engine NISSAN ALMERA N15 1995 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 1463 of 1701

Replacethermocontrol

amp.

Note

No Note

CHECK POWER SUPPLY FORTHERMO

Co"NTROL AMP.

Refer toHA-49.

Reconnect

thermocontrolamp.harness

connector.

CHECK BODYGROUND CIRCUITFOR

THERMO CONTROL AMP.

Disconnect thermocontrolamp.harness

connector.

Does continuity existbetween thermo

control amp.harness terminal

@

and

body ground? OK

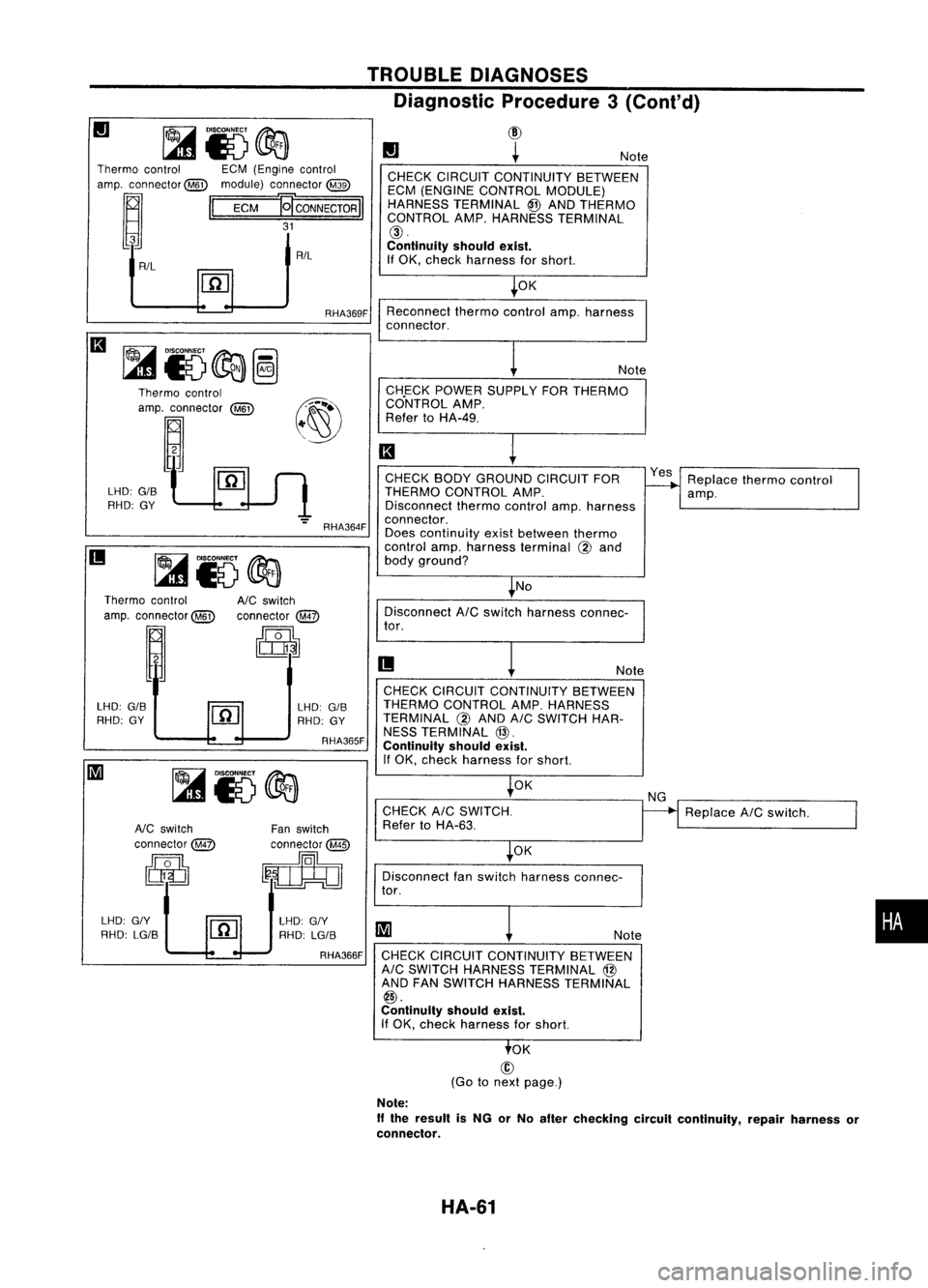

CHECK

CIRCUIT CONTINUITY BETWEEN

ECM (ENGINE CONTROL MODULE)

HARNESS TERMINAL @AND THERMO

CONTROL AMP.HARNESS TERMINAL

@.

Continuity shouldexist.

If OK, check harness forshort.

II

TROUBLE

DIAGNOSES

Diagnostic Procedure3(Conl'd)

(!)

~

RHA364F

:~~~~~;;:~:

@)~

LHO:

G/S'~

rn

(l

RHO: GY'L-.D--J

1

Thermo

control ECM(Engine control

amp. connector@) module)connector

@

~ II

ECM ?,CONNECTOOII

I

AIL ~_tR/L

II

II

DisconnectAICswitch harness connec-

tor.

Thermo

control

amp. connector @)

~

A/C

switch

connector

@

~

II

Note

LHO: GIS

RHO: GY LHO:

GIS

RHO: GY

RHA365F CHECK

CIRCUIT CONTINUITY BETWEEN

THERMO CONTROL AMP.HARNESS

TERMINAL

@

AND AICSWITCH HAR-

NESS TERMINAL

@.

Continuity shouldexist.

If OK, check harness forshort.

•

Replace

AICswitch.

Note

OK

OK

CHECK

AICSWITCH.

Refer toHA-63.

Disconnect fanswitch harness connec-

tor.

LHO: G/Y

RHO: LG/S

Fan

switch

connector

@ID

~

RHA366F CHECKCIRCUIT CONTINUITY BETWEEN

AIC SWITCH HARNESS TERMINAL @

AND FANSWITCH HARNESS TERMINAL

@.

Continuity shouldexist.

If OK, check harness forshort.

