engine NISSAN ALMERA N15 1995 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 1541 of 1701

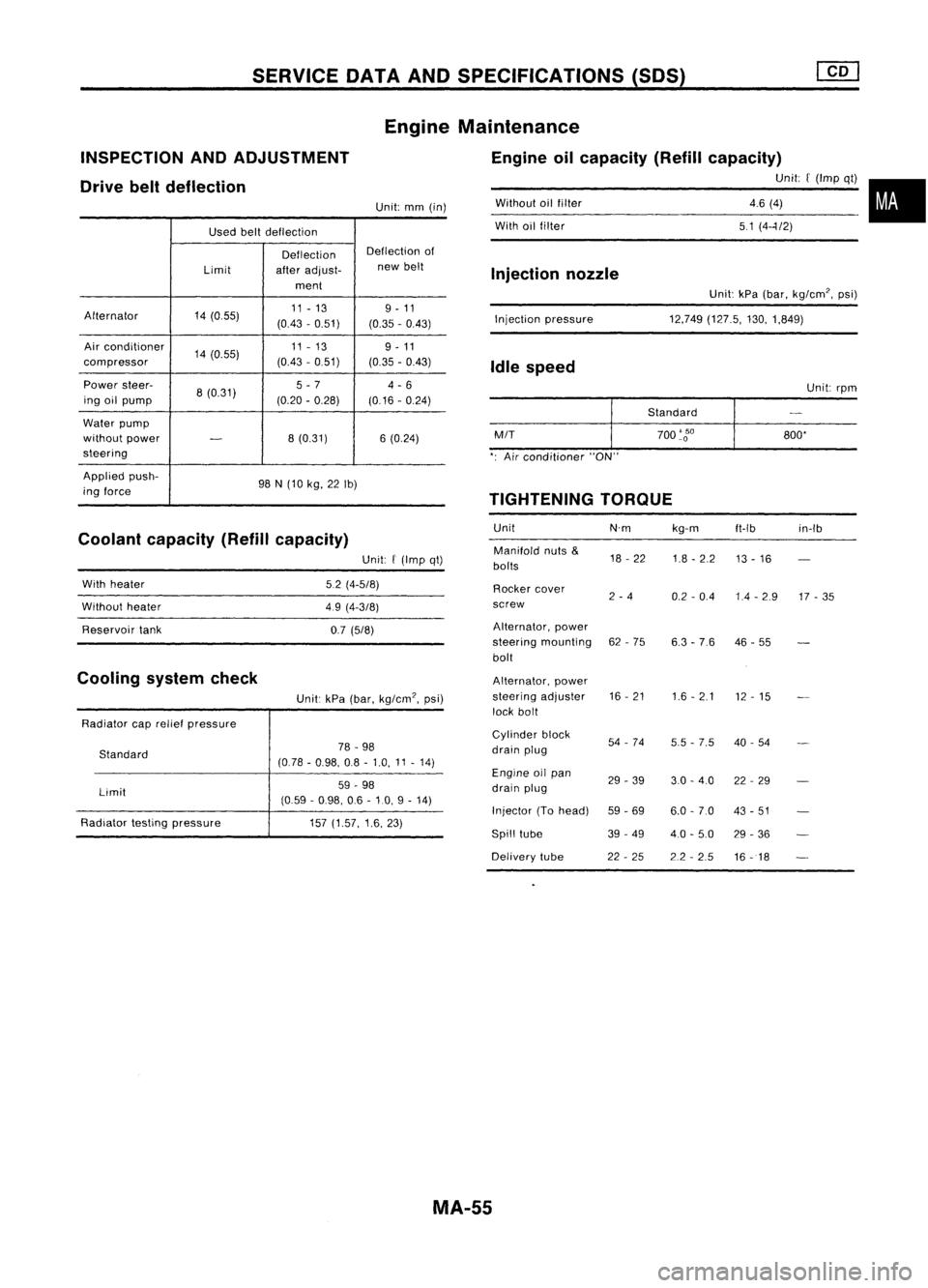

SERVICEDATAANDSPECIFICATIONS (50S)

Used beltdeflection

Deflection Deflection

of

Limit afteradjust- new

belt

ment

Alternator 14(055) 11

-13 9-11

(0.43 -0.51)

(0.35-0.43)

Air conditioner

14(0.55) 11

-13

9-11

compressor (0.43

-0.51)

(0.35-0.43)

Power steer-

8(0.31) 5

-7

4-6

ing oilpump (0.20-0.28)

(0.16-0.24)

Water pump

without power

-

8

(0.31) 6(0.24)

steering

Applied push-

98N(10 kg, 22Ib)

ing force

Coolant capacity (Refillcapacity)

INSPECTION

ANDADJUSTMENT

Drive beltdeflection

Unit:kPa(bar, kg/cm', psi)

12,749 (127.5, 130,1,849)

Without

oilfilter

With oilfilter

Injection pressure

Injection

nozzle

Idle speed

Unit:rpm

Standard

M/T

700

'go

800'

': Air conditioner "ON"

TIGHTENING TORQUE

Unit N'mkg-m

ft-Ib in-Ib

Manifold nuts

&

18-22

1.8-2.2

bolts 13

-16

Rocker cover

2-4

0.2-0.4 1.4-2.9 17-35

screw

Alternator, power

steering mounting 62-75

6.3-76 46

-55

bolt

Alternator, power

steering adjuster 16

-21

1.6-2.1

12-15

lock bolt

Cylinder block

54-74

5.5-7.5 40

-54

drain plug

Engine oilpan

29-39 3.0-4.0 22-29

drain plug

Injector (Tohead)

59-69 6.0-7.0 43-51

Spill tube 39-49

4.0-5.0 29-36

Delivery tube 22-25 2.2-2.5

16-18

Engine

Maintenance

Engine oilcapacity (Refillcapacity)

Unit:[(Imp qt)•

46 (4)

51 (4--1/2)

Unit:

mm(in)

Unit:

f

(Imp qt)

5.2 (4-5/8)

49 (4-3/8)

0.7 (5/8)

Unit: kPa(bar, kg/cm', psi)

78 -98

(0.78 -0.98, 08-1.0, 11-14)

59 -98

(0.59 -0.98, 06-10, 9-14)

157 (1.57, 1.6,23)

