NISSAN ALMERA TINO 2001 Service Repair Manual

ALMERA TINO 2001

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57352/w960_57352-0.png

NISSAN ALMERA TINO 2001 Service Repair Manual

Trending: octane, suspension, clutch, brake sensor, AUX, power steering, hood open

Page 191 of 3051

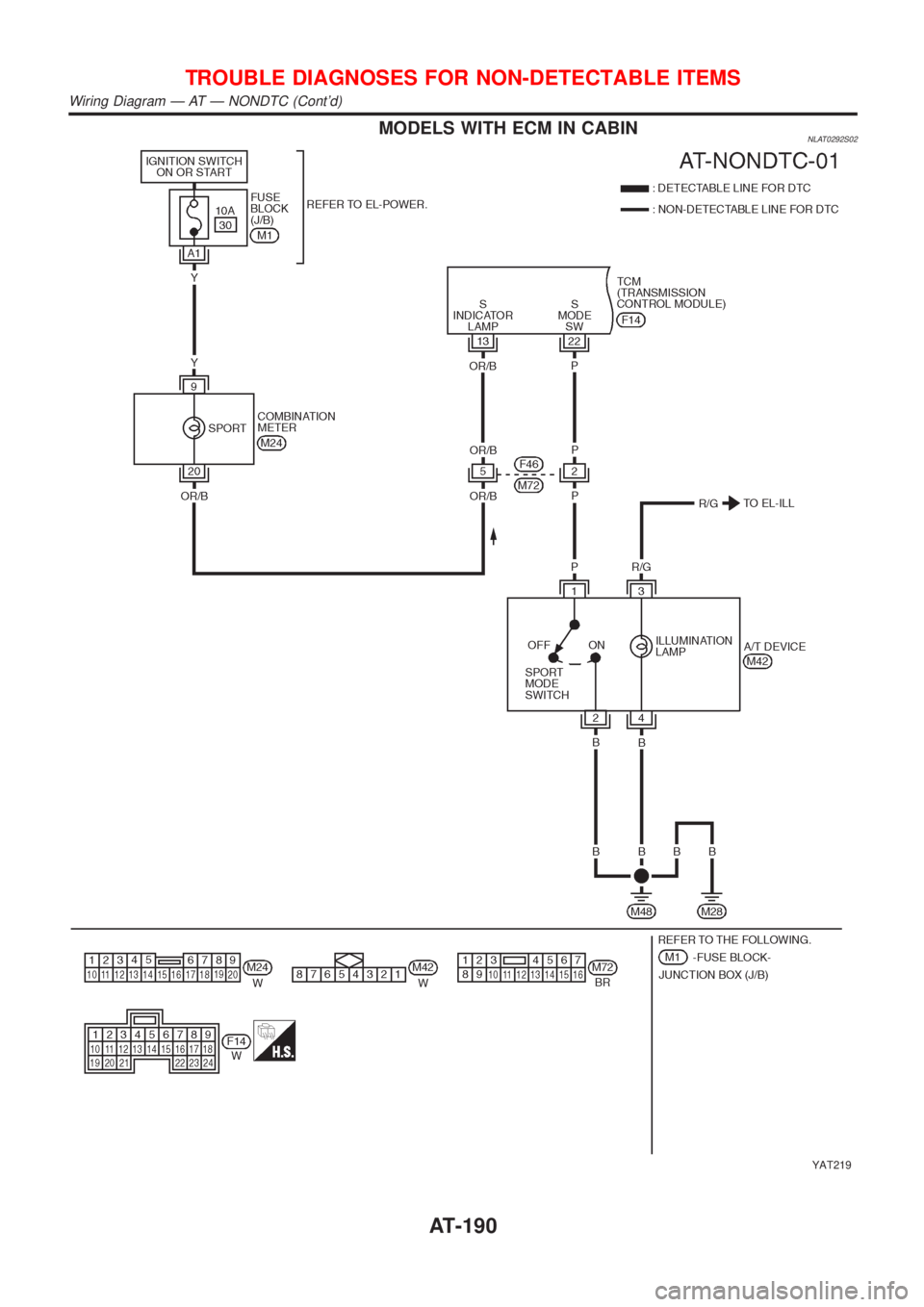

MODELS WITH ECM IN CABINNLAT0292S02

YAT219

TROUBLE DIAGNOSES FOR NON-DETECTABLE ITEMS

Wiring Diagram Ð AT Ð NONDTC (Cont'd)