NC

switch

connector@

[ij

LHO: G/Y

RHO: LG/S

OK

@

(Go tonext page.)

Note:

If

the result isNG orNo after checking circuitcontinuity, repairharness or

connector.

HA-61

Page 1465 of 1701

Circuitcheck

~

AlC switch

connector TROUBLE

DIAGNOSES

Electrical Components Inspection(Cont'd)

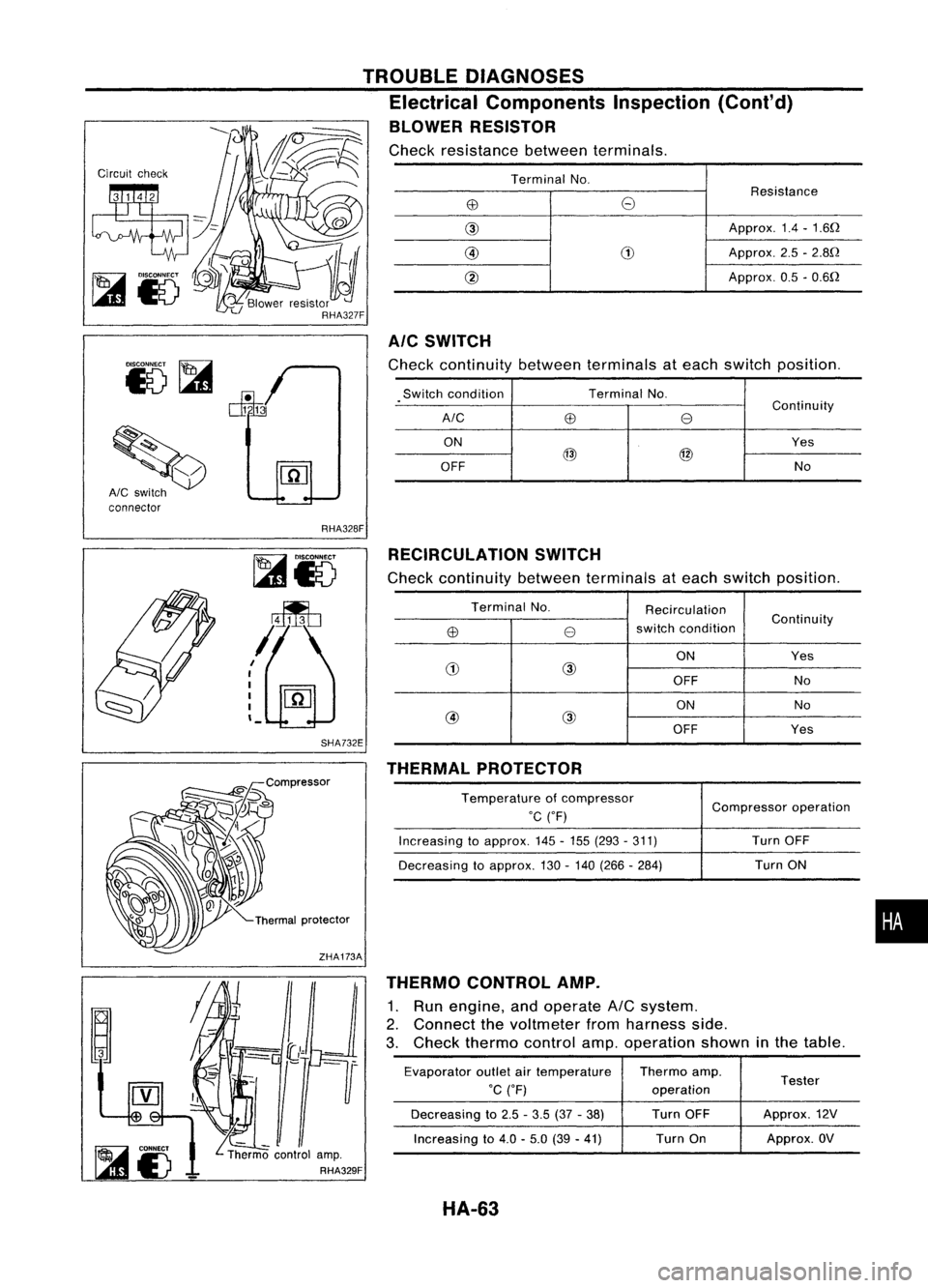

BLOWER RESISTOR

Check resistance betweenterminals.

Terminal No.

Resistance

EB

8

@

Approx.1.4-1.6Q

@

(1)

Approx.2.5-2.8Q

@

Approx.0.5-0.6Q

AIC SWITCH

Check continuity betweenterminals ateach switch position.

.

Switch

condition TerminalNo.

Continuity

A/C

EB

e

ON Yes

@

@

OFF No

RHA328F RECIRCULATION SWITCH

Check continuity betweenterminals ateach switch position.

I

I

I

I

I

'-

SHA732E

Terminal

No.

Recirculation

switch condition Continuity

EB

e

ON Yes

(1)

@

OFF No

ON No

@ @

OFF Yes

THERMAL PROTECTOR

THERMO CONTROL AMP.

1. Run engine, andoperate

AIC

system.

2. Connect thevoltmeter fromharness side.

3. Check thermo controlamp.operation showninthe table.

Evaporator outletairtemperature Thermoamp.

Tester

°C CF) operation

Decreasing to2.5 -3.5 (37-38) TurnOFF Approx.

