NISSAN ALMERA N16 2003 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 2003, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2003Pages: 3189, PDF Size: 54.76 MB

Page 2051 of 3189

TROUBLE DIAGNOSIS

ATC-71

C

D

E

F

G

H

I

K

L

MA

B

AT C

In the most extreme case (very low ambient) the blower starting delay will be 150 seconds as described

above. After this delay, the blower will operate at low speed until the engine coolant temperature rises above

56°C (133°F), at which time the blower speed will increase to the objective speed.

Start Up From Usual or HOT SOAK Condition (Automatic mode)

The blower will begin operation momentarily after the A/C button is pushed. The blower speed will gradually

rise to the objective speed over a time period of 3 seconds or less (actual time depends on the objective

blower speed).

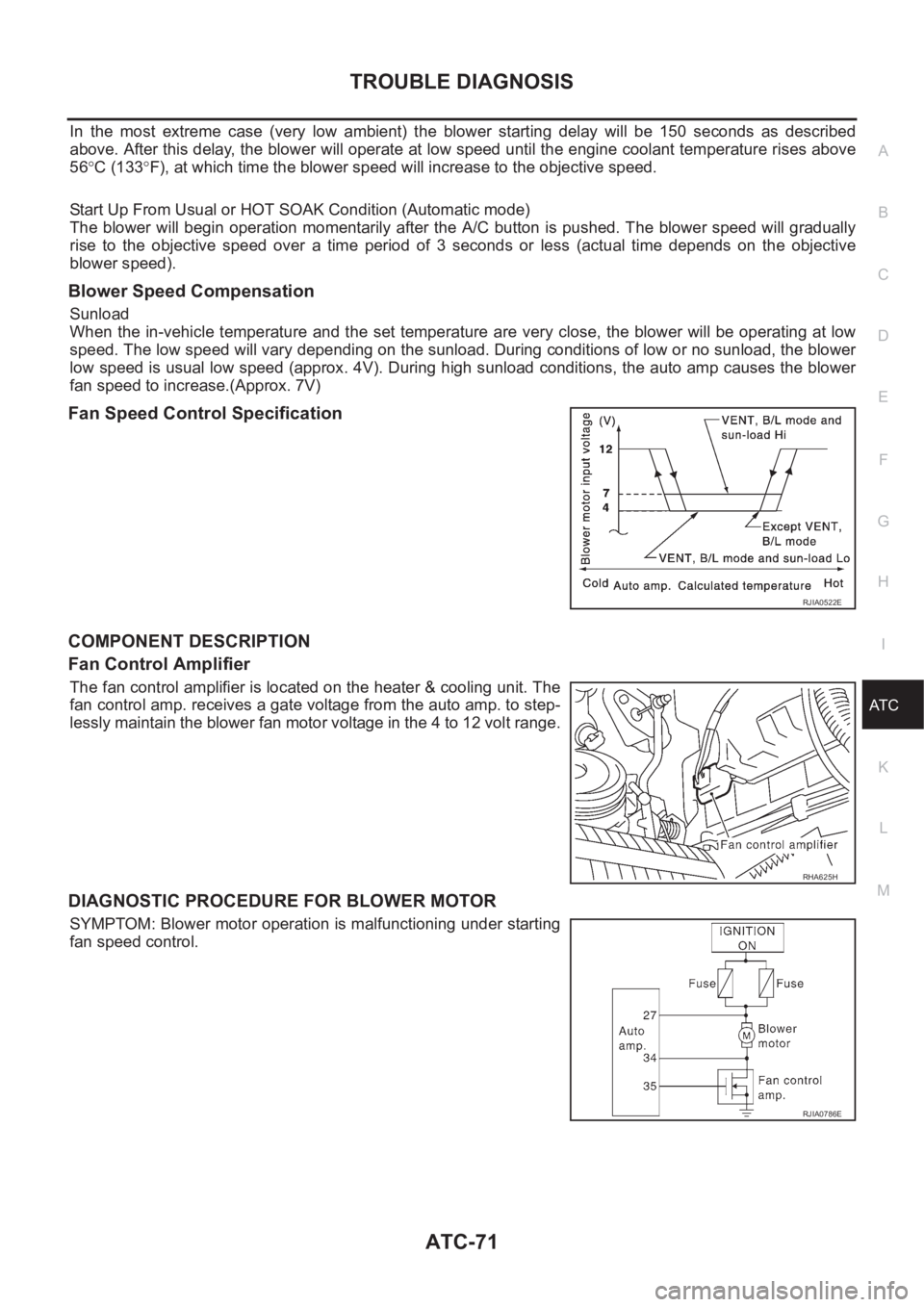

Blower Speed Compensation

Sunload

When the in-vehicle temperature and the set temperature are very close, the blower will be operating at low

speed. The low speed will vary depending on the sunload. During conditions of low or no sunload, the blower

low speed is usual low speed (approx. 4V). During high sunload conditions, the auto amp causes the blower

fan speed to increase.(Approx. 7V)

