NISSAN ALMERA TINO 2001 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA TINO, Model: NISSAN ALMERA TINO 2001Pages: 3051, PDF Size: 46.38 MB

Page 2841 of 3051

NLMT0067

SMT722DB

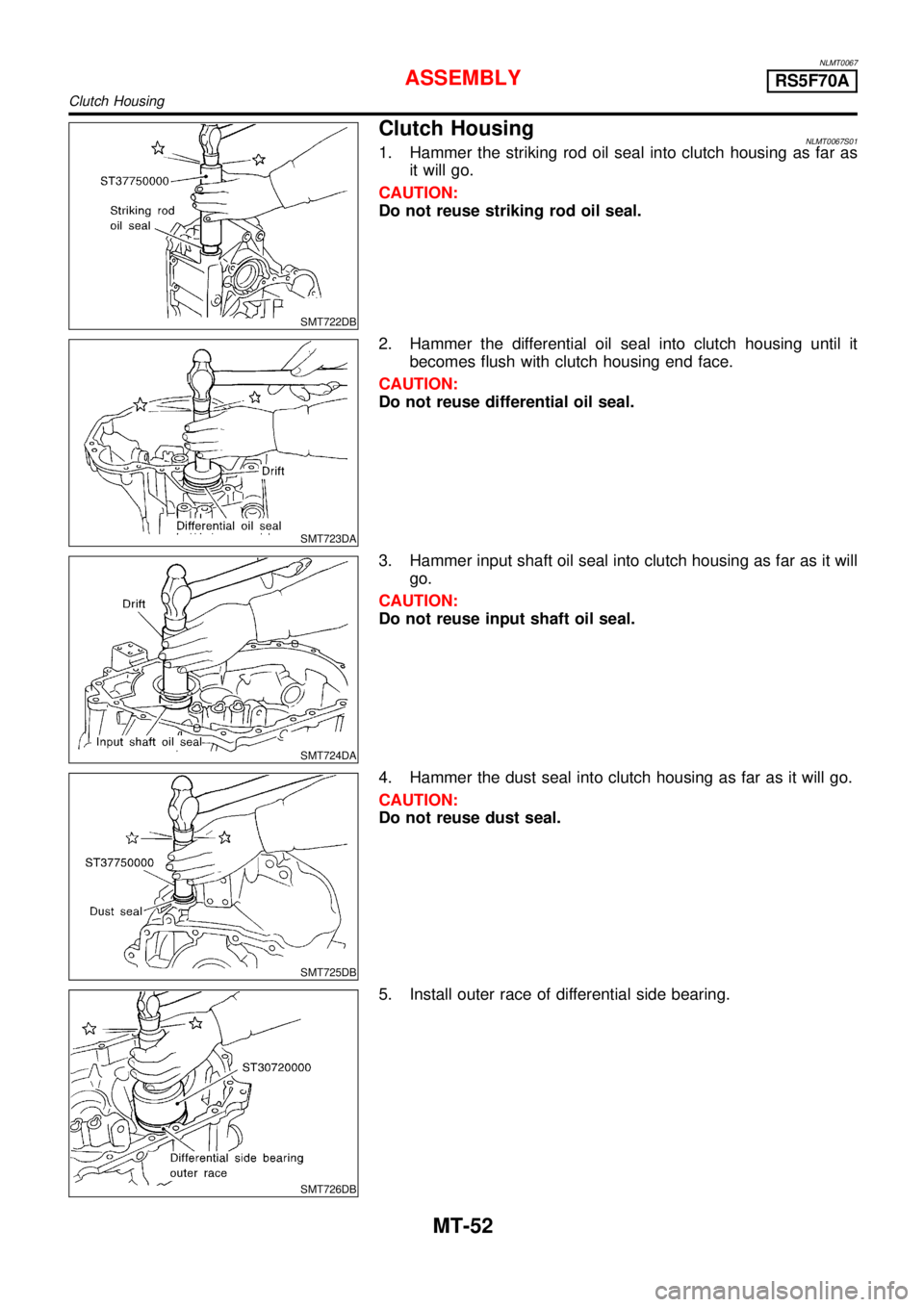

Clutch HousingNLMT0067S011. Hammer the striking rod oil seal into clutch housing as far as

it will go.

CAUTION:

Do not reuse striking rod oil seal.

SMT723DA

2. Hammer the differential oil seal into clutch housing until it

becomes flush with clutch housing end face.

CAUTION:

Do not reuse differential oil seal.

SMT724DA

3. Hammer input shaft oil seal into clutch housing as far as it will

go.

CAUTION:

Do not reuse input shaft oil seal.

SMT725DB

4. Hammer the dust seal into clutch housing as far as it will go.

CAUTION:

Do not reuse dust seal.

