engine NISSAN ALMERA N15 1995 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 1497 of 1701

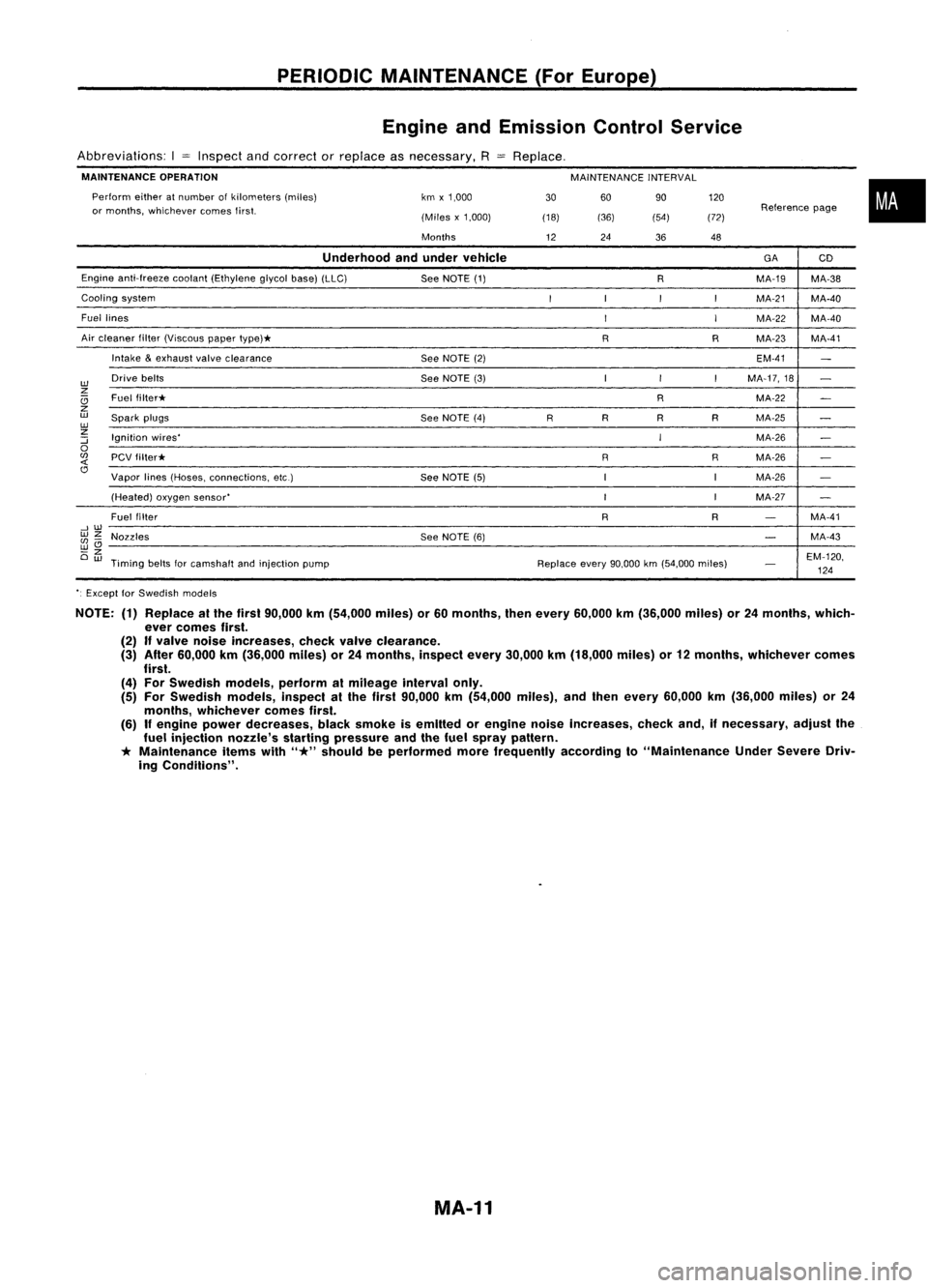

PERIODICMAINTENANCE (ForEurope)

Engine andEmission ControlService

Abbreviations: I

=

Inspect andcorrect orreplace asnecessary,

R

MAINTENANCE OPERATION

MAINTENANCEINTERVAL

60 90

(36) (54)

Perform

eitheratnumber ofkilometers (miles)

or months, whichever comesfirst. km

x1,000

(Miles x1,000)

Months

Replace,

30

(18)

12 24

36120

(72) 48

Reference

page

•

Underhood andunder vehicle

GA

CD

Engine anti-freeze cootant(Ethylene glycolbase)(LLC)

SeeNOTE (1)

RMA-19

MA-38

Cooling system

I

I

I

I

MA-21 MA-40

Fuel lines

I

I

MA-22

MA-40

Air cleaner filter(Viscous papertype)*

RRMA-23 MA-41

Intake

&

exhaust valveclearance

SeeNOTE (2) EM-41

-

w

Drive

belts

SeeNOTE (3) I

I

I

MA-17,18

-

z

Ci

Fuel

filter* RMA-22

-

z

w

Spark plugs

SeeNOTE (4)

RR

RRMA-25

-

w

z

Ignition wires'

IMA-26

:::;

-

0

(fJ

PCVfilter* RRMA-26

-

<{

Cl

Vapor lines(Hoses, connections, etc.)

SeeNOTE (5) IIMA-26

-

(Heated) oxygensensor'

I

IMA-27

-

Fuel filter

RR

-

MA-41

--,w

wz

Nozzles SeeNOTE (6)

-

MA-43

(fJ-

wCl

-z

EM-120,

Ow

Timing beltsforcamshalt andinjection pump Replaceevery90,000 km(54,000 miles)

-

124

'. Except forSwedish models

NOTE: (1)Replace atthe first 90,000 km(54,000 miles)or60 months, thenevery 60,000 km(36,000 miles)or24 months, which-

ever comes first.

(2)

If

valve noise Increases, checkvalveclearance.

(3) After 60,000 km(36,000 miles)or24 months, inspectevery30,000 km(18,000 miles)or12 months, whichever comes

first.

(4) For Swedish models,performalmileage intervalonly.

(5) For Swedish models,inspectalthe first 90,000 km(54,000 miles),andthen every 60,000 km(36,000 miles)or24

months, whichever comesfirst.

(6)

If

engine powerdecreases, blacksmoke isemitted orengine noiseincreases, checkand,ifnecessary, adjustthe

fuel injection nozzle'sstartingpressure andthefuel spray pattern.

*

Maintenance itemswith

"*"

should beperformed morefrequently accordingto"Maintenance UnderSevere Driv-

ing Conditions".

