NISSAN ALMERA TINO 2001 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA TINO, Model: NISSAN ALMERA TINO 2001Pages: 3051, PDF Size: 46.38 MB

Page 1661 of 3051

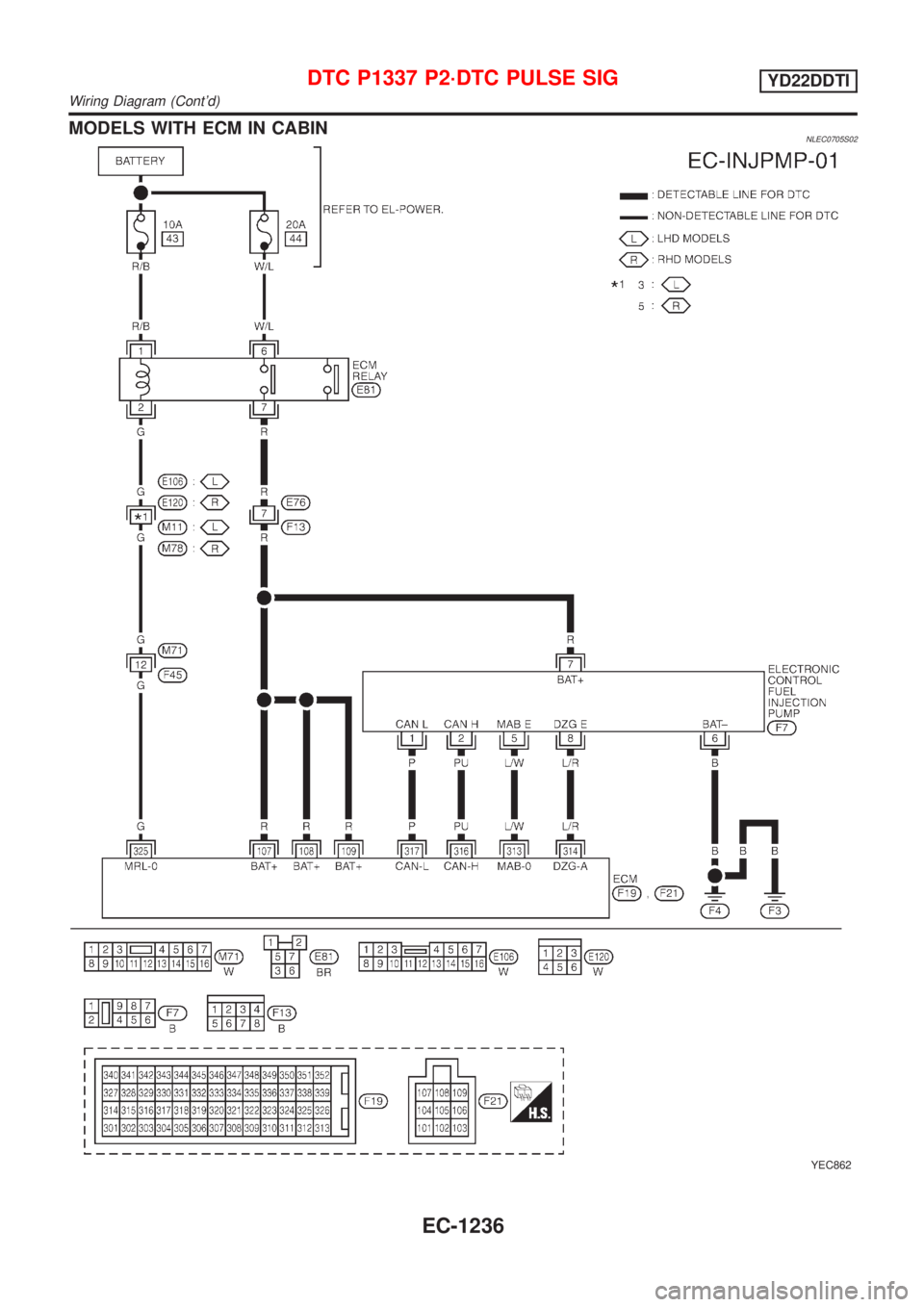

MODELS WITH ECM IN CABINNLEC0705S02

YEC862

DTC P1337 P2´DTC PULSE SIGYD22DDTI

Wiring Diagram (Cont'd)

