engine NISSAN ALMERA N15 1995 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 1518 of 1701

![NISSAN ALMERA N15 1995 Service Manual ENGINEMAINTENANCE [][]

Checking CoolingSystem(Cont'd)

Pull thenegative-pressure valvetoopen it.Check thatitcloses

completely whenreleased.

CHECKING COOLINGSYSTEMFORLEAKS

Apply pressure tothe c NISSAN ALMERA N15 1995 Service Manual ENGINEMAINTENANCE [][]

Checking CoolingSystem(Cont'd)

Pull thenegative-pressure valvetoopen it.Check thatitcloses

completely whenreleased.

CHECKING COOLINGSYSTEMFORLEAKS

Apply pressure tothe c](/img/5/57349/w960_57349-1517.png)

ENGINEMAINTENANCE [][]

Checking CoolingSystem(Cont'd)

Pull thenegative-pressure valvetoopen it.Check thatitcloses

completely whenreleased.

CHECKING COOLINGSYSTEMFORLEAKS

Apply pressure tothe cooling systemwithcaptester tocheck

f~r leakage.

Testing pressure:

157 kPa (1.57 bar,1.6kg/cm

2,

23psi)

CAUTION:

Higher pressure thanthespecified valuemaycause damage to

radiator.

SMA811C

SMA803A

Checking

FuelLines

Inspect fuellines andtank forimproper attachment, leaks,

cracks, damage, looseconnections, chafingordeterioration.

If necessary, repairorreplace faultyparts.

3 (0.12) Unit:mm(in)

_._-- --,"'~'r---1

"

,

-

-

---;--,

-,---

•• J..

_J- __

28 (1.10)

~ Fuel hose clamps

1.0 -1.5 N.m

(0.10 -0.15 kg-m,

8.7 -13.0 in-Ib)

MMA104A

• FUEL PRESRELEASE.

0

FUEL PUMP WILLSTOP BY

TOUCHING STARTDURING

IDLE_

CRANK AFEW TIMES AFTER

ENGINE STALL.

---S-T~-RT--

SEF823KCAUTION:

Tighten high-pressure rubberhoseclamp sothat clamp endis

3 mm (0.12 in)from hose end.

Tightening torquespecifications arethesame forallrubber

hose clamps.

Ensure thatscrew doesnotcontact adjacent parts.

Changing FuelFilter

WARNING:

Before removing fuelfilter, release fuelpressure fromfuelline

to eliminate danger.

rF.i\

1.Start engine.

~ 2.Perform "FUELPRESSURE RELEASE"in"WORK

SUPPORT" modewithCONSULT.

3. After engine stalls,crankengine twoorthree times

to make surethatfuel pressure isreleased.

