NISSAN ALMERA TINO 2001 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA TINO, Model: NISSAN ALMERA TINO 2001Pages: 3051, PDF Size: 46.38 MB

Page 1331 of 3051

4 CHECK GROUND CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect camshaft position sensor harness connector.

3. Check harness continuity between CMPS terminal 5 and engine ground.

Refer to ªWiring Diagramº, EC-903.

Continuity should exist.

4. Also check harness for short to power.

OK or NG

OK©GO TO 5.

NG©Repair open circuit or short to power in harness or connectors.

5 CHECK INPUT SIGNAL CIRCUIT-I

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 35 and CMPS terminal 6.

Refer to ªWiring Diagramº, EC-903.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 6.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

6 CHECK IGNITION COIL, POWER TRANSISTOR

Refer to ªComponent Inspectionº, EC-907.

OK or NG

OK©GO TO 7.

NG©Replace malfunctioning component(s).

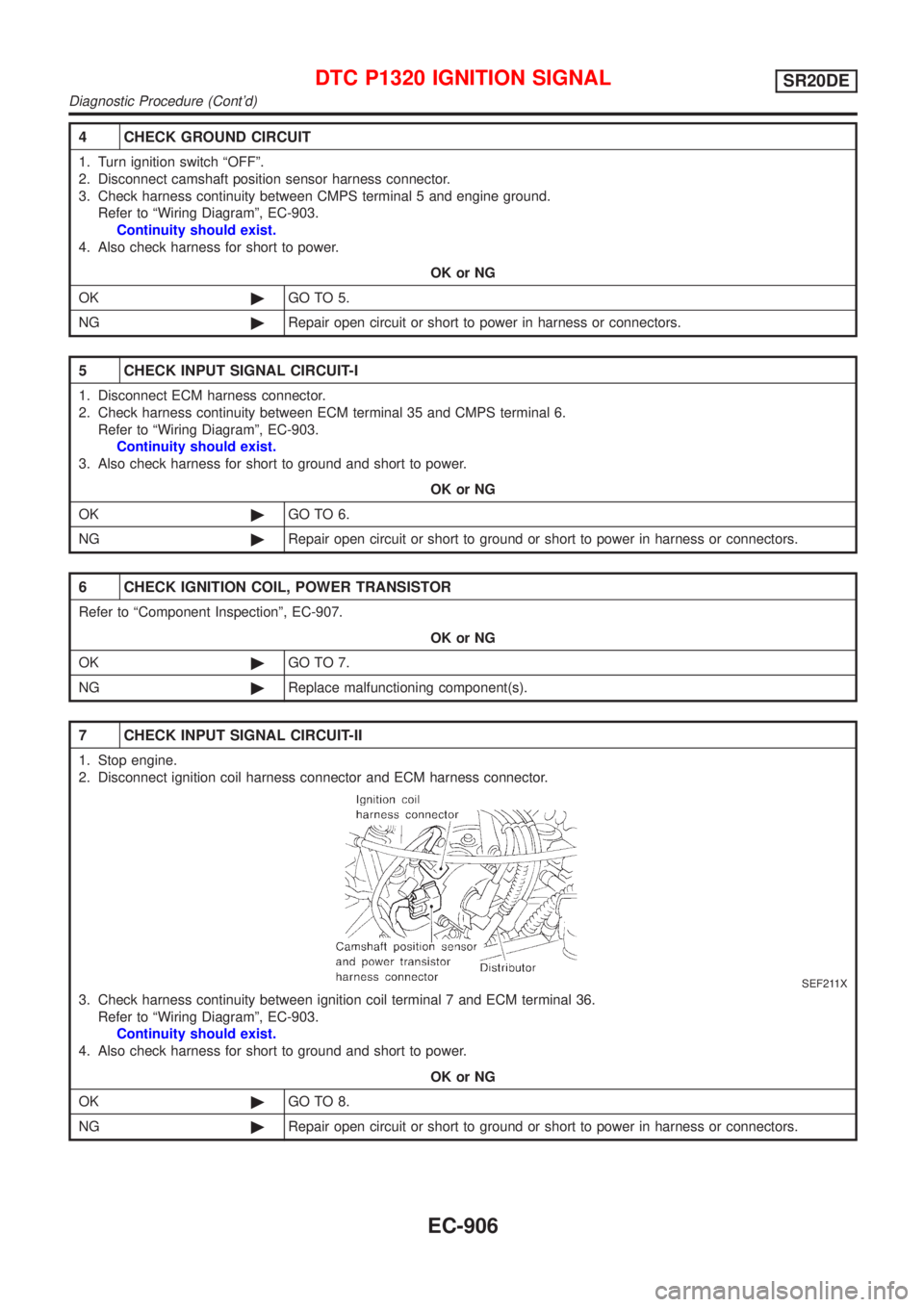

7 CHECK INPUT SIGNAL CIRCUIT-II

1. Stop engine.

2. Disconnect ignition coil harness connector and ECM harness connector.

SEF211X

3. Check harness continuity between ignition coil terminal 7 and ECM terminal 36.

Refer to ªWiring Diagramº, EC-903.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 8.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

DTC P1320 IGNITION SIGNALSR20DE

Diagnostic Procedure (Cont'd)

EC-906

Page 1332 of 3051

8 CHECK RESISTOR

Refer to ªComponent Inspectionº EC-908.

OK or NG

OK©GO TO 9.

NG©Replace distributor cap.

9 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-670.