Fan Speed Control Specification

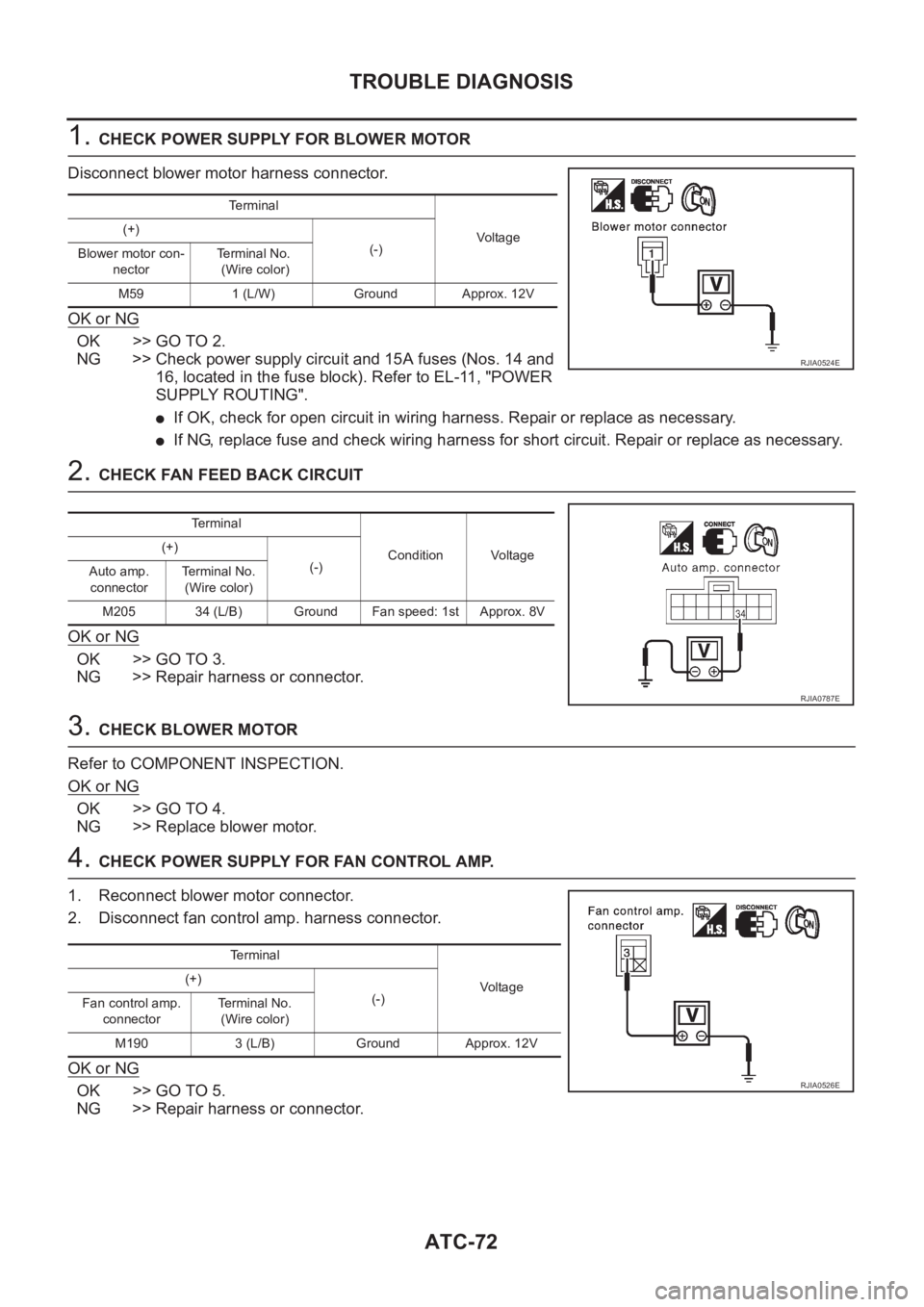

COMPONENT DESCRIPTION

Fan Control Amplifier

The fan control amplifier is located on the heater & cooling unit. The

fan control amp. receives a gate voltage from the auto amp. to step-

lessly maintain the blower fan motor voltage in the 4 to 12 volt range.

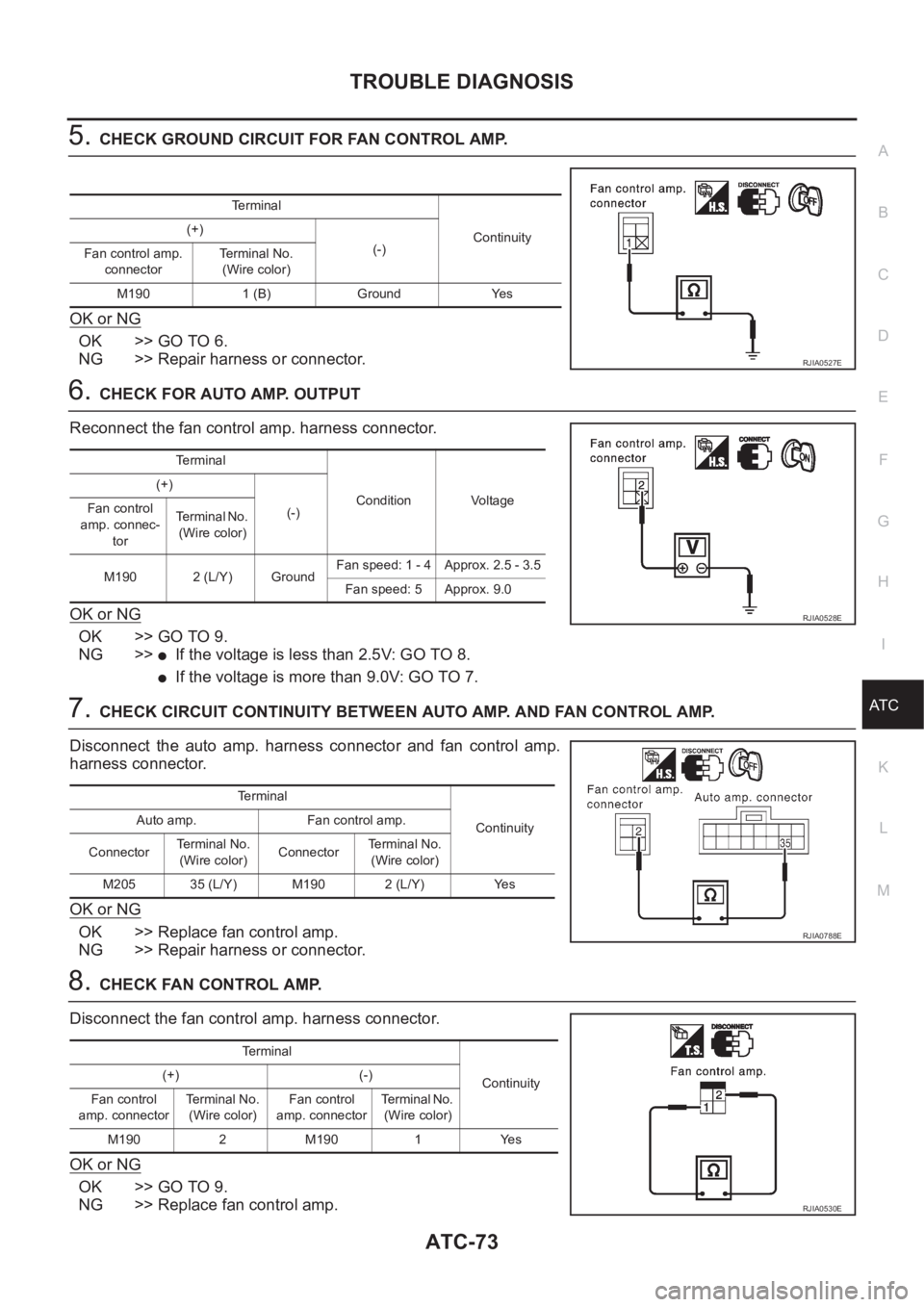

DIAGNOSTIC PROCEDURE FOR BLOWER MOTOR

SYMPTOM: Blower motor operation is malfunctioning under starting

fan speed control.

RJIA0522E

RHA625H

RJIA0786E

Page 2052 of 3189

ATC-72

TROUBLE DIAGNOSIS

1. CHECK POWER SUPPLY FOR BLOWER MOTOR

Disconnect blower motor harness connector.

OK or NG

OK >> GO TO 2.

NG >> Check power supply circuit and 15A fuses (Nos. 14 and

16, located in the fuse block). Refer to EL-11, "POWER

SUPPLY ROUTING".