Standard

Limit

With

heater

Without heater

Reservoir tank

Radiator caprelief pressure

Radiator testingpressure

Cooling

systemcheck

MA-55

Page 1549 of 1701

REMOVALANDINSTALLATION

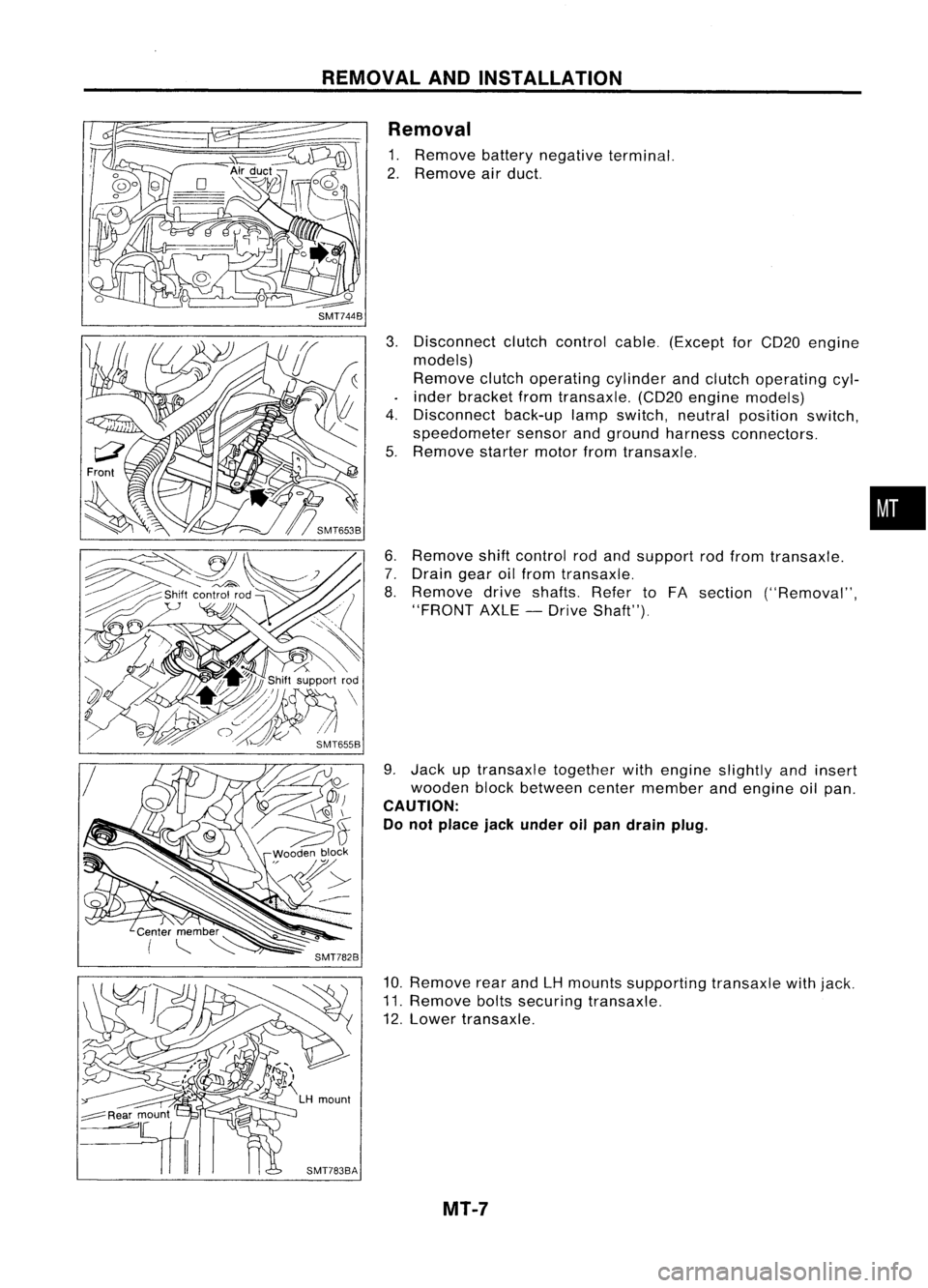

Removal

1. Remove batterynegative terminal.

2. Remove airduct.

3. Disconnect clutchcontrol cable.(Except forCD20 engine

models)

Remove clutchoperating cylinderandclutch operating cyl-

inder bracket fromtransaxle. (CD20engine models)

4. Disconnect back-uplampswitch, neutralposition switch,

speedometer sensorandground harness connectors.

5. Remove startermotorfromtransaxle.

6. Remove shiftcontrol rodand support rodfrom transaxle.

7. Drain gearoilfrom transaxle.

8. Remove driveshafts. RefertoFA section ("Removal",

"FRONT AXLE-Drive Shaft").

9. Jack uptransaxle togetherwithengine slightly andinsert

wooden blockbetween centermember andengine oilpan.

CAUTION:

Do not place jackunder oilpan drain plug.

10. Remove rearandLHmounts supporting transaxlewithjack.

11. Remove boltssecuring transaxle.

12. Lower transaxle.

MT-7

•

Page 1550 of 1701

@

M/T

toengine

CD

REMOVAL

ANDINSTAllATION

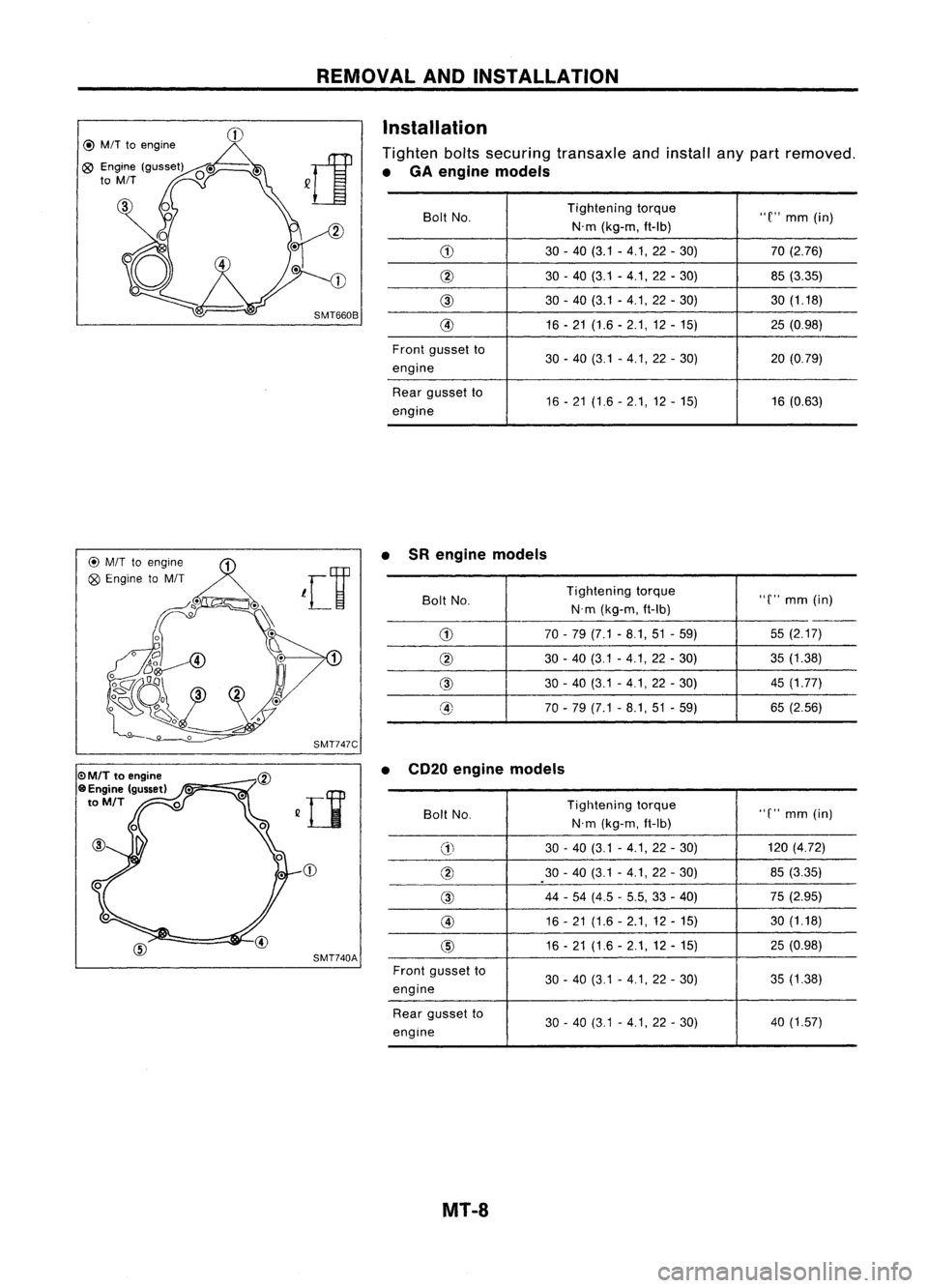

Installation

Tighten boltssecuring transaxle andinstall anypart removed.