4. Turn ignition switchoff.

MA-32

Page 1519 of 1701

ENGINEMAINTENANCE ~

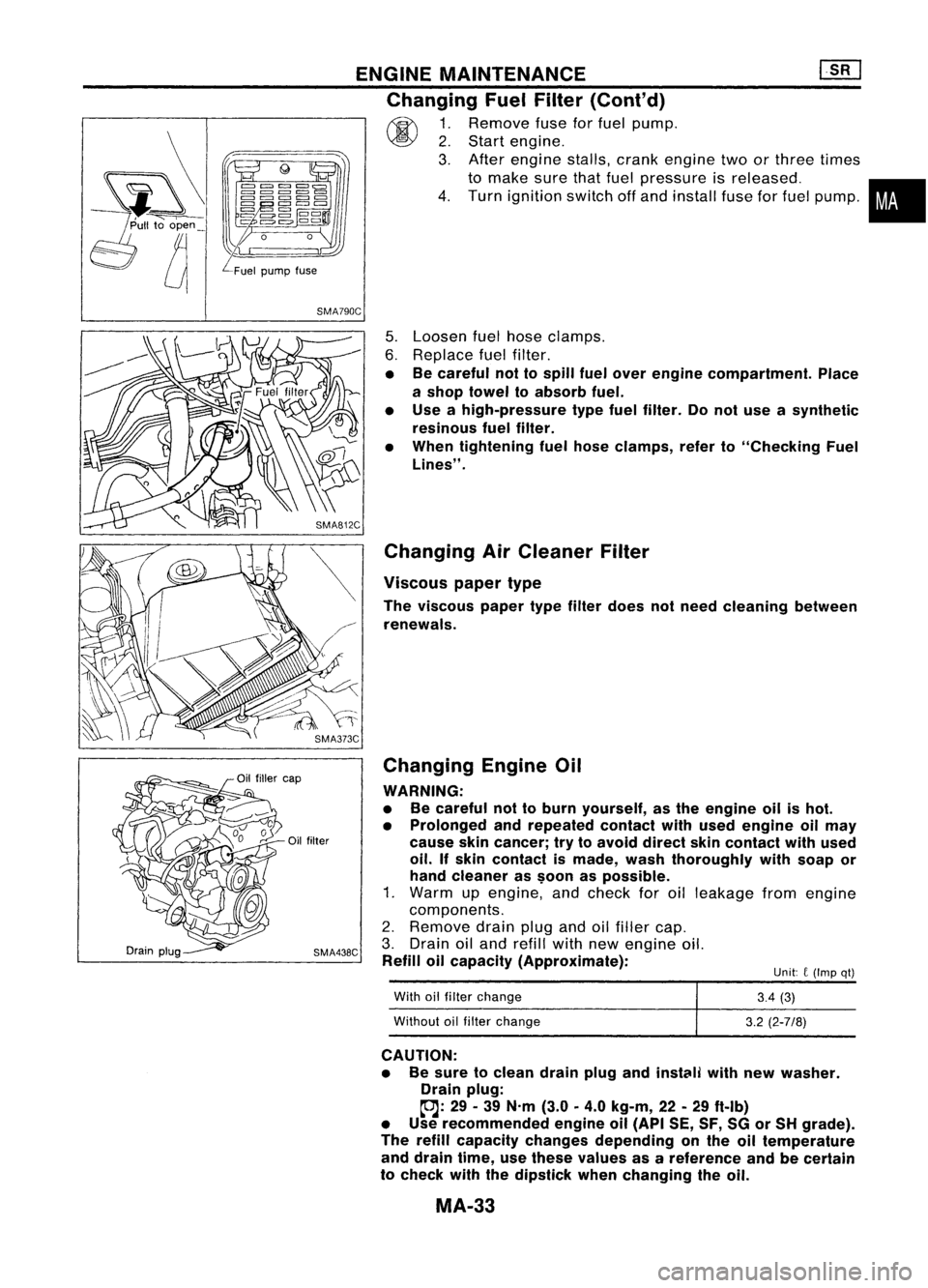

Changing FuelFilter (Cont'd)

~ 1.Remove fuseforfuel pump.

~ 2.Start engine.

3. After engine stalls,crankengine twoorthree times

to make surethatfuel pressure isreleased. •

4. Turn ignition switchoffand install fuseforfuel pump.

i

Unit: C(Imp qt)

SMA790C

5.Loosen fuelhose clamps.

6. Replace fuelfilter.

• Becareful nottospill fuelover engine compartment. Place

a shop towel toabsorb fuel.

• Use ahigh-pressure typefuelfilter. Donot use asynthetic

resinous fuelfilter.

• When tightening fuelhose clamps, referto"Checking Fuel

Lines" .

Changing AirCleaner Filter

Viscous papertype

The viscous papertypefilter does notneed cleaning between

renewals.

Changing EngineOil

WARNING:

• Becareful nottoburn yourself, asthe engine oilishot.

• Prolonged andrepeated contactwithused engine oilmay

cause skincancer; trytoavoid direct skincontact withused

oil. Ifskin contact ismade, washthoroughly withsoap or

hand cleaner as$oon aspossible.

1. Warm upengine, andcheck foroilleakage fromengine

components.

2. Remove drainplugandoilfiller cap.

3. Drain oiland refill withnewengine oil.

Refill oilcapacity (Approximate):

With oilfilter change

Without oilfilter change

3.4

(3)

3.2 (2-7/8)

CAUTION: • Besure toclean drainplugandinstClili withnewwasher.

Drain plug:

~: 29-39 N'm (3.0

0

4.0 kg-m, 22-29 ftolb)

• Use recommended engineoil(API SE,SF,SGorSH grade).

The refill capacity changes depending onthe oiltemperature

and drain time,usethese values asareference andbecertain

to check withthedipstick whenchanging theoil.

MA-33

Page 1520 of 1701

![NISSAN ALMERA N15 1995 Service Manual ENGINEMAINTENANCE [}[]

Changing EngineOil(Cont'd)

4. Check oillevel.

5. Start engine andcheck areaaround drainplugandoilfilter

for oilleakage.

6. Run engine forafew minutes, thenturnitoff. After NISSAN ALMERA N15 1995 Service Manual ENGINEMAINTENANCE [}[]

Changing EngineOil(Cont'd)

4. Check oillevel.

5. Start engine andcheck areaaround drainplugandoilfilter

for oilleakage.

6. Run engine forafew minutes, thenturnitoff. After](/img/5/57349/w960_57349-1519.png)

ENGINEMAINTENANCE [}[]

Changing EngineOil(Cont'd)

4. Check oillevel.

5. Start engine andcheck areaaround drainplugandoilfilter

for oilleakage.

6. Run engine forafew minutes, thenturnitoff. After several

minutes, checkoillevel.

Refill oil10this

"H" level.

Do not overfill.

SMA390C

Changing OilFilter

1. Remove oilfilter withTool.

WARNING:

Be careful nottoburn yourself, asthe engine andtheengine

oil are hot.

2. Clean oilfilter mounting surfaceoncylinder block.Coat

rubber sealofnew oilfilter withengine oil.

2/3

ofaturn

-------

OK SMA010

3.Screw inthe oilfilter untilaslight resistance isfelt, then

tighten anadditional 2/3turn.

4. Add engine oil.

Refer toChanging EngineOil.

• Clean excess oilfrom engine.

Changing SparkPlugs(Platinum-tipped type)

1. Disconnect ignitionwiresfromspark plugsatboot. Donot

pull onthe wire.

MA-34

Page 1521 of 1701

g

16

mm

(0.63

In)

