NISSAN ALMERA N15 1995 Service Manual

Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 691 of 1701

SFA113AASFA114A

FRONT

AXLE

Wheel HubandKnuckle (Conl'd)

3. Separate tie-rodfromknuckle withTool.

Install studnutonstud bolttoprevent damage tostud bolt.

4. Separate driveshaftfrom knuckle bylightly tapping it.Ifit

is hard toremove, useapuller.

Cover bootswithshop towel soas not todamage themwhen

-removing driveshaft.

5. Remove strutlower mounting bolts.

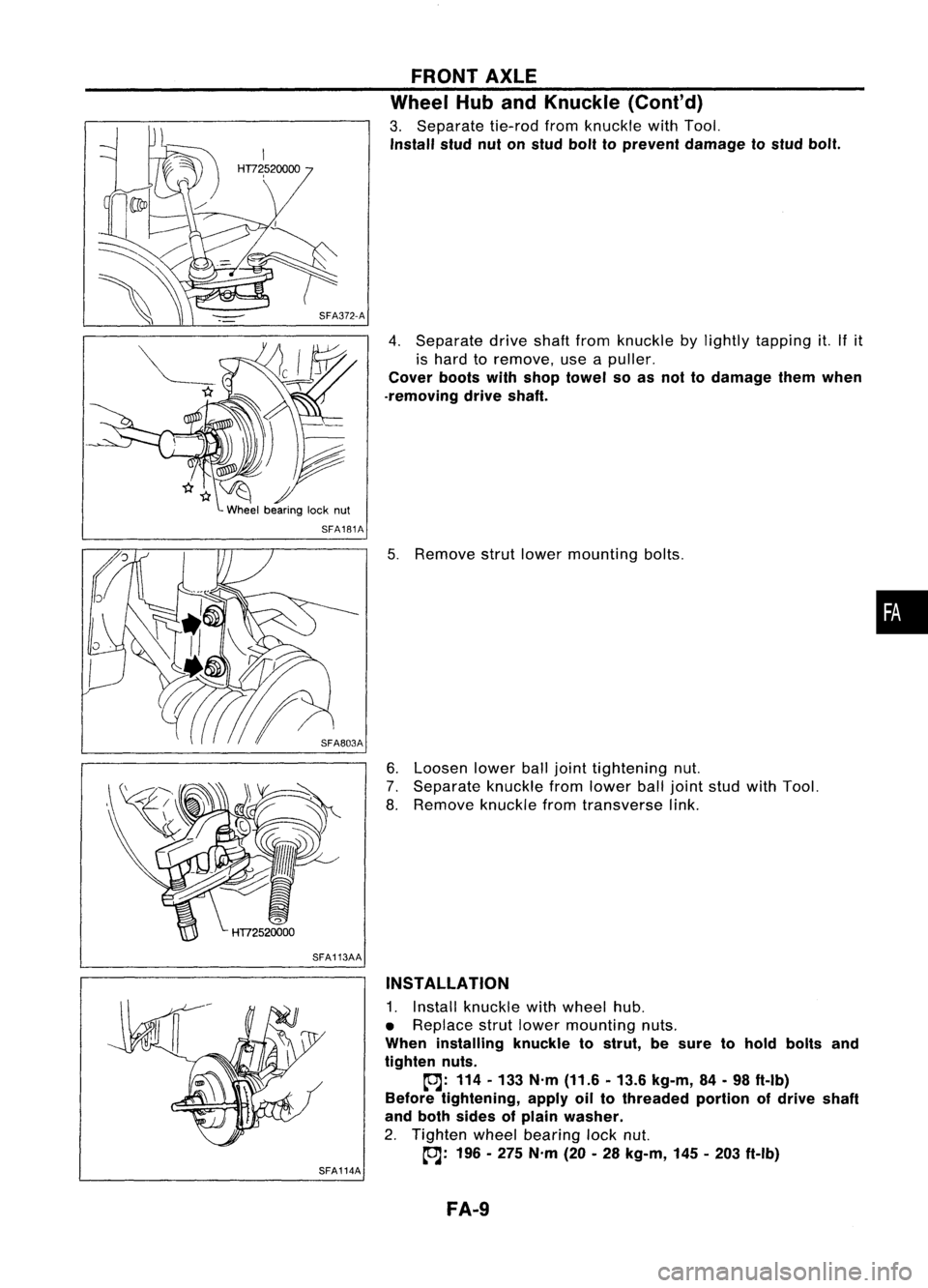

6. Loosen lowerballjoint tightening nut.

7. Separate knucklefromlower balljoint studwithTool.

8. Remove knucklefromtransverse link.

INSTALLATION

1. Install knuckle withwheel hub.

• Replace strutlower mounting nuts.

When installing knuckletostrut, besure tohold bolts and

tighten nuts.

~: 114-133 N'm (11.6 •13.6 kg-m, 84.98 ft.lb)

Before tightening, applyoiltothreaded portionofdrive shaft

and both sides ofplain washer.

2. Tighten wheelbearing locknut.

~: 196-275 N'm (20•28 kg-m, 145-203 ft-Ib)

FA-9

•

Page 692 of 1701

SFA116A

SFA654A

FRONT

AXLE

Wheel HubandKnuckle (Cont'd)