EC-1236

Page 1662 of 3051

Diagnostic ProcedureNLEC0706

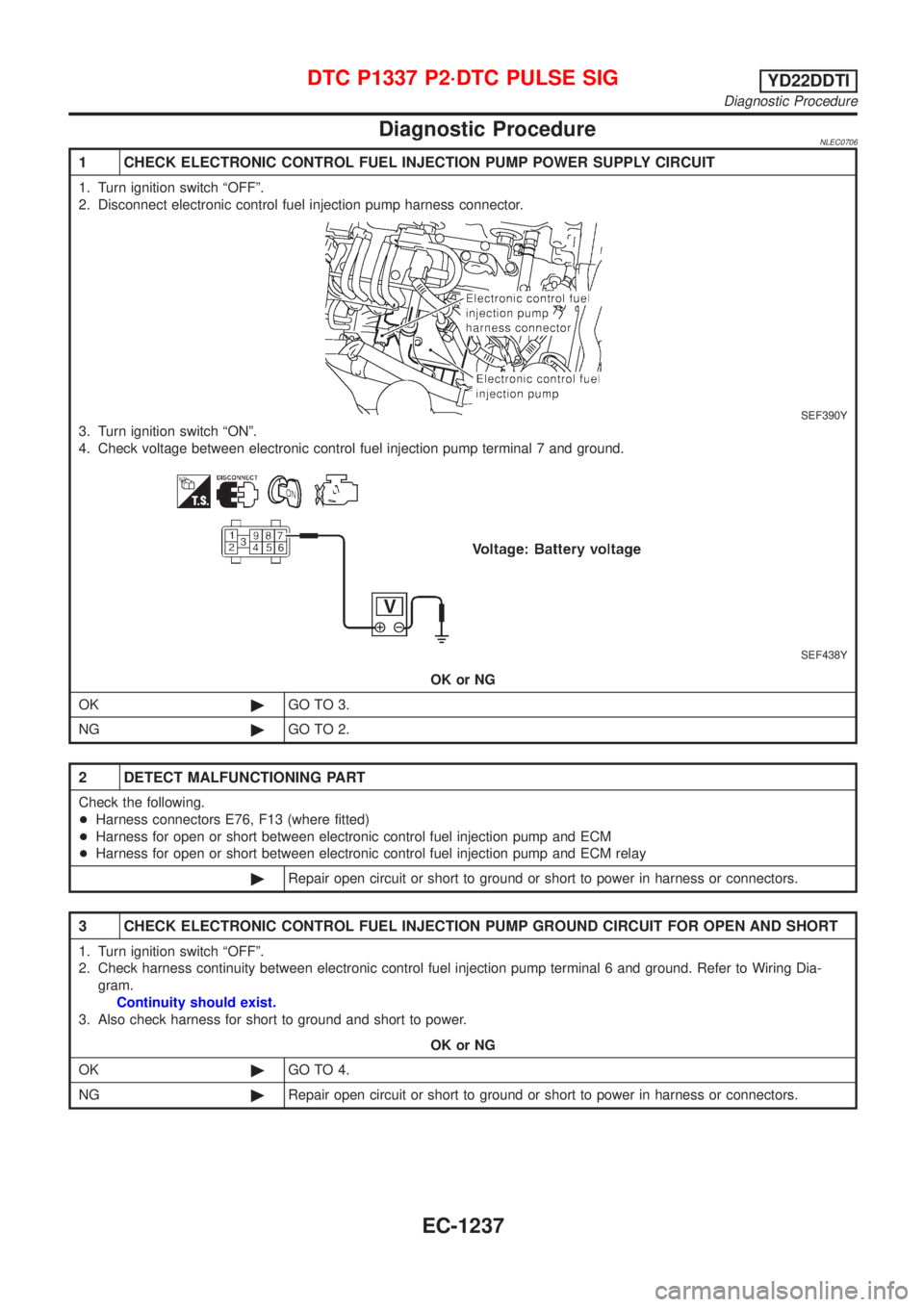

1 CHECK ELECTRONIC CONTROL FUEL INJECTION PUMP POWER SUPPLY CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect electronic control fuel injection pump harness connector.

SEF390Y

3. Turn ignition switch ªONº.

4. Check voltage between electronic control fuel injection pump terminal 7 and ground.

SEF438Y

OK or NG

OK©GO TO 3.

NG©GO TO 2.

2 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors E76, F13 (where fitted)

+Harness for open or short between electronic control fuel injection pump and ECM

+Harness for open or short between electronic control fuel injection pump and ECM relay

©Repair open circuit or short to ground or short to power in harness or connectors.

3 CHECK ELECTRONIC CONTROL FUEL INJECTION PUMP GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Check harness continuity between electronic control fuel injection pump terminal 6 and ground. Refer to Wiring Dia-

gram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 4.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

