NISSAN ALMERA TINO 2001 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA TINO, Model: NISSAN ALMERA TINO 2001Pages: 3051, PDF Size: 46.38 MB

Page 1681 of 3051

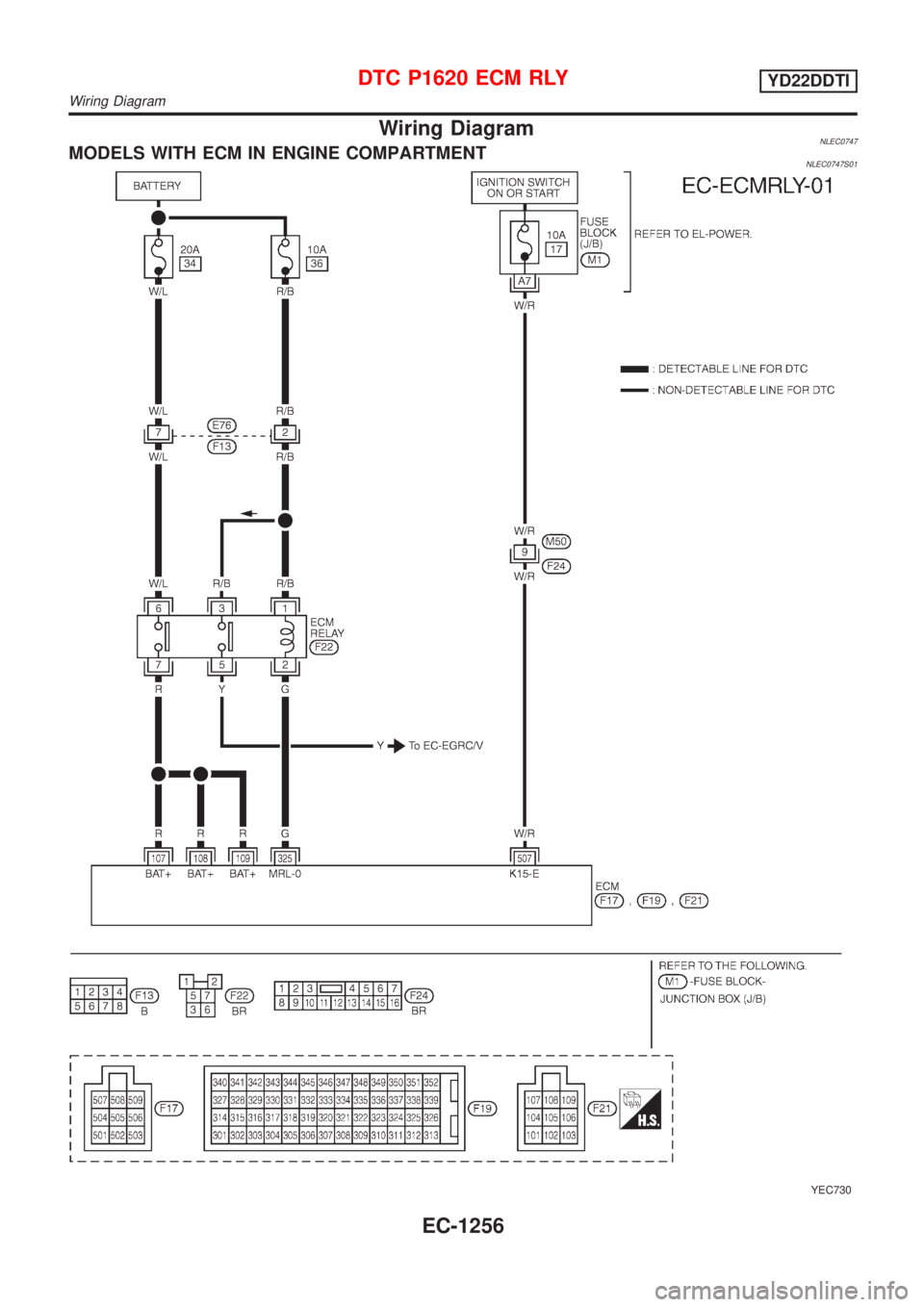

Wiring DiagramNLEC0747MODELS WITH ECM IN ENGINE COMPARTMENTNLEC0747S01

