NISSAN ALMERA TINO 2001 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA TINO, Model: NISSAN ALMERA TINO 2001Pages: 3051, PDF Size: 46.38 MB

Page 211 of 3051

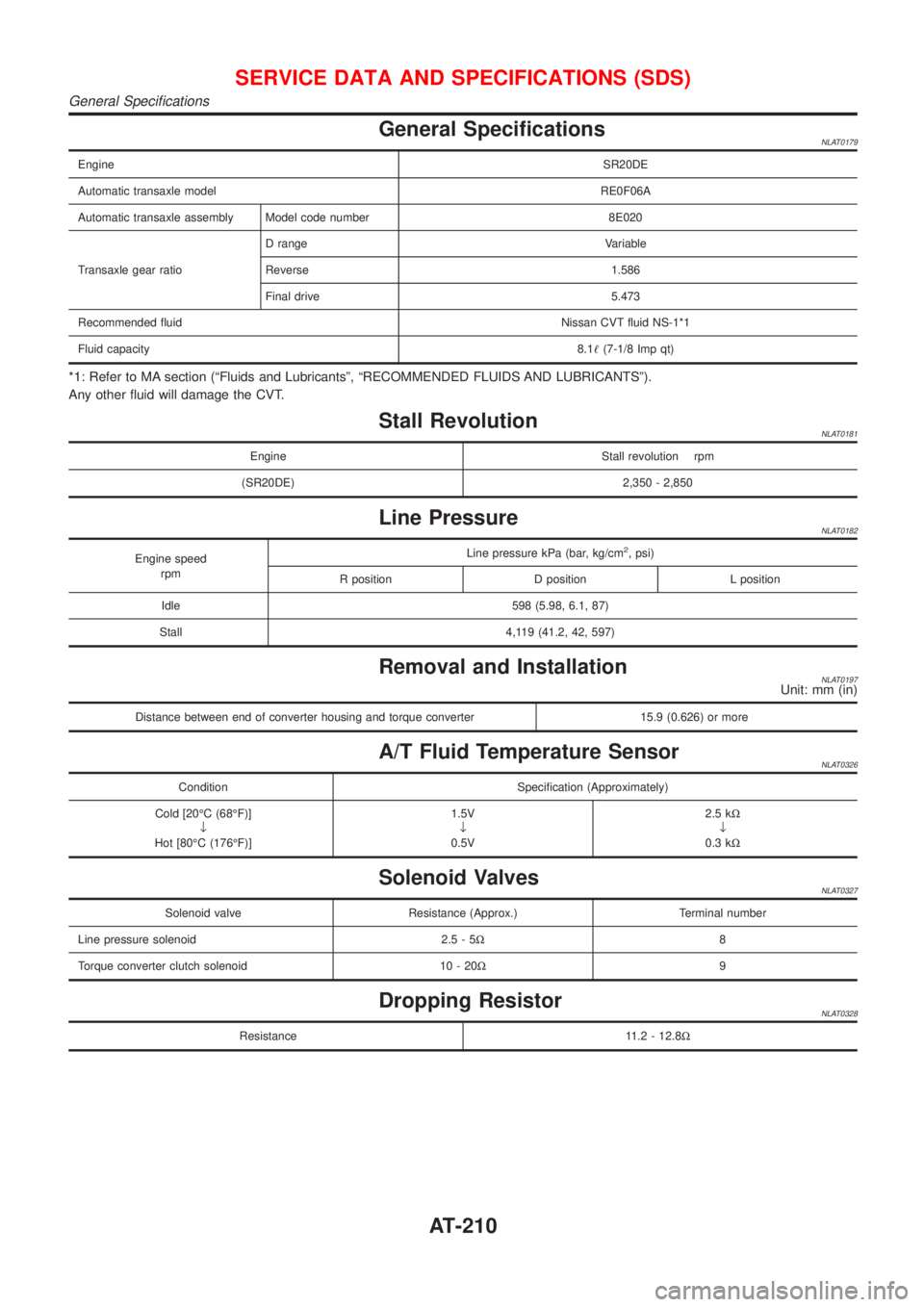

General SpecificationsNLAT0179

EngineSR20DE

Automatic transaxle modelRE0F06A

Automatic transaxle assembly Model code number 8E020

Transaxle gear ratioD range Variable

Reverse 1.586

Final drive 5.473

Recommended fluidNissan CVT fluid NS-1*1

Fluid capacity8.1!(7-1/8 Imp qt)

*1: Refer to MA section (ªFluids and Lubricantsº, ªRECOMMENDED FLUIDS AND LUBRICANTSº).

Any other fluid will damage the CVT.

Stall RevolutionNLAT0181

Engine Stall revolution rpm

(SR20DE) 2,350 - 2,850

Line PressureNLAT0182

Engine speed

rpmLine pressure kPa (bar, kg/cm2, psi)

R position D position L position

Idle 598 (5.98, 6.1, 87)

Stall 4,119 (41.2, 42, 597)

Removal and InstallationNLAT0197Unit: mm (in)

Distance between end of converter housing and torque converter 15.9 (0.626) or more

A/T Fluid Temperature SensorNLAT0326

Condition Specification (Approximately)

Cold [20ÉC (68ÉF)]

¯

Hot [80ÉC (176ÉF)]1.5V

¯

0.5V2.5 kW

¯

0.3 kW

Solenoid ValvesNLAT0327

Solenoid valve Resistance (Approx.) Terminal number

Line pressure solenoid 2.5 - 5W8

Torque converter clutch solenoid 10 - 20W9

Dropping ResistorNLAT0328

Resistance 11.2 - 12.8W

SERVICE DATA AND SPECIFICATIONS (SDS)