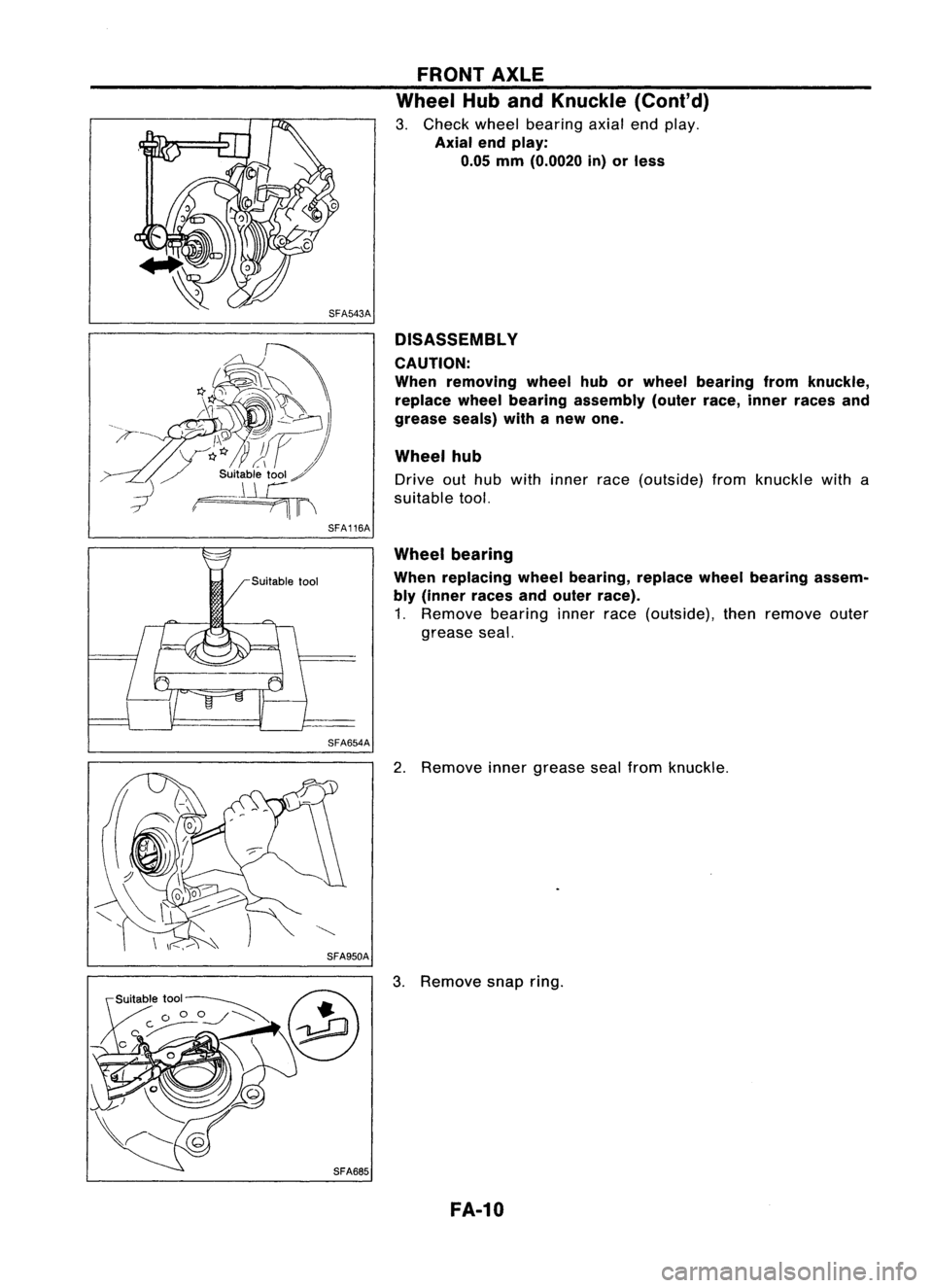

3. Check wheelbearing axialendplay.

Axial endplay:

0.05 mm(0.0020 in)orless

DISASSEMBL Y

CAUTION:

When removing wheelhuborwheel bearing fromknuckle,

replace wheelbearing assembly (outerrace,inner races and

grease seals)withanew one.

Wheel hub

Drive outhub with inner race(outside) fromknuckle witha

suitable tool.

Wheel bearing

When replacing wheelbearing, replacewheelbearing assem-

bly (inner racesandouter race).

1. Remove bearinginnerrace(outside), thenremove outer

grease seal.

2. Remove innergrease sealfrom knuckle.

3. Remove snapring.

FA-10

Page 693 of 1701

SFA496AFRONT

AXLE

Wheel HubandKnuckle (Cont'd)