YEC730

DTC P1620 ECM RLYYD22DDTI

Wiring Diagram

EC-1256

Page 1682 of 3051

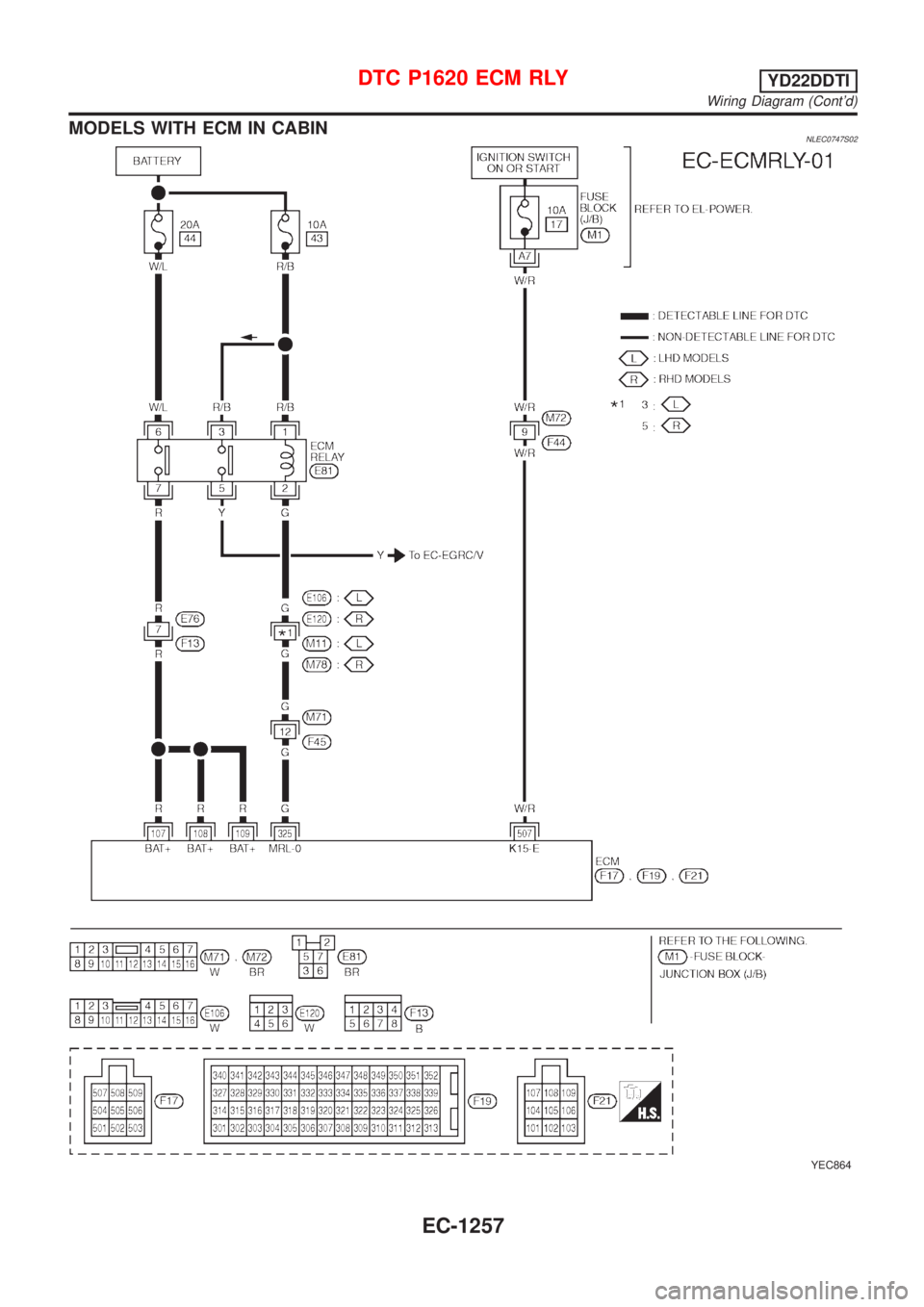

MODELS WITH ECM IN CABINNLEC0747S02

YEC864

DTC P1620 ECM RLYYD22DDTI

Wiring Diagram (Cont'd)

