engine NISSAN ALMERA N15 1995 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 1528 of 1701

ENGINEMAINTENANCE

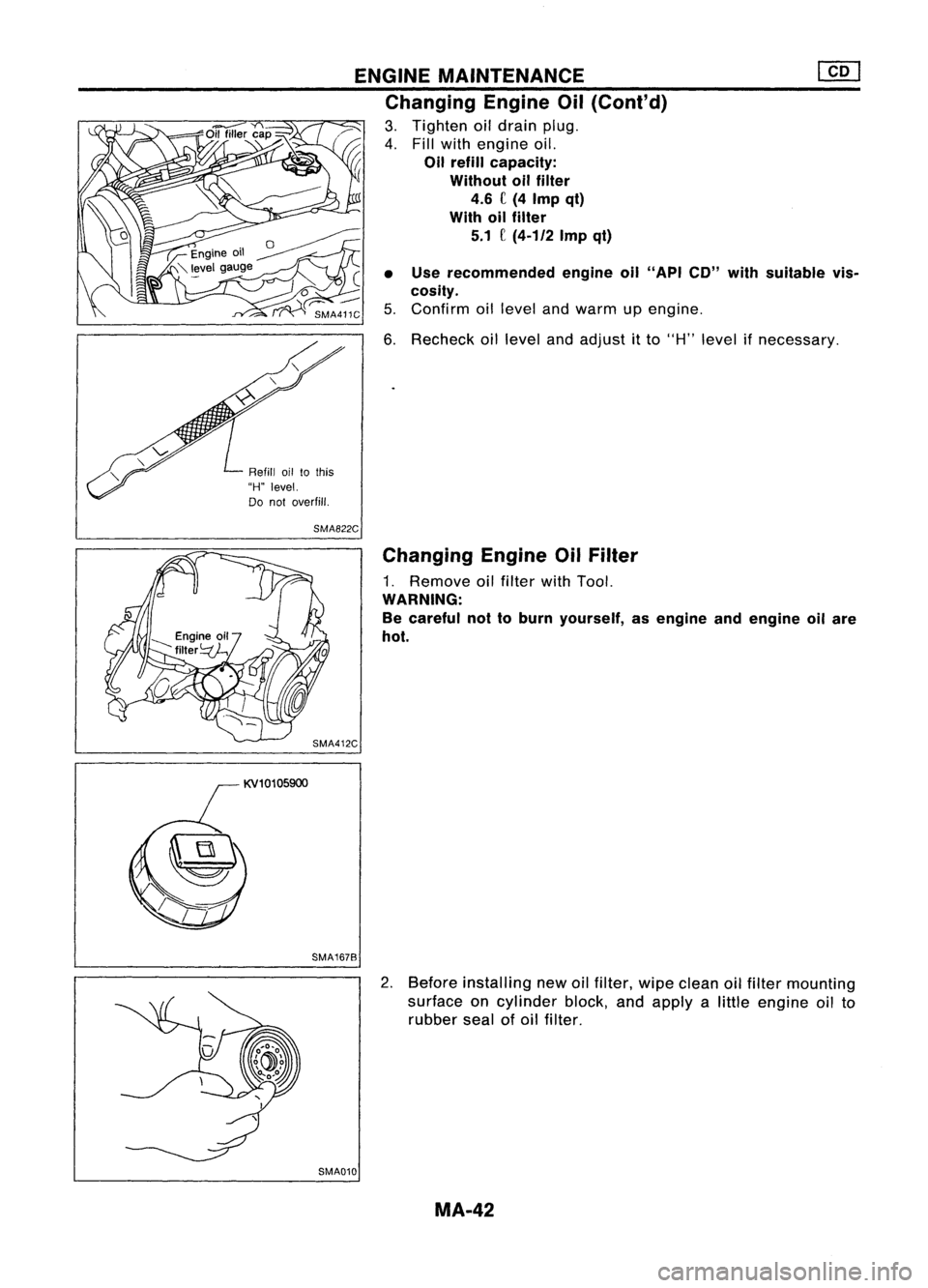

Changing EngineOil(Cont'd)

3. Tighten oildrain plug.

4. Fillwith engine oil.

Oil refill capacity:

Without oilfilter

4.6 C(4 Imp qt)

With oilfilter

5.1 C

(4-1/2

Impqt)

• Use recommended engineoil"API CD"with suitable vis-

cosity.

5. Confirm oillevel andwarm upengine.

6. Recheck oillevel andadjust itto "H" level ifnecessary.

Refill oiltothis

"H" level.

Do not overfill.

SMA822C

Changing EngineOilFilter

1. Remove oilfilter withTool.

WARNING:

Be careful nottoburn yourself, asengine andengine oilare

hot.

SMA412C

SMA167B

2.Before installing newoilfilter, wipeclean oilfilter mounting

surface oncylinder block,andapply alittle engine oilto

rubber sealofoil filter.

SMA010 MA-42

Page 1529 of 1701

![NISSAN ALMERA N15 1995 Service Manual

2/3

ofaturn

ENGINE

MAINTENANCE @Q]

Changing EngineOilFilter (Cont'd)

3. Screw oilfilter onuntil aslight resistance isfelt, then tighten

an additional 2/3turn.

4. Warm upengine andcheck oillevel NISSAN ALMERA N15 1995 Service Manual

2/3

ofaturn

ENGINE

MAINTENANCE @Q]

Changing EngineOilFilter (Cont'd)

3. Screw oilfilter onuntil aslight resistance isfelt, then tighten

an additional 2/3turn.

4. Warm upengine andcheck oillevel](/img/5/57349/w960_57349-1528.png)

2/3

ofaturn

ENGINE

MAINTENANCE @Q]

Changing EngineOilFilter (Cont'd)

3. Screw oilfilter onuntil aslight resistance isfelt, then tighten

an additional 2/3turn.