12V

Increasing to4.0 -5.0 (39-41) Turn

On Approx.OV

Temperature

ofcompressor

°C

(OF)

Increasing toapprox. 145-155 (293 -311)

Decreasing toapprox. 130-140 (266 -284) Compressor

operation

Turn OFF

Turn ON

•

HA-63

Page 1469 of 1701

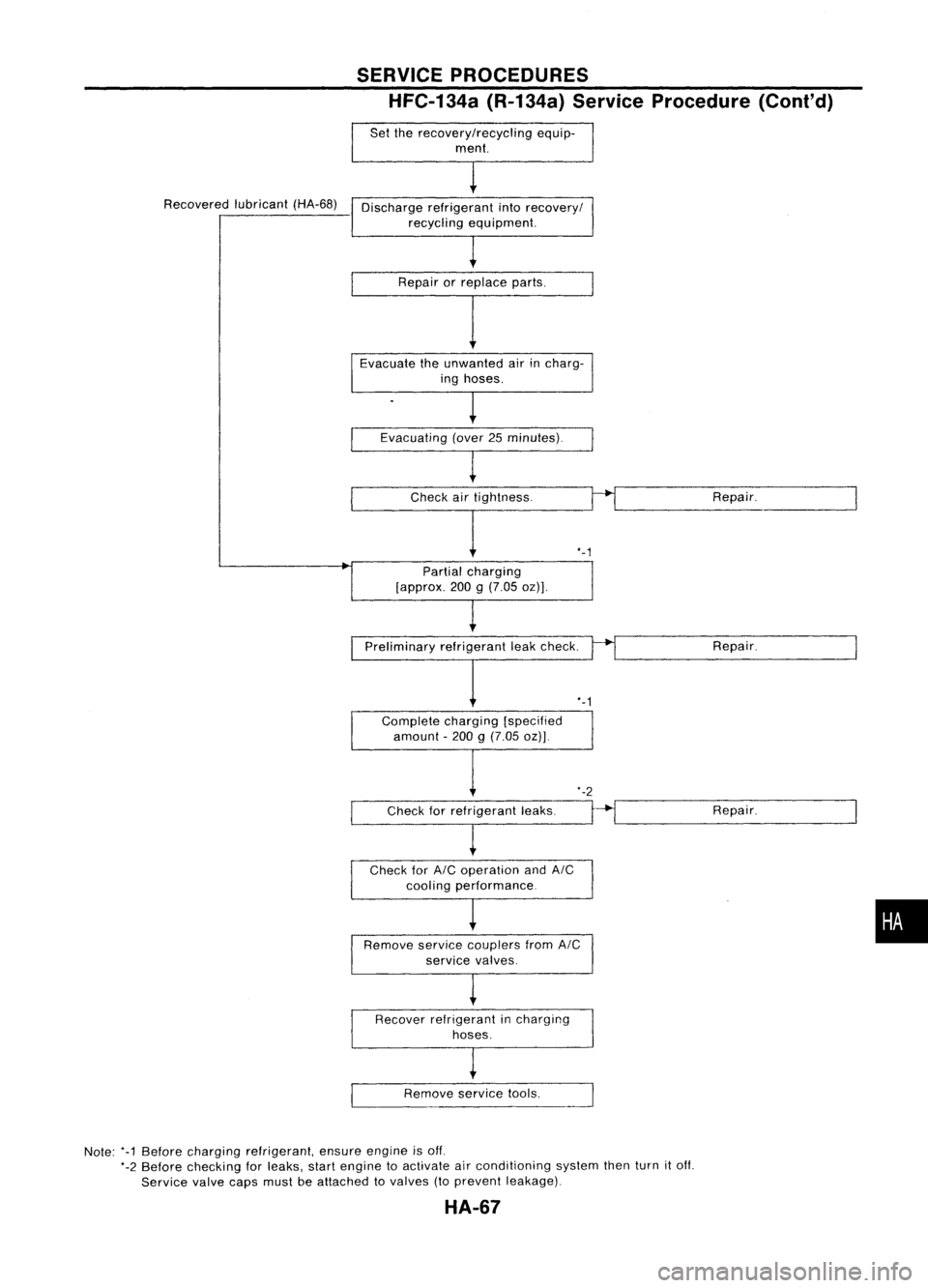

Recoveredlubricant(HA-68)

SERVICE

PROCEDURES

HFC-134a (R-134a)ServiceProcedure (Cont'd)

Set therecoverylrecycling equip-

ment.

Discharge refrigerant into

recoveryl

recycling equipment.

Repair orreplace parts.

Evacuate theunwanted airincharg-

ing hoses.

Evacuating (over25minutes).

Check airtightness.

I

Partial charging

[approx. 200g(7.05 oz)J.

'-1

Repair.

Preliminary refrigerantleakcheck.

,-1

Complete charging[specified

amount -200 g(7.05 oz)J. Repair.

'-2

---C-h-e-c-k-f-o-r -re-f-r-ig-e-r-a-nt-Ie-a-k-s-.

--H

Repair.

--r.---~. '---.---

Check for

AIC

operation and

AIC

cooling performance

Remove servicecouplers from

AIC

service valves.

Recover refrigerant incharging

hoses.

Remove servicetools.

Note: '-1Before charging refrigerant, ensureengineisoff.

'-2 Before checking forleaks, startengine toactivate airconditioning systemthenturnitoff.

Service valvecapsmustbeattached tovalves (toprevent leakage).

