NISSAN ALMERA TINO 2001 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA TINO, Model: NISSAN ALMERA TINO 2001Pages: 3051, PDF Size: 46.38 MB

Page 2831 of 3051

+Measure wear of 1st and 2nd baulk ring.

a) Place baulk rings in position on synchronizer cone.

b) While holding baulk ring against synchronizer cone as far as it

will go, measure dimensions“A”and“B”.

Standard:

A 0.6 - 0.8 mm (0.024 - 0.031 in)

B 0.6 - 1.1 mm (0.024 - 0.043 in)

Wear limit:

0.2 mm (0.008 in)

+If dimension“A”or“B”is smaller than the wear limit,

replace outer baulk ring, inner baulk ring and synchro-

nizer cone as a set.

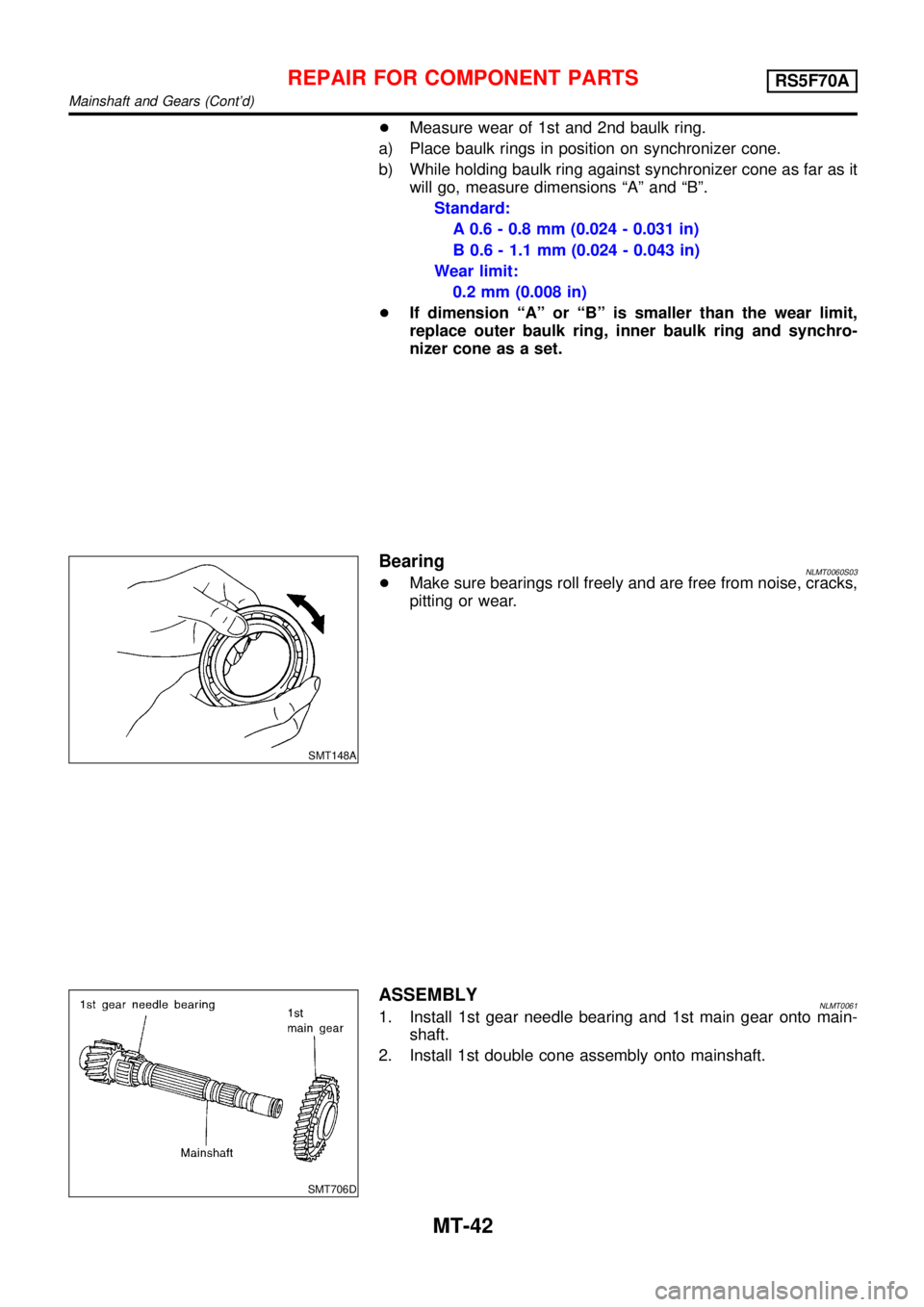

SMT148A

BearingNLMT0060S03+Make sure bearings roll freely and are free from noise, cracks,

pitting or wear.

SMT706D

ASSEMBLYNLMT00611. Install 1st gear needle bearing and 1st main gear onto main-

shaft.