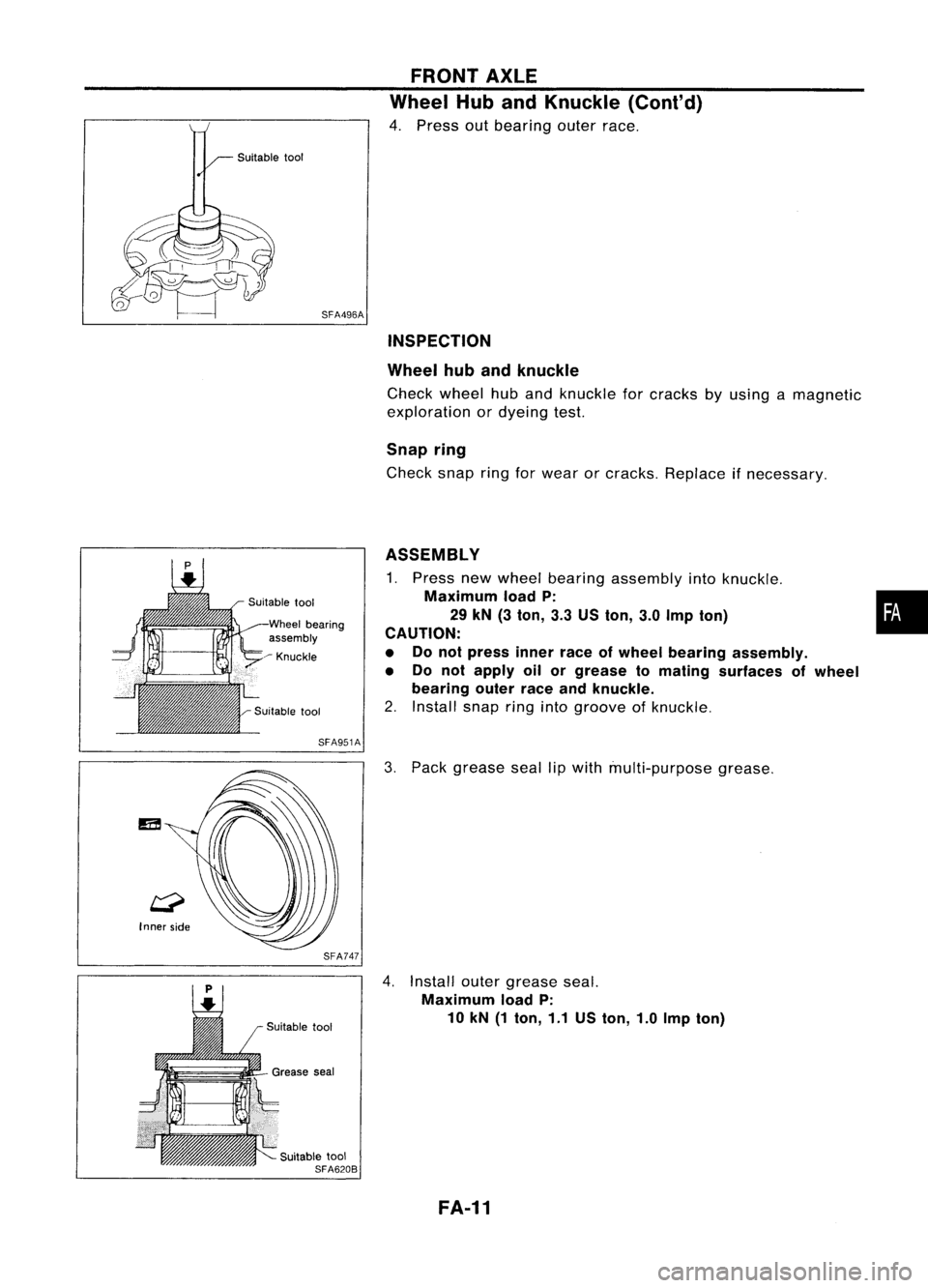

4. Press outbearing outerrace.

INSPECTION

Wheel hubandknuckle

Check wheel huband knuckle forcracks byusing amagnetic

exploration ordyeing test.

Snap ring

Check snapringforwear orcracks. Replace ifnecessary.

Wheel bearing

assembly

~ Knuckle

SFA951A

SFA747

Suitable tool

SFA620B ASSEMBLY

1. Press newwheel bearing assembly intoknuckle.

Maximum loadP: •

29 kN (3ton, 3.3USton, 3.0Imp ton)

i

CAUTION:

• Donot press innerraceofwheel bearing assembly.

• Do not apply oilorgrease tomating surfaces ofwheel

bearing outerraceandknuckle.

2. Install snapringintogroove ofknuckle.

3. Pack grease seallipwith multi-purpose grease.

4. Install outergrease seal.

Maximum loadP:

10 kN (1ton, 1.1USton, 1.0Imp ton)

FA-11

Page 694 of 1701

Wheelbearing

assembly SFA953A

SFA090A

FRONT

AXLE

Wheel HubandKnuckle (Cont'd)

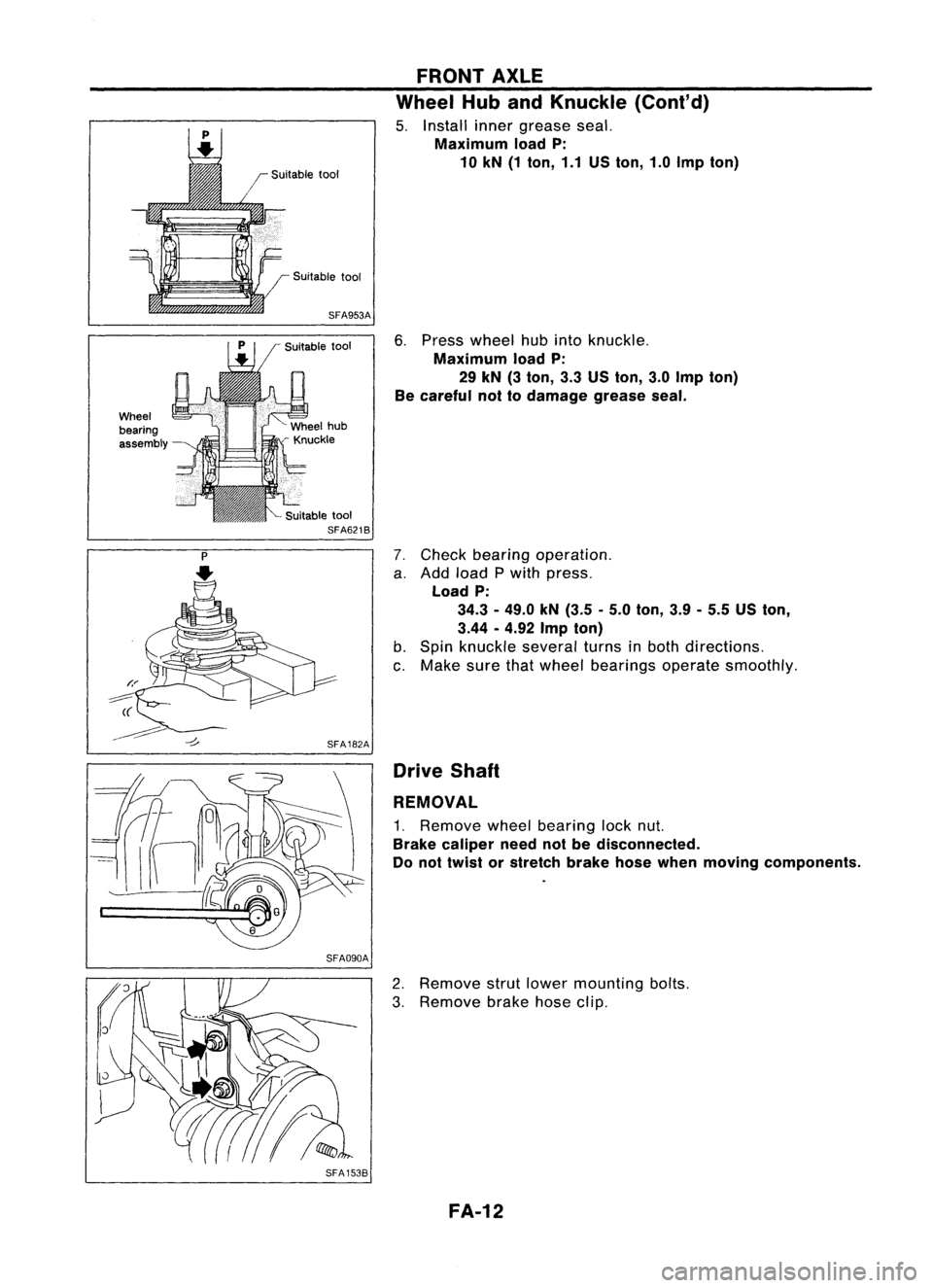

5. Install innergrease seal.

Maximum loadP:

10 kN (1ton, 1.1USton, 1.0Imp ton)

6. Press wheel hubinto knuckle.

Maximum loadP:

29 kN (3ton, 3.3USton, 3.0Imp ton)

Be careful nottodamage greaseseal.