●If OK, check for open circuit in wiring harness. Repair or replace as necessary.

●If NG, replace fuse and check wiring harness for short circuit. Repair or replace as necessary.

2. CHECK FAN FEED BACK CIRCUIT

OK or NG

OK >> GO TO 3.

NG >> Repair harness or connector.

3. CHECK BLOWER MOTOR

Refer to COMPONENT INSPECTION.

OK or NG

OK >> GO TO 4.

NG >> Replace blower motor.

4. CHECK POWER SUPPLY FOR FAN CONTROL AMP.

1. Reconnect blower motor connector.

2. Disconnect fan control amp. harness connector.

OK or NG

OK >> GO TO 5.

NG >> Repair harness or connector.

Terminal

Vo l ta g e (+)

(-)

Blower motor con-

nectorTerminal No.

(Wire color)

M59 1 (L/W) Ground Approx. 12V

RJIA0524E

Te r m i n a l

Condition Voltage (+)

(-)

Auto amp.

connectorTerminal No.

(Wire color)

M205 34 (L/B) Ground Fan speed: 1st Approx. 8V

RJIA0787E

Te r m i n a l

Voltag e (+)

(-)

Fan control amp.

connectorTerminal No.

(Wire color)

M190 3 (L/B) Ground Approx. 12V

RJIA0526E

Page 2053 of 3189

TROUBLE DIAGNOSIS

ATC-73

C

D

E

F

G

H

I

K

L

MA

B

AT C

5.CHECK GROUND CIRCUIT FOR FAN CONTROL AMP.

OK or NG

OK >> GO TO 6.

NG >> Repair harness or connector.

6.CHECK FOR AUTO AMP. OUTPUT

Reconnect the fan control amp. harness connector.

OK or NG

OK >> GO TO 9.

NG >>

●If the voltage is less than 2.5V: GO TO 8.

●If the voltage is more than 9.0V: GO TO 7.

7.CHECK CIRCUIT CONTINUITY BETWEEN AUTO AMP. AND FAN CONTROL AMP.

Disconnect the auto amp. harness connector and fan control amp.

harness connector.

OK or NG

OK >> Replace fan control amp.

NG >> Repair harness or connector.

8.CHECK FAN CONTROL AMP.

Disconnect the fan control amp. harness connector.

OK or NG

OK >> GO TO 9.

NG >> Replace fan control amp.

Te r m i n a l

Continuity (+)

(-)

Fan control amp.

connectorTerminal No.

(Wire color)

M190 1 (B) Ground Yes

RJIA0527E

Terminal

Condition Voltage (+)

(-) Fan control

amp. connec-

torTe r m i n a l N o .

(Wire color)

M190 2 (L/Y) GroundFan speed: 1 - 4 Approx. 2.5 - 3.5

Fan speed: 5 Approx. 9.0

RJIA0528E

Terminal

Continuity Auto amp. Fan control amp.

ConnectorTerminal No.

(Wire color)Connector Terminal No.

(Wire color)

M205 35 (L/Y) M190 2 (L/Y) Yes

RJIA0788E

Terminal

Continuity (+) (-)

Fan control

amp. connectorTe r m i n a l N o .

(Wire color)Fan control

amp. connectorTerminal No.

(Wire color)

M190 2 M190 1 Yes

RJIA0530E

Page 2054 of 3189

ATC-74

TROUBLE DIAGNOSIS

9. CHECK CIRCUIT CONTINUITY BETWEEN AUTO AMP. AND FAN CONTROL AMP.

OK or NG

OK >> Replace auto amp.

NG >> Repair harness or connector.

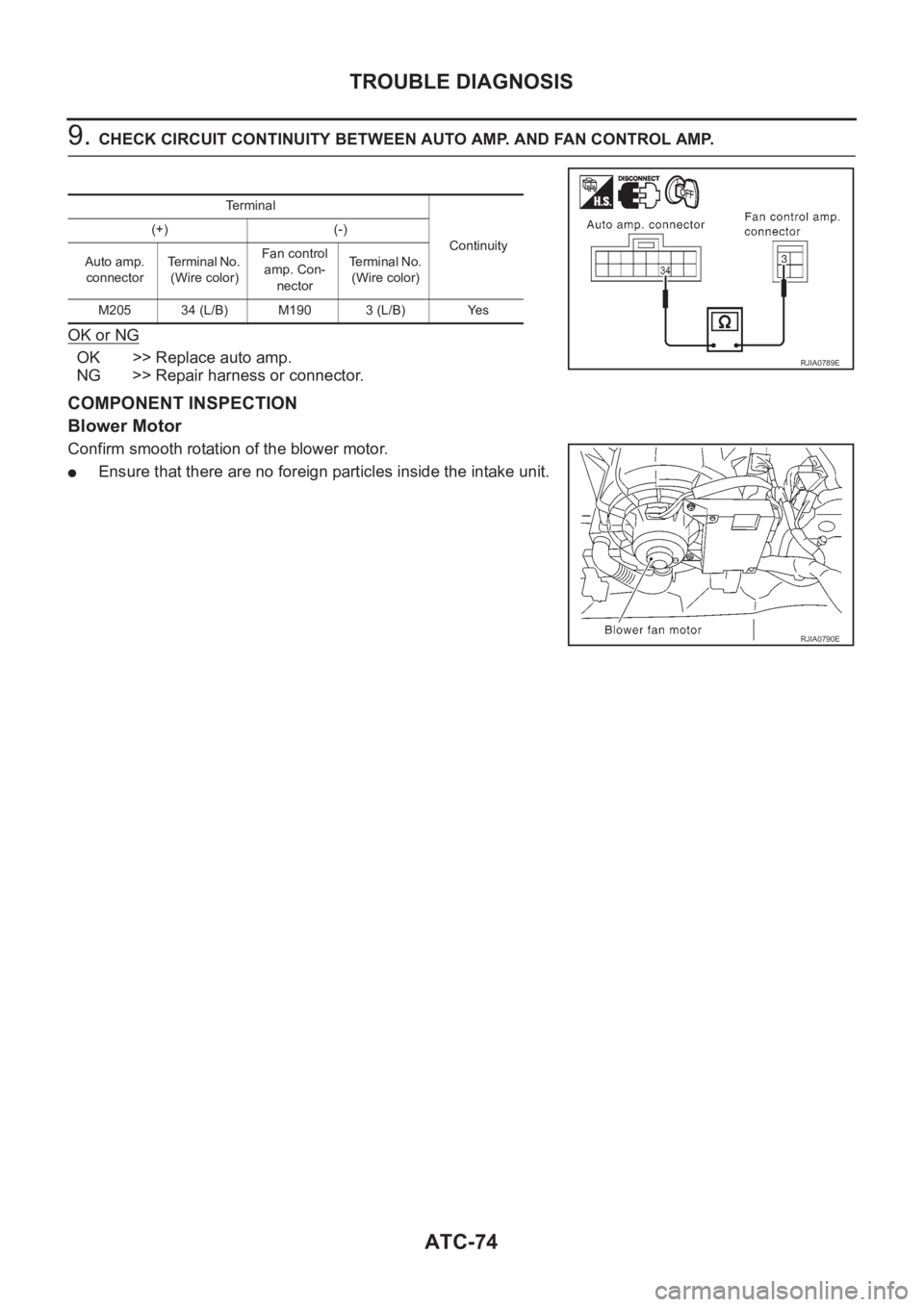

COMPONENT INSPECTION

Blower Motor

Confirm smooth rotation of the blower motor.