SMT726DB

5. Install outer race of differential side bearing.

ASSEMBLYRS5F70A

Clutch Housing

MT-52

Page 2842 of 3051

SMT727D

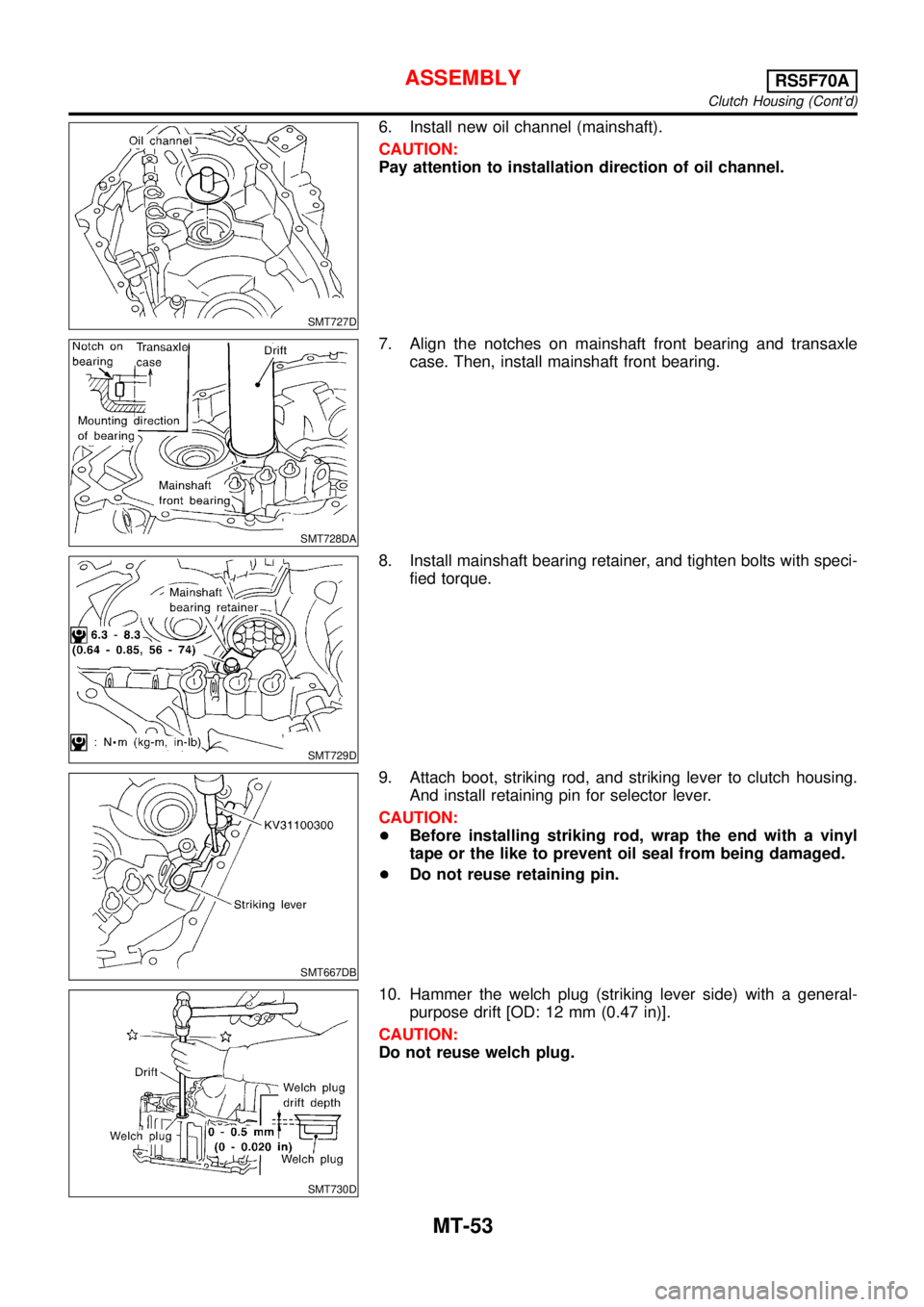

6. Install new oil channel (mainshaft).

CAUTION:

Pay attention to installation direction of oil channel.

SMT728DA

7. Align the notches on mainshaft front bearing and transaxle

case. Then, install mainshaft front bearing.

SMT729D

8. Install mainshaft bearing retainer, and tighten bolts with speci-

fied torque.

SMT667DB

9. Attach boot, striking rod, and striking lever to clutch housing.

And install retaining pin for selector lever.

CAUTION:

+Before installing striking rod, wrap the end with a vinyl

tape or the like to prevent oil seal from being damaged.

+Do not reuse retaining pin.

SMT730D

10. Hammer the welch plug (striking lever side) with a general-

purpose drift [OD: 12 mm (0.47 in)].

CAUTION:

Do not reuse welch plug.

ASSEMBLYRS5F70A

Clutch Housing (Cont’d)

MT-53

Page 2843 of 3051

![NISSAN ALMERA TINO 2001 Service Repair Manual SMT731D

11. Install selector, selector shaft, and selector shaft pin into clutch

housing.

SMT732D

12. Hammer the welch plug (selector shaft side) with a general-

purpose drift [OD: 12 mm (0.47 in)].

C NISSAN ALMERA TINO 2001 Service Repair Manual SMT731D

11. Install selector, selector shaft, and selector shaft pin into clutch

housing.

SMT732D

12. Hammer the welch plug (selector shaft side) with a general-

purpose drift [OD: 12 mm (0.47 in)].

C](/img/5/57352/w960_57352-2842.png)

SMT731D

11. Install selector, selector shaft, and selector shaft pin into clutch

housing.

SMT732D

12. Hammer the welch plug (selector shaft side) with a general-

purpose drift [OD: 12 mm (0.47 in)].

CAUTION:

Do not reuse welch plug.

SMT733DA

SMT734D

13. Install select check leaf spring, return spring, steel ball, reverse

gate, selector arm, bushing, and return bearing. Then, tighten

two reamer bolts with specified torque.

CAUTION:

Use correct reamer bolts for each installation point, because

each bolt has a different length.