MA-11

Page 1499 of 1701

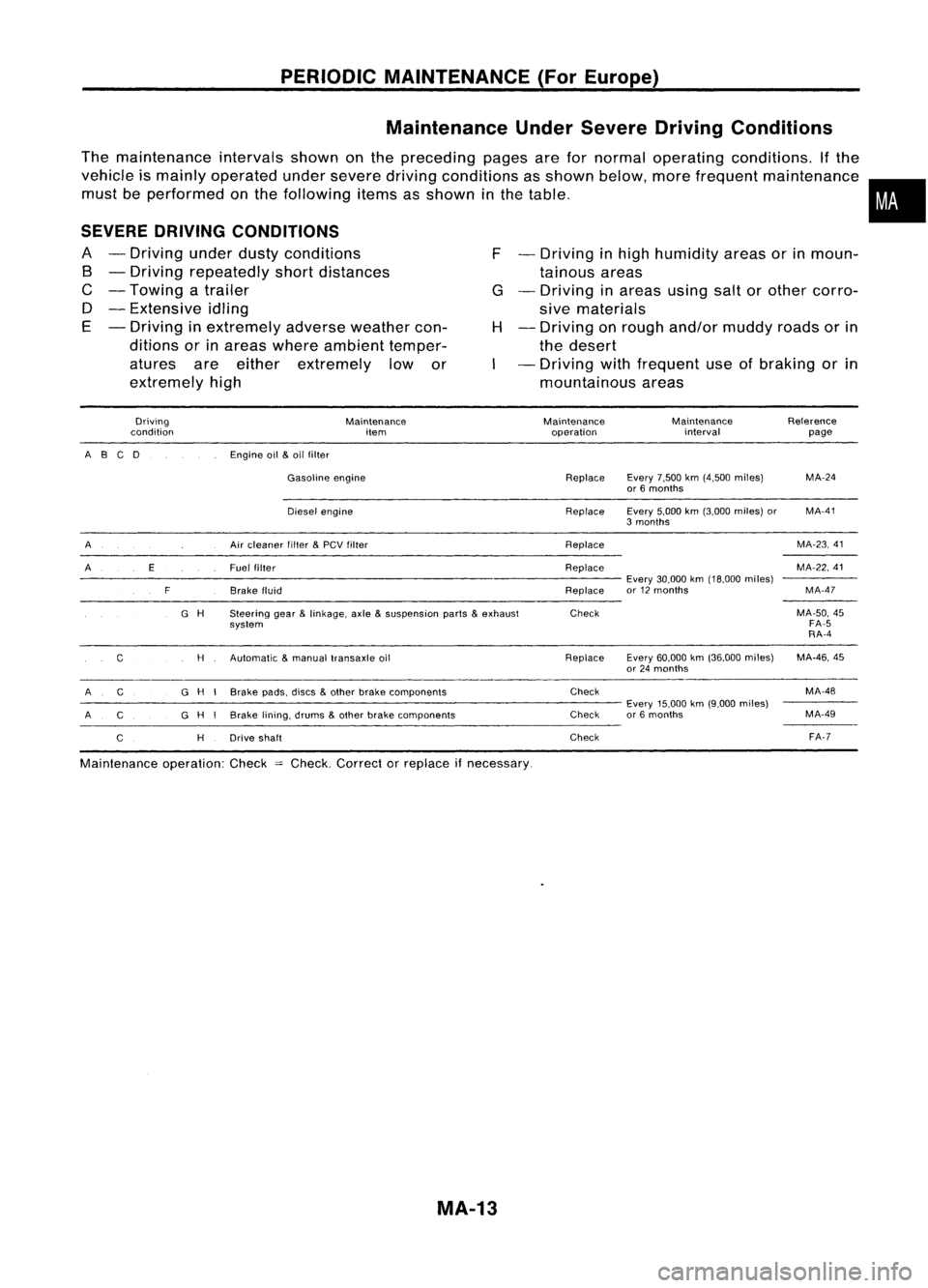

PERIODICMAINTENANCE (ForEurope)

Maintenance UnderSevere Driving Conditions

The maintenance intervalsshownonthe preceding pagesarefornormal operating conditions. Ifthe

vehicle ismainly operated undersevere drivingconditions asshown below,morefrequent maintenance •

must beperformed onthe following itemsasshown inthe table. •

SEVERE DRIVING CONDITIONS

A -Driving underdustyconditions

B -Driving repeatedly shortdistances

C -Towing atrailer

D -Extensive idling

E -Driving inextremely adverseweather con-

ditions orinareas where ambient temper-

atures areeither extremely lowor

extremely high F

-Driving inhigh humidity areasorinmoun-

tainous areas

G -Driving inareas usingsaltorother corro-

sive materials

H -Driving onrough and/or muddy roadsorin

the desert

- Driving withfrequent useofbraking orin

mountainous areas

Driving

MaintenanceMaintenance

MaintenanceReference

condition itemoperationintervalpage

A B

C D Engine

oil

&

oil filter

Gasoline engine ReplaceEvery

7.500km(4,500 miles) MA-24

or 6months

Diesel engine ReplaceEvery5.000km(3,000 miles) or MA-41

3 months

A Aircleaner IiIter

&

PCV filter Replace MA-23,

41

A E Fuel

filter ReplaceMA-22,41

Every 30,000 km(18,000 miles)

F Brakefluid Replaceor

12months MA-47

G H

Steering gear

&

linkage, axle

&

suspension parts

&

exhaust Check MA-50,45

system FA-5

RA-4

C H

Automatic

&

manual transaxle oil Replace

Every60,000 km(36,000 miles) MA-46,45

or 24 months

A C GH

I

Brake pads,discs

&

other brake components Check MA-48

Every 15,000 km(9,000 miles)

A C GH

I

Brake

lining,drums

&

other brake components Check

or6months MA-49

C H

Driveshaft CheckFA-7

Maintenance operation:Check

=

Check. Correct orreplace

if

necessary.

