engine NISSAN ALMERA N15 1995 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 1508 of 1701

ENGINEMAINTENANCE ~

Checking CoolingSystem(Cont'd)

Pull thenegative-pressure valvetoopen it.Check thatitcloses

completely whenreleased.

SMA871B CHECKING COOLINGSYSTEMFORLEAKS

Apply pressure tothe cooling systemwithcaptester tocheck

for. leakage.

Testing pressure:

157 kPa (1.57 bar,1.6kg/cm

2,

23psi)

CAUTION: Higher pressure thanthespecified valuemaycause damage to

radiator.

Checking Fuellines

Inspect fuellines andtank forimproper attachment andfor

leaks, cracks, damage, looseconnections, chafinganddeteri-

oration. If necessary, repairorreplace faultyparts.

SMA803A

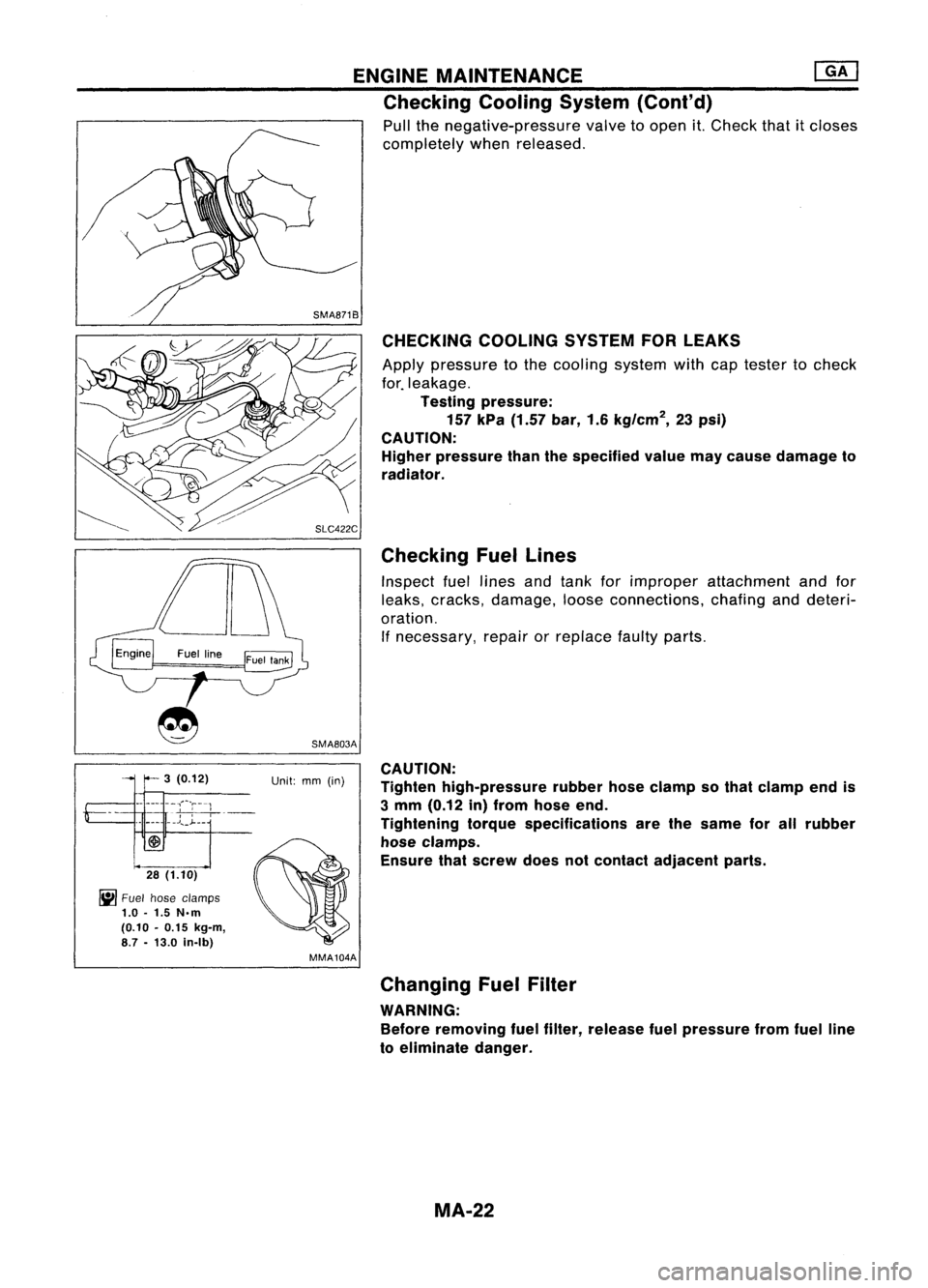

3 (0.12) Unit:mm(in)

-- --- ----,;~-r--1

"

,

-,-,-,

~-

_______ .J",_~__

28 (1.10)

~ Fuel hose clamps

1.0 -1.5 N.m

(0.10 -0.15 kg-m,

8.7 -13.0 in-Ib)

MMA104ACAUTION:

Tighten high-pressure rubberhoseclamp sothat clamp endis

3 mm (0.12 in)from hose end.

Tightening torquespecifications arethesame forallrubber

hose clamps.

Ensure thatscrew doesnotcontact adjacent parts.

Changing FuelFilter

WARNING: Before removing fuelfilter, release fuelpressure fromfuelline

to eliminate danger.