●Ensure that there are no foreign particles inside the intake unit.

Te r m i n a l

Continuity (+) (-)

Auto amp.

connectorTerminal No.

(Wire color)Fan control

amp. Con-

nectorTe r m i n a l N o .

(Wire color)

M205 34 (L/B) M190 3 (L/B) Yes

RJIA0789E

RJIA0790E

Page 2055 of 3189

TROUBLE DIAGNOSIS

ATC-75

C

D

E

F

G

H

I

K

L

MA

B

AT C

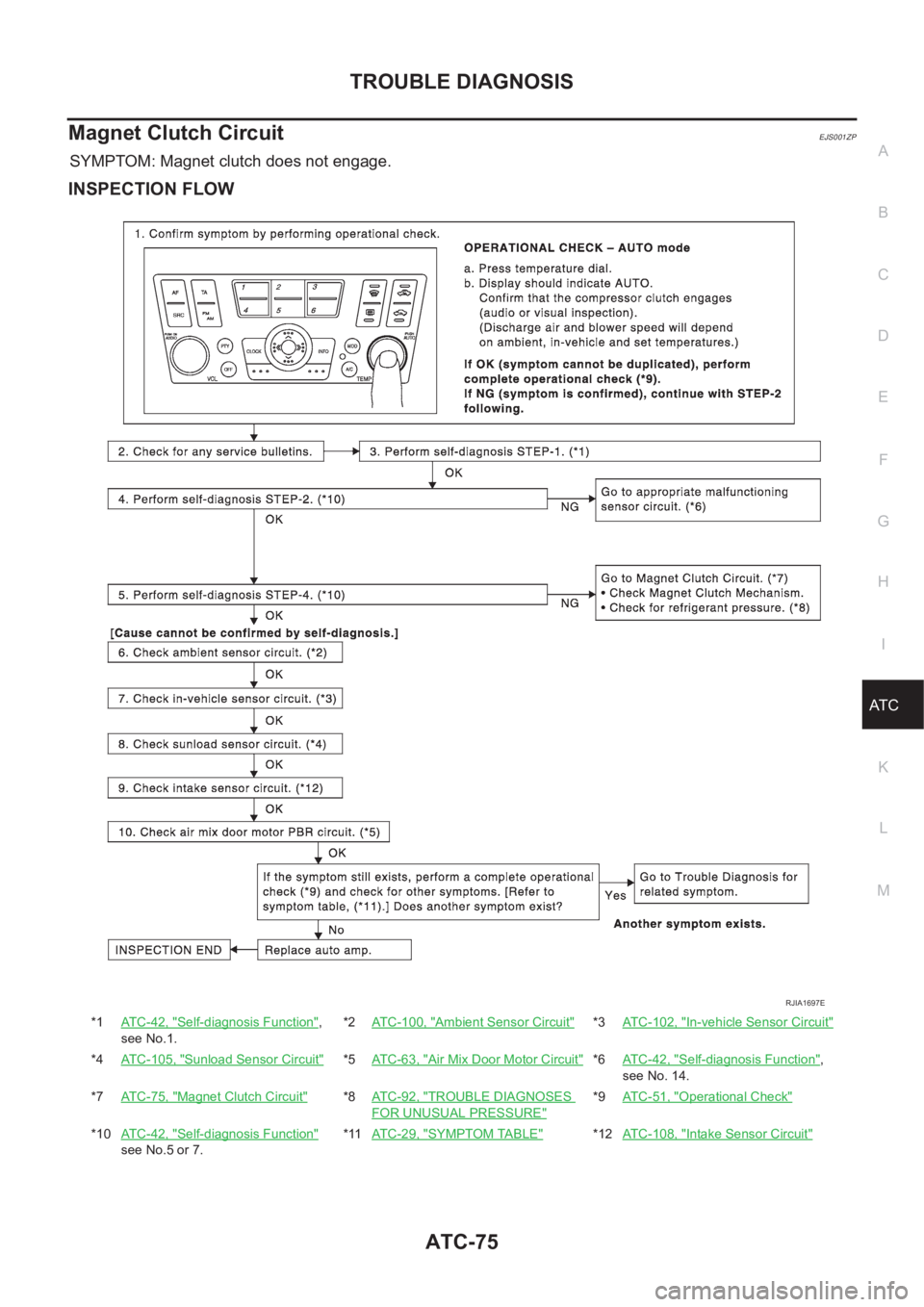

Magnet Clutch CircuitEJS001ZP

SYMPTOM: Magnet clutch does not engage.

INSPECTION FLOW

*1ATC-42, "Self-diagnosis Function",

see No.1.*2ATC-100, "Ambient Sensor Circuit"*3ATC-102, "In-vehicle Sensor Circuit"

*4ATC-105, "Sunload Sensor Circuit"*5AT C - 6 3 , "Air Mix Door Motor Circuit"*6ATC-42, "Self-diagnosis Function",

see No. 14.

*7ATC-75, "

Magnet Clutch Circuit"*8AT C - 9 2 , "TROUBLE DIAGNOSES

FOR UNUSUAL PRESSURE"

*9ATC-51, "Operational Check"

*10ATC-42, "Self-diagnosis Function"

see No.5 or 7.*11AT C - 2 9 , "

SYMPTOM TABLE"*12ATC-108, "Intake Sensor Circuit"