• GA engine models

Bolt No. Tightening

torque

"C"mm (in)

N'm (kg-m, ft-Ib)

G) 30-40 (3.1 -4.1,22 -30) 70

(2.76)

@ 30-40 (3.1 -4.1,22 -30) 85(3.35)

@

30-40 (3.1 -4.1, 22-30) 30(1.18)

@ 16-21 (1.6 -2.1,12 -15) 25(0.98)

Front gusset to

30-40 (3.1 -4.1,22 -30) 20(0.79)

engine

Rear gusset to

16-21 (1.6 -2.1,12 -15) 16

(0.63)

engine

@

M/T

toengine ~

Q9

Engine toM/T

leV

~o". Q~.\

17

SMT747C

CD

SMT740A •

SRengine models

Bolt No. Tightening

torque

"C"mm (in)

N'm (kg-m, ft-Ib)

--

G)

70-79 (7.1 -8.1,51 -59) 55

(2.17)

@

30-40 (3.1 -4.1,22 -30) 35

(1.38)

@

30-40 (3.1 -4.1,22 -30) 45

(1.77)

@ 70-79 (7.1 -8.1,51 -59) 65

(2.56)

• CD20 engine models

Boll No. Tightening

torque

"C"mm (in)

N'm (kg-m, ft-Ib)

G)

30

-40 (3.1 -4.1, 22-30) 120

(4.72)

@

30-40 (3.1 -4.1,22 -30) 85

(3.35)

@

44

-54 (4.5 -5.5, 33-40) 75

(2.95)

@

16-21 (1.6 -2.1,12 -15) 30

(1.18)

@

16-21 (1.6 -2.1,12 -15) 25

(0.98)

Front gusset to

30-40 (3.1 -4.1, 22-30) 35

(1.38)

engine

Rear gusset to

30-40 (3.1 -4.1, 22-30) 40

(1.57)

engine

MT-8

Page 1551 of 1701

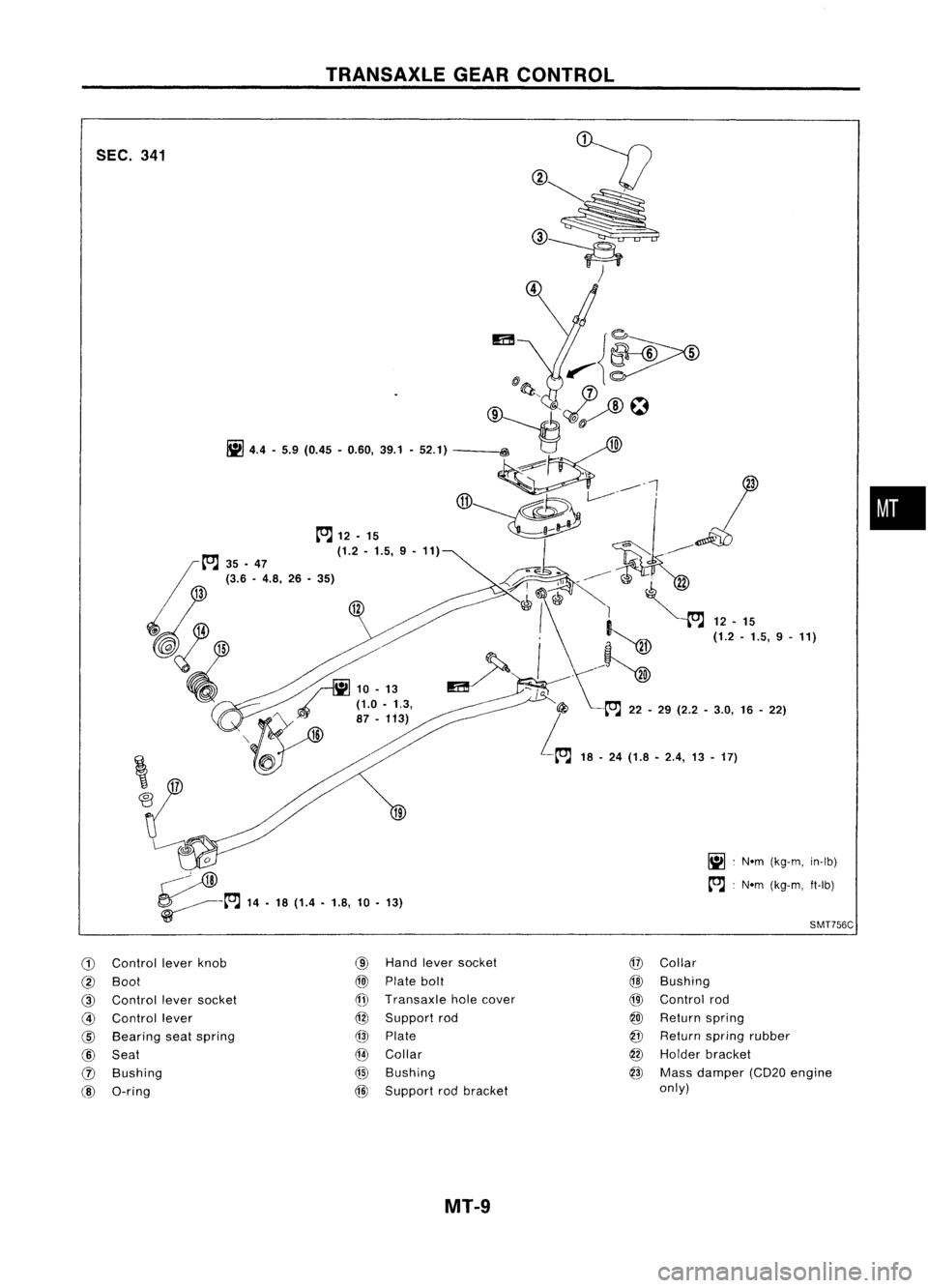

TRANSAXlEGEAR

CONTROL

•

~ .Nom (k

g-m, in-Ib)

~ :Nom (kg-m, ft-Ib)

12

~

4.4.5.9 (0.45

•060

.

,39.1. 52.1)

m

.

..--~~

~~O 't~~~

t"J t"J

12•15

(jj)~~~~l '

3

35 •47 (1.2•15

._le'

(3 6 .,9 •11)

~~

-

.