©INSPECTION END

SEF237X

SEF238X

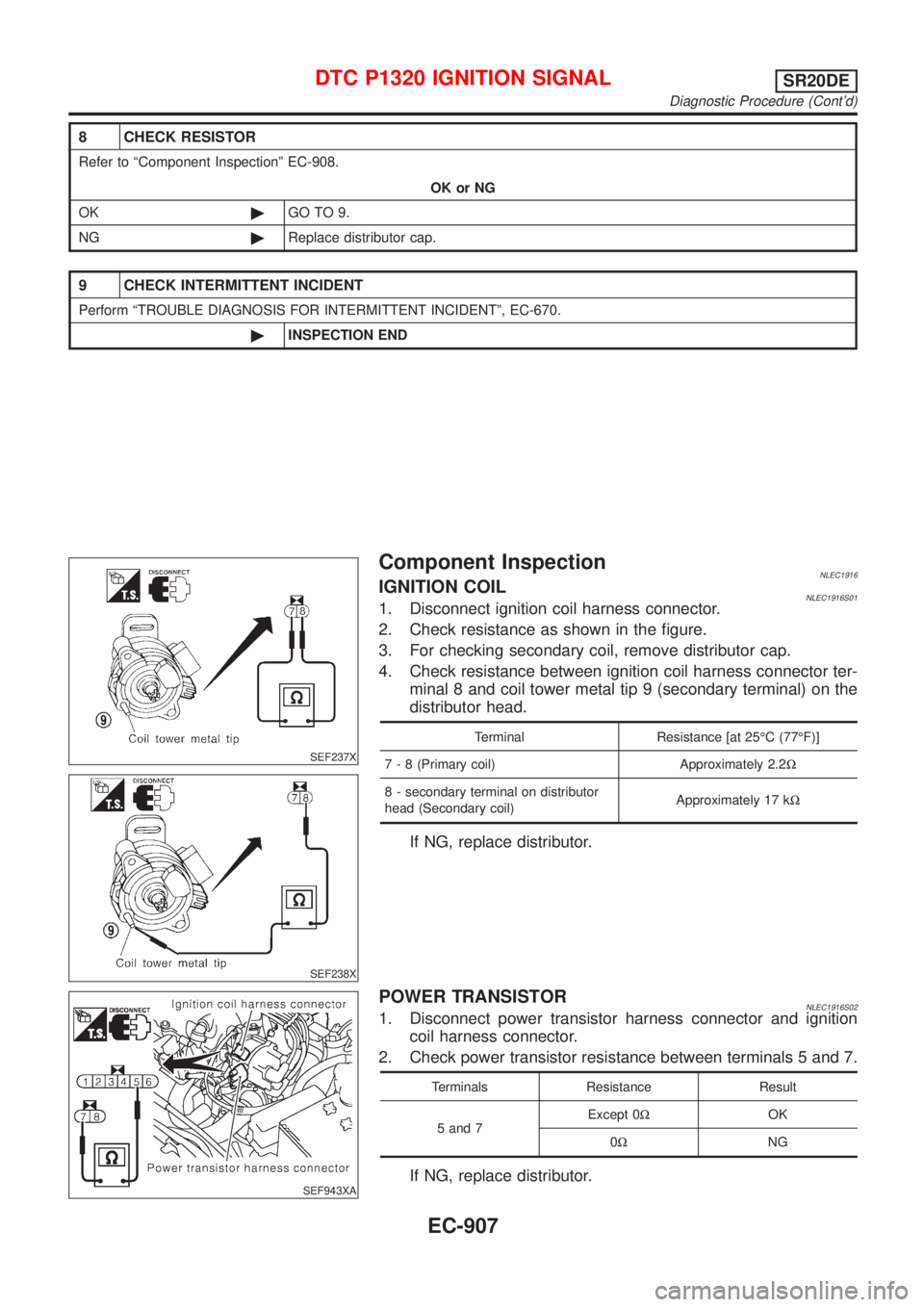

Component InspectionNLEC1916IGNITION COILNLEC1916S011. Disconnect ignition coil harness connector.

2. Check resistance as shown in the figure.

3. For checking secondary coil, remove distributor cap.

4. Check resistance between ignition coil harness connector ter-

minal 8 and coil tower metal tip 9 (secondary terminal) on the

distributor head.

Terminal Resistance [at 25ÉC (77ÉF)]

7 - 8 (Primary coil) Approximately 2.2W

8 - secondary terminal on distributor

head (Secondary coil)Approximately 17 kW

If NG, replace distributor.

SEF943XA

POWER TRANSISTORNLEC1916S021. Disconnect power transistor harness connector and ignition

coil harness connector.

2. Check power transistor resistance between terminals 5 and 7.

Terminals Resistance Result

5 and 7Except 0WOK

0WNG

If NG, replace distributor.

DTC P1320 IGNITION SIGNALSR20DE

Diagnostic Procedure (Cont'd)

EC-907

Page 1333 of 3051

![NISSAN ALMERA TINO 2001 Service Repair Manual SEF944X

RESISTORNLEC1916S031. Disconnect resistor harness connector.

2. Check resistance as shown in the figure.

Resistance: Approximately 5 kW[at 25ÉC (77ÉF)]

If NG, replace distributor cap.

DTC P1 NISSAN ALMERA TINO 2001 Service Repair Manual SEF944X

RESISTORNLEC1916S031. Disconnect resistor harness connector.

2. Check resistance as shown in the figure.

Resistance: Approximately 5 kW[at 25ÉC (77ÉF)]

If NG, replace distributor cap.

DTC P1](/img/5/57352/w960_57352-1332.png)

SEF944X

RESISTORNLEC1916S031. Disconnect resistor harness connector.

2. Check resistance as shown in the figure.

Resistance: Approximately 5 kW[at 25ÉC (77ÉF)]

If NG, replace distributor cap.