MA-22

Page 1509 of 1701

ENGINEMAINTENANCE @KJ

Changing FuelFilter (Cont'd)

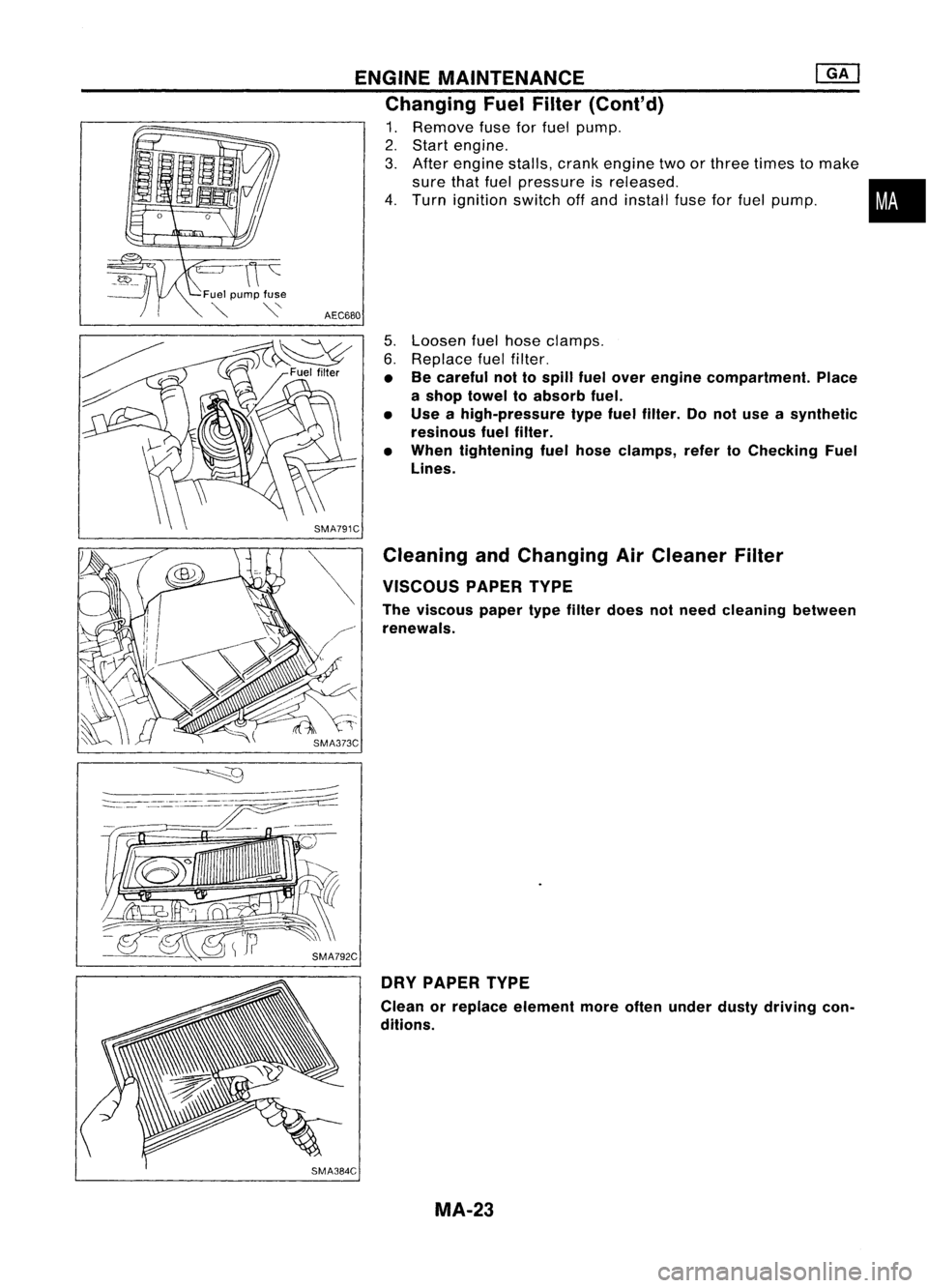

1. Remove fuseforfuel pump.

2. Start engine.

3. After engine stalls,crankengine twoorthree times tomake

sure thatfuel pressure isreleased. •

4. Turn ignition switchoffand install fuseforfuel pump.

i

AECBBO

5.Loosen fuelhose clamps.

6. Replace fuelfilter.

• Becareful nottospill fuelover engine compartment. Place

a shop towel toabsorb fuel.

• Use ahigh-pressure typefuelfilter. Donot use asynthetic

resinous fuelfilter.

• When tightening fuelhose clamps, refertoChecking Fuel

Lines.

Cleaning andChanging AirCleaner Filter

VISCOUS PAPERTYPE

The viscous papertypefilter does notneed cleaning between

renewals.

DRY PAPER TYPE

Clean orreplace element moreoftenunder dustydriving con-

ditions.

