NISSAN ALMERA TINO 2001 Service Repair Manual

ALMERA TINO 2001

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57352/w960_57352-0.png

NISSAN ALMERA TINO 2001 Service Repair Manual

Trending: automatic transmission fluid, refrigerant type, schematic relay, seat memory, wiring diagram, check transmission fluid, automatic transmission

Page 2861 of 3051

SMT752C

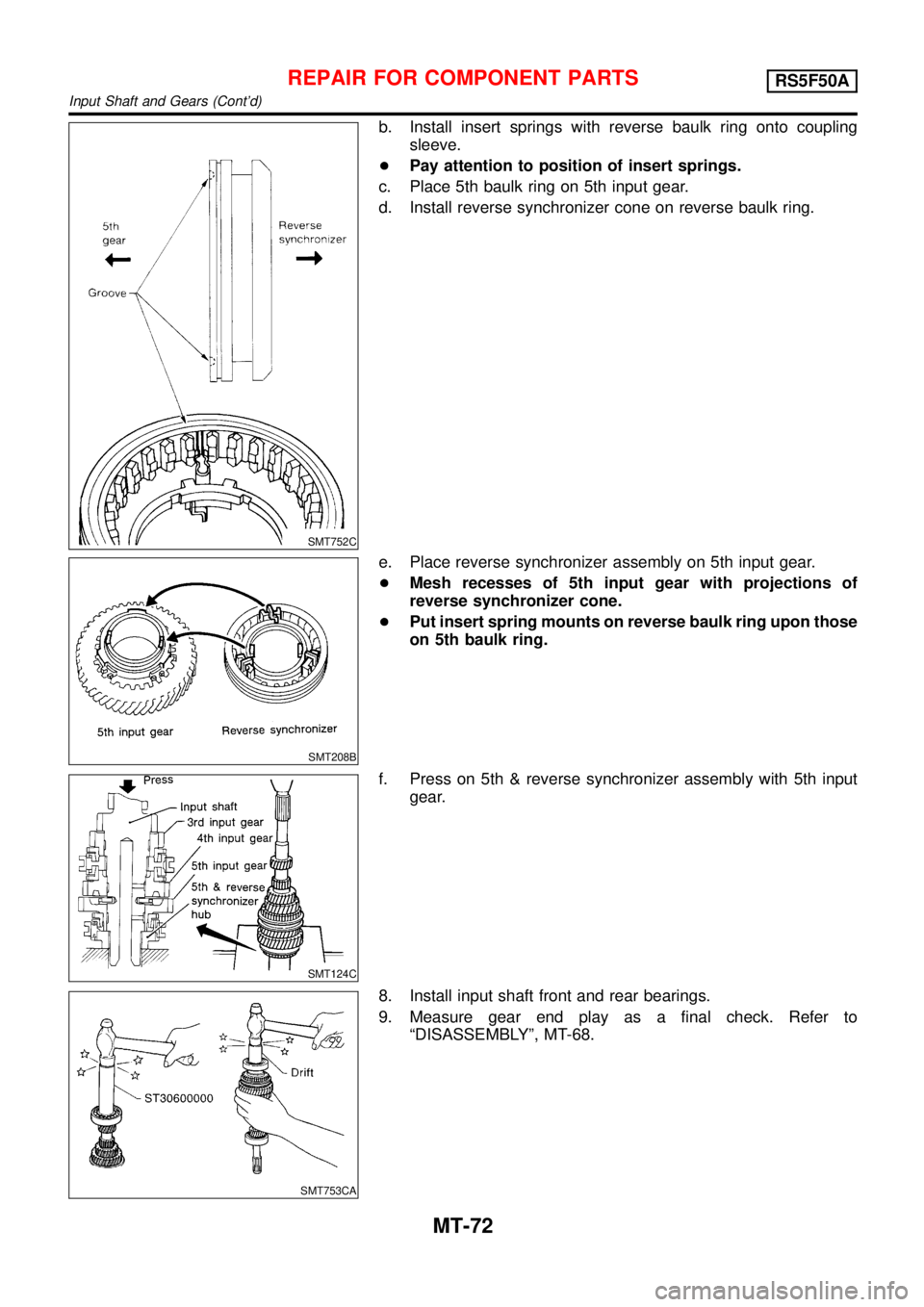

b. Install insert springs with reverse baulk ring onto coupling

sleeve.

+Pay attention to position of insert springs.

c. Place 5th baulk ring on 5th input gear.

d. Install reverse synchronizer cone on reverse baulk ring.

SMT208B

e. Place reverse synchronizer assembly on 5th input gear.

+Mesh recesses of 5th input gear with projections of

reverse synchronizer cone.

+Put insert spring mounts on reverse baulk ring upon those

on 5th baulk ring.

SMT124C

f. Press on 5th & reverse synchronizer assembly with 5th input

gear.

SMT753CA

8. Install input shaft front and rear bearings.

9. Measure gear end play as a final check. Refer to

“DISASSEMBLY”, MT-68.

REPAIR FOR COMPONENT PARTSRS5F50A

Input Shaft and Gears (Cont’d)