DTC P1320 IGNITION SIGNALSR20DE

Component Inspection (Cont'd)

EC-908

Page 1334 of 3051

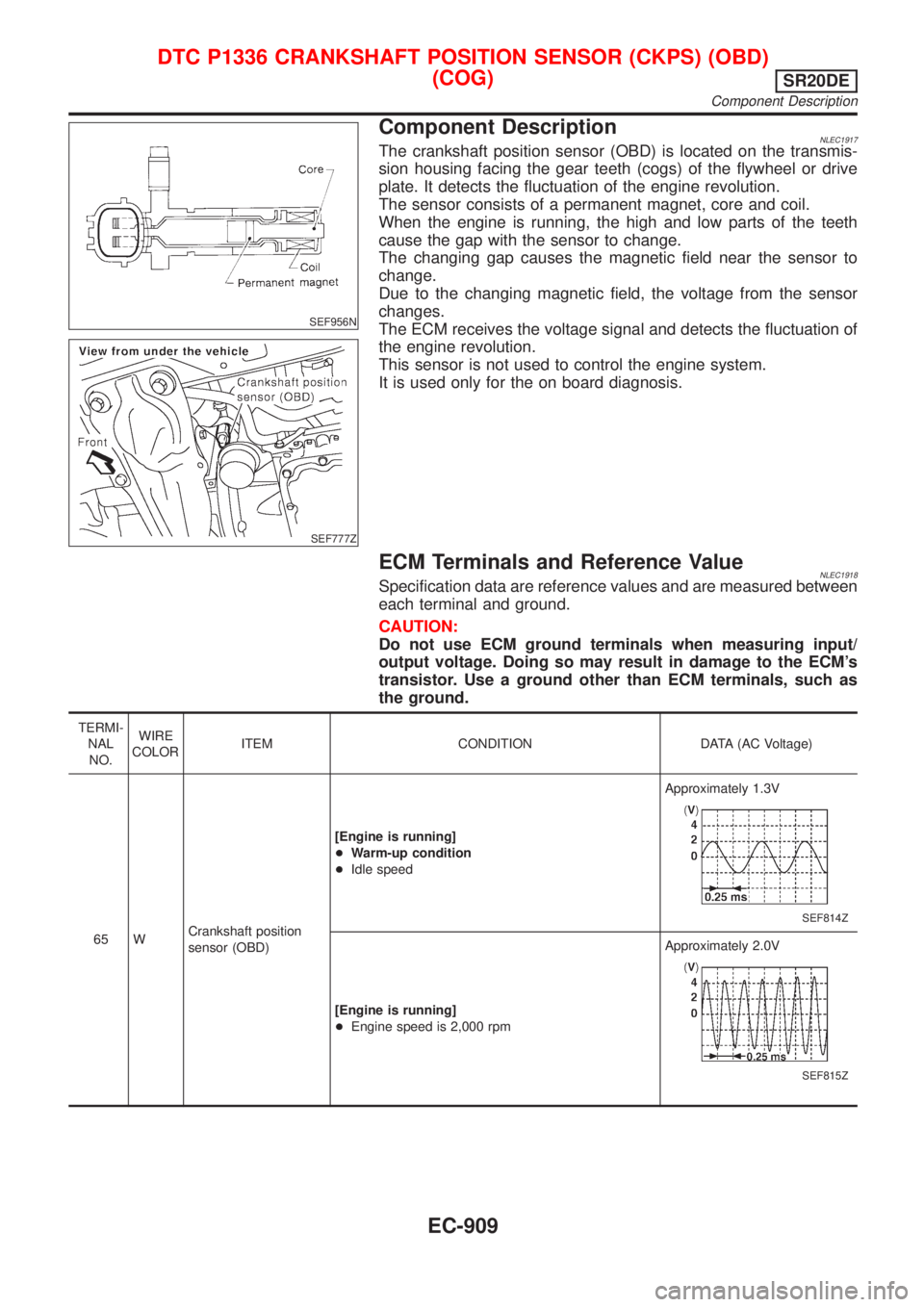

SEF956N

SEF777Z

Component DescriptionNLEC1917The crankshaft position sensor (OBD) is located on the transmis-

sion housing facing the gear teeth (cogs) of the flywheel or drive

plate. It detects the fluctuation of the engine revolution.

The sensor consists of a permanent magnet, core and coil.

When the engine is running, the high and low parts of the teeth

cause the gap with the sensor to change.

The changing gap causes the magnetic field near the sensor to

change.

Due to the changing magnetic field, the voltage from the sensor

changes.

The ECM receives the voltage signal and detects the fluctuation of

the engine revolution.

This sensor is not used to control the engine system.

It is used only for the on board diagnosis.

ECM Terminals and Reference ValueNLEC1918Specification data are reference values and are measured between

each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/

output voltage. Doing so may result in damage to the ECM's

transistor. Use a ground other than ECM terminals, such as

the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (AC Voltage)

65 WCrankshaft position

sensor (OBD)[Engine is running]

+Warm-up condition

+Idle speedApproximately 1.3V

SEF814Z

[Engine is running]

+Engine speed is 2,000 rpmApproximately 2.0V

SEF815Z

DTC P1336 CRANKSHAFT POSITION SENSOR (CKPS) (OBD)

(COG)