DTC P1337 P2´DTC PULSE SIGYD22DDTI

Diagnostic Procedure

EC-1237

Page 1663 of 3051

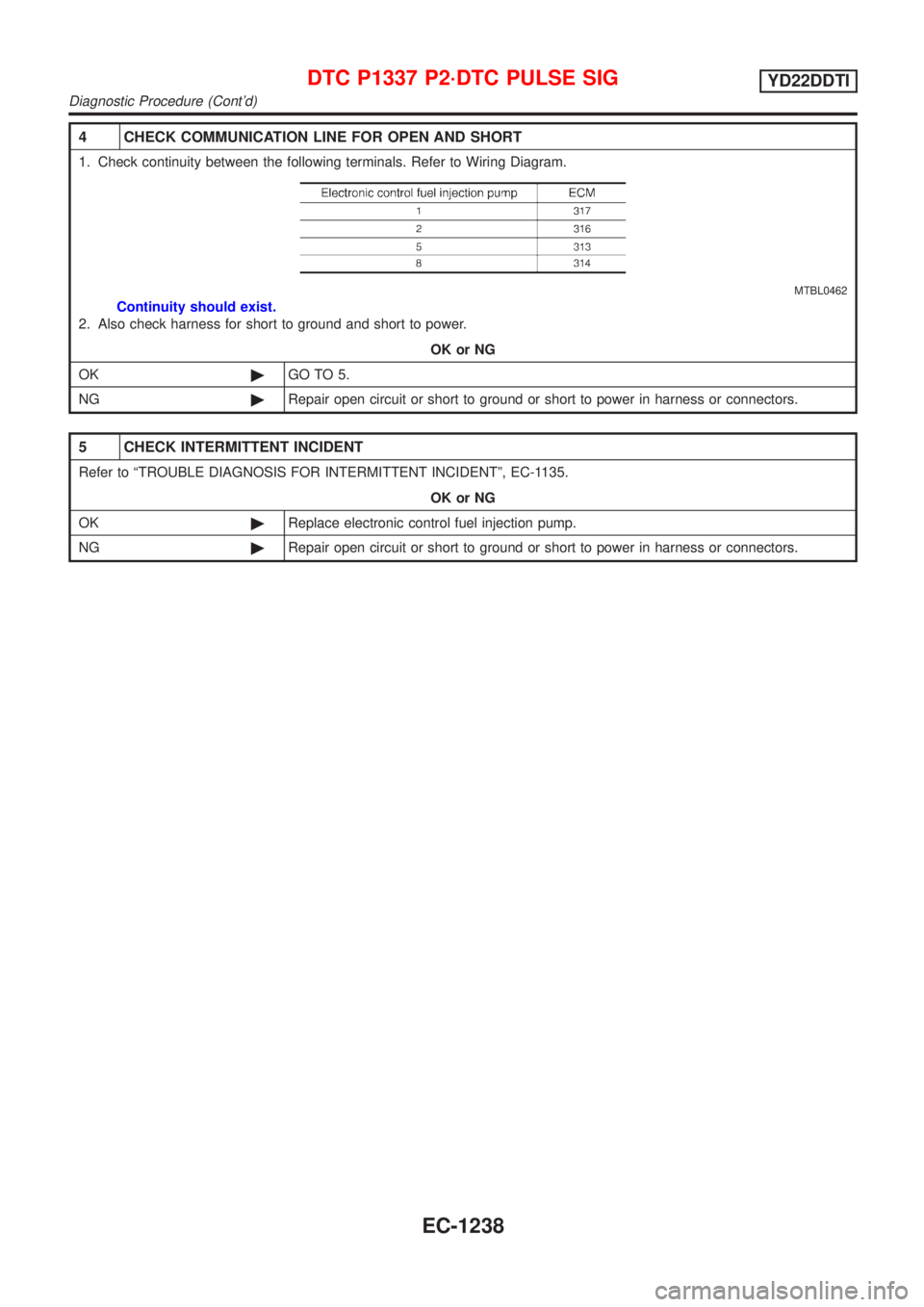

4 CHECK COMMUNICATION LINE FOR OPEN AND SHORT

1. Check continuity between the following terminals. Refer to Wiring Diagram.

MTBL0462

Continuity should exist.

2. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 5.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

5 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-1135.

OK or NG

OK©Replace electronic control fuel injection pump.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

DTC P1337 P2´DTC PULSE SIGYD22DDTI

Diagnostic Procedure (Cont'd)