MA-13

Page 1500 of 1701

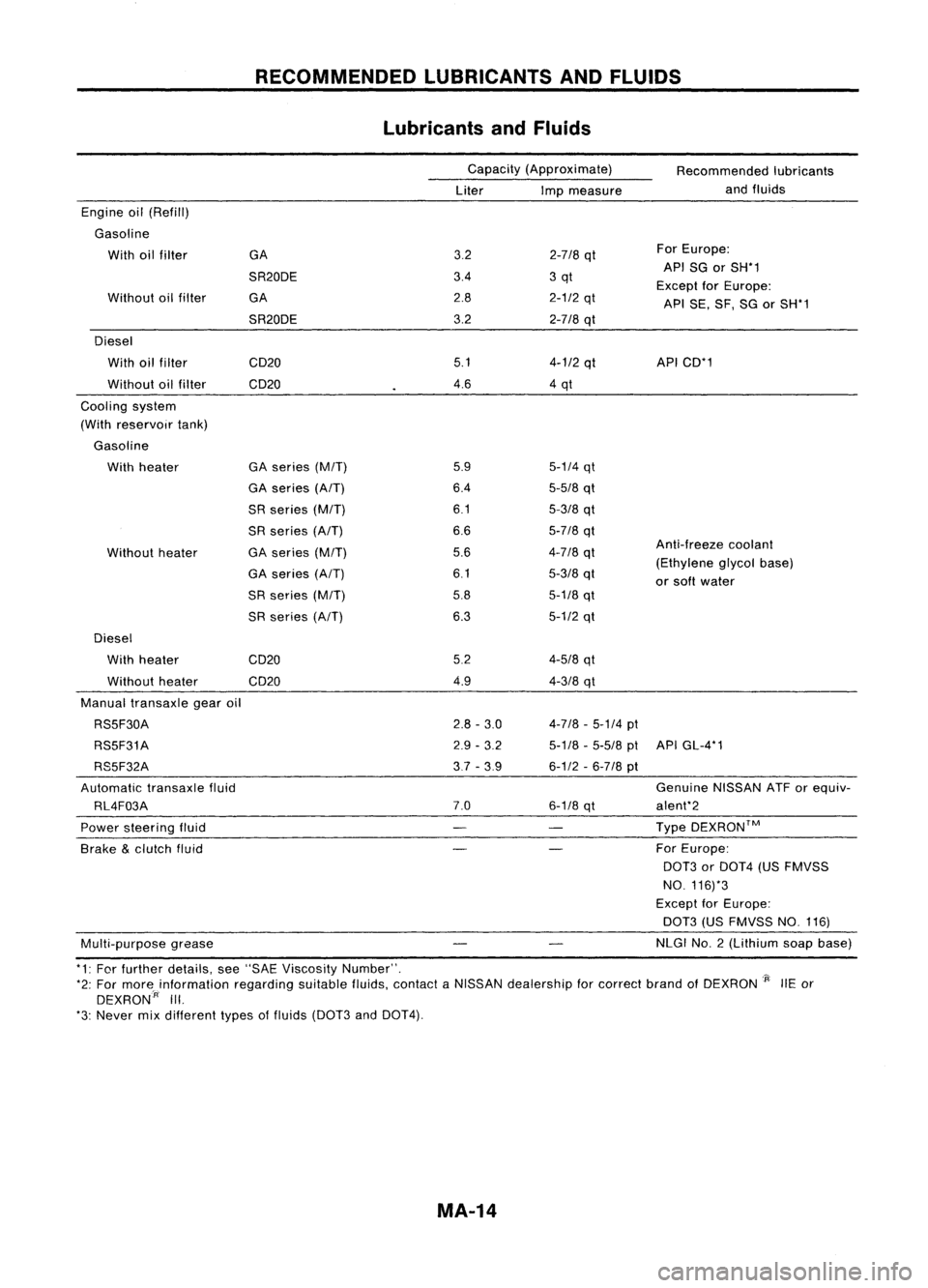

RECOMMENDEDLUBRICANTSANDFLUIDS

Lubricants andFluids

Capacity (Approximate)

Liter Impmeasure Recommended

lubricants

and fluids

Anti-freeze coolant

(Ethylene glycolbase)

or soft water

5-1/4

qt

5-5/8

qt

5-3/8

qt

5-7/8

qt

4-7/8

qt

5-3/8

qt

5-1/8

qt

5-1/2

qt

3.2

2-7/8

qt For

Europe:

3.4 3qt API

SGorSH*1

Except forEurope:

2.8

2-1/2

qt

APISE,SF,SGorSH*1

3.2

2-718

qt

5.1

4-1/2

qt API

CD*1

4.6 4qt

5.9

6.4

6.1

6.6

5.6

6.1

5.8

6.3

GA

SR20DE GA

SR20DE

GA series

(M/T)

GA series

(A/T)

SR series

(M/T)

SR series

(A/T)

GA series

(M/T)

GA series

(A/T)

SR series

(M/T)

SR series (AfT)

Without

heater

Without

oilfilter

Engine

oil(Refill)

Gasoline With oilfilter

Diesel With oilfilter CD20

Without oilfilter CD20

Cooling system

(With reservoir tank)

Gasoline With heater

Diesel With heater

Without heater CD20

CD20 5.2

4.9

4-5/8

qt

4-3/8

qt

Manual transaxle gearoil

RS5F30A

RS5F31A

RS5F32A

Automatic transaxlefluid

RL4F03A

Power steering fluid

Brake

&

clutch fluid

Multi-purpose grease

2.8

-3.0

2.9 -3.2

3,7 -3.9

7.0

4-7/8

-5-1/4

pt

5-1/8 -5-5/8

ptAPIGL-4*1

6-1/2 -6-7/8

pt

Genuine NISSANATForequiv-

6-1/8

qt alent*2

Type DEXRON™

For Europe:

0013

orDOT4 (USFMVSS

NO. 116)*3

Except forEurope:

DOT3 (USFMVSS NO.116)

NLGI NO.2 (Lithium soapbase)

*1: For further details, see"SAE Viscosity Number". _

*2: For morainformation regardingsuitablefluids,contact aNISSAN dealership forcorrect brandofDEXRON

'P:

liE or

DEXRON:

A

III.

*3: Never mixdifferent typesoffluids (DOT3 and

0014).