SMT735D

14. Install oil pocket.

ASSEMBLYRS5F70A

Clutch Housing (Cont’d)

MT-54

Page 2844 of 3051

SMT736D

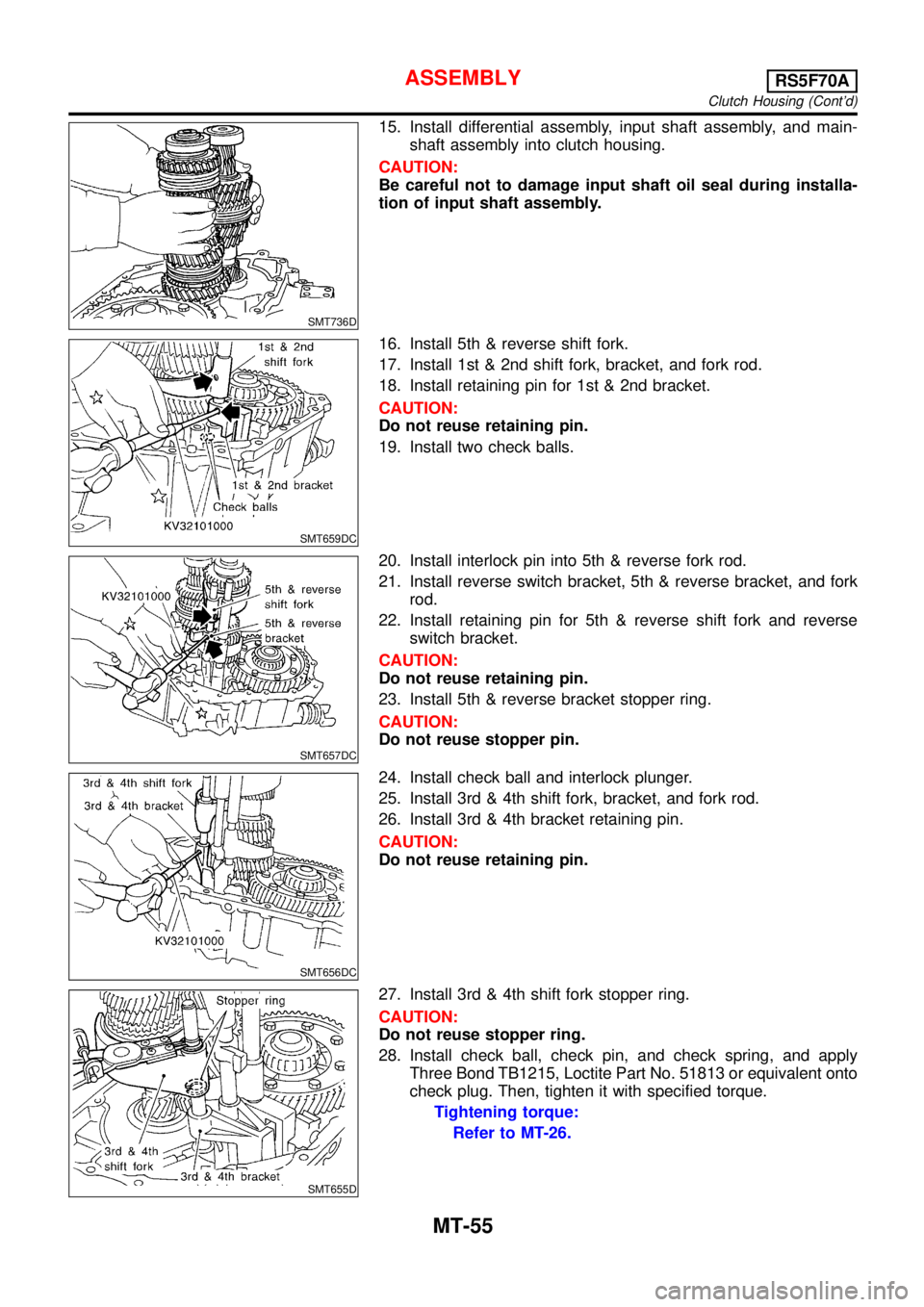

15. Install differential assembly, input shaft assembly, and main-

shaft assembly into clutch housing.

CAUTION:

Be careful not to damage input shaft oil seal during installa-

tion of input shaft assembly.

SMT659DC

16. Install 5th & reverse shift fork.

17. Install 1st & 2nd shift fork, bracket, and fork rod.

18. Install retaining pin for 1st & 2nd bracket.

CAUTION:

Do not reuse retaining pin.

19. Install two check balls.

SMT657DC

20. Install interlock pin into 5th & reverse fork rod.

21. Install reverse switch bracket, 5th & reverse bracket, and fork

rod.

22. Install retaining pin for 5th & reverse shift fork and reverse

switch bracket.

CAUTION:

Do not reuse retaining pin.

23. Install 5th & reverse bracket stopper ring.

CAUTION:

Do not reuse stopper pin.

SMT656DC

24. Install check ball and interlock plunger.

25. Install 3rd & 4th shift fork, bracket, and fork rod.

26. Install 3rd & 4th bracket retaining pin.

CAUTION:

Do not reuse retaining pin.

SMT655D

27. Install 3rd & 4th shift fork stopper ring.

CAUTION:

Do not reuse stopper ring.

28. Install check ball, check pin, and check spring, and apply

Three Bond TB1215, Loctite Part No. 51813 or equivalent onto

check plug. Then, tighten it with specified torque.

Tightening torque:

Refer to MT-26.

