engine NISSAN ALMERA N15 1995 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 1616 of 1701

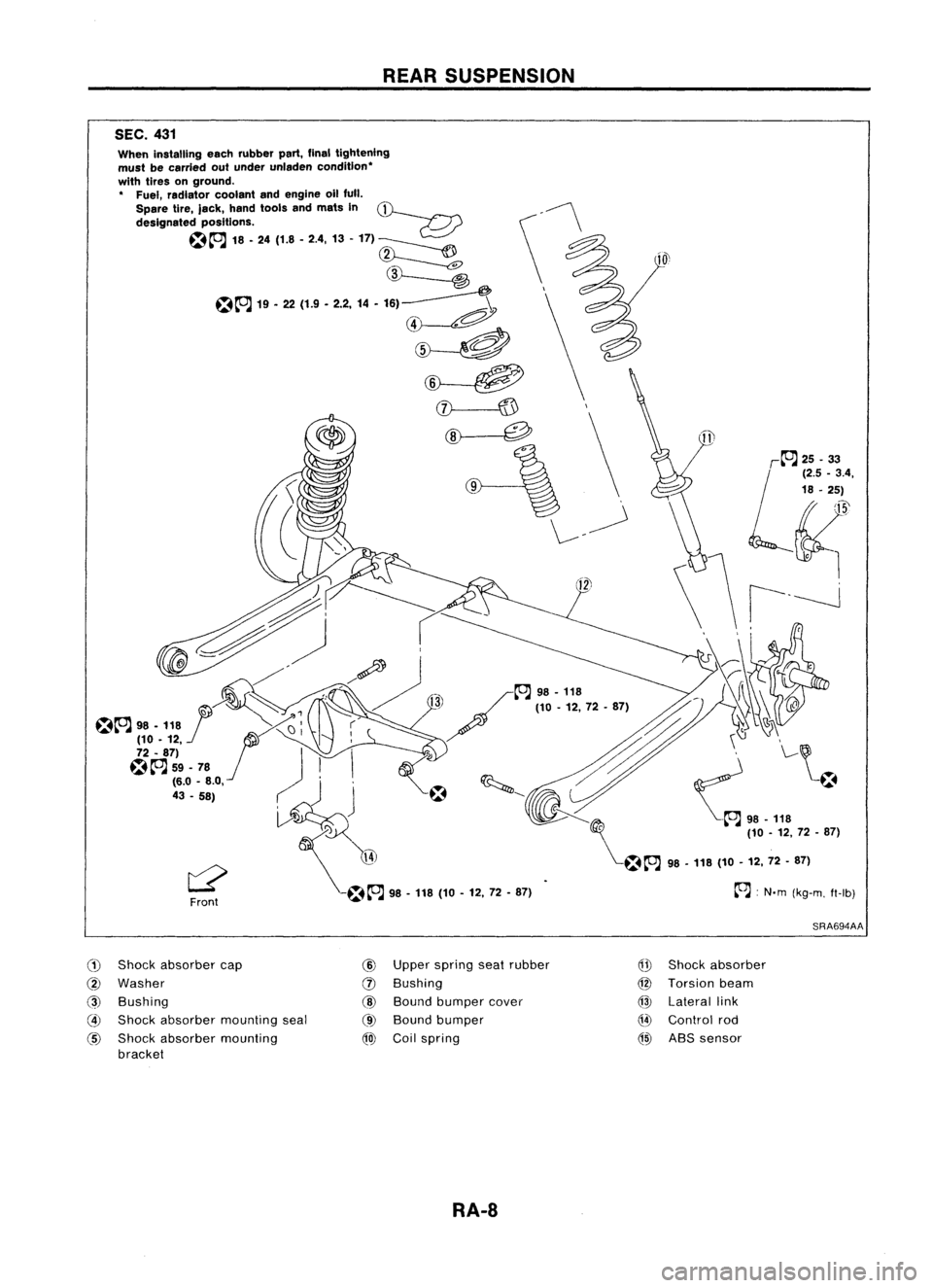

REARSUSPENSION

SEC. 431

~:N'm (kg-m. fl-Ib)

L'~

~;.;

~~.4,

18 •25)

~'

\ \ i---J

~~ ~

- ~98•118 (

I~ / 110-12,72-87) ~-~~~

@

~

"

\..-~

~ ~;:;:Y ~ '-~.

--...~~ ~~98-118

~ (10-12, 72•87)

~~A

98-118 (10-12, 72-87)

When

installing eachrubber part,finaltightening

must becarried outunder unladen condition"

with tires onground.

" Fuel, radiator coolantandengine allfull.

Spare tire,jack, handtools andmats In~

designated positions. ~

~~ 18.24(1.8.2.4, 13-17)~

~

~A

19•22 (1.9 -2.2, 14•16)~

~

~

~

:\\

\--/

Front

SRA694AA

(1)

Shock absorber cap

@

Washer

@

Bushing

@

Shock absorber mounting seal

@

Shock absorber mounting

bracket

@

Upper spring seatrubber

(J)

Bushing

@

Bound bumper cover

@

Bound bumper

@J

Coilspring

Q!J

Shock absorber

@

Torsion beam

@

Lateral link

Q4)

Control rod

@)