Wrench

withamagnet

to hold spark plug

ENGINE

MAINTENANCE

lliJ

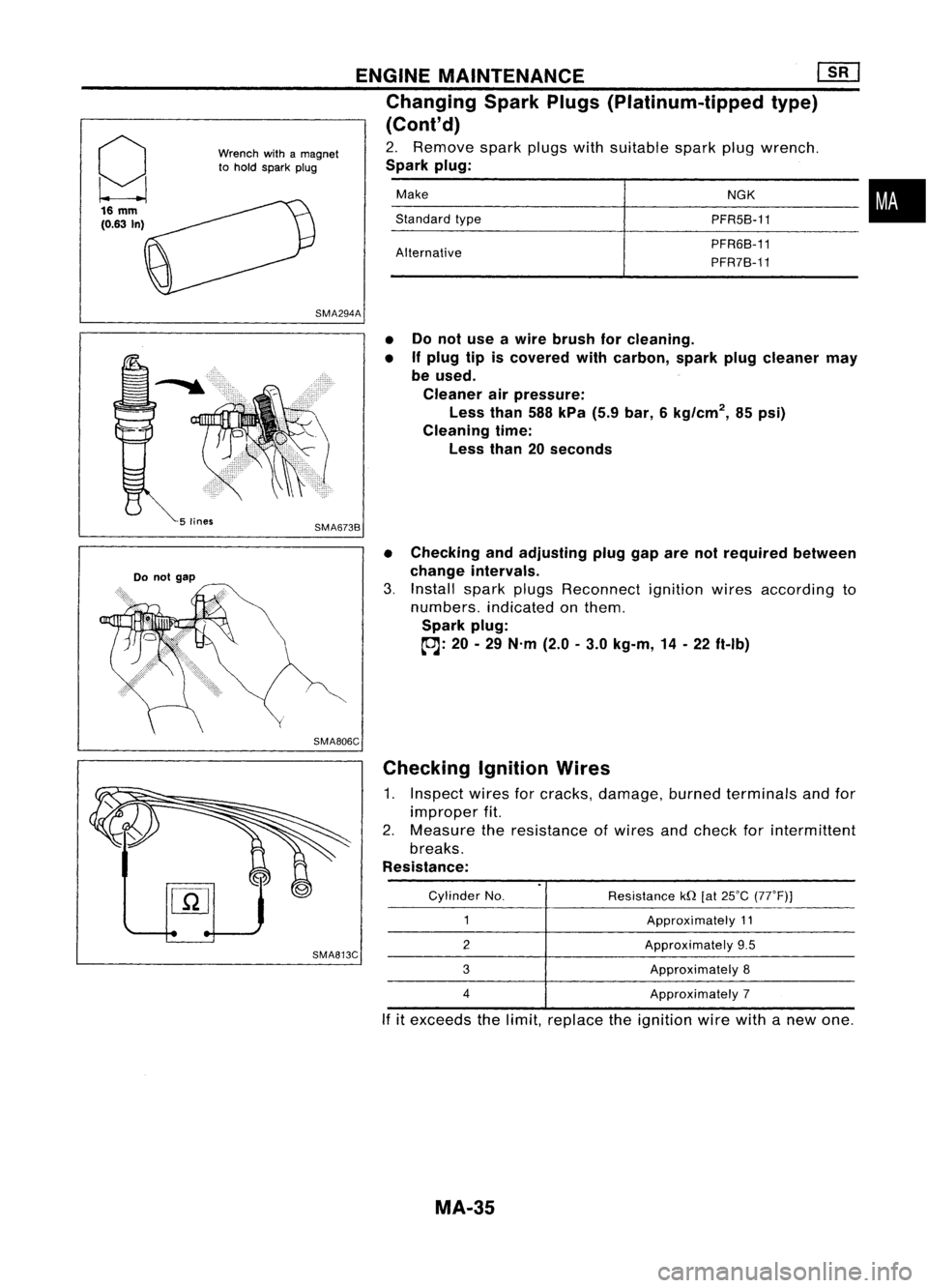

Changing SparkPlugs(Platinum-tipped type)

(Cont'd)

2. Remove sparkplugswithsuitable sparkplugwrench.

Spark plug:

Make NGK

•

Standard

type

PFR5B-11

Alternative PFR6B-11

PFR7B-11

SMA294A

Do

not

gap •

Donot use awire brush forcleaning.

• If

plug tipiscovered withcarbon, sparkplugcleaner may

be used.

Cleaner airpressure:

Less than588kPa (5.9bar, 6kg/cm

2,

85psi)

Cleaning time:

Less than20seconds

• Checking andadjusting pluggaparenotrequired between

change intervals.

3. Install sparkplugsReconnect ignitionwiresaccording to

numbers. indicatedonthem.

Spark plug:

~: 20-29 N'm (2.0-3.0 kg-m, 14-22 ft-Ib)

SMA806C Checking IgnitionWires

1. Inspect wiresforcracks, damage, burnedterminals andfor

improper fit.

2. Measure theresistance ofwires andcheck forintermittent

breaks.

Resistance:

SMA813C

Cylinder

No.

2

3

4

Resistance

kQ[at25°C (77°F)]

Approximately 11

Approximately 9.5

Approximately 8

Approximately 7

If itexceeds thelimit, replace theignition wirewithanew one.