HA-67

•

Page 1470 of 1701

SERVICEPROCEDURES

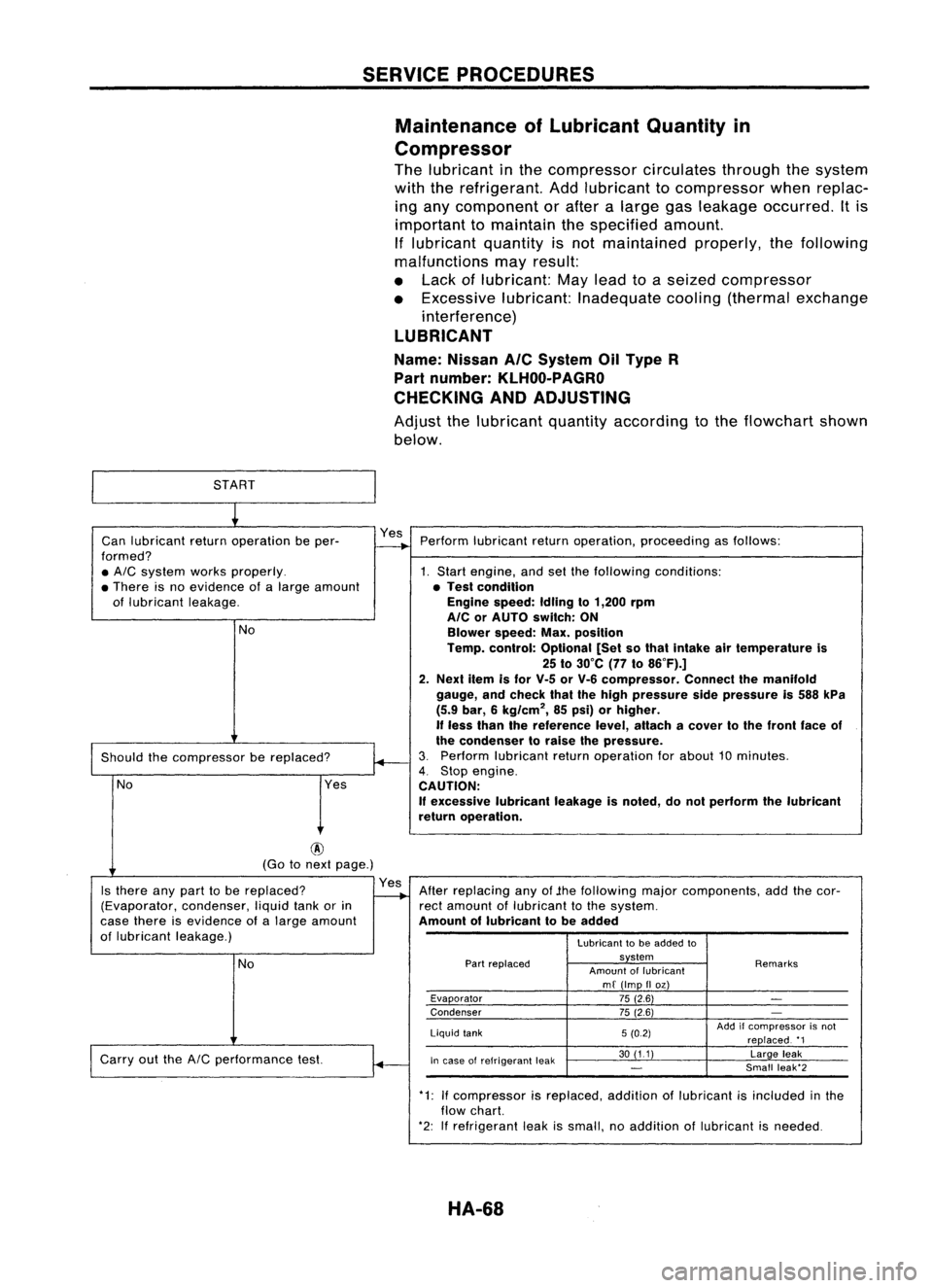

Maintenance ofLubricant Quantityin

Compressor

The lubricant inthe compressor circulatesthroughthesystem

with therefrigerant. Addlubricant tocompressor whenreplac-

ing any component orafter alarge gasleakage occurred. Itis

important tomaintain thespecified amount.

If lubricant quantityisnot maintained properly,thefollowing

malfunctions mayresult:

• Lack oflubricant: Maylead toaseized compressor

• Excessive lubricant:Inadequate cooling(thermal exchange

interference)

LUBRICANT

Name: Nissan

Ale

System OilType R

Part number:

KLHOO-PAGRO

CHECKING ANDADJUSTING

Adjust thelubricant quantityaccording tothe flowchart shown

below.

START

~

Can lubricant returnoperation beper- Yes

Perform lubricant returnoperation, proceeding asfollows:

formed?

-+

• AIC

system worksproperly. 1.Start engine, andsetthefollowing conditions:

• There isno evidence ofalarge amount •Test condition

of lubricant leakage. Engine

speed:Idlingto1,200 rpm

AlC orAUTO switch: ON

No Blowerspeed:Max.position

Temp. control: Optional [Setsothat Intake airtemperature is

25 to30°C (77to86°F).]

2. Next itemisfor V-5 orV-6 compressor. Connectthemanifold

gauge, andcheck thatthehigh pressure sidepressure is588 kPa

(5.9 bar, 6kg/cm

2,

85psi) orhigher,

If

less than thereference level,attach acover tothe front faceof

~

the

condenser toraise thepressure.

Should thecompressor bereplaced?

3.

Perform lubricant returnoperation forabout 10minutes.

4.

Stop engine.

No Yes

CAUTION:

If

excessive lubricantleakageisnoted, donot perform thelubricant

return operation.

@

(Go tonext page.)

Is there anypart tobe replaced? Yes

Afterreplacing anyof.the following majorcomponents, addthecor-

(Evaporator, condenser,liquidtankorin

-..

rectamount oflubricant tothe system.

case there isevidence ofalarge amount Amountoflubricant tobe added

of lubricant leakage.)

Lubricanttobe added to

No

Part

replaced system

Remarks

Amount oflubricant

mf (Imp IIoz)

Evaporator 75(2.6)

-

Condenser 75(2.6)

-

Liquid tank 5(0.2) Add

ifcompressor isnot

replaced. '1

Carry outthe

AIC

performance test.

~

In

case ofrefrigerant leak 30

(11) Largeleak

-

Small

leak'2

.

*1:Ifcompressor isreplaced. additionoflubricant isincluded inthe

flow chart.

*2: Ifrefrigerant leakissmall, noaddition oflubricant isneeded.