AT-190

Page 192 of 3051

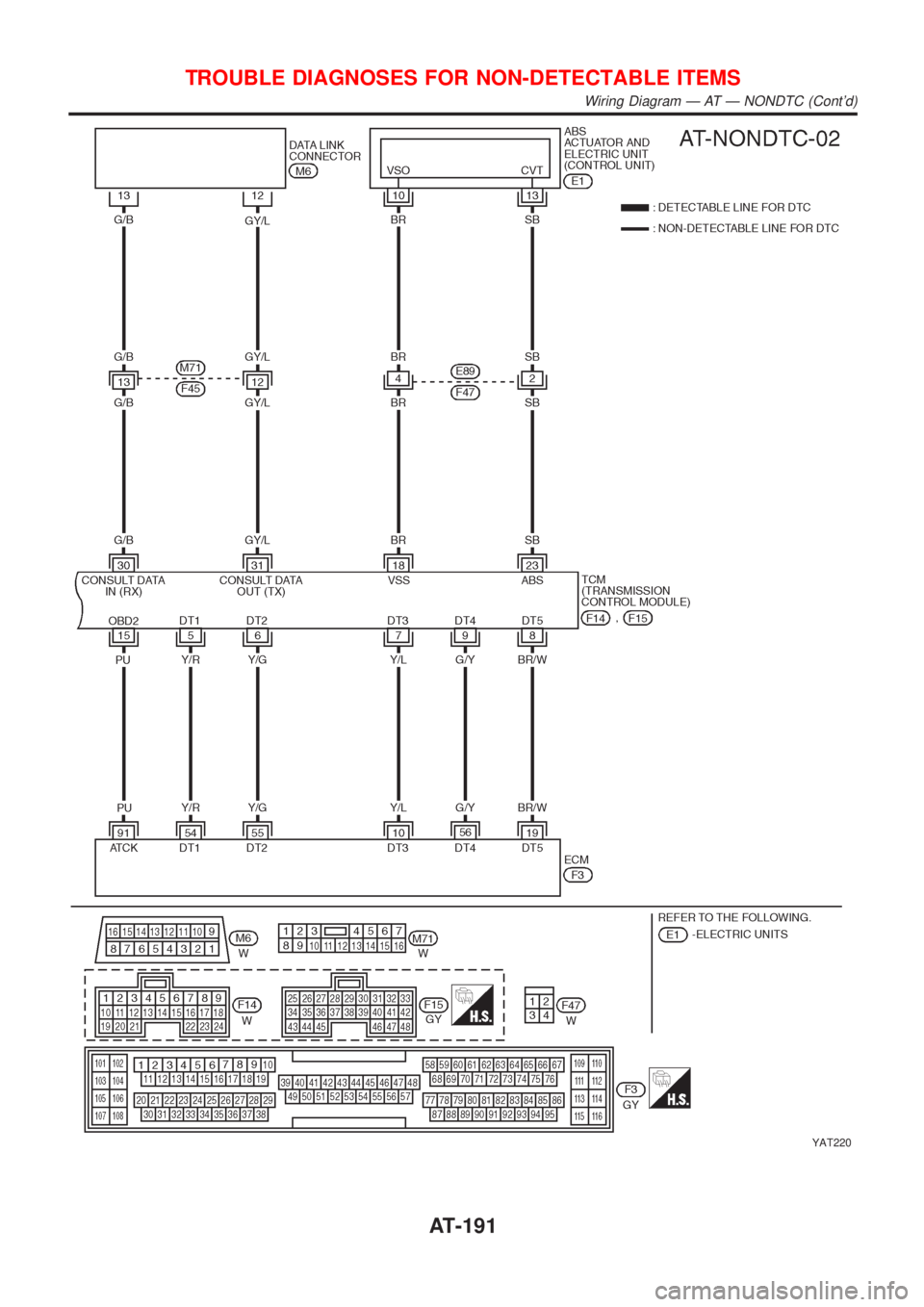

YAT220

TROUBLE DIAGNOSES FOR NON-DETECTABLE ITEMS

Wiring Diagram Ð AT Ð NONDTC (Cont'd)

AT-191

Page 193 of 3051

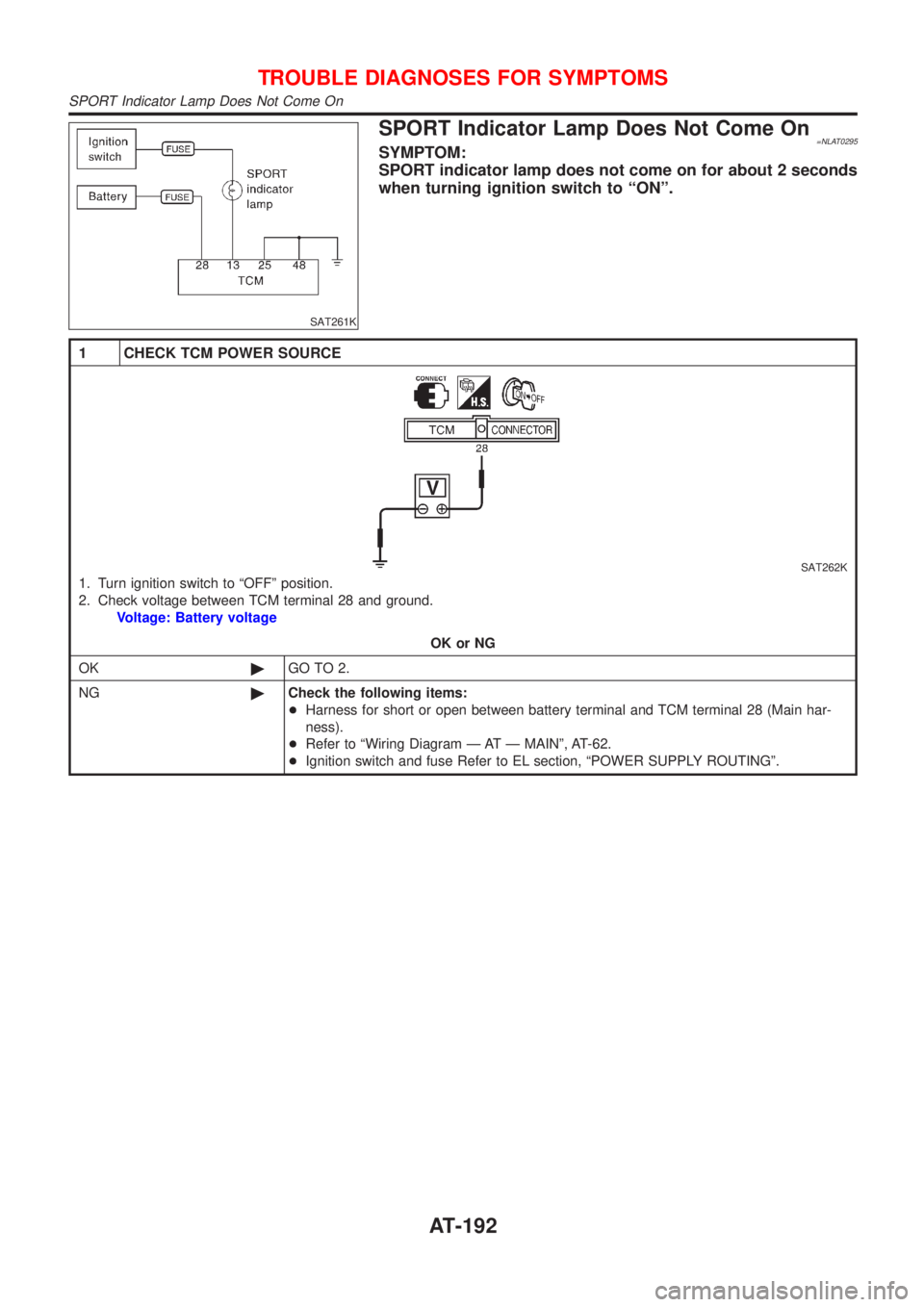

SAT261K

SPORT Indicator Lamp Does Not Come On=NLAT0295SYMPTOM:

SPORT indicator lamp does not come on for about 2 seconds

when turning ignition switch to ªONº.

1 CHECK TCM POWER SOURCE

SAT262K

1. Turn ignition switch to ªOFFº position.

2. Check voltage between TCM terminal 28 and ground.

Voltage: Battery voltage

OK or NG

OK©GO TO 2.

NG©Check the following items:

+Harness for short or open between battery terminal and TCM terminal 28 (Main har-

ness).

+Refer to ªWiring Diagram Ð AT Ð MAINº, AT-62.

+Ignition switch and fuse Refer to EL section, ªPOWER SUPPLY ROUTINGº.