ABSsensor

RA-8

Page 1620 of 1701

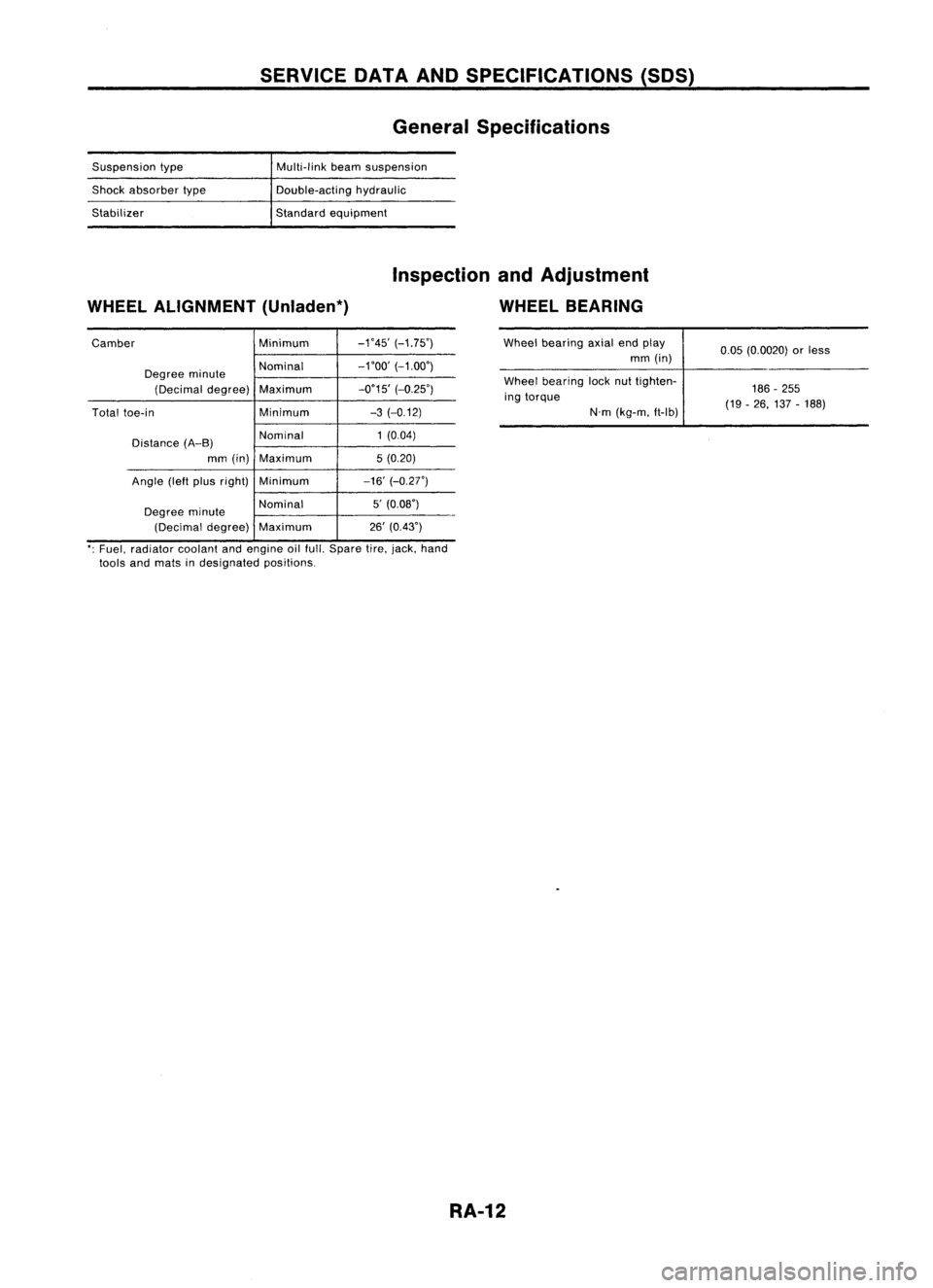

SERVICEDATAANDSPECIFICATIONS (50S)

General Specifications

Suspension type

Shock absorber type

Stabilizer Multi-link

beamsuspension

Double-acting hydraulic

Standard equipment

WHEEL ALIGNMENT (Unladen*) Inspection

andAdjustment

WHEEL BEARING

Camber Minimum-1'45'

(-1.75')

Degree minute Nominal

-1'00'

(-1.00')

(Decimal degree) Maximum -0'15'

(-0.25')

Total toe-in Minimum-3

(-0.12)

Distance (A-B) Nominal

1

(0.04)

mm (in) Maximum 5(0.20)

Angle (leftpius right) Minimum -16'(-0.27')

Degree minute Nominal

5'

(0.08')

(Decimal degree)Maximum 26'

(0.43') Wheel

bearing axialendplay

mm (in)

Wheel bearing locknuttighten-

ing torque

N'm(kg-m. ft-lb) 0.05

(0.0020) orless

186 -255

(19 -26, 137 -188)

': Fuel, radiator coolantandengine oilfull. Spare tire.jack, hand

tools andmats indesignated positions.