HA-68

Page 1472 of 1701

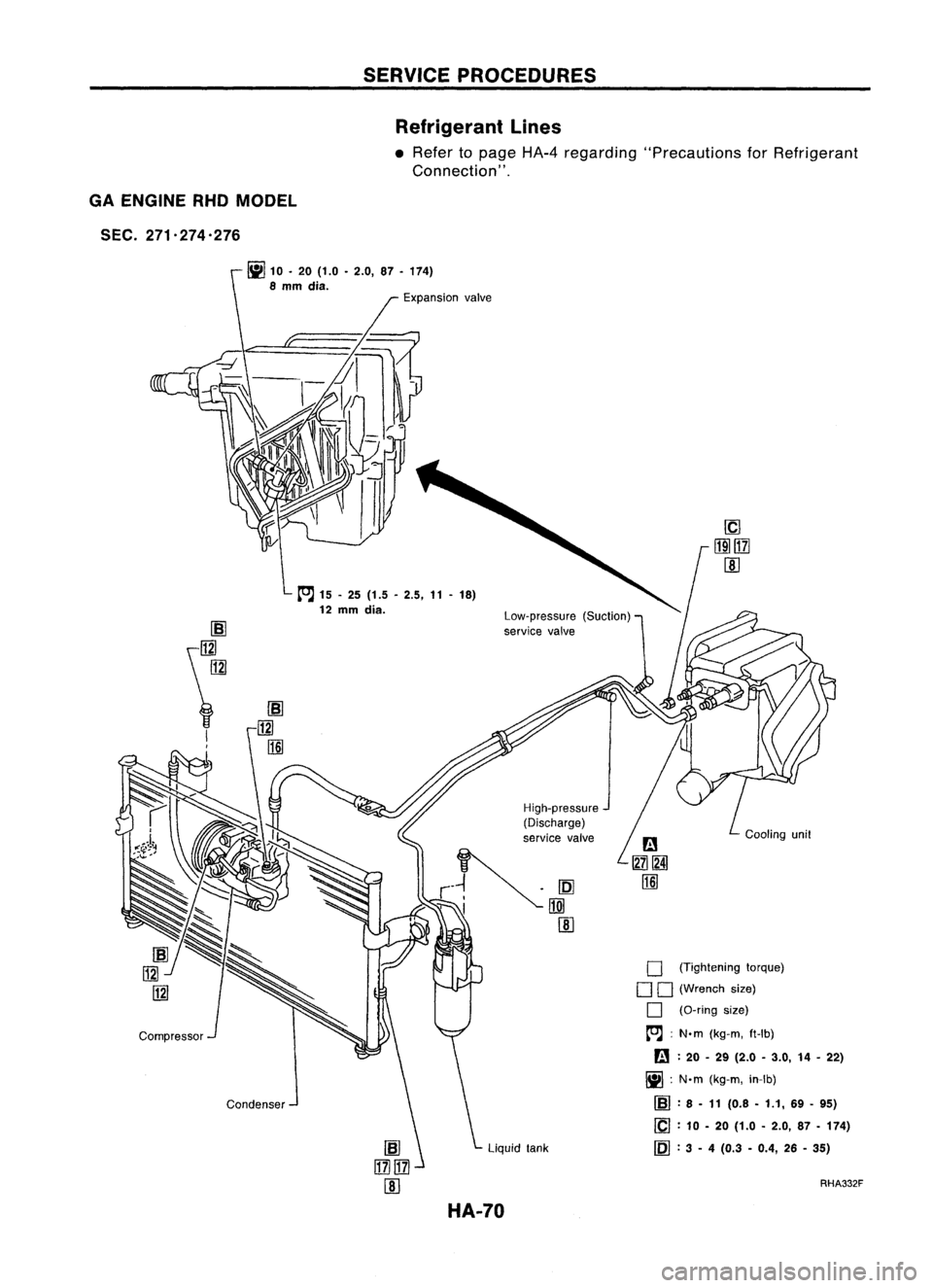

SERVICEPROCEDURES

Refrigerant Lines

• Refer topage HA-4regarding "Precautions forRefrigerant

Connection" .

GA ENGINE

RHO

MODEL

SEC. 271.274.276

fil10'20(1.0 .2.0, 87.174)

8

mm

dia.

Liquidtank

Condenser Expansion

valve

[O;J

15-25 (1.5 -2.5, 11-18)

12

mm

dia.

Low-pressure(Suction)

service valve

o

(Tightening torque)

o

0

(Wrench size)

o

(O-ring size)

[O;J :

N.m (kg-m, ft-Ib)

rn :

20 •29 (2.0 •3.0, 14-22)

fiI :

N.m (kg-m, in-Ib)

IBl :

8 •11 (0.8 -1.1, 69-95)

[C] :

10 -20 (1.0 -2.0, 87-174)

~ :3 -4 (0.3 -0.4, 26-35)