4. Warm upengine andcheck oillevel.

5. Adjust oillevel ifnecessary. •

Refer toStep 4in "Changing EngineOil",MA-42.

i

• Clean excess oilfrom engine.

SMA229B Checking InjectionNozzle

1. Remove injection deliverytubesandfuel spill tube.

2. Remove nozzlewithasuitable tool[span 27mm (1.06 in)].

WARNING:

When usingnozzle tester,becareful nottoallow diesel fuel

sprayed fromnozzle tocome intocontact withyour hand or

body, andmake surethatyour eyes areproperly protected.

3. Clean andcheck nozzles.

4. Install nozzle toinjection nozzletesterandbleed airfrom

flare nut.

5. Check initialinjection pressure bypumping testerhandle

one time persecond.

EF791A

6.Install injector topressure tester.

7. Check initialinjection pressure bypumping testerhandle

slowly (onetime persecond).

Injection pressure:

12,749 kPa(127.5 bar,130kg/cm

2,

1,849psi)

• Always checkinitialinjection pressure beforeinstalling new

nozzle.

Good

\

I

,

,

I

Wrong SEF672A

8.Check fuelspray pattern bypumping testerhandle quickly

(4 or 6times persecond).

9. Ifinitial injection pressure orinjection nozzleisnot normal,

adjust orclean injection nozzleorreplace it.

Refer toEC section forinjection pressure adjustment.

10. Install allinjection nozzlesandsecurely connectfuelspill

tube anddelivery tubes.

11. Bleed airfrom fuelsystem andcheck forfuel leakage with

engine running.

EF794A

MA.43

Page 1530 of 1701

ENGINEMAINTENANCE

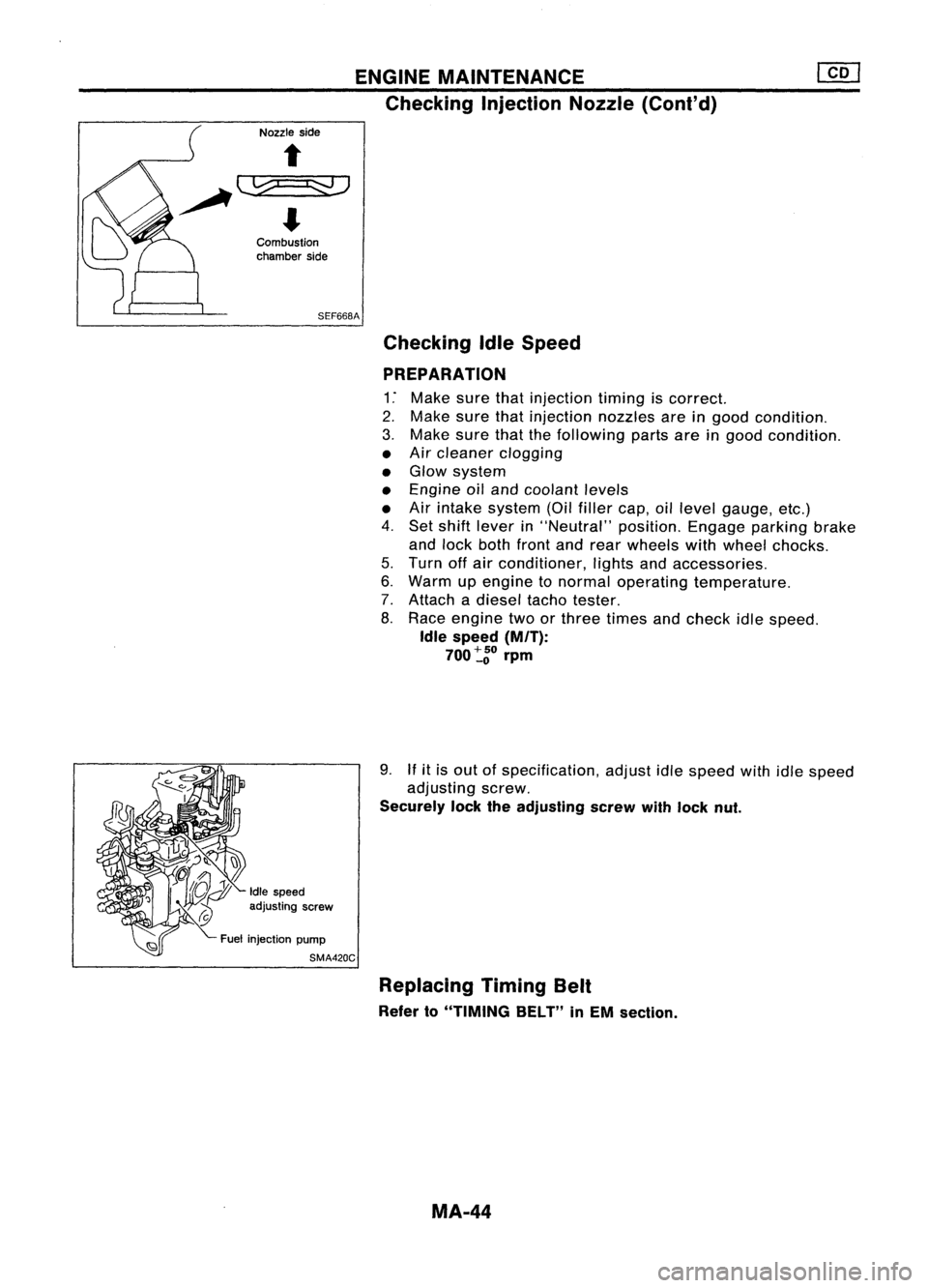

Checking InjectionNozzle(Cont'd)

Nozzle side

Combustion

chamber side

SEF668A Checking IdleSpeed

PREPARATION

1: Make surethatinjection timingiscorrect.

2. Make surethatinjection nozzlesareingood condition.

3. Make surethatthefollowing partsareingood condition.

• Air cleaner clogging

• Glow system

• Engine oiland coolant levels

• Air intake system (Oilfiller cap,oillevel gauge, etc.)