RA-12

Page 1649 of 1701

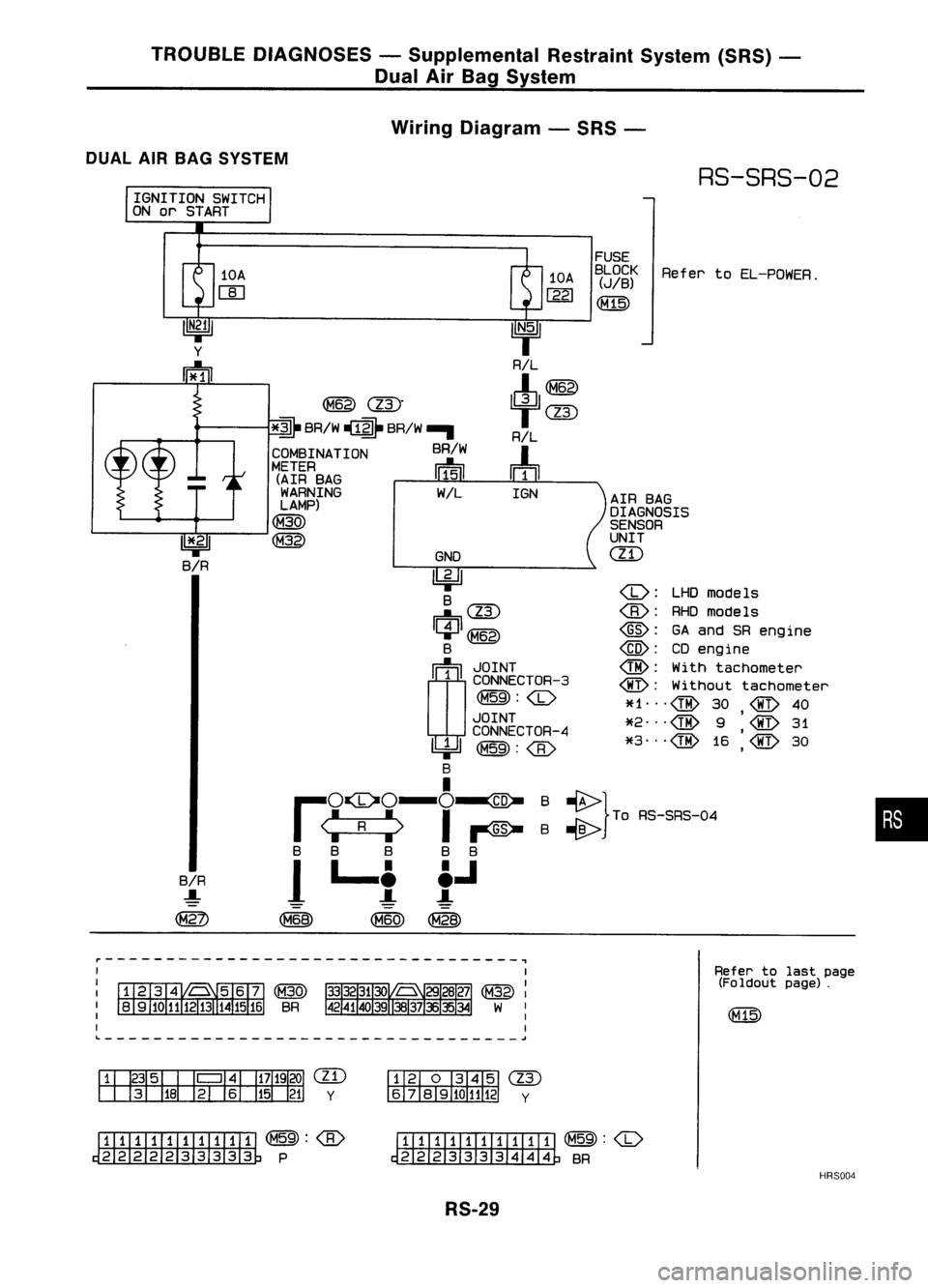

TROUBLEDIAGNOSES -Supplemental RestraintSystem(SRS)-

Dual AirBag System

Wiring Diagram -SRS -

DUAL AIRBAG SYSTEM

RS-SRS-02

IGNITION SWITCH

ON orSTART

::} ToAS-SAS-D.

•

Refer

toEL-POWER.

@:

GAand SRengine

@:

CDengine

@:

Withtachometer

@:

Without tachometer

~f1 ...

@

30

@

40

,

*2

@

9

@

31

*3

@

16

'@

30

,

AIR

BAG

DIAGNOSIS

SENSOR

UNIT

ill)

FUSE

BLOCK

(JIB)

(M15)

10A

1221

IGN

GNO

~ B

~(ll)

C:J~

B

rn~

I

~g~~~CTOR-3

~:

JOINT

CONNECTOR-4

~~:

I

,..O~O-O-ID-

I

<:

R

:>

I~

B B B BB

1

L..t t.J

~ (M60)~

~

(ll)"

*~

BRIW ~ BRIW-.

COMBINATION BRIW

METER ~

(AIR BAG 111511

WARNING WIL

LAMP)

(M30)

~

10A

W

BIR

.....

~

11*.21

BIR

~----------------------------------~

Refertolast page

(Foldout page).

L ~

em

y

(IT)

y

~(M59):

~P

ITIII:illJIIIII

~:

~ BR

HRS004

RS-29

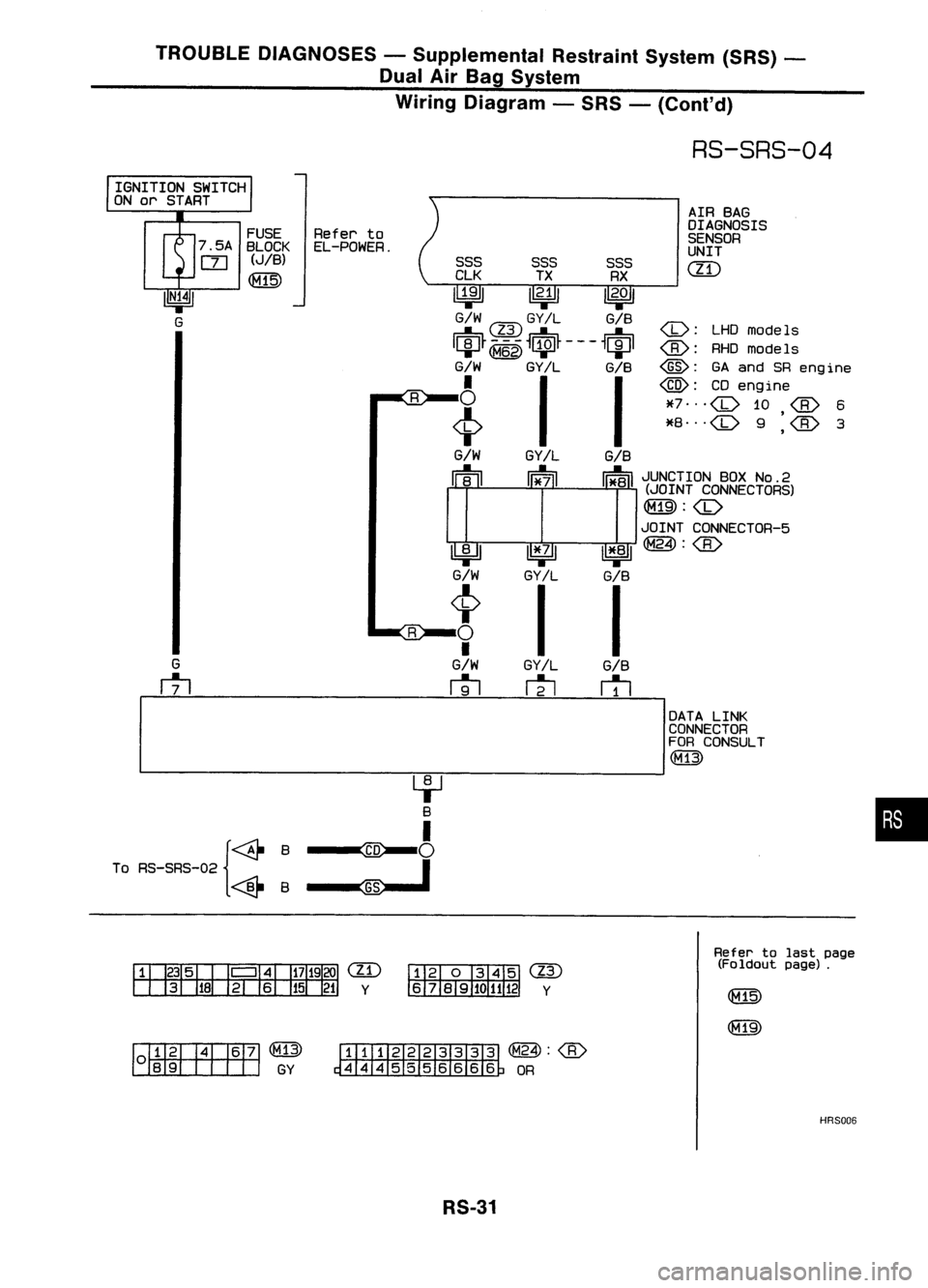

Page 1651 of 1701

TROUBLEDIAGNOSES -Supplemental RestraintSystem(SRS)-

Dual AirBag System

Wiring Diagram -SRS -(Cont'd)