7. Check bearing operation.

a. Add load Pwith press.

Load P:

34.3 -49.0 kN(3.5 -5.0 ton, 3.9-5.5 USton,

3.44 •4.92 Impton)

b. Spin knuckle severalturnsinboth directions.

c. Make surethatwheel bearings operatesmoothly.

Drive Shaft

REMOVAL

1. Remove wheelbearing locknut.

Brake caliper neednotbedisconnected.

Do not twist orstretch brakehosewhen moving components.

SFA1538

2.

Remove strutlower mounting bolts.

3. Remove brakehoseclip.

FA-12

Page 695 of 1701

AfTmodel

SFA730FRONT

AXLE

Drive Shaft(Coni' d)

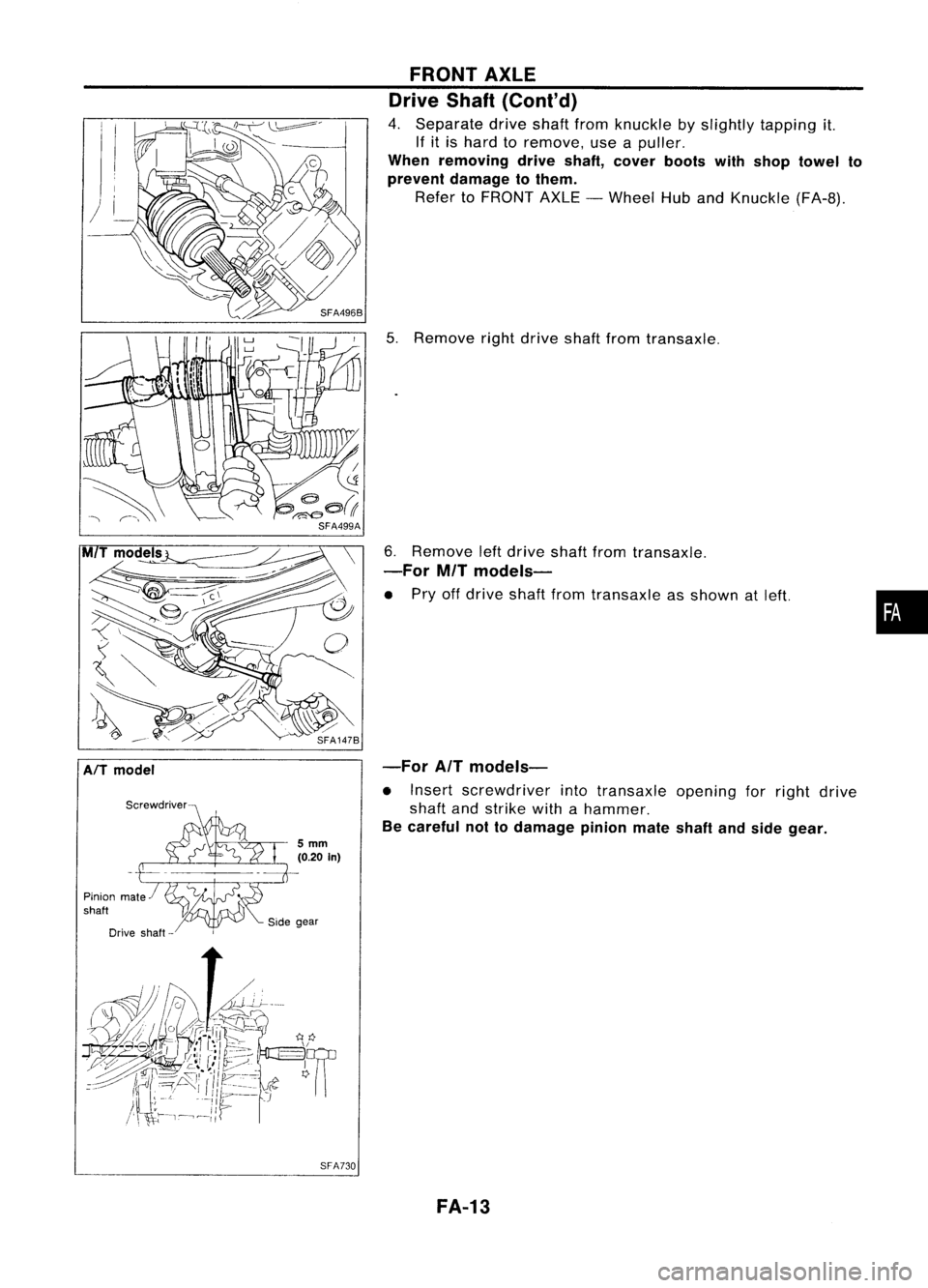

4. Separate driveshaftfromknuckle byslightly tapping it.

If it is hard toremove, useapuller.

When removing driveshaft, cover bootswithshop towel to

prevent damage tothem.

Refer toFRONT AXLE-Wheel HubandKnuckle (FA-8).

5. Remove rightdrive shaftfromtransaxle.

6. Remove leftdrive shaftfromtransaxle.

-For MITmodels-

• Pry offdrive shaftfromtransaxle asshown atleft.

-For AITmodels-

• Insert screwdriver intotransaxle openingforright drive

shaft andstrike withahammer.

Be careful nottodamage pinionmateshaftandside gear.

