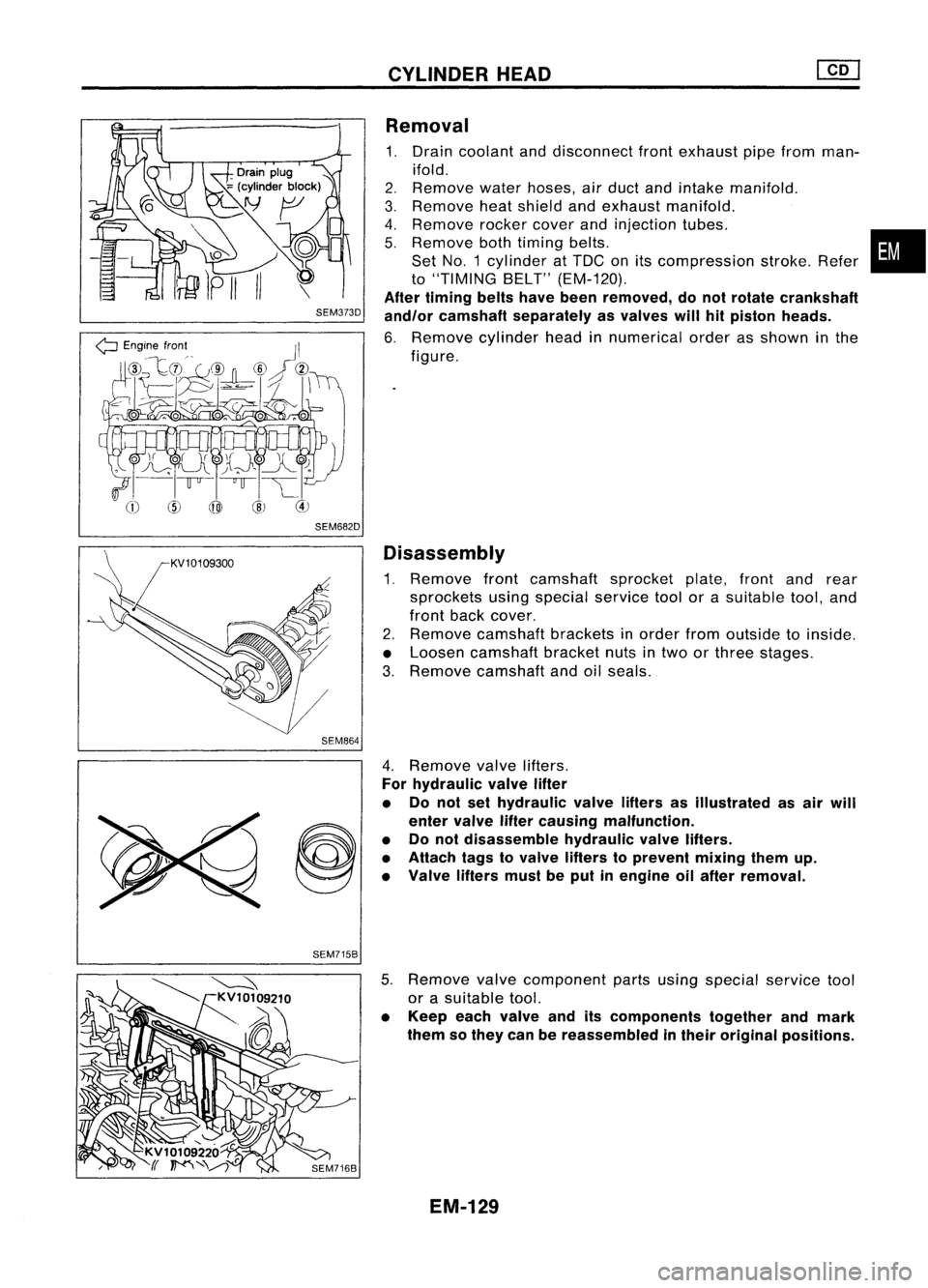

HEAD

Removal

1. Drain coolant anddisconnect frontexhaust pipefrom man-

ifold.