MA-14

Page 1501 of 1701

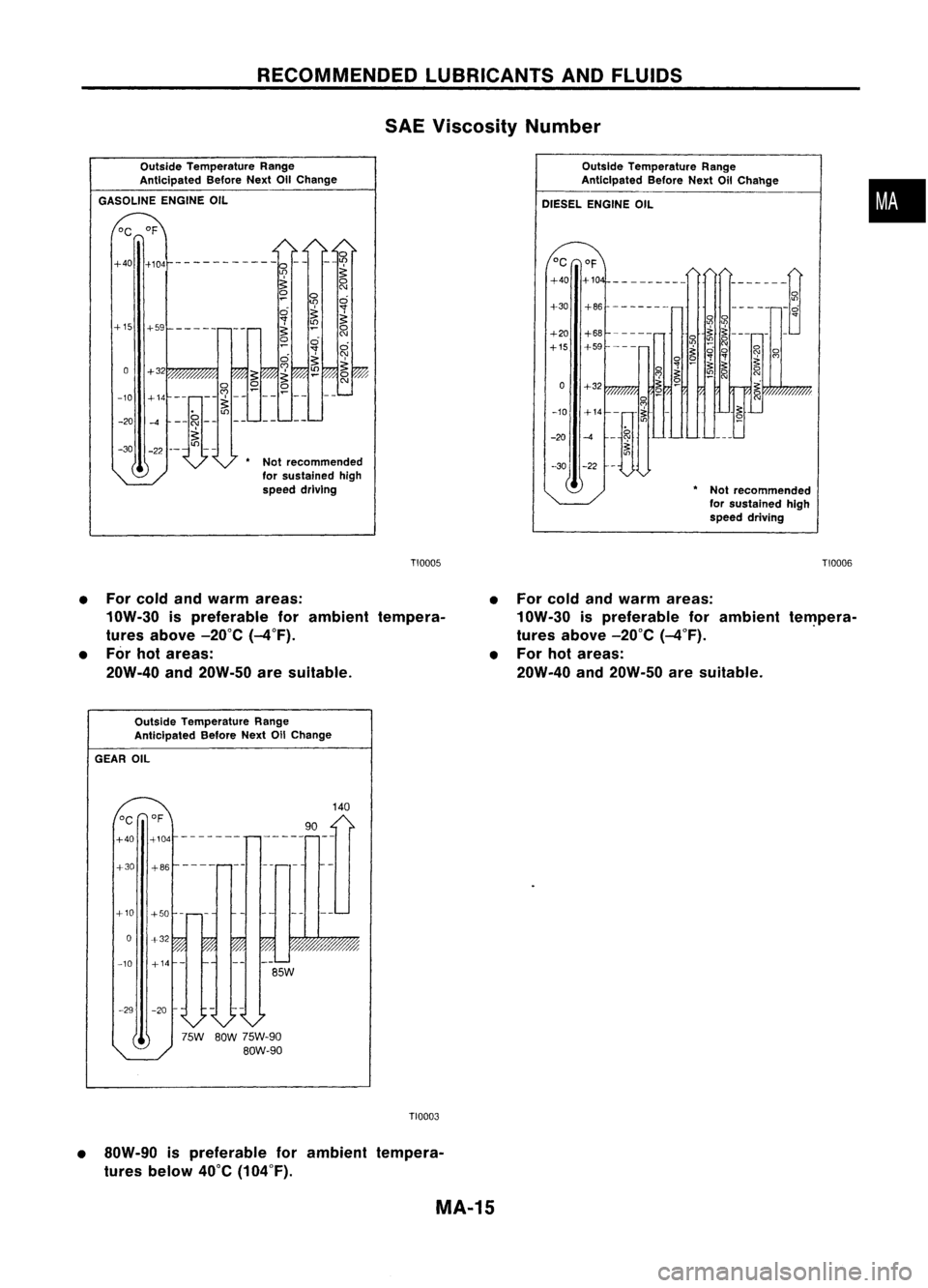

RECOMMENDEDLUBRICANTSANDFLUIDS

Outside Temperature Range

Anticipated BeforeNextOilChange

GASOLINE ENGINEOIL

SAE

Viscosity Number

OutsideTemperature Range

Anticipated BeforeNextOilChahge

DIESEL ENGINE OIL

•

°C of

+40 +10

---------

------~

+30 +86

-------

------0

0

o

...

'"

'"

+20 +68

0

~

~

---

-

-

'!2

0

+15 +59

'"

'"

0

~

0

0

'i'

0

~

'i

't

'"

?: ~

;:

0

~

0

'7 '"

N

-

'"

0 +32

~ ~

0

-10 +14

-t

;:

~

-20

-4

-'i'

~

-30 -22

•Not recommended

for sustained high

speed driving

lI)

~

0 0

~

'"

0

0

~'

'i

~~

~

0

(\J

0

-30

*

Not recommended

for sustained high

speed driving

-20

+32

-10 +14

+15

+59-----

TI0005

TIOOG6

• For cold andwarm areas:

10W-30 ispreferable forambient tempera-

tures above -20°C(-4°F).

• For hotareas:

20W-40 and20W-50 aresuitable. •

For cold andwarm areas:

10W-30 ispreferable forambient te~pera-

tures above -20°C(-4°F).

• For hotareas:

20W.40 and20W-50 aresuitable.

Outside Temperature Range

Anticipated BeforeNext011Change

GEAR OIL

140

°C

of

90

+40 +104

-------

+30 +86

+10 +50

-

0

%

-10

-29 -20

75W BOW75W-90

BOW-90

TI0003

• SOW-90 ispreferable forambient tempera-

tures below 40°C(104°F).