EC-1238

Page 1664 of 3051

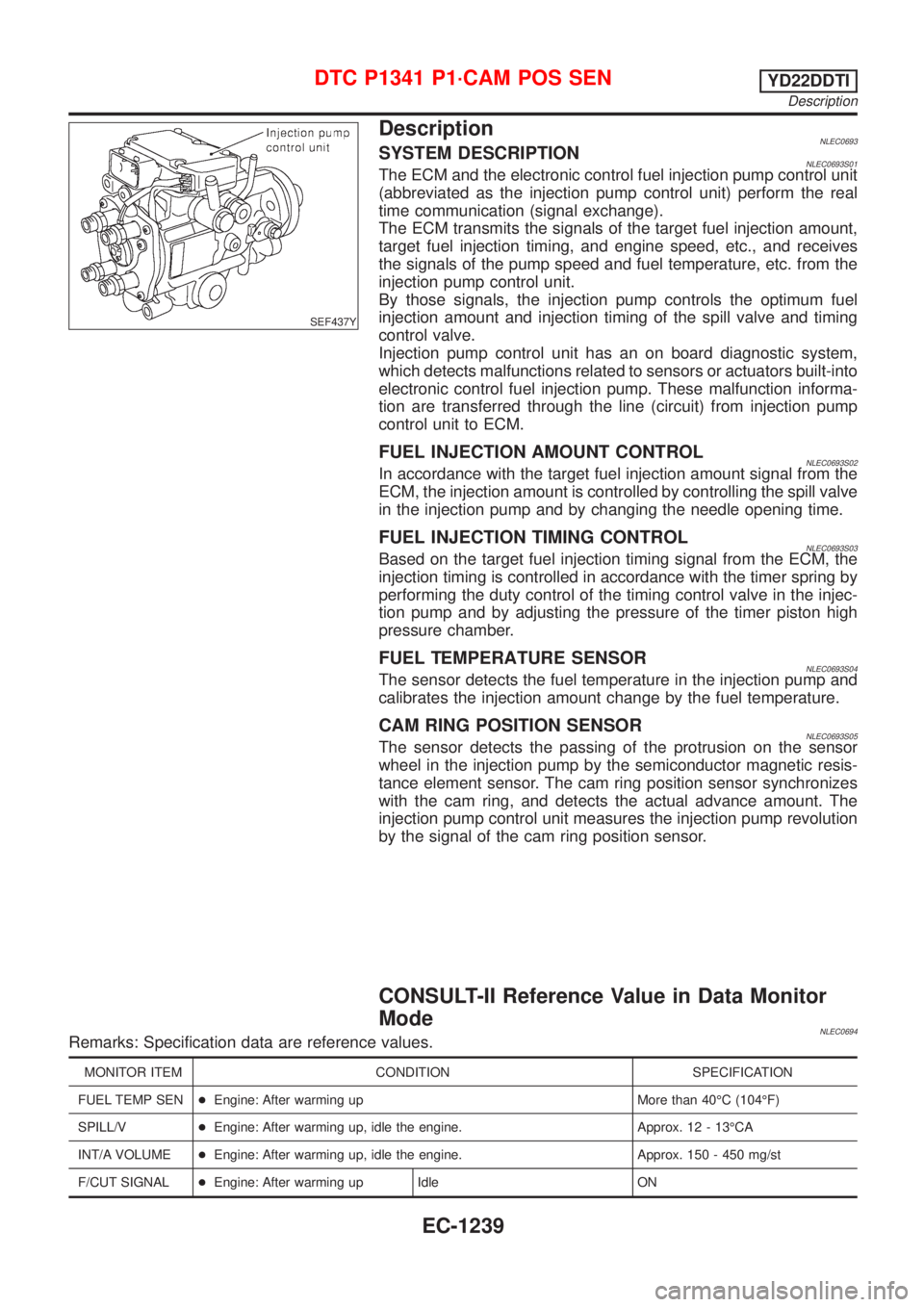

SEF437Y

DescriptionNLEC0693SYSTEM DESCRIPTIONNLEC0693S01The ECM and the electronic control fuel injection pump control unit

(abbreviated as the injection pump control unit) perform the real

time communication (signal exchange).

The ECM transmits the signals of the target fuel injection amount,

target fuel injection timing, and engine speed, etc., and receives

the signals of the pump speed and fuel temperature, etc. from the

injection pump control unit.

By those signals, the injection pump controls the optimum fuel

injection amount and injection timing of the spill valve and timing

control valve.

Injection pump control unit has an on board diagnostic system,

which detects malfunctions related to sensors or actuators built-into

electronic control fuel injection pump. These malfunction informa-

tion are transferred through the line (circuit) from injection pump

control unit to ECM.

FUEL INJECTION AMOUNT CONTROLNLEC0693S02In accordance with the target fuel injection amount signal from the

ECM, the injection amount is controlled by controlling the spill valve

in the injection pump and by changing the needle opening time.

FUEL INJECTION TIMING CONTROLNLEC0693S03Based on the target fuel injection timing signal from the ECM, the

injection timing is controlled in accordance with the timer spring by

performing the duty control of the timing control valve in the injec-

tion pump and by adjusting the pressure of the timer piston high

pressure chamber.

FUEL TEMPERATURE SENSORNLEC0693S04The sensor detects the fuel temperature in the injection pump and

calibrates the injection amount change by the fuel temperature.

CAM RING POSITION SENSORNLEC0693S05The sensor detects the passing of the protrusion on the sensor

wheel in the injection pump by the semiconductor magnetic resis-

tance element sensor. The cam ring position sensor synchronizes

with the cam ring, and detects the actual advance amount. The

injection pump control unit measures the injection pump revolution

by the signal of the cam ring position sensor.

CONSULT-II Reference Value in Data Monitor

Mode

NLEC0694Remarks: Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

FUEL TEMP SEN+Engine: After warming up More than 40ÉC (104ÉF)