TROUBLE DIAGNOSES FOR SYMPTOMS

SPORT Indicator Lamp Does Not Come On

AT-192

Page 194 of 3051

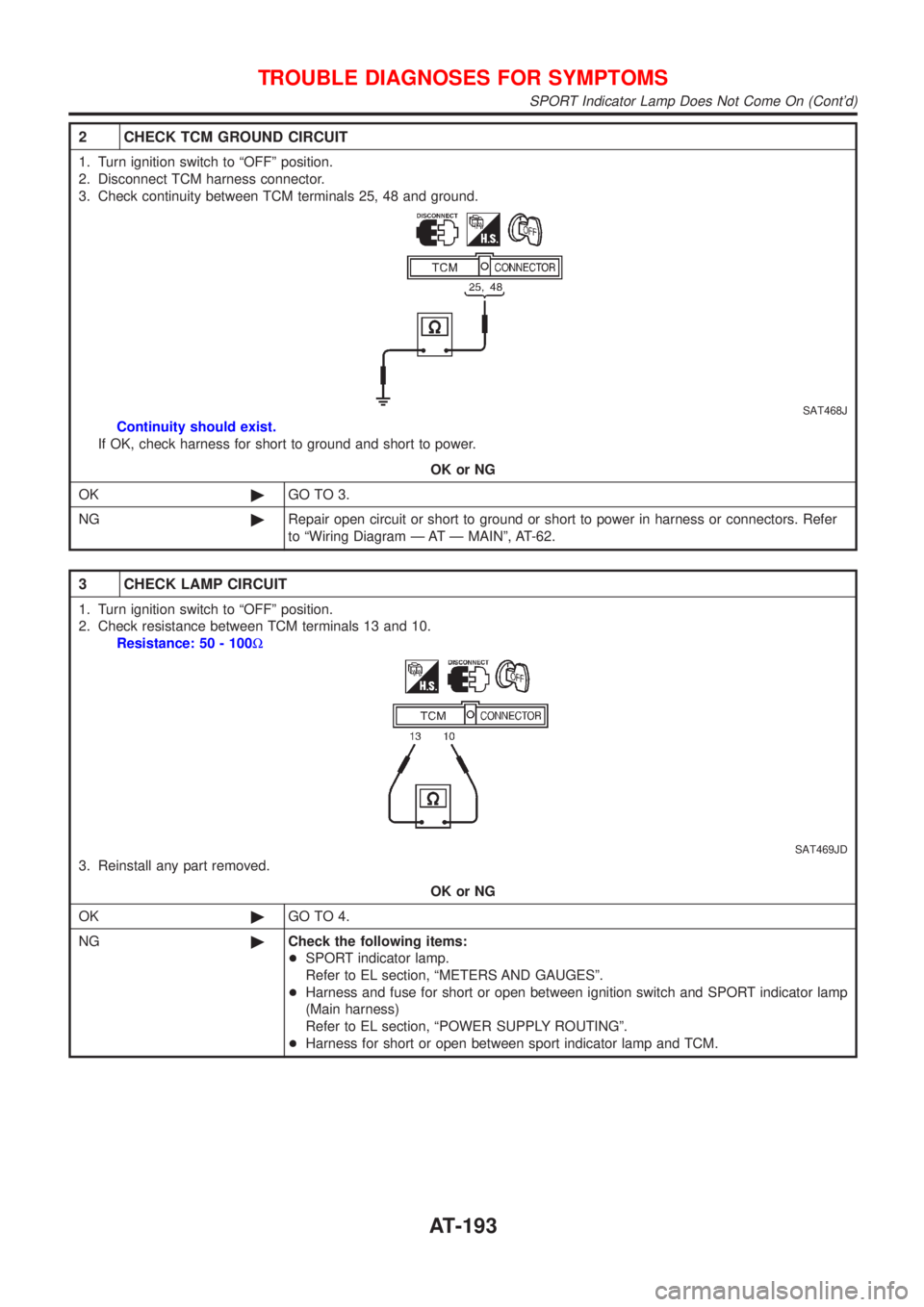

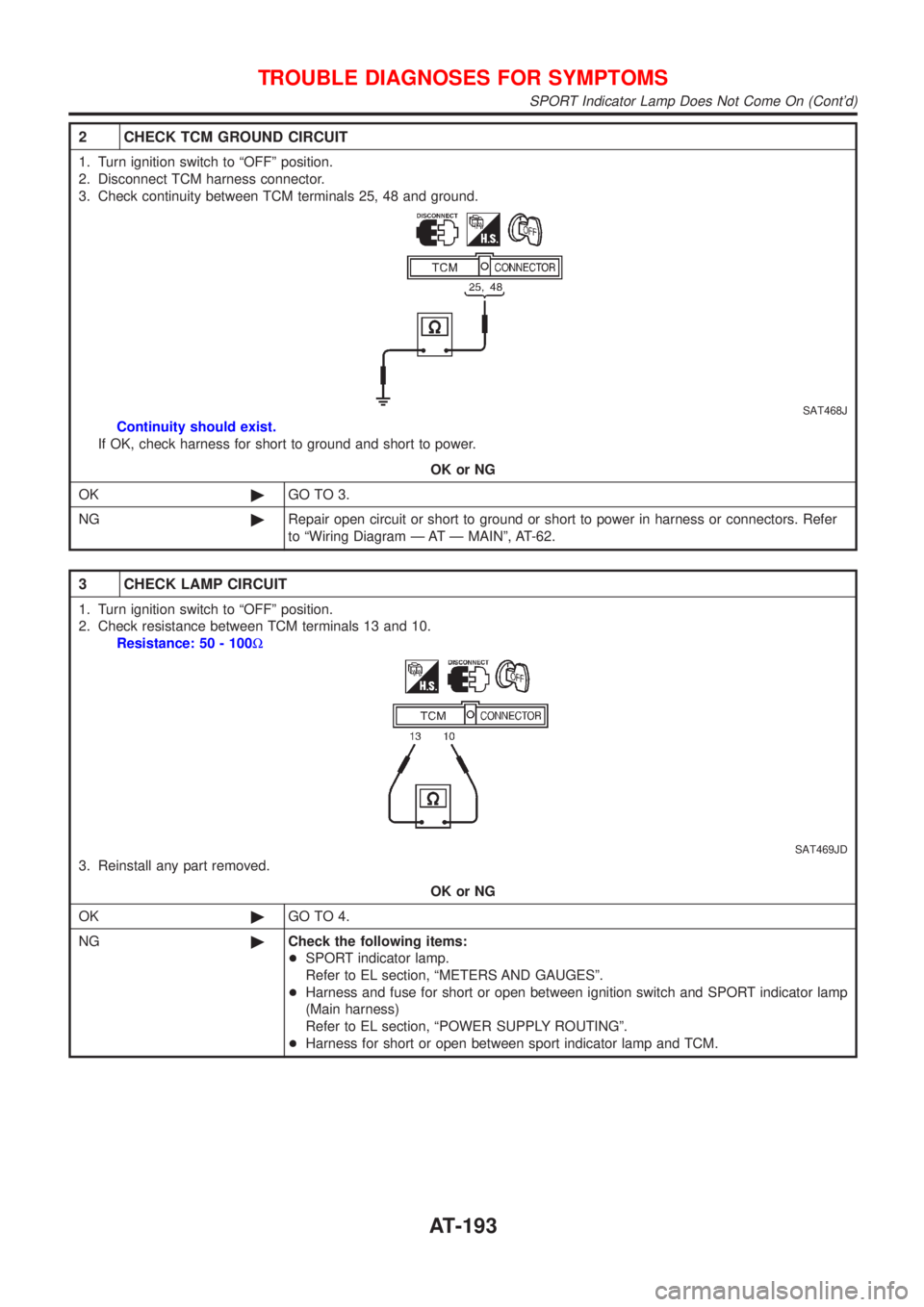

2 CHECK TCM GROUND CIRCUIT

1. Turn ignition switch to ªOFFº position.

2. Disconnect TCM harness connector.

3. Check continuity between TCM terminals 25, 48 and ground.

SAT468J

Continuity should exist.

If OK, check harness for short to ground and short to power.

OK or NG

OK©GO TO 3.

NG©Repair open circuit or short to ground or short to power in harness or connectors. Refer

to ªWiring Diagram Ð AT Ð MAINº, AT-62.

3 CHECK LAMP CIRCUIT

1. Turn ignition switch to ªOFFº position.

2. Check resistance between TCM terminals 13 and 10.

Resistance: 50 - 100W

SAT469JD

3. Reinstall any part removed.

OK or NG

OK©GO TO 4.

NG©Check the following items:

+SPORT indicator lamp.

Refer to EL section, ªMETERS AND GAUGESº.