ASSEMBLYRS5F70A

Clutch Housing (Cont’d)

MT-55

Page 2845 of 3051

SMT737DA

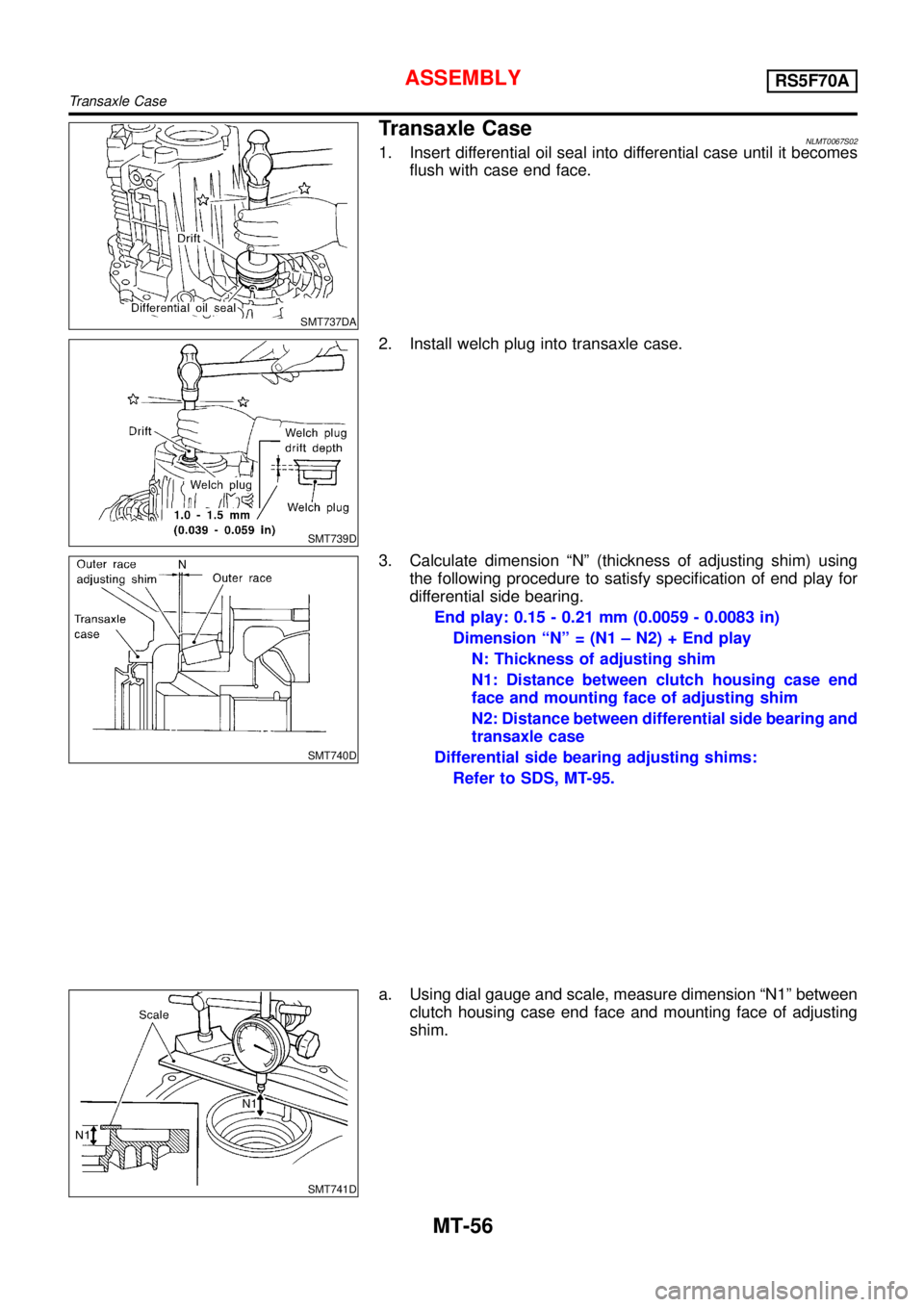

Transaxle CaseNLMT0067S021. Insert differential oil seal into differential case until it becomes

flush with case end face.

SMT739D

2. Install welch plug into transaxle case.

SMT740D

3. Calculate dimension“N”(thickness of adjusting shim) using

the following procedure to satisfy specification of end play for

differential side bearing.

End play: 0.15 - 0.21 mm (0.0059 - 0.0083 in)

Dimension“N”= (N1–N2) + End play

N: Thickness of adjusting shim

N1: Distance between clutch housing case end

face and mounting face of adjusting shim

N2: Distance between differential side bearing and

transaxle case

Differential side bearing adjusting shims:

Refer to SDS, MT-95.

SMT741D

a. Using dial gauge and scale, measure dimension“N1”between

clutch housing case end face and mounting face of adjusting

shim.