SR20DE

Component Description

EC-909

Page 1335 of 3051

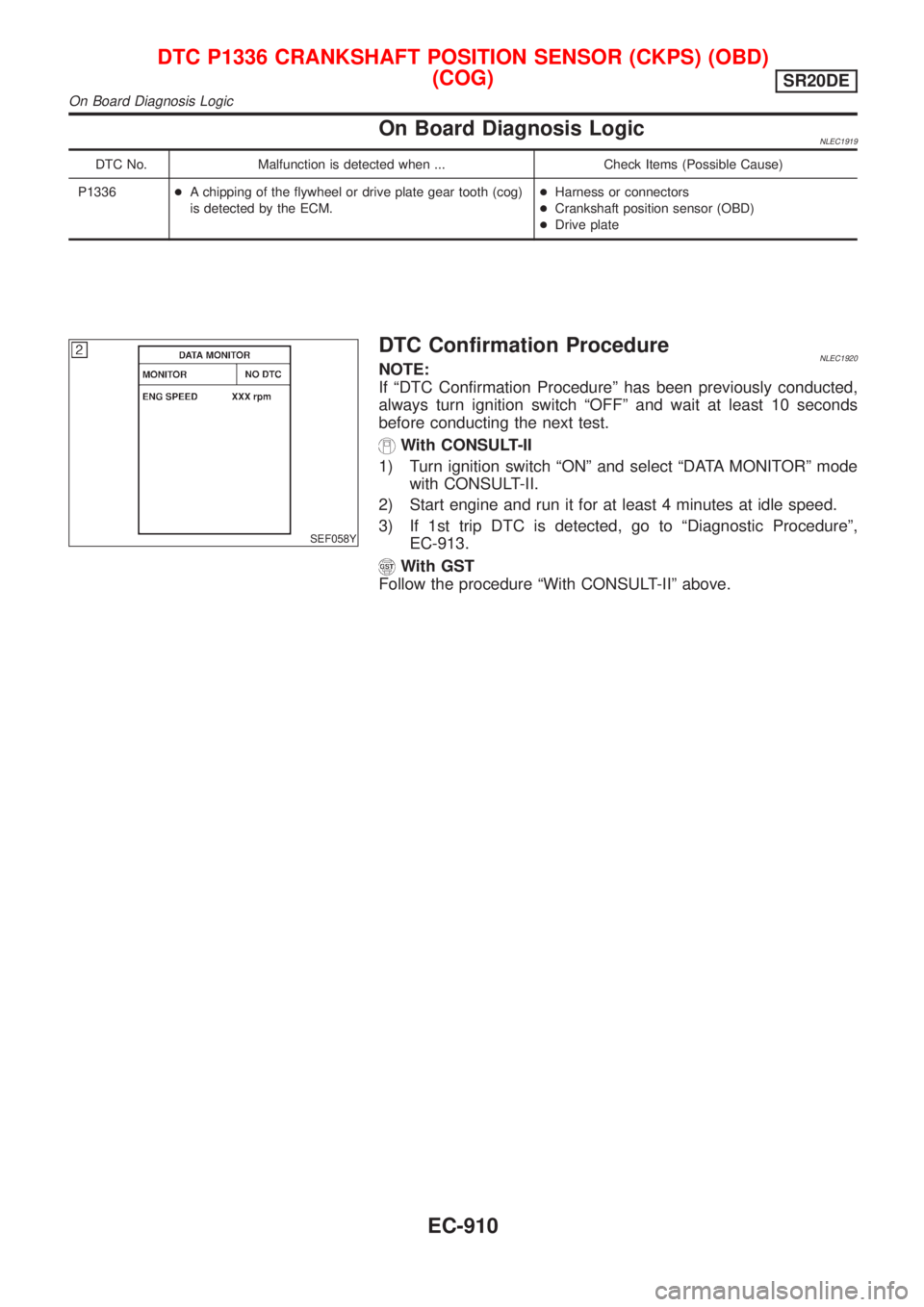

On Board Diagnosis LogicNLEC1919

DTC No. Malfunction is detected when ... Check Items (Possible Cause)

P1336+A chipping of the flywheel or drive plate gear tooth (cog)

is detected by the ECM.+Harness or connectors

+Crankshaft position sensor (OBD)

+Drive plate

SEF058Y

DTC Confirmation ProcedureNLEC1920NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 10 seconds

before conducting the next test.

With CONSULT-II

1) Turn ignition switch ªONº and select ªDATA MONITORº mode

with CONSULT-II.

2) Start engine and run it for at least 4 minutes at idle speed.

3) If 1st trip DTC is detected, go to ªDiagnostic Procedureº,

EC-913.

With GST

Follow the procedure ªWith CONSULT-IIº above.

DTC P1336 CRANKSHAFT POSITION SENSOR (CKPS) (OBD)

(COG)