RS-SRS-04

AIR BAG

OIAGNOSIS

SENSOR

UNIT

em

:

LHOmodels

@:

GAand SReng ine

@:

CDengine

*7 ...

,

*8 ...

,

G/B

~

GY/L

~

~

G/W

t

o

•

G/W

~

SSS

SSSSSS

ClK TXRX

~ ~11

2

.°1

G/W

@

GY

IL

G/B

IciJ~

G/W

GY/L

G/B

i

II

G/W

GY/L

G/B

~ ~~JUNCTION BOXNO.2

II B.II 11*711 II*BII(JOINT CONNECTORS)

JOINT CONNECTOR-5

1*:1 II*.BI~:

GY/l

G/B

I I

FUSE

Referto

7 .5A BLOCK El-POWER.

rn

(JIB)

~

G

rtl

IGNITION

SWITCH

ON or START

4-J

B

I

To RS-SRS-02 {~B ~

i

<@-B~

•

em

Y

@

Y

Refer

tolast page

(Foldout page).

~Q@

~GY

~(M24):

~ OR

HRS006

RS-31

Page 1653 of 1701

TROUBLEDIAGNOSES -Supplemental RestraintSystem(SRS)-

Dual AirBag System

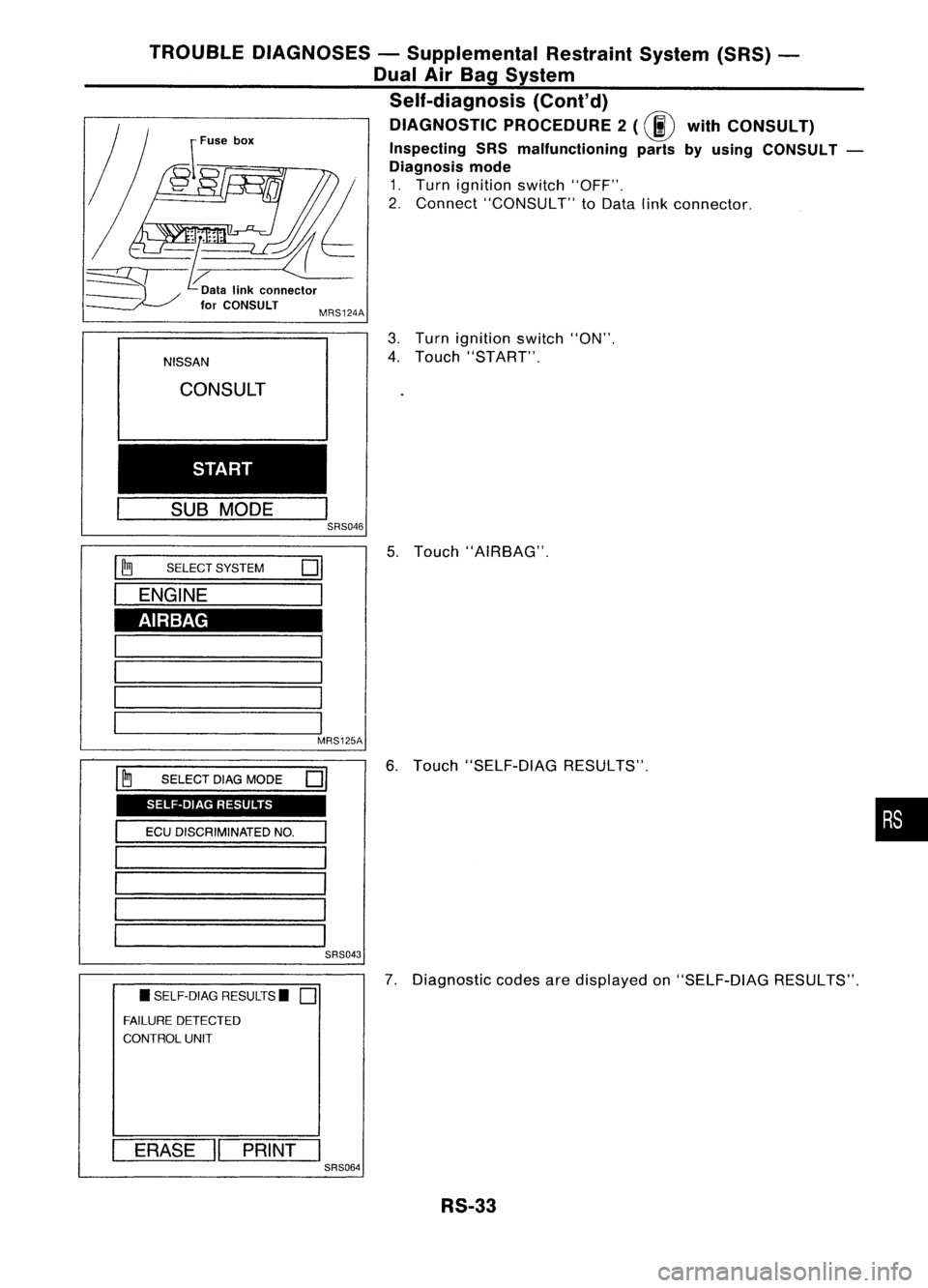

Self-diagnosis (Cont'd)

DIAGNOSTIC PROCEDURE2

(00

withCONSULT)

Inspecting SRSmalfunctioning partsbyusing CONSULT -

Diagnosis mode

1. Turn ignition switch"OFF".

2. Connect "CONSULT" toData linkconnector.

MRS124A

AIRBAG SELF-DIAG RESULTS

NISSAN

CONSULT

START

SUB MODE

I

SRS046

I ~

SELECT SYSTEM

01

I

ENGINE

1

1 '

1-----1

I

I

I 1

MRS125A

I ~

SELECT DIAGMODE

01

I

ECUDISCRIMINATED NO.