ASSEMBLYRS5F70A

Transaxle Case

MT-56

Page 2846 of 3051

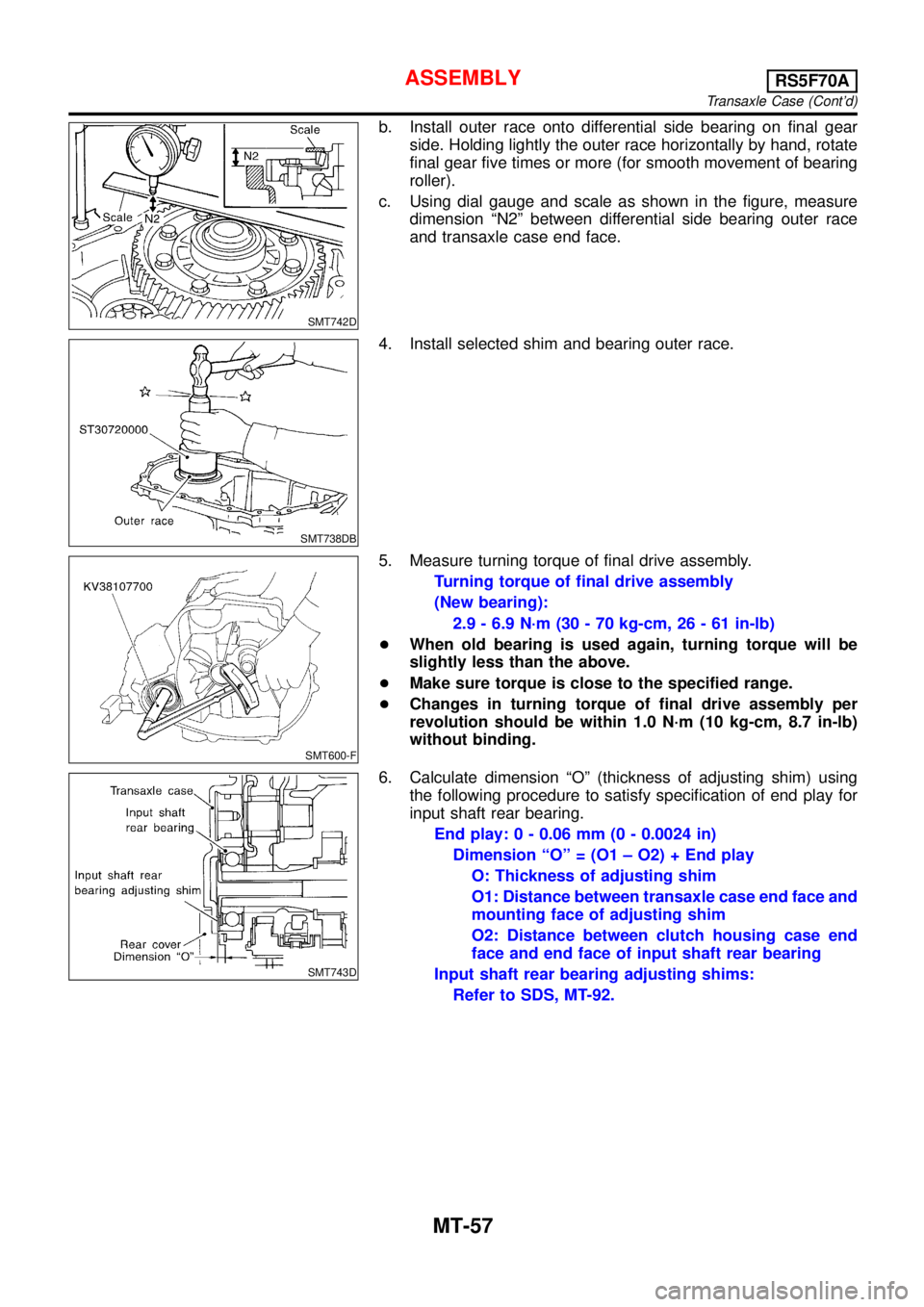

SMT742D

b. Install outer race onto differential side bearing on final gear

side. Holding lightly the outer race horizontally by hand, rotate

final gear five times or more (for smooth movement of bearing

roller).

c. Using dial gauge and scale as shown in the figure, measure

dimension“N2”between differential side bearing outer race

and transaxle case end face.

SMT738DB

4. Install selected shim and bearing outer race.

SMT600-F

5. Measure turning torque of final drive assembly.

Turning torque of final drive assembly

(New bearing):

2.9 - 6.9 N·m (30 - 70 kg-cm, 26 - 61 in-lb)

+When old bearing is used again, turning torque will be

slightly less than the above.

+Make sure torque is close to the specified range.

+Changes in turning torque of final drive assembly per

revolution should be within 1.0 N·m (10 kg-cm, 8.7 in-lb)

without binding.

SMT743D

6. Calculate dimension“O”(thickness of adjusting shim) using

the following procedure to satisfy specification of end play for

input shaft rear bearing.

End play: 0 - 0.06 mm (0 - 0.0024 in)

Dimension“O”= (O1–O2) + End play

O: Thickness of adjusting shim

O1: Distance between transaxle case end face and

mounting face of adjusting shim

O2: Distance between clutch housing case end

face and end face of input shaft rear bearing

Input shaft rear bearing adjusting shims:

Refer to SDS, MT-92.

ASSEMBLYRS5F70A

Transaxle Case (Cont’d)