FA-13

•

Page 696 of 1701

RH

SFA394BB

FRONT

AXLE

Drive Shaft(Cont'd)

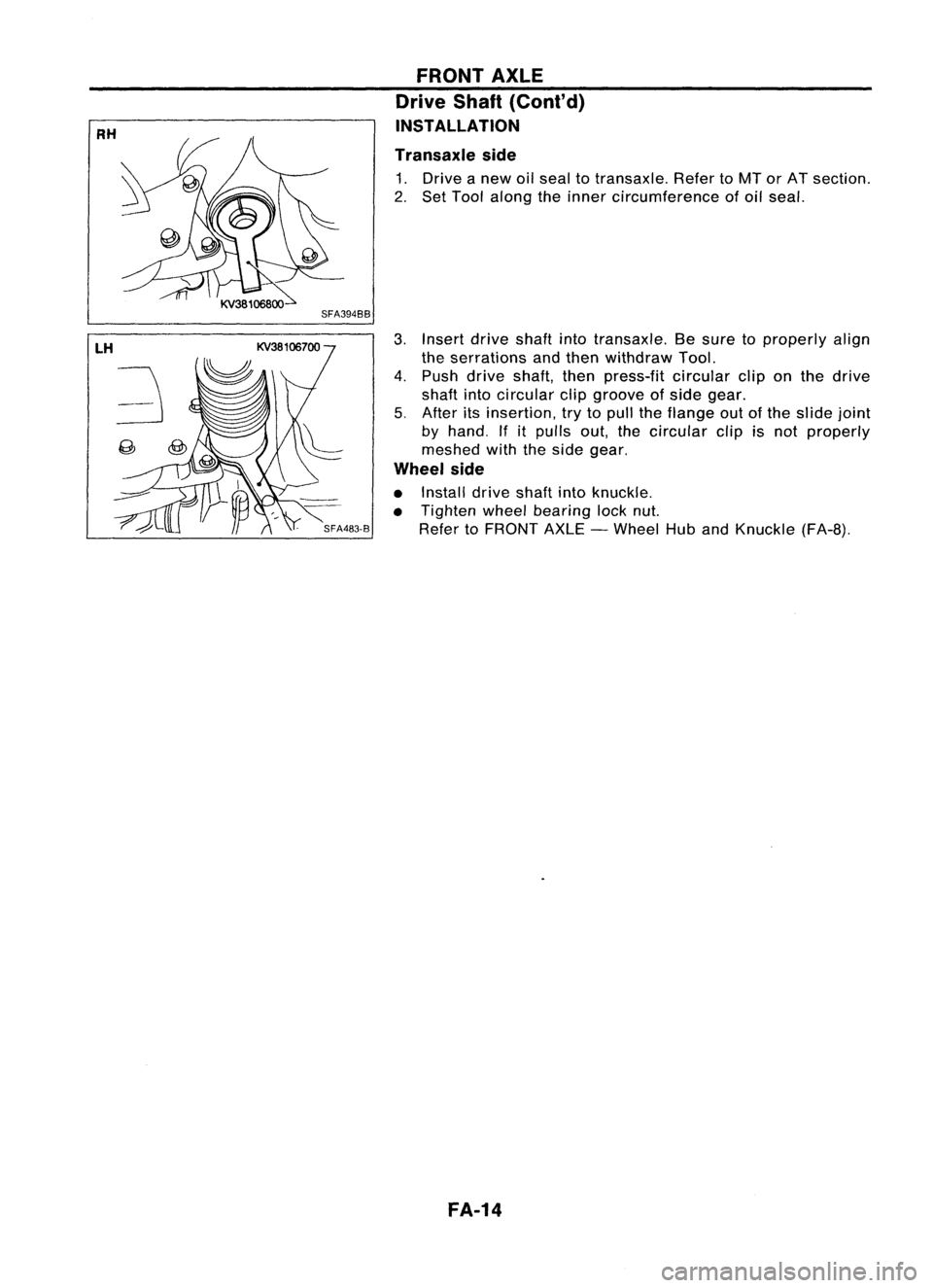

INSTALLATION

Transaxle side

1. Drive anew oilseal totransaxle. RefertoMT orAT section.

2. Set Tool along theinner circumference ofoil seal.

3. Insert driveshaft

into

transaxle. Besure toproperly align

the serrations andthen withdraw Tool.

4. Push drive shaft, thenpress-fit circularcliponthe drive

shaft intocircular clipgroove ofside gear.

5. After itsinsertion, trytopull theflange outofthe slide joint

by hand. Ifitpulls out,the

circular

clipisnot properly

meshed withtheside gear.

Wheel side

• Install driveshaftintoknuckle.

• Tighten wheelbearing locknut.

Refer toFRONT AXLE-Wheel HubandKnuckle (FA-B).

FA-14

Page 697 of 1701

FRONTAXLE

Drive Shaft(Cont'd)

COMPONENTS

ZF90/TS79Ctypeleftside

Diesel engine models only

•

~

Transaxle

side

r-J\

Transaxle

~side

o

p

,~

Wheel

side(ZF80, ZF90type)