MT-72

Page 2862 of 3051

SMT191A

Mainshaft and Gears

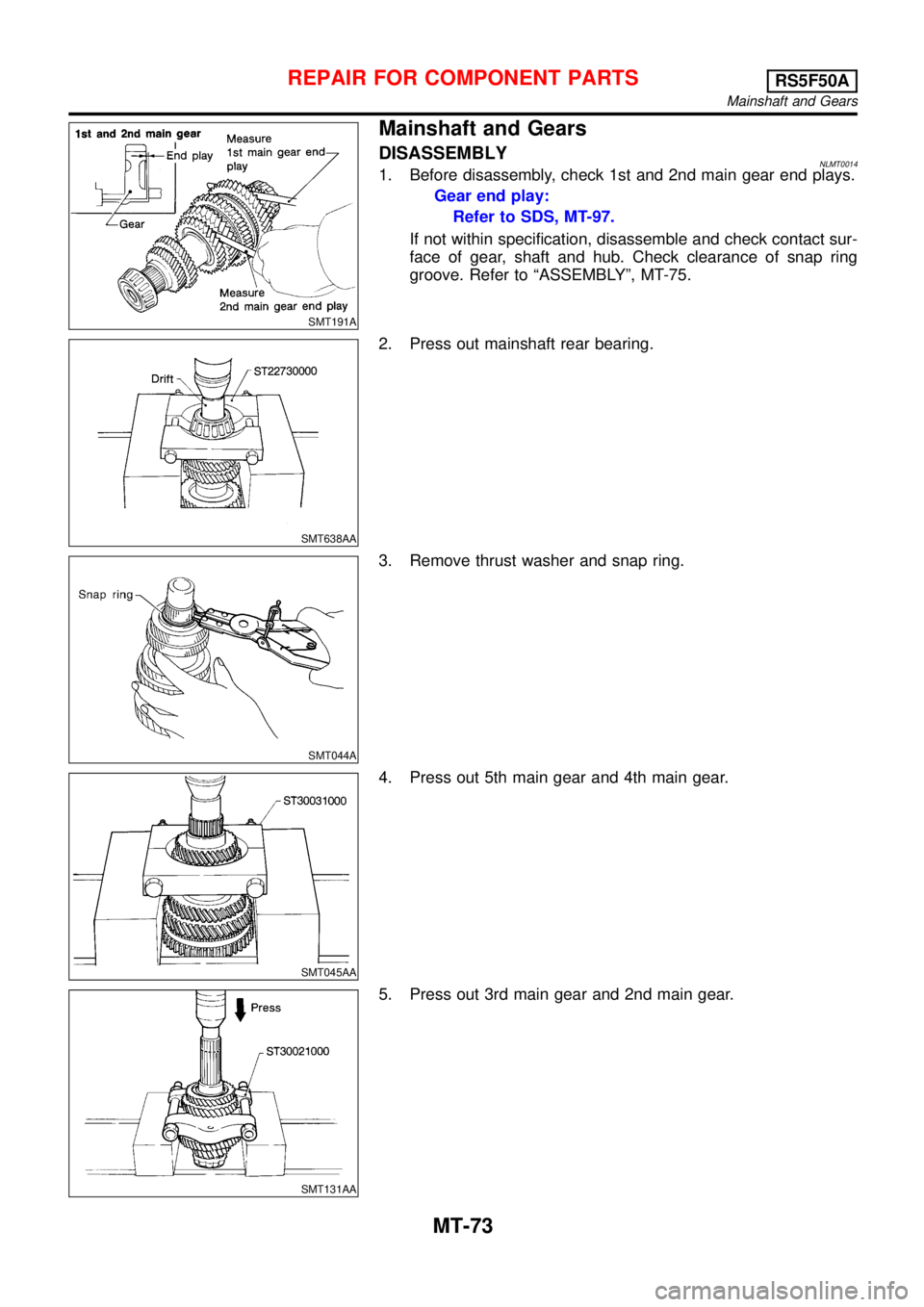

DISASSEMBLYNLMT00141. Before disassembly, check 1st and 2nd main gear end plays.

Gear end play:

Refer to SDS, MT-97.

If not within specification, disassemble and check contact sur-

face of gear, shaft and hub. Check clearance of snap ring

groove. Refer to“ASSEMBLY”, MT-75.

SMT638AA

2. Press out mainshaft rear bearing.

SMT044A

3. Remove thrust washer and snap ring.

SMT045AA

4. Press out 5th main gear and 4th main gear.

SMT131AA

5. Press out 3rd main gear and 2nd main gear.

REPAIR FOR COMPONENT PARTSRS5F50A

Mainshaft and Gears

MT-73

Page 2863 of 3051

SMT047A

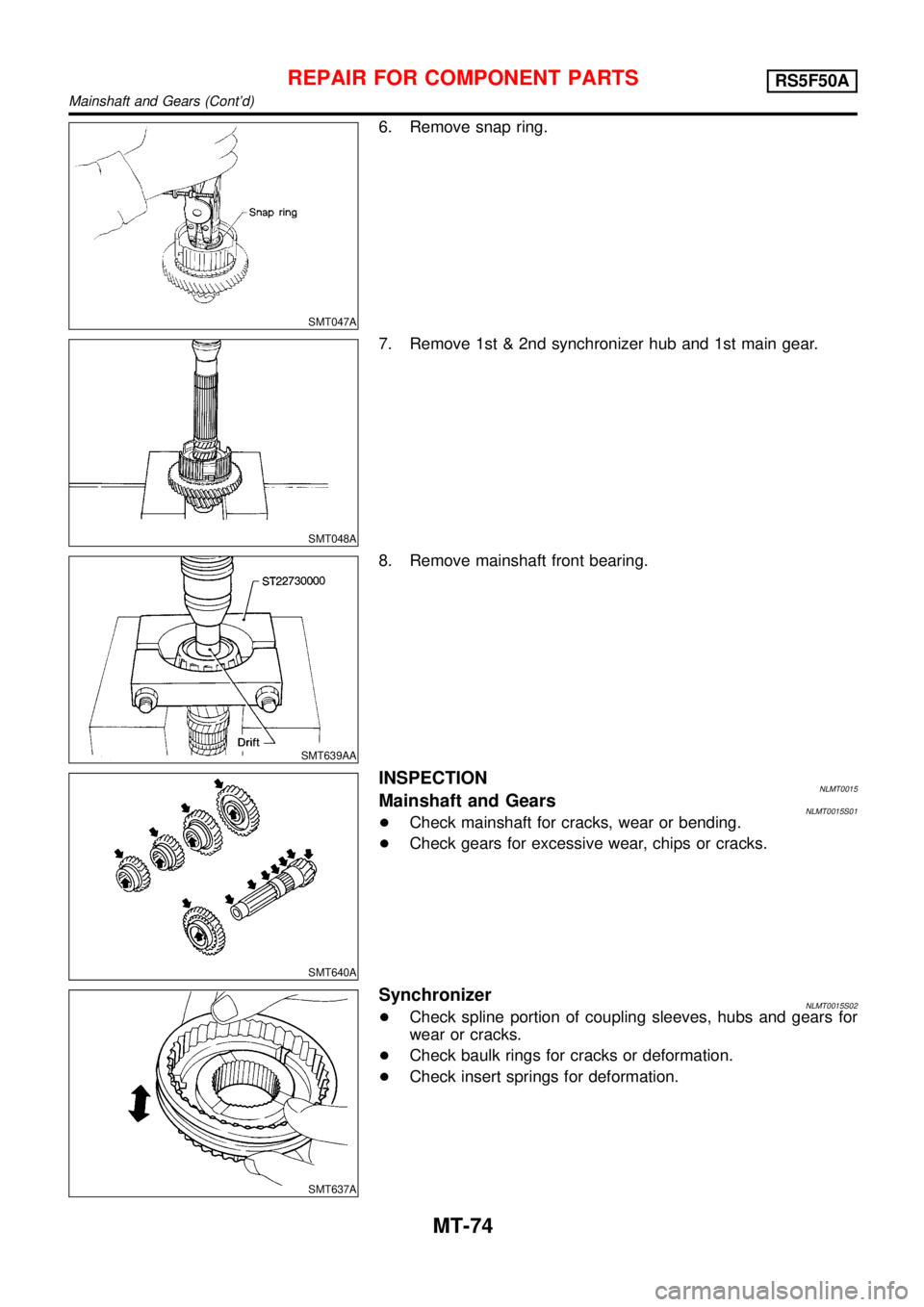

6. Remove snap ring.

SMT048A

7. Remove 1st & 2nd synchronizer hub and 1st main gear.

SMT639AA

8. Remove mainshaft front bearing.

SMT640A

INSPECTIONNLMT0015Mainshaft and GearsNLMT0015S01+Check mainshaft for cracks, wear or bending.

+Check gears for excessive wear, chips or cracks.