4. Set shift lever in"Neutral" position.Engageparkingbrake

and lock both front andrear wheels withwheel chocks.

5. Turn offair conditioner, lightsandaccessories.

6. Warm upengine tonormal operating temperature.

7. Attach adiesel tachotester.

8. Race engine twoorthree times andcheck idlespeed.

Idle speed (M/T):

700~go rprn

9.

If

itis out ofspecification, adjustidlespeed withidlespeed

adjusting screw.

Securely locktheadjusting screwwithlock nut.

Idle speed

adjusting screw

Fuel injection pump

SMA420C

Replacing TimingBelt

Refer to"TIMING BELT"inEM section.

MA-44

Page 1531 of 1701

CHASSISANDBODY MAINTENANCE

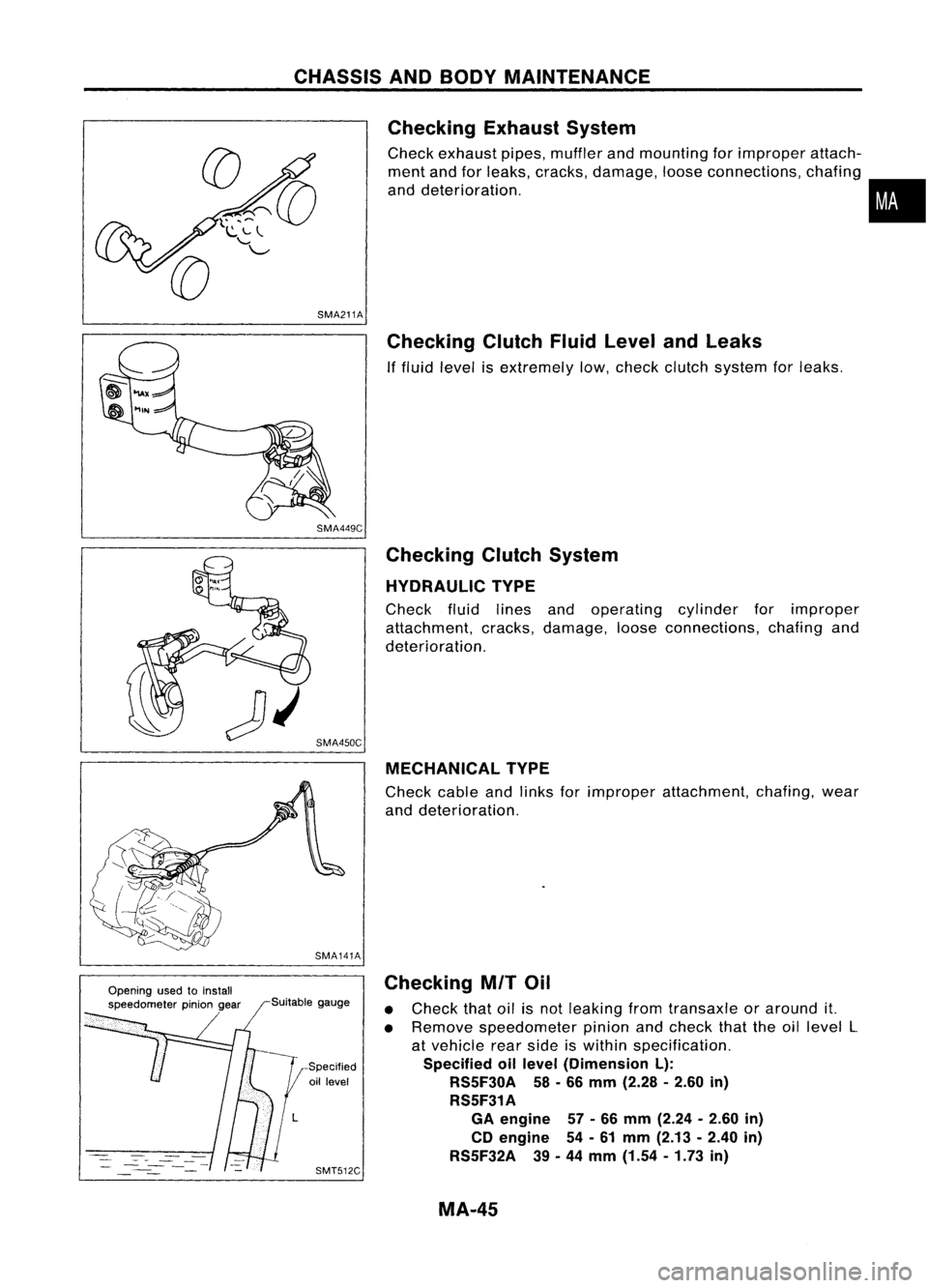

Checking ExhaustSystem

Check exhaust pipes,muffler andmounting forimproper attach-

ment andforleaks, cracks, damage, looseconnections, chafing

and deterioration. •

SMA211A Checking ClutchFluidLevel andLeaks

If fluid level isextremely low,check clutch system forleaks.

SMA449C Checking ClutchSystem

HYDRAULIC TYPE

Check fluidlines andoperating cylinderforimproper

attachment, cracks,damage, looseconnections, chafingand

deterioration.

jJ

I

SMA"",

MECHANICAL TYPE

Check cableandlinks forimproper attachment, chafing,wear

and deterioration.

SMA141A Checking MITOil

• Check thatoilisnot leaking fromtransaxle oraround it.

• Remove speedometer pinionandcheck thattheoillevel L

at vehicle rearside iswithin specification.