Wheel ~

side

Wheel side

8

.~

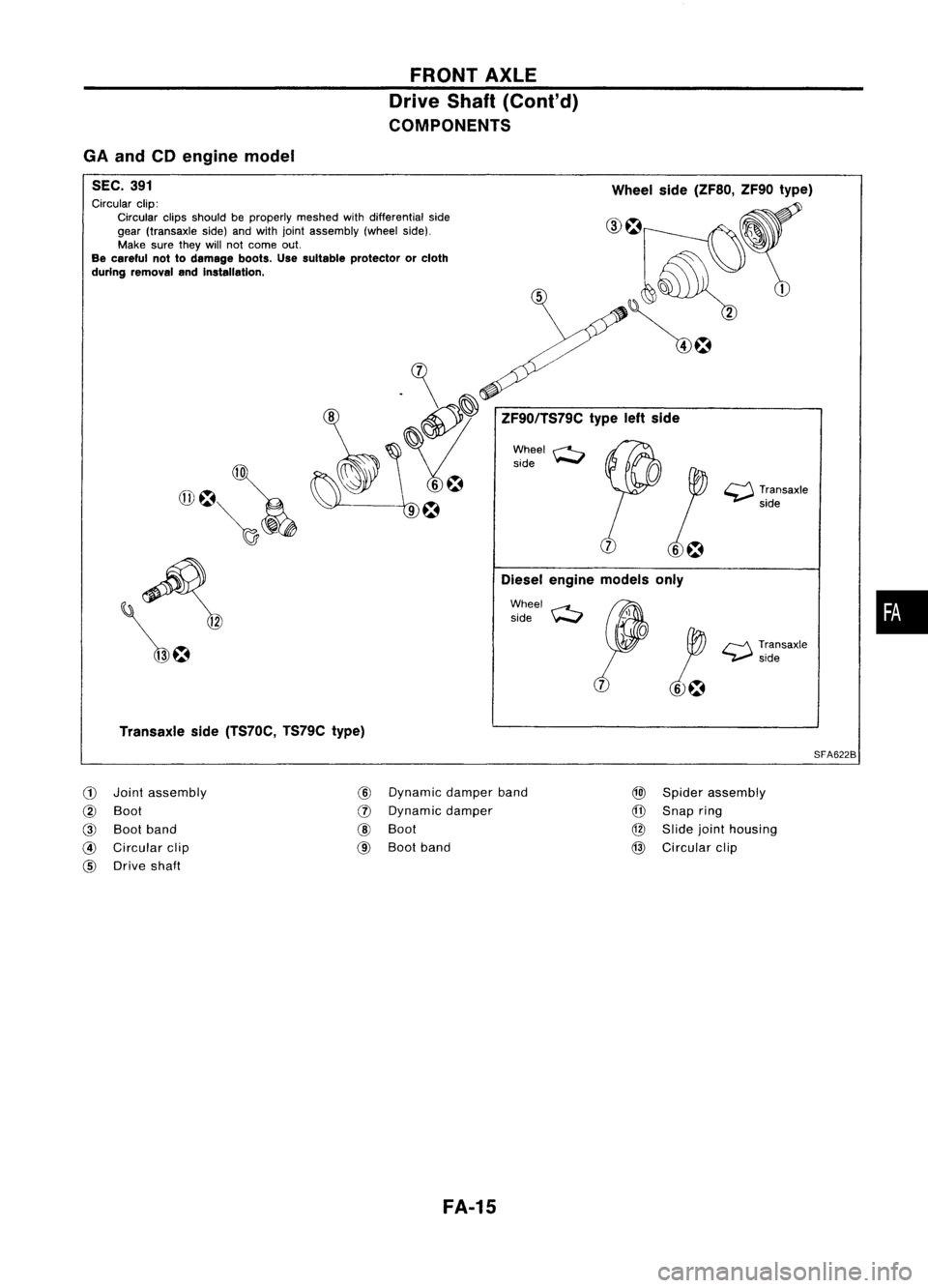

\~

Circular

clip:

Circular clipsshould beproperly meshedwithdifferential side

gear (transaxle side)andwith joint assembly (wheelside).

Make suretheywillnotcome out.

Be careful nottodamage boots.Usesuitable protector orcloth

during removal andinstallation.

GA

and CDengine model

SEC. 391

Transaxle side(TS70C, TS79Ctype)

SFA622B

CD

Joint

assembly

@

Dynamic damperband

@)

Spider assembly

@

Boot

(J)