SMT637A

SynchronizerNLMT0015S02+Check spline portion of coupling sleeves, hubs and gears for

wear or cracks.

+Check baulk rings for cracks or deformation.

+Check insert springs for deformation.

REPAIR FOR COMPONENT PARTSRS5F50A

Mainshaft and Gears (Cont’d)

MT-74

Page 2864 of 3051

SMT420CA

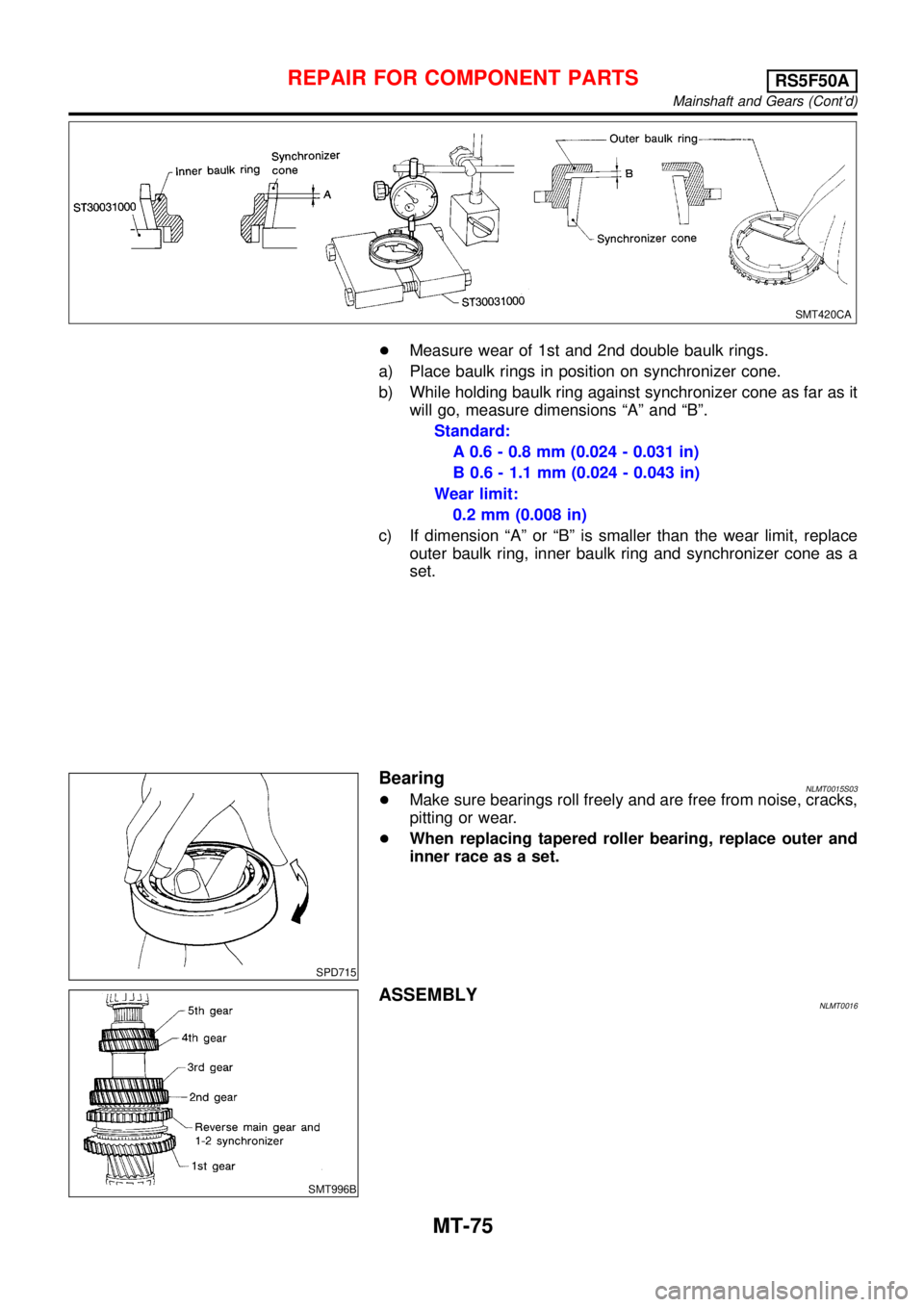

+Measure wear of 1st and 2nd double baulk rings.

a) Place baulk rings in position on synchronizer cone.

b) While holding baulk ring against synchronizer cone as far as it

will go, measure dimensions“A”and“B”.

Standard:

A 0.6 - 0.8 mm (0.024 - 0.031 in)

B 0.6 - 1.1 mm (0.024 - 0.043 in)

Wear limit:

0.2 mm (0.008 in)

c) If dimension“A”or“B”is smaller than the wear limit, replace

outer baulk ring, inner baulk ring and synchronizer cone as a

set.

SPD715

BearingNLMT0015S03+Make sure bearings roll freely and are free from noise, cracks,

pitting or wear.

+When replacing tapered roller bearing, replace outer and

inner race as a set.

SMT996B

ASSEMBLYNLMT0016

REPAIR FOR COMPONENT PARTSRS5F50A

Mainshaft and Gears (Cont’d)