Specified

Specifiedoillevel (Dimension L):

oil level

RS5F30A58-66 mm (2.28 -2.60 in)

RS5F31A GA engine 57-66 mm (2.24 -2.60 in)

CD engine 54-61 mm (2.13 -2.40 in)

RS5F32A 39-44 mm (1.54 -1.73 in)

SMT512C

MA-45

Page 1532 of 1701

CHASSISANDBODY MAINTENANCE

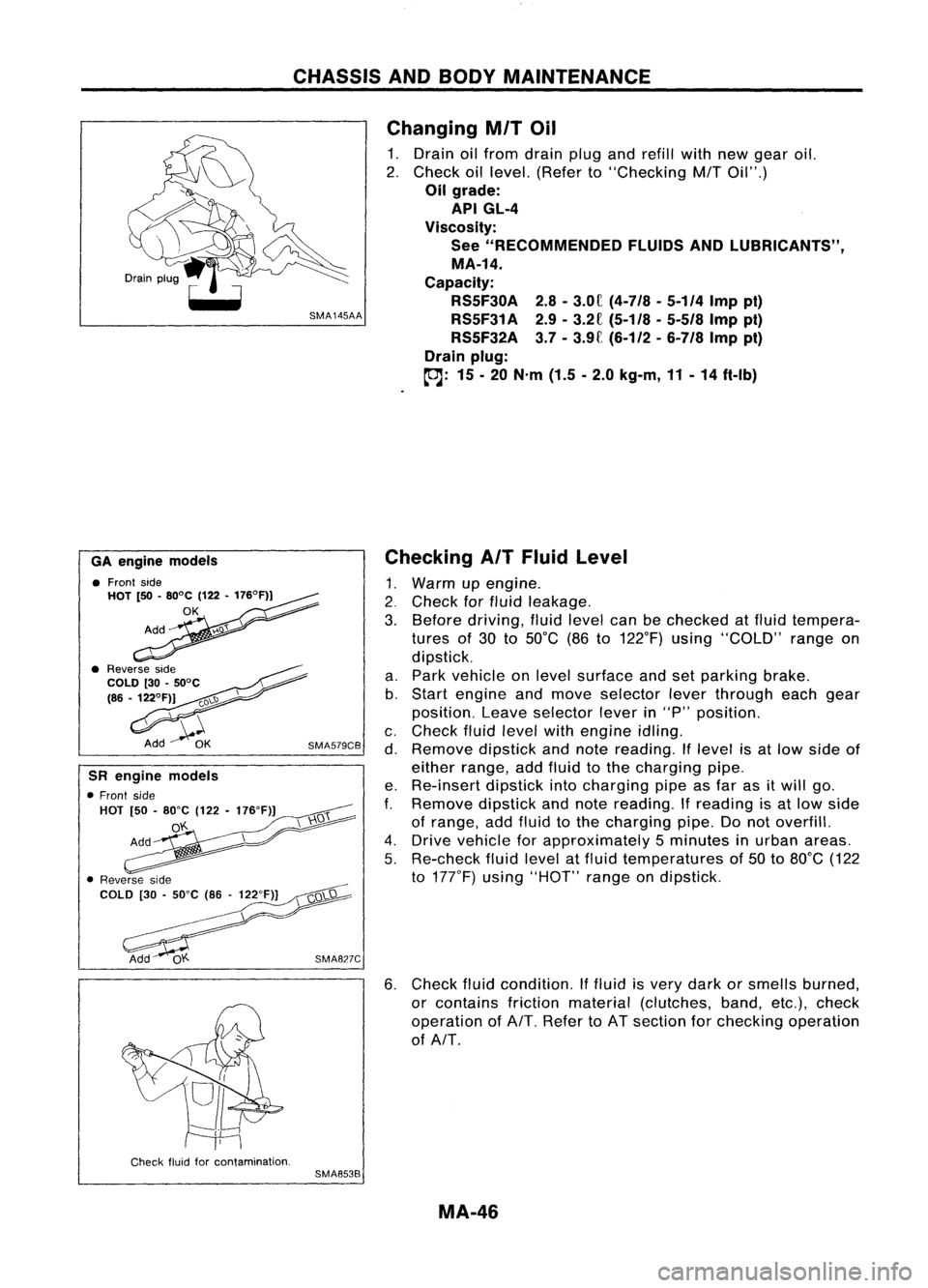

Changing

MIT

Oil

1. Drain oilfrom drain plugandrefill withnewgear oil.

2. Check oillevel. (Refer to"Checking

M/T

Oil".)

Oil grade:

API GL-4

Viscosity: See "RECOMMENDED FLUIDSANDLUBRICANTS",

MA-14.

Capacity: RS5F30A 2.8-3.0f

(4-7/8 -5-114

Imppi)

RS5F31A 2.9-3.2£

(5-1/8 -5-518

Imppt)

RS5F32A 3.7-3.9£ (6-112 -

6-7/8

Imppt)

Drain plug:

(OJ:

15-20 N'm (1.5-2.0 kg-m, 11-14 ft-Ib)

6. Check fluidcondition. Iffluid isvery dark orsmells burned,

or contains frictionmaterial (clutches, band,etc.),check

operation ofAlT. Refer toAT section forchecking operation

of AlT.

Checking

AIT

Fluid Level

1. Warm upengine .

2. Check forfluid leakage.

3. Before driving, fluidlevel canbechecked atfluid tempera-

tures of30 to50°C (86to122°F) using"COLD" rangeon

dipstick.

a. Park vehicle onlevel surface andsetparking brake.

b. Start engine andmove selector leverthrough eachgear

position. Leaveselector leverin"P" position.

c. Check fluidlevel withengine idling.

d. Remove dipstickandnote reading. Iflevel isat low side of

either range, addfluid tothe charging pipe.

e. Re-insert dipstickintocharging pipeasfar asitwill go.

f.

Remove dipstickandnote reading.

If

reading isat low side

of range, addfluid tothe charging pipe.Donot overfill.

4. Drive vehicle forapproximately 5minutes inurban areas.

5. Re-check fluidlevel atfluid temperatures of50 to80°C (122

to 177°F) using"HOT" rangeondipstick.

SMA827C

SMA579CB

GA

engine models

• Front side

HOT [50•80°C (122•176°F))

OK

SR engine models

• Front side

HOT [50•80"C (122-176"F)]

o'f..