SPILL/V+Engine: After warming up, idle the engine. Approx. 12 - 13ÉCA

INT/A VOLUME+Engine: After warming up, idle the engine. Approx. 150 - 450 mg/st

F/CUT SIGNAL+Engine: After warming up Idle ON

DTC P1341 P1´CAM POS SENYD22DDTI

Description

EC-1239

Page 1665 of 3051

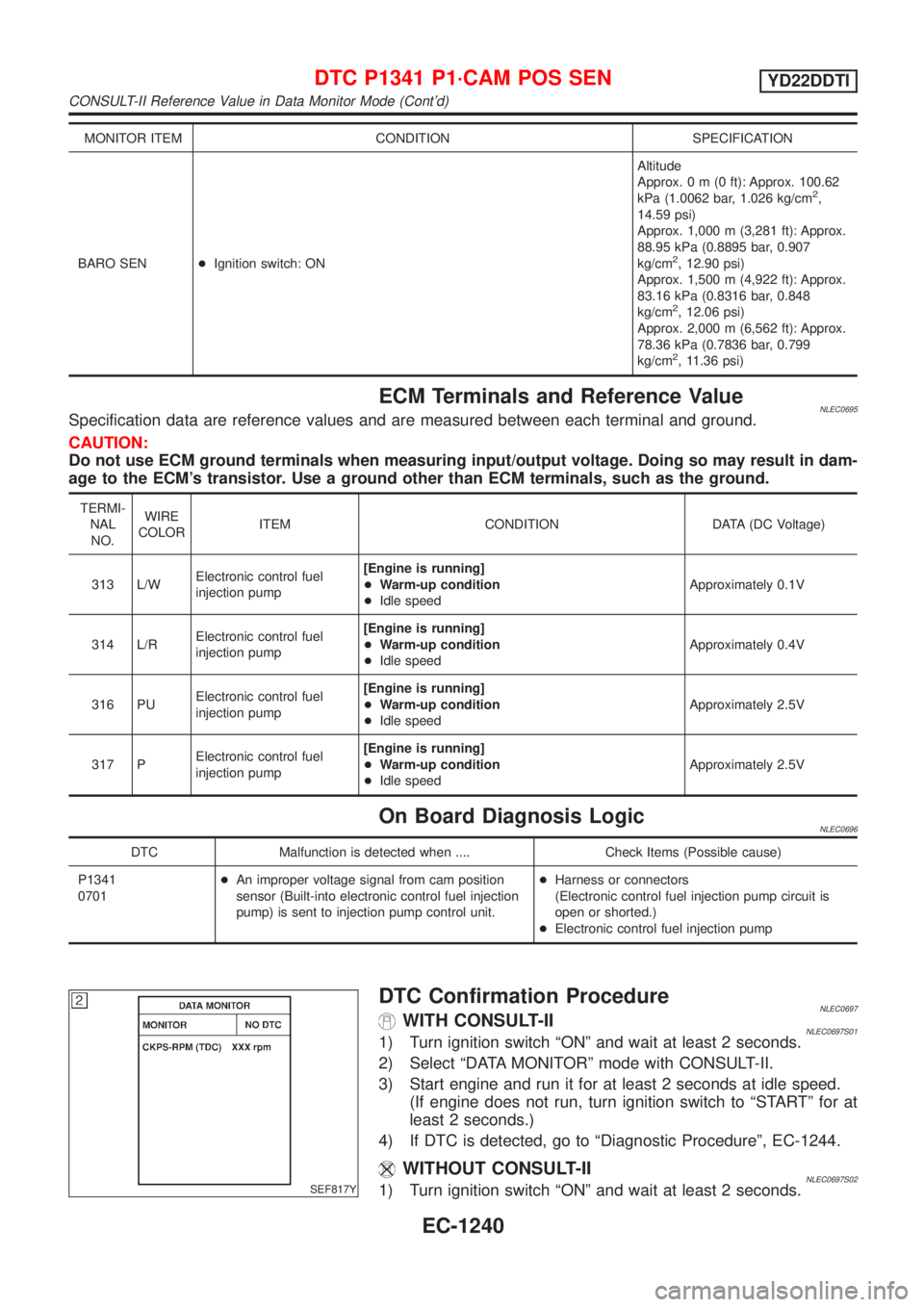

MONITOR ITEM CONDITION SPECIFICATION

BARO SEN+Ignition switch: ONAltitude

Approx.0m(0ft): Approx. 100.62

kPa (1.0062 bar, 1.026 kg/cm

2,

14.59 psi)

Approx. 1,000 m (3,281 ft): Approx.

88.95 kPa (0.8895 bar, 0.907

kg/cm

2, 12.90 psi)

Approx. 1,500 m (4,922 ft): Approx.

83.16 kPa (0.8316 bar, 0.848

kg/cm

2, 12.06 psi)

Approx. 2,000 m (6,562 ft): Approx.

78.36 kPa (0.7836 bar, 0.799

kg/cm

2, 11.36 psi)

ECM Terminals and Reference ValueNLEC0695Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

313 L/WElectronic control fuel

injection pump[Engine is running]

+Warm-up condition

+Idle speedApproximately 0.1V

314 L/RElectronic control fuel

injection pump[Engine is running]

+Warm-up condition

+Idle speedApproximately 0.4V

316 PUElectronic control fuel

injection pump[Engine is running]

+Warm-up condition

+Idle speedApproximately 2.5V

317 PElectronic control fuel

injection pump[Engine is running]

+Warm-up condition

+Idle speedApproximately 2.5V

On Board Diagnosis LogicNLEC0696

DTC Malfunction is detected when .... Check Items (Possible cause)

P1341

0701+An improper voltage signal from cam position

sensor (Built-into electronic control fuel injection

pump) is sent to injection pump control unit.+Harness or connectors

(Electronic control fuel injection pump circuit is

open or shorted.)

+Electronic control fuel injection pump

SEF817Y

DTC Confirmation ProcedureNLEC0697WITH CONSULT-IINLEC0697S011) Turn ignition switch ªONº and wait at least 2 seconds.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Start engine and run it for at least 2 seconds at idle speed.

(If engine does not run, turn ignition switch to ªSTARTº for at

least 2 seconds.)

4) If DTC is detected, go to ªDiagnostic Procedureº, EC-1244.

WITHOUT CONSULT-IINLEC0697S021) Turn ignition switch ªONº and wait at least 2 seconds.

DTC P1341 P1´CAM POS SENYD22DDTI

CONSULT-II Reference Value in Data Monitor Mode (Cont'd)

EC-1240

Page 1666 of 3051

2) Start engine and run it for at least 2 seconds at idle speed.

(If engine does not run, turn ignition switch to ªSTARTº for at

least 2 seconds.)

3) Turn ignition switch ªOFFº, wait at least 5 seconds and then

turn ªONº.

4) Perform ªDiagnostic Test Mode II (Self-diagnostic results)º with

ECM.

5) If DTC is detected, go to ªDiagnostic Procedureº, EC-1244.

DTC P1341 P1´CAM POS SENYD22DDTI

DTC Confirmation Procedure (Cont'd)