Dynamic damper

@

Snap ring

@

Boot band

@

Boot

@

Slide jointhousing

@

Circular clip

@

Boot band

@

Circular clip

@

Drive shaft

FA-15

Page 698 of 1701

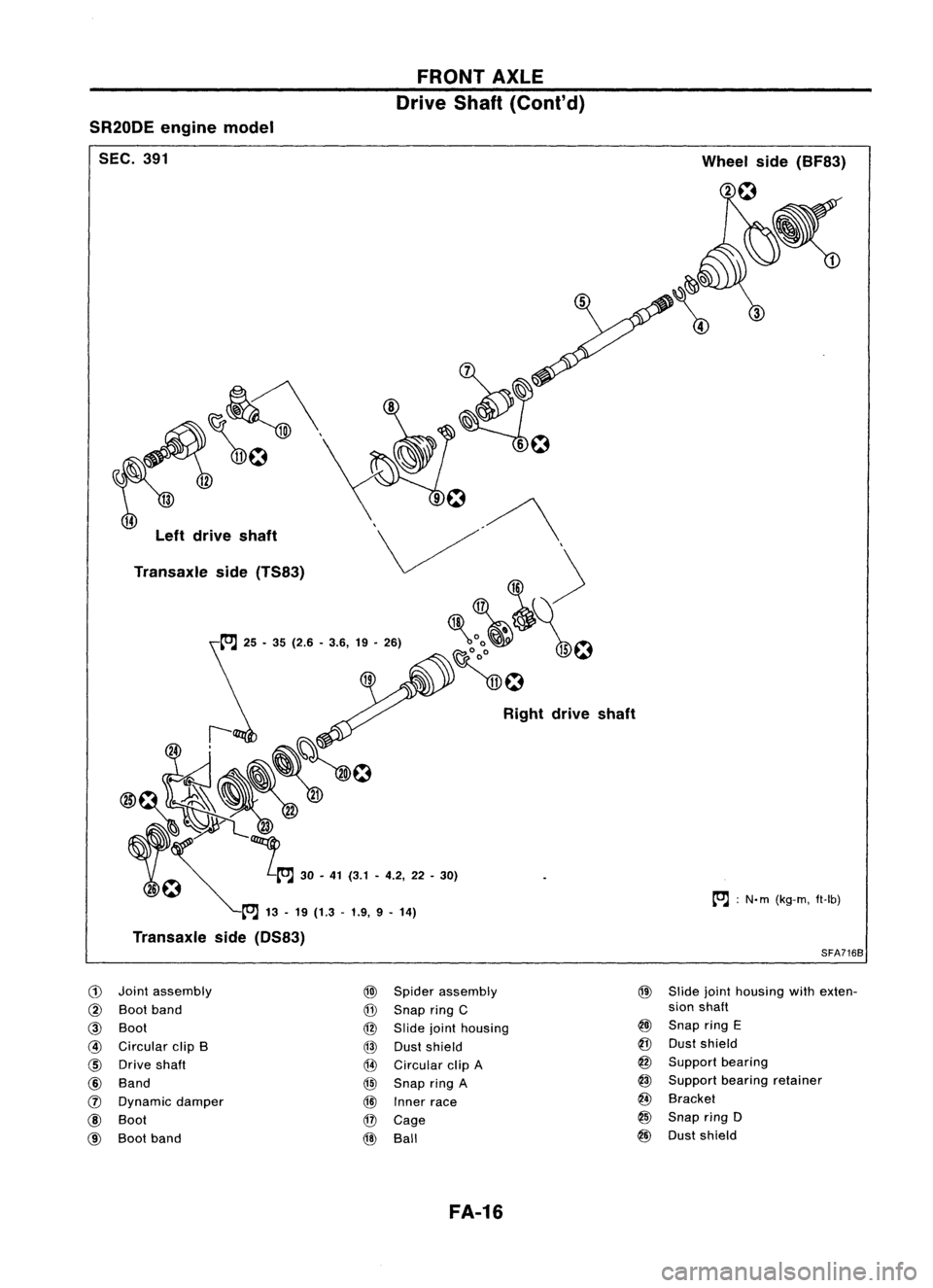

~RONTAXLE

Drive Sh

f

a t(Cont'd)

Wheelside(BF83)

20

tOJ :

N-m (kg-m,

ft-Ib)

SFA716B

@

Slide jointh'

S'

ouslng,

Ion shaft withexten-

@J

Snap ringE

@

Dustshield

@

S

@

upport bearing

Support bearin

@

Bracket gretainer

@

Snap ring0

@

Dust shield

Right

driveshaft

@l

S'd

@

pierassembly

Snap ringC

@

Slide jointh.

13'

0 ouslng

\!'V

ustshield

@

Circular clipA

@

Snap ringA

@l

Inner race

@

Cage

@

Ball

@~ti~~o

f:~~ 2!~ ~

30.41

(3.1.4.2,22 -301

T ~

13-19 (13

ransaxle side(0 .-

1.9, 9•

14)

S83)

~'Vz~

r:~~

@O'

Left drive h

s aft

Transa I

x

e side (TS83)

tOJ

25.35 (26

.

•3.6,

19.26)

SR20DE

eng-

me model

SEC. 391

G)

Jo'

t

In

assembly

@

Boot band

@

Boot

@

Circular clipB

@

Drive shaft

@

Band

tJ)

Dynamic dam

@

Boot per

@

Boot band

FA-16

Page 699 of 1701

SFA963FRONT

AXLE

Drive Shaft(Cont'd)

OISASSEMBL Y

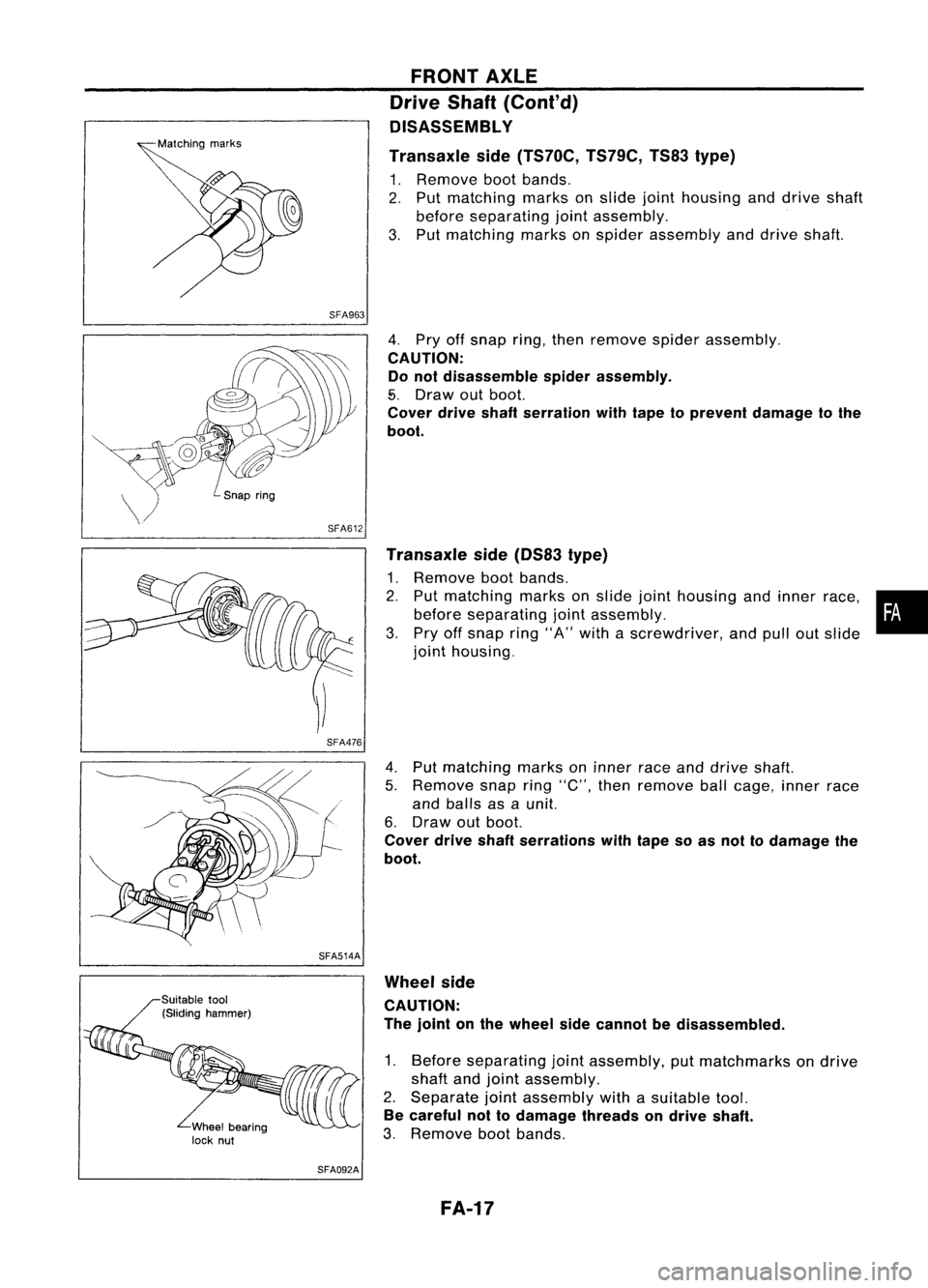

Transaxle side(TS70C, TS79C,TS83type)

1. Remove bootbands.

2. Put matching marksonslide jointhousing anddrive shaft

before separating jointassembly.