MT-57

Page 2847 of 3051

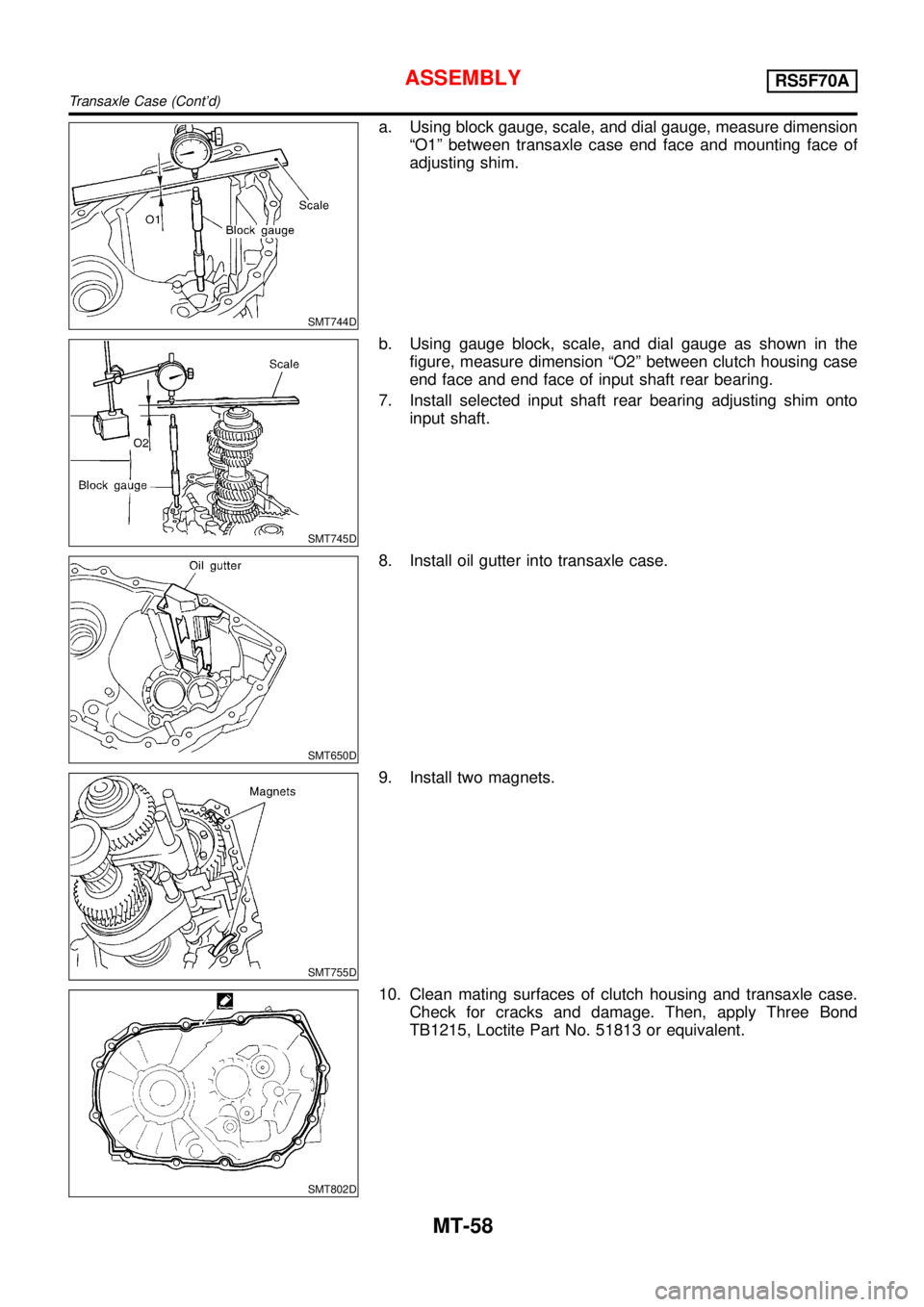

SMT744D

a. Using block gauge, scale, and dial gauge, measure dimension

“O1”between transaxle case end face and mounting face of

adjusting shim.

SMT745D

b. Using gauge block, scale, and dial gauge as shown in the

figure, measure dimension“O2”between clutch housing case

end face and end face of input shaft rear bearing.

7. Install selected input shaft rear bearing adjusting shim onto

input shaft.

SMT650D

8. Install oil gutter into transaxle case.

SMT755D

9. Install two magnets.

SMT802D

10. Clean mating surfaces of clutch housing and transaxle case.

Check for cracks and damage. Then, apply Three Bond

TB1215, Loctite Part No. 51813 or equivalent.

ASSEMBLYRS5F70A

Transaxle Case (Cont’d)