Check fluidforcontamination.

SMA853B

MA-46

Page 1533 of 1701

CHASSISANDBODY MAINTENANCE

OK MINMax,

line

Min, line

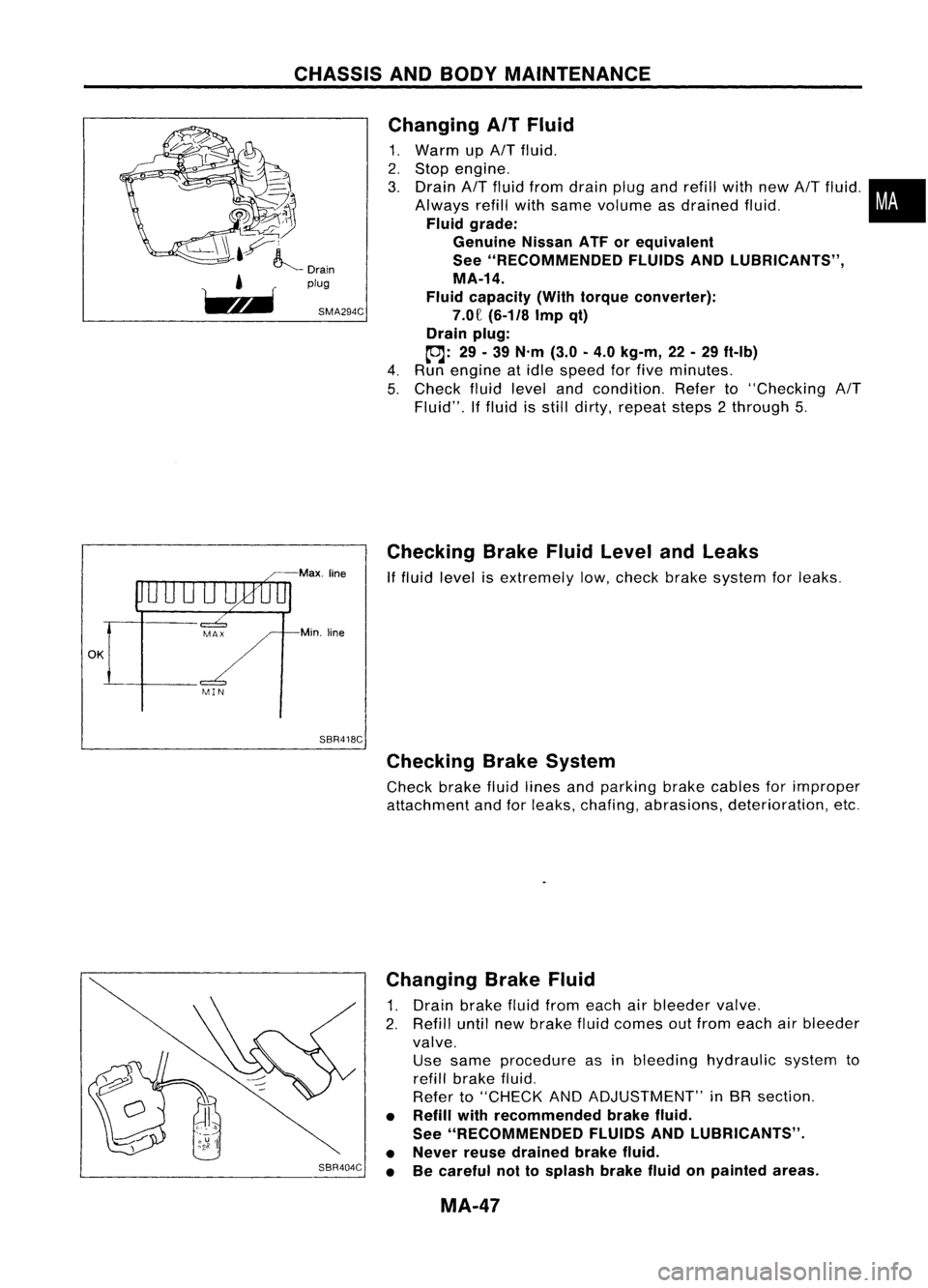

SBR418C Changing

AITFluid

1. Warm up

AIT

fluid.

2. Stop engine.

3. Drain

AIT

fluid from drain plugandrefill withnew

AIT

fluid .•

Always refillwithsame volume asdrained fluid.

i

Fluid grade:

Genuine NissanATForequivalent

See "RECOMMENDED FLUIDSANDlUBRICANTS",

MA-14.

Fluid capacity (Withtorque converter):

7.0£

(6-1/8

Impqt)

Drain plug:

toJ:

29.39

N'm

(3.0-4.0

kg-m,

22-29

ft-Ib)

4. Run engine atidle speed forfive minutes.

5. Check fluidlevel andcondition. Referto"Checking

AIT

Fluid". Iffluid isstill dirty, repeat steps2through 5.

Checking BrakeFluidLevel andLeaks

If

fluid level isextremely low,check brakesystem forleaks.

Checking BrakeSystem

Check brakefluidlines andparking brakecables forimproper

attachment andforleaks, chafing, abrasions, deterioration, etc.

SBR404C Changing

BrakeFluid

1. Drain brake fluidfrom each airbleeder valve.

2. Refill untilnewbrake fluidcomes outfrom each airbleeder

valve. Use same procedure asinbleeding hydraulic systemto

refill brake fluid.

Refer to"CHECK ANDADJUSTMENT" inBR section.

• Refill withrecommended brakefluid.

See "RECOMMENDED FLUIDSANDlUBRICANTS".

• Never reusedrained brakefluid.

• Becareful nottosplash brakefluidonpainted areas.