+Harness and fuse for short or open between ignition switch and SPORT indicator lamp

(Main harness)

Refer to EL section, ªPOWER SUPPLY ROUTINGº.

+Harness for short or open between sport indicator lamp and TCM.

TROUBLE DIAGNOSES FOR SYMPTOMS

SPORT Indicator Lamp Does Not Come On (Cont'd)

AT-193

Page 195 of 3051

4 CHECK SYMPTOM

Check again.

OK or NG

OK©INSPECTION END

NG©1. Perform TCM input/output signal inspection.

2. If NG, recheck TCM pin terminals for damage or loose connection with harness con-

nector.

TROUBLE DIAGNOSES FOR SYMPTOMS

SPORT Indicator Lamp Does Not Come On (Cont'd)

AT-194

Page 196 of 3051

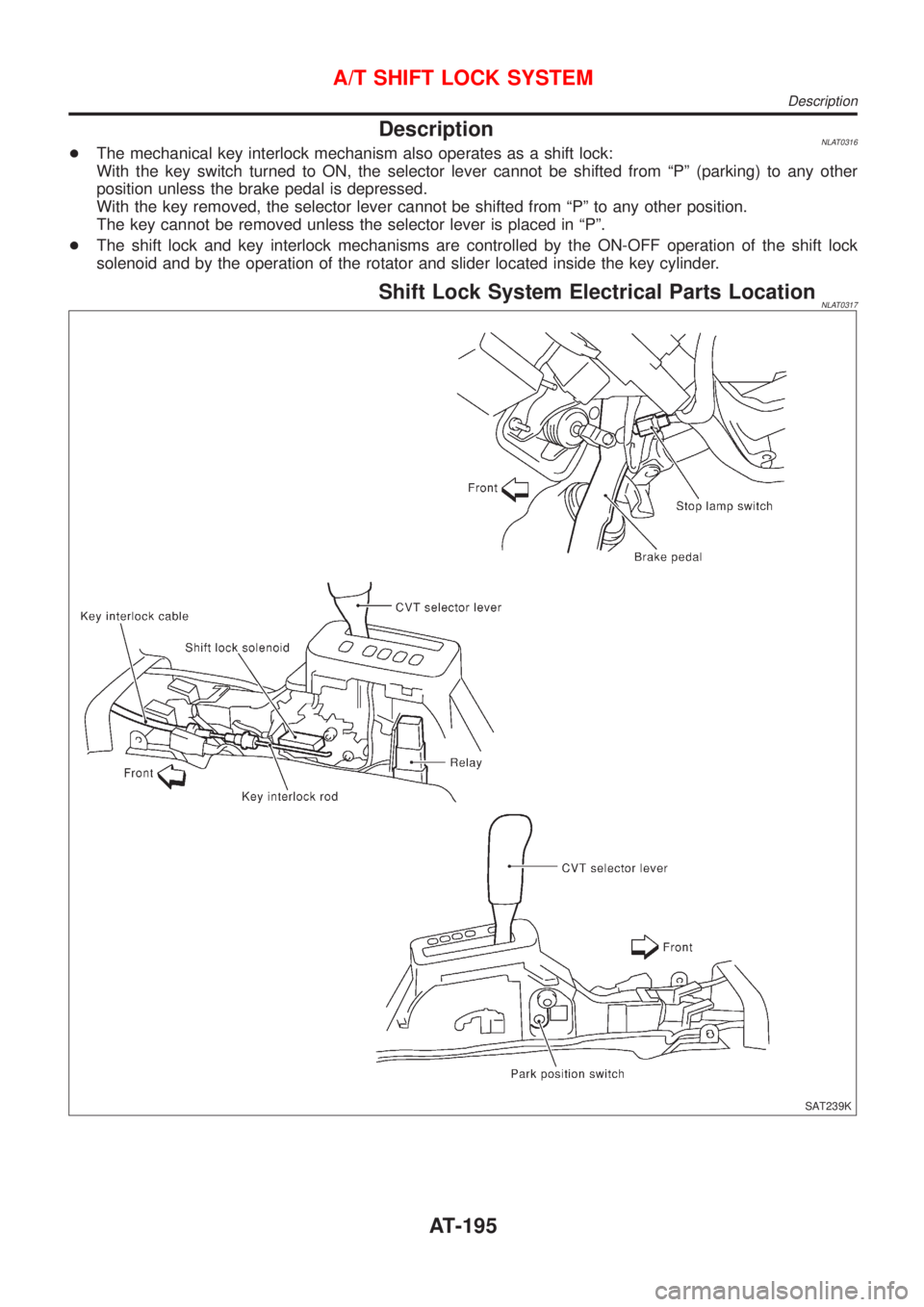

DescriptionNLAT0316+The mechanical key interlock mechanism also operates as a shift lock:

With the key switch turned to ON, the selector lever cannot be shifted from ªPº (parking) to any other

position unless the brake pedal is depressed.