SMA384C MA-23

Page 1510 of 1701

ENGINEMAINTENANCE

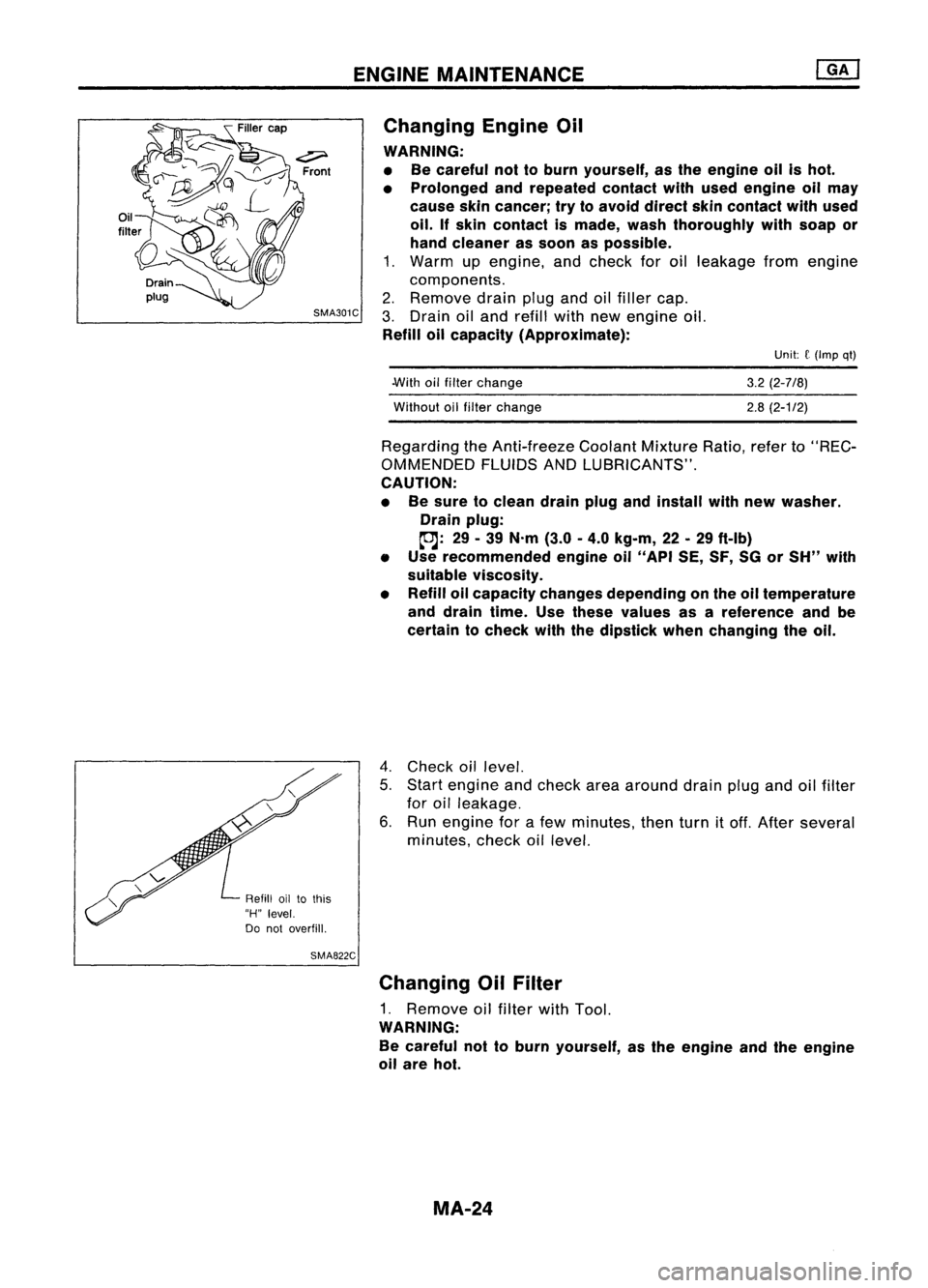

Changing EngineOil

WARNING:

• Becareful nottoburn yourself, asthe engine oilishot.

• Prolonged andrepeated contactwithused engine oilmay

cause skincancer; trytoavoid direct skincontact withused

oil.

If

skin contact ismade, washthoroughly withsoap or

hand cleaner assoon aspossible.

1. Warm upengine, andcheck foroilleakage fromengine

components.

2. Remove drainplugandoilfiller cap.

3. Drain oiland refill withnewengine oil.

Refill oilcapacity (Approximate):

Unit:

f

(Imp qt)

.With oilfilter change

Without oilfilter change

3.2

(2-7/8)

2.8 (2-1/2)

Regarding theAnti-freeze CoolantMixtureRatio,referto"REC-

OMMENDED FLUIDSANDLUBRICANTS".

CAUTION:

• Besure toclean drainplugandinstall withnew washer.

Drain plug:

~: 29-39 N'm (3.0-4.0 kg-m, 22-29 ft-Ib)

• Use recommended engineoil"API SE,SF,SGorSH" with

suitable viscosity.

• Refill oilcapacity changesdepending onthe oiltemperature

and drain time.Usethese values asareference andbe

certain tocheck withthedipstick whenchanging theoil.

4. Check oillevel.

5. Start engine andcheck areaaround drainplugandoilfilter

for oilleakage.

6. Run engine forafew minutes, thenturnitoff. After several

minutes, checkoillevel.

Refill oiltothis

"H" level.

Do not overfill.

SMA822C

Changing OilFilter

1. Remove oilfilter withTool.

WARNING:

Be careful nottoburn yourself, asthe engine andtheengine

oil are hot.

MA-24

Page 1511 of 1701

ENGINEMAINTENANCE ~

Changing OilFilter (Cont'd)

2. Before installing newoilfilter, clean theoilfilter mounting

surface oncylinder block,andcoat therubber sealofoil fil-

ter with alittle engine oil.

SMA010

•

2/3 ofaturn

g 16

mm

(0.63 In) SMA302CA

Wrench withamagnet

to hold spark plug

SMA294A

3.

Screw inthe oilfilter untilaslight resistance isfelt, then

tighten anadditional 2/3turn.

4. Add engine oil.

Refer toChanging EngineOil.

• Clean excess oilfrom engine.