..--~

/" rIiJ

10.13 ~

I\~~ ~ ;~;

'~.5, 9•11)

, {y"'''

(1.0•

1.3, "",/'

>

"@

'\ _Y 87•113)

I

16

iI5J

t

t"J

22•29 (2.2 .

L,

3.0.16•22)

-~ 18.24(1.8 •2

.4, 13•17)

f?:!-

:g.~

~

14. 18(1

W

.4.18 1

.,

O.13)

SEC.

341

Control leverknb

Boot

0

Control leversocke

Control lever t

Bearing seats.

Seat pring

Bushing

O-ring Hand

Iever socket

Plate bolt

Transaxle hI

S

0

e cover

upport rod

Plate

Collar

Bushing

Support rodbracket

@

@

@)

@

@

@

@

Collar

Bushing

Control rod

Return spring

Return s.

pring rubb

Hold er

er bracket

Mass dame

only) pr(CD20 engine

MT-9

Page 1552 of 1701

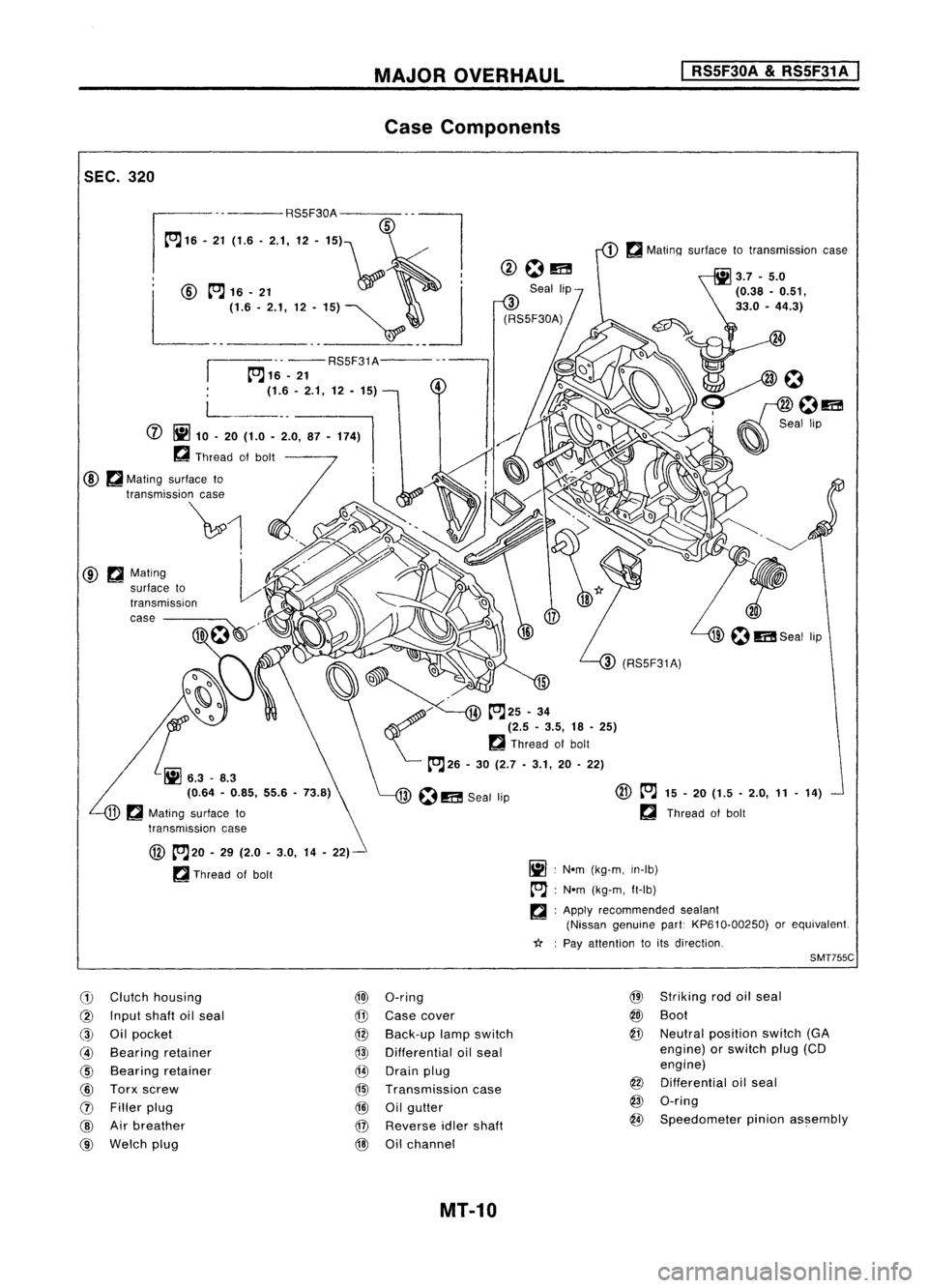

SEC.320 MAJOR

OVERHAUL

Case Components

I

RS5F30A

&

RS5F31 A

I

.. -- RS5F31A---

~16 -21

(1.6 -2.1, 12. 15)

@ ~Mating

surface to

transmiSSion

case ----

@

~20 -29 (2.0 -3.0, 14-22)-

~ Thread ofbolt

(1)

Clutch housing

@)

O-ring

@

Input shaftoilseal

@

Case cover

@

Oilpocket

@

Back-up lampswitch

@

Bearing retainer

@

Differential oilseal

@

Bearing retainer

@

Drain plug

@

Torx screw

@l

Transmission case

(J)

Filler plug

@

Oilgutter

@

Airbreather

@

Reverse idlershaft

@

Welch plug

@

Oilchannel

MT-10

@

~

15-20 (1.5 -2.0, 11-14)

~ Thread ofbolt

Ij] :

Nom (kg-m, in-Ib)

tr'J :

Nom (kg-m, ft-Ib)

~ :Apply recommended sealant

(Nissan genuine part:KP610-00250) orequivalent.

*: :

Pay attention toits direction.

SMT755C

@

Striking rodoilseal

@J

Boot

@

Neutral position switch(GA

engine) orswitch plug(CD

engine)