EC-1257

Page 1683 of 3051

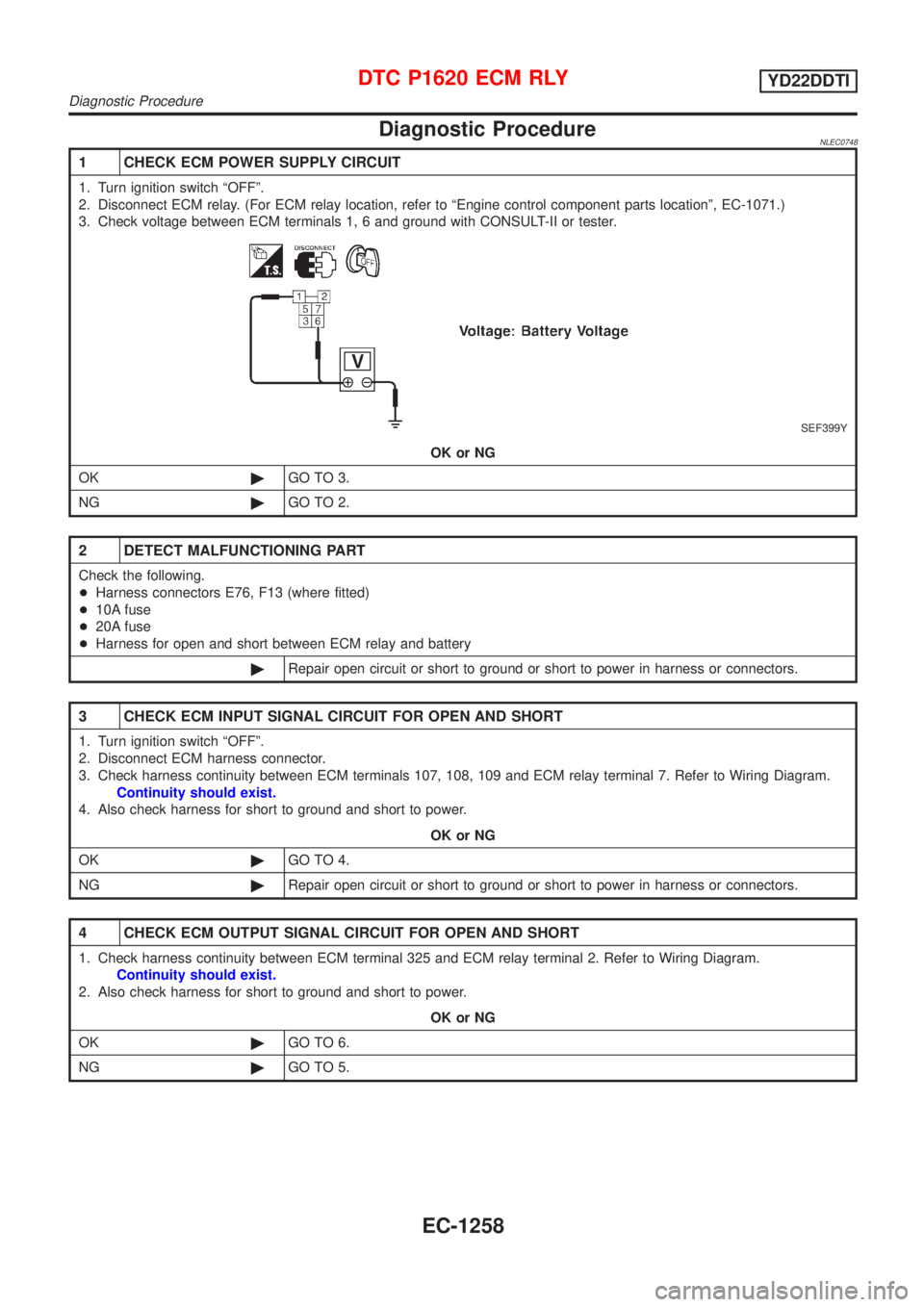

Diagnostic ProcedureNLEC0748

1 CHECK ECM POWER SUPPLY CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM relay. (For ECM relay location, refer to ªEngine control component parts locationº, EC-1071.)