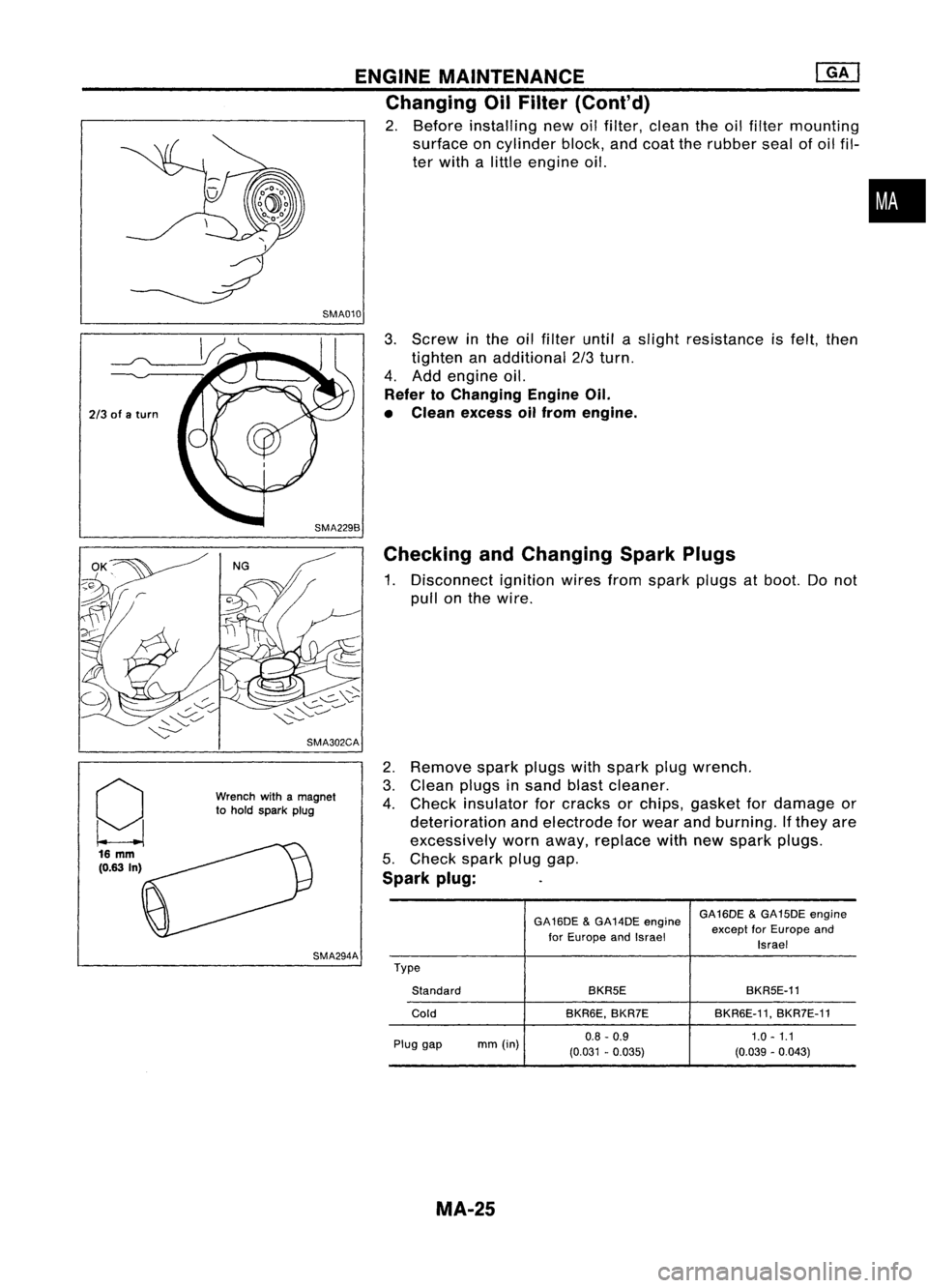

Checking andChanging SparkPlugs

1. Disconnect ignitionwiresfromspark plugsatboot. Donot

pull onthe wire.

2. Remove sparkplugswithspark plugwrench.

3. Clean plugsinsand blastcleaner.

4. Check insulator forcracks orchips, gasket fordamage or

deterioration andelectrode forwear andburning. Ifthey are

excessively wornaway, replace withnewspark plugs.

5. Check sparkpluggap.

Spark plug:

GA16DE&GA14DE engine GA16DE

&GA15DE engine

for Europe andIsrael except

forEurope and

Israel

Type Standard BKR5E

BKR5E-11

Cold BKR6E,BKR7E BKR6E-11,

BKR7E-11

Plug gap mm(in) 0.8

-0.9 1.0-1.1

(0.031 -0.035) (0.039-0.043)

MA-25

Page 1512 of 1701

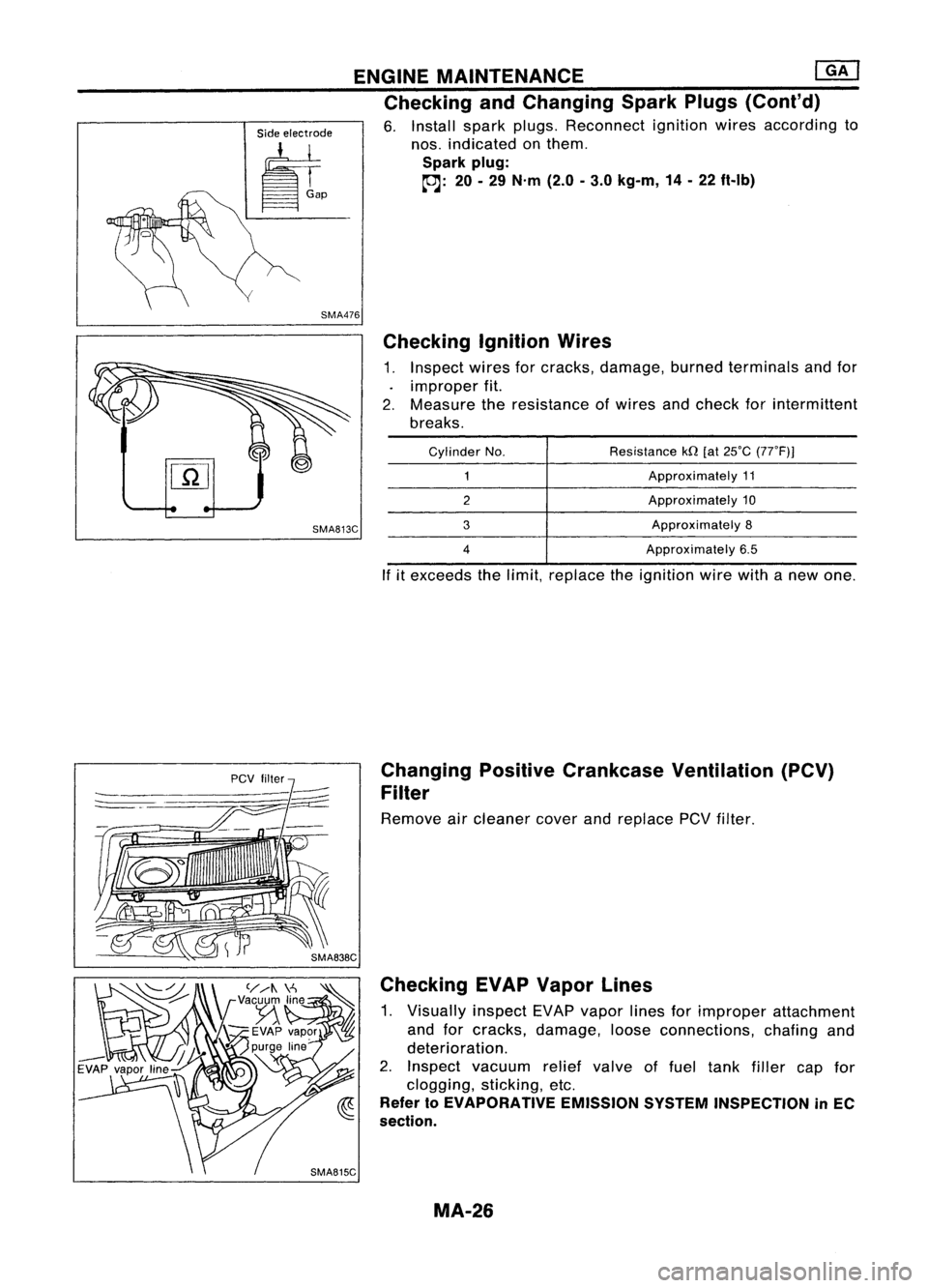

SMA476

Side

electrode

It, ENGINE

MAINTENANCE ~

Checking andChanging SparkPlugs(Cont'd)

6. Install sparkplugs. Reconnect ignitionwiresaccording to

nos. indicated onthem.