RHA332F

HA-70

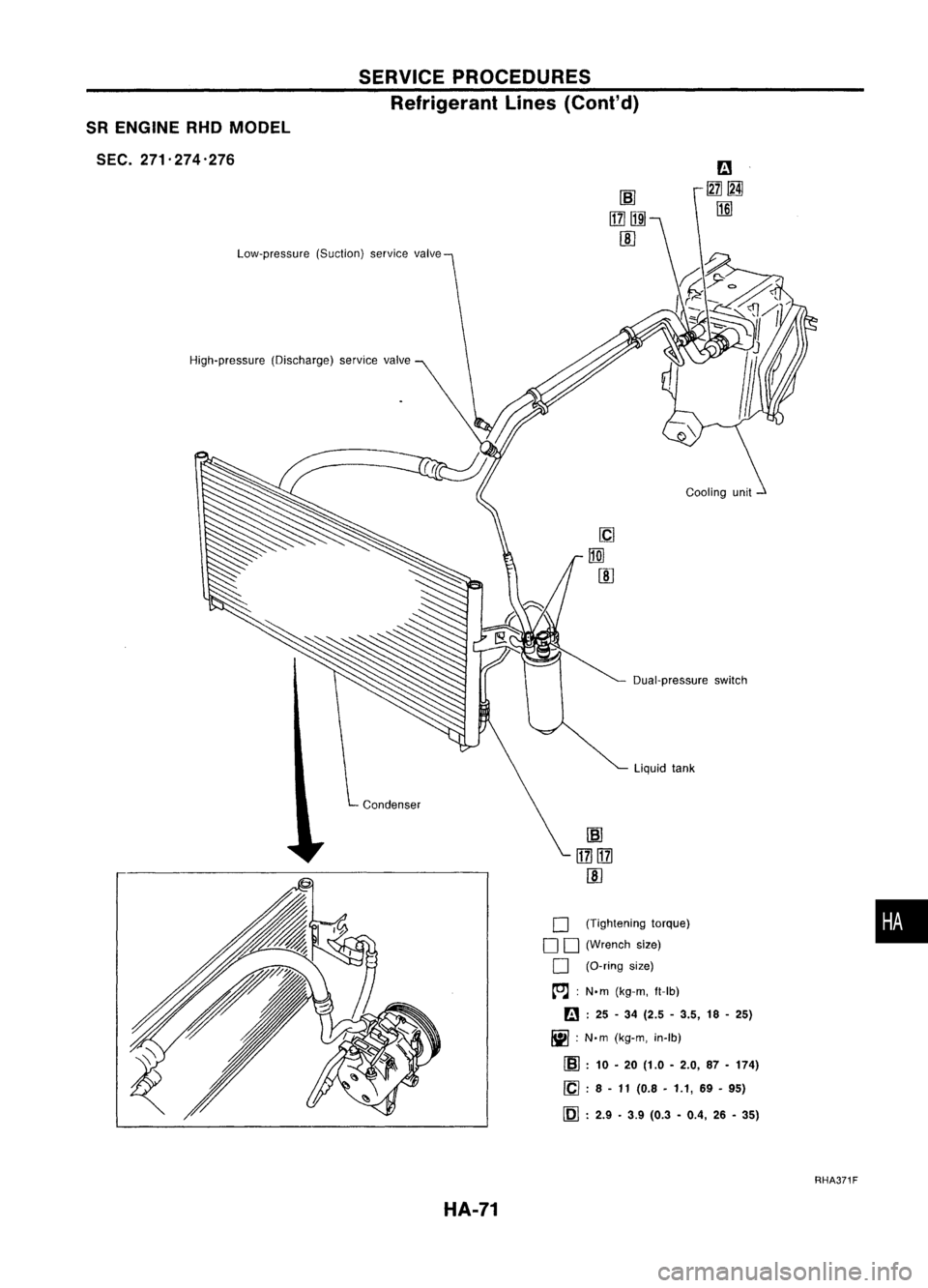

Page 1473 of 1701

S~~~~:~::--_~S~ER ~V~1~C~E~P;.R;O~C¥E¥,D~U~fo;;r.:i) _

R ENGINE RHDMO Ref" RES

5

DEL

ngerant

L"

EC. 271.274 '276

mes(Cont' d)

Low-pressure (Suct'

Ion)

se'

rVlce valve

High-pressure (0'Ischarg )

e service valve

Coolingunit

Dual-pressure switch

Liquid tank

Condenser

o

(Tightening t

o

orque)

o

(Wrench size)

o

(D-ring size)

~: N'm(k

g-m,

ft-Ib)

r.:.1 :

25 -34 (

IiiiI

2.5-3.5 18

~ :N.m ( ,-25)

kg-m, in-Ib)

(SJ :

10 -20 (1

'Cl .

.0-2.0, 87-174)

~ .8 -11 (0

.8

-1.1 69

1)1 . '-95)

lMJ .2.9 .3 9 (

. 0.3 -04 26

., -35)

RHA371F

HA-71

•

Page 1474 of 1701

SERVICEPROCE

R

f•

DURES

e ngerant

L.

mes (Cont'd)

CD ENGINE RHOMODEL

SEC. 271'274-276

iii

10-20 (1.0 -2

8

mm

dia. .0,87-174)

Expansion valve

Liquid tank

[SJ

\~

il!1d

I

I

Compressor Condenser

[O.J

15-25 (1.5 -2

12

mm

d' .5,11-18)

la.

Low-pressure (

service valveSuction) Hi~h-pressure

(Discharge)

service valve

D

(Tightening t

DO orque)

(Wrench size)

o

(O-ring size)

[O.J :

N'm (k

g-m,

ft-Ib)

a :

20 -29 (20

iii :

N'm .-3.0, 14-22)

(kg-m, in-Ib)

[SJ :

8 -11 (0.8 -1

ICl :

10 .1,69-95)

- 20 (1.0 •2

[Q] :

3 _4 .0,87-174)

(0.3 -04 26

.,

•35)