MT-75

Page 2865 of 3051

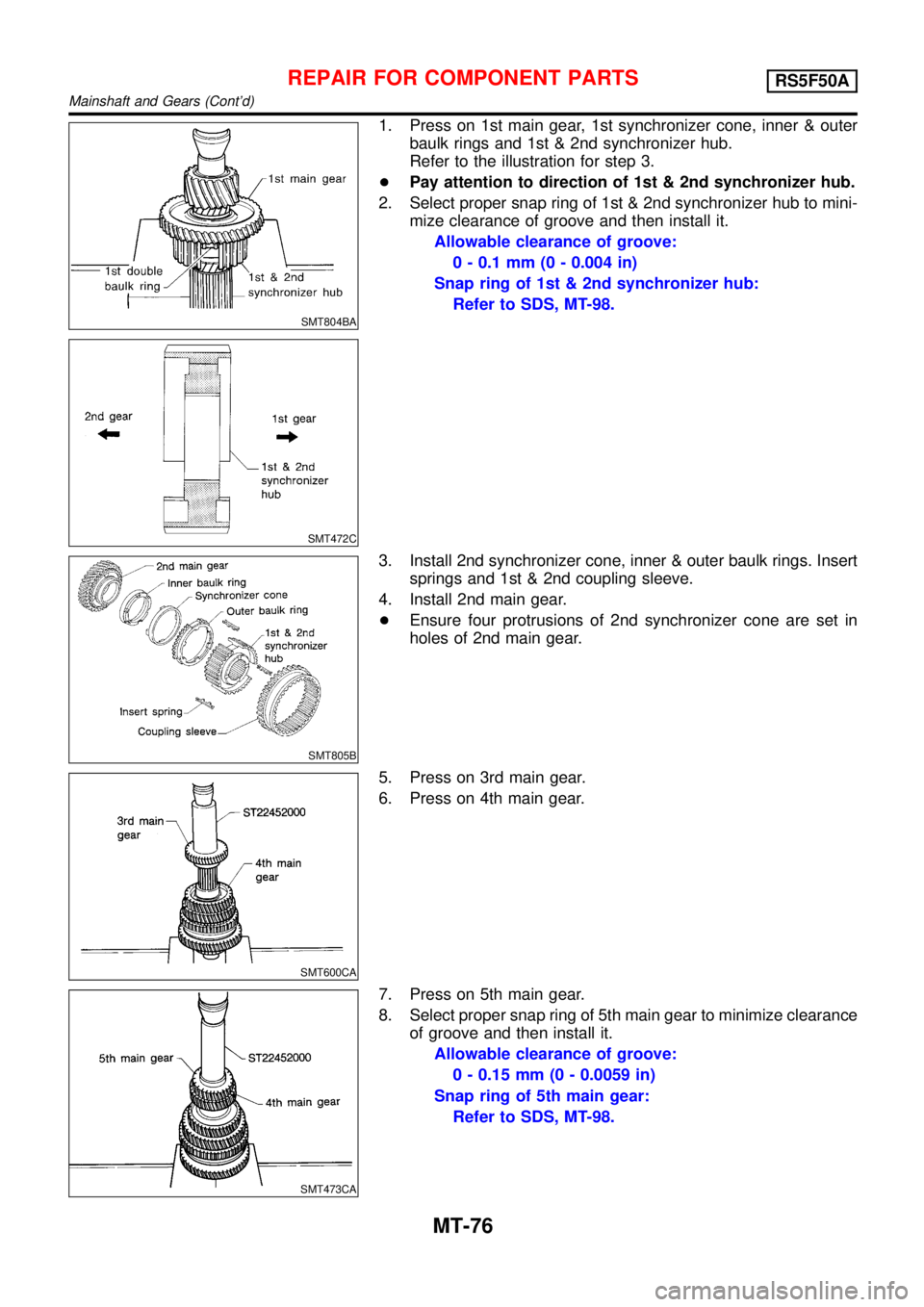

SMT804BA

SMT472C

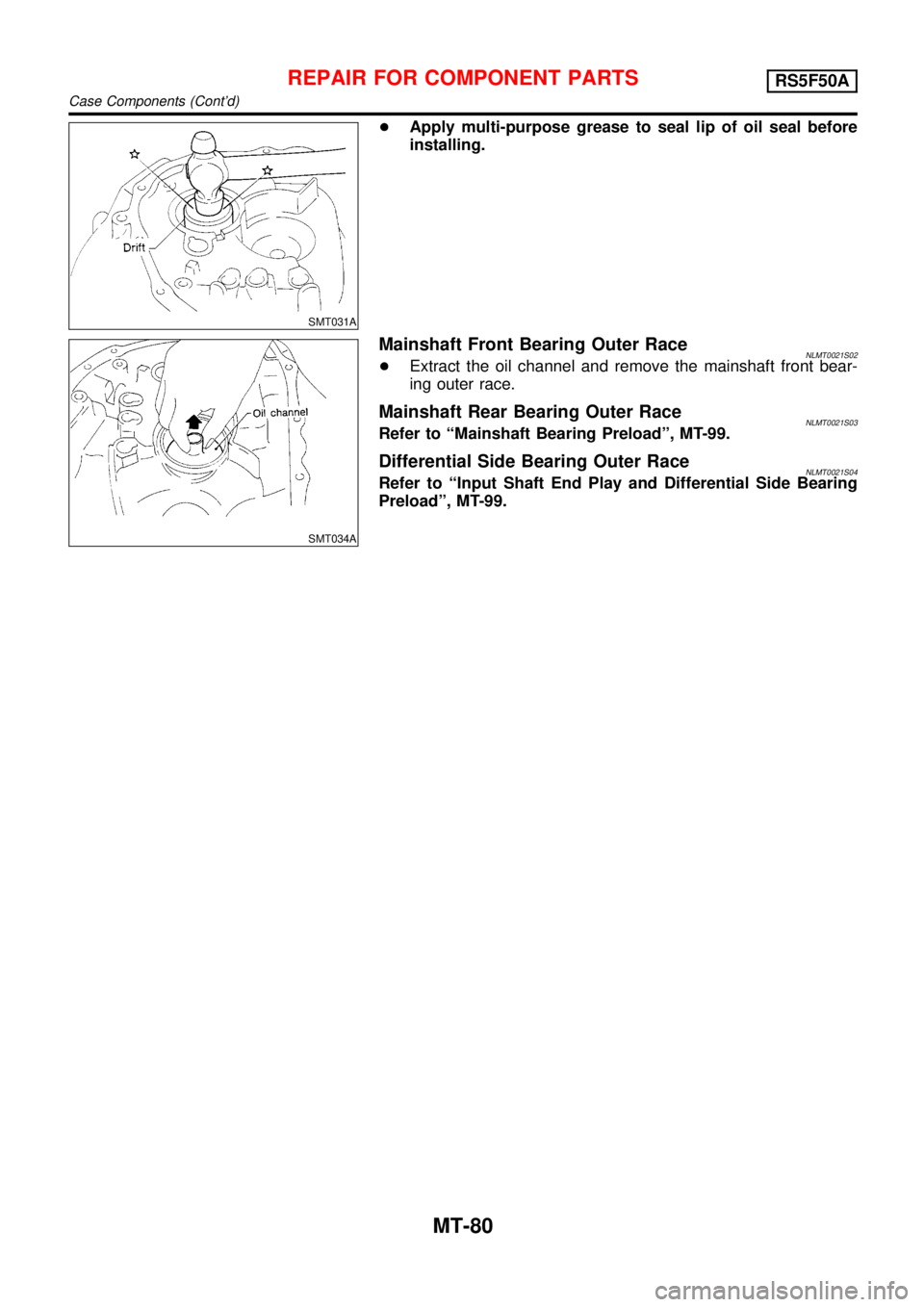

1. Press on 1st main gear, 1st synchronizer cone, inner & outer

baulk rings and 1st & 2nd synchronizer hub.

Refer to the illustration for step 3.

+Pay attention to direction of 1st & 2nd synchronizer hub.

2. Select proper snap ring of 1st & 2nd synchronizer hub to mini-

mize clearance of groove and then install it.

Allowable clearance of groove:

0 - 0.1 mm (0 - 0.004 in)

Snap ring of 1st & 2nd synchronizer hub:

Refer to SDS, MT-98.