General Specifications

AT-210

Page 212 of 3051

FRONT & REAR AXLE

SECTION

AX

CONTENTS

FRONT AXLE..................................................................2

Precautions ..................................................................2

PRECAUTIONS.........................................................2

Preparation ..................................................................2

SPECIAL SERVICE TOOLS........................................2

COMMERCIAL SERVICE TOOLS................................2

Noise, Vibration and Harshness (NVH)

Troubleshooting ...........................................................3

NVH TROUBLESHOOTING CHART............................3

On-vehicle Service.......................................................3

FRONT AXLE PARTS................................................3

FRONT WHEEL BEARING.........................................3

DRIVE SHAFT...........................................................4

Wheel Hub and Knuckle ..............................................5

COMPONENTS.........................................................5

REMOVAL.................................................................5

INSTALLATION..........................................................7

DISASSEMBLY..........................................................7

INSPECTION.............................................................8

ASSEMBLY...............................................................8

Drive Shaft .................................................................10

COMPONENTS.......................................................10

REMOVAL............................................................... 11

INSTALLATION........................................................ 11

DISASSEMBLY........................................................12

INSPECTION...........................................................14

ASSEMBLY.............................................................14

Service Data and Specifications (SDS).....................19

DRIVE SHAFT.........................................................19

DYNAMIC DAMPER (WHERE FITTED).....................20

WHEEL BEARING (FRONT).....................................20

REAR AXLE...................................................................21

Precautions ................................................................21

PRECAUTIONS.......................................................21

Preparation ................................................................21

SPECIAL SERVICE TOOLS......................................21

COMMERCIAL SERVICE TOOLS..............................21

Noise, Vibration and Harshness (NVH)

Troubleshooting .........................................................22

On-vehicle Service.....................................................22

REAR AXLE PARTS.................................................22

REAR WHEEL BEARING.........................................22

Wheel Hub .................................................................23

COMPONENTS.......................................................23

REMOVAL...............................................................23

INSTALLATION........................................................24

Service Data and Specifications (SDS).....................26

WHEEL BEARING (REAR).......................................26

Page 213 of 3051

SBR686C

Precautions

PRECAUTIONSNLAX0001+When installing rubber parts, final tightening must be car-

ried out under unladen condition* with tires on ground.

*: Fuel, radiator coolant and engine oil full. Spare tire, jack,

hand tools and mats in designated positions.

+After installing removed suspension parts, check wheel

alignment and adjust if necessary.

+Use flare nut wrench when removing or installing brake

tubes.

+Always torque brake lines when installing.

Preparation

SPECIAL SERVICE TOOLSNLAX0002

Tool number

Tool nameDescription

HT72520000

Ball joint remover

NT146

Removing tie-rod outer end and lower ball joint

KV38106800

Differential side oil seal

protector

NT147

Installing drive shaft

KV38106800

COMMERCIAL SERVICE TOOLSNLAX0003

Tool name Description

1 Flare nut crowfoot

2 Torque wrench

NT360

Removing and installing each brake piping

a: 10 mm (0.39 in)