2. Install 1st double cone assembly onto mainshaft.

REPAIR FOR COMPONENT PARTSRS5F70A

Mainshaft and Gears (Cont’d)

MT-42

Page 2832 of 3051

SMT695D

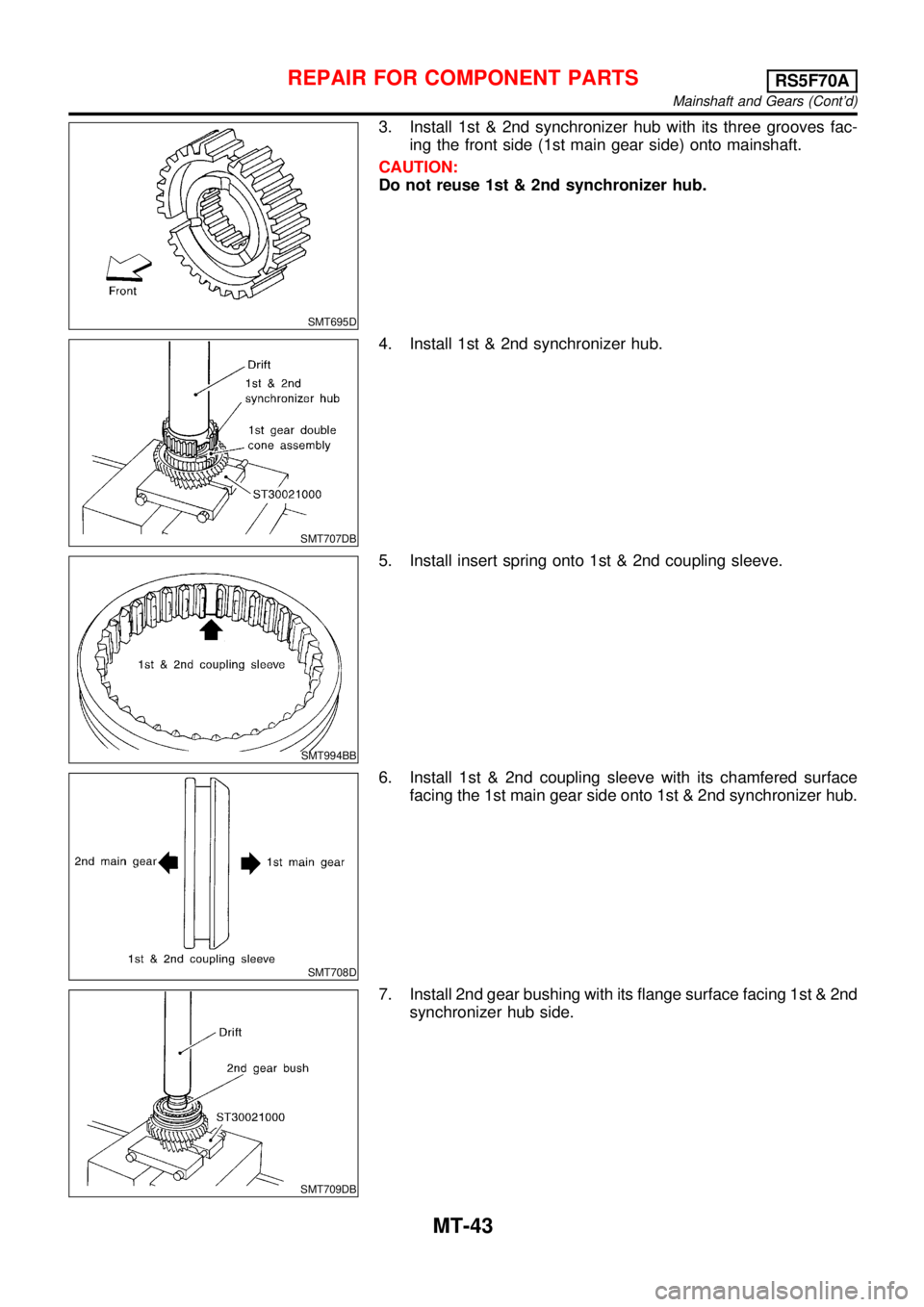

3. Install 1st & 2nd synchronizer hub with its three grooves fac-

ing the front side (1st main gear side) onto mainshaft.

CAUTION:

Do not reuse 1st & 2nd synchronizer hub.

SMT707DB

4. Install 1st & 2nd synchronizer hub.

SMT994BB

5. Install insert spring onto 1st & 2nd coupling sleeve.

SMT708D

6. Install 1st & 2nd coupling sleeve with its chamfered surface

facing the 1st main gear side onto 1st & 2nd synchronizer hub.

SMT709DB

7. Install 2nd gear bushing with its flange surface facing 1st & 2nd

synchronizer hub side.

REPAIR FOR COMPONENT PARTSRS5F70A

Mainshaft and Gears (Cont’d)