MA-47

Page 1536 of 1701

0

0

•

0

0

~ /0

H

H

0

0

(2)

4wheels

5 wheels

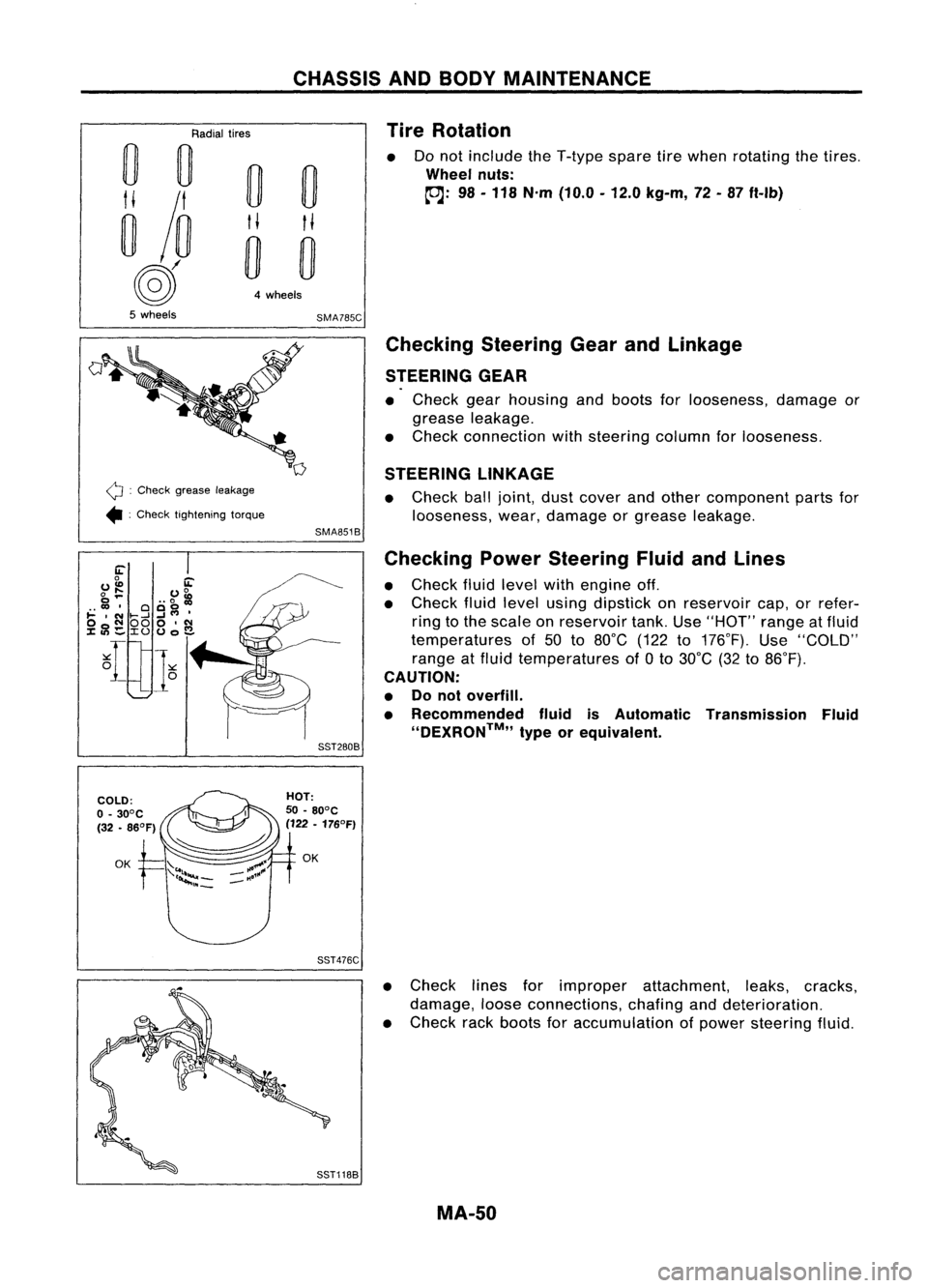

SMA785C

Radial

tires

CHASSIS

ANDBODY MAINTENANCE

Tire Rotation

Do not include theT-type sparetirewhen rotating thetires .

Wheel nuts:

~: 98-118 N'm (10.0 -12.0 kg-m, 72-87 ft-Ib)

Q :

Check grease leakage

• :Check tightening torque

Checking

SteeringGearandLinkage

STEERING GEAR

• Check gearhousing andboots forlooseness, damageor

grease leakage.

• Check connection withsteering columnforlooseness.

STEERING LINKAGE

• Check balljoint, dustcover andother component partsfor

looseness, wear,damage orgrease leakage.

SMA851B

Checking PowerSteering FluidandLines

• Check fluidlevel withengine off.

• Check fluidlevel using dipstick onreservoir cap,orrefer-

ring tothe scale onreservoir tank.Use"HOT" rangeatfluid

temperatures of50 to80°C (122to176°F). Use"COLD"

range atfluid temperatures of

a

to 30°C (32to86°F).

CAUTION:

• Donot overfill.

• Recommended fluidisAutomatic Transmission Fluid

''DEXRON™,, typeorequivalent.

SST280B

SST476C

•Check linesforimproper attachment, leaks,cracks,

damage, looseconnections, chafinganddeterioration.

• Check rackboots foraccumulation ofpower steering fluid.

MA-50

Page 1538 of 1701

CHASSISANDBODY MAINTENANCE

Checking BodyCorrosion

Visually checkthebody sheet metalpanelforcorrosion, paintdamage (scratches, chipping,rubbing,

etc.) ordamage tothe anti-corrosion materials.Inparticular, checkthefollowing locations.

Hemmed portion

Hood frontend,door lower end,trunk lidrear end, etc.

Panel joint

Side sillofrear fender andcenter pillar,rearwheel housing ofrear fender, aroundstruttower inengine

compartment, etc.

Panel edge

Trunk lidopening, sunroofopening, fenderwheelarch flange,fuelfiller lidflange, around holesinpanel,

etc.

Parts contact

Waist molding, windshield molding,bump.er,etc.