SMT805B

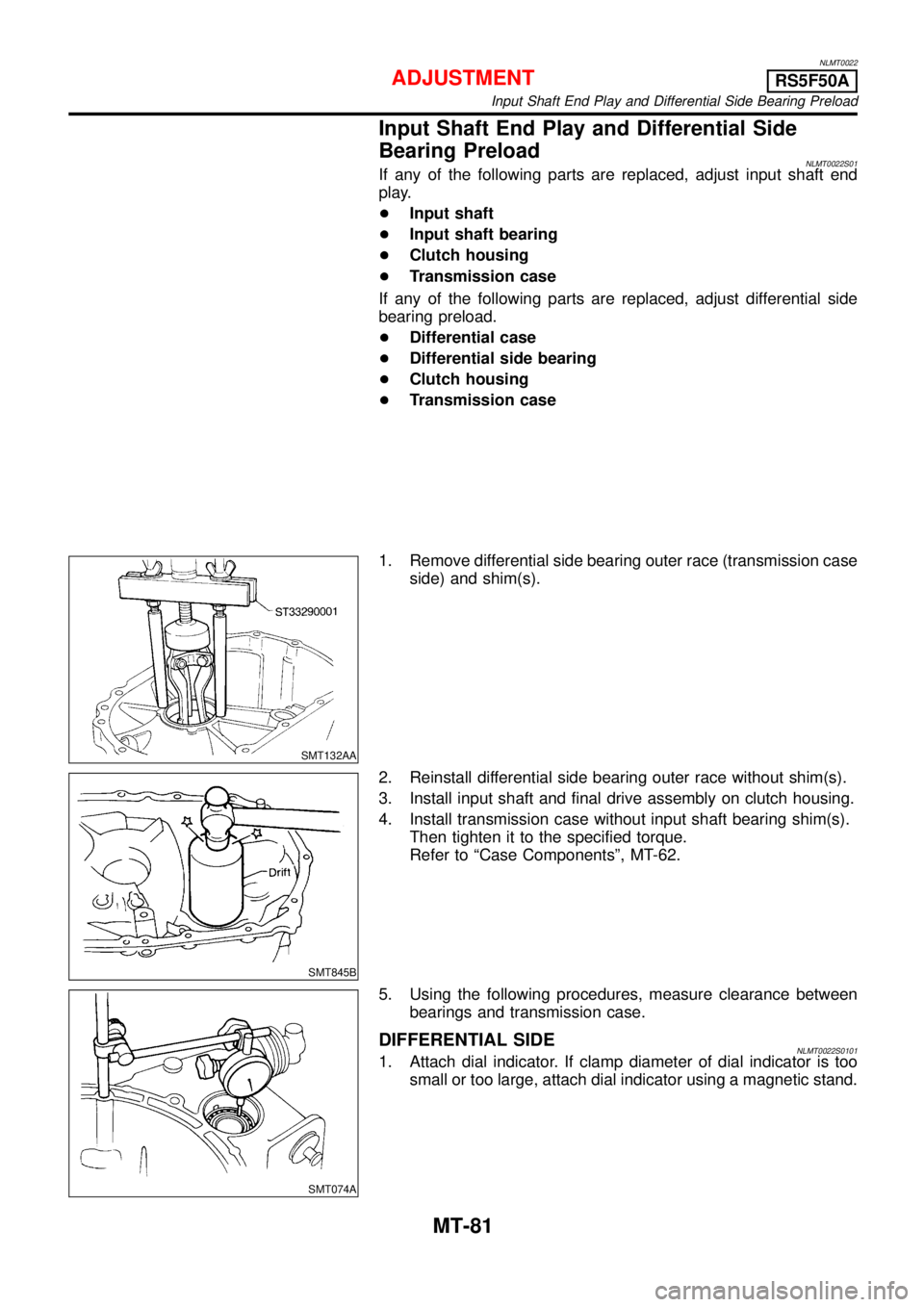

3. Install 2nd synchronizer cone, inner & outer baulk rings. Insert

springs and 1st & 2nd coupling sleeve.

4. Install 2nd main gear.

+Ensure four protrusions of 2nd synchronizer cone are set in

holes of 2nd main gear.

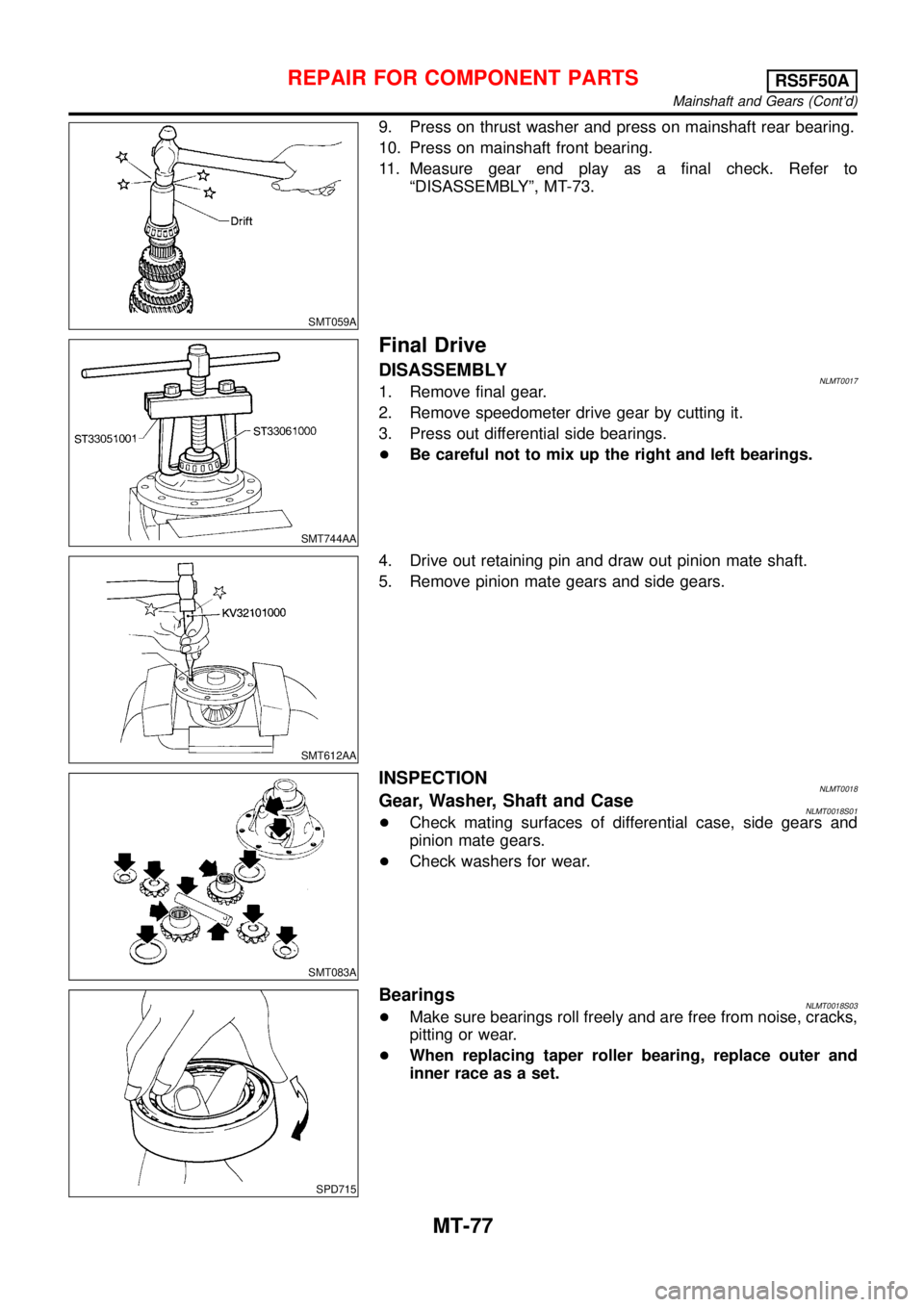

SMT600CA

5. Press on 3rd main gear.

6. Press on 4th main gear.

SMT473CA

7. Press on 5th main gear.

8. Select proper snap ring of 5th main gear to minimize clearance

of groove and then install it.