FRONT AXLE

Precautions

AX-2

Page 214 of 3051

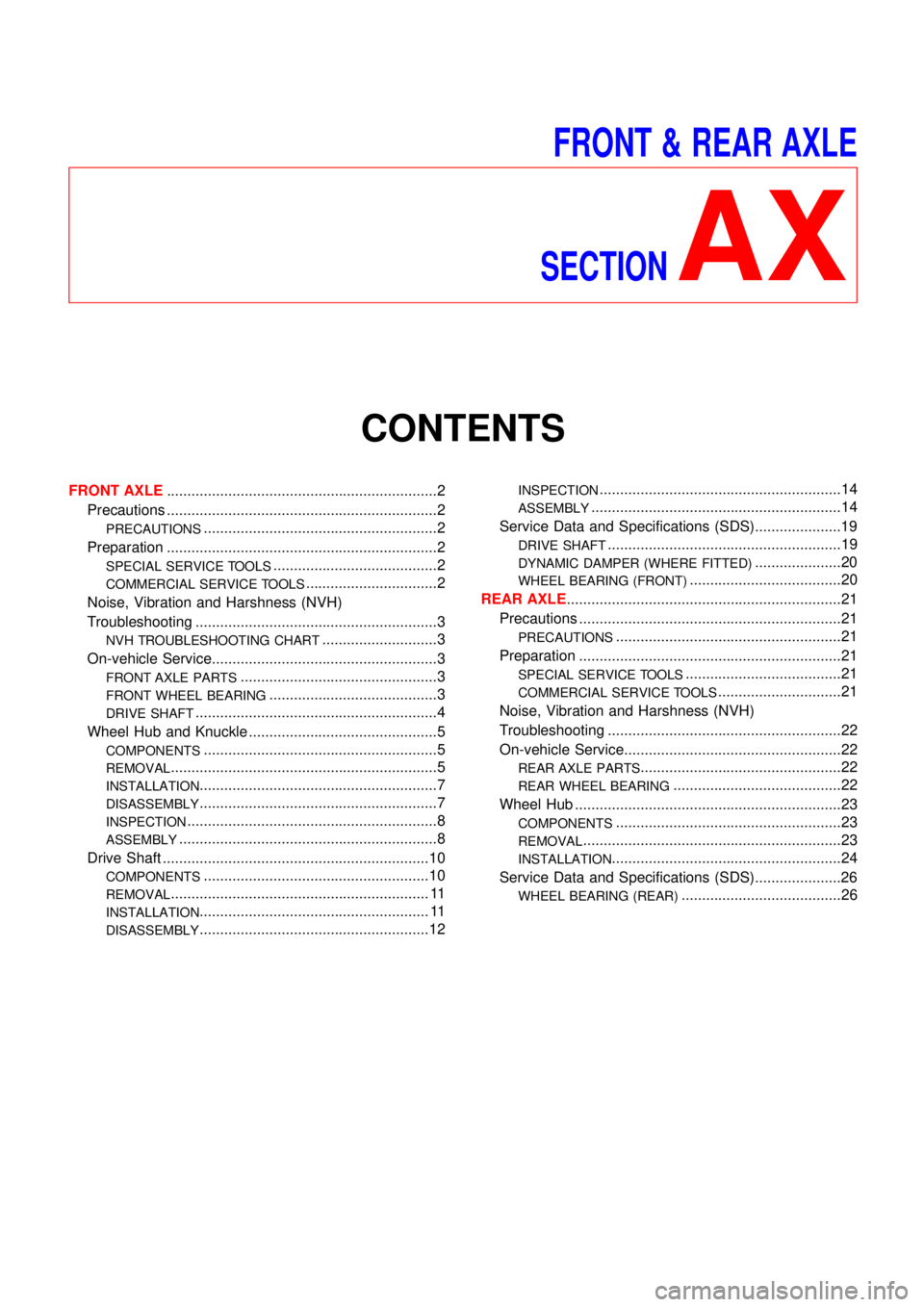

Noise, Vibration and Harshness (NVH)

Troubleshooting

=NLAX0004NVH TROUBLESHOOTING CHARTNLAX0004S01Use the chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

Reference page—

AX-14

—

AX-5, 23

—

AX-3, 22

—

—

SU-4

SU-4

SU-4

BR-6

ST-5

Possible cause and

SUSPECTED PARTS

Excessive joint angle

Joint sliding resistance

Imbalance

Improper installation, looseness

Parts interference

Wheel bearing damage

DRIVE SHAFT

AXLE

SUSPENSION

TIRES

ROAD WHEEL

BRAKES

STEERING

SymptomDRIVE SHAFTNoise, Vibration× × × ×××× ×

Shake× × × ×××× ×

AXLENoise×× × ×××× ×

Shake×× × ×××× ×

Vibration×× × ×× ×

Shimmy×× ×××× ×

Judder× ×××× ×

Poor quality ride or

handling××× ×××

×: Applicable

SMA525A

On-vehicle Service

FRONT AXLE PARTSNLAX0005Check front axle and front suspension parts for excessive play,

cracks, wear or other damage.

+Shake each front wheel to check for excessive play.

+Make sure that cotter pin is inserted.

+Retighten all axle and suspension nuts and bolts to the speci-

fied torque.

Tightening torque:

Refer to SU-4, “FRONT SUSPENSION”.

SFA805B

FRONT WHEEL BEARINGNLAX0006+Check that wheel bearings operate smoothly.

+Check axial end play.

Axial end play:

0.05 mm (0.0020 in)

If out of specification or wheel bearing does not turn smoothly,

replace wheel bearing assembly.

Refer to “Wheel Hub and Knuckle”, “FRONT AXLE”, AX-5.