MT-43

Page 2833 of 3051

SMT710DB

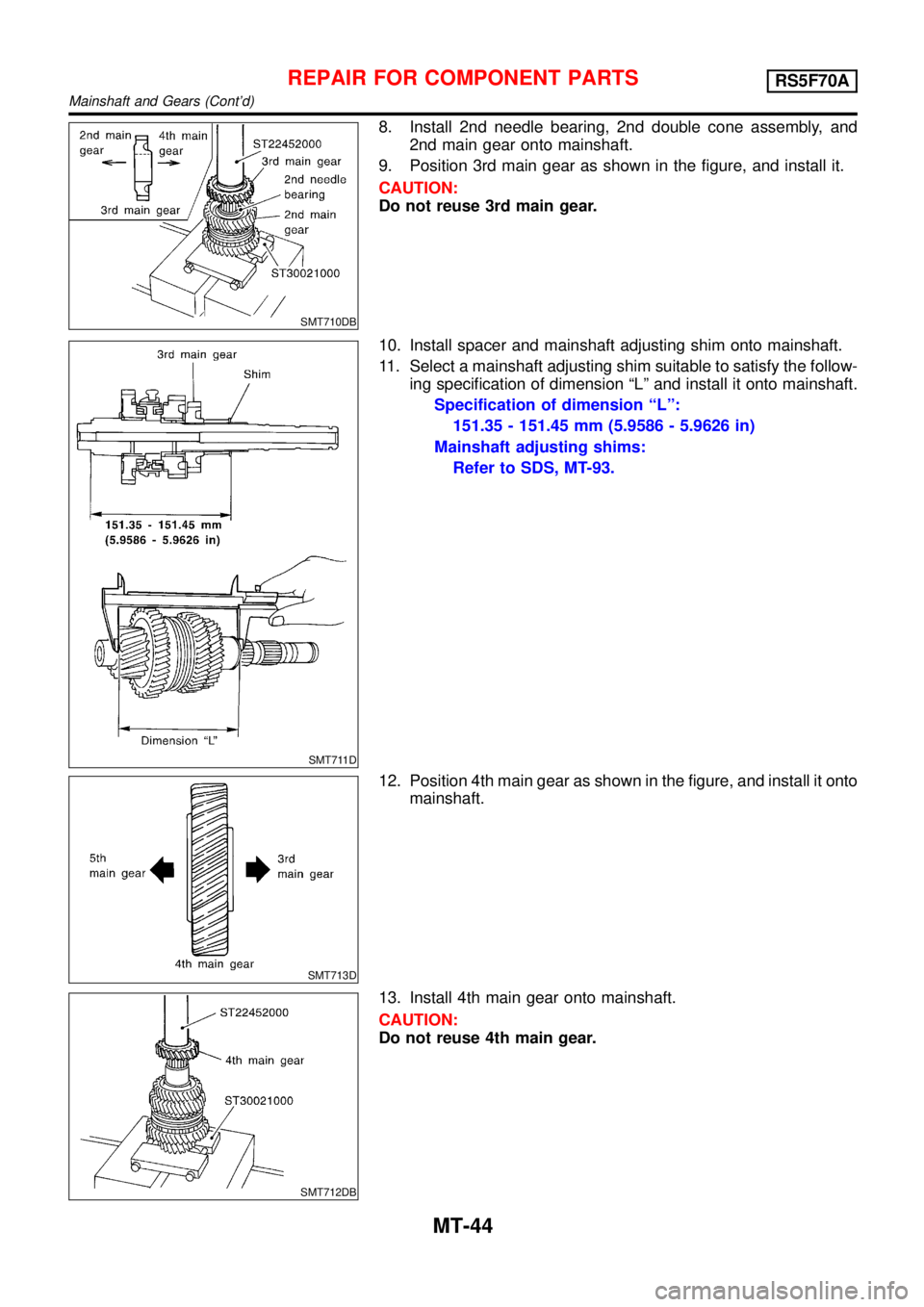

8. Install 2nd needle bearing, 2nd double cone assembly, and

2nd main gear onto mainshaft.

9. Position 3rd main gear as shown in the figure, and install it.

CAUTION:

Do not reuse 3rd main gear.

SMT711D

10. Install spacer and mainshaft adjusting shim onto mainshaft.

11. Select a mainshaft adjusting shim suitable to satisfy the follow-

ing specification of dimension“L”and install it onto mainshaft.

Specification of dimension“L”:

151.35 - 151.45 mm (5.9586 - 5.9626 in)

Mainshaft adjusting shims:

Refer to SDS, MT-93.

SMT713D

12. Position 4th main gear as shown in the figure, and install it onto

mainshaft.

SMT712DB

13. Install 4th main gear onto mainshaft.

CAUTION:

Do not reuse 4th main gear.

REPAIR FOR COMPONENT PARTSRS5F70A

Mainshaft and Gears (Cont’d)