RJIA1697E

Page 2056 of 3189

ATC-76

TROUBLE DIAGNOSIS

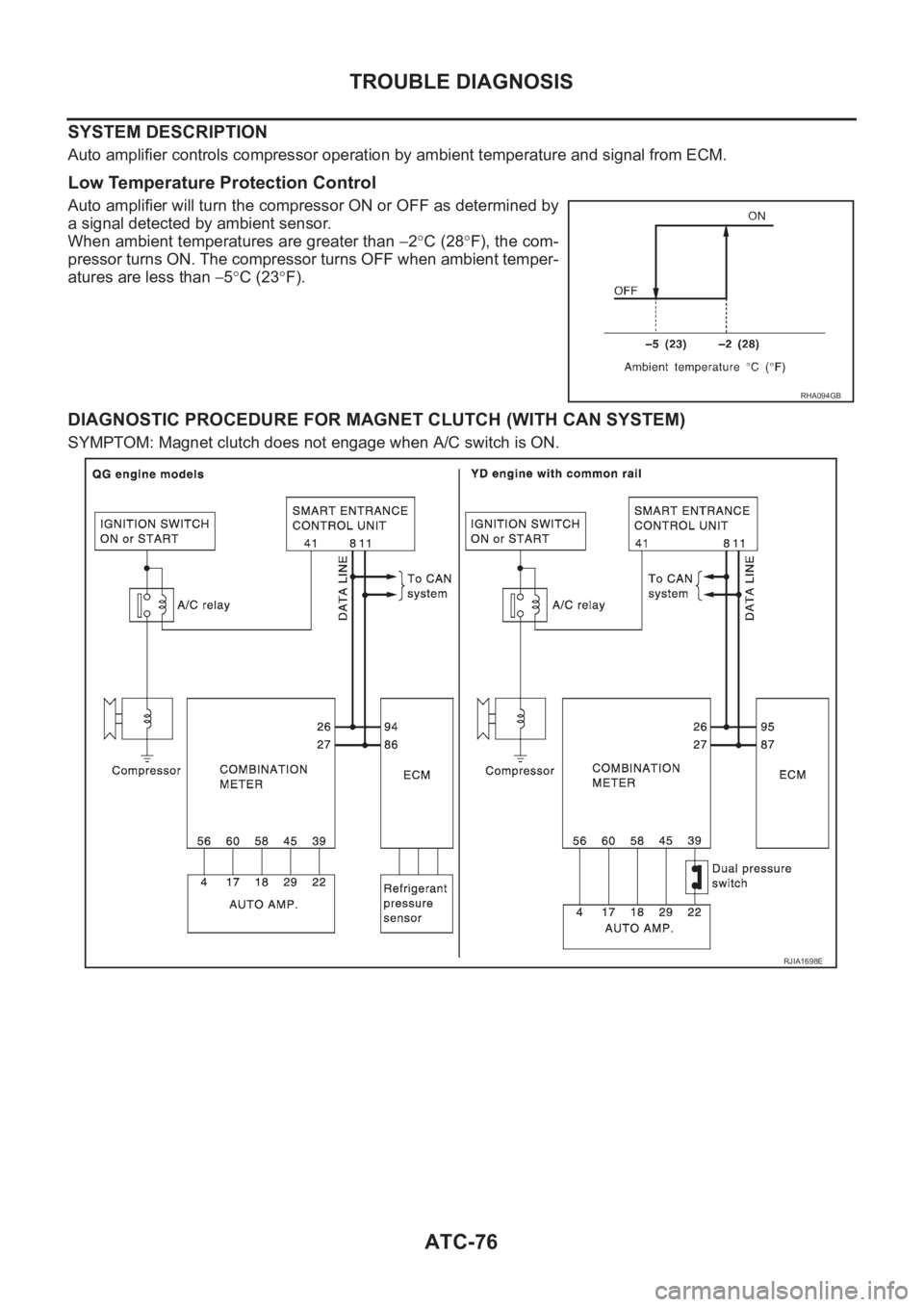

SYSTEM DESCRIPTION

Auto amplifier controls compressor operation by ambient temperature and signal from ECM.

Low Temperature Protection Control

Auto amplifier will turn the compressor ON or OFF as determined by

a signal detected by ambient sensor.

When ambient temperatures are greater than −2°C (28°F), the com-

pressor turns ON. The compressor turns OFF when ambient temper-

atures are less than −5°C (23°F).

DIAGNOSTIC PROCEDURE FOR MAGNET CLUTCH (WITH CAN SYSTEM)

SYMPTOM: Magnet clutch does not engage when A/C switch is ON.