@

Differential oilseal

@

O-ring

@

Speedometer pinionassembly

Page 1602 of 1701

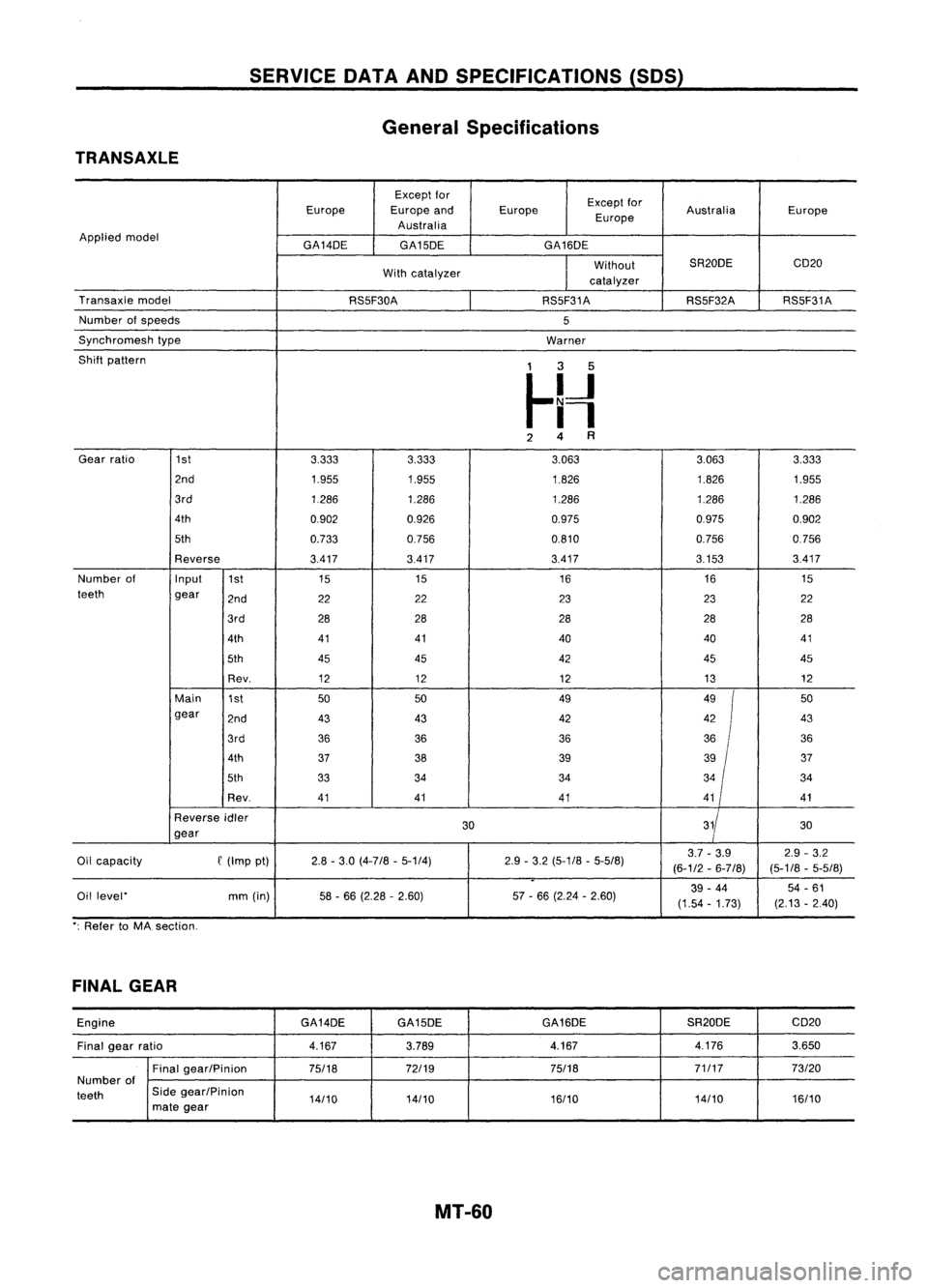

TRANSAXLE SERVICE

DATAANDSPECIFICATIONS (SDS)

General Specifications

Except for

Exceptfor

Europe Europeand Europe

EuropeAustralia

Europe

Australia

Applied model

GA14DEGA15DE GA16DE

Without SR20DE

CD20

With catalyzer

catalyzer

Transaxle model

RS5F30ARS5F31ARS5F32ARS5F31A

Number ofspeeds

5

Synchromesh type

Warner

Shift pattern

1

3

5

~tJ

II

2

4

A

Gear ratio 1st 3.333

3.333 3.0633.0633.333

2nd 1.9551.955 1.826 1.8261.955

3rd 12861.286 1.2861.2861.286

4th 0.9020.926 0.975

0.975

0.902

5th 0.7330.756 0.810

0.7560,756

Reverse 3.4173.417 3.417 3.1533.417

Number of Input

1st 15 15

16

1615

teeth gear

2nd 22 22 23 2322

3rd 28 28 28 28

28

4th 41 41 40 40

41

5th 45 45 42 4545

Rev. 12

12 12 1312

Main 1st 50 50 49 4950

gear 2nd 43

43 42

4243

3rd 36

36 36 3636

4th 37 38 39

39/

37

5th 33 34

34 3434

Rev. 41 41

41 41

41

Reverse idler

30 3130

gear

Oil capacity

C

(Imp pt) 2.8-3.0 (4-7/8 -5-1/4) 2.9-3.2 (5-1/8 -5-5/8) 3.7

-3.9 2.9

-3.2

(6-1/2 -6-7/8) (5-1/8-5-5/8)

.

Oillevel* mm(in) 58-66 (2.28 -2.60) 57-66 (2.24 -2.60) 39

-44 54

-61

(1.54 -1.73) (2.13-2.40)

*: Refer toMA. section.

FINAL GEAR

Engine GA14DEGA15DE GA16DESR20DE

CD20

Final gearratio 4.1673.789 4.167 4.176

3.650

Final gear/Pinion 75/1872/19

75/1871/17

73/20

Number of

teeth Side

gear/Pinion

14/1014/10 16/1014/10

16/10

mate gear

MT.60

Page 1604 of 1701

Thicknessmm(in)

Partnumber

0.10 (0.0039) 32137-M8000

0.15 (0.0059) 32137-M8001

0.20 (0.0079) 32137-M8002

0.25 (0.0098) 32137-M8003

0.30 (0.0118) 32137-M8004

035 (0.0138) 32137-M8005

0.40 (0.0157) 32137-M8006

0.45 (00177) 32137-M8007

0.50 (0.0197) 32137-M8008

0.55 (0.0217) 32137-M8009

0.60 (0.0236) 32137-M8010

0.65 (0.0256) 32137-M8011

0.70 (0.0276) 32137

-M8012

0.75 (0.0295) 32137-M8013

080 (0.0315) 32137-M8014

0.85 (0.0335) 32137-M8015

0.90 (0.0354) 32137

-M8016

095 (0.0374) 32137-M8017

1.00 (0.0394) 32137-M8018

Table forselecting mainshaft bearing

adjusting shim

38424-02111

38424-02112

38424-02113

38424-02114

38424-02115

Part

number

Part number

38424-01 M10

38424-01 M11

38424-01 M12

38424-01M13 0.1

-0.2 mm

(0.004 -0.008 in)

0.1 -0.2 mm

(0.004 -0.008 in)

Thickness

mm(in)

0.75 -0.80 (0.0295 -0.0315)

0.80 -0.85 (0.0315 -0.0335)

0.85 -0.90 (0.0335 -0.0354)

0.90 -0.95 (0.0354 -0.0374)

0.95 -1.00 (0.0374 -0.0394)

Thickness mm(in)

076 -0.81 (0.0299 -0.0319)

0.81 -0.86 (0.0319 -0.0339)

0.86 -0.91 (0.0339 -0.0358)

0.91 -0.96 (0.0358 -0.0378)