EC-1241

Page 1667 of 3051

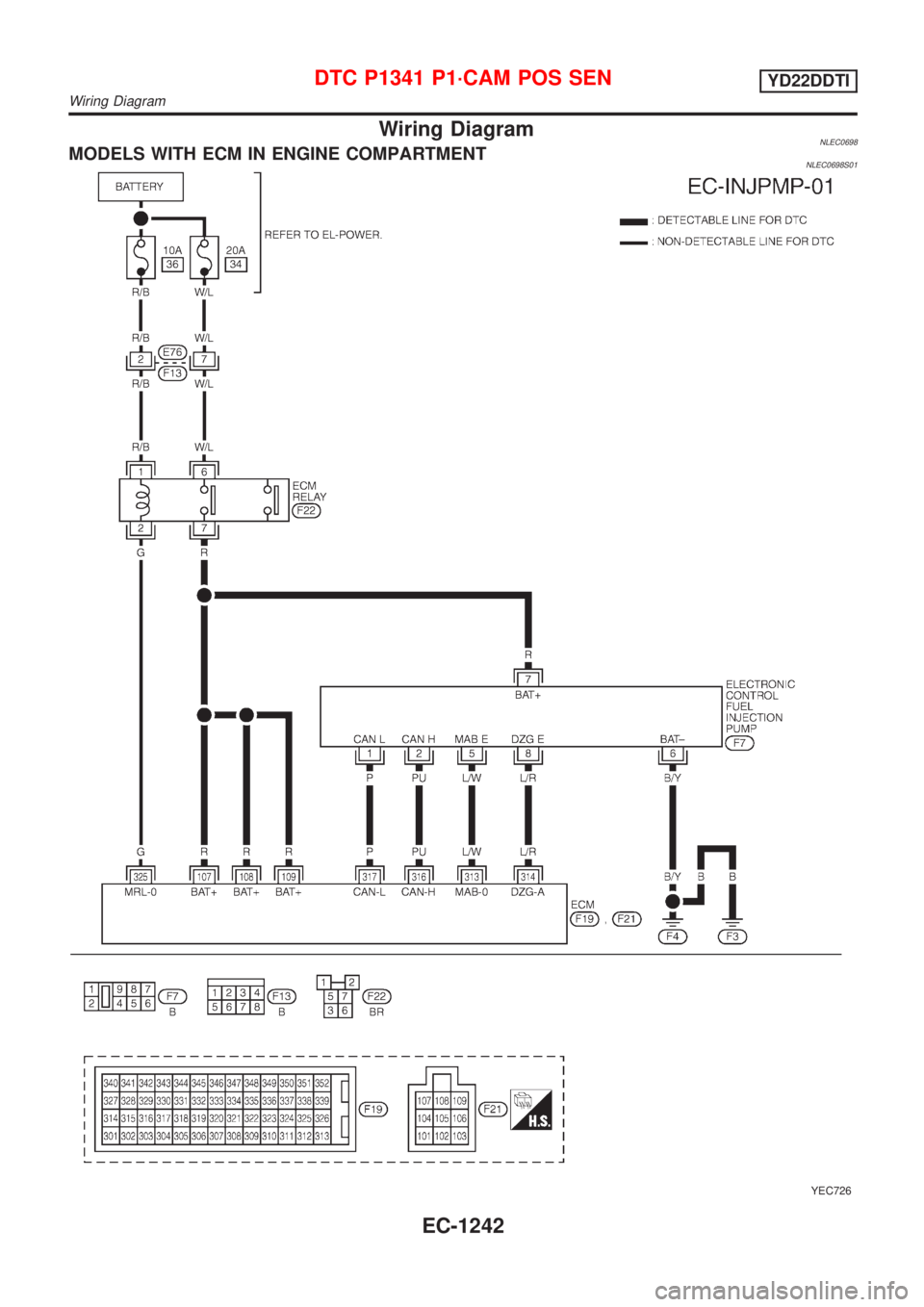

Wiring DiagramNLEC0698MODELS WITH ECM IN ENGINE COMPARTMENTNLEC0698S01

YEC726

DTC P1341 P1´CAM POS SENYD22DDTI

Wiring Diagram

EC-1242

Page 1668 of 3051

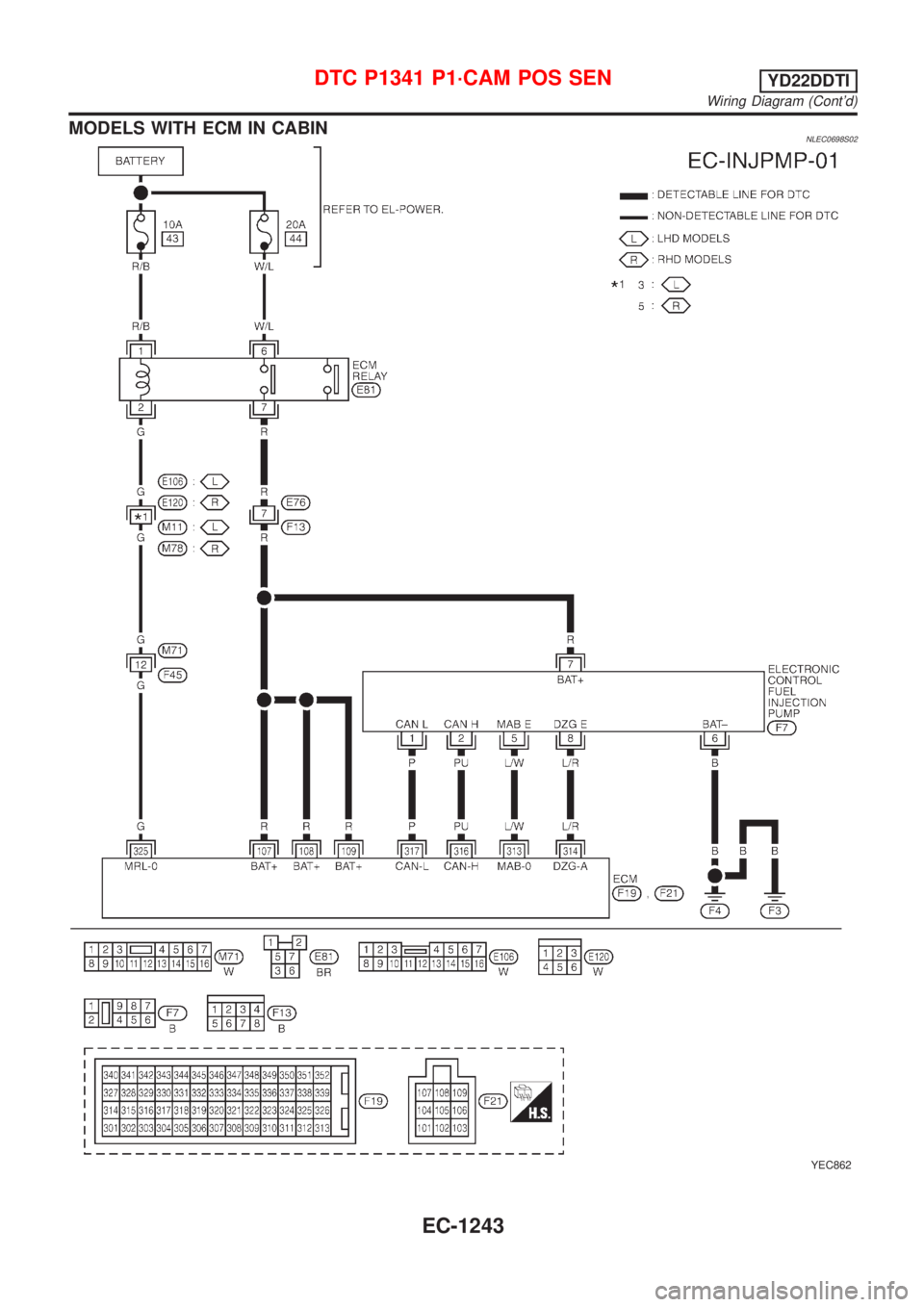

MODELS WITH ECM IN CABINNLEC0698S02

YEC862