RHA094GB

RJIA1698E

Page 2057 of 3189

TROUBLE DIAGNOSIS

ATC-77

C

D

E

F

G

H

I

K

L

MA

B

AT C

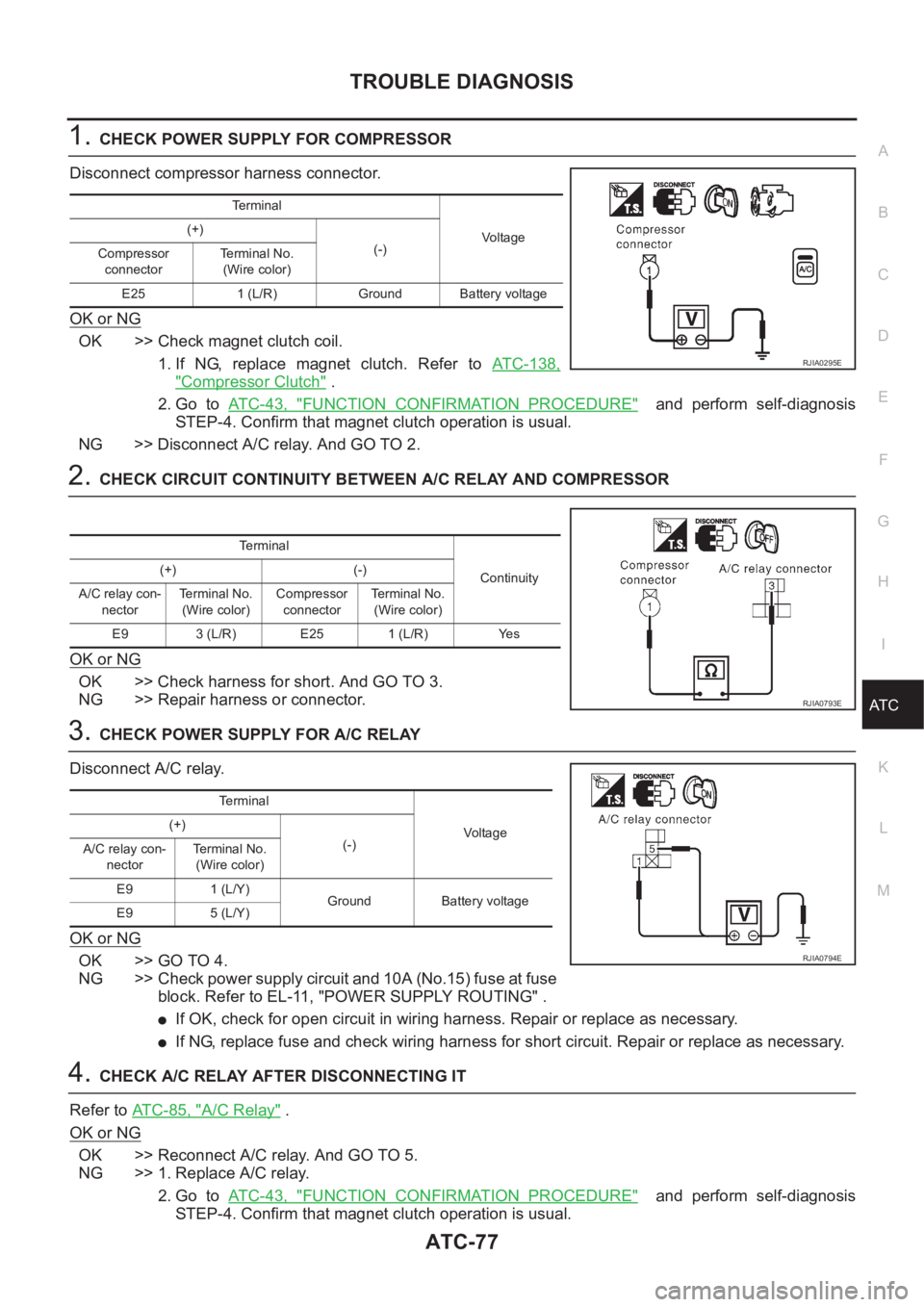

1.CHECK POWER SUPPLY FOR COMPRESSOR

Disconnect compressor harness connector.

OK or NG

OK >> Check magnet clutch coil.

1. If NG, replace magnet clutch. Refer to ATC-138,

"Compressor Clutch" .

2. Go to AT C - 4 3 , "

FUNCTION CONFIRMATION PROCEDURE" and perform self-diagnosis

STEP-4. Confirm that magnet clutch operation is usual.

NG >> Disconnect A/C relay. And GO TO 2.

2.CHECK CIRCUIT CONTINUITY BETWEEN A/C RELAY AND COMPRESSOR

OK or NG

OK >> Check harness for short. And GO TO 3.

NG >> Repair harness or connector.

3.CHECK POWER SUPPLY FOR A/C RELAY

Disconnect A/C relay.

OK or NG

OK >> GO TO 4.

NG >> Check power supply circuit and 10A (No.15) fuse at fuse

block. Refer to EL-11, "POWER SUPPLY ROUTING" .

●If OK, check for open circuit in wiring harness. Repair or replace as necessary.

●If NG, replace fuse and check wiring harness for short circuit. Repair or replace as necessary.

4.CHECK A/C RELAY AFTER DISCONNECTING IT

Refer to ATC-85, "

A/C Relay" .

OK or NG

OK >> Reconnect A/C relay. And GO TO 5.

NG >> 1. Replace A/C relay.

2. Go to AT C - 4 3 , "

FUNCTION CONFIRMATION PROCEDURE" and perform self-diagnosis

STEP-4. Confirm that magnet clutch operation is usual.

Terminal

Vo lta g e (+)

(-)

Compressor

connectorTe r m i n a l N o .

(Wire color)

E25 1 (L/R) Ground Battery voltage

RJIA0295E

Terminal

Continuity (+) (-)

A/C relay con-

nectorTerminal No.

(Wire color)Compressor

connectorTerminal No.

(Wire color)

E9 3 (L/R) E25 1 (L/R) Yes

RJIA0793E

Terminal

Vo l ta g e (+)

(-)

A/C relay con-

nectorTerminal No.

(Wire color)

E9 1 (L/Y)

Ground Battery voltage

E9 5 (L/Y)

RJIA0794E

Page 2058 of 3189

ATC-78

TROUBLE DIAGNOSIS

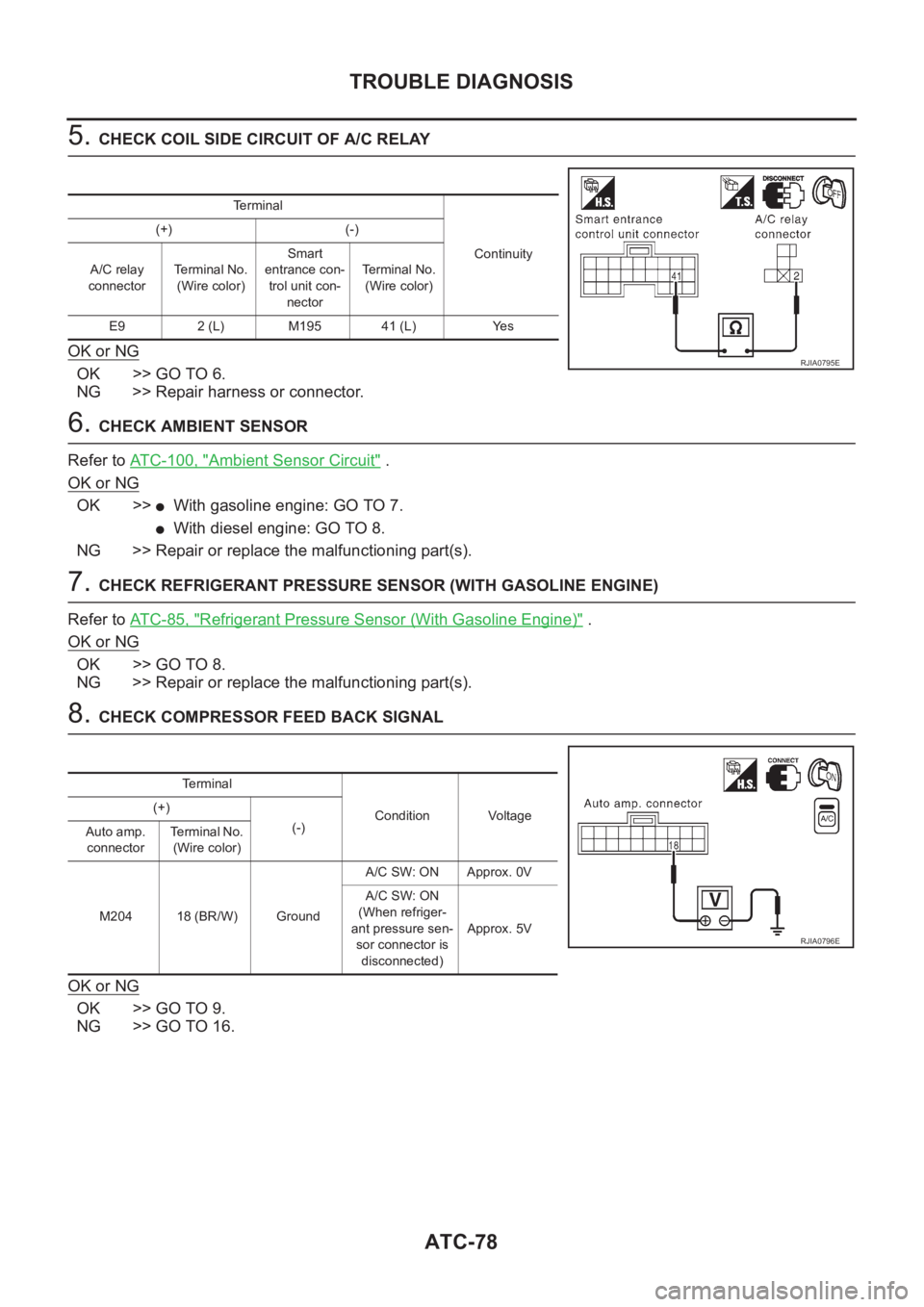

5. CHECK COIL SIDE CIRCUIT OF A/C RELAY

OK or NG

OK >> GO TO 6.