3. Check voltage between ECM terminals 1, 6 and ground with CONSULT-II or tester.

SEF399Y

OK or NG

OK©GO TO 3.

NG©GO TO 2.

2 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors E76, F13 (where fitted)

+10A fuse

+20A fuse

+Harness for open and short between ECM relay and battery

©Repair open circuit or short to ground or short to power in harness or connectors.

3 CHECK ECM INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM terminals 107, 108, 109 and ECM relay terminal 7. Refer to Wiring Diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 4.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

4 CHECK ECM OUTPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Check harness continuity between ECM terminal 325 and ECM relay terminal 2. Refer to Wiring Diagram.

Continuity should exist.

2. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 6.

NG©GO TO 5.

DTC P1620 ECM RLYYD22DDTI

Diagnostic Procedure

EC-1258

Page 1684 of 3051

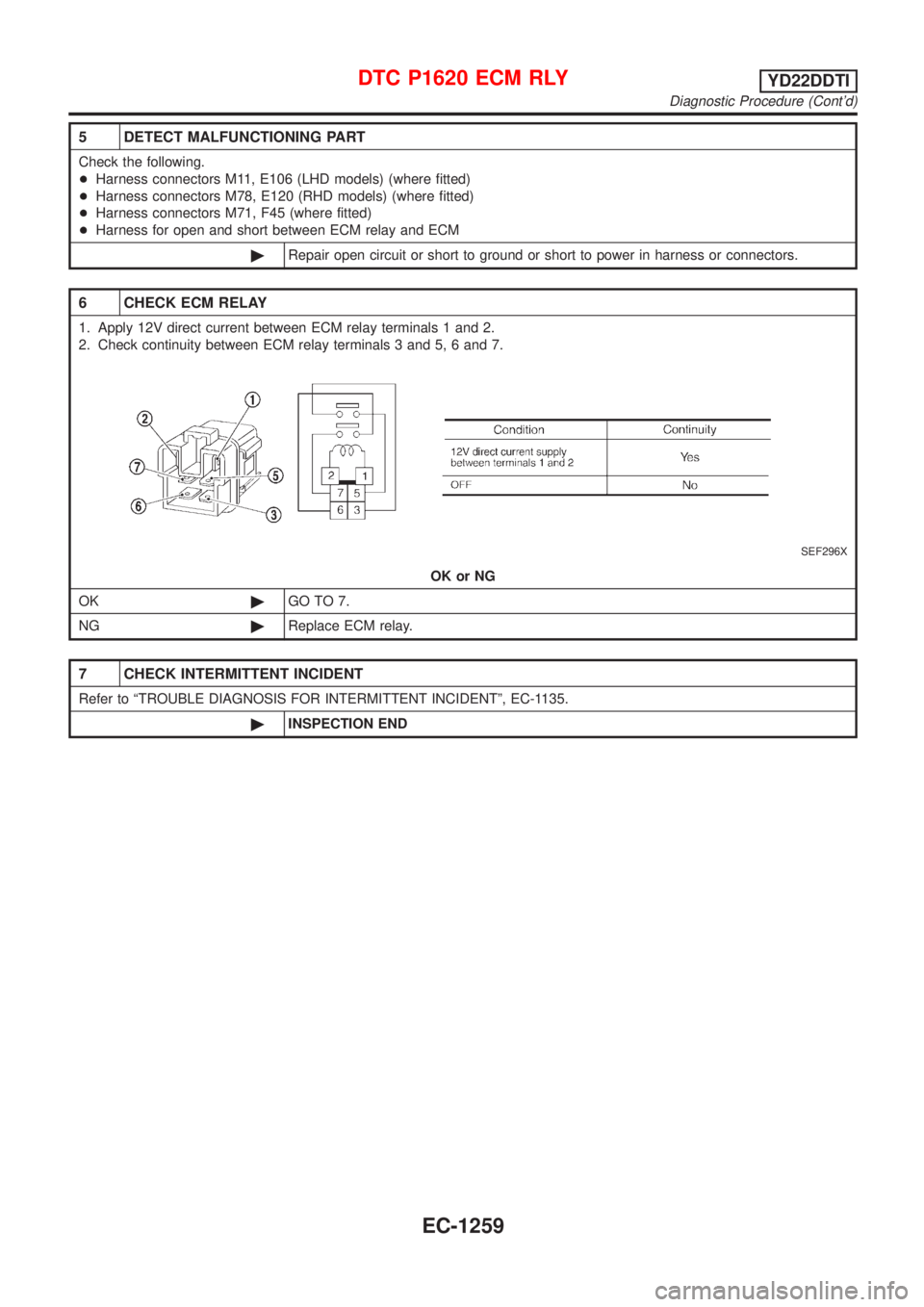

5 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors M11, E106 (LHD models) (where fitted)

+Harness connectors M78, E120 (RHD models) (where fitted)

+Harness connectors M71, F45 (where fitted)

+Harness for open and short between ECM relay and ECM

©Repair open circuit or short to ground or short to power in harness or connectors.

6 CHECK ECM RELAY

1. Apply 12V direct current between ECM relay terminals 1 and 2.

2. Check continuity between ECM relay terminals 3 and 5, 6 and 7.

SEF296X

OK or NG

OK©GO TO 7.

NG©Replace ECM relay.

7 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-1135.

©INSPECTION END

DTC P1620 ECM RLYYD22DDTI

Diagnostic Procedure (Cont'd)

EC-1259

Page 1685 of 3051

SEC220B