Spark plug:

~: 20-29 N'm (2.0-3.0 kg-m, 14-22 ft-Ib)

Checking IgnitionWires

1. Inspect wiresforcracks, damage, burnedterminals andfor

improper fit.

2. Measure theresistance ofwires andcheck forintermittent

breaks.

SMA813C

Cylinder

No.

2

3

4

Resistance

kQ[at25'C (77'F)]

Approximately 11

Approximately 10

Approximately 8

Approximately 6.5

If itexceeds thelimit, replace theignition wirewithanew one.

Changing PositiveCrankcase Ventilation (PCV)

Filter

Remove aircleaner coverandreplace

pev

filter.

Checking EVAPVapor Lines

1. Visually inspectEVAPvapor linesforimproper attachment

and forcracks, damage, looseconnections, chafingand

deterioration.

2. Inspect vacuum reliefvalve offuel tank filler capfor

clogging, sticking,etc.

Refer

10

EVAPORATIVE EMISSIONSYSTEMINSPECTION inEC

section.

MA-26

Page 1513 of 1701

ENGINEMAINTENANCE

SEF051PA SEF909P

*

NO FAIL

0

~y~r

GrJ-~

Data linkconnector forCONSULT

(Connect CHKandIGN terminals

with asuitable harness.)

•

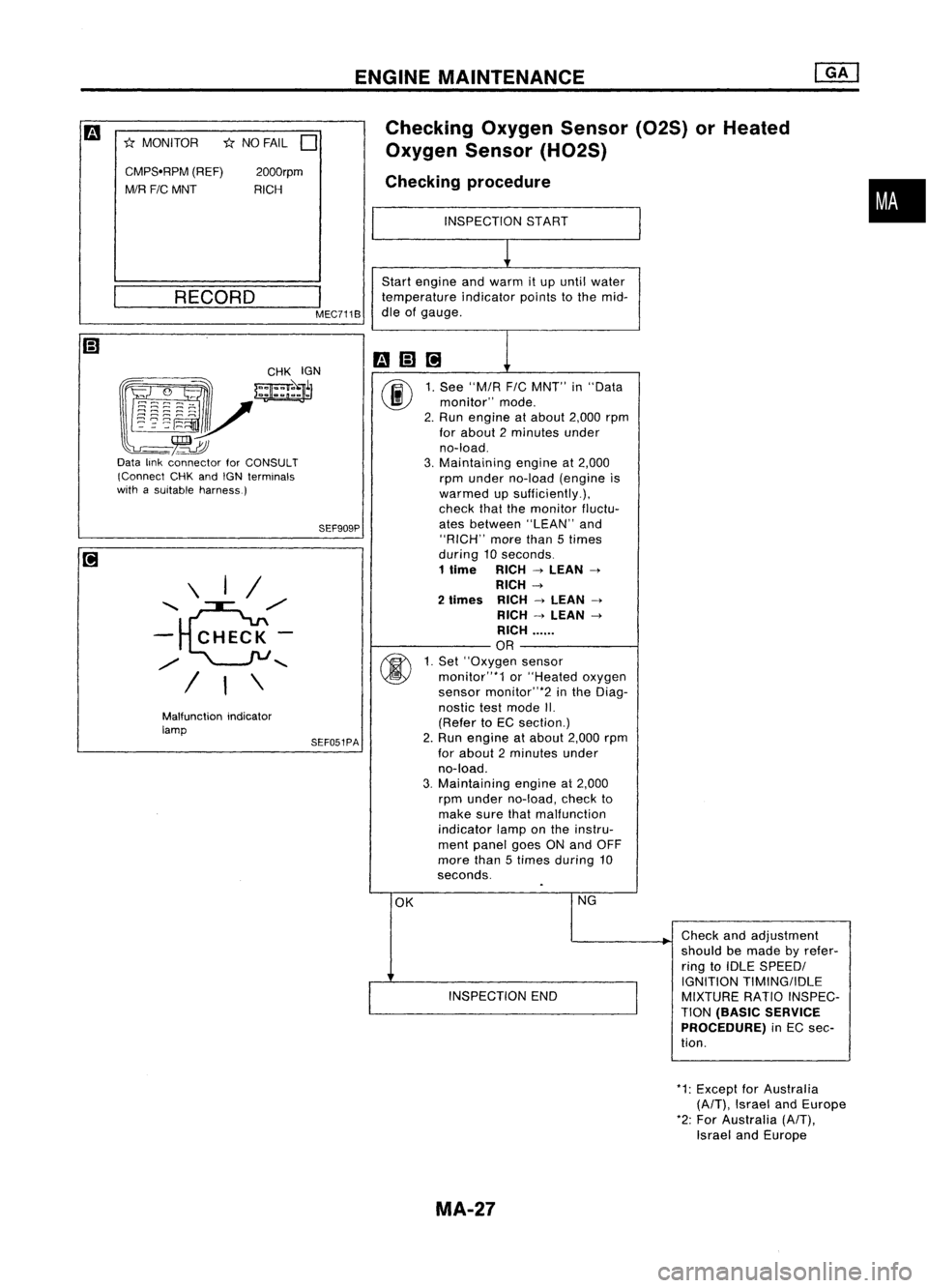

Checking

OxygenSensor(02S)orHeated

Oxygen Sensor(H02S)

Checking procedure

INSPECTION START

~

Start engine andwarm itup until water

temperature indicatorpointstothe mid-

dle ofgauge.

mm@]

1

00

1.

See "MIA

FIC

MNT" in"Data

monitor" mode.

2. Run engine atabout 2,000rpm

for about 2minutes under

no-load.

3. Maintaining engineat2,000

rpm under no-load (engine is

warmed upsufficiently.),

check thatthemonitor fluctu-

ates between "LEAN"and

"RICH" morethan5times

during 10seconds.

1

lime

RICH

->

LEAN

->

RICH

->

2

limes

RICH

->

LEAN

->

RICH

->

LEAN

->

RICH ......

OR

00

1.

Set' 'Oxygen sensor

monitor"*1 or"Heated oxygen

sensor monitor"*2 inthe Diag-

nostic testmode II.

(Refer toEC section.)

2. Run engine atabout 2,000rpm

for about 2minutes under

no-load.