DTC P1341 P1´CAM POS SENYD22DDTI

Wiring Diagram (Cont'd)

EC-1243

Page 1669 of 3051

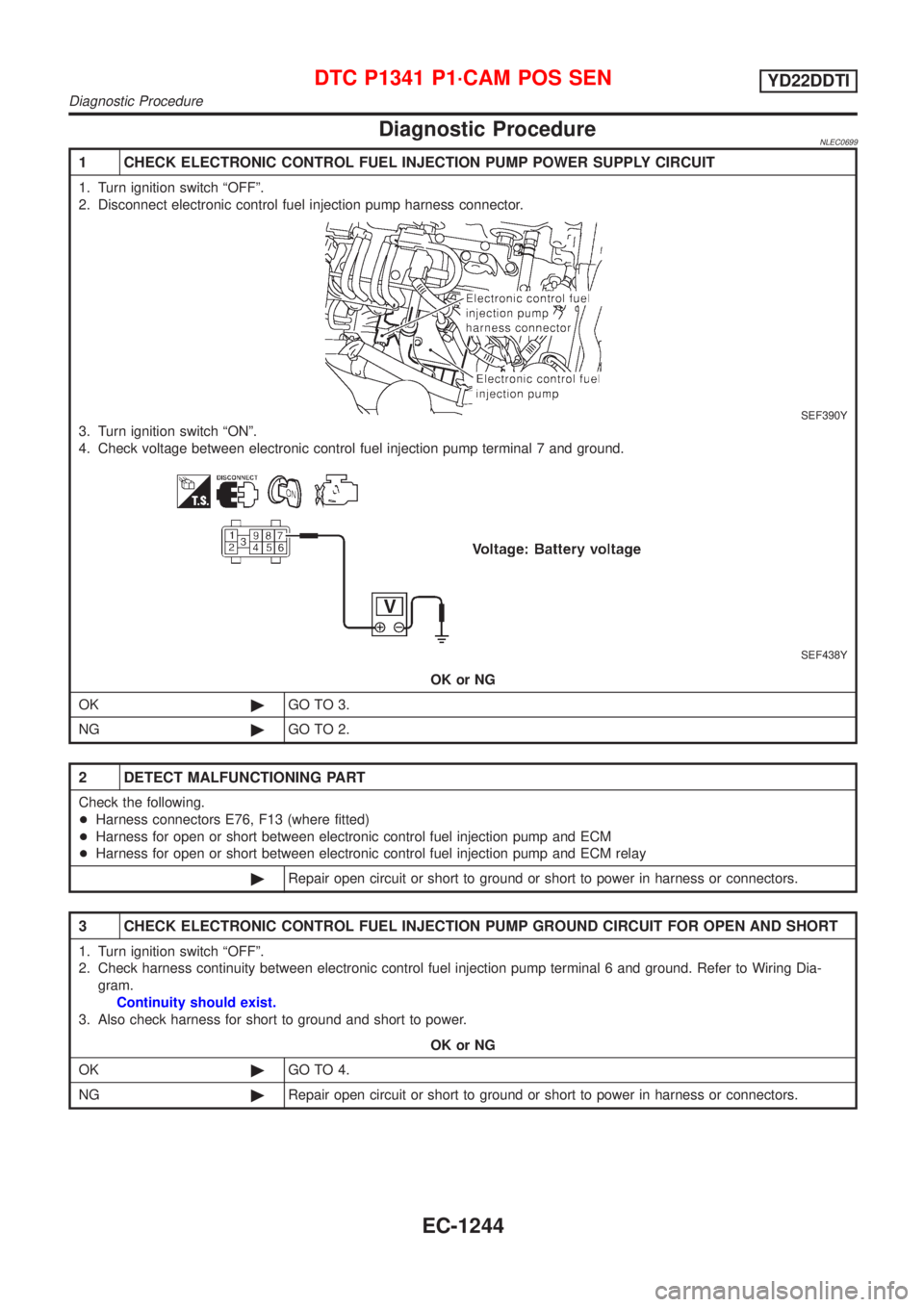

Diagnostic ProcedureNLEC0699

1 CHECK ELECTRONIC CONTROL FUEL INJECTION PUMP POWER SUPPLY CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect electronic control fuel injection pump harness connector.