DescriptionNLEC0749The ECM consists of a microcomputer and connectors for signal

input and output and for power supply. The unit controls the engine.

On Board Diagnosis LogicNLEC0750

DTC Malfunction is detected when ... Check Items (Possible Cause)

P1621

0903+ECM input signal processing function is malfunc-

tioning.+ECM

(ECCS-D control module)

SEF817Y

DTC Confirmation ProcedureNLEC0751WITH CONSULT-IINLEC0751S011) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Turn ignition switch ªOFFº, wait at least 20 seconds and then

turn ªONº.

4) If DTC is detected, go to ªDiagnostic Procedureº, EC-1261.

WITHOUT CONSULT-IINLEC0751S021) Turn ignition switch ªONº and wait at least 2 seconds.

2) Turn ignition switch ªOFFº, wait at least 20 seconds and then

turn ªONº.

3) Perform ªDiagnostic Test Mode II (Self-diagnostic results)º with

ECM.

4) If DTC is detected, go to ªDiagnostic Procedureº, EC-1261.

DTC P1621 ECM 15YD22DDTI

Description

EC-1260

Page 1686 of 3051

Diagnostic ProcedureNLEC0752

1 INSPECTION START

With CONSULT-II

1. Turn ignition switch ªONº.

2. Select ªSELF DIAG RESULTSº mode with CONSULT-II.

3. Touch ªERASEº.

4. Perform ªDTC Confirmation Procedureº, EC-1260, again.

5. Is the DTC P1621 displayed again?

Without CONSULT-II

1. Turn ignition switch ªONº.

2. Erase the Diagnostic Test Mode II (Self-diagnostic results) memory.

3. Perform ªDTC Confirmation Procedureº, EC-1260, again.

4. Perform ªDiagnostic Test Mode II (Self-diagnostic results)º.

5. Is the DTC 0903 displayed again?

YesorNo

Ye s©Replace ECM.

No©INSPECTION END

DTC P1621 ECM 15YD22DDTI

Diagnostic Procedure

EC-1261

Page 1687 of 3051

On Boar dDiagnosi sLogic

DTC Malfunctionis detecte dwhe n... CheckItem s(Possibl eCause)