MA-35

Page 1522 of 1701

ENGINEMAINTENANCE

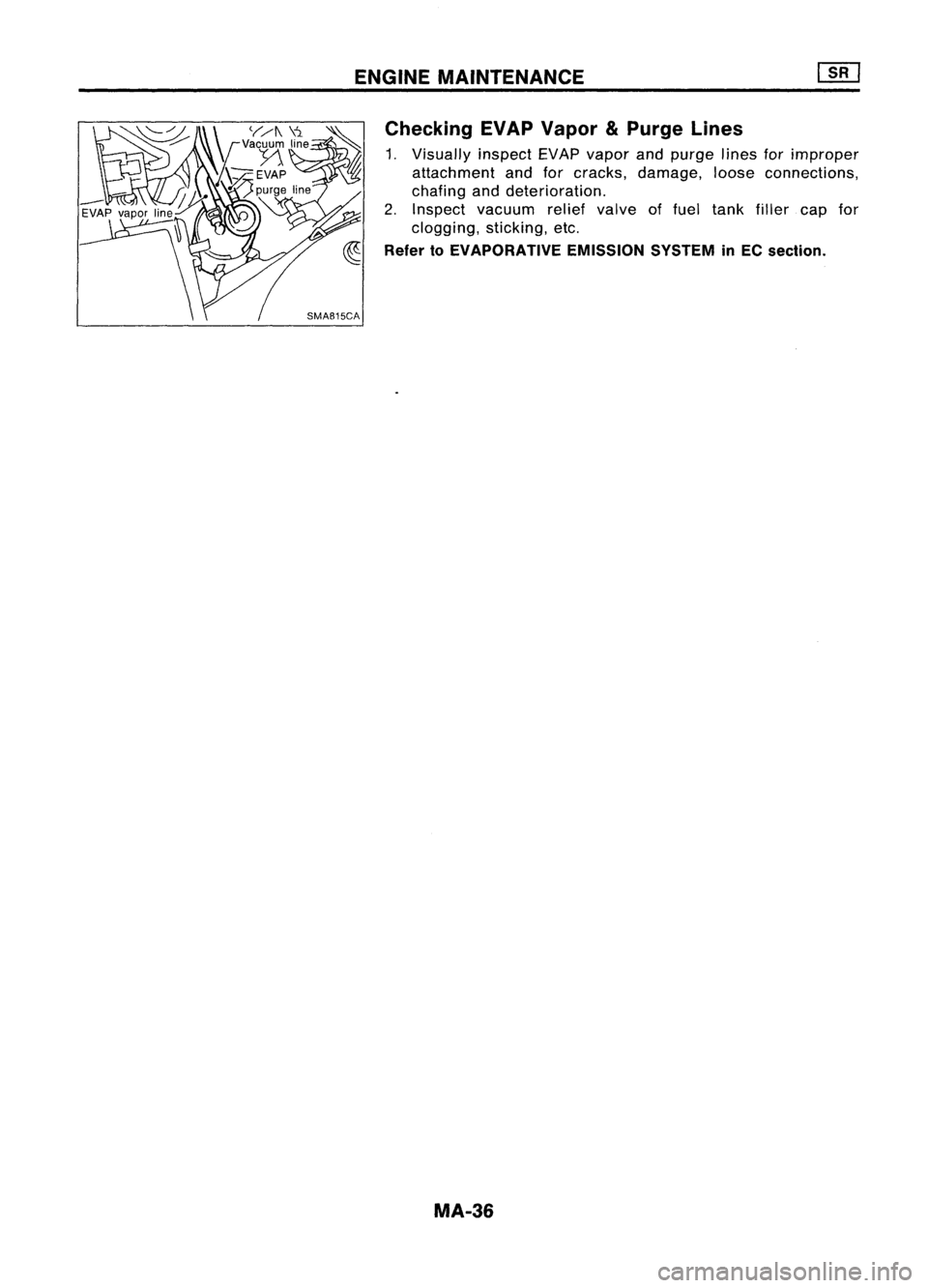

Checking EVAPVapor

&

Purge Lines

1. Visually inspectEVAP

vapor

andpurge linesforimproper

attachment andforcracks, damage, looseconnections,

chafing anddeterioration.

2. Inspect vacuum reliefvalve offuel tank filler capfor

clogging, sticking,etc.

Refer toEVAPORATIVE EMISSIONSYSTEMinEC section.