Allowable clearance of groove:

0 - 0.15 mm (0 - 0.0059 in)

Snap ring of 5th main gear:

Refer to SDS, MT-98.

REPAIR FOR COMPONENT PARTSRS5F50A

Mainshaft and Gears (Cont’d)

MT-76

Page 2866 of 3051

SMT059A

9. Press on thrust washer and press on mainshaft rear bearing.

10. Press on mainshaft front bearing.

11. Measure gear end play as a final check. Refer to

“DISASSEMBLY”, MT-73.

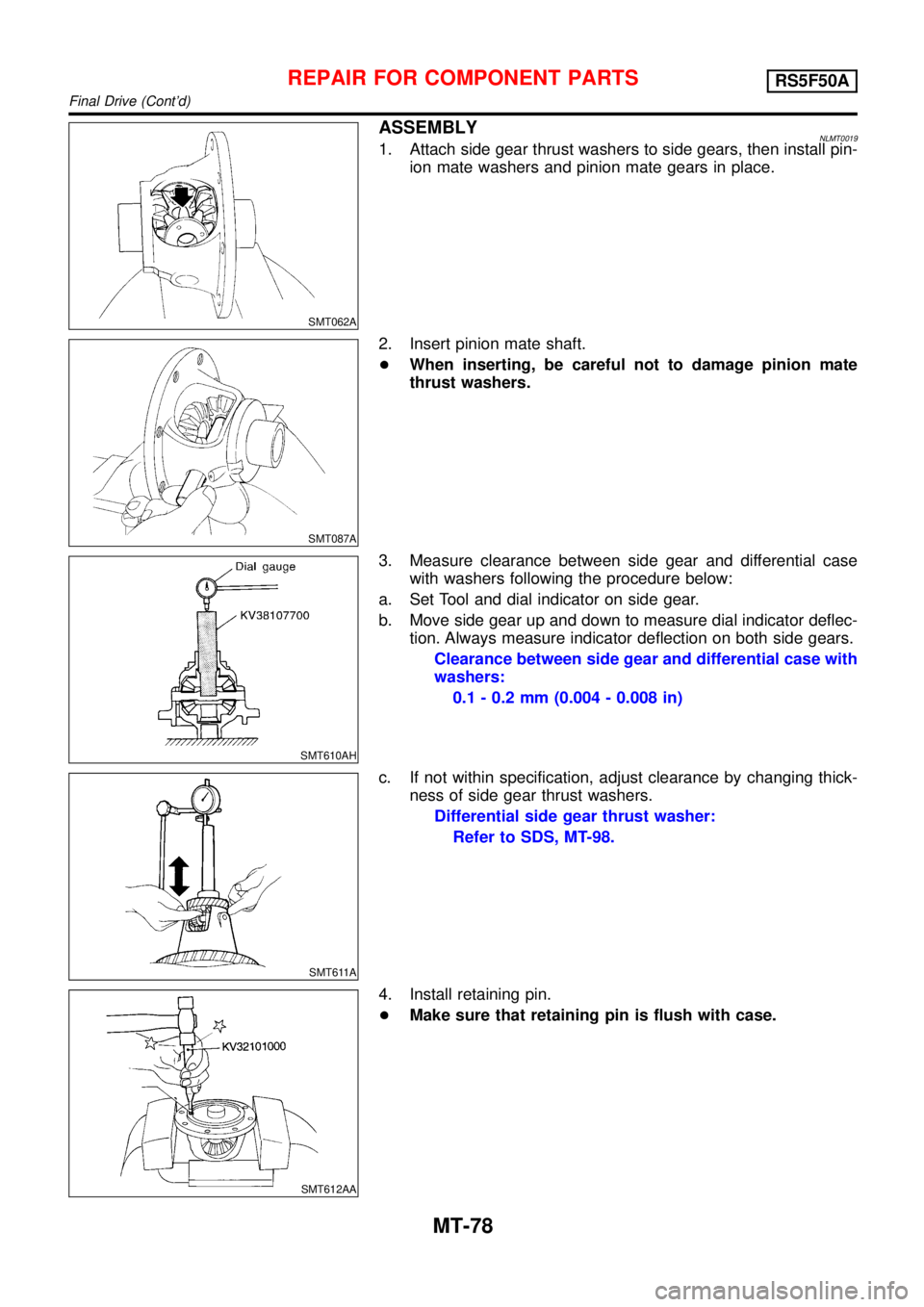

SMT744AA

Final Drive

DISASSEMBLYNLMT00171. Remove final gear.

2. Remove speedometer drive gear by cutting it.

3. Press out differential side bearings.

+Be careful not to mix up the right and left bearings.

SMT612AA

4. Drive out retaining pin and draw out pinion mate shaft.

5. Remove pinion mate gears and side gears.

SMT083A

INSPECTIONNLMT0018Gear, Washer, Shaft and CaseNLMT0018S01+Check mating surfaces of differential case, side gears and

pinion mate gears.

+Check washers for wear.

SPD715

BearingsNLMT0018S03+Make sure bearings roll freely and are free from noise, cracks,

pitting or wear.

+When replacing taper roller bearing, replace outer and

inner race as a set.

REPAIR FOR COMPONENT PARTSRS5F50A

Mainshaft and Gears (Cont’d)

MT-77

Page 2867 of 3051

SMT062A

ASSEMBLYNLMT00191. Attach side gear thrust washers to side gears, then install pin-

ion mate washers and pinion mate gears in place.

SMT087A

2. Insert pinion mate shaft.

+When inserting, be careful not to damage pinion mate

thrust washers.

SMT610AH

3. Measure clearance between side gear and differential case

with washers following the procedure below:

a. Set Tool and dial indicator on side gear.

b. Move side gear up and down to measure dial indicator deflec-

tion. Always measure indicator deflection on both side gears.

Clearance between side gear and differential case with

washers:

0.1 - 0.2 mm (0.004 - 0.008 in)

SMT611A

c. If not within specification, adjust clearance by changing thick-

ness of side gear thrust washers.

Differential side gear thrust washer:

Refer to SDS, MT-98.

SMT612AA

4. Install retaining pin.

+Make sure that retaining pin is flush with case.