MT-44

Page 2834 of 3051

SMT714DB

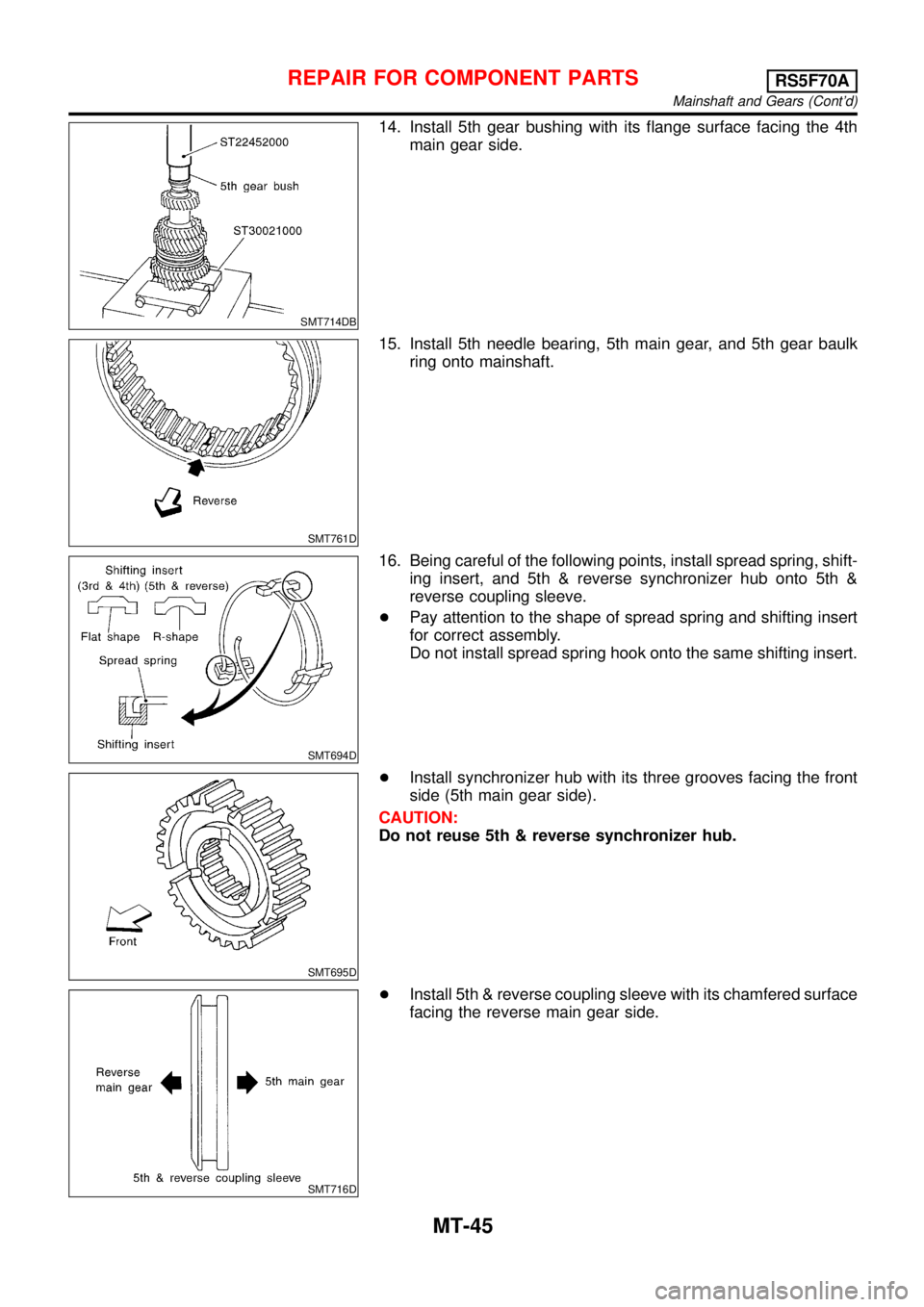

14. Install 5th gear bushing with its flange surface facing the 4th

main gear side.

SMT761D

15. Install 5th needle bearing, 5th main gear, and 5th gear baulk

ring onto mainshaft.

SMT694D

16. Being careful of the following points, install spread spring, shift-

ing insert, and 5th & reverse synchronizer hub onto 5th &

reverse coupling sleeve.

+Pay attention to the shape of spread spring and shifting insert

for correct assembly.

Do not install spread spring hook onto the same shifting insert.

SMT695D

+Install synchronizer hub with its three grooves facing the front

side (5th main gear side).

CAUTION:

Do not reuse 5th & reverse synchronizer hub.

SMT716D

+Install 5th & reverse coupling sleeve with its chamfered surface

facing the reverse main gear side.

REPAIR FOR COMPONENT PARTSRS5F70A

Mainshaft and Gears (Cont’d)