FRONT AXLE

Noise, Vibration and Harshness (NVH) Troubleshooting

AX-3

Page 215 of 3051

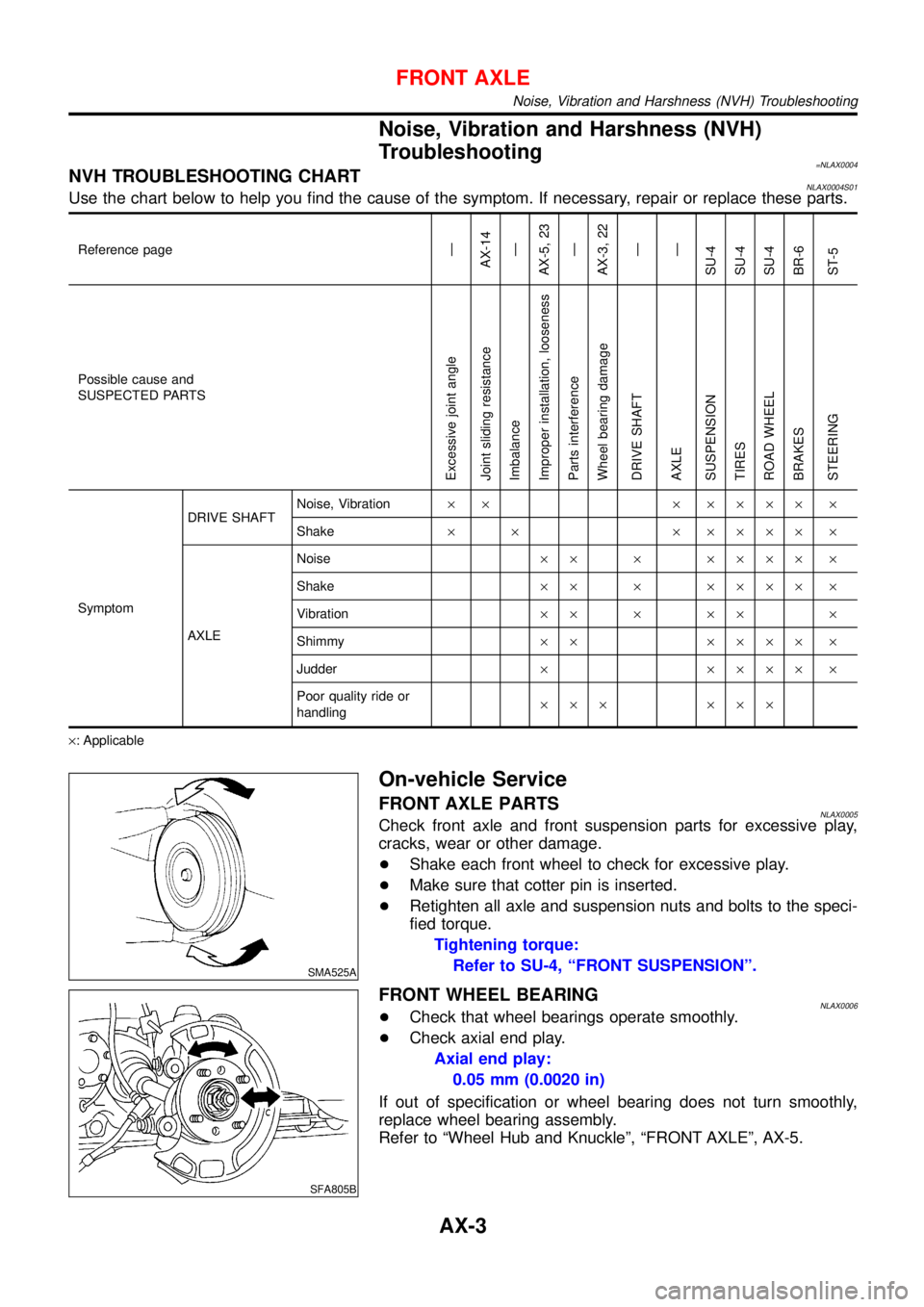

SFA108A

DRIVE SHAFTNLAX0007Check for grease leakage or other damage.

FRONT AXLE

On-vehicle Service (Cont’d)