With the key removed, the selector lever cannot be shifted from ªPº to any other position.

The key cannot be removed unless the selector lever is placed in ªPº.

+The shift lock and key interlock mechanisms are controlled by the ON-OFF operation of the shift lock

solenoid and by the operation of the rotator and slider located inside the key cylinder.

Shift Lock System Electrical Parts LocationNLAT0317

SAT239K

A/T SHIFT LOCK SYSTEM

Description

AT-195

Page 197 of 3051

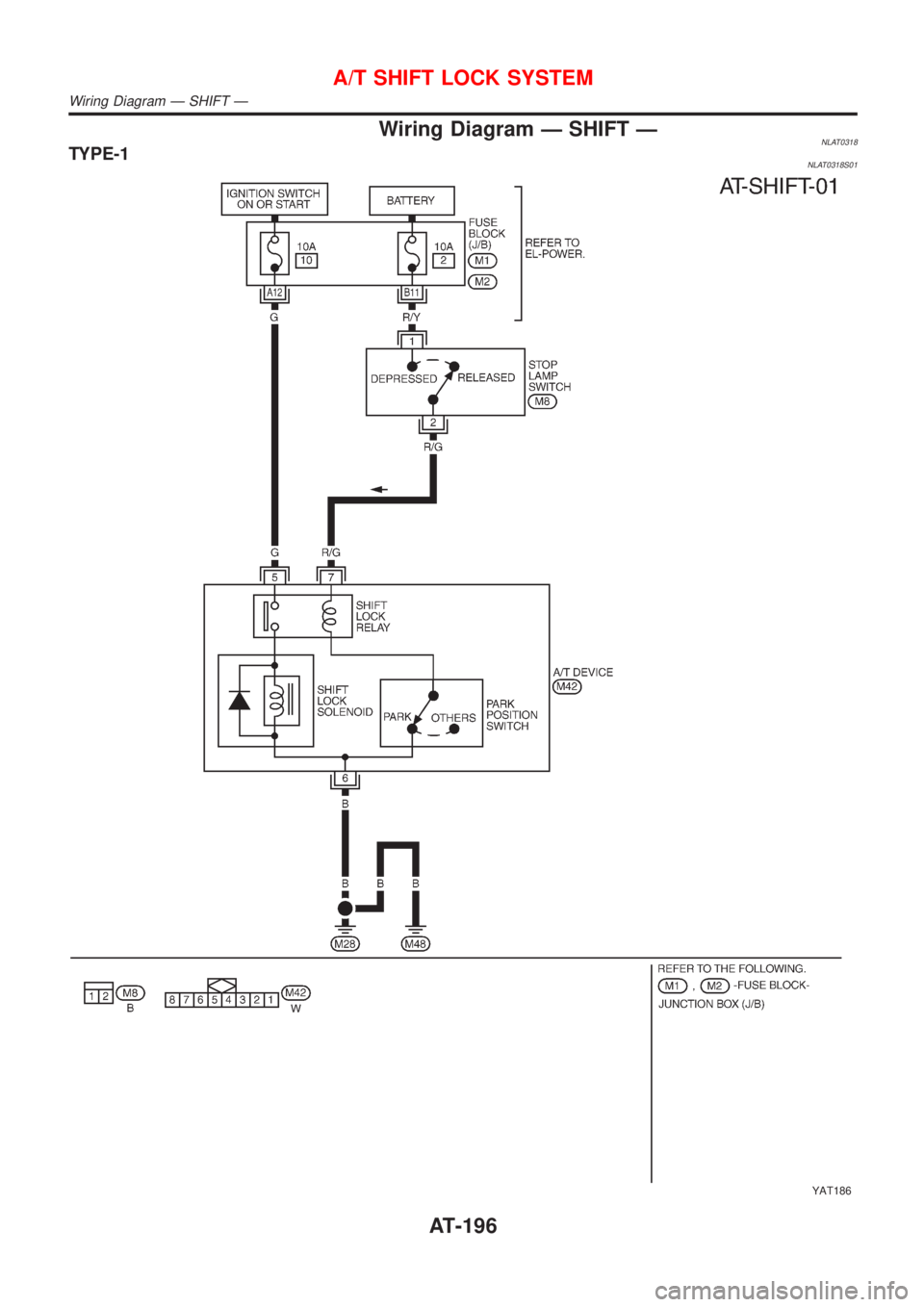

Wiring Diagram Ð SHIFT ÐNLAT0318TYPE-1NLAT0318S01

YAT186

A/T SHIFT LOCK SYSTEM

Wiring Diagram Ð SHIFT Ð

AT-196

Page 198 of 3051

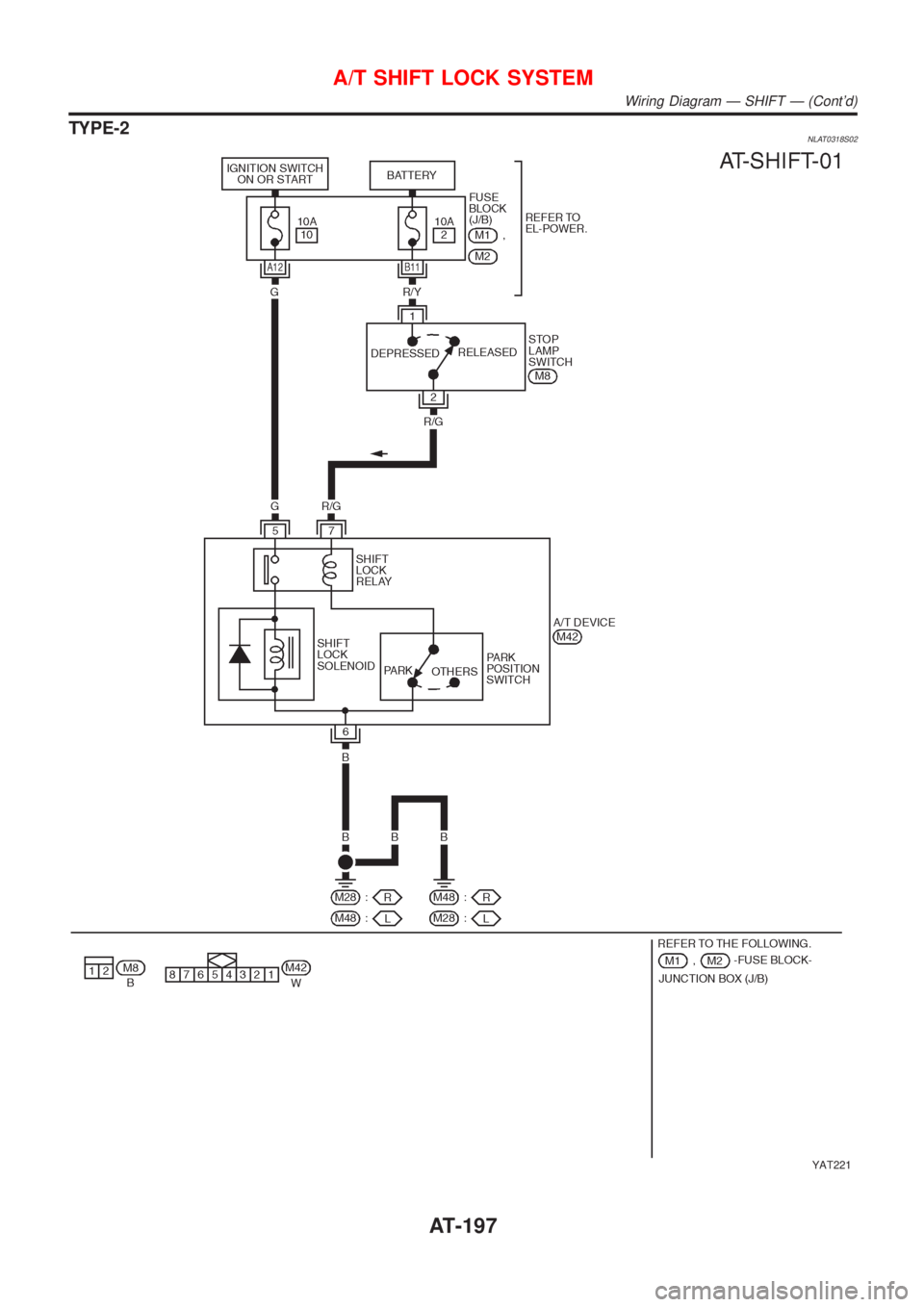

TYPE-2NLAT0318S02

YAT221

A/T SHIFT LOCK SYSTEM

Wiring Diagram Ð SHIFT Ð (Cont'd)

AT-197

Page 199 of 3051

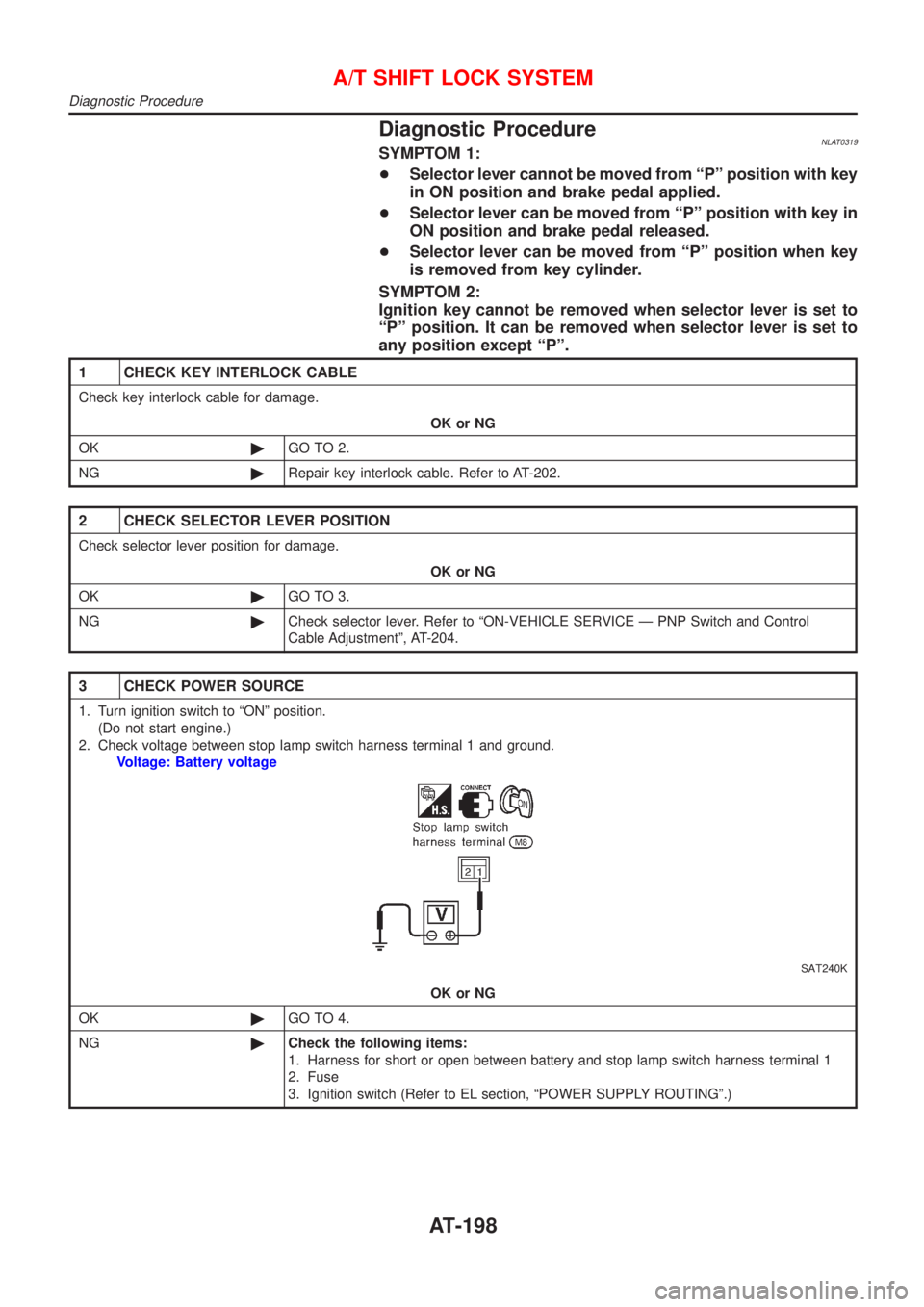

Diagnostic ProcedureNLAT0319SYMPTOM 1:

+Selector lever cannot be moved from ªPº position with key

in ON position and brake pedal applied.

+Selector lever can be moved from ªPº position with key in

ON position and brake pedal released.

+Selector lever can be moved from ªPº position when key

is removed from key cylinder.

SYMPTOM 2:

Ignition key cannot be removed when selector lever is set to

ªPº position. It can be removed when selector lever is set to

any position except ªPº.

1 CHECK KEY INTERLOCK CABLE

Check key interlock cable for damage.

OK or NG

OK©GO TO 2.

NG©Repair key interlock cable. Refer to AT-202.

2 CHECK SELECTOR LEVER POSITION

Check selector lever position for damage.

OK or NG

OK©GO TO 3.

NG©Check selector lever. Refer to ªON-VEHICLE SERVICE Ð PNP Switch and Control

Cable Adjustmentº, AT-204.