REPAIR FOR COMPONENT PARTSRS5F50A

Final Drive (Cont’d)

MT-78

Page 2868 of 3051

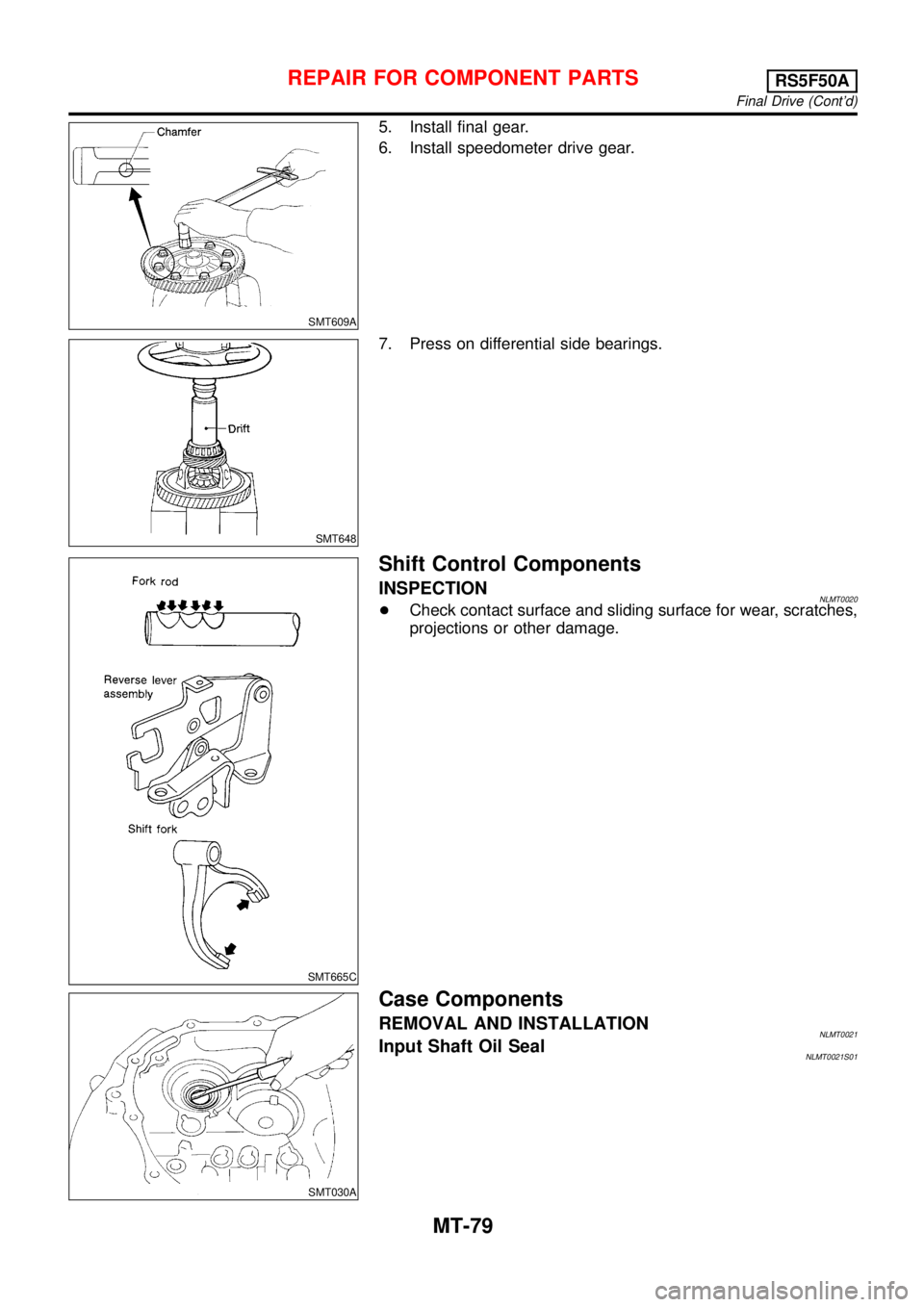

SMT609A

5. Install final gear.

6. Install speedometer drive gear.

SMT648

7. Press on differential side bearings.

SMT665C

Shift Control Components

INSPECTIONNLMT0020+Check contact surface and sliding surface for wear, scratches,

projections or other damage.

SMT030A

Case Components

REMOVAL AND INSTALLATIONNLMT0021Input Shaft Oil SealNLMT0021S01

REPAIR FOR COMPONENT PARTSRS5F50A

Final Drive (Cont’d)