I

'======

1 -

1 -

1========

SRS043

• SELF-DIAG RESULTS.

0

FAILURE DETECTED

CONTROL UNIT

I

ERASE

II

PRINT

I

SRS064

3.

Turn ignition switch"ON".

4. Touch "START".

5. Touch "AIRBAG".

6. Touch "SELF-DIAG RESULTS".

7. Diagnostic codesaredisplayed on"SELF-DIAG RESULTS".

RS-33

•

Page 1658 of 1701

TROUBLEDIAGNOSES -Supplemental RestraintSystem(SRS)-

Dual AirBag System

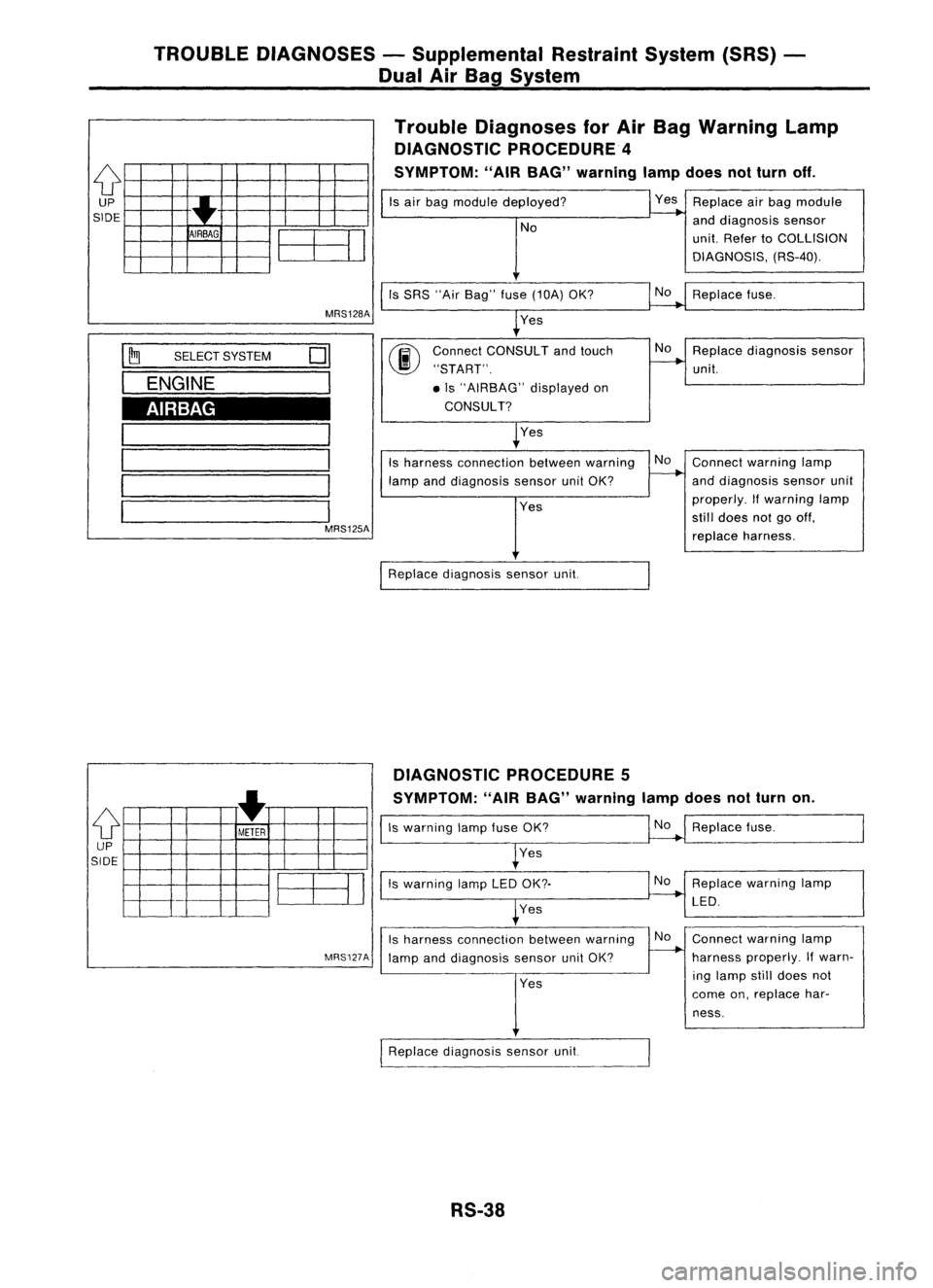

Trouble Diagnoses forAir Bag Warning Lamp

DIAGNOSTIC PROCEDURE 4

SYMPTOM: "AIRBAG" warning lampdoesnotturn off.

{f

UP

SIDE

•

T

AIRBAG

EE3J

Is

air bag module deployed?

No

Is SRS "AirBag" fuse(10A) OK?

Yes Replace

airbag module

and diagnosis sensor

unit. Refer toCOLLISION

DIAGNOSIS, (RS-40).

Replace fuse.

I ~

SELECT SYSTEM

01

I

ENGINE

I

AIRBAG

MRS125A

00

Connect

CONSULT andtouch No

Replace diagnosis sensor

"START".

----....

unit.

• Is "AIRBAG" displayedon

CONSULT?

~Yes

Is harness connection betweenwarning No

Connect warning lamp

lamp anddiagnosis sensorunitOK?

~

anddiagnosis sensorunit

Yes properly.

Ifwarning lamp

still does notgooff,

replace harness.

[RePlace diagnosissensorunit.

DIAGNOSTIC PROCEDURE 5

SYMPTOM: "AIRBAG" warning lampdoesnotturn on.

{f

+

METER

UP

SIDE

EE3J

MRS127A

Is

warning lampfuseOK?

Yes

Is warning lampLEDOK?

Yes

Is harness connection betweenwarning

lamp anddiagnosis sensorunitOK?