MT-45

Page 2835 of 3051

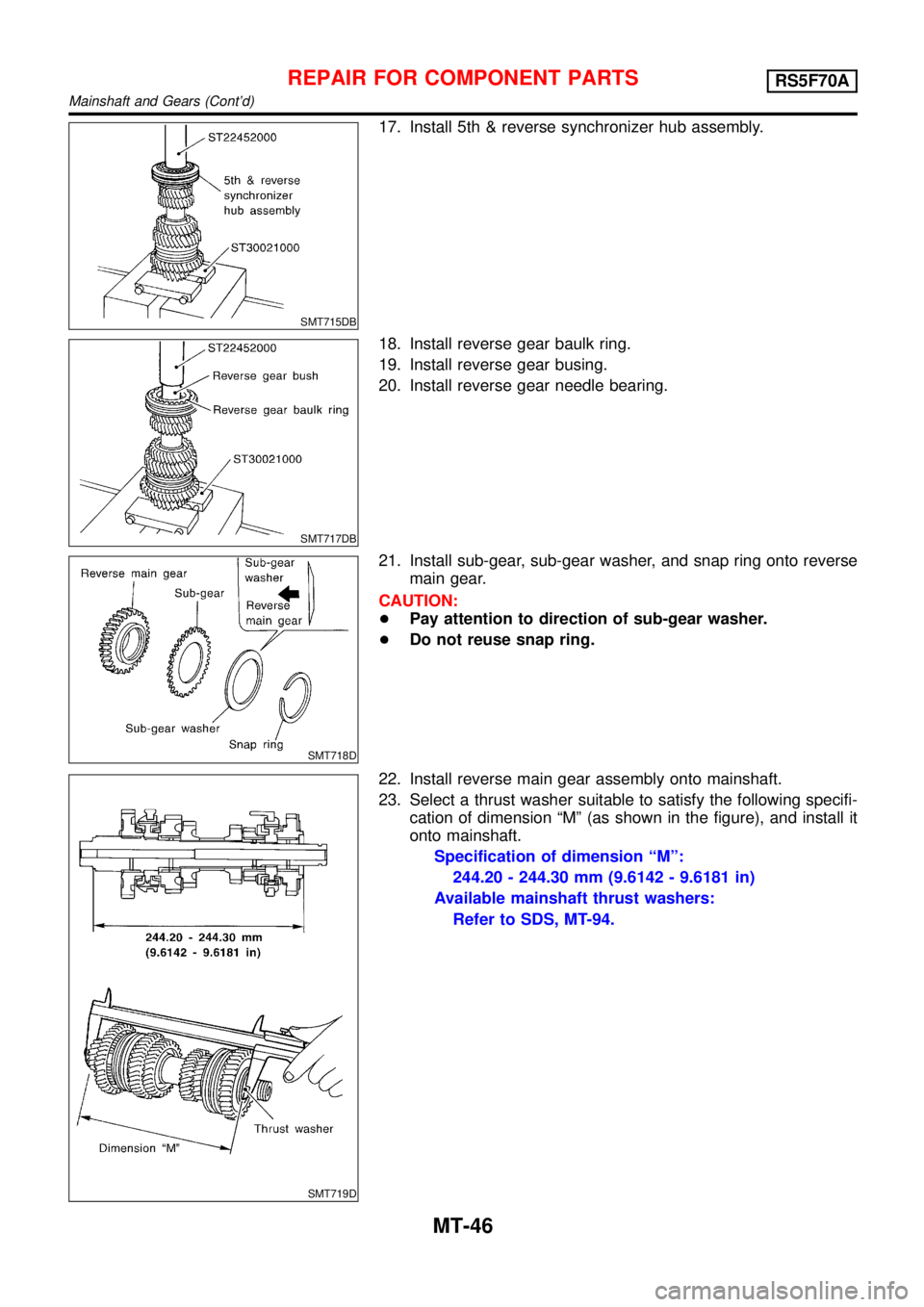

SMT715DB

17. Install 5th & reverse synchronizer hub assembly.

SMT717DB

18. Install reverse gear baulk ring.

19. Install reverse gear busing.

20. Install reverse gear needle bearing.

SMT718D

21. Install sub-gear, sub-gear washer, and snap ring onto reverse

main gear.

CAUTION:

+Pay attention to direction of sub-gear washer.

+Do not reuse snap ring.

SMT719D

22. Install reverse main gear assembly onto mainshaft.

23. Select a thrust washer suitable to satisfy the following specifi-

cation of dimension“M”(as shown in the figure), and install it

onto mainshaft.

Specification of dimension“M”:

244.20 - 244.30 mm (9.6142 - 9.6181 in)

Available mainshaft thrust washers:

Refer to SDS, MT-94.

REPAIR FOR COMPONENT PARTSRS5F70A

Mainshaft and Gears (Cont’d)

MT-46

Page 2836 of 3051

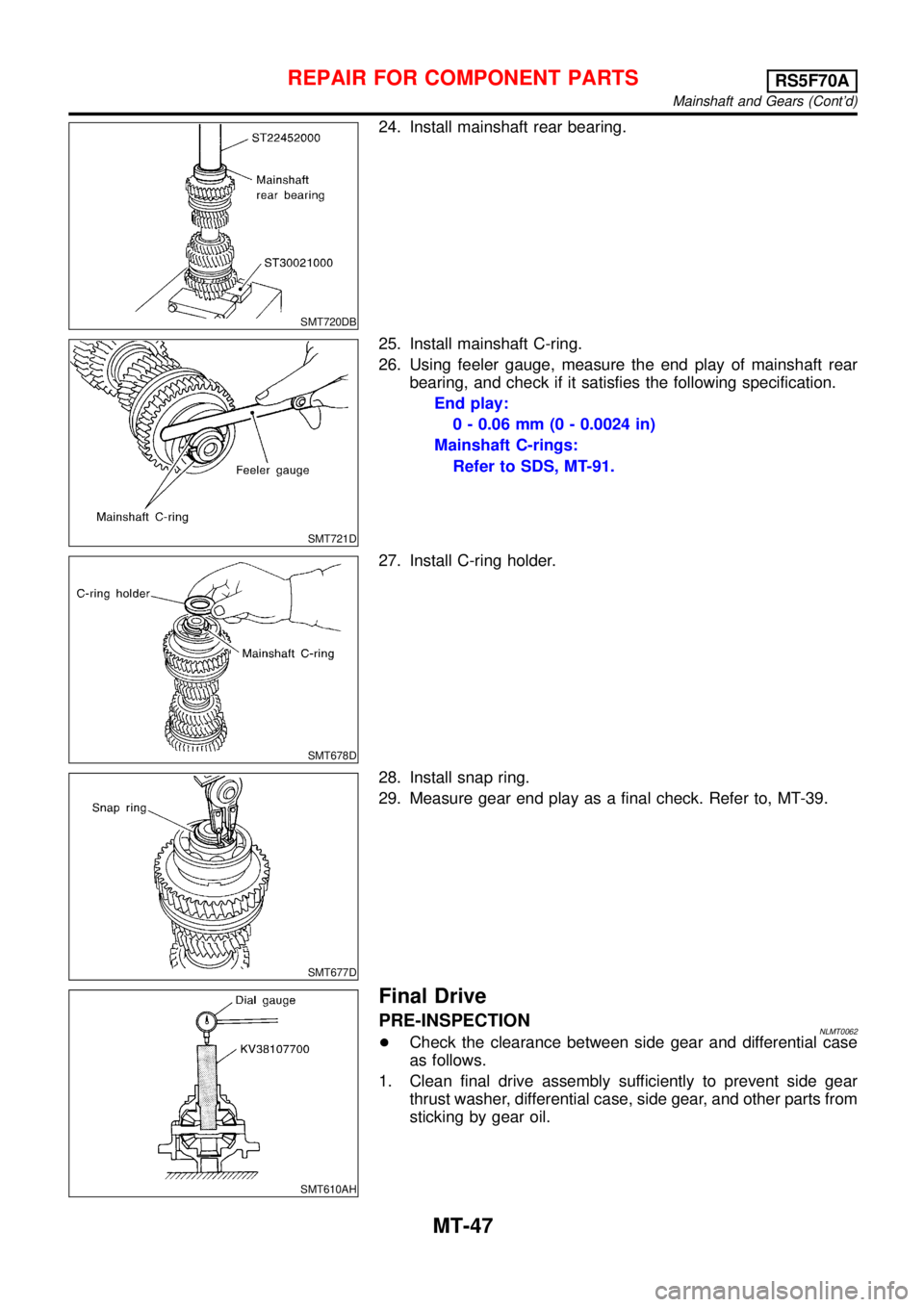

SMT720DB

24. Install mainshaft rear bearing.

SMT721D

25. Install mainshaft C-ring.

26. Using feeler gauge, measure the end play of mainshaft rear

bearing, and check if it satisfies the following specification.