2. Remove

waterhoses, airduct andintake manifold.

3. Remove

heatshield andexhaust manifold.

4. Remove

rocker

cover

andinjection tubes.

5. Remove

bothtiming belts.

Set NO.1 cylinder atTDC onitscompression stroke.Refer

to

"TIMING BELT"(EM-120).

After timing beltshavebeen removed, donot rotate crankshaft

and/or camshaft separately asvalves willhitpiston heads.

6. Remove

cylinderheadinnumerical orderasshown inthe

figure.

Disassembly

1. Remove frontcamshaft sprocketplate,frontandrear

sprockets usingspecial

service

toolorasuitable tool,and

front back

cover.

2. Remove

camshaft bracketsinorder fromoutside toinside.

• Loosen camshaft bracketnutsintwo orthree stages.

3. Remove

camshaft andoilseals.

•

SEM715B 4.

Remove valve

lifters.

For hydraulic valvelifter

• Do not sethydraulic valvelifters asillustrated asair will

enter valve liftercausing malfunction.

• Donot disassemble hydraulicvalvelifters.

• Attach tagstovalve lifters toprevent mixingthemup.

• Valve liftersmustbeput inengine oilafter removal.

5. Remove

valve

component partsusing special

service

tool

or asuitable tool.

• Keep eachvalve anditscomponents togetherandmark

them sothey canbereassembled intheir original positions.

EM-129

Page 1315 of 1701

![NISSAN ALMERA N15 1995 Service Manual SEM202

SEM731BA

Grade number

Tightening sequence

r

1

@@

~.~.~

o

,..0

W

@

@ @

Facing frontofengine

(position 2)

SEM528DCYLINDER

HEAD

[£Q]

Inspection {Cont'd)

4. Remove cambracket capsan NISSAN ALMERA N15 1995 Service Manual SEM202

SEM731BA

Grade number

Tightening sequence

r

1

@@

~.~.~

o

,..0

W

@

@ @

Facing frontofengine

(position 2)

SEM528DCYLINDER

HEAD

[£Q]

Inspection {Cont'd)

4. Remove cambracket capsan](/img/5/57349/w960_57349-1314.png)

SEM202

SEM731BA

Grade number

Tightening sequence

r

1

@@

~.~.~

o

,..0

W

@

@ @

Facing frontofengine

(position 2)

SEM528DCYLINDER

HEAD

[£Q]

Inspection {Cont'd)

4. Remove cambracket capsandmeasure maximum widthof

plastigage. Camshaft bearingclearance:

Limit

0.1 mm (0.004 in)

5. Ifclearance appearstoexceed thelimit, replace camshaft

or cylinder head.

• Which partstobe replaced shouldbedecided uponafter

measuring thediameters ofthe parts concerned.

Assembly

1. Install valvecomponent parts.

Install valvespring withitsnarrow pitchsidetoward cylinder

head side.

• Always installnewvalve oilseals.

Refer tooil seal replacement.

• Before installing oilseal, install valve-spring seat.

• When installing valve,applyengine oilonthe valve stem

and lipofvalve oilseal.

• Check whether thevalve faceisfree from foreign matter.

• Install valvespring retainers onthe intake sideandvalve

rotators onthe exhaust side.

• Valve rotators cannotbedisassembled.

2. Install camshaft andbrackets andtighten bracket nutstothe

specified torqueintwo orthree stages.

Camshaft-bracket nuts:

~: 18-22 N'm (1.8-2.2 kg-m, 13-16 ft-Ib)

• Tighten bracketfromcenter tooutside.

• Apply sealant tobrackets No.1and No.5.

• When installing "brackets, setcamshaft sothat thepinof

camshaft fronthead isuppermost.

• Install newcamshaft oilseals.

Refer tooil seal replacement.

17.5 (0.689)

o

o

13.0

(0.512)

NO.1 journal bracket No.5journal bracket

Unit: mm(in)

SEM676D

EM-136