RHA333F

HA-72

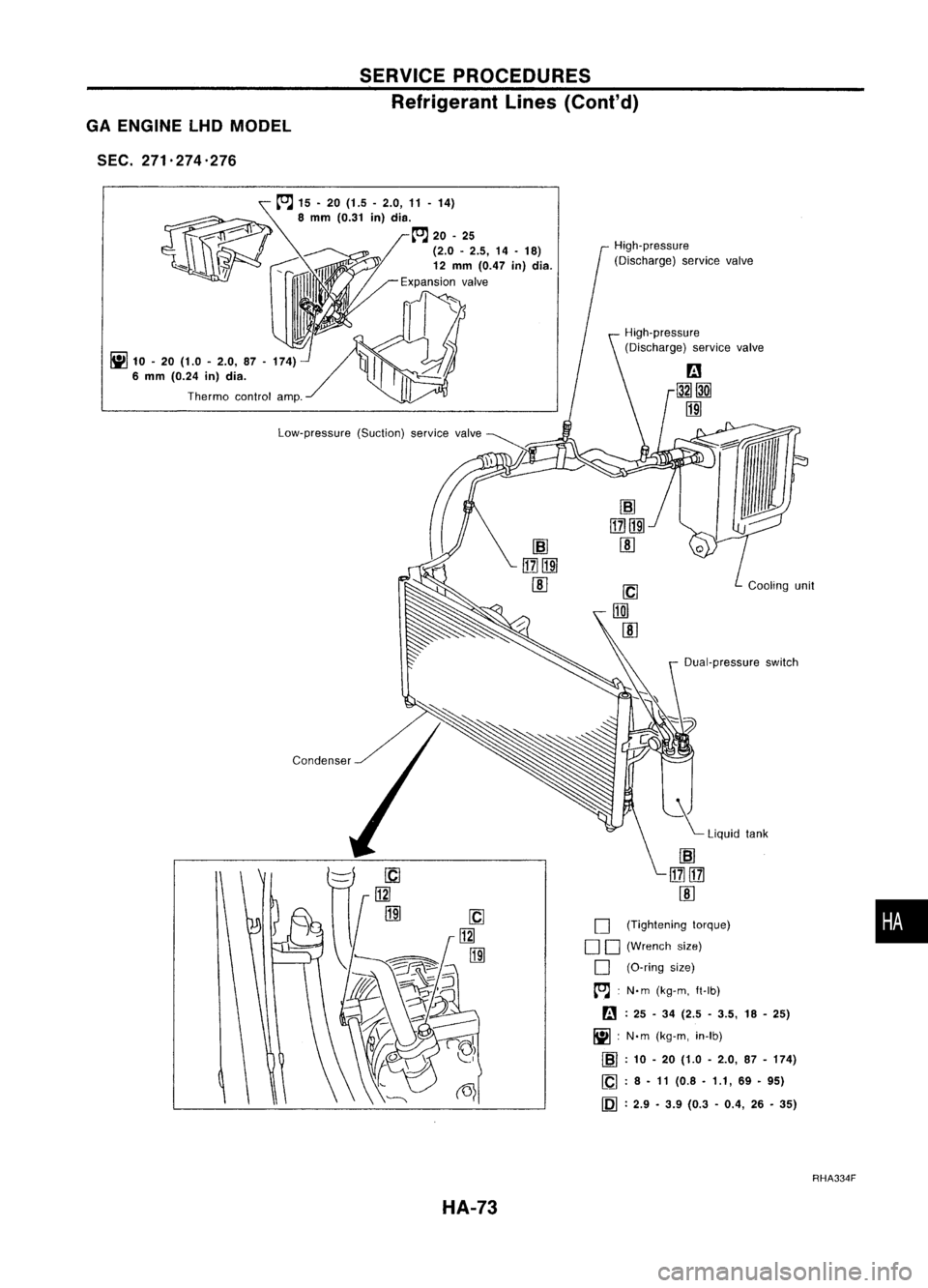

Page 1475 of 1701

SERVICEPROCEDURES

Refrigerant Lines(Cont'd)

GA ENGINE lHDMODEL

SEC. 271.274.276

Low-pressure (Suction)servicevalve

~

10-20 (1.0 -2.0, 87-174)

6 mm (0.24 in)dia.

Thermo controlamp.

•

Dual-pressure

switch

~ Liquid tank

High-pressure

(Discharge) servicevalve

High-pressure

(Discharge) servicevalve

o

(Tightening torque)

D D (Wrench size)

D (O-ring size)

~ :N'm (kg-m, ft-lb)

~ :25 -34 (2.5 -3.5, 18-25)

~ :N'm (kg-m, in-Ib)

rm :

10 -20 (1.0 -2.0, 87-174)

~ :8 •11 (0.8 •1.1, 69•95)

~ :2.9 •3.9 (0.3 -0.4, 26•35)

~

15•20 (1.5 -2.0, 11-14)

~ 8

mm

(0.31

in)

die.

___ ==- - ~

20-25

(2.0 -2.5, 14-18)

."""\ ~t;,

12mm (0.47 in)dia.

Expansion valve

RHA334F

HA-73

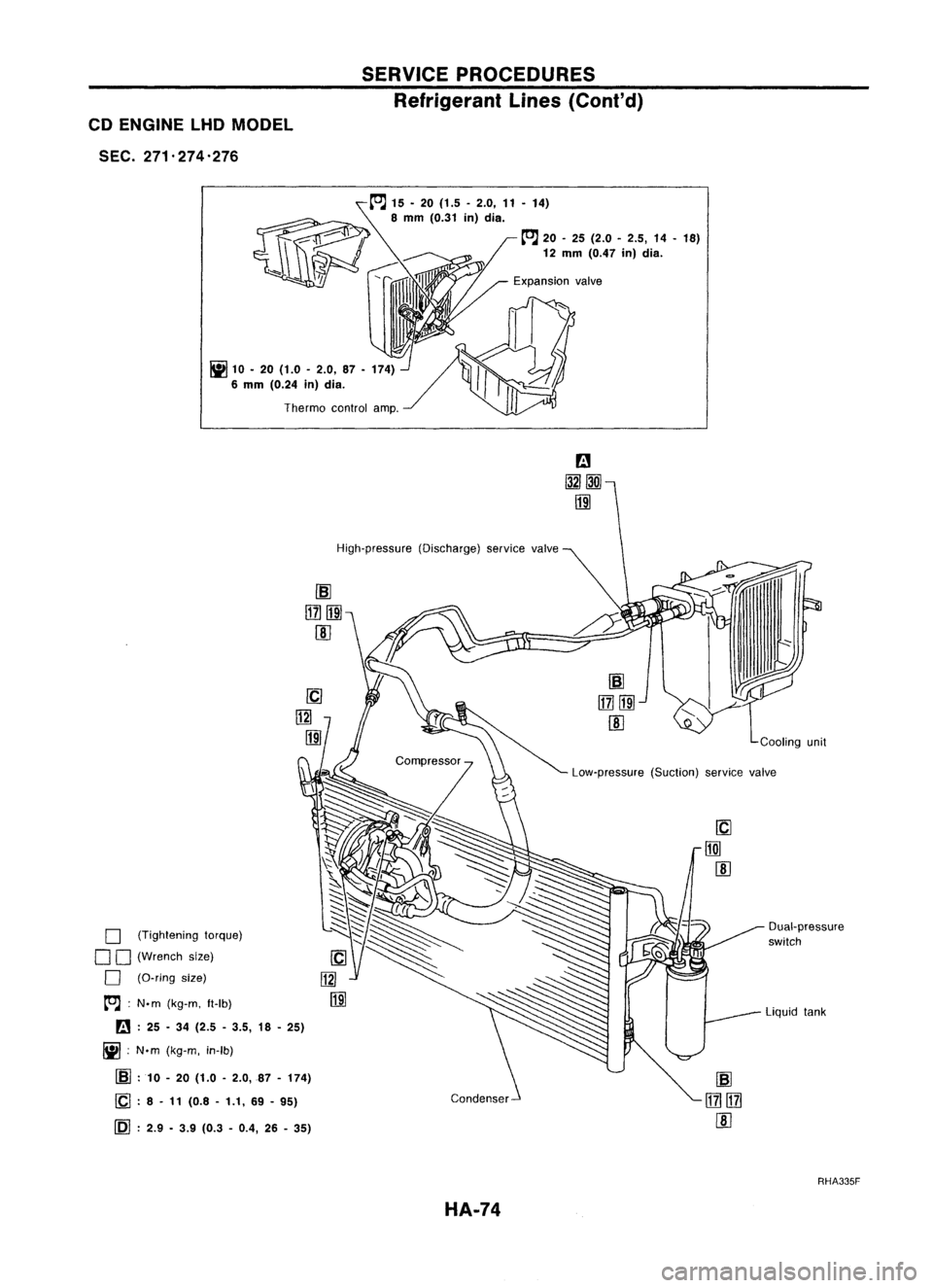

Page 1476 of 1701

SERVICEPROCEDURES

Refrigerant Lines

(Cont'd)