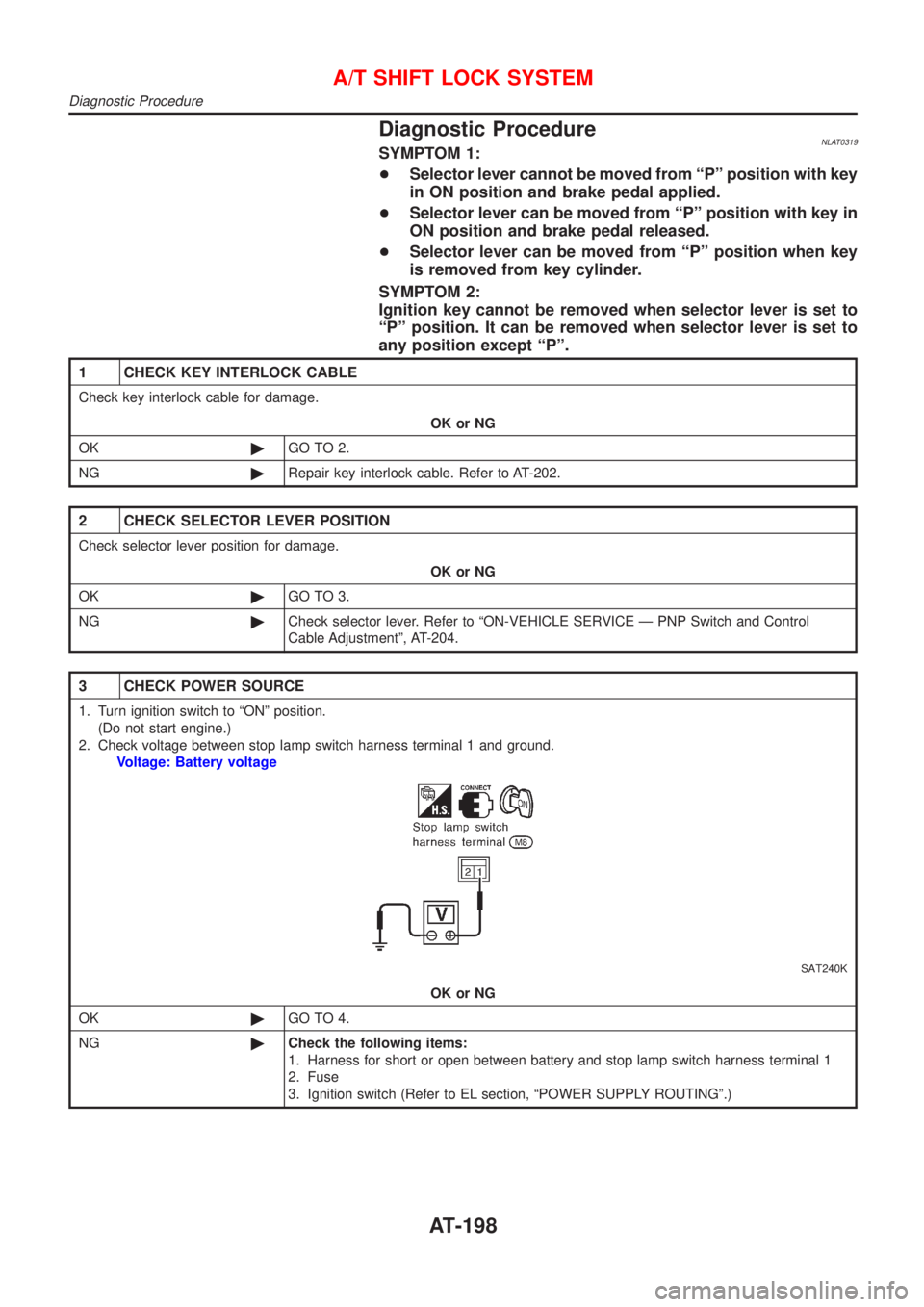

3 CHECK POWER SOURCE

1. Turn ignition switch to ªONº position.

(Do not start engine.)

2. Check voltage between stop lamp switch harness terminal 1 and ground.

Voltage: Battery voltage

SAT240K

OK or NG

OK©GO TO 4.

NG©Check the following items:

1. Harness for short or open between battery and stop lamp switch harness terminal 1

2. Fuse

3. Ignition switch (Refer to EL section, ªPOWER SUPPLY ROUTINGº.)

A/T SHIFT LOCK SYSTEM

Diagnostic Procedure

AT-198

Page 200 of 3051

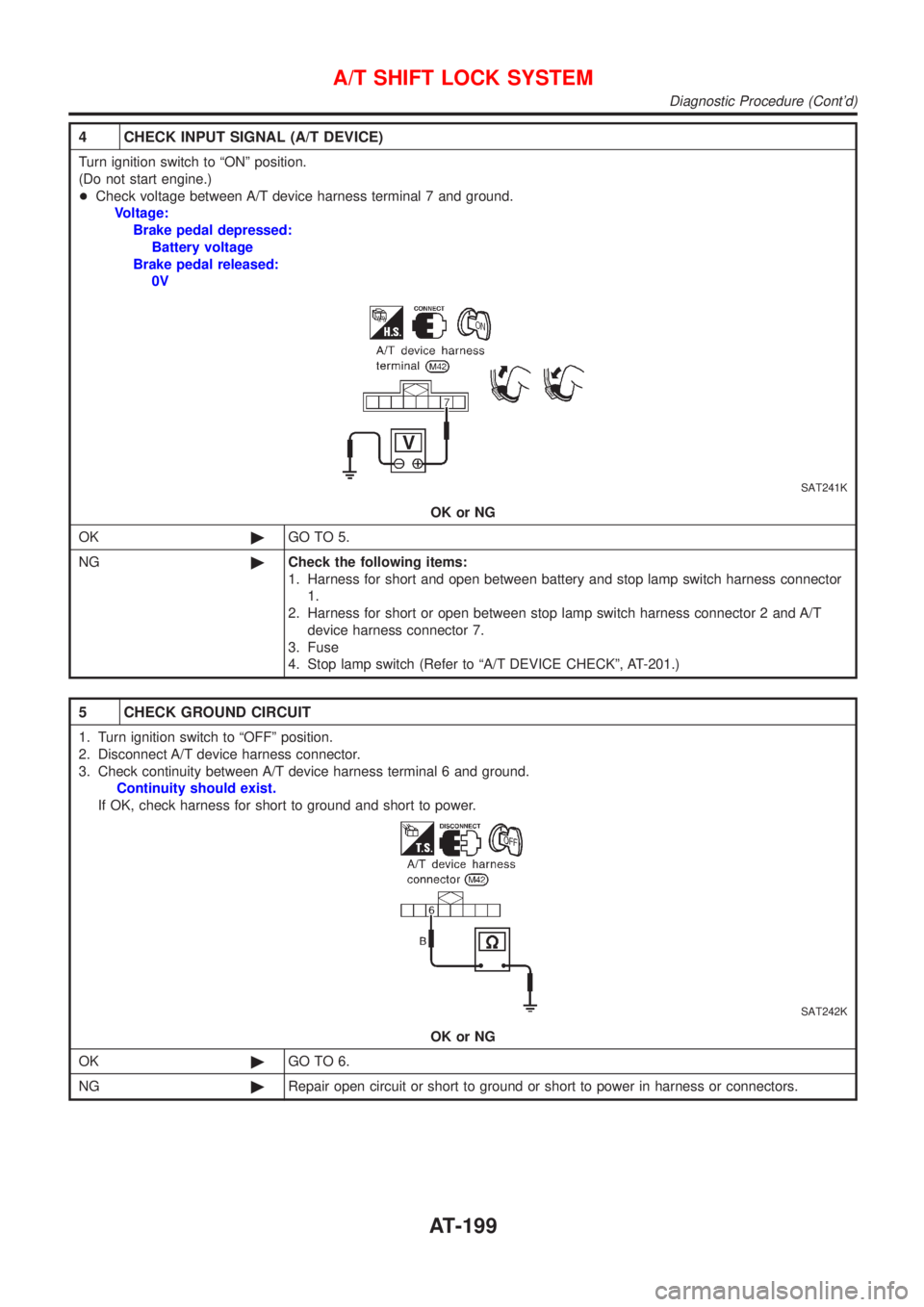

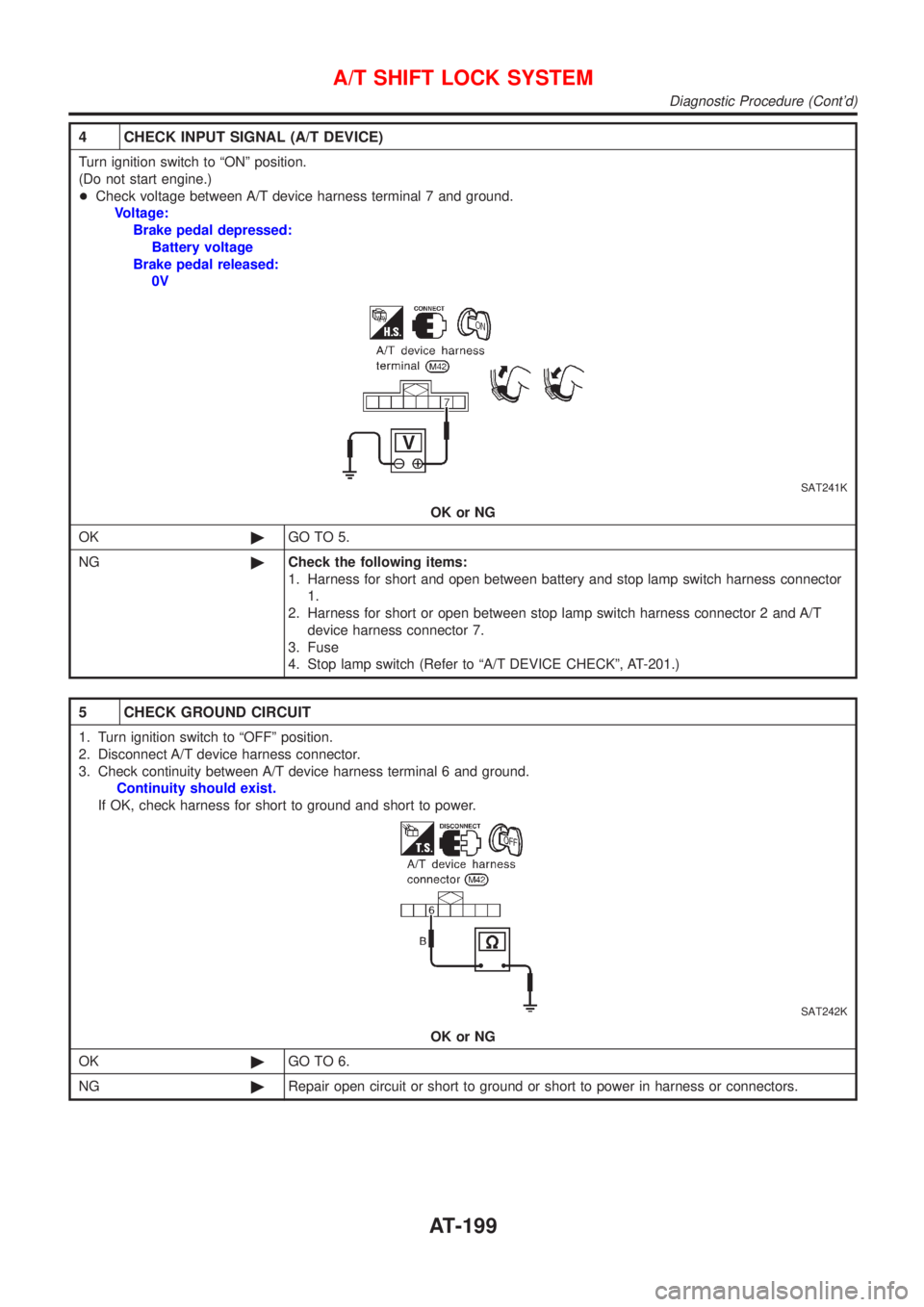

4 CHECK INPUT SIGNAL (A/T DEVICE)

Turn ignition switch to ªONº position.

(Do not start engine.)

+Check voltage between A/T device harness terminal 7 and ground.

Voltage:

Brake pedal depressed:

Battery voltage

Brake pedal released:

0V

SAT241K

OK or NG

OK©GO TO 5.

NG©Check the following items:

1. Harness for short and open between battery and stop lamp switch harness connector

1.

2. Harness for short or open between stop lamp switch harness connector 2 and A/T

device harness connector 7.

3. Fuse

4. Stop lamp switch (Refer to ªA/T DEVICE CHECKº, AT-201.)

5 CHECK GROUND CIRCUIT

1. Turn ignition switch to ªOFFº position.

2. Disconnect A/T device harness connector.

3. Check continuity between A/T device harness terminal 6 and ground.

Continuity should exist.

If OK, check harness for short to ground and short to power.

SAT242K

OK or NG

OK©GO TO 6.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

A/T SHIFT LOCK SYSTEM

Diagnostic Procedure (Cont'd)

AT-199

Trending: seat adjustment, ignition, BT-21, spare wheel, height, change key battery, light