SR20DE

On Board Diagnosis Logic

EC-910

Page 1336 of 3051

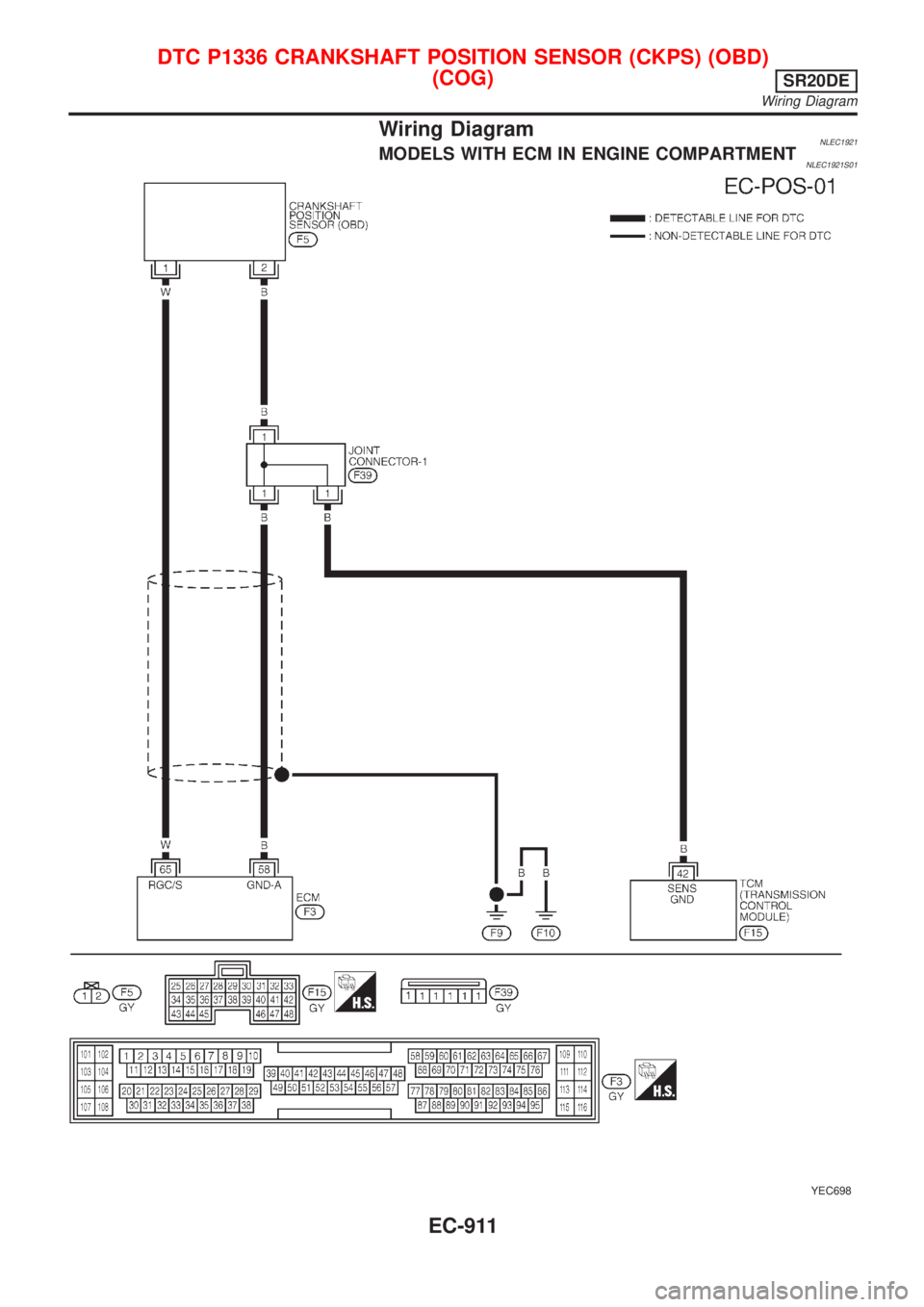

Wiring DiagramNLEC1921MODELS WITH ECM IN ENGINE COMPARTMENTNLEC1921S01

YEC698

DTC P1336 CRANKSHAFT POSITION SENSOR (CKPS) (OBD)

(COG)

SR20DE

Wiring Diagram

EC-911

Page 1337 of 3051

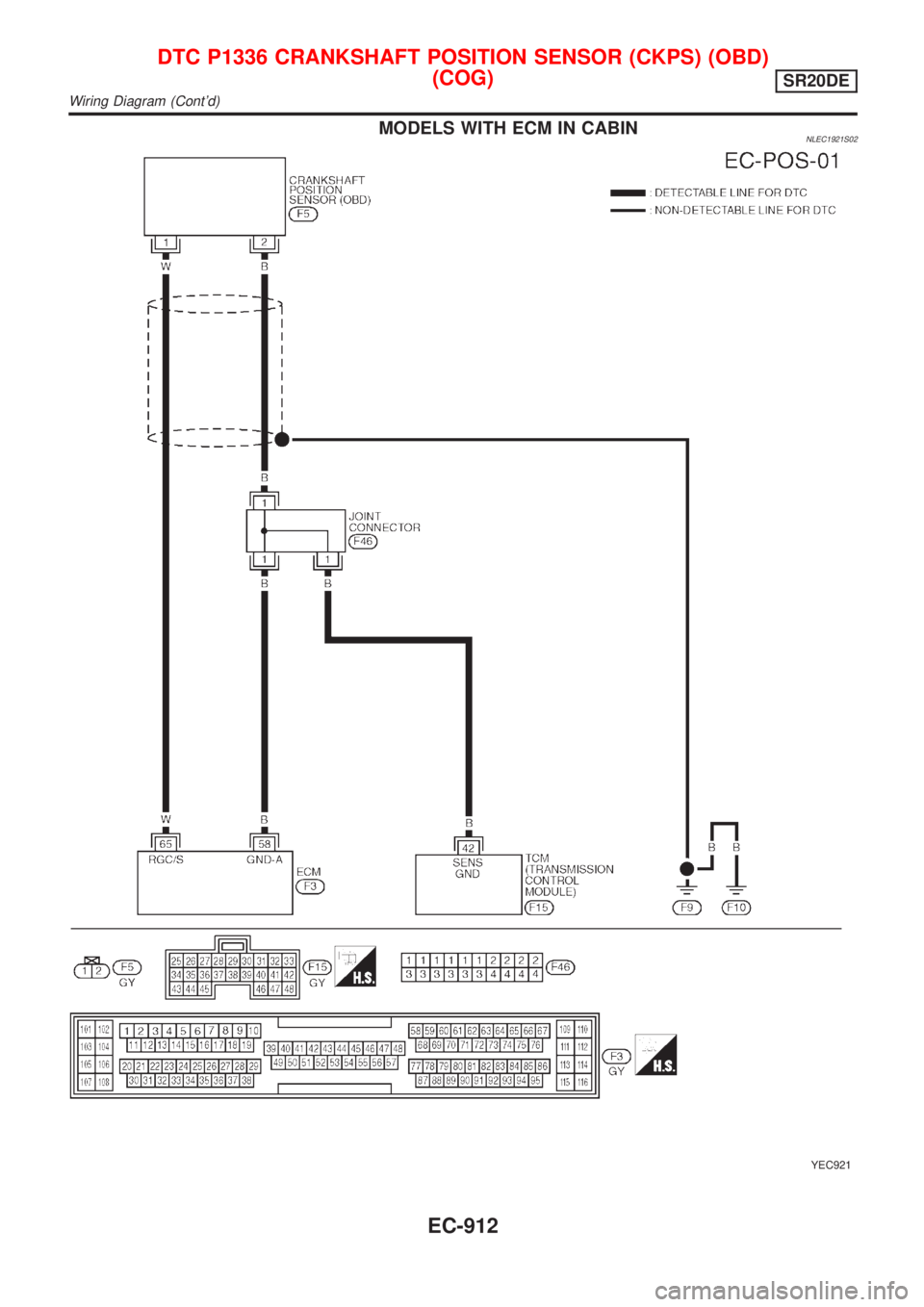

MODELS WITH ECM IN CABINNLEC1921S02

YEC921

DTC P1336 CRANKSHAFT POSITION SENSOR (CKPS) (OBD)