Wit hCONSU LT -II

Withou tCONSU LT -II

1 INSPECTIO NSTART

On Board Diagnosis Logic

Page 1688 of 3051

2 CHEC KBATTE RY AN DALTERN ATOR

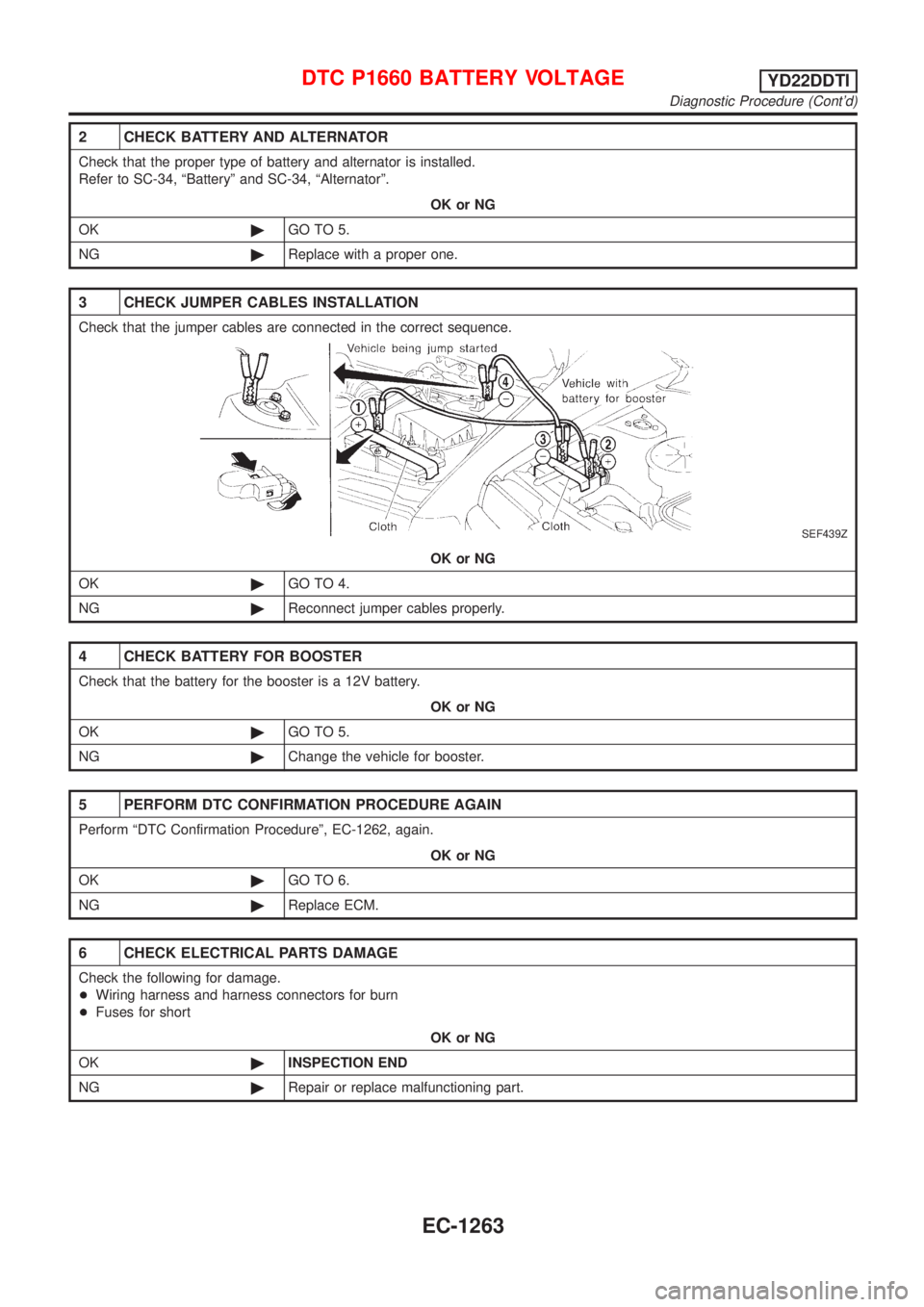

3 CHEC KJUMPE RCABLE SINS TALL ATION

SEF439Z

4 CHEC KBATTE RY FO RBOOSTER

5 PERFOR MDT CCONFIRM ATIO NPROCEDUR EAGAIN

6 CHEC KELECTRICA LPART SDAMAGE

Diagnostic Procedure (Cont'd)