Yes

I

Replace diagnosis sensorunit.

RS-38

No

Replace fuse.

Replace warning lamp

LED.

Connect warning lamp

harness properly. Ifwarn-

ing lamp stilldoes not

come on,replace har-

ness.

Page 1667 of 1701

STEERINGSYSTEM

SECTIONST

CONTENTS

PRECAUTIONS ANDPREPARATION 2

Precautions 2

Special Service Tools 3

Commercial ServiceTools 4

ON-VEHICLE SERVICE

5

Checking SteeringWheelPlay 5

Checking NeutralPosition onSteering Wheel 5

Front Wheel Turning Angle 5

Checking GearHousing Movement 5

Checking andAdjusting DriveBelts(For

power steering) 6

Checking FluidLevel 6

Checking FluidLeakage 6

Bleeding Hydraulic System 7

Checking SteeringWheelTurning Force(For

power steering) 7

Checking Hydraulic System 8

STEERING WHEElANDSTEERING COLUMN 9

Removal andInstallation 9

Disassembly andAssembly 12

Inspection 13

MANUAL STEERING GEARANDLINKAGE

(Model R24N) 14

Removal

andInstallation 14

Disassembly 15

Inspection 15

Assembly andAdjustment... 16

POWER STEERING GEARANDLINKAGE (Model

PR24AC) 19

Removal andInstallation 19

Disassembly 22

Inspection 22

Assembly ,.. 23

Adjustment 27

POWER STEERING OILPUMP 29

Pre-disassembly Inspection 30

Disassembly 30

Inspection 31

Assembly 31

POWER STEERING OILCOOLER

33

Oil Cooler (Heavy dutykitfor CD20 engine

model) 33

Removal andInstallation 33

SERVICE DATAANDSPECIFICATIONS

(505)34

General Specifications 34

Inspection andAdjustment 34

•

Page 1672 of 1701

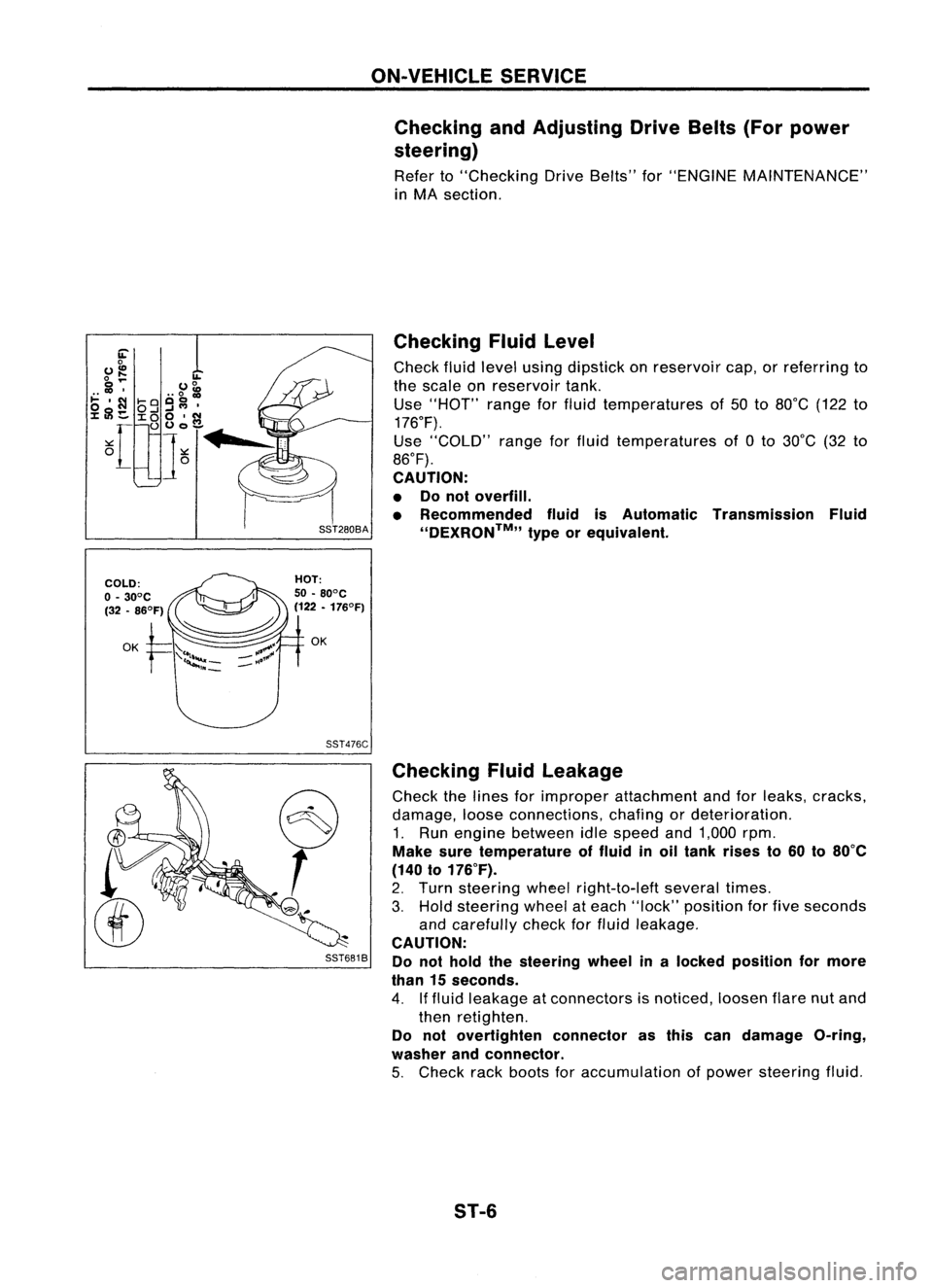

ON-VEHICLESERVICE

Checking andAdjusting DriveBelts(Forpower

steering)

Refer to"Checking DriveBelts" for"ENGINE MAINTENANCE"

in MA section.

SST476C

S

r

SST681B Checking

Fluidlevel

Check fluidlevel using dipstick onreservoir cap,orreferring to

the scale onreservoir tank.

Use "HOT" rangeforfluid temperatures of50 to80°C (122to

176°F).

Use "COLD" rangeforfluid temperatures of0to 30°C (32to

86°F).