(COG)

SR20DE

Wiring Diagram (Cont'd)

EC-912

Page 1338 of 3051

Diagnostic ProcedureNLEC1922

1 RETIGHTEN GROUND SCREWS

1. Turn ignition switch ªOFFº.

2. Loosen and retighten engine ground screws.

©GO TO 2.

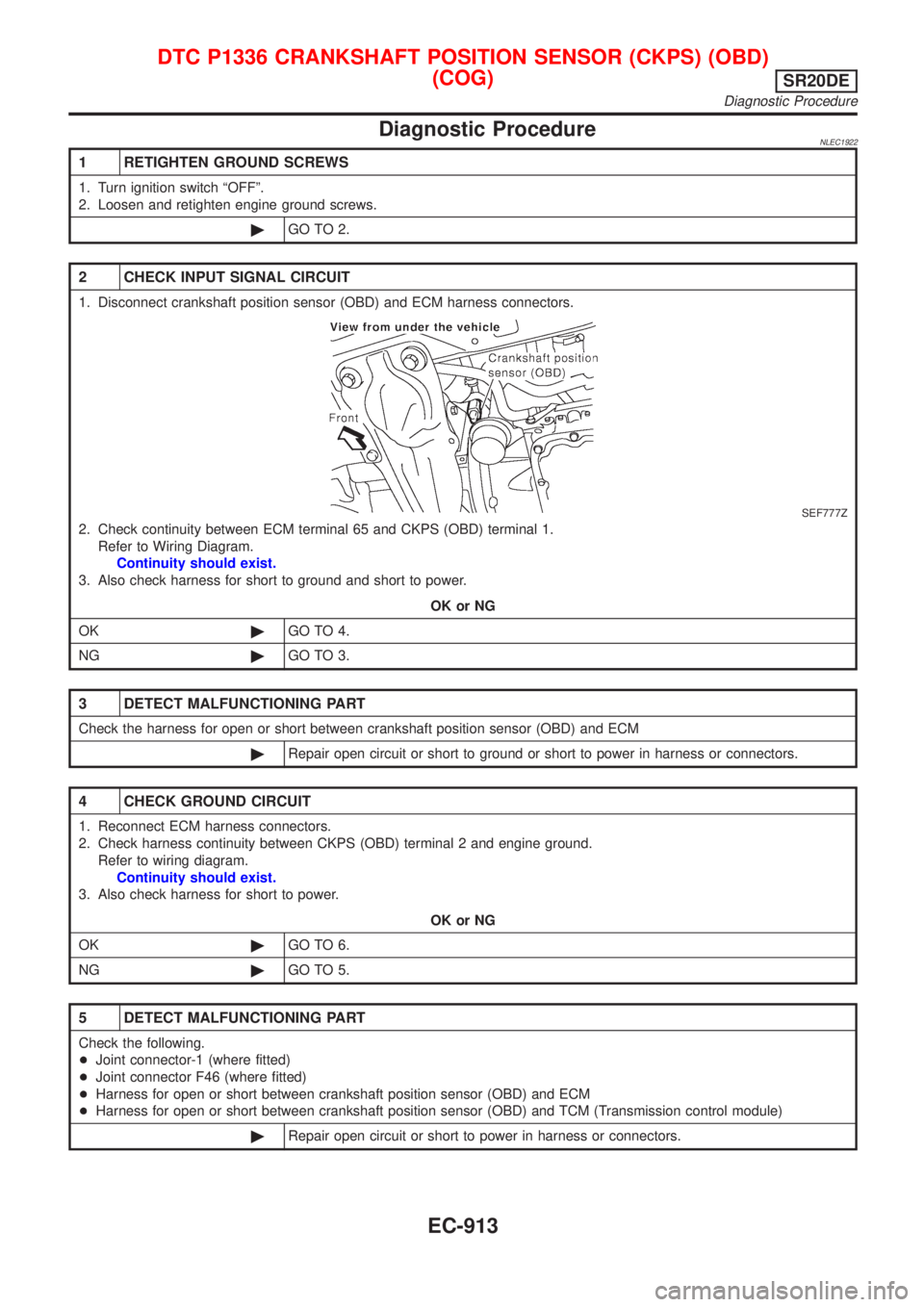

2 CHECK INPUT SIGNAL CIRCUIT

1. Disconnect crankshaft position sensor (OBD) and ECM harness connectors.

SEF777Z

2. Check continuity between ECM terminal 65 and CKPS (OBD) terminal 1.

Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 4.

NG©GO TO 3.

3 DETECT MALFUNCTIONING PART

Check the harness for open or short between crankshaft position sensor (OBD) and ECM

©Repair open circuit or short to ground or short to power in harness or connectors.

4 CHECK GROUND CIRCUIT

1. Reconnect ECM harness connectors.

2. Check harness continuity between CKPS (OBD) terminal 2 and engine ground.

Refer to wiring diagram.

Continuity should exist.

3. Also check harness for short to power.

OK or NG

OK©GO TO 6.

NG©GO TO 5.

5 DETECT MALFUNCTIONING PART

Check the following.