Page 1689 of 3051

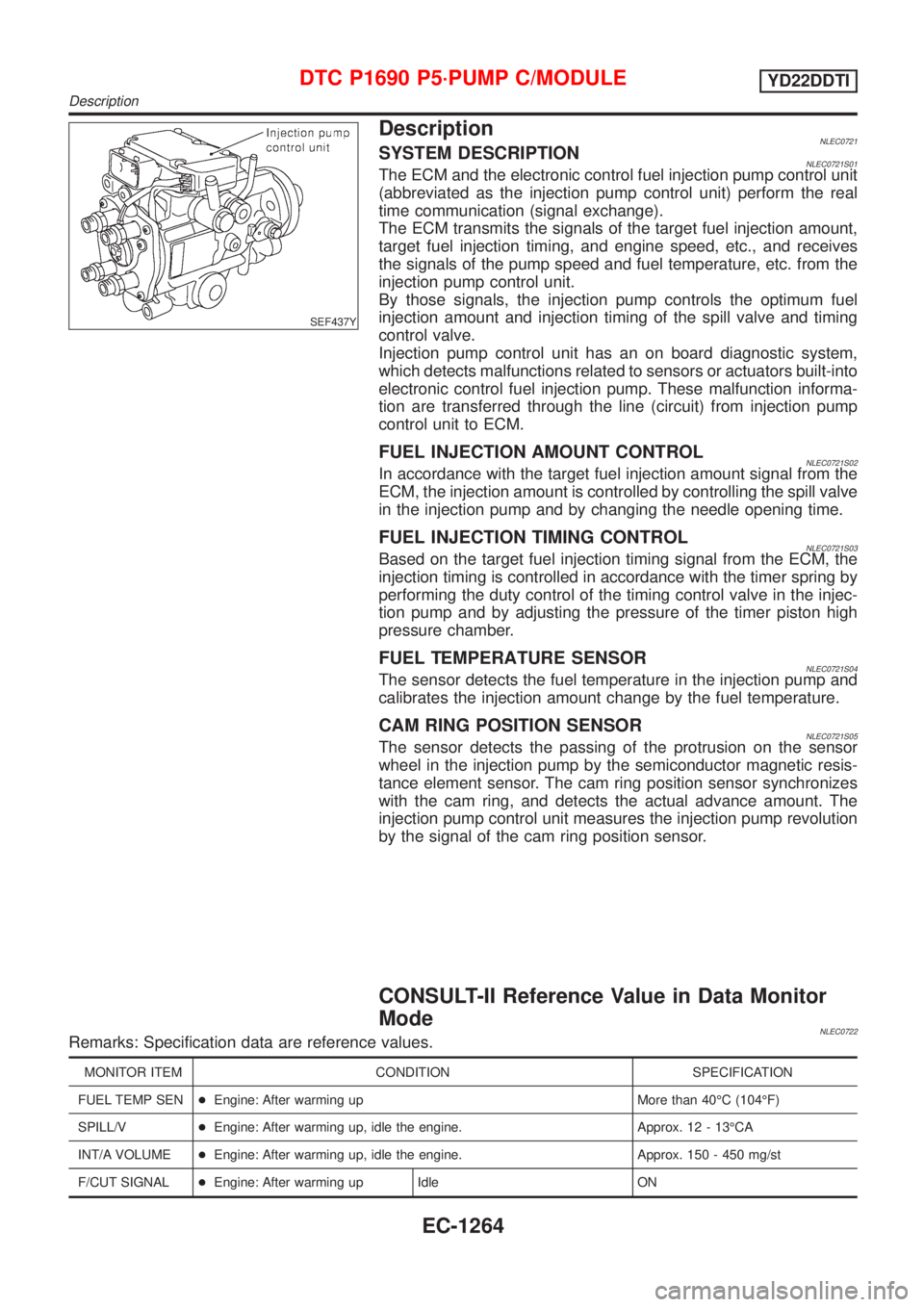

SEF437Y

DescriptionNLEC0721SYSTEM DESCRIPTIONNLEC0721S01The ECM and the electronic control fuel injection pump control unit

(abbreviated as the injection pump control unit) perform the real

time communication (signal exchange).

The ECM transmits the signals of the target fuel injection amount,

target fuel injection timing, and engine speed, etc., and receives

the signals of the pump speed and fuel temperature, etc. from the

injection pump control unit.