MT-58

Page 2848 of 3051

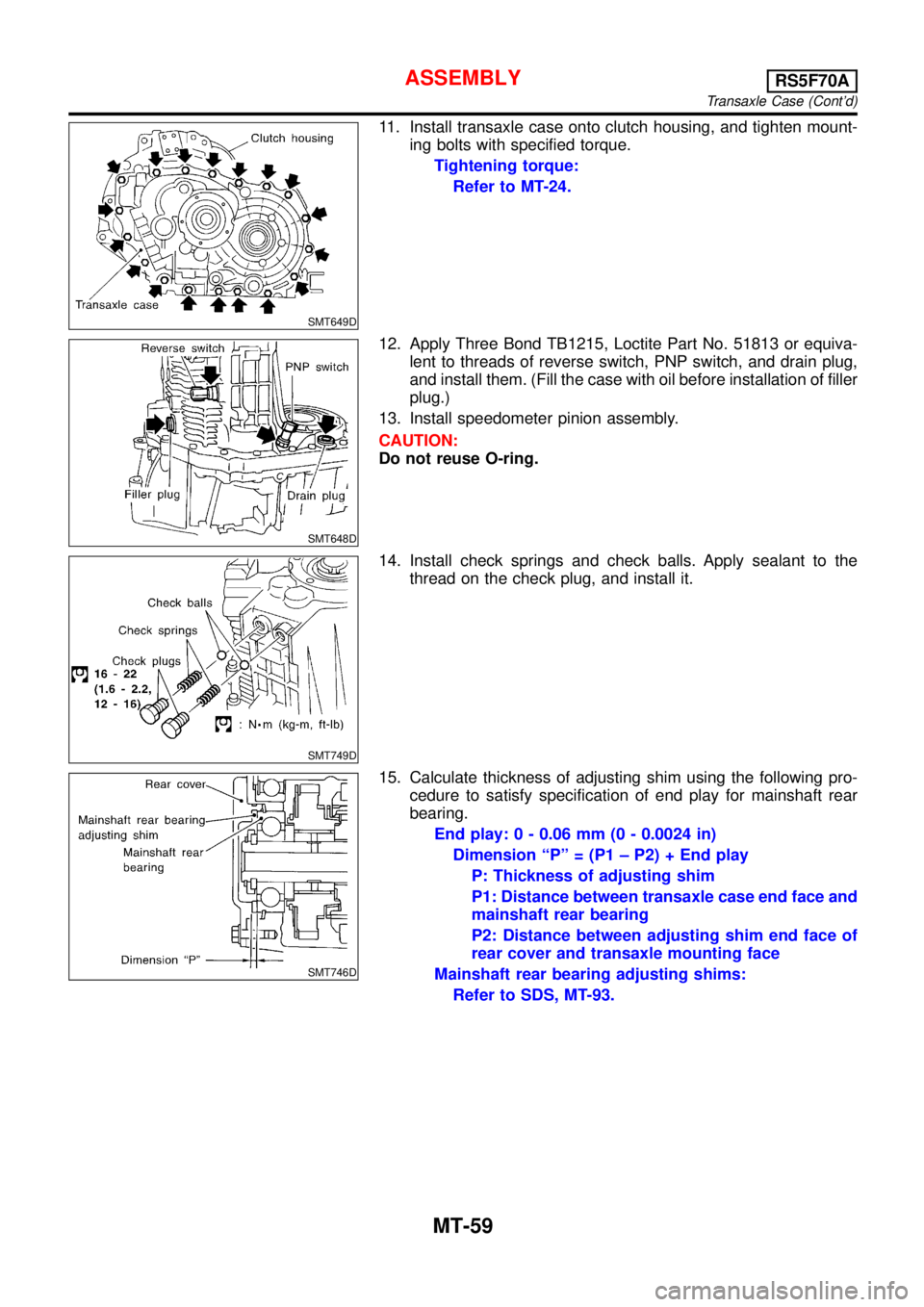

SMT649D

11. Install transaxle case onto clutch housing, and tighten mount-

ing bolts with specified torque.

Tightening torque:

Refer to MT-24.

SMT648D

12. Apply Three Bond TB1215, Loctite Part No. 51813 or equiva-

lent to threads of reverse switch, PNP switch, and drain plug,

and install them. (Fill the case with oil before installation of filler

plug.)

13. Install speedometer pinion assembly.

CAUTION:

Do not reuse O-ring.

SMT749D

14. Install check springs and check balls. Apply sealant to the

thread on the check plug, and install it.

SMT746D

15. Calculate thickness of adjusting shim using the following pro-

cedure to satisfy specification of end play for mainshaft rear

bearing.

End play: 0 - 0.06 mm (0 - 0.0024 in)

Dimension“P”= (P1–P2) + End play

P: Thickness of adjusting shim

P1: Distance between transaxle case end face and

mainshaft rear bearing

P2: Distance between adjusting shim end face of

rear cover and transaxle mounting face

Mainshaft rear bearing adjusting shims:

Refer to SDS, MT-93.

ASSEMBLYRS5F70A

Transaxle Case (Cont’d)

MT-59

Page 2849 of 3051

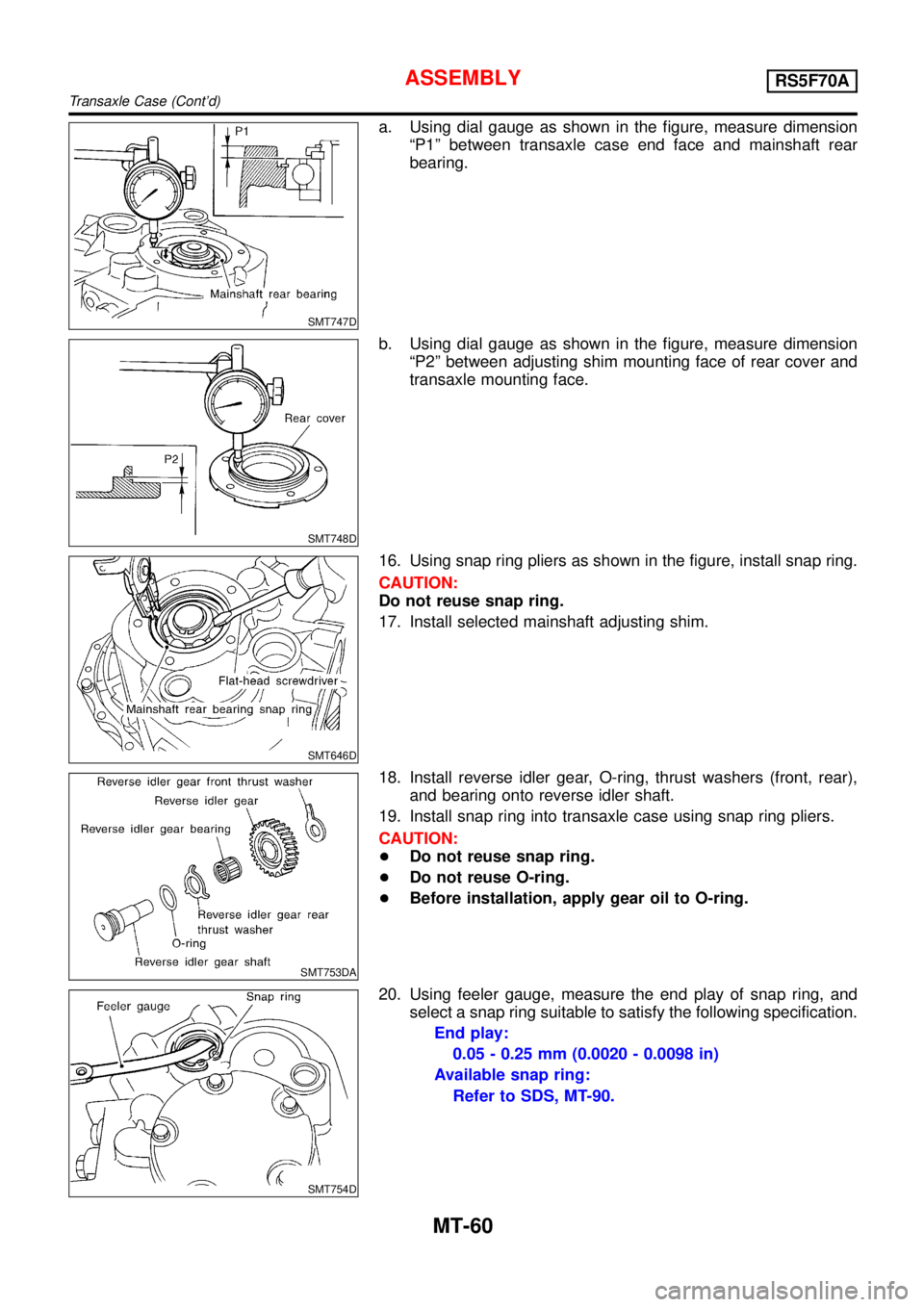

SMT747D

a. Using dial gauge as shown in the figure, measure dimension

“P1”between transaxle case end face and mainshaft rear

bearing.