Protectors

Damage orcondition ofmudguard, fenderprotector, chippingprotector, etc.

Anti-corrosion materials

Damage orseparation ofanti-corrosion materialsunderthebody.

Drain holes

Condition ofdrain holes atdoor andside sill.

When repairing corrodedareas,refertothe Corrosion RepairManual.

MA-52

Page 1539 of 1701

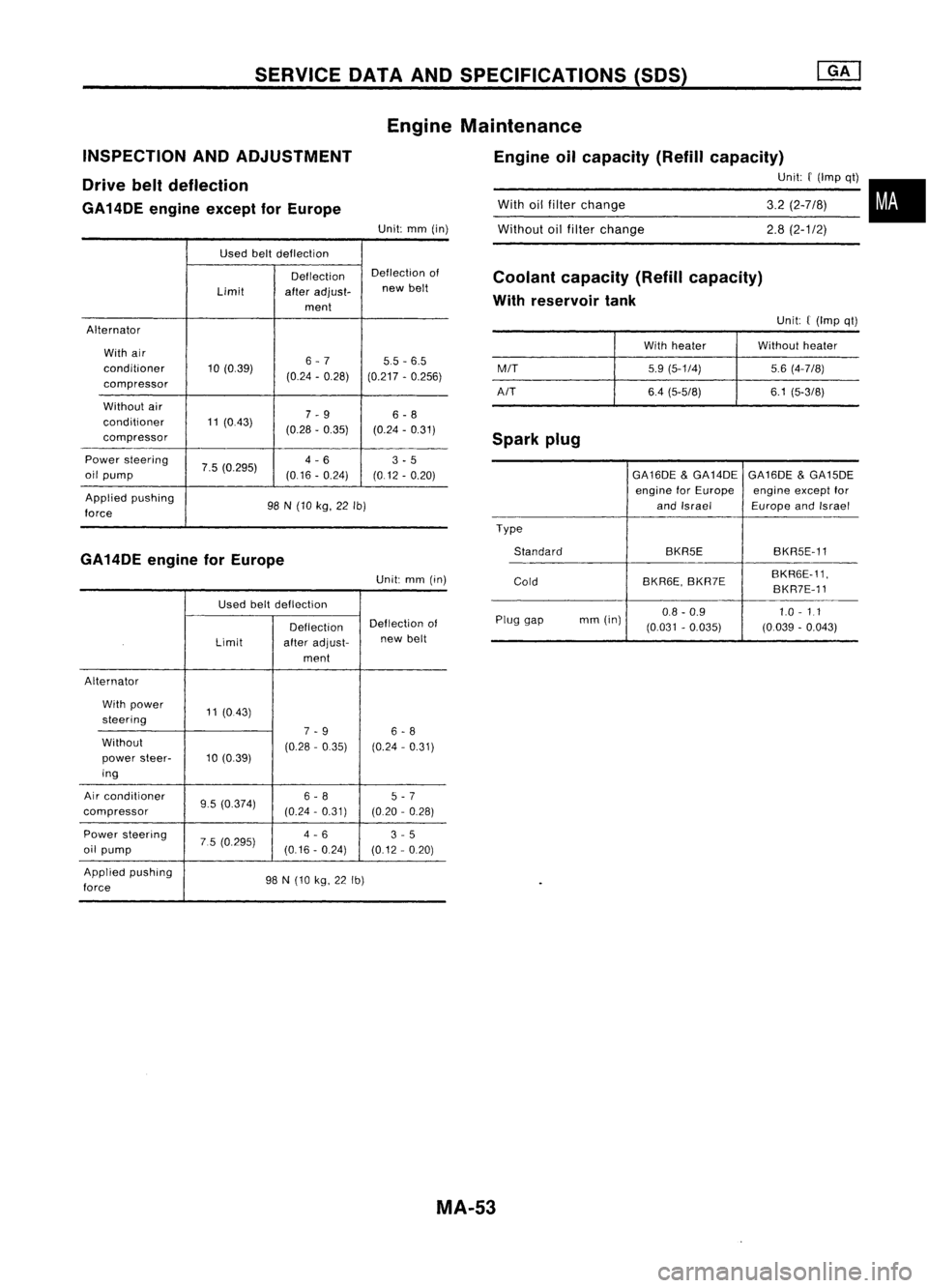

SERVICEDATAANDSPECIFICATIONS (SOS)

Engine Maintenance

Engine oilcapacity (Refillcapacity)

Unit:

r

(Imp qt)

INSPECTION

ANDADJUSTMENT

Drive beltdeflection

GA14DE engineexceptforEurope

Unit:mm(in)

With

oilfilter change

Without oilfilter change

3.2

(2-7/8)

2.8

(2-1/2)

•

Used beltdeflection

Deflection Deflection

of

Limit afteradjust- new

belt

ment

Alternator With air

6-7 55-6.5

conditioner 10(0.39)

(0.24-0.28)

(0.217-0.256)

compressor

Without air

7-9 6-8

conditioner 11(0.43)

(0.28-0.35) (0.24-0.31)

compressor

Power steering

7.5(0.295) 4

-6

3-5

oil pump

(0.16-0.24) (0.12-0.20)

Applied pushing

98N(10 kg, 22Ib)

force

GA14DE engineforEurope

Unit:mm(in)

Used beltdeflection

Deflection Deflection

of

Limit afteradjust- new

belt

ment

Alternator

With power

11(0.43)

steering

7-9

6-8

Without (0.28-0.35) (0.24-0.31)

power steer- 10(0.39)

ing

Air conditioner

9.5(0.374) 6

-8 5

-7

compressor (0.24

-0.31) (0.20-0.28)

Power steering

75(0.295) 4

-6 3-5

oil pump (0.16

-0.24)

(0.12-0.20)

Applied pushing

98N(10 kg,22Ib)

force

Coolant

capacity (Refillcapacity)

With reservoir tank

Unit:((Imp qt)