By those signals, the injection pump controls the optimum fuel

injection amount and injection timing of the spill valve and timing

control valve.

Injection pump control unit has an on board diagnostic system,

which detects malfunctions related to sensors or actuators built-into

electronic control fuel injection pump. These malfunction informa-

tion are transferred through the line (circuit) from injection pump

control unit to ECM.

FUEL INJECTION AMOUNT CONTROLNLEC0721S02In accordance with the target fuel injection amount signal from the

ECM, the injection amount is controlled by controlling the spill valve

in the injection pump and by changing the needle opening time.

FUEL INJECTION TIMING CONTROLNLEC0721S03Based on the target fuel injection timing signal from the ECM, the

injection timing is controlled in accordance with the timer spring by

performing the duty control of the timing control valve in the injec-

tion pump and by adjusting the pressure of the timer piston high

pressure chamber.

FUEL TEMPERATURE SENSORNLEC0721S04The sensor detects the fuel temperature in the injection pump and

calibrates the injection amount change by the fuel temperature.

CAM RING POSITION SENSORNLEC0721S05The sensor detects the passing of the protrusion on the sensor

wheel in the injection pump by the semiconductor magnetic resis-

tance element sensor. The cam ring position sensor synchronizes

with the cam ring, and detects the actual advance amount. The

injection pump control unit measures the injection pump revolution

by the signal of the cam ring position sensor.

CONSULT-II Reference Value in Data Monitor

Mode

NLEC0722Remarks: Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

FUEL TEMP SEN+Engine: After warming up More than 40ÉC (104ÉF)

SPILL/V+Engine: After warming up, idle the engine. Approx. 12 - 13ÉCA

INT/A VOLUME+Engine: After warming up, idle the engine. Approx. 150 - 450 mg/st

F/CUT SIGNAL+Engine: After warming up Idle ON

DTC P1690 P5´PUMP C/MODULEYD22DDTI

Description

EC-1264

Page 1690 of 3051

MONITOR ITEM CONDITION SPECIFICATION

BARO SEN+Ignition switch: ONAltitude

Approx.0m(0ft): Approx. 100.62

kPa (1.0062 bar, 1.026 kg/cm

2,

14.59 psi)

Approx. 1,000 m (3,281 ft): Approx.

88.95 kPa (0.8895 bar, 0.907

kg/cm

2, 12.90 psi)

Approx. 1,500 m (4,922 ft): Approx.

83.16 kPa (0.8316 bar, 0.848

kg/cm

2, 12.06 psi)

Approx. 2,000 m (6,562 ft): Approx.

78.36 kPa (0.7836 bar, 0.799

kg/cm

2, 11.36 psi)

ECM Terminals and Reference ValueNLEC0723Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

313 L/WElectronic control fuel

injection pump[Engine is running]

+Warm-up condition

+Idle speedApproximately 0.1V

314 L/RElectronic control fuel

injection pump[Engine is running]

+Warm-up condition

+Idle speedApproximately 0.4V

316 PUElectronic control fuel

injection pump[Engine is running]

+Warm-up condition

+Idle speedApproximately 2.5V

317 PElectronic control fuel

injection pump[Engine is running]

+Warm-up condition

+Idle speedApproximately 2.5V

On Board Diagnosis LogicNLEC0724

DTC Malfunction is detected when .... Check Items (Possible cause)

P1690

0705+Injection pump control unit does not function

properly.+Electronic control fuel injection pump

SEF817Y

DTC Confirmation ProcedureNLEC0725WITH CONSULT-IINLEC0725S011) Turn ignition switch ªONº and wait at least 2 seconds.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Start engine and run it for at least 2 seconds at idle speed.

(If engine does not run, turn ignition switch to ªSTARTº for at

least 2 seconds.)

4) If DTC is detected, go to ªDiagnostic Procedureº, EC-1266.

WITHOUT CONSULT-IINLEC0725S021) Turn ignition switch ªONº and wait at least 2 seconds.

DTC P1690 P5´PUMP C/MODULEYD22DDTI

CONSULT-II Reference Value in Data Monitor Mode (Cont'd)

EC-1265