MA-36

Page 1523 of 1701

ENGINEMAINTENANCE

SEF051PA SEF909P

*

NO FAIL

D

Malfunction indicator

lamp

•

Checking

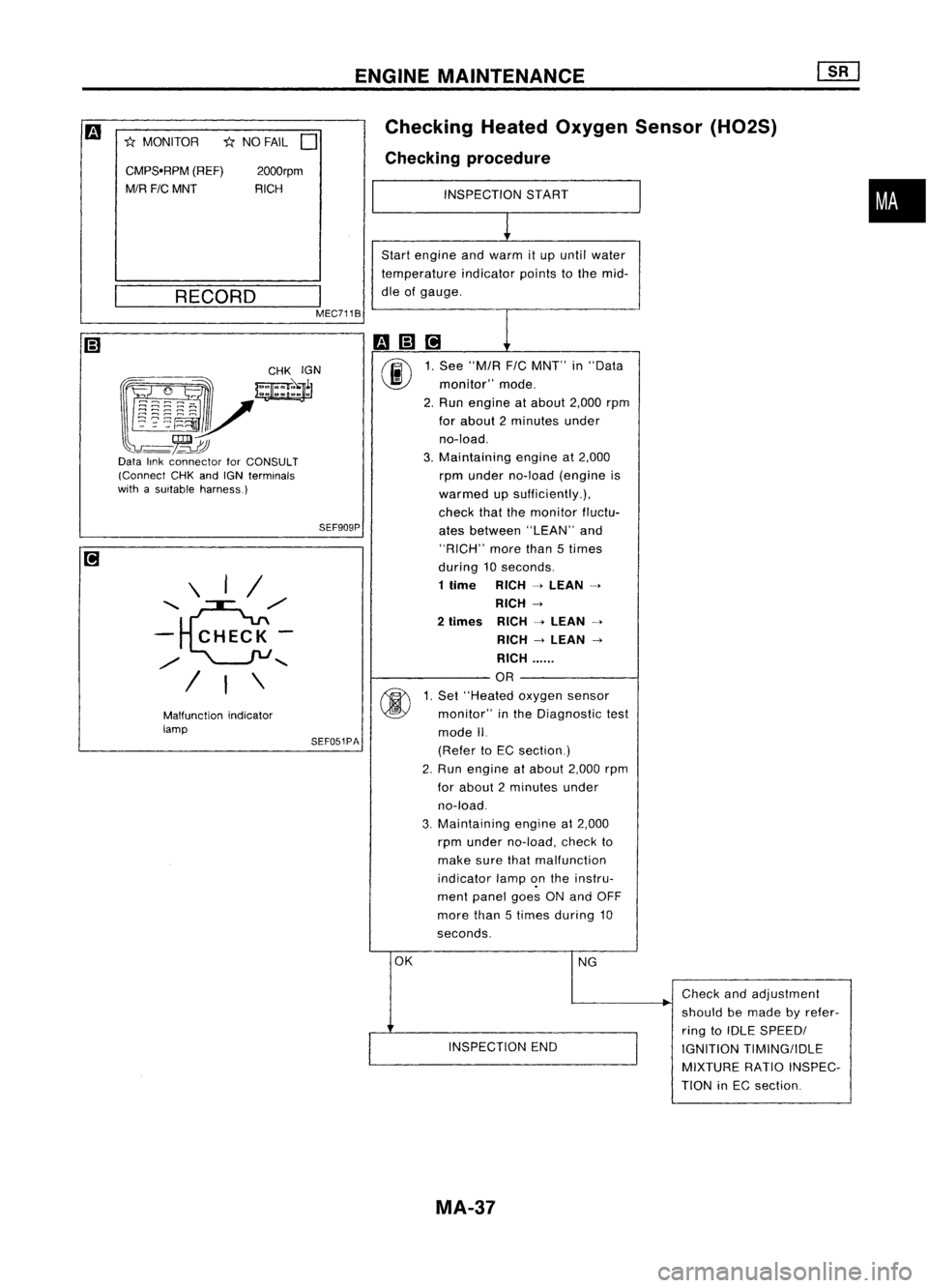

HeatedOxygen Sensor(H02S)

Checking procedure

INSPECTION START

1

Start engine andwarm itup until water

temperature indicatorpointstothe mid-

dle ofgauge.

m(;]ri

1

00

1.

See "M/R F/CMNT" in"Data

monitor" mode.

2. Run engine atabout 2,000rpm

for about 2minutes under

no-load.

3. Maintaining engineat2,000

rpm under no-load (engine is

warmed upsufficiently.),

check thatthemonitor fluctu-

ates between "LEAN"and

"RICH" morethan5times

during 10seconds.

1 time RICH

-4

LEAN

-4

RICH

-4

2

times RICH

-4

LEAN

-4

RICH

-4

LEAN

-4

RICH ......

OR

@

1.

Set "Heated oxygensensor

monitor" inthe Diagnostic test

mode II.

(Refer toEC section)

2. Run engine atabout 2,000rpm

for about 2minutes under

no-load.

3. Maintaining

engineat2,000

rpm under no-load, checkto

make surethatmalfunction

indicator lamp~nthe instru-

ment panel goesONand OFF

more than5times during 10

seconds.

OK NG

.

Check

andadjustment

should bemade byrefer-

ring toIDLE SPEEDI

INSPECTION END

IGNITIONTIMING/IDLE

MIXTURE RATIOINSPEC-

TION inEC section

2000rpm

RICH

\ I/

........ e./

- CHECK-

./

........

/ I\

CMPS.RPM

(REF)