Allowable

clearance between

side gear anddifferential case

with washer

Allowable

clearance between

side gear anddifferential case

with washer

• Except forGA16DE andCD20 engine models

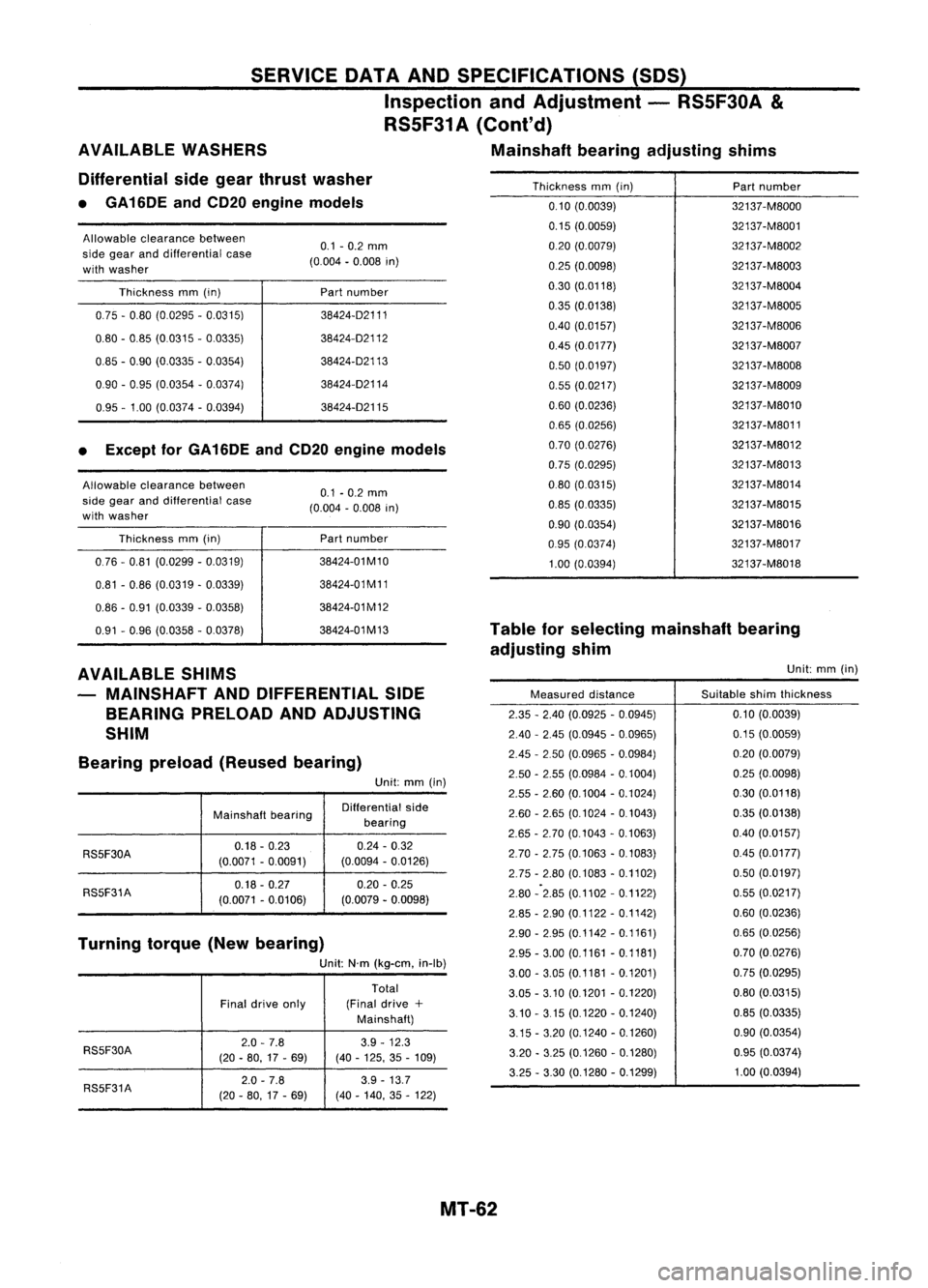

SERVICE

DATAANDSPECIFICATIONS (SDS)

Inspection andAdjustment -RS5F30A

&

RS5F31 A(Cont'd)

AVAILABLE WASHERS Mainshaftbearingadjusting shims

Differential sidegear thrust washer

• GA16DE andCD20 engine models

AVAILABLE SHIMS

MAINSHAFT ANDDIFFERENTIAL SIDE

BEARING PRELOAD ANDADJUSTING

SHIM

Bearing preload(Reused bearing)

Unit:mm(in)

Mainshafl bearing Oifferential

side

bearing

RS5F30A 0.18

-0.23 0.24-0.32

(0.0071 -0.0091) (0.0094

-0.0126)

RS5F31A 0.18

-0.27 0.20

-0.25

(0.0071 -0.0106) (0.0079

-0.0098)

Turning torque(Newbearing)

Unit:N'm(kg-em, in-Ib)

Total

Final drive only (Final

drive+

Mainshafl)

RS5F30A 2.0

-7.8 3.9-12.3

(20 -80, 17-69) (40

-125, 35-109)

2.0 -7.8 3.9

-13.7

RS5F31A (20-80, 17-69) (40-140, 35-122) Measured

distance

2.35 -2.40 (0.0925 -0.0945)

2.40 -2.45 (0.0945 -0.0965)

2.45 -2.50 (0.0965 -0.0984)

2.50 -2.55 (0.0984 -0.1004)

2.55 -2.60 (0.1004 -0.1024)

2.60 -2.65 (0.1024 -0.1043)

2.65 -2.70 (0.1043 -0.1063)

2.70 -2.75 (0.1063 -0.1083)

2.75 -2.80 (0.1083 -0.1102)

2.80 -2.85 (0.1102 -0.1122)

2.85 -2.90 (0.1122 -0.1142)

2.90 -2.95 (0.1142 -0.1161)

2.95 -3.00 (0.1161 -0.1181)

3.00 -3.05 (0.1181 -0.1201)

3.05 -3.10 (0.1201 -0.1220)

3.10 -315 (0.1220 -0.1240)

3.15 -3.20 (0.1240 -0.1260)

3.20 -3.25 (0.1260 -0.1280)

3.25 -3.30 (0.1280 -0.1299) Unit:

mm(in)

Suitable shimthickness

0.10 (0.0039)

0.15 (0.0059)

0.20 (0.0079)

0.25 (0.0098)

0.30 (0.0118)

0.35 (0.0138)

0.40 (0.0157)

0.45 (0.0177)

0.50 (0.0197)

0.55 (0.0217)

0.60 (0.0236)

0.65 (0.0256)

0.70 (0.0276)

0.75 (0.0295)

0.80 (0.0315)

0.85 (0.0335)

0.90 (0.0354)

0.95 (0.0374)

1.00 (0.0394)