CAUTION:

• Donot overfill.

• Recommended fluidisAutomatic Transmission Fluid

''DEXRON™,, typeorequivalent.

Checking Fluidleakage

Check thelines forimproper attachment andforleaks, cracks,

damage, looseconnections, chafingordeterioration.

1. Run engine between idlespeed and1,000 rpm.

Make suretemperature offluid inoil tank rises to60 to80°C

(140 to176°F).

2. Turn steering wheelright-to-Ieft severaltimes.

3. Hold steering wheelateach "lock" position forfive seconds

and carefully checkforfluid leakage.

CAUTION:

Do not hold thesteering wheelinalocked position formore

than 15seconds.

4. Iffluid leakage atconnectors isnoticed, loosenflarenutand

then retighten.

Do not overtighten connectorasthis candamage O-ring,

washer andconnector.

5. Check rackboots foraccumulation ofpower steering fluid.

ST-6

Page 1673 of 1701

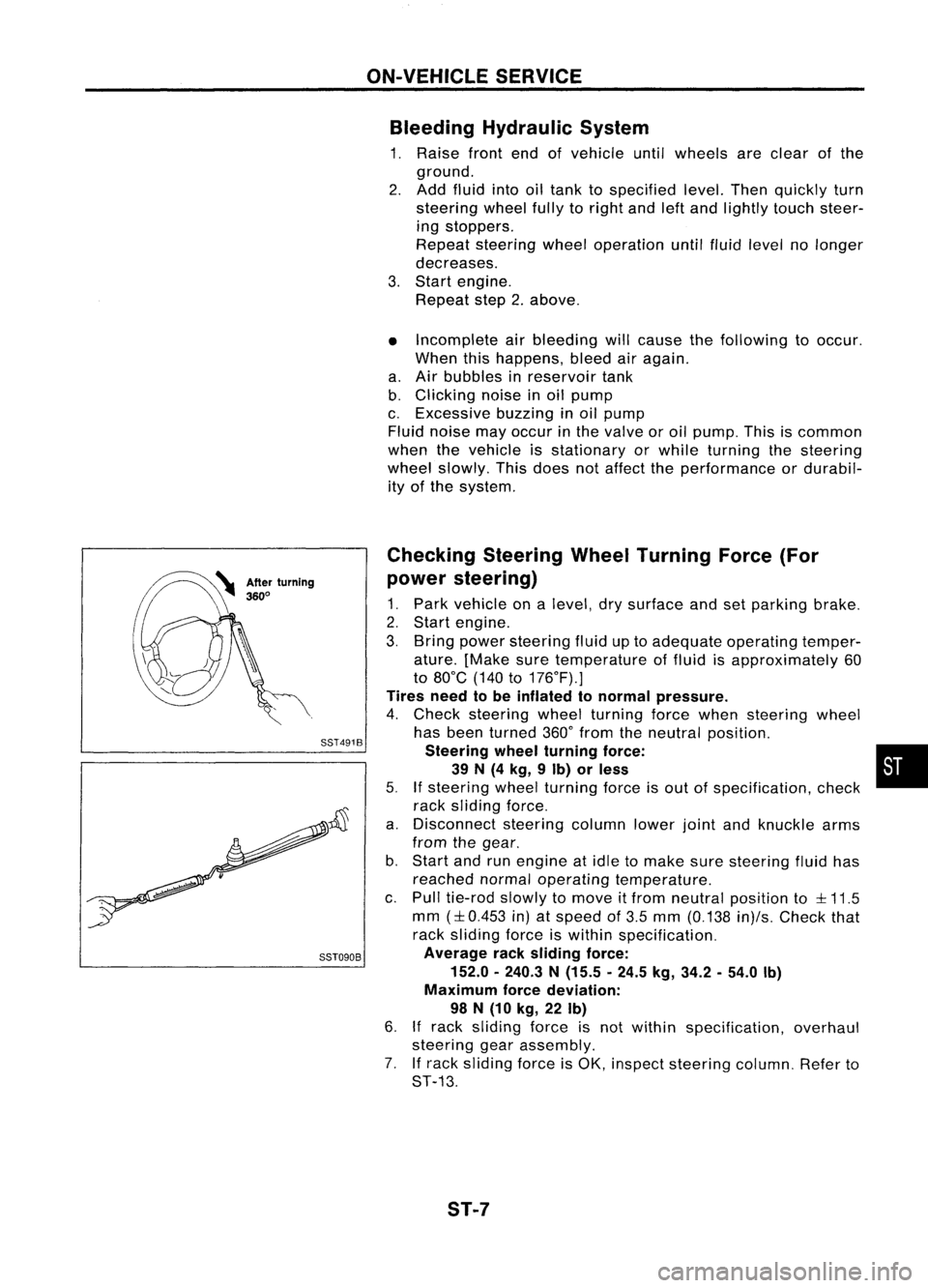

SST491B

SST090B ON-VEHICLE

SERVICE

Bleeding Hydraulic System

1. Raise frontendofvehicle untilwheels areclear ofthe

ground.

2. Add fluid intooiltank tospecified level.Thenquickly turn

steering wheelfullytoright andleftand lightly touchsteer-

ing stoppers.

Repeat steering wheeloperation untilfluid level nolonger

decreases.

3. Start engine.

Repeat step2.above.

• Incomplete airbleeding willcause thefollowing tooccur.

When thishappens, bleedairagain.

a. Air bubbles inreservoir tank

b. Clicking noiseinoil pump

c. Excessive buzzinginoil pump

Fluid noise mayoccur inthe valve oroil pump. Thisiscommon

when thevehicle isstationary orwhile turning thesteering

wheel slowly. Thisdoes notaffect theperformance ordurabil-

ity ofthe system.

Checking SteeringWheelTurning Force(For

power steering)

1. Park vehicle onalevel, drysurface andsetparking brake.

2. Start engine.

3. Bring power steering fluiduptoadequate operating temper-

ature. [Make suretemperature offluid isapproximately 60

to 80°C (140to176°F).]

Tires needtobe inflated tonormal pressure.

4. Check steering wheelturning forcewhen steering wheel

has been turned 360°from theneutral position.

Steering wheelturning force: •

39 N(4 kg, 9Ib) orless

5.