+Joint connector-1 (where fitted)

+Joint connector F46 (where fitted)

+Harness for open or short between crankshaft position sensor (OBD) and ECM

+Harness for open or short between crankshaft position sensor (OBD) and TCM (Transmission control module)

©Repair open circuit or short to power in harness or connectors.

DTC P1336 CRANKSHAFT POSITION SENSOR (CKPS) (OBD)

(COG)

SR20DE

Diagnostic Procedure

EC-913

Page 1339 of 3051

6 CHECK IMPROPER INSTALLATION

Loosen and retighten the fixing bolt of the crankshaft position sensor (OBD). Then retest.

Trouble is not fixed.©GO TO 7.

7 CHECK CRANKSHAFT POSITION SENSOR (OBD)

Refer to ªComponent Inspectionº, EC-914.

OK or NG

OK©GO TO 8.

NG©Replace crankshaft position sensor (OBD).

8 CHECK GEAR TOOTH

Visually check for chipping drive plate gear tooth (cog).

OK or NG

OK©GO TO 9.

NG©Replace the drive plate.

9 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-670.

©INSPECTION END

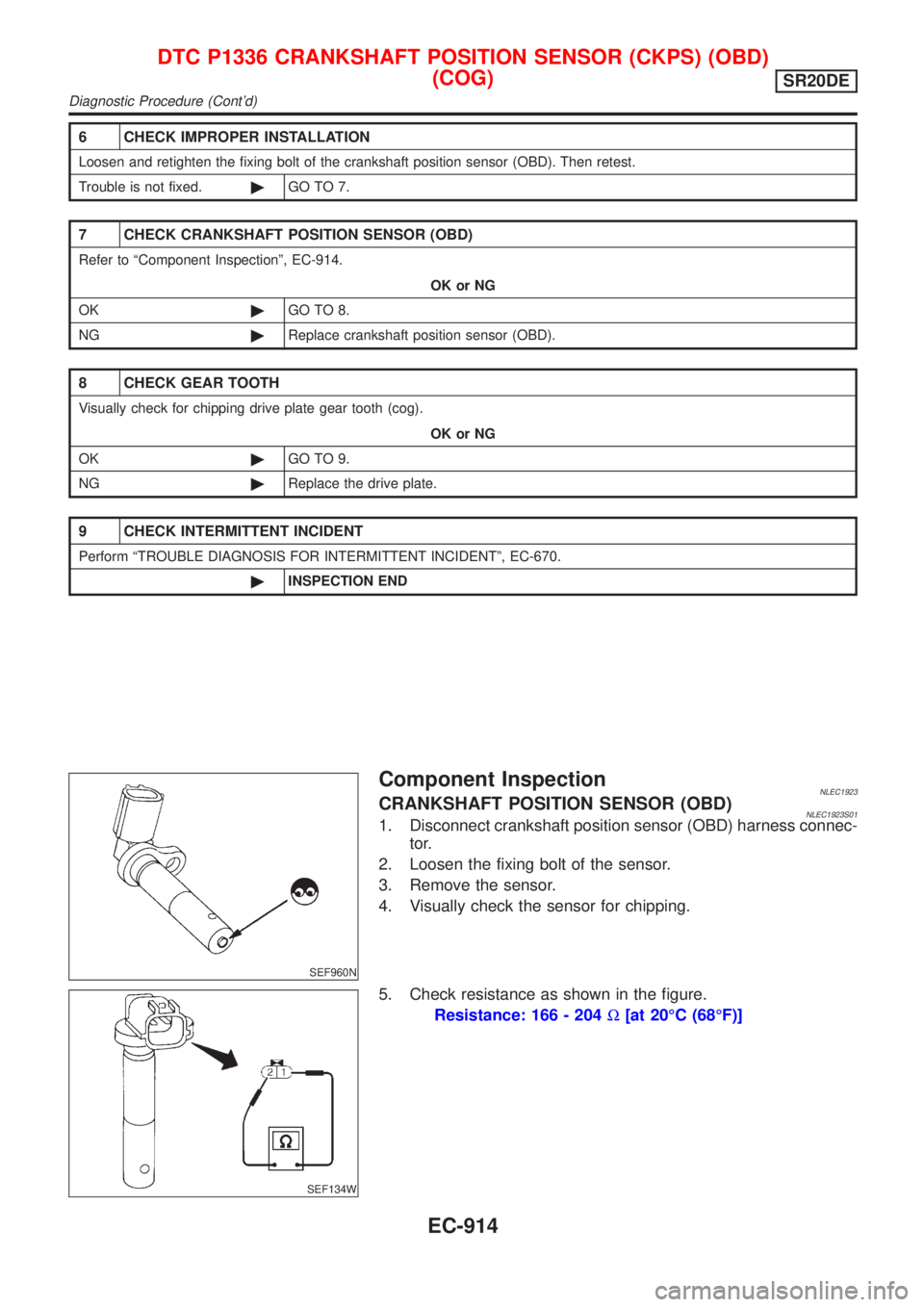

SEF960N

Component InspectionNLEC1923CRANKSHAFT POSITION SENSOR (OBD)NLEC1923S011. Disconnect crankshaft position sensor (OBD) harness connec-

tor.