3. Maintaining engineat2,000

rpm under no-load, checkto

make surethatmalfunction

indicator lamponthe instru-

ment panel goesONand OFF

more than5times during 10

seconds.

OK NG

Checkandadjustment

should bemade byrefer-

ring toIDLE SPEEDI

I

IGNITION

TIMINGIIDLE

INSPECTION END

MIXTURERATIOINSPEC-

TION

(BASIC SERVICE

PROCEDURE)

inEC sec-

tion.

I

MEC711B

2000rpm

RICH

RECORD

Malfunction indicator

lamp \

I/

'e/'

-

CHECK-

/

"

/ I\

CMPS'RPM

(REF)

MIR FIC

MNT

*

MONITOR

*1:Except forAustralia

(A/T),

Israel andEurope

*2: For Australia

(A/T),

Israel andEurope

MA-27

Page 1514 of 1701

ENGINEMAINTENANCE

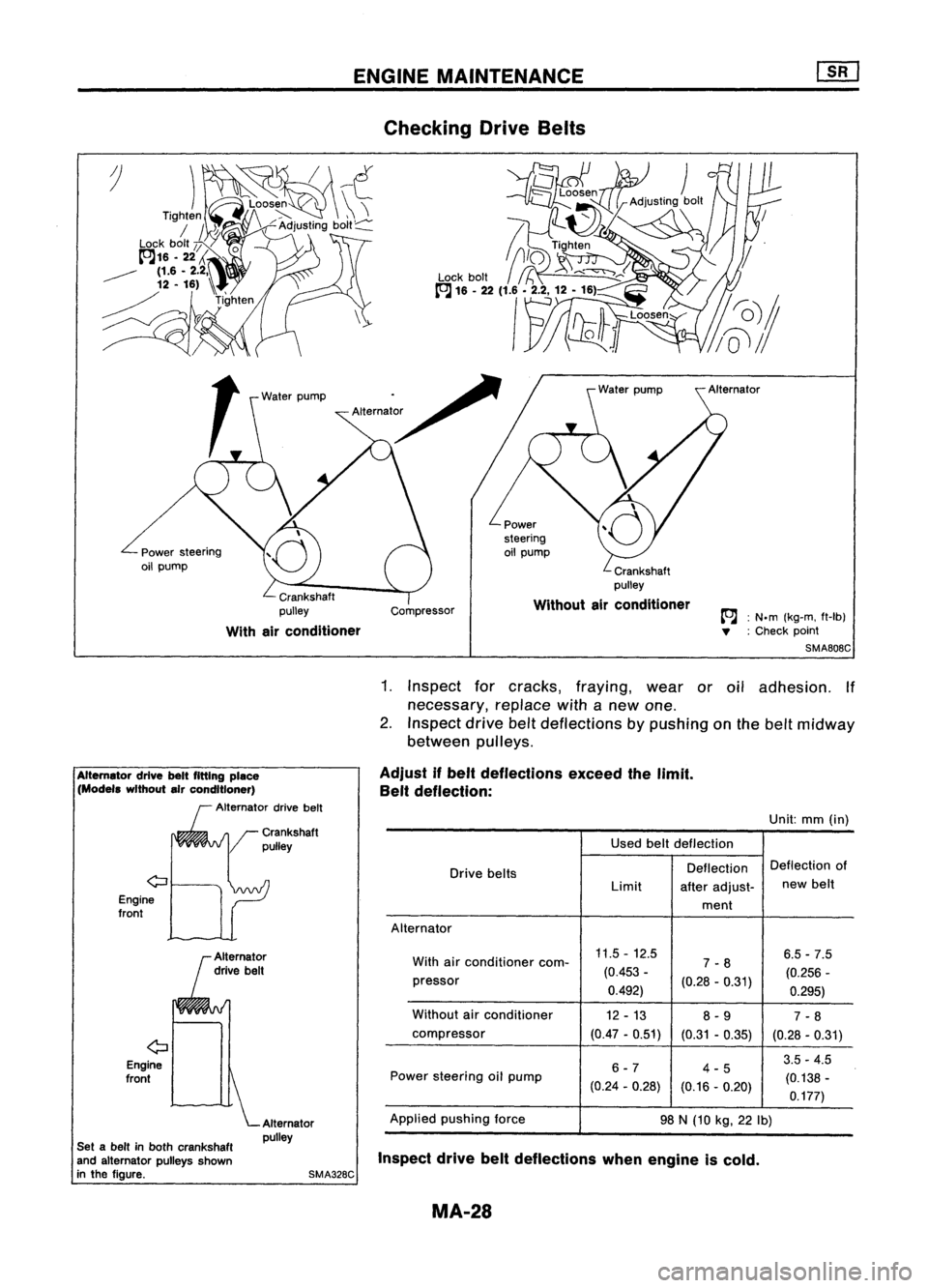

Checking DriveBelts

Crankshaft

pulley

With airconditioner Compressor Crankshaft

pulley

Without airconditioner

A:

N.m (kg-m, ft-Ib)

" :Check point

SMA808C

Used beltdeflection

Drive belts Deflection

Deflection

of

Limit afteradjust- new

belt

ment

Alternator

With airconditioner com-11.5

-12.5

6.5-7.5

7 -8

pressor (0.453

-

(0.28-0.31) (0.256

-

0.492) 0.295)

Without airconditioner

12-13

8-9

7-8

compressor (0.47-0.51)

(0.31-0.35)

(0.28-0.31)

6-7 4-53.5

-4.5

Power steering oilpump

(0.24-0.28)

(0.16-0.20) (0.138

-

0.177)

Applied pushing force

98N(10 kg,22Ib)

Unit:

mm(in)

1.

Inspect forcracks, fraying, wearoroil adhesion. If

necessary, replacewithanew one.

2. Inspect drivebeltdeflections bypushing onthe belt midway

between pulleys.

Adjust ifbelt deflections exceedthelimit.

Belt deflection:

Inspect drivebeltdeflections whenengine iscold.

SMA328C

Alternator

pulley

r

Crankshaft

/ pulley

Alternator

drive belt

<;:J

Engine

front

o

Engine

front

Altemetor

drivebeltfitting piece

(Modell withoutelrconditioner)

Alternator drivebelt

Set abelt inboth crankshaft

and alternator pulleysshown

in the figure.