CD ENGINE LHDMODEL

SEC. 271'274'276

[O.J

15. 20(1.5 -2.0, 11-14)

8

mm

(0.31

in)

dia.

[O.J

20-25 (2.0 -2.5, 14-18)

12 mm (0.47 in)dia.

~ 10•20 (1.0 -2.0, 87•174)

6 mm (0.24 in)dia.

Thermo controlamp.

High-pressure (Discharge)servicevalve

o

(Tightening torque)

o

0

(Wrench size)

o

(O-ring size)

[O.J :

N'm (kg-m, It-Ib)

B :

25 -34 (2.5 -3.5, 18-25)

~ :N'm (kg-m, in-Ib)

[SJ

:10 -20 (1.0 -2.0,87 -174)

[Q :

8 -11 (0.8 -1.1, 69-95)

[Q] :

2.9 •3.9 (0.3 -0.4, 26-35)

HA-74

Cooling

unit

Low-pressure (Suction)service

valve

Liquid tank

RHA335F

Page 1477 of 1701

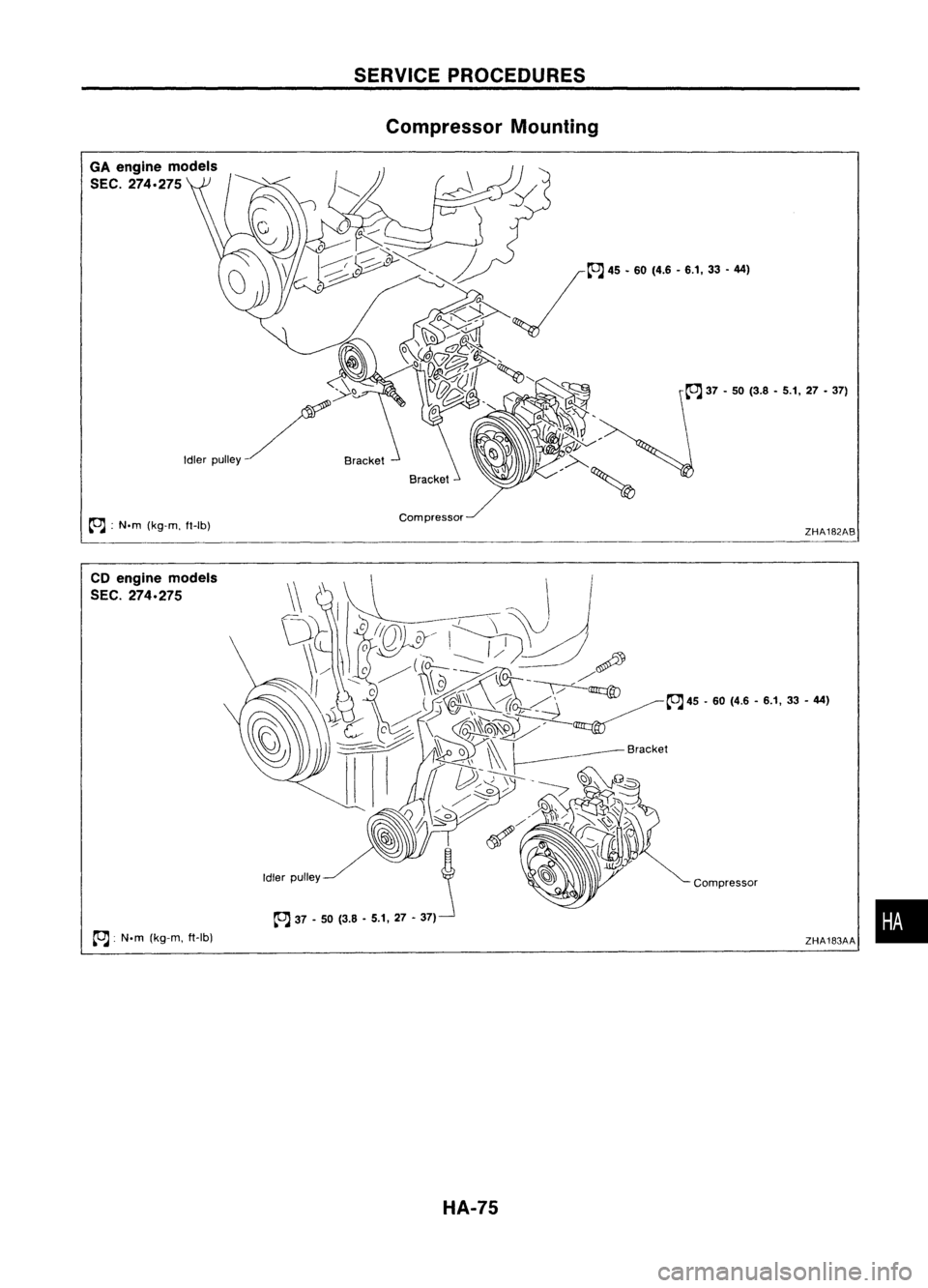

GAengine models

SEC.

274.275

~ :N.m (kg-m, ft-Ib)

CD engine models

SEC.

274.275

~ :N.m (kg-m, ft-Ib)

SERVICE

PROCEDURES

Compressor Mounting

HA-75 ZHA182AB

ZHA183AA •