MA-15

Page 1502 of 1701

RECOMMENDEDLUBRICANTSANDFLUIDS

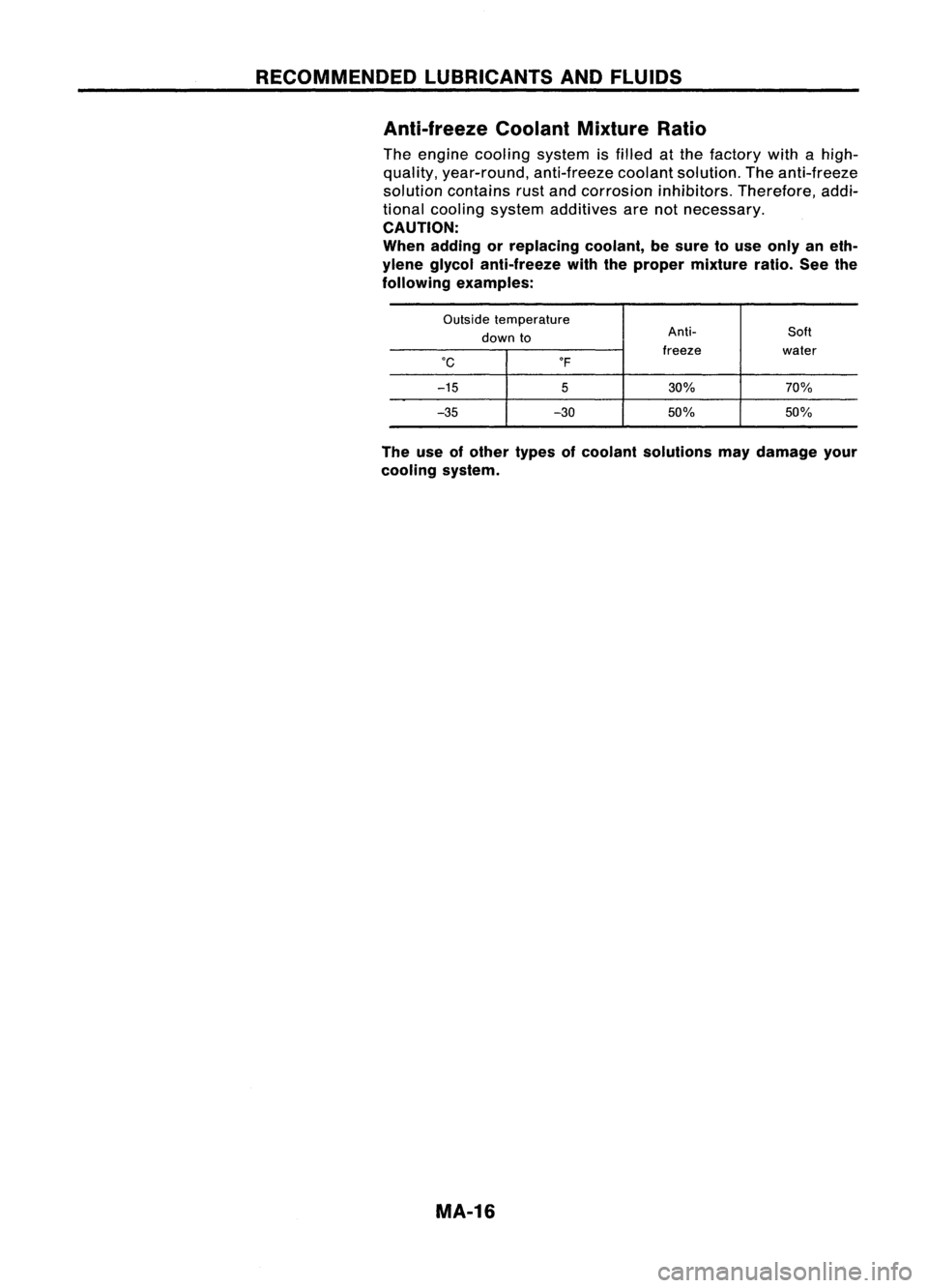

Anti-freeze CoolantMixtureRatio

The engine cooling systemisfilled atthe factory withahigh-

quality, year-round, anti-freezecoolantsolution. Theanti-freeze

solution contains rustandcorrosion inhibitors. Therefore, addi-

tional cooling systemadditives arenotnecessary.

CAUTION:

When adding orreplacing coolant,besure touse only aneth-

ylene glycol anti-freeze withtheproper mixture ratio.Seethe

following examples:

Outside temperature

down to Anti-

Soft

freeze water

'C

'F

-15 530%

70%

-35 -30

50%

50%

The useofother types ofcoolant solutions maydamage your

cooling system.

MA-16

Page 1503 of 1701

ENGINEMAINTENANCE

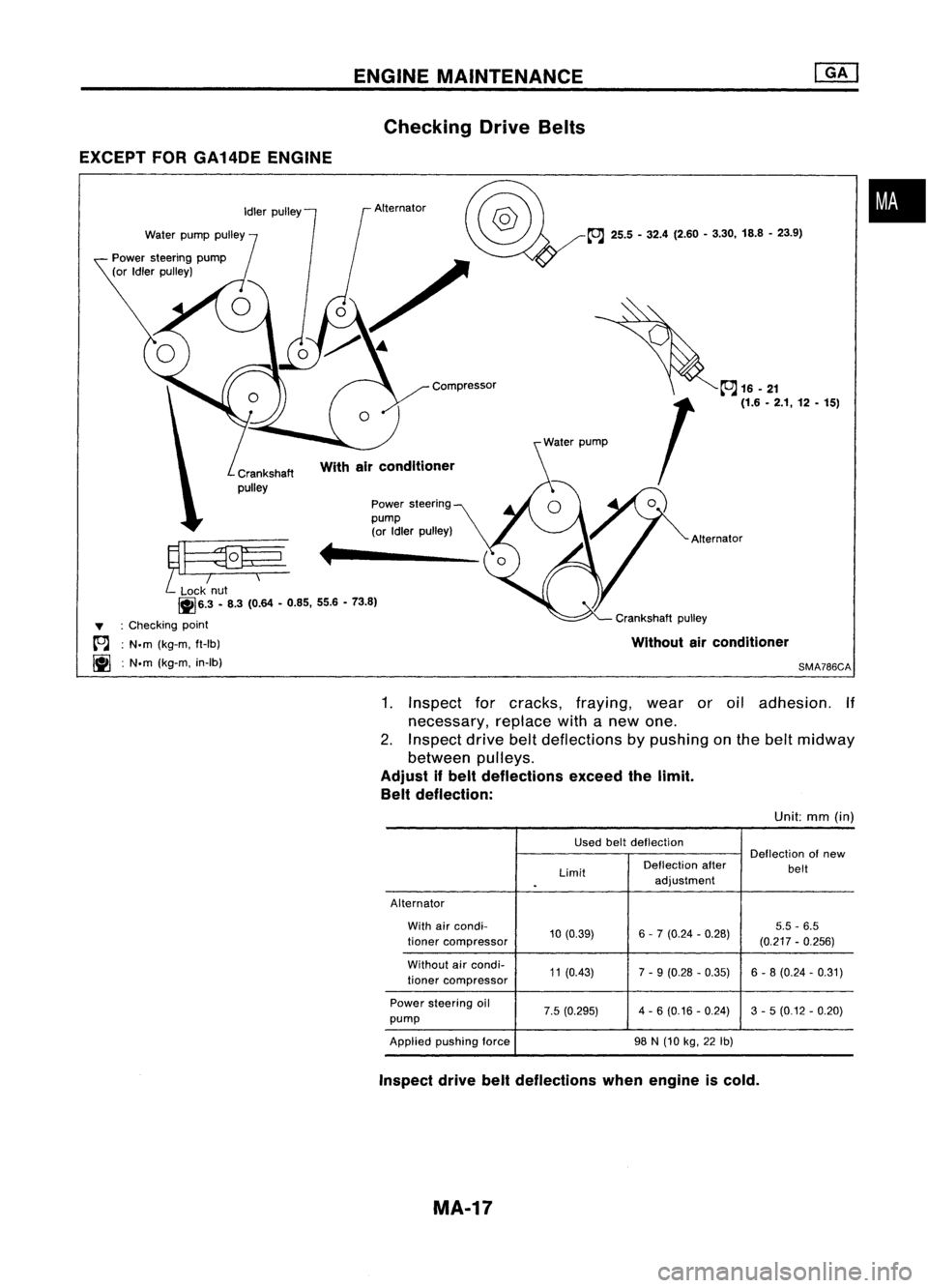

EXCEPT FORGA14DE ENGINE Checking

DriveBelts

•

~ 16-21

(1.6 •2.1, 12•15)

Alternator

SMA786CA

Without

airconditioner

Crankshaft

pUlley

~

25.5 -32.4 (2.60 -3.30, 18.8-23.9)

Compressor

Power steering

pump (or Idler pulley)

With

airconditioner

Idler

pulley

Crankshaft

pulley

Power

steering pump

(or Idler pulley)

~.