MA-28

Page 1515 of 1701

FrontFront

CiIt

LOOSEN

'--

Radiator ENGINE

MAINTENANCE

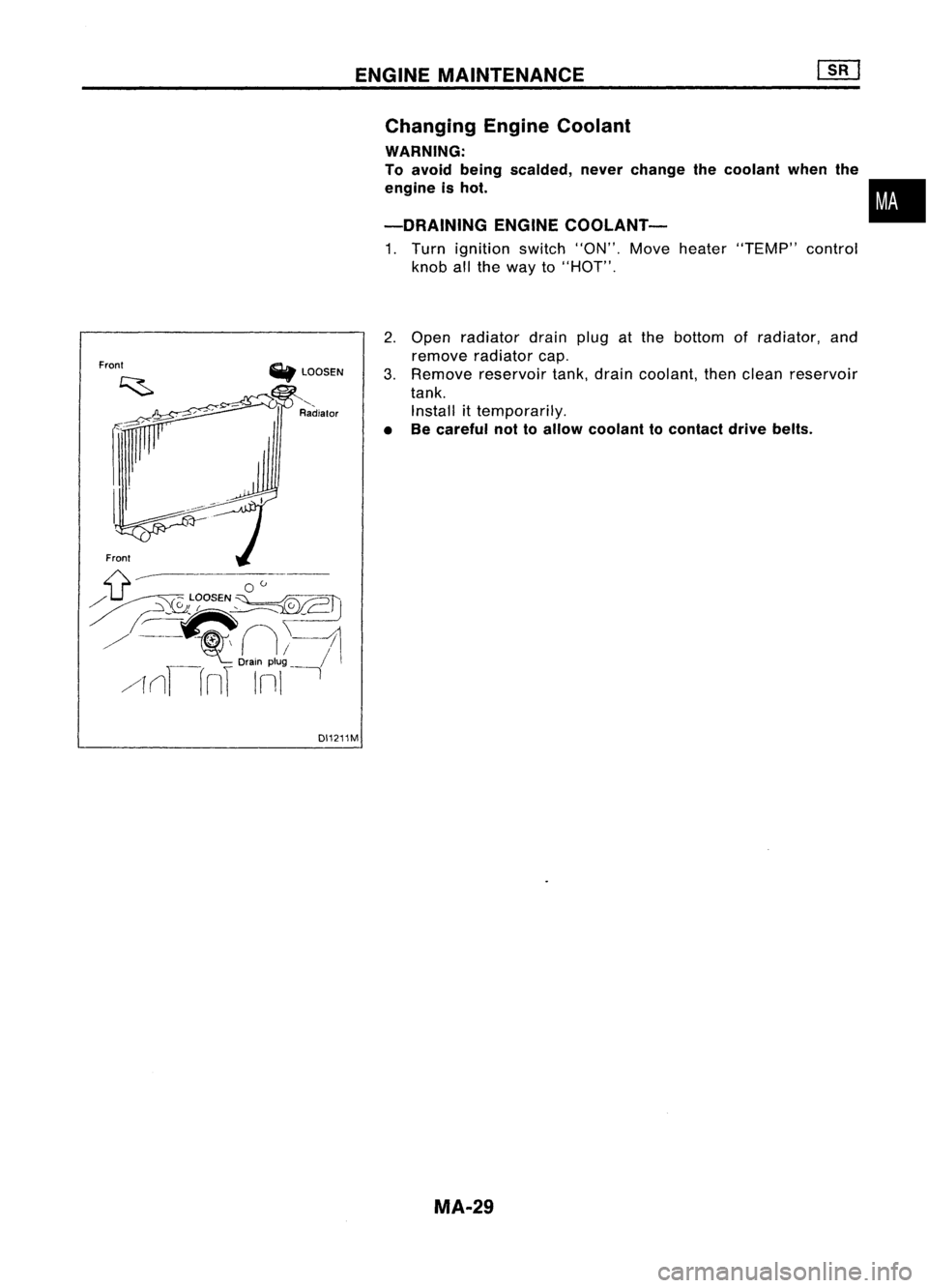

Changing EngineCoolant

WARNING:

To avoid being scalded, neverchange thecoolant whenthe

engine ishot.

-DRAINING ENGINECOOLANT-

1. Turn ignition switch"ON".Moveheater "TEMP" control

knob allthe way to"HOT".

2. Open radiator drainplugatthe bottom ofradiator, and

remove radiator cap.

3. Remove reservoir tank,drain coolant, thenclean reservoir

tank. Install ittemporarily.

• Becareful nottoallow coolant tocontact drivebelts.

•

DI1211M MA-29

Page 1516 of 1701

Withheater

Withoutheater

M/T

6.1(5-3/8)

5.8(5-1/8)

AfT 6.6(5-7/8)

6.3(5-1/2)

Unit:

r

(Imp qt)