AX-4

Page 216 of 3051

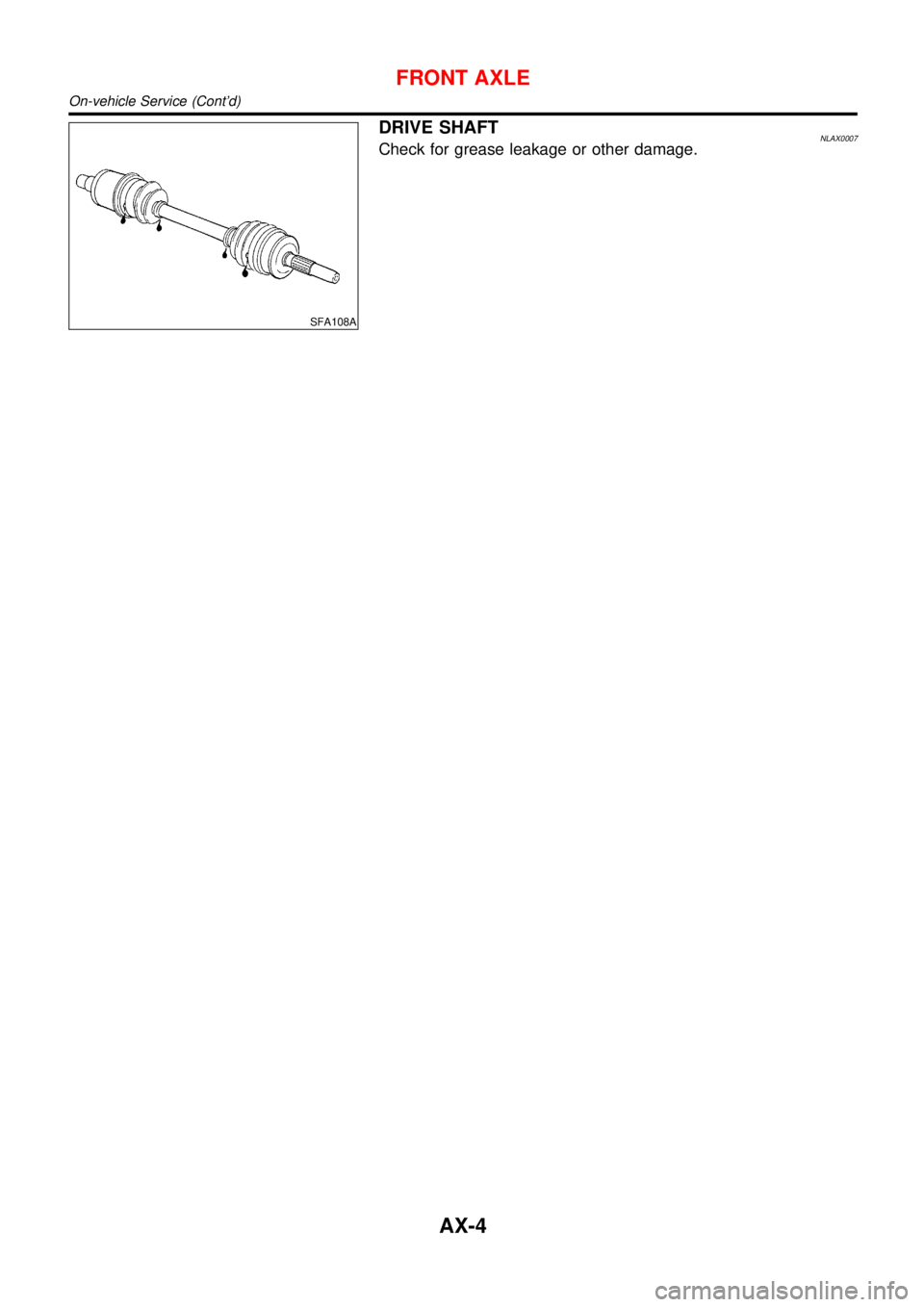

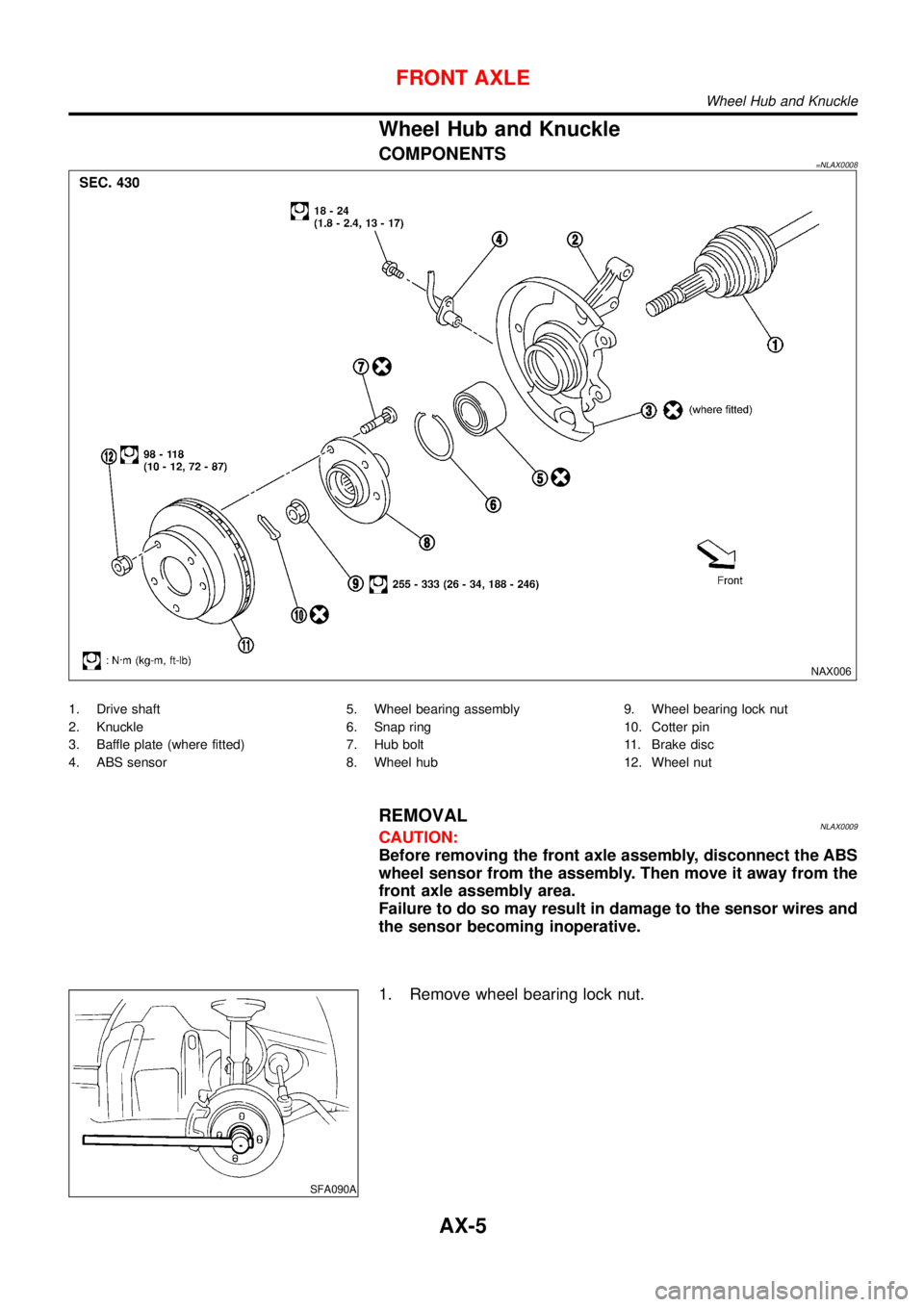

Wheel Hub and Knuckle

COMPONENTS=NLAX0008

NAX006

1. Drive shaft

2. Knuckle

3. Baffle plate (where fitted)

4. ABS sensor5. Wheel bearing assembly

6. Snap ring

7. Hub bolt

8. Wheel hub9. Wheel bearing lock nut

10. Cotter pin

11. Brake disc

12. Wheel nut

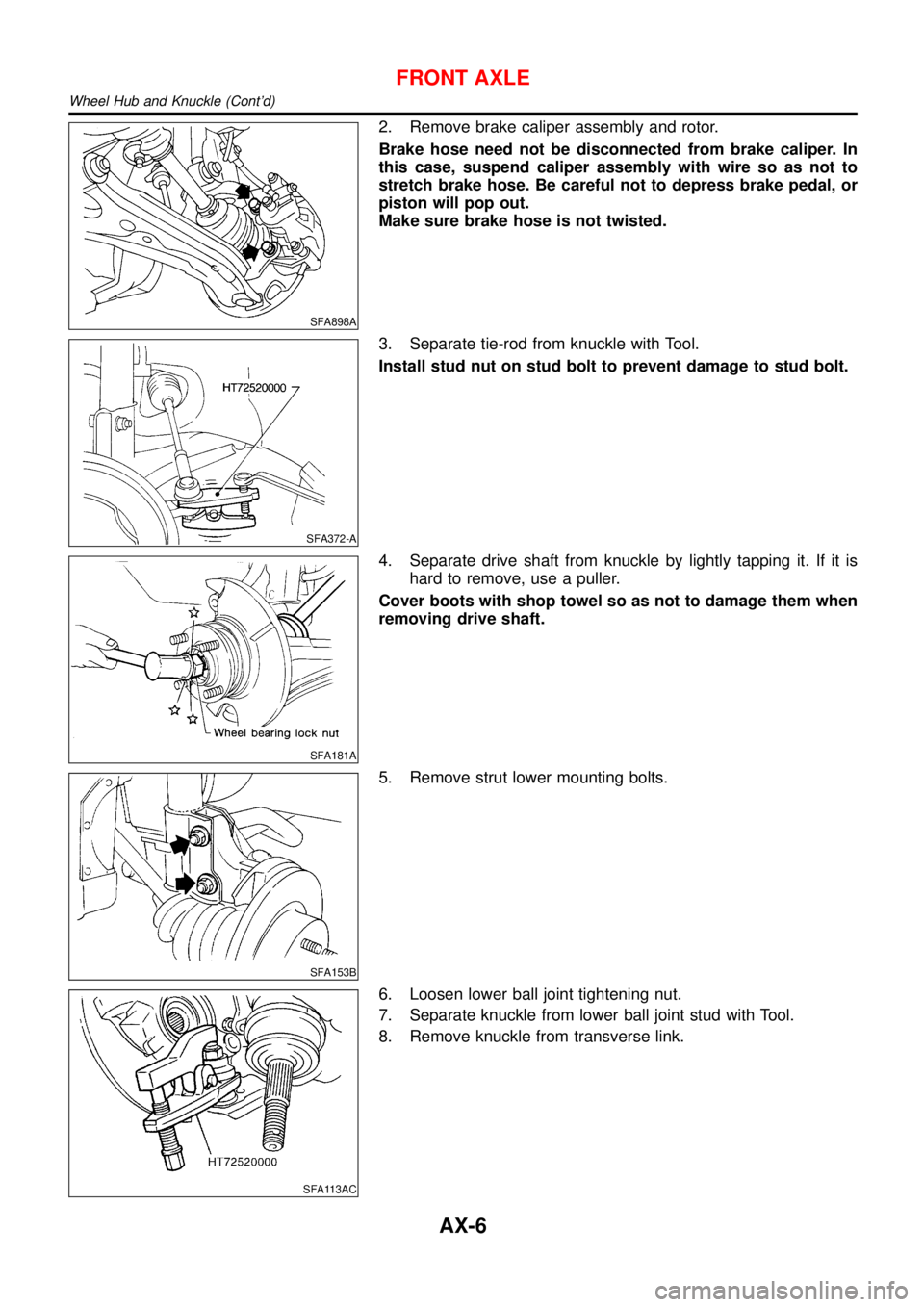

REMOVALNLAX0009CAUTION:

Before removing the front axle assembly, disconnect the ABS

wheel sensor from the assembly. Then move it away from the

front axle assembly area.

Failure to do so may result in damage to the sensor wires and

the sensor becoming inoperative.

SFA090A

1. Remove wheel bearing lock nut.

FRONT AXLE

Wheel Hub and Knuckle

AX-5

Page 217 of 3051

SFA898A

2. Remove brake caliper assembly and rotor.

Brake hose need not be disconnected from brake caliper. In

this case, suspend caliper assembly with wire so as not to

stretch brake hose. Be careful not to depress brake pedal, or

piston will pop out.

Make sure brake hose is not twisted.

SFA372-A

3. Separate tie-rod from knuckle with Tool.

Install stud nut on stud bolt to prevent damage to stud bolt.

SFA181A

4. Separate drive shaft from knuckle by lightly tapping it. If it is

hard to remove, use a puller.

Cover boots with shop towel so as not to damage them when

removing drive shaft.

SFA153B

5. Remove strut lower mounting bolts.

SFA113AC

6. Loosen lower ball joint tightening nut.

7. Separate knuckle from lower ball joint stud with Tool.

8. Remove knuckle from transverse link.

FRONT AXLE

Wheel Hub and Knuckle (Cont’d)