MT-62

Page 1610 of 1701

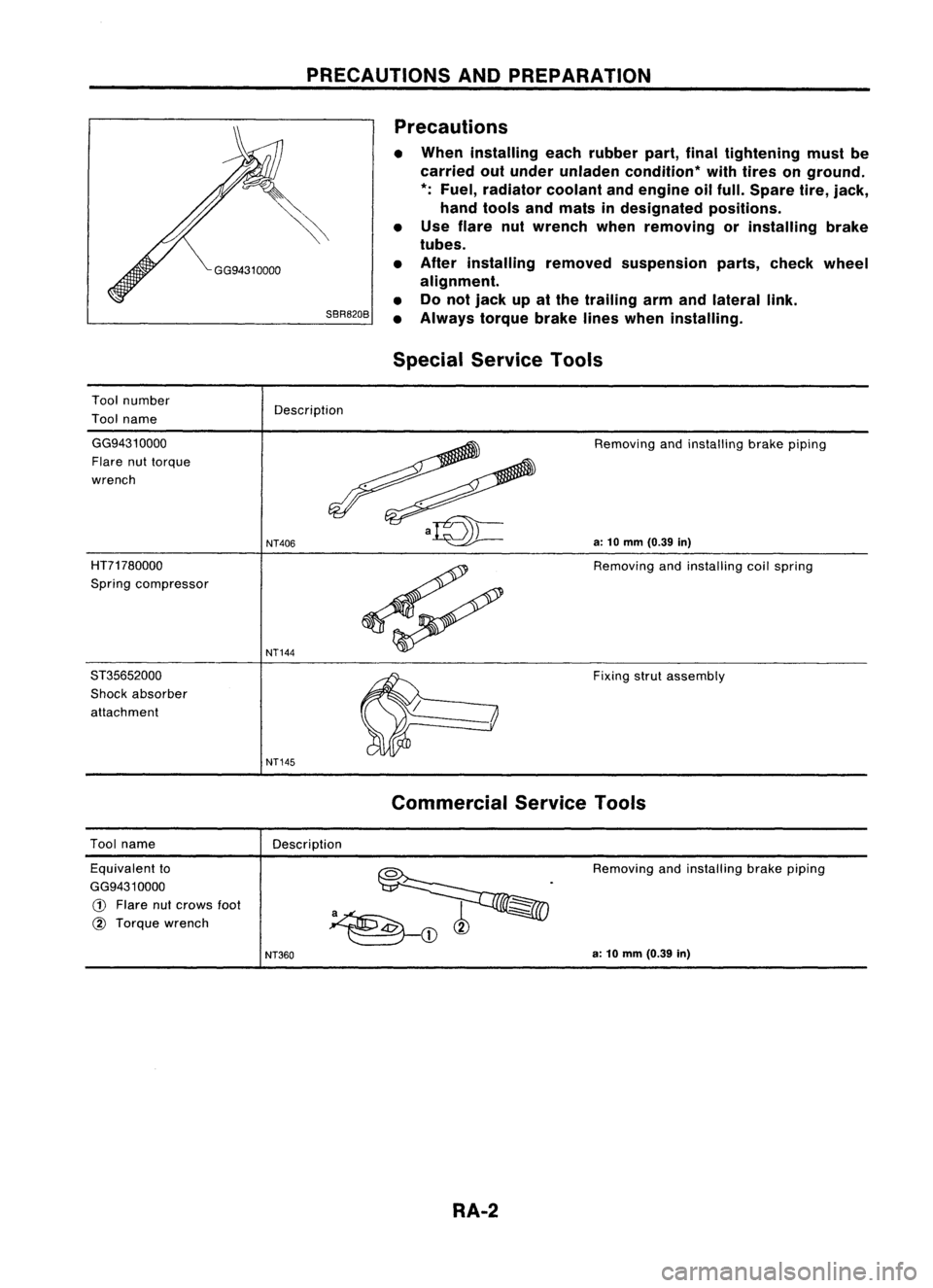

PRECAUTIONSANDPREPARATION

SBR820B Precautions

• When installing eachrubber part,finaltightening mustbe

carried outunder unladen condition* withtires onground.

*:

Fuel, radiator coolantandengine oilfull. Spare tire,jack,

hand tools andmats indesignated positions.

• Use flare nutwrench whenremoving orinstalling brake

tubes.

• After installing removedsuspension parts,check wheel

alignment.

• Donot jack upatthe trailing armandlateral link.

• Always torquebrakelineswhen installing.

Special Service Tools

Tool number

Tool name Description

GG9431 0000

Flare nuttorque

wrench

HT71780000

Spring compressor

ST35652000

Shock absorber

attachment

NT406

NT144

NT145

Removing

andinstalling brakepiping

a:

10

mm

(0.39

in)

Removing andinstalling coilspring

Fixing strutassembly

Tool name

Description

Commercial

ServiceTools

Equivalent to

GG9431 0000

G)

Flare nutcrows

foot

@

Torque wrench Removing

andinstalling brakepiping

NT360

a:

10

mm

(0.39

in)

RA-2

Page 1611 of 1701

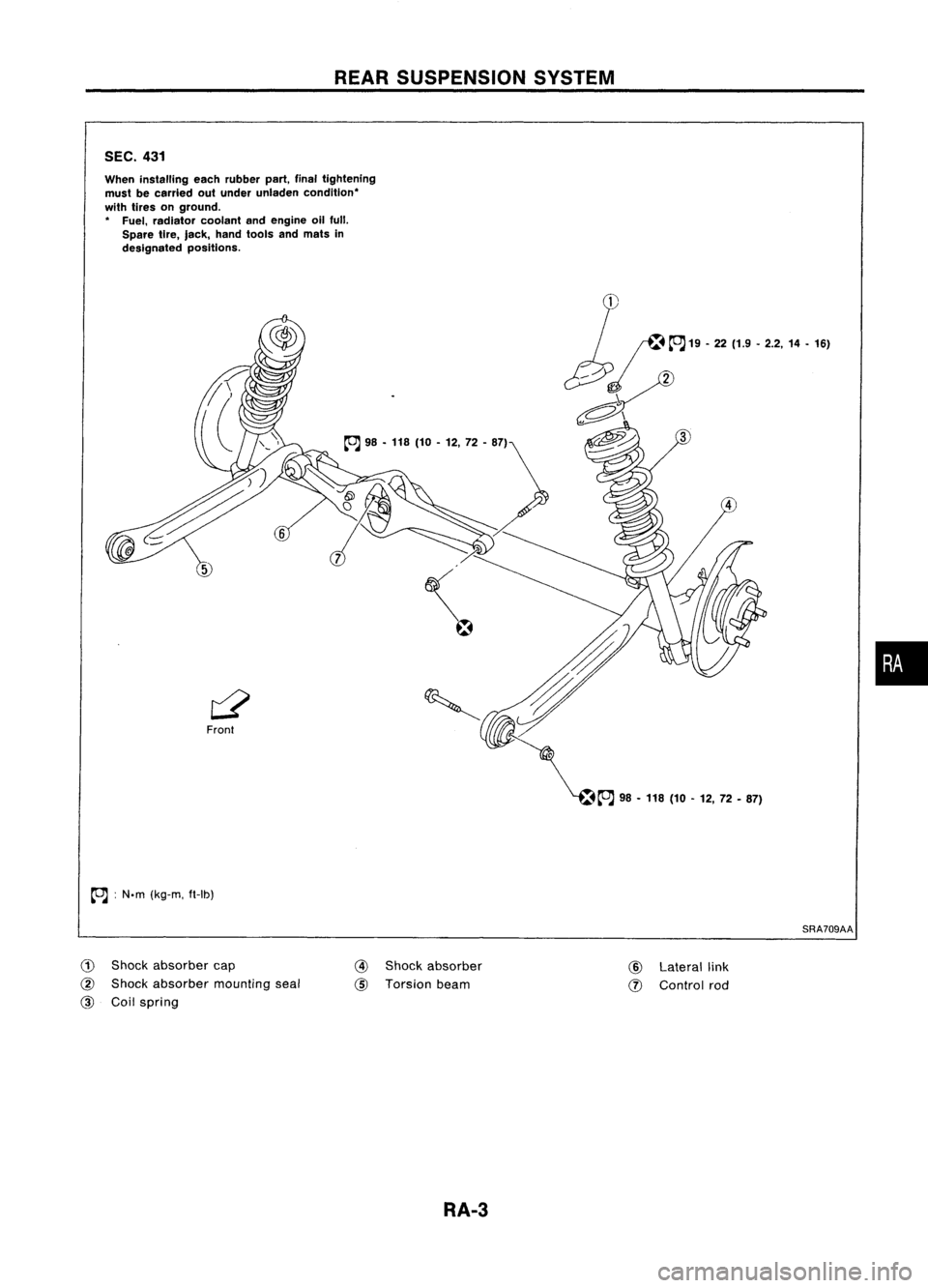

REARSUSPENSION SYSTEM

SEC. 431

When installing eachrubber part,finaltightening

must becarried outunder unladen condition'

with tires onground.