If

steering wheelturning forceisout ofspecification, check

rack sliding force.

a. Disconnect steeringcolumnlowerjointandknuckle arms

from thegear.

b. Start andrunengine atidle tomake suresteering fluidhas

reached normaloperating temperature.

c. Pull tie-rod slowlytomove itfrom neutral position to

::l::

11.5

mm

(::l::

0.453 in)atspeed of3.5 mm (0.138 in)/s.Check that

rack sliding forceiswithin specification.

Average racksliding force:

152.0 -240.3 N(15.5 -24.5 kg,34.2 -54.0 Ib)

Maximum forcedeviation:

98 N(10 kg, 22Ib)

6.

If

rack sliding forceisnot within specification, overhaul

steering gearassembly.

7. Ifrack sliding forceisOK, inspect steering column.Referto

ST-13.

ST-7

Page 1674 of 1701

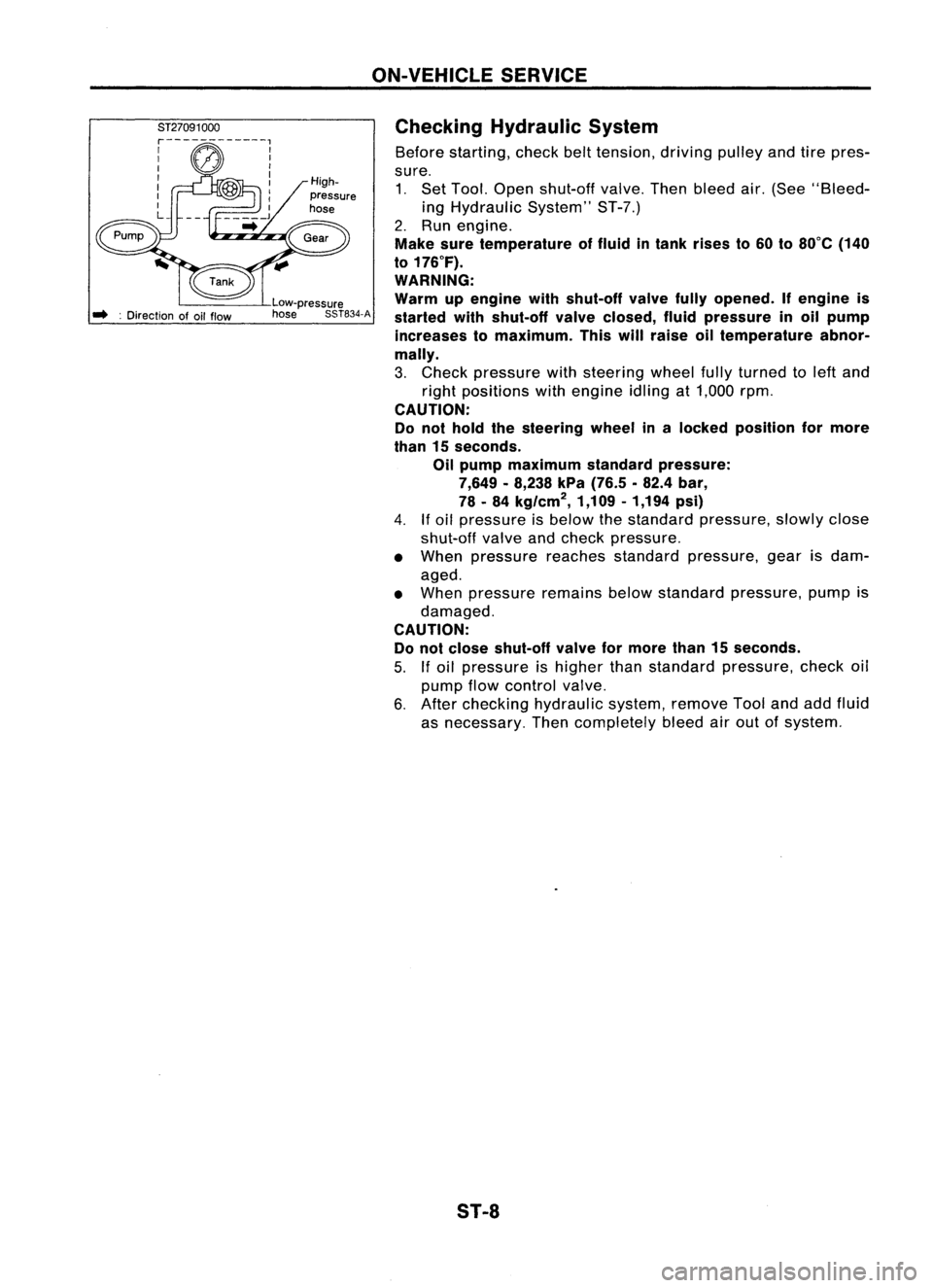

ST27091000

.. :Direction ofoil flow Low-pressure

hose SST834-AON-VEHICLE

SERVICE

Checking Hydraulic System

Before starting, checkbelttension, drivingpulleyandtirepres-

sure. 1. Set Tool. Open shut-off valve.Thenbleed air.(See "Bleed-

ing Hydraulic System"ST-7.)

2. Run engine.

Make suretemperature offluid intank rises to60 to80°C (140

to 176°F).

WARNING:

Warm upengine withshut-off valvefullyopened. Ifengine is

started withshut-off valveclosed, fluidpressure inoil pump

increases tomaximum. Thiswillraise oiltemperature abnor-

mally.

3. Check pressure withsteering wheelfullyturned toleft and

right positions withengine idlingat1,000 rpm.

CAUTION:

Do not hold thesteering wheelinalocked position formore

than 15seconds.

Oil pump maximum standardpressure:

7,649 -8,238 kPa(76.5 .82.4 bar,

78 -84 kg/cm

2,

1,109-1,194 psi)

4.

If

oil pressure isbelow thestandard pressure, slowlyclose

shut-off valveandcheck pressure.

• When pressure reachesstandard pressure, gearisdam-

aged.

• When pressure remainsbelowstandard pressure, pumpis

damaged.

CAUTION: Do not close shut-off valveformore than15seconds.

5.

If

oil pressure ishigher thanstandard pressure, checkoil

pump flowcontrol valve.

6. After checking hydraulic system,removeToolandaddfluid

as necessary. Thencompletely bleedairout ofsystem.

S1-8