~6.3 -8.3 (0.64 -0.85, 55.6-73.8)

~ :Checking point

A :

N.m (kg-m, ft-lb)

III :

N.m (kg-m, in-Ib)

1.Inspect forcracks, fraying, wearoroil adhesion. If

necessary, replacewithanew one.

2. Inspect drivebeltdeflections bypushing onthe belt midway

between pulleys.

Adjust ifbelt deflections exceedthelimit.

Belt deflection:

Unit:mm(in)

Used beltdeflection

Deflectionofnew

Limit Deflection

after

belt

.

adjustment

Alternator With aircondi-

10(0.39) 6-7 (0.24 -0.28) 5.5

-6.5

lioner compressor

(0.217-0.256)

Without aircondi-

11(0.43) 7-9 (0.28 -0.35) 6-8 (0.24 -0.31)

lioner compressor

Power steering oil

7.5(0.295) 4

-6 (0.16 -0.24) 3-5 (0.12 -0.20)

pump

Applied pushing force

98

N

(10

kg,

22

Ib)

Inspect drivebeltdeflections whenengine iscold.

MA-17

Page 1504 of 1701

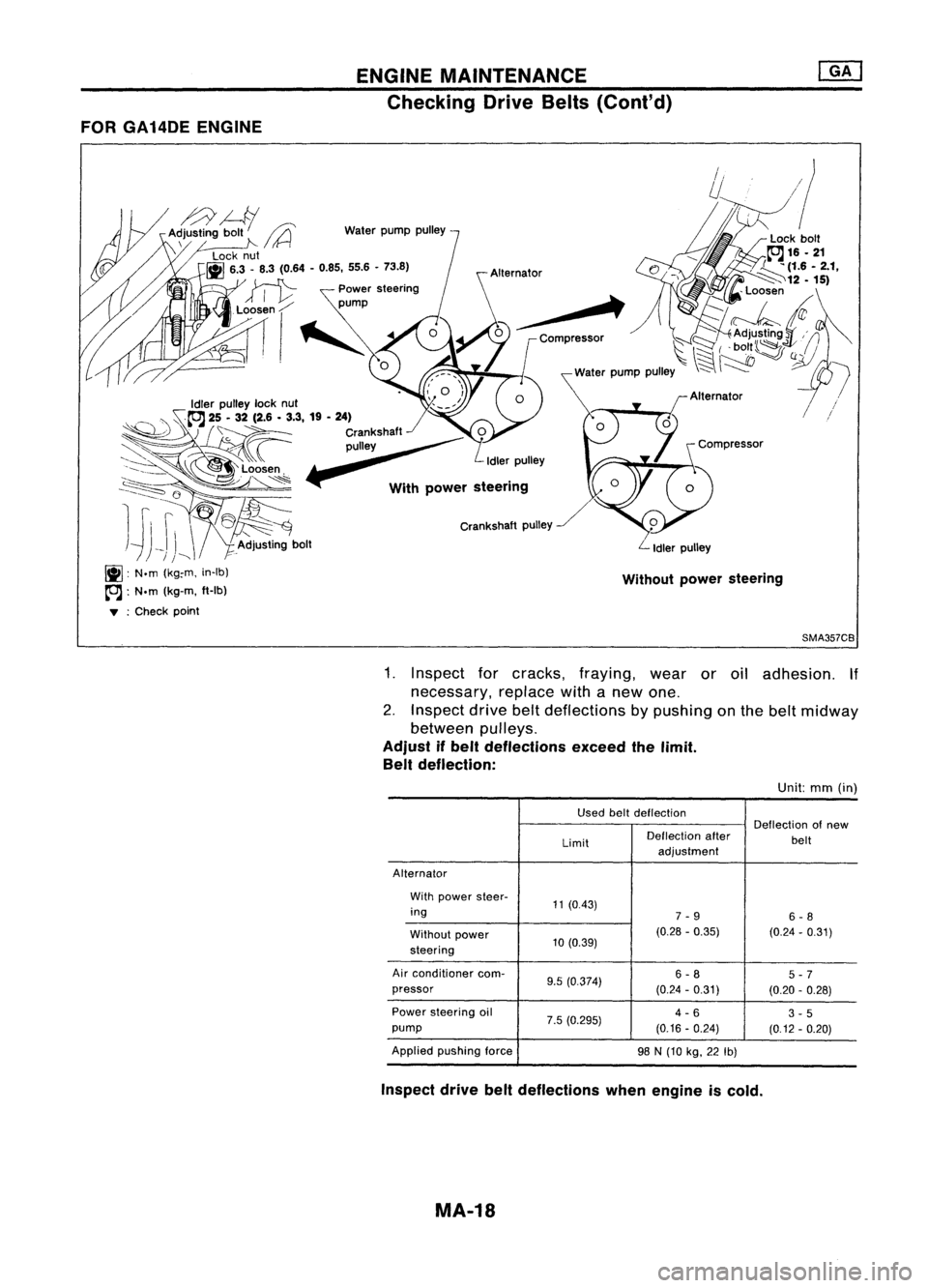

ENGINEMAINTENANCE

Checking DriveBelts(Cont'd)

FOR GA14DE ENGINE

L

Idler pulley

Crankshaft

pulley

Withoutpowersteering

Idler

pulley locknut __

~ 25•32 (2.6 •3.3, 19-24)

)~'\c, ~ Crankshaft

'~~UlleY

~ ~\ Idlerpulley

Loosen

/

~

.

~~- - Withpower steering

SMA357CB

1. Inspect forcracks, fraying, wearoroil adhesion. If

necessary, replacewithanew one.

2. Inspect drivebeltdeflections bypushing onthe belt midway

between pulleys.

Adjust ifbelt deflections exceedthelimit.

Belt deflection:

Unit:mm(in)

Used beltdeflection

Deflectionofnew

Limit Deflection

alter

belt

adjustment

Alternator

With power steer-

11(0.43)

ing 7-9

6-8

Without power (0.28

-0.35)

(0.24-0.31)

steering 10

(0.39)

Air conditioner com-

9.5(0.374) 6

-8

5-7

pressor (0.24-0.31)

(0.20-0.28)

Power steering oil

7.5(0.295) 4-6

3-5

pump (0.16-0.24)

(0.12-0.20)

Applied pushing force

98N(10 kg, 22Ib)

Inspect drivebeltdeflections whenengine iscold.