End play:

0 - 0.06 mm (0 - 0.0024 in)

Mainshaft C-rings:

Refer to SDS, MT-91.

SMT678D

27. Install C-ring holder.

SMT677D

28. Install snap ring.

29. Measure gear end play as a final check. Refer to, MT-39.

SMT610AH

Final Drive

PRE-INSPECTIONNLMT0062+Check the clearance between side gear and differential case

as follows.

1. Clean final drive assembly sufficiently to prevent side gear

thrust washer, differential case, side gear, and other parts from

sticking by gear oil.

REPAIR FOR COMPONENT PARTSRS5F70A

Mainshaft and Gears (Cont’d)

MT-47

Page 2837 of 3051

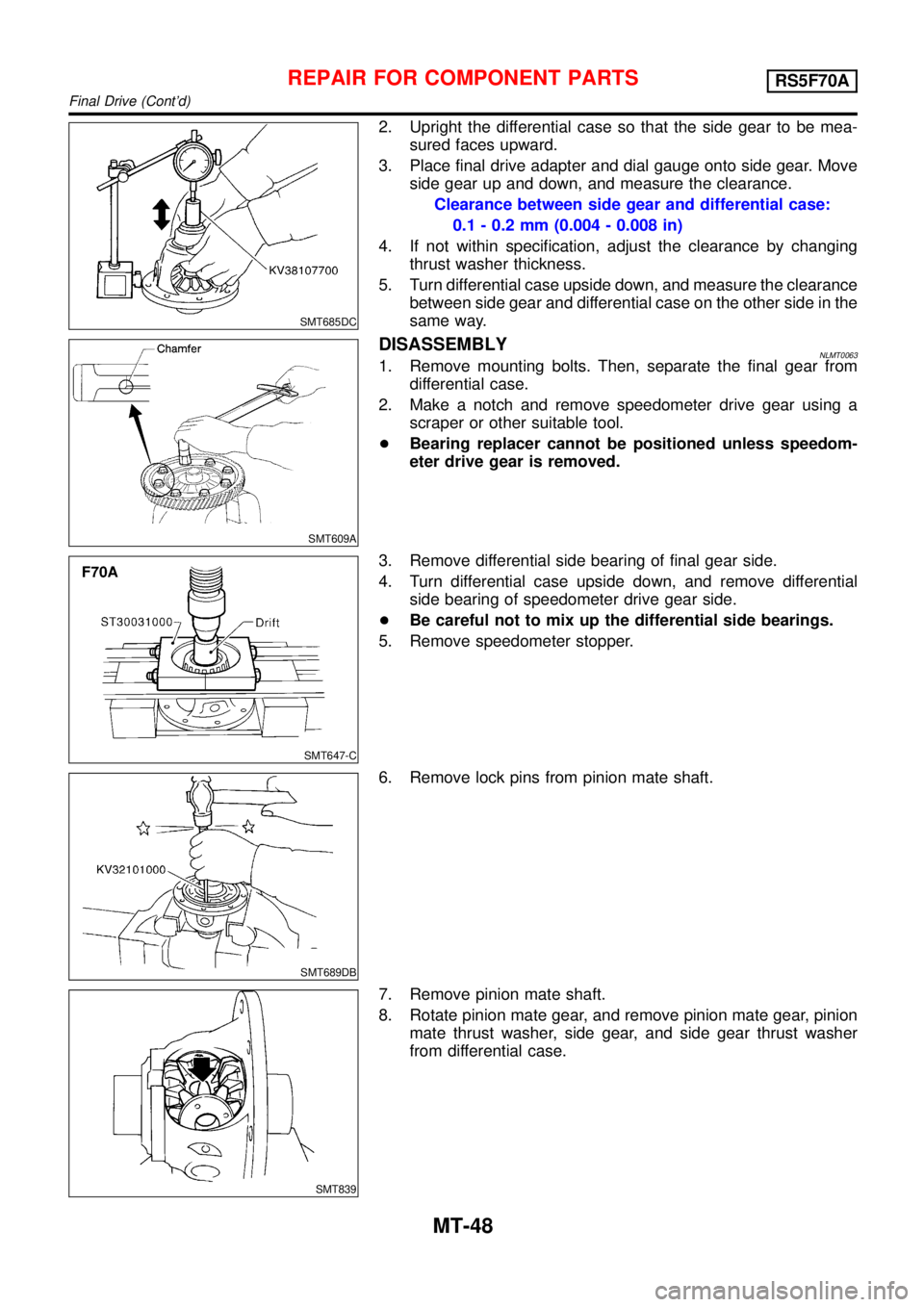

SMT685DC

2. Upright the differential case so that the side gear to be mea-

sured faces upward.