AX-6

Page 218 of 3051

SFA114A

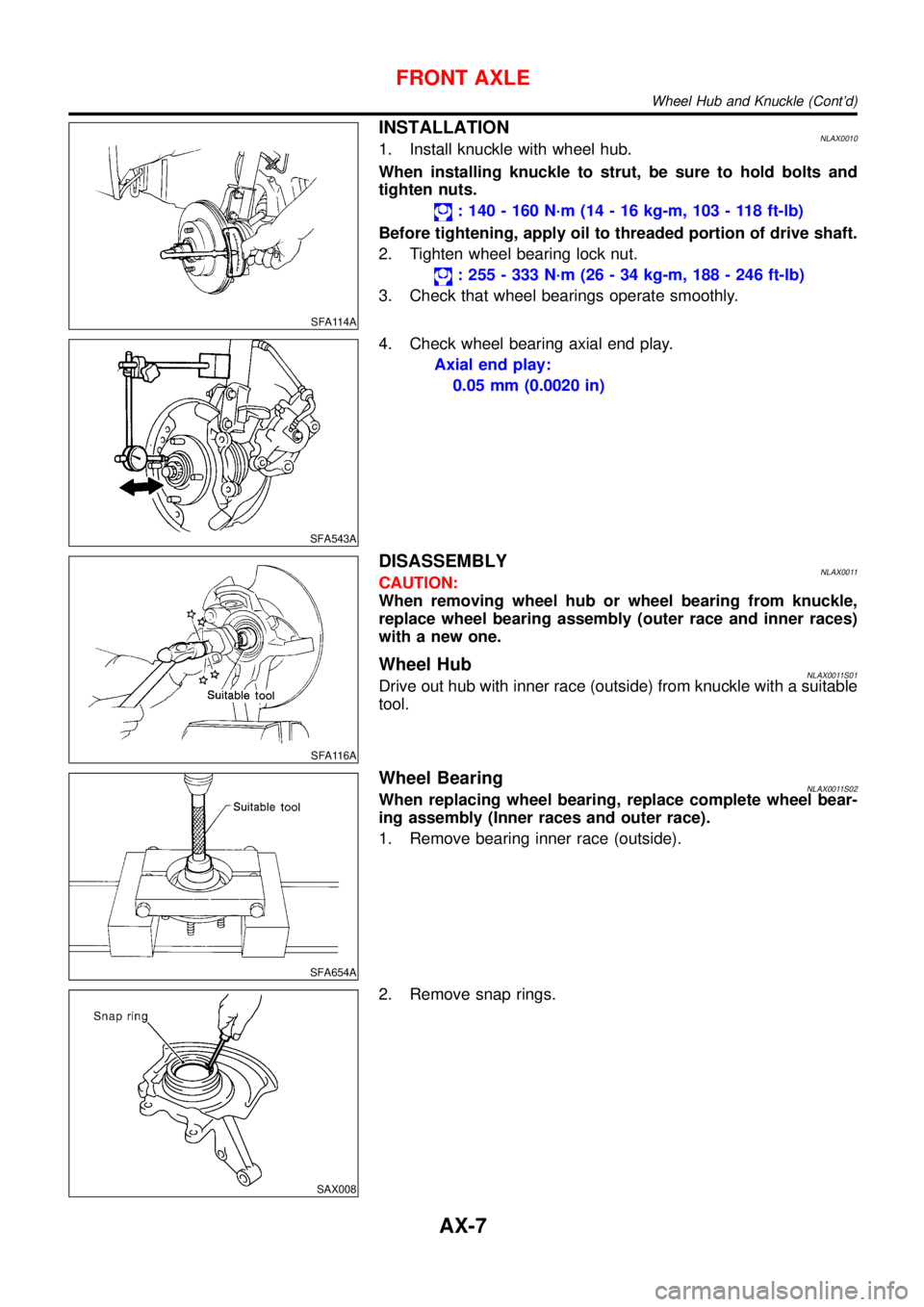

INSTALLATIONNLAX00101. Install knuckle with wheel hub.

When installing knuckle to strut, be sure to hold bolts and

tighten nuts.

: 140 - 160 N·m (14 - 16 kg-m, 103 - 118 ft-lb)

Before tightening, apply oil to threaded portion of drive shaft.

2. Tighten wheel bearing lock nut.

: 255 - 333 N·m (26 - 34 kg-m, 188 - 246 ft-lb)

3. Check that wheel bearings operate smoothly.

SFA543A

4. Check wheel bearing axial end play.

Axial end play:

0.05 mm (0.0020 in)

SFA116A

DISASSEMBLYNLAX0011CAUTION:

When removing wheel hub or wheel bearing from knuckle,

replace wheel bearing assembly (outer race and inner races)

with a new one.

Wheel HubNLAX0011S01Drive out hub with inner race (outside) from knuckle with a suitable

tool.

SFA654A

Wheel BearingNLAX0011S02When replacing wheel bearing, replace complete wheel bear-

ing assembly (Inner races and outer race).

1. Remove bearing inner race (outside).

SAX008

2. Remove snap rings.

FRONT AXLE

Wheel Hub and Knuckle (Cont’d)

AX-7

Page 219 of 3051

SFA905A

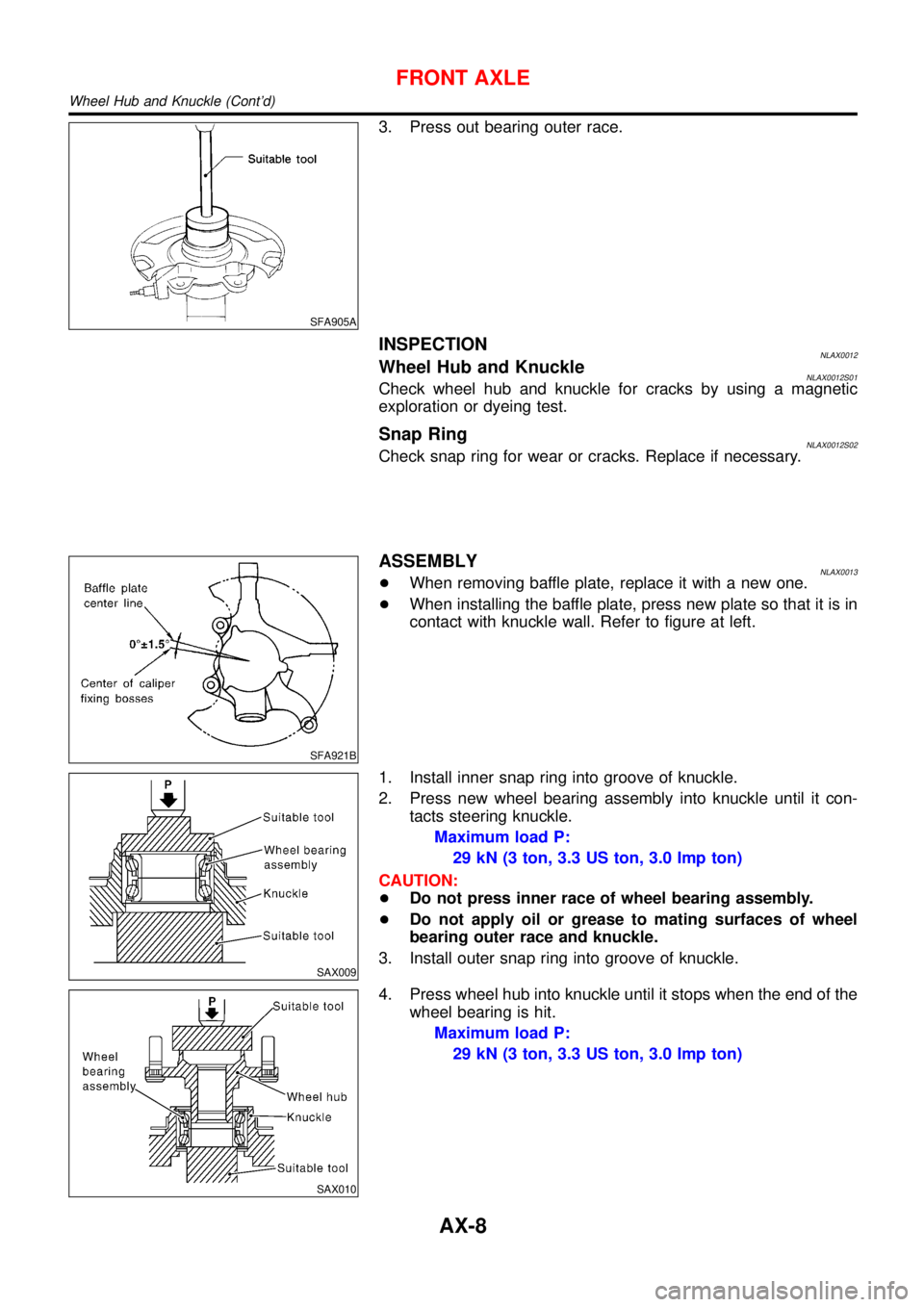

3. Press out bearing outer race.

INSPECTIONNLAX0012Wheel Hub and KnuckleNLAX0012S01Check wheel hub and knuckle for cracks by using a magnetic

exploration or dyeing test.