M/R FICMNT

*

MONITOR

__ R_E_C_O_R_D __

I

MEC711B

~~~~:?~;~

~~r

l~~~~V

-~~

Data linkconnector forCONSULT

(Connect CHKandIGN terminals

with asuitable harness.)

MA-37

Page 1524 of 1701

ENGINEMAINTENANCE

Air conditioner

compressor

SMA442C

AMA054 Manifold

NutCheck

1. Remove exhaustmanifold cover.

2. Tighten manifold boltsandnuts tothe specified torque.

Refer to"SERVICE DATAANDSPECIFICATIONS (SOS)".

3. Install exhaust manifold cover.

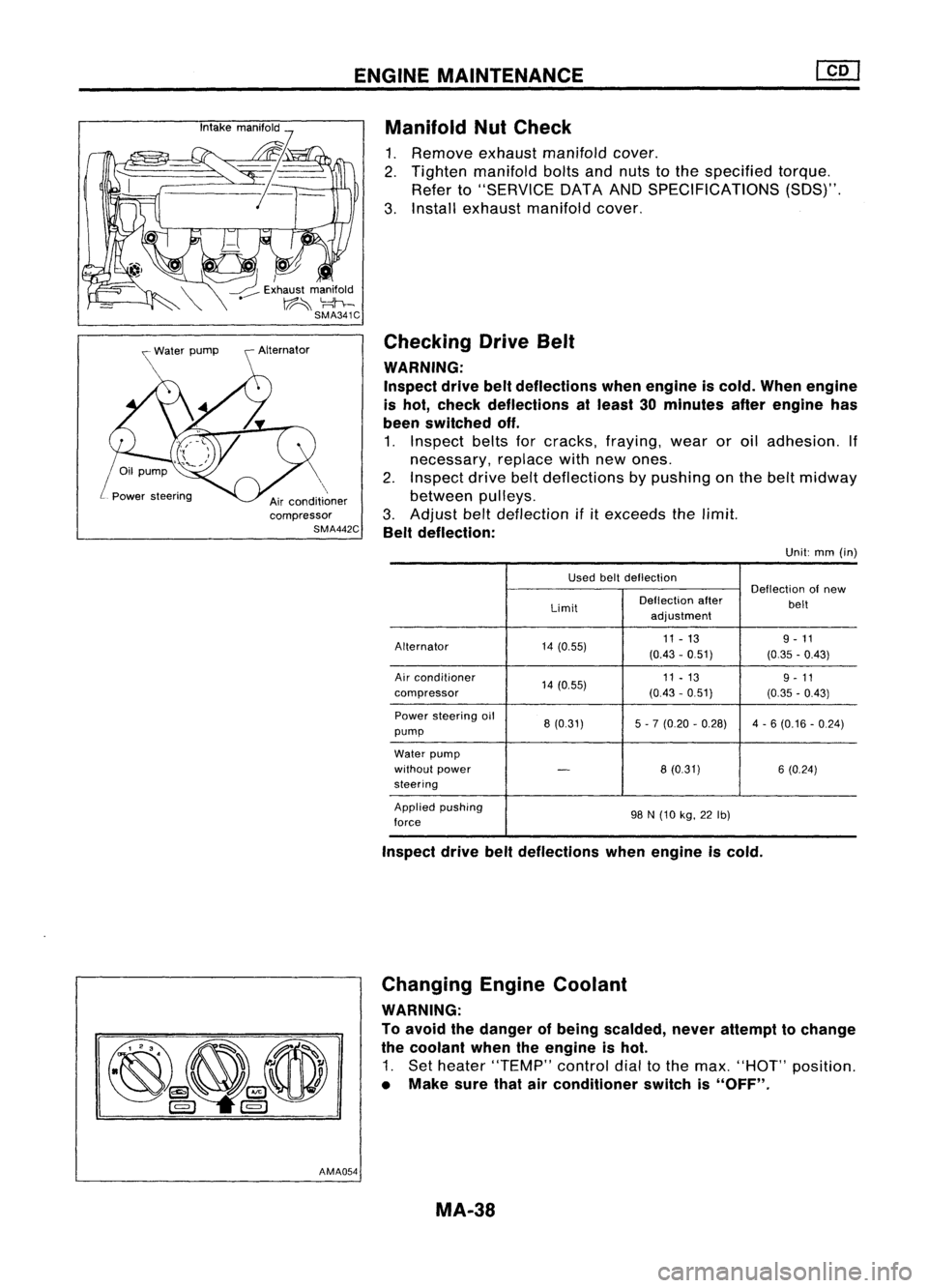

Checking DriveBelt

WARNING:

Inspect drivebeltdeflections whenengine iscold. When engine

is hot, check deflections atleast 30minutes afterengine has

been switched off.

1. Inspect beltsforcracks, fraying, wearoroil adhesion. If

necessary, replacewithnewones.

2. Inspect drivebeltdeflections bypushing onthe belt midway

between pulleys.

3. Adjust belt

deflection

if

it

exceeds thelimit.

Belt deflection:

Unit:mm(in)

Used beltdeflection

Deflectionofnew

Limit Deflection

after

belt

adjustment

Alternator 14(0.55) 11

-13 9-11

(0.43 -051) (0.35-0.43)

Air conditioner

14(0.55) 11

-13

9-11

compressor (0.43-051) (0.35-0.43)

Power steering oil

8(0.31) 5-7 (0.20 -0.28) 4-6 (0.16 -0.24)

pump

Water pump

without power

-

8(0.31) 6(0.24)

steering

Applied pushing

98N(10 kg,22Ib)

force

Inspect drivebeltdeflections whenengine iscold.

Changing EngineCoolant

WARNING:

To avoid thedanger ofbeing scalded, neverattempt tochange

the coolant whentheengine ishot.

1. Set heater "TEMP" controldialtothe max. "HOT" position.

• Make surethatairconditioner switchis"OFF".

MA-38

Page 1525 of 1701

![NISSAN ALMERA N15 1995 Service Manual ENGINEMAINTENANCE

@[]

Changing EngineCoolant (Cont'd)

2. Open drainplugs onthe bottom rightofradiator andonthe

left side ofcylinder block.

3. Remove radiatorcapand drain coolant.

4. Close drain NISSAN ALMERA N15 1995 Service Manual ENGINEMAINTENANCE

@[]

Changing EngineCoolant (Cont'd)