SEF390Y

3. Turn ignition switch ªONº.

4. Check voltage between electronic control fuel injection pump terminal 7 and ground.

SEF438Y

OK or NG

OK©GO TO 3.

NG©GO TO 2.

2 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors E76, F13 (where fitted)

+Harness for open or short between electronic control fuel injection pump and ECM

+Harness for open or short between electronic control fuel injection pump and ECM relay

©Repair open circuit or short to ground or short to power in harness or connectors.

3 CHECK ELECTRONIC CONTROL FUEL INJECTION PUMP GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Check harness continuity between electronic control fuel injection pump terminal 6 and ground. Refer to Wiring Dia-

gram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 4.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

DTC P1341 P1´CAM POS SENYD22DDTI

Diagnostic Procedure

EC-1244

Page 1670 of 3051

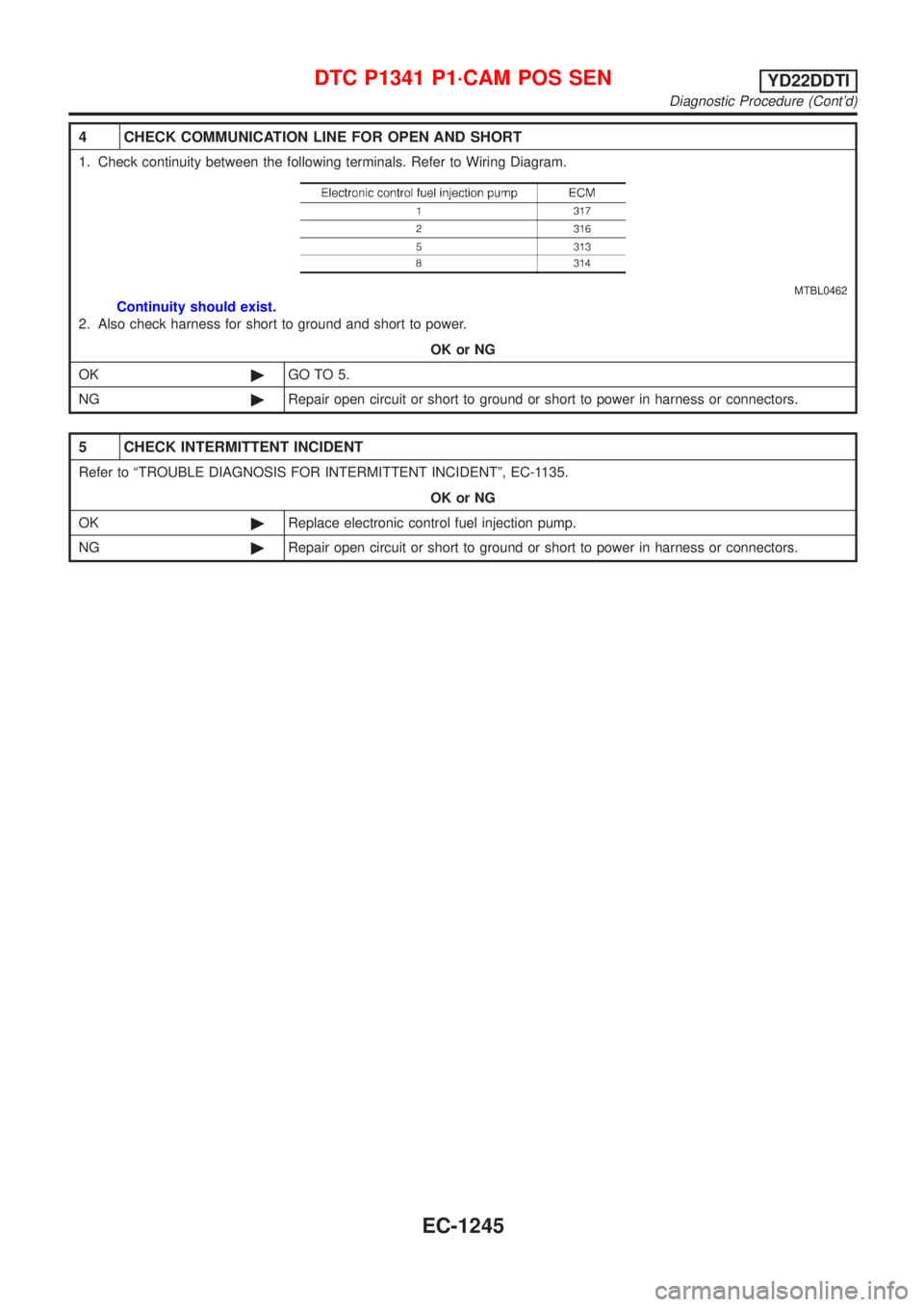

4 CHECK COMMUNICATION LINE FOR OPEN AND SHORT

1. Check continuity between the following terminals. Refer to Wiring Diagram.

MTBL0462

Continuity should exist.

2. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 5.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

5 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-1135.

OK or NG

OK©Replace electronic control fuel injection pump.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

DTC P1341 P1´CAM POS SENYD22DDTI

Diagnostic Procedure (Cont'd)

EC-1245