2. Loosen the fixing bolt of the sensor.

3. Remove the sensor.

4. Visually check the sensor for chipping.

SEF134W

5. Check resistance as shown in the figure.

Resistance: 166 - 204W[at 20ÉC (68ÉF)]

DTC P1336 CRANKSHAFT POSITION SENSOR (CKPS) (OBD)

(COG)

SR20DE

Diagnostic Procedure (Cont'd)

EC-914

Page 1340 of 3051

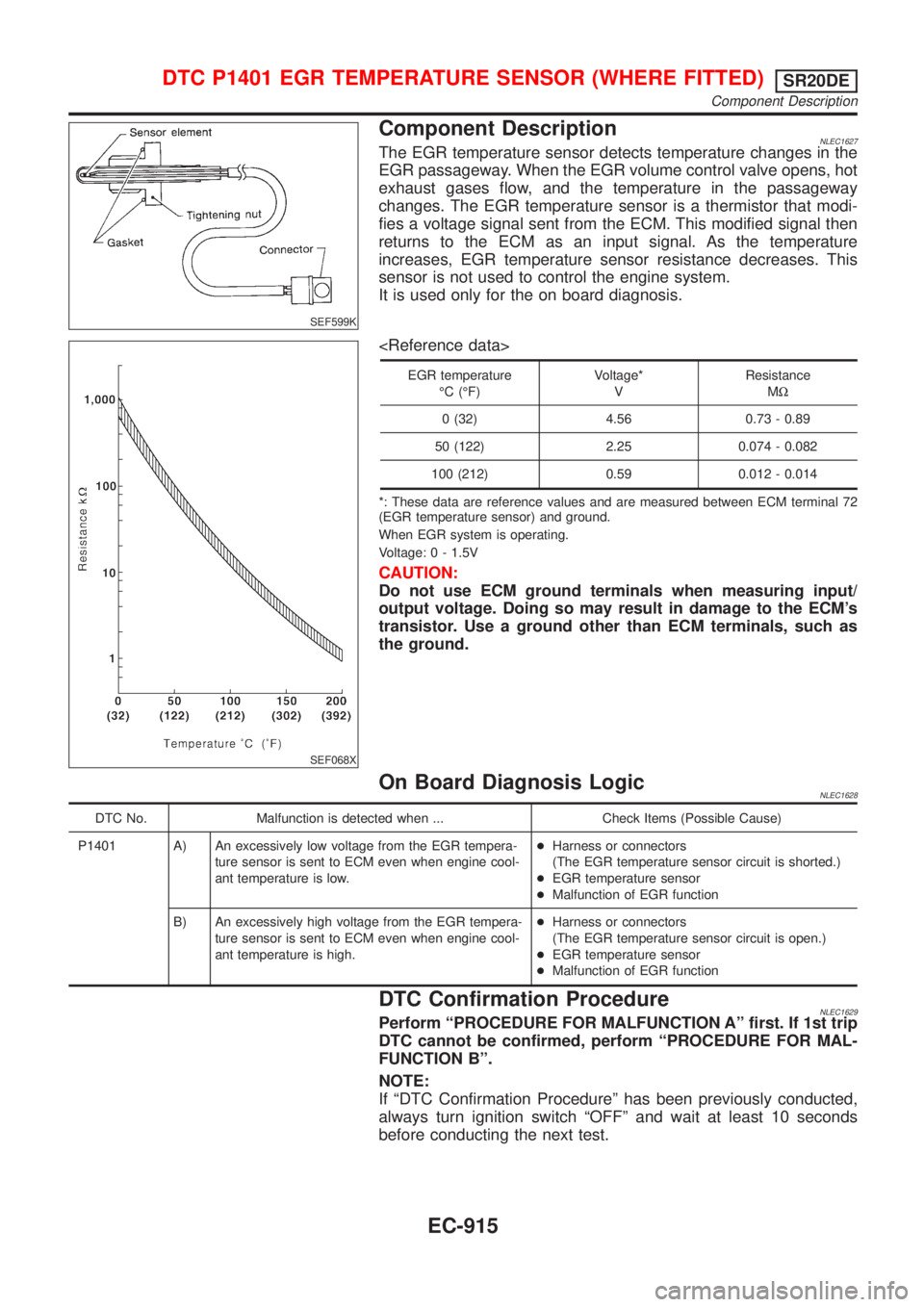

SEF599K

Component DescriptionNLEC1627The EGR temperature sensor detects temperature changes in the

EGR passageway. When the EGR volume control valve opens, hot

exhaust gases flow, and the temperature in the passageway

changes. The EGR temperature sensor is a thermistor that modi-

fies a voltage signal sent from the ECM. This modified signal then

returns to the ECM as an input signal. As the temperature

increases, EGR temperature sensor resistance decreases. This

sensor is not used to control the engine system.

It is used only for the on board diagnosis.

SEF068X

EGR temperature

ÉC (ÉF)Voltage*

VResistance

MW

0 (32) 4.56 0.73 - 0.89

50 (122) 2.25 0.074 - 0.082

100 (212) 0.59 0.012 - 0.014

*: These data are reference values and are measured between ECM terminal 72

(EGR temperature sensor) and ground.

When EGR system is operating.

Voltage: 0 - 1.5V

CAUTION:

Do not use ECM ground terminals when measuring input/

output voltage. Doing so may result in damage to the ECM's

transistor. Use a ground other than ECM terminals, such as

the ground.

On Board Diagnosis LogicNLEC1628

DTC No. Malfunction is detected when ... Check Items (Possible Cause)

P1401 A) An excessively low voltage from the EGR tempera-

ture sensor is sent to ECM even when engine cool-

ant temperature is low.+Harness or connectors

(The EGR temperature sensor circuit is shorted.)

+EGR temperature sensor

+Malfunction of EGR function

B) An excessively high voltage from the EGR tempera-

ture sensor is sent to ECM even when engine cool-

ant temperature is high.+Harness or connectors

(The EGR temperature sensor circuit is open.)

+EGR temperature sensor

+Malfunction of EGR function

DTC Confirmation ProcedureNLEC1629Perform ªPROCEDURE FOR MALFUNCTION Aº first. If 1st trip

DTC cannot be confirmed, perform ªPROCEDURE FOR MAL-

FUNCTION Bº.

NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 10 seconds

before conducting the next test.

DTC P1401 EGR TEMPERATURE SENSOR (WHERE FITTED)SR20DE

Component Description

EC-915