2. Open drainplugs onthe bottom rightofradiator andonthe

left side ofcylinder block.

3. Remove radiatorcapand drain coolant.

4. Close drain](/img/5/57349/w960_57349-1524.png)

ENGINEMAINTENANCE

@[]

Changing EngineCoolant (Cont'd)

2. Open drainplugs onthe bottom rightofradiator andonthe

left side ofcylinder block.

3. Remove radiatorcapand drain coolant.

4. Close drainplugs andfillradiator withwater uptofiller •

neck. •

5. Warm upengine andrepeat steps2,3and 4one ortwo

times todrain oldcoolant.

Drain plug(Radiator)

6.Open airbleeder onintake manifold.

7. Fill radiator withcoolant uptofiller neck.

Follow instructions attachedtoanti-freeze containerforanti-

freeze towater mixing ratio.

Pour coolant slowlytoallow airinsystem toescape.

Coolant capacity:

Regarding theAnti-freeze CoolantMixtureRatio,referto"REC-

OMMENDED FLUIDSANDLUBRICANTS".

8. Securely closeairbleeder.

9. Fill reservoir tankwithcoolant upto"MAX" level.

10. Warm upengine atabout 2,000rpmtonormal operating

temperature.

11. Stop engine andallow

it

to cool.

12. Check coolant levelandrefill reservoir tankifnecessary.

• Clean excess coolant fromengine.

MAX.

MIN.

SMA412B

With

heater

Without heater

5.2

(4-5/8)

4.9 (4-3/8)

Unit:

C(Imp qt)

Water outlet

SLC053B CAUTION:

When heater unitisremoved orreplaced, refillengine coolant

as shown, removing heaterhoseatfeeding connector on

engine.

MA-39

Page 1526 of 1701

ENGINEMAINTENANCE

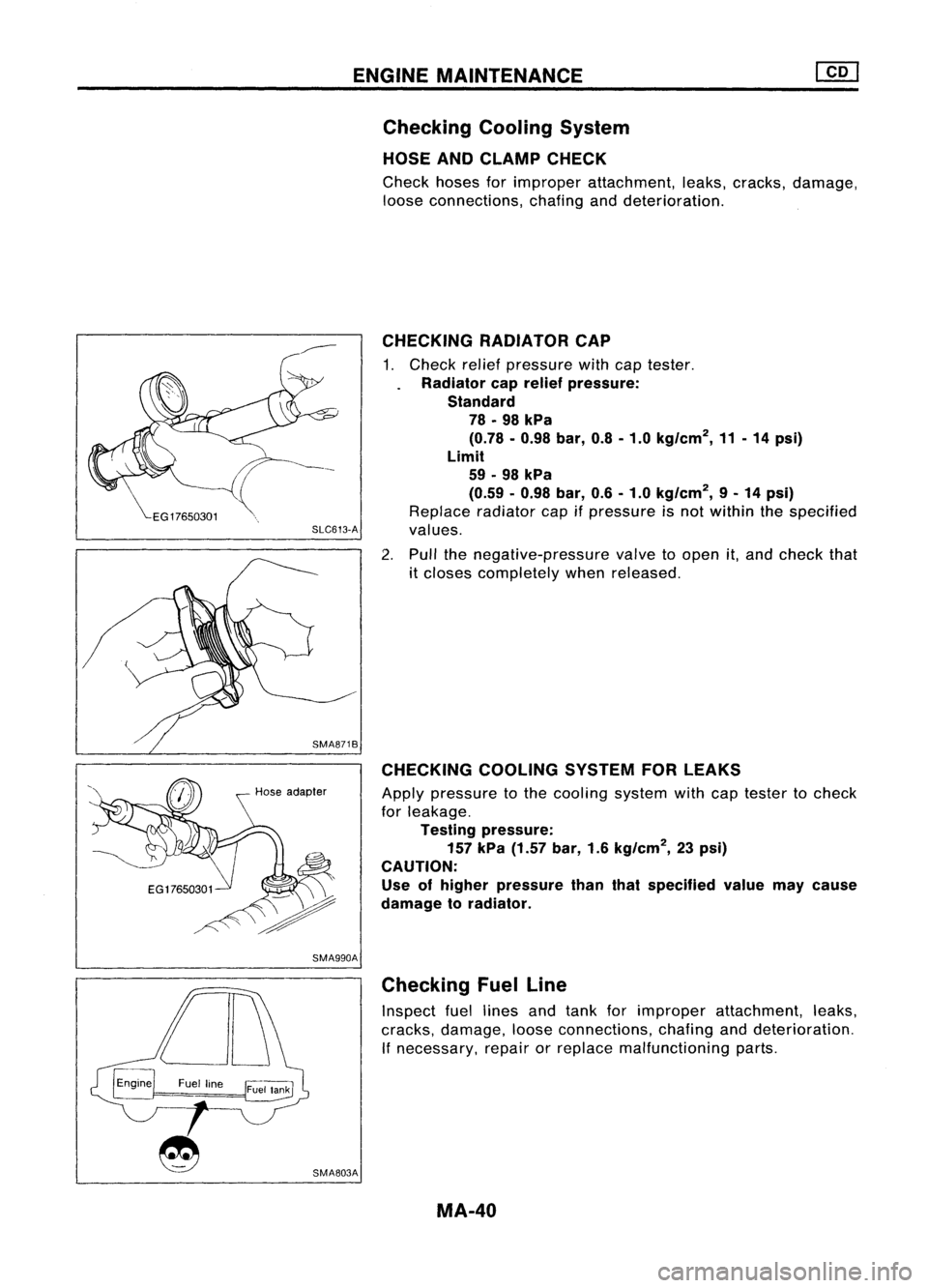

Checking CoolingSystem

HOSE ANDCLAMP CHECK

Check hosesforimproper attachment, leaks,cracks, damage,

loose connections, chafinganddeterioration.

CHECKING COOLINGSYSTEMFORLEAKS

Apply pressure tothe cooling systemwithcaptester tocheck

for leakage.

Testing pressure:

157

kPa

(1.57

bar,

1.6

kg/cm

2,

23psi)

CAUTION: Use ofhigher pressure thanthatspecified valuemaycause

damage toradiator.

CHECKING

RADIATORCAP

1. Check reliefpressure withcaptester.