NG >> Repair harness or connector.

6. CHECK AMBIENT SENSOR

Refer to ATC-100, "

Ambient Sensor Circuit" .

OK or NG

OK >>●With gasoline engine: GO TO 7.

●With diesel engine: GO TO 8.

NG >> Repair or replace the malfunctioning part(s).

7. CHECK REFRIGERANT PRESSURE SENSOR (WITH GASOLINE ENGINE)

Refer to AT C - 8 5 , "

Refrigerant Pressure Sensor (With Gasoline Engine)" .

OK or NG

OK >> GO TO 8.

NG >> Repair or replace the malfunctioning part(s).

8. CHECK COMPRESSOR FEED BACK SIGNAL

OK or NG

OK >> GO TO 9.

NG >> GO TO 16.

Terminal

Continuity (+) (-)

A/C relay

connectorTerminal No.

(Wire color)Smart

entrance con-

trol unit con-

nectorTerminal No.

(Wire color)

E9 2 (L) M195 41 (L) Yes

RJIA0795E

Terminal

Condition Voltage (+)

(-)

Auto amp.

connectorTerminal No.

(Wire color)

M204 18 (BR/W) GroundA/C SW: ON Approx. 0V

A/C SW: ON

(When refriger-

ant pressure sen-

sor connector is

disconnected)Approx. 5V

RJIA0796E

Page 2059 of 3189

TROUBLE DIAGNOSIS

ATC-79

C

D

E

F

G

H

I

K

L

MA

B

AT C

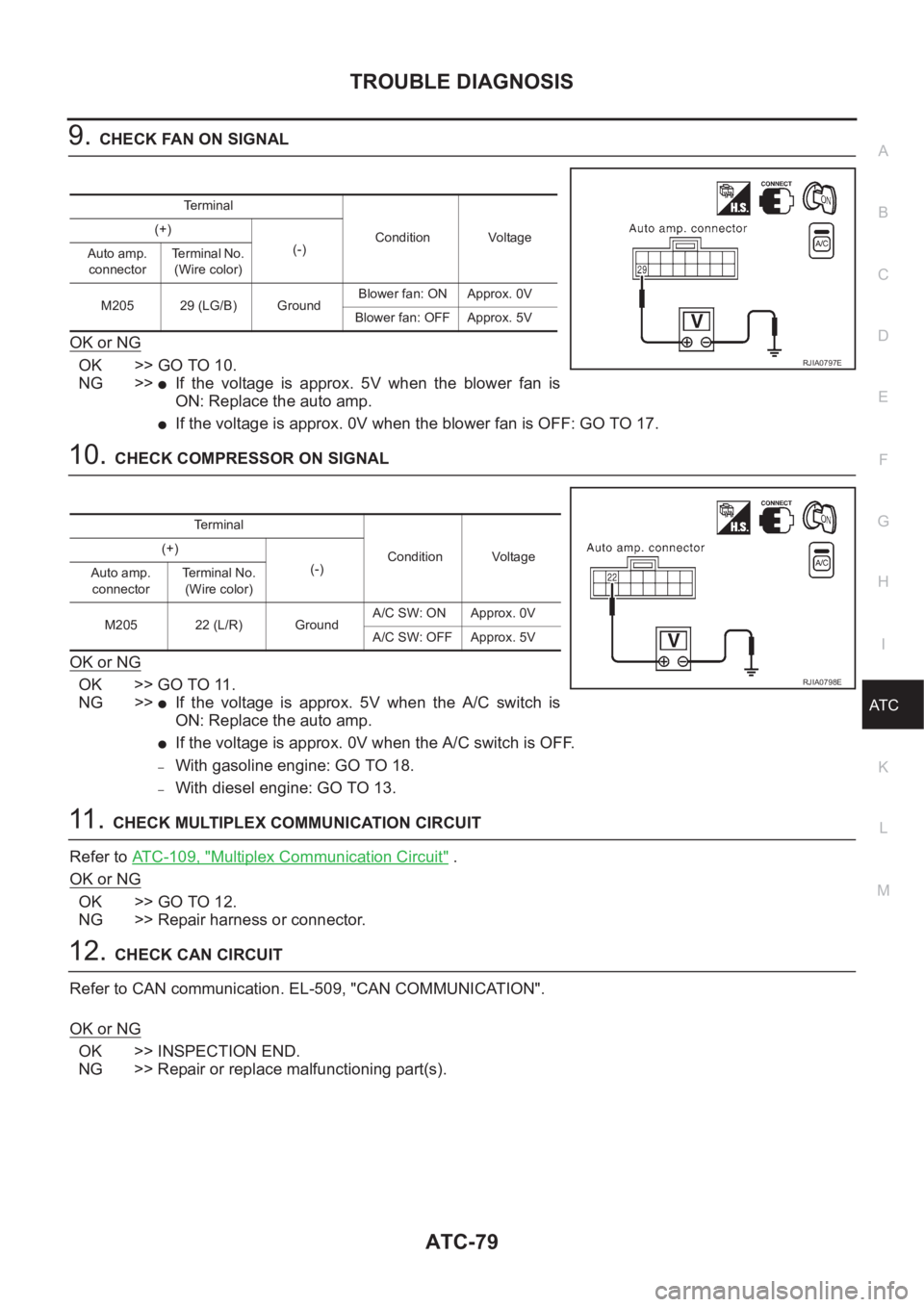

9.CHECK FAN ON SIGNAL

OK or NG

OK >> GO TO 10.

NG >>

●If the voltage is approx. 5V when the blower fan is

ON: Replace the auto amp.

●If the voltage is approx. 0V when the blower fan is OFF: GO TO 17.

10.CHECK COMPRESSOR ON SIGNAL

OK or NG

OK >> GO TO 11.

NG >>

●If the voltage is approx. 5V when the A/C switch is

ON: Replace the auto amp.

●If the voltage is approx. 0V when the A/C switch is OFF.

–With gasoline engine: GO TO 18.

–With diesel engine: GO TO 13.