, Fuel, radiator coolantandengine oilfull.

Spare tire,lack, handtools andmats in

designated positions.

~ :N.m (kg-m, fHb)

SRA709AA

•

G)

Shock absorber cap

@

Shock absorber mountingseal

@

Coilspring

@

Shock absorber

@

Torsion beam

RA-3 @

Lateral link

(J)

Control rod

Page 1613 of 1701

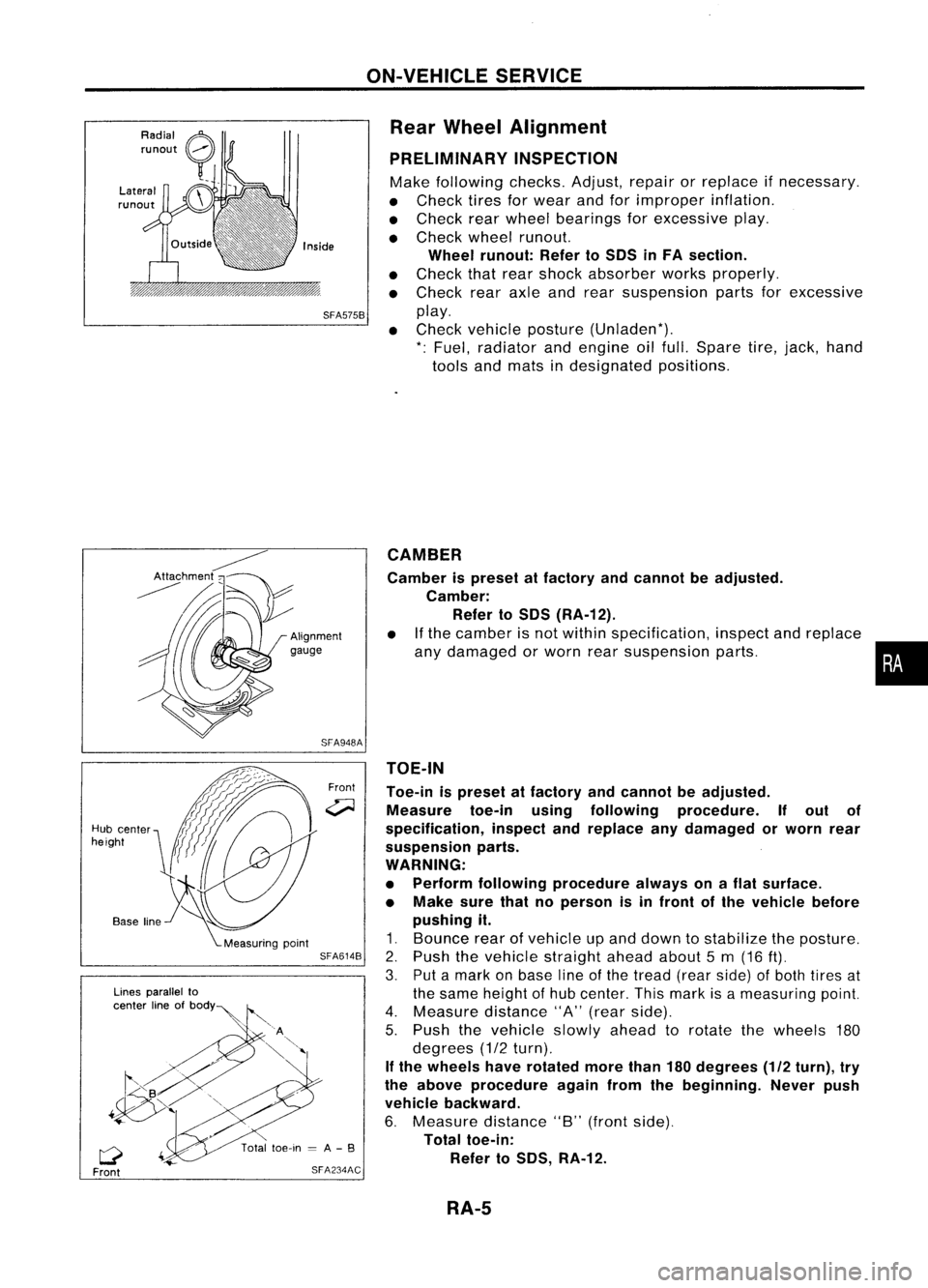

ON-VEHICLESERVICE

Rear Wheel Alignment

PRELIMINARY INSPECTION

Make following checks.Adjust,repairorreplace ifnecessary.

• Check tiresforwear andforimproper inflation.

• Check rearwheel bearings forexcessive play.

• Check wheelrunout.

Wheel runout: RefertoSOS inFA section.

• Check thatrear shock absorber worksproperly.

• Check rearaxleandrear suspension partsforexcessive

SFA575B

play.

• Check vehicle posture (Unladen*).

*: Fuel, radiator andengine oilfull. Spare tire,jack, hand

tools andmats indesignated positions.

•

CAMBER

Camber ispreset atfactory andcannot beadjusted.

Camber: Refer toSOS (RA-12).

• Ifthe camber isnot within specification, inspectandreplace

any damaged orworn rearsuspension parts.

TOE-IN

Toe-in ispreset atfactory andcannot beadjusted.

Measure toe-inusingfollowing procedure. Ifout of

specification, inspectandreplace anydamaged orworn rear

suspension parts.

WARNING:

• Perform following procedure alwaysonaflat surface.

• Make surethatnoperson isin front ofthe vehicle before

pushing it.

1. Bounce rearofvehicle upand down tostabilize theposture.

2. Push thevehicle straight aheadabout5m (16

ft).

3. Putamark onbase lineofthe tread (rearside) ofboth tires at

the same height ofhub center. Thismark isameasuring point.

4. Measure distance"A"(rear side).

5. Push thevehicle slowlyaheadtorotate thewheels 180

degrees (1/2turn).

If the wheels haverotated morethan180degrees (1/2turn), try

the above procedure againfromthebeginning. Neverpush

vehicle backward.

6. Measure distance"B"(front side).

Total toe-in:

Refer toSOS, RA-12.

Front

SFA948A

SFA614B

SFA234AC

Lines

parallel to

center lineofbOdY~

Q

Front

Hub

center

height

RA-5