3. Place final drive adapter and dial gauge onto side gear. Move

side gear up and down, and measure the clearance.

Clearance between side gear and differential case:

0.1 - 0.2 mm (0.004 - 0.008 in)

4. If not within specification, adjust the clearance by changing

thrust washer thickness.

5. Turn differential case upside down, and measure the clearance

between side gear and differential case on the other side in the

same way.

SMT609A

DISASSEMBLYNLMT00631. Remove mounting bolts. Then, separate the final gear from

differential case.

2. Make a notch and remove speedometer drive gear using a

scraper or other suitable tool.

+Bearing replacer cannot be positioned unless speedom-

eter drive gear is removed.

SMT647-C

3. Remove differential side bearing of final gear side.

4. Turn differential case upside down, and remove differential

side bearing of speedometer drive gear side.

+Be careful not to mix up the differential side bearings.

5. Remove speedometer stopper.

SMT689DB

6. Remove lock pins from pinion mate shaft.

SMT839

7. Remove pinion mate shaft.

8. Rotate pinion mate gear, and remove pinion mate gear, pinion

mate thrust washer, side gear, and side gear thrust washer

from differential case.

REPAIR FOR COMPONENT PARTSRS5F70A

Final Drive (Cont’d)

MT-48

Page 2838 of 3051

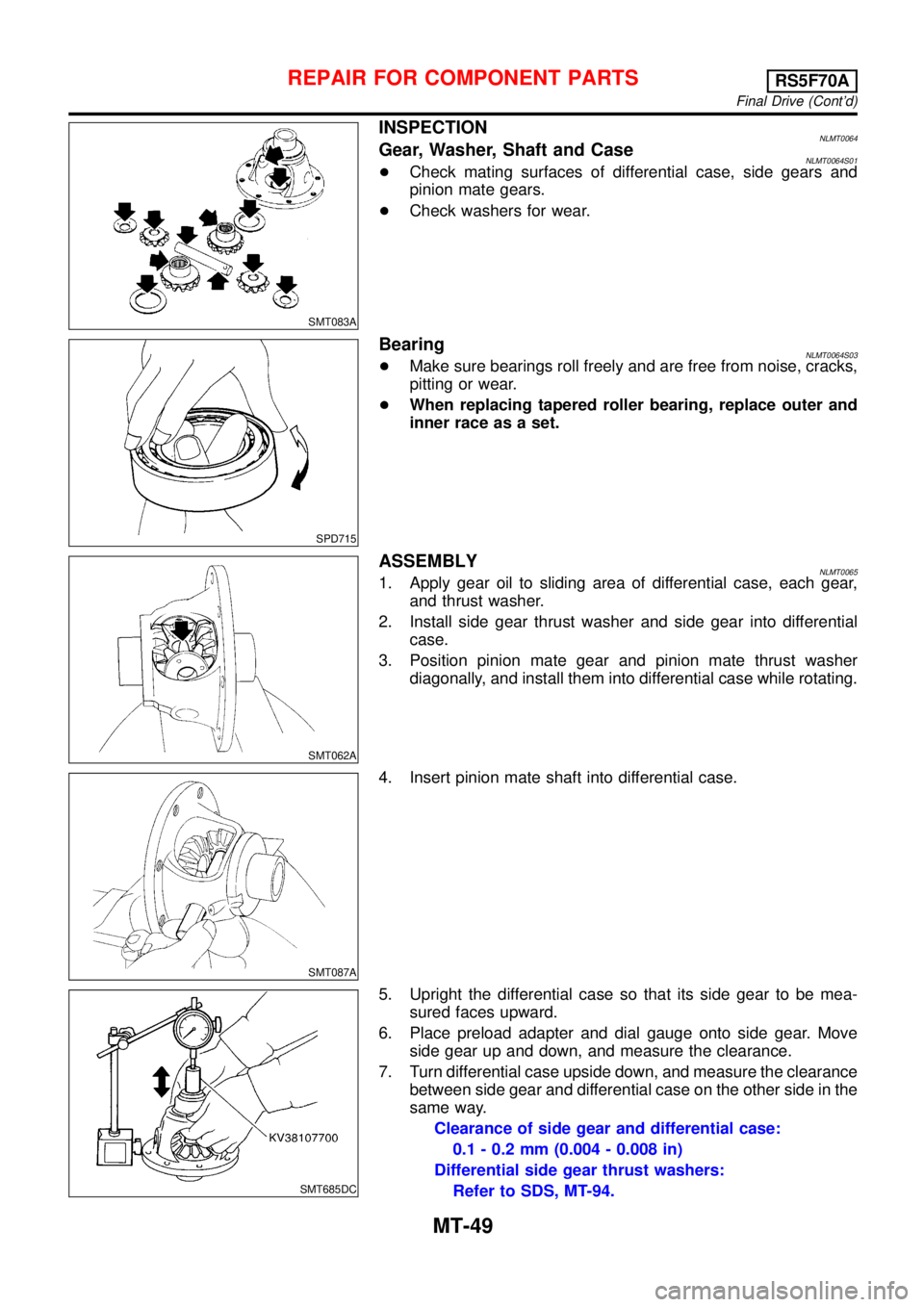

SMT083A

INSPECTIONNLMT0064Gear, Washer, Shaft and CaseNLMT0064S01+Check mating surfaces of differential case, side gears and

pinion mate gears.

+Check washers for wear.

SPD715

BearingNLMT0064S03+Make sure bearings roll freely and are free from noise, cracks,

pitting or wear.

+When replacing tapered roller bearing, replace outer and

inner race as a set.