Radiator caprelief pressure:

Standard

78.98

kPa

(0.78.0.98

bar,

0.8-1.0

kg/cm

2,

11-14

psi)

Limit

59 -98

kPa

(0.59 -0.98

bar,

0.6-1.0

kg/cm

2,

9-14

psi)

Replace radiatorcapifpressure isnot within thespecified

SLC613-A

values.

2. Pull thenegative-pressure valvetoopen it,and check that

it closes completely whenreleased.

Hose adapter

SMA990A

SMA803A Checking

FuelLine

Inspect fuellines andtank forimproper attachment, leaks,

cracks, damage, looseconnections, chafinganddeterioration.

If necessary, repairorreplace malfunctioning parts.

MA-40

Page 1527 of 1701

ENGINEMAINTENANCE

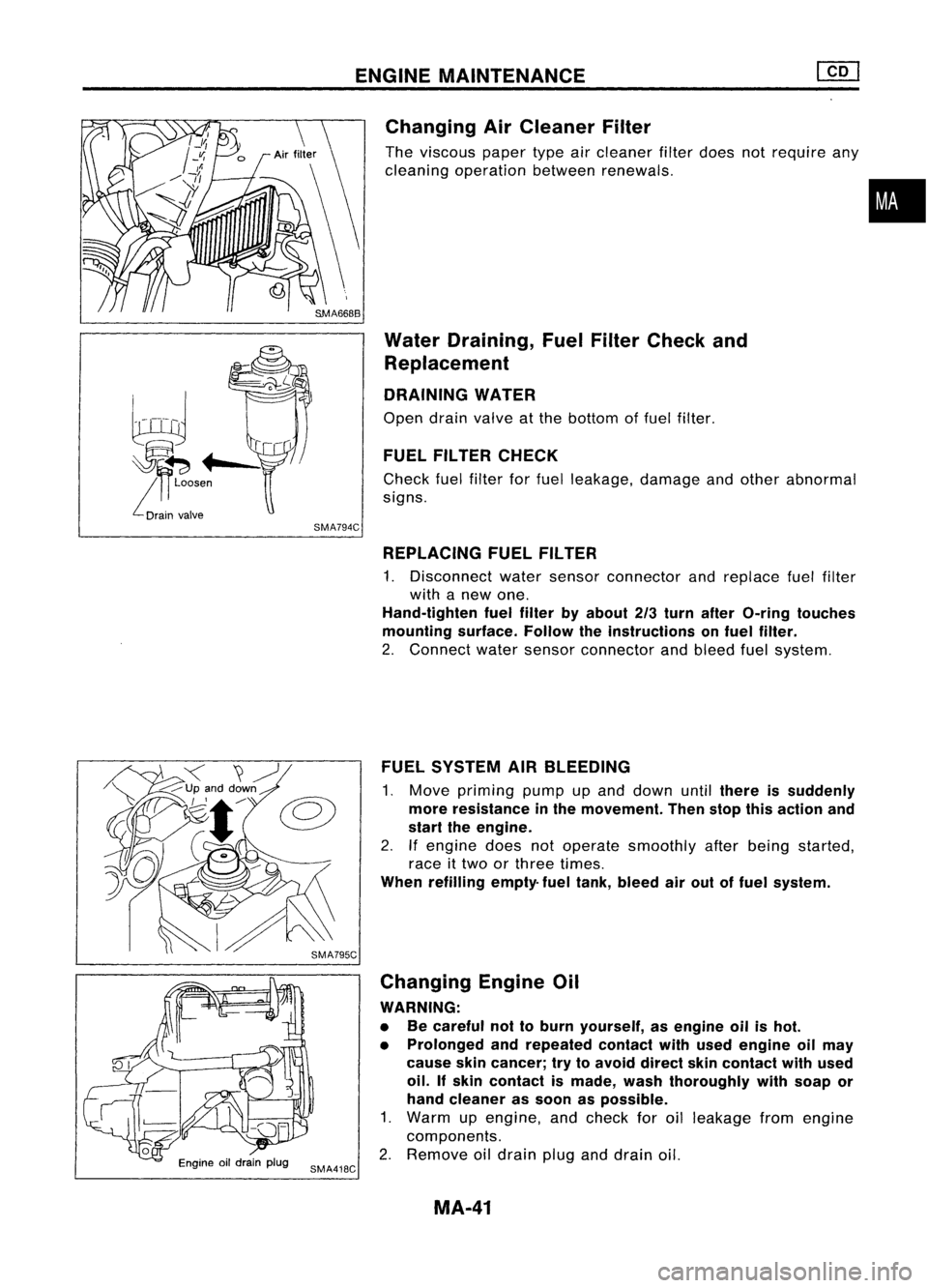

Changing AirCleaner Filter

The viscous papertypeaircleaner filterdoes notrequire any

cleaning operation betweenrenewals.

Water Draining, FuelFilter Check and

Replacement

DRAINING WATER

Open drainvalve atthe bottom offuel filter.

FUEL FILTER CHECK

Check fuelfilter forfuel leakage, damageandother abnormal

signs.

•

SMA794C REPLACING FUELFILTER

1. Disconnect watersensor connector andreplace fuelfilter

with anew one.

Hand-tighten fuelfilter byabout 2/3turn after O-ring touches

mounting surface.Followtheinstructions onfuel filter.

2. Connect watersensor connector andbleed fuelsystem.

FUEL SYSTEM AIRBLEEDING

1. Move priming pumpupand down until

there issuddenly

more resistance inthe movement. Thenstopthisaction and

start theengine.

2. Ifengine doesnotoperate smoothly afterbeing started,

race ittwo orthree times.

When refilling empty-fueltank, bleed airout offuel system.

Changing EngineOil

WARNING:

• Becareful nottoburn yourself, asengine oilishot.

• Prolonged andrepeated contactwithused engine oilmay

cause skincancer; trytoavoid direct skincontact withused

oil. Ifskin contact ismade, washthoroughly withsoap or

hand cleaner assoon aspossible.

1. Warm upengine, andcheck foroilleakage fromengine

components.

2. Remove oildrain pluganddrain oil.

MA-41