Snap RingNLAX0012S02Check snap ring for wear or cracks. Replace if necessary.

SFA921B

ASSEMBLYNLAX0013+When removing baffle plate, replace it with a new one.

+When installing the baffle plate, press new plate so that it is in

contact with knuckle wall. Refer to figure at left.

SAX009

1. Install inner snap ring into groove of knuckle.

2. Press new wheel bearing assembly into knuckle until it con-

tacts steering knuckle.

Maximum load P:

29 kN (3 ton, 3.3 US ton, 3.0 Imp ton)

CAUTION:

+Do not press inner race of wheel bearing assembly.

+Do not apply oil or grease to mating surfaces of wheel

bearing outer race and knuckle.

3. Install outer snap ring into groove of knuckle.

SAX010

4. Press wheel hub into knuckle until it stops when the end of the

wheel bearing is hit.

Maximum load P:

29 kN (3 ton, 3.3 US ton, 3.0 Imp ton)

FRONT AXLE

Wheel Hub and Knuckle (Cont’d)

AX-8

Page 220 of 3051

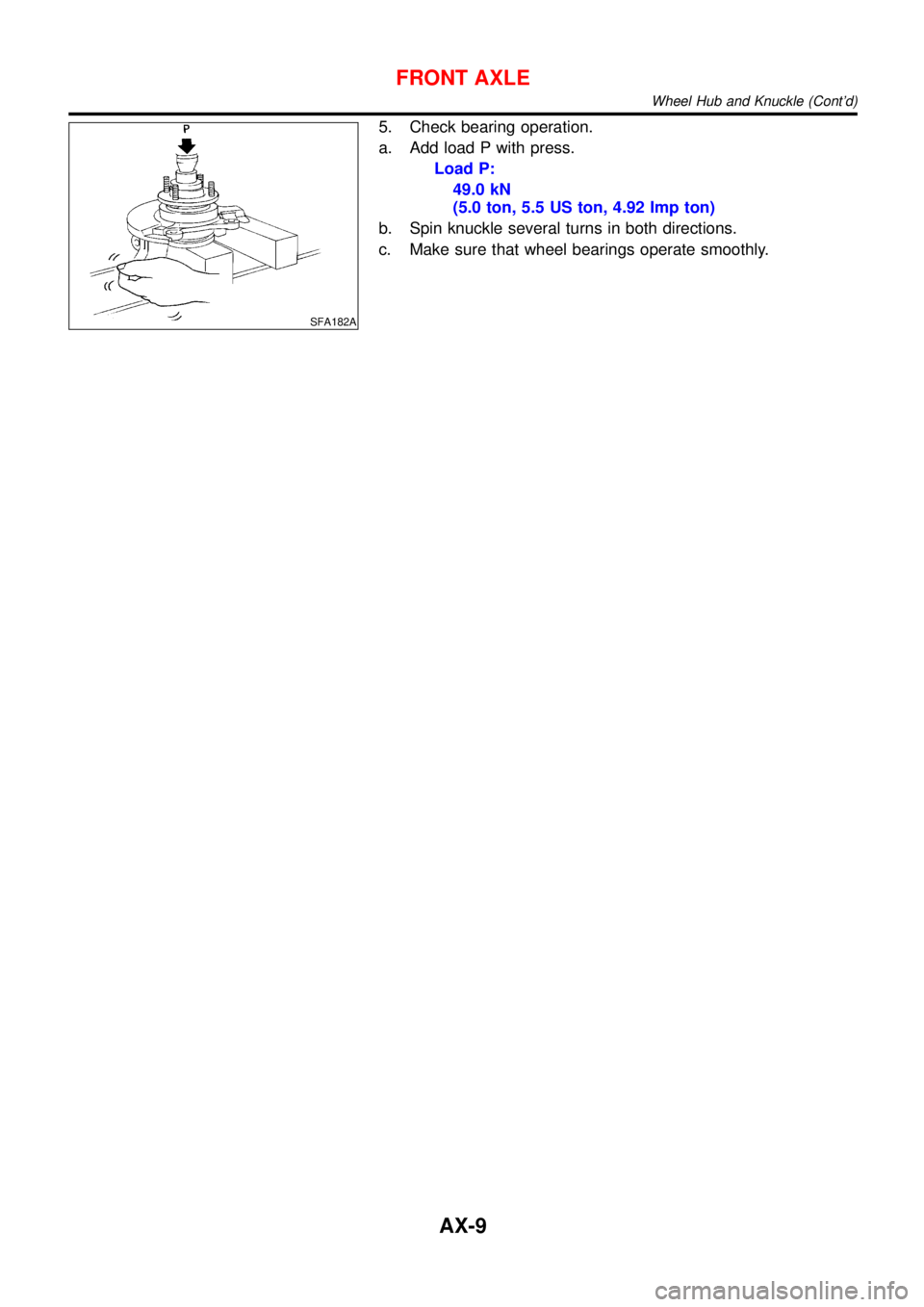

SFA182A

5. Check bearing operation.

a. Add load P with press.

Load P:

49.0 kN

(5.0 ton, 5.5 US ton, 4.92 Imp ton)

b. Spin knuckle several turns in both directions.

c. Make sure that wheel bearings operate smoothly.

FRONT AXLE

Wheel Hub and Knuckle (Cont’d)

AX-9