3. Put matching marksonspider assembly anddrive shaft.

SFA476

SFA514A

SFA092A

4.

Pry offsnap ring,thenremove spiderassembly.

CAUTION: Do not disassemble spiderassembly.

5. Draw outboot.

Cover driveshaftserration withtape toprevent damage tothe

boot.

Transaxle side(OS83 type)

1. Remove bootbands.

2. Put matching marksonslide jointhousing andinner race, •

before separating jointassembly.

i

3. Pry offsnap ring"A"with ascrewdriver, andpulloutslide

joint housing.

4. Put matching marksoninner raceanddrive shaft.

5. Remove snapring"C", then remove ballcage, innerrace

and balls asaunit.

6. Draw outboot.

Cover driveshaftserrations withtape soas not todamage the

boot.

Wheel side

CAUTION:

The joint onthe wheel sidecannot bedisassembled.

1. Before separating jointassembly, putmatchmarks ondrive

shaft andjoint assembly.

2. Separate jointassembly withasuitable tool.

Be careful nottodamage threadsondrive shaft.

3. Remove bootbands.

FA-17

Page 700 of 1701

SFA692FRONT

AXLE

Drive Shaft(Cont'd)

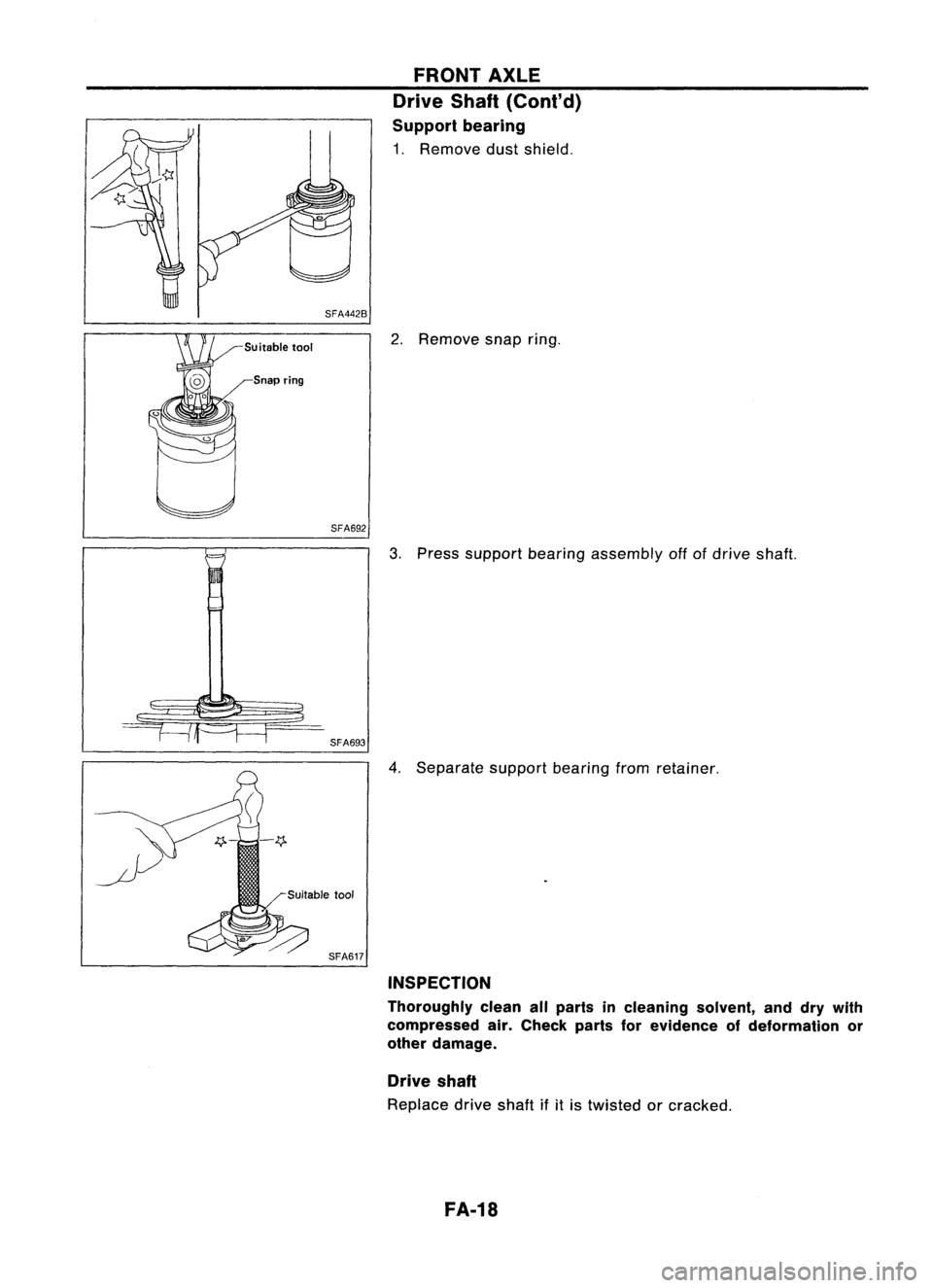

Support bearing

1. Remove dustshield.

2. Remove snapring.

3. Press support bearingassembly offofdrive shaft.

4. Separate supportbearingfromretainer.

INSPECTION

Thoroughly cleanallparts incleaning solvent,anddrywith

compressed air.Check partsforevidence ofdeformation or

other damage.

Drive shaft

Replace driveshaftifitis twisted orcracked.

FA-18