MA-18

Page 1505 of 1701

ENGINEMAINTENANCE

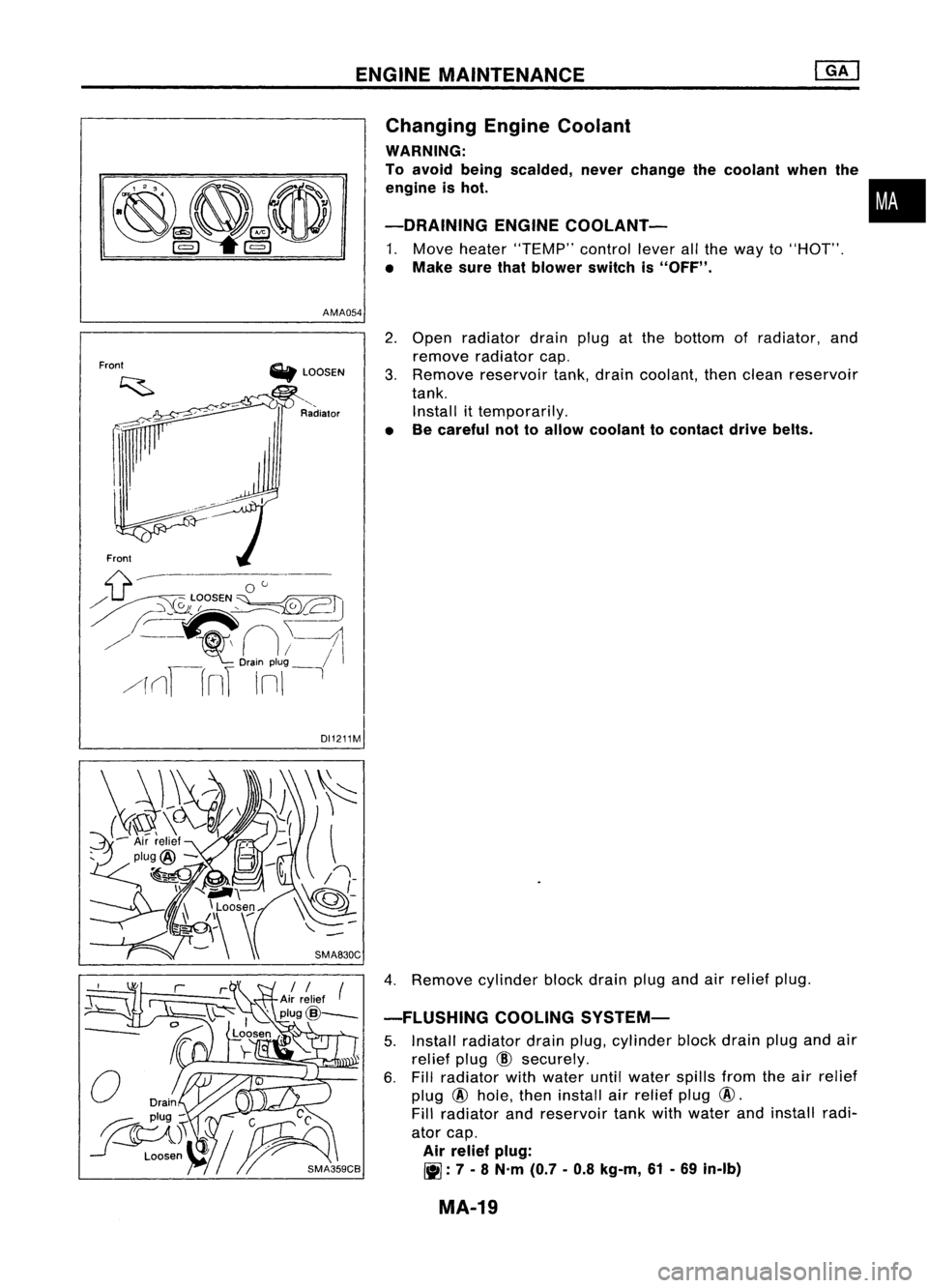

AMA054 Changing

EngineCoolant

WARNING:

To avoid being scalded, neverchange thecoolant whenthe

engine ishot.

-DRAINING ENGINECOOlANT-

1. Move heater "TEMP" controlleverallthe way to"HOT".

• Make surethatblower switchis"OFF".

•

Front

Fronl

'*'

LOOSEN

'--

Radialor

DI1211M

2.

Open radiator drainplugatthe bottom ofradiator, and

remove radiator cap.

3. Remove reservoir tank,drain coolant, thenclean reservoir

tank. Install ittemporarily.

• Becareful nottoallow coolant tocontact drivebelts.

4. Remove cylinder blockdrain plugandairrelief plug.

-FLUSHING COOLINGSYSTEM-

S. Install radiator drainplug,cylinder blockdrain plugandair

relief plug

CID

securely.

6. Fill radiator withwater untilwater spillsfromtheairrelief

plug @hole, theninstall airrelief plug@.

Fill radiator andreservoir tankwithwater andinstall radi-

ator cap.

Air relief plug:

~ :7 -

8 N'm (0.7-0.8 kg-m, 61-69 in-Ib)

MA-19

Page 1506 of 1701

![NISSAN ALMERA N15 1995 Service Manual

MAX,

MIN.

ENGINE

MAINTENANCE [QK]

Changing EngineCoolant (Cont'd)

7. Warm upengine untilcooling fanoperates, thenrace

engine 2or 3times under no-load.

8. Stop engine andwait until itcools down NISSAN ALMERA N15 1995 Service Manual

MAX,

MIN.

ENGINE

MAINTENANCE [QK]

Changing EngineCoolant (Cont'd)

7. Warm upengine untilcooling fanoperates, thenrace

engine 2or 3times under no-load.

8. Stop engine andwait until itcools down](/img/5/57349/w960_57349-1505.png)

MAX,

MIN.

ENGINE

MAINTENANCE [QK]

Changing EngineCoolant (Cont'd)

7. Warm upengine untilcooling fanoperates, thenrace

engine 2or 3times under no-load.

8. Stop engine andwait until itcools down.

9. Drain water.

10. Repeat steps2through 9until clear water begins todrain

from radiator.

-REFILLING ENGINECOOLANT-

11. Install reservoir tank,radiator drainplug,cylinder block

drain plugandairrelief plug

@.