SMT748D

b. Using dial gauge as shown in the figure, measure dimension

“P2”between adjusting shim mounting face of rear cover and

transaxle mounting face.

SMT646D

16. Using snap ring pliers as shown in the figure, install snap ring.

CAUTION:

Do not reuse snap ring.

17. Install selected mainshaft adjusting shim.

SMT753DA

18. Install reverse idler gear, O-ring, thrust washers (front, rear),

and bearing onto reverse idler shaft.

19. Install snap ring into transaxle case using snap ring pliers.

CAUTION:

+Do not reuse snap ring.

+Do not reuse O-ring.

+Before installation, apply gear oil to O-ring.

SMT754D

20. Using feeler gauge, measure the end play of snap ring, and

select a snap ring suitable to satisfy the following specification.

End play:

0.05 - 0.25 mm (0.0020 - 0.0098 in)

Available snap ring:

Refer to SDS, MT-90.

ASSEMBLYRS5F70A

Transaxle Case (Cont’d)

MT-60

Page 2850 of 3051

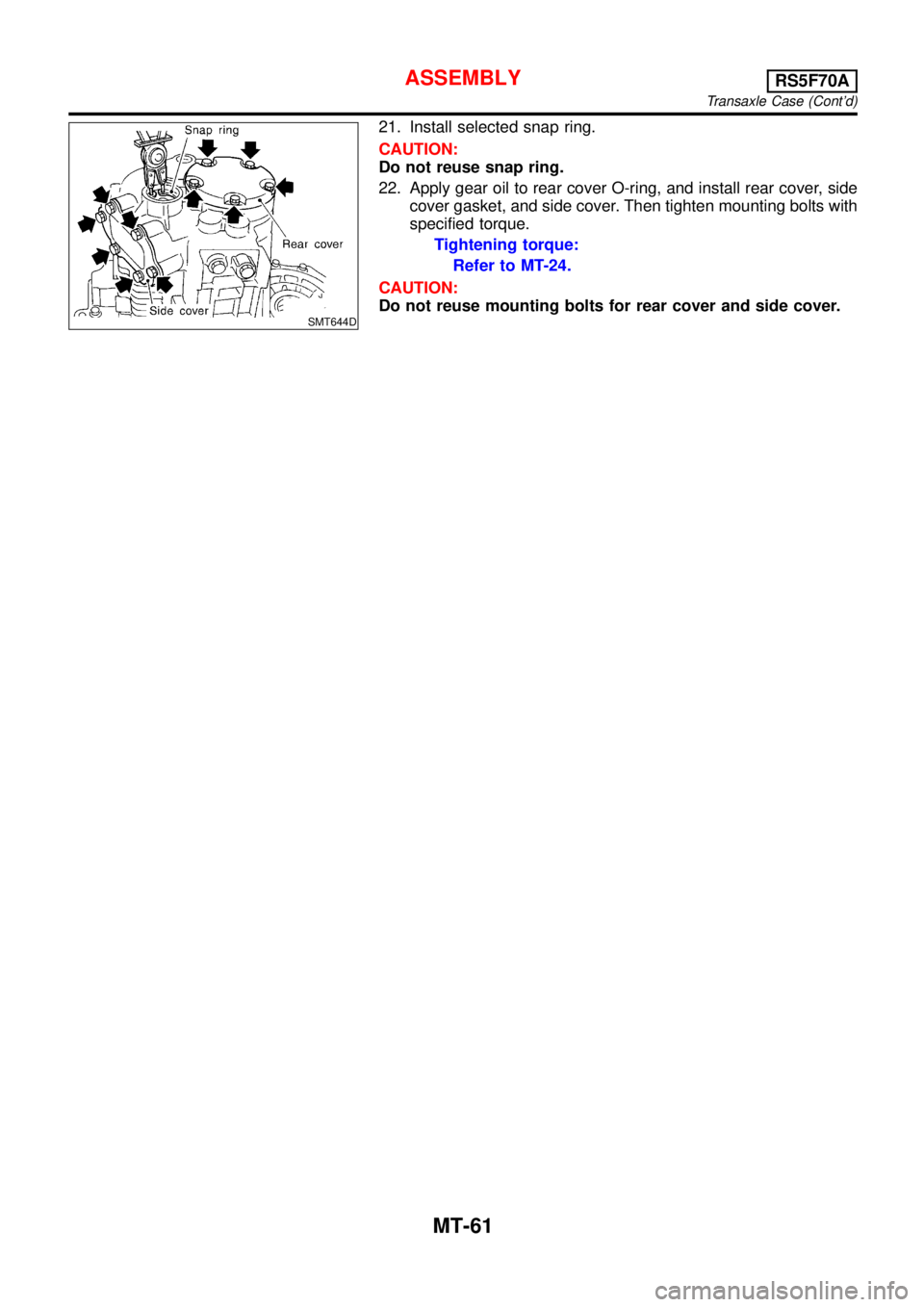

SMT644D

21. Install selected snap ring.

CAUTION:

Do not reuse snap ring.

22. Apply gear oil to rear cover O-ring, and install rear cover, side

cover gasket, and side cover. Then tighten mounting bolts with

specified torque.

Tightening torque:

Refer to MT-24.

CAUTION:

Do not reuse mounting bolts for rear cover and side cover.

ASSEMBLYRS5F70A

Transaxle Case (Cont’d)

MT-61