11 . CHECK MULTIPLEX COMMUNICATION CIRCUIT

Refer to ATC-109, "

Multiplex Communication Circuit" .

OK or NG

OK >> GO TO 12.

NG >> Repair harness or connector.

12.CHECK CAN CIRCUIT

Refer to CAN communication. EL-509, "CAN COMMUNICATION".

OK or NG

OK >> INSPECTION END.

NG >> Repair or replace malfunctioning part(s).

Terminal

Condition Voltage (+)

(-)

Auto amp.

connectorTerminal No.

(Wire color)

M205 29 (LG/B) GroundBlower fan: ON Approx. 0V

Blower fan: OFF Approx. 5V

RJIA0797E

Terminal

Condition Voltage (+)

(-)

Auto amp.

connectorTerminal No.

(Wire color)

M205 22 (L/R) GroundA/C SW: ON Approx. 0V

A/C SW: OFF Approx. 5V

RJIA0798E

Page 2060 of 3189

ATC-80

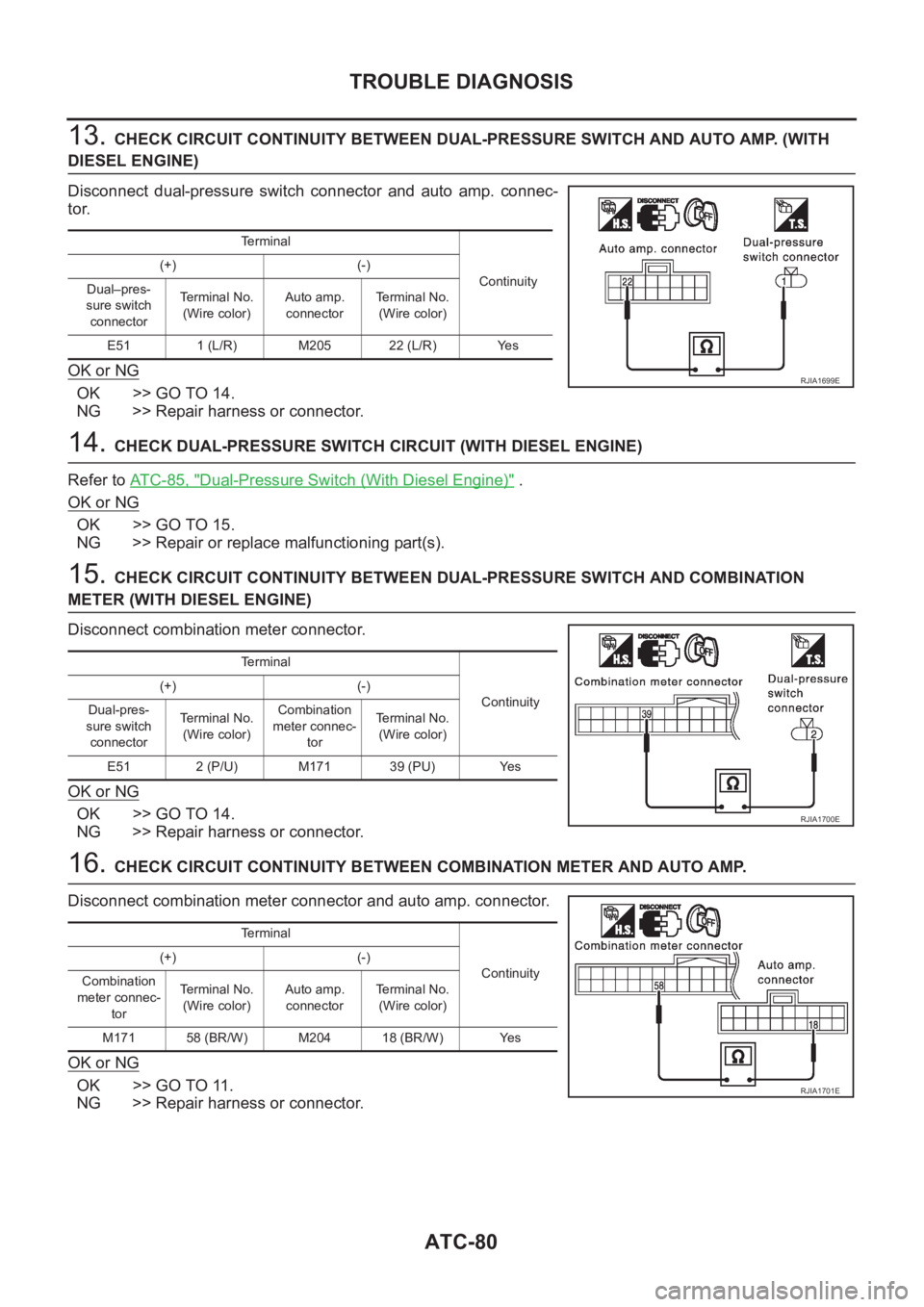

TROUBLE DIAGNOSIS

13. CHECK CIRCUIT CONTINUITY BETWEEN DUAL-PRESSURE SWITCH AND AUTO AMP. (WITH

DIESEL ENGINE)

Disconnect dual-pressure switch connector and auto amp. connec-

tor.

OK or NG

OK >> GO TO 14.

NG >> Repair harness or connector.

14. CHECK DUAL-PRESSURE SWITCH CIRCUIT (WITH DIESEL ENGINE)

Refer to AT C - 8 5 , "

Dual-Pressure Switch (With Diesel Engine)" .

OK or NG

OK >> GO TO 15.

NG >> Repair or replace malfunctioning part(s).

15. CHECK CIRCUIT CONTINUITY BETWEEN DUAL-PRESSURE SWITCH AND COMBINATION

METER (WITH DIESEL ENGINE)

Disconnect combination meter connector.

OK or NG

OK >> GO TO 14.

NG >> Repair harness or connector.

16. CHECK CIRCUIT CONTINUITY BETWEEN COMBINATION METER AND AUTO AMP.

Disconnect combination meter connector and auto amp. connector.

OK or NG

OK >> GO TO 11.

NG >> Repair harness or connector.

Terminal

Continuity (+) (-)

Dual–pres-

sure switch

connectorTe r m i n a l N o .

(Wire color)Auto amp.

connectorTerminal No.

(Wire color)

E51 1 (L/R) M205 22 (L/R) Yes

RJIA1699E

Terminal

Continuity (+) (-)

Dual-pres-

sure switch

connectorTe r m i n a l N o .

(Wire color)Combination

meter connec-

torTerminal No.

(Wire color)

E51 2 (P/U) M171 39 (PU) Yes

RJIA1700E

Terminal

Continuity (+) (-)

Combination

meter connec-

torTe r m i n a l N o .

(Wire color)Auto amp.

connectorTerminal No.

(Wire color)

M171 58 (BR/W) M204 18 (BR/W) Yes

RJIA1701E