• Apply sealant tothe thread ofcylinder blockdrainplug.

toJ:

34-44 N.m (3.5-4.5 kg-m, 25-33 ft-Ib)

12. Fill radiator withcoolant untilcoolant spillsfromtheair

relief plug

@

hole, theninstall airrelief plug

@.

13. Fill radiator andreservoir tankwithcoolant uptospecified

level andinstall radiator cap.

Air relief plug:

~: 7-8 N.m (0.7-0.8 kg-m, 61-69 in-Ib)

For coolant mixture ratio,refertoMA-16.

Coolant capacity (Withreservoir tank):

Unit:f(Imp qt)

With heater

Withoutheater

M/T 5.9(5-1/4) 5.6(4-7/8)

AIT 6.4(5-5/8) 6.1(5-3/8)

Reservoir tankcapacity (forMAX level):

o.n

(5/8Impqt)

Pour coolant through coolantfillerneckslowly toallow airin

system toescape.

14. Warm upengine tonormal operating temperature.

15. Run engine at2,500 rpmfor10seconds andreturn toidle

speed.

• Repeat 2or 3times.

Watch coolant temperature gaugesoas not tooverheat the

engine.

SMA4128

MA-20

Page 1507 of 1701

SLC053B

Water

inlet

Wateroutlet ENGINE

MAINTENANCE

@KJ

Changing EngineCoolant (Cont'd)

16. Stop engine andcool itdown.

• Cool down usingafan toreduce thetime.

17. Remove theradiator fillercapand check coolant level.

• If

necessary, refillradiator uptofiller neckwithcoolant. •

18. Refill reservoir tanktoMax linewith coolant. •

19. Repeat step14through step18two ormore times.

20. Warm upengine, andcheck forsound ofcoolant flowwhile

running enginefromidleupto4,000 rpmwith heater tem-

perature controlsetatseveral positions betweenCOOLand

HOT.

• Sound maybenoticeable atheater watercock.

21. Ifsound isheard, bleedairfrom cooling systembyrepeat-

ing steps 14through 18until coolant levelnolonger drops.

• Clean excess coolant fromengine.

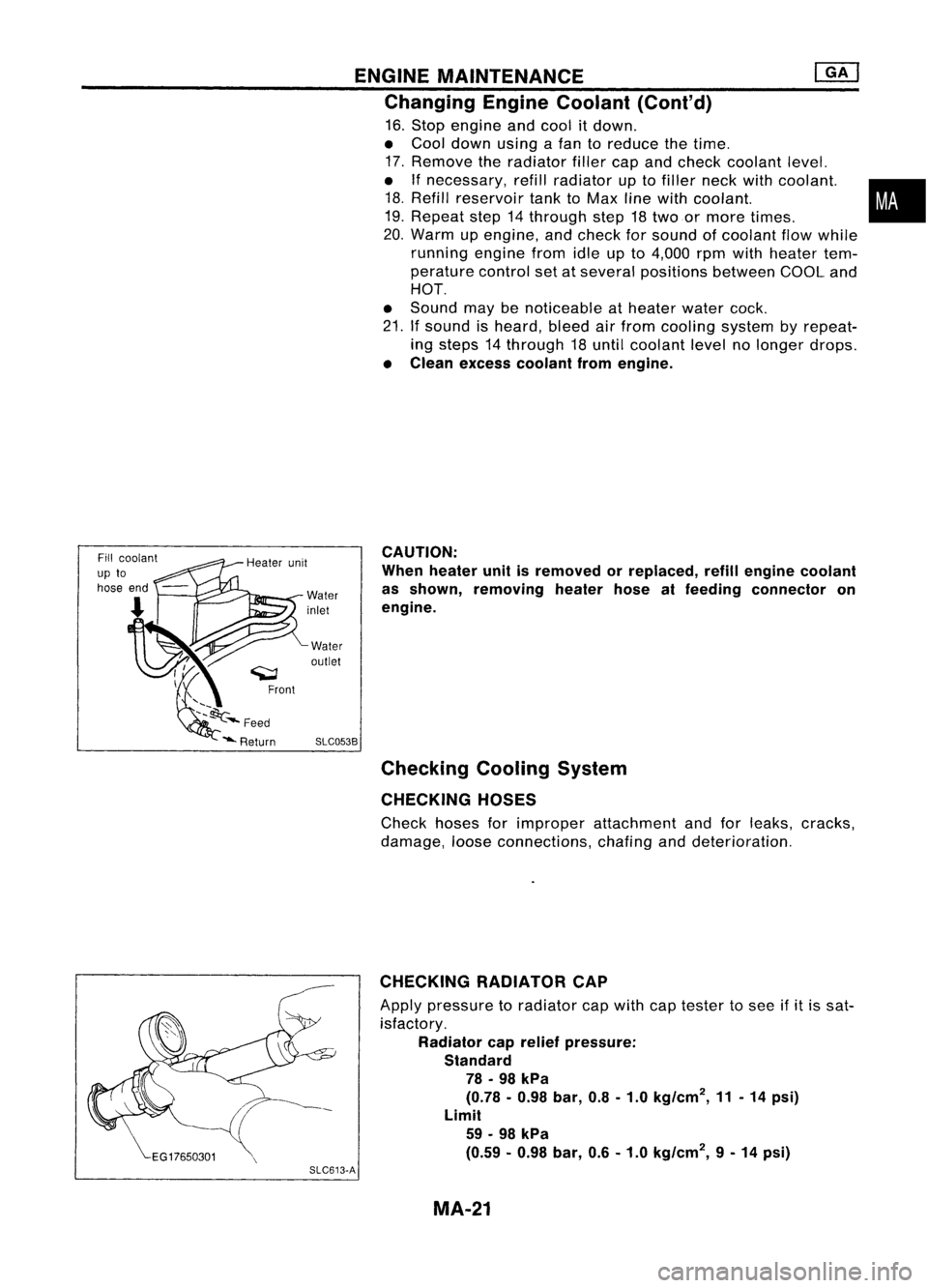

CAUTION:

When heater unitisremoved orreplaced, refillengine coolant

as shown, removing heaterhoseatfeeding connector on

engine.

Checking CoolingSystem

CHECKING HOSES

Check hosesforimproper attachment andforleaks, cracks,

damage, looseconnections, chafinganddeterioration.

CHECKING RADIATORCAP

Apply pressure toradiator capwith captester tosee if

it

is sat-

isfactory.

Radiator caprelief pressure:

Standard 78 -98 kPa

(0.78 •0.98 bar,0.8-1.0 kg/cm

2,

11.14 psi)

Limit

59 -98 kPa

(0.59 -0.98 bar,0.6-1.0 kg/cm

2,

9-14 psi)

SLC613-A

MA-21