MT-79

Page 2869 of 3051

SMT031A

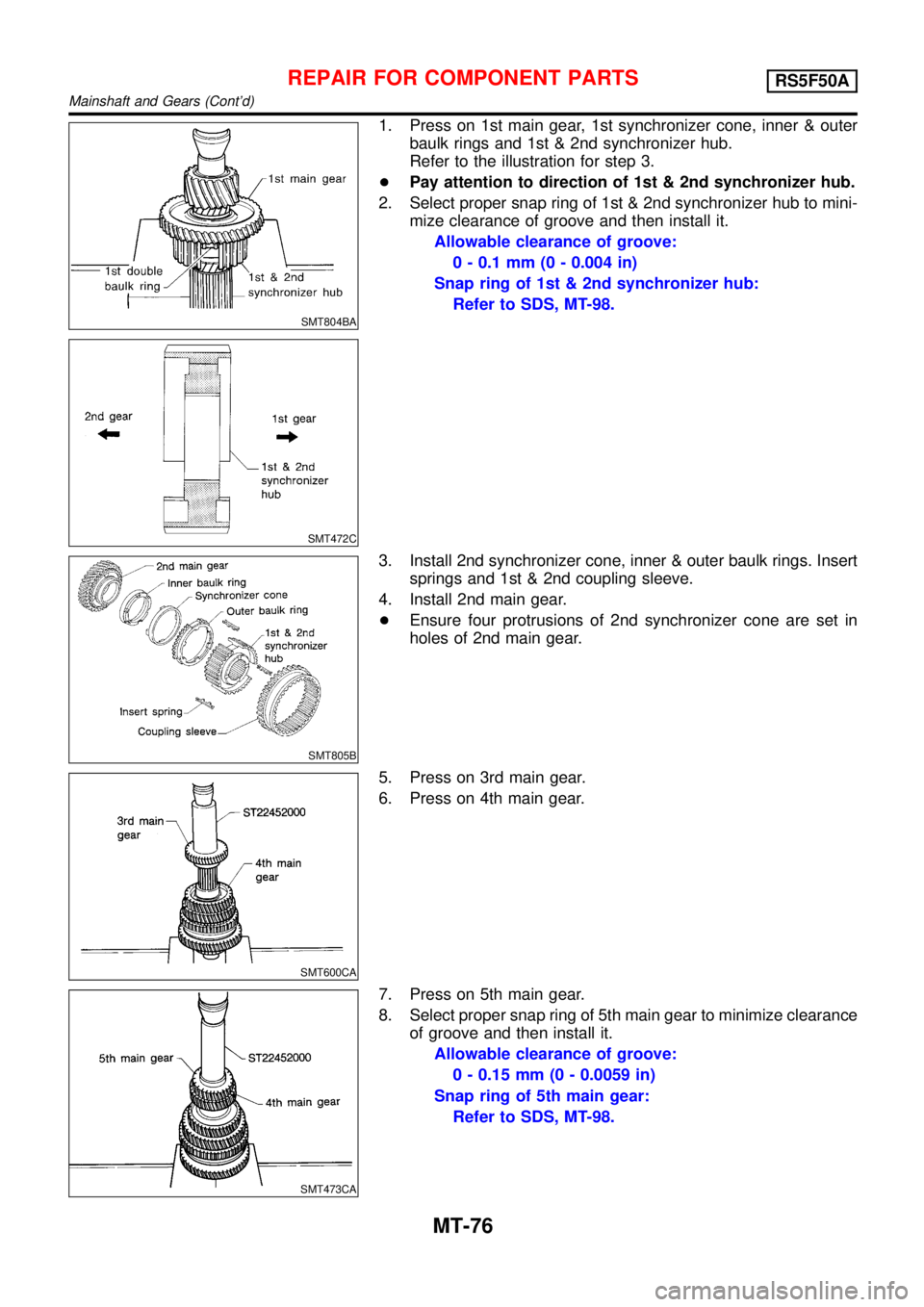

+Apply multi-purpose grease to seal lip of oil seal before

installing.

SMT034A

Mainshaft Front Bearing Outer RaceNLMT0021S02+Extract the oil channel and remove the mainshaft front bear-

ing outer race.

Mainshaft Rear Bearing Outer RaceNLMT0021S03Refer to“Mainshaft Bearing Preload”, MT-99.

Differential Side Bearing Outer RaceNLMT0021S04Refer to“Input Shaft End Play and Differential Side Bearing

Preload”, MT-99.

REPAIR FOR COMPONENT PARTSRS5F50A

Case Components (Cont’d)

MT-80

Page 2870 of 3051

NLMT0022

Input Shaft End Play and Differential Side

Bearing Preload

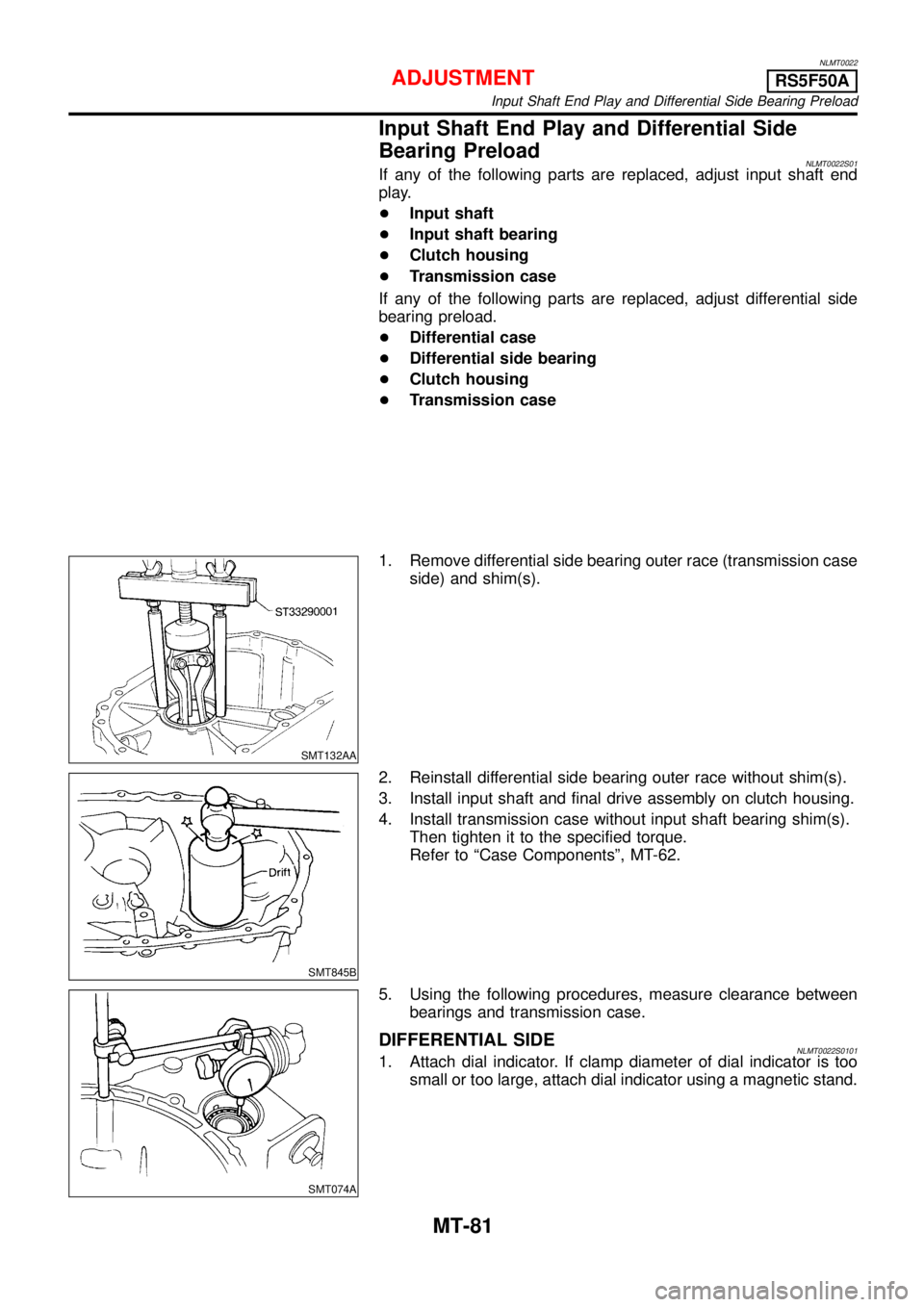

NLMT0022S01If any of the following parts are replaced, adjust input shaft end

play.

+Input shaft

+Input shaft bearing

+Clutch housing

+Transmission case

If any of the following parts are replaced, adjust differential side

bearing preload.

+Differential case

+Differential side bearing

+Clutch housing

+Transmission case

SMT132AA

1. Remove differential side bearing outer race (transmission case

side) and shim(s).

SMT845B

2. Reinstall differential side bearing outer race without shim(s).

3. Install input shaft and final drive assembly on clutch housing.

4. Install transmission case without input shaft bearing shim(s).

Then tighten it to the specified torque.

Refer to“Case Components”, MT-62.

SMT074A

5. Using the following procedures, measure clearance between

bearings and transmission case.

DIFFERENTIAL SIDENLMT0022S01011. Attach dial indicator. If clamp diameter of dial indicator is too

small or too large, attach dial indicator using a magnetic stand.

ADJUSTMENTRS5F50A

Input Shaft End Play and Differential Side Bearing Preload

MT-81

Trending: four wheel drive, change time, Fan, CD changer, sat nav, Trim, automatic transmission