With heater Without

heater

M/T

5.9(5-1/4) 5.6(4-7/8)

A/T 6.4(5-5/8) 6.1(5-3/8)

Spark plug

GA16DE

&

GA14DE

GA16DE

&

GA15DE

engine forEurope engineexceptfor

and Israel EuropeandIsrael

Type Standard BKR5EBKR5E-11

Cold BKR6E,

BKR7E BKR6E-11,

BKR7E-11

Plug gap mm

(in) 0.8

-0.9 1.0

-

1.1

(0.031 -0.035) (0.039-0.043)

MA-53

Page 1540 of 1701

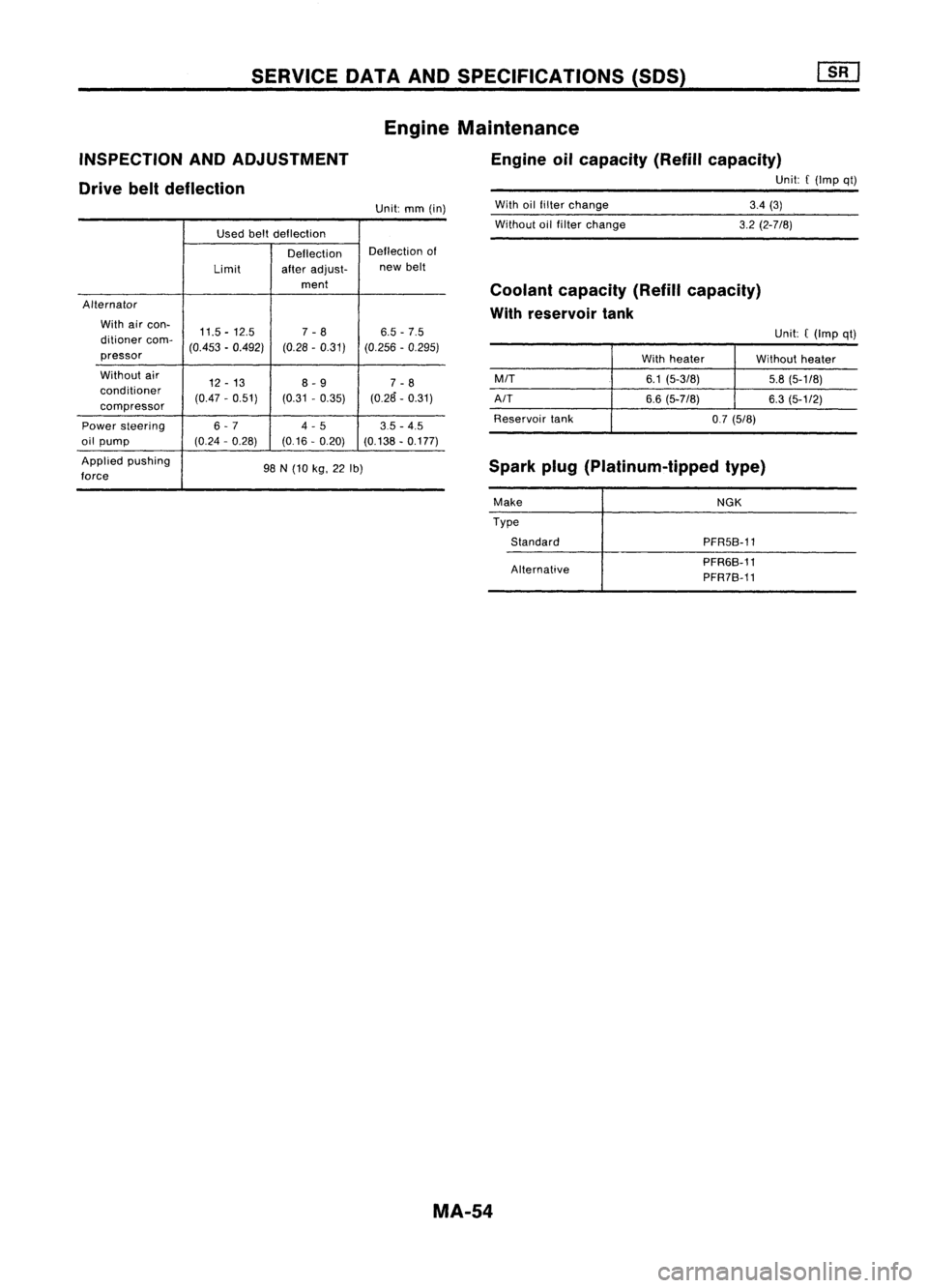

SERVICEDATAANDSPECIFICATIONS (SOS)

INSPECTION ANDADJUSTMENT

Drive beltdeflection Engine

Maintenance

Engine oilcapacity (Refillcapacity)

Unit:

f

(Imp qt)

Unit:

f

(Imp qt)

Spark plug(Platinum-tipped type)

Coolant

capacity (Refillcapacity)

With reservoir tank

Withheater Withoutheater

MIT

6.1(5-3/8)

5.8(5-1/8)

AIT

6.6(5-718) 6.3(5-1/2)

Reservoir tank

07(5/8)

3.4

(3)

3.2 (2-7/8)

With

oilfilter change

Without oilfilter change

Unit:

mm(in)

Used beltdeflection

Deflection Deflection

of

Limit afteradjust- new

belt

ment

Alternator With aircon-

11.5-12.5 7-8 6.5-7.5

ditioner com-

(0.453-0.492) (0.28

-0.31) (0.256-0.295)

pressor

Without air

12-13 8-9 7-8

conditioner

(0.47-0.51) (0.31-0.35) (0.28-0.31)

compressor

Power steering 6-7 4-5 3.5-4.5

oil pump (0.24-0.28) (0.16-0.20) (0.138-0.177)

Applied pushing

98N(10 kg,22Ib)

force

Make

Type

Standard

Alternative NGK

PFR58-11

PFR68-11 PFR78-11

MA-54