-FLUSHING

COOLINGSYSTEM-

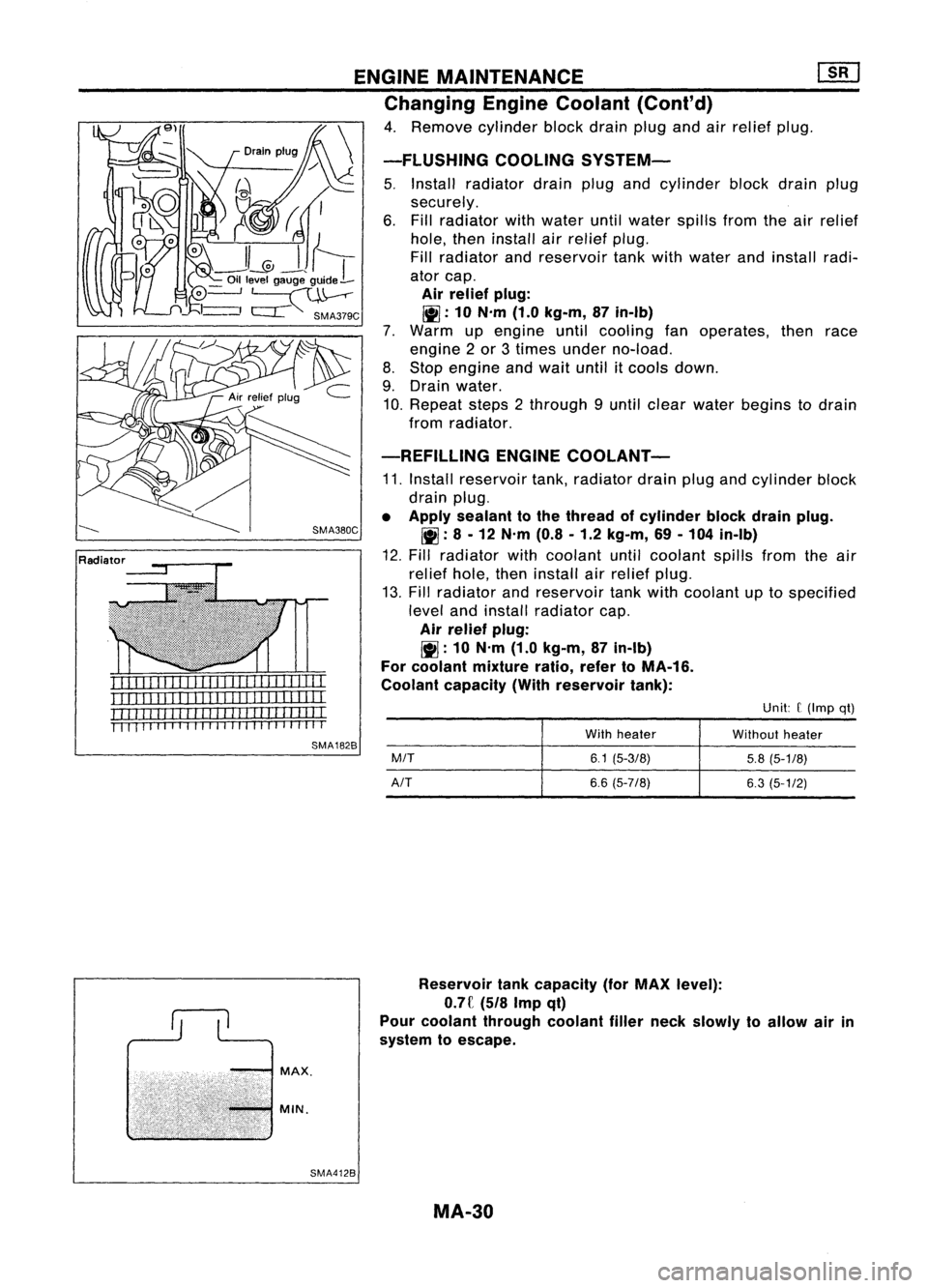

5. Install radiator drainplugandcylinder blockdrainplug

securely.

6. Fill radiator withwater untilwater spillsfromtheairrelief

hole, theninstall airrelief plug.

Fill radiator andreservoir tankwithwater andinstall radi-

ator cap.

Air relief plug:

!II:

10N.m (1.0kg-m, 87in-lb)

7. Warm upengine untilcooling fanoperates, thenrace

engine 2or 3times under no-load.

8. Stop engine andwait until itcools down.

9. Drain water.

10. Repeat steps2through 9until clear water begins todrain

from radiator.

-REFILLING ENGINECOOLANT-

11. Install reservoir tank,radiator drainplugandcylinder block

drain plug.

• Apply sealant tothe thread ofcylinder blockdrainplug.

!II :

8 -12 N.m (0.8-1.2 kg-m, 69-104 in-lb)

12. Fill radiator withcoolant untilcoolant spillsfromtheair

relief hole,theninstall airrelief plug.

13. Fill radiator andreservoir tankwithcoolant uptospecified

level andinstall radiator cap.

Air relief plug:

~ :10 N'm (1.0kg-m, 87in-lb)

For coolant mixture ratio,refertoMA-16.

Coolant capacity (Withreservoir tank):

ENGINE

MAINTENANCE ~

Changing EngineCoolant (Cont'd)

4. Remove cylinderblockdrainplugandairrelief plug.

SMA380C

MAX.

MIN.

Reservoir

tankcapacity (forMAX level):

o.n

(5/8Impqt)

Pour coolant through coolantfillerneck slowly toallow airin

system toescape.

SMA4128 MA-30

Page 1517 of 1701

![NISSAN ALMERA N15 1995 Service Manual SLC0538

Water

inlet

Water

outlet ENGINE

MAINTENANCE [][]

Changing EngineCoolant (Cont'd)

14. Warm upengine tonormal operating temperature.

15. Run engine at2,500 rpmfor10seconds andreturn toidle

NISSAN ALMERA N15 1995 Service Manual SLC0538

Water

inlet

Water

outlet ENGINE

MAINTENANCE [][]

Changing EngineCoolant (Cont'd)

14. Warm upengine tonormal operating temperature.

15. Run engine at2,500 rpmfor10seconds andreturn toidle](/img/5/57349/w960_57349-1516.png)

SLC0538

Water

inlet

Water

outlet ENGINE

MAINTENANCE [][]

Changing EngineCoolant (Cont'd)

14. Warm upengine tonormal operating temperature.

15. Run engine at2,500 rpmfor10seconds andreturn toidle

speed .

• Repeat 2or 3times. •

Wat~h coolant temperature gaugesoasnot tooverheat the

i

engme.

16. Stop engine andcool itdown.

• Cool down usingafan toreduce thetime.

17. Refill reservoir tanktoMax linewith coolant.

18. Repeat step15through step17two ormore times.

19. Warm upengine, andcheck forsound ofcoolant flowwhile

running enginefromidleupto4,000 rpmwith heater tem-

perature controlsetatseveral positions betweenCOOLand

HOT.

• Sound maybenoticeable atheater watercock.

20.

If

sound isheard, bleedairfrom cooling systembyrepeat-

ing steps 14through 17until coolant levelnolonger drops.

• Clean excess coolant fromengine.

CAUTION:

When heater unitisremoved orreplaced, refillengine coolant

as shown, removing heaterhoseatfeeding connector on

engine.

Checking CoolingSystem

CHECKING HOSES

Check hosesforimproper attachment andforleaks, cracks,

damage, looseconnections, chafinganddeterioration.

CHECKING RADIATORCAP

Apply pressure toradiator capwith captester tosee ifit is sat-

isfactory.

Radiator caprelief pressure:

Standard 78 -98 kPa

(0.78 -0.98 bar,0.8-1.0 kg/cm

2,

11-14 psi)

limit

59-98 kPa

(0.59 -0.98 bar,0.6-1.0 kg/cm

2,

9-14 psi)

MA-31