SMT062A

ASSEMBLYNLMT00651. Apply gear oil to sliding area of differential case, each gear,

and thrust washer.

2. Install side gear thrust washer and side gear into differential

case.

3. Position pinion mate gear and pinion mate thrust washer

diagonally, and install them into differential case while rotating.

SMT087A

4. Insert pinion mate shaft into differential case.

SMT685DC

5. Upright the differential case so that its side gear to be mea-

sured faces upward.

6. Place preload adapter and dial gauge onto side gear. Move

side gear up and down, and measure the clearance.

7. Turn differential case upside down, and measure the clearance

between side gear and differential case on the other side in the

same way.

Clearance of side gear and differential case:

0.1 - 0.2 mm (0.004 - 0.008 in)

Differential side gear thrust washers:

Refer to SDS, MT-94.

REPAIR FOR COMPONENT PARTSRS5F70A

Final Drive (Cont’d)

MT-49

Page 2839 of 3051

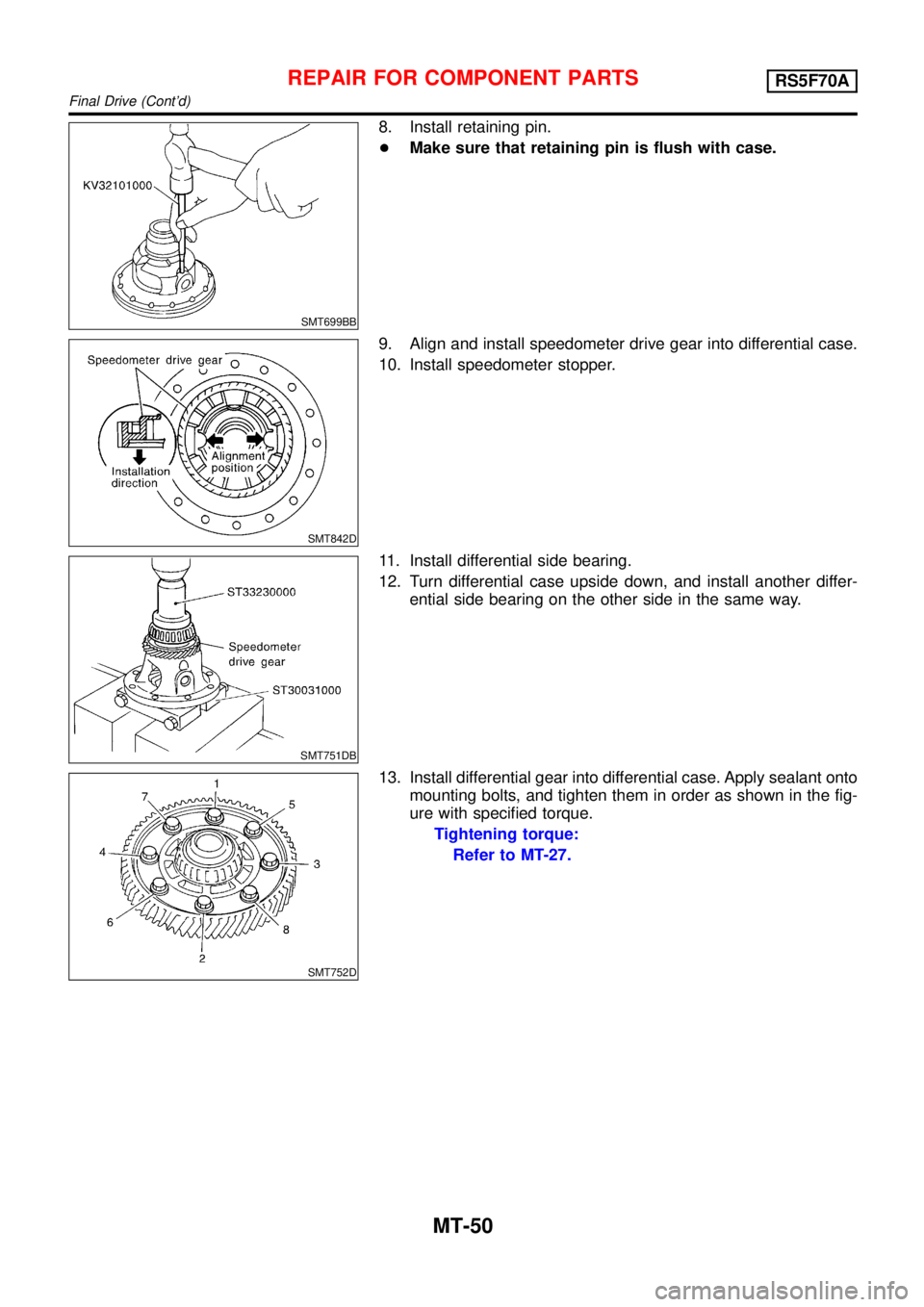

SMT699BB

8. Install retaining pin.

+Make sure that retaining pin is flush with case.

SMT842D

9. Align and install speedometer drive gear into differential case.

10. Install speedometer stopper.

SMT751DB

11. Install differential side bearing.

12. Turn differential case upside down, and install another differ-

ential side bearing on the other side in the same way.

SMT752D

13. Install differential gear into differential case. Apply sealant onto

mounting bolts, and tighten them in order as shown in the fig-

ure with specified torque.

Tightening torque:

Refer to MT-27.

REPAIR FOR COMPONENT PARTSRS5F70A

Final Drive (Cont’d)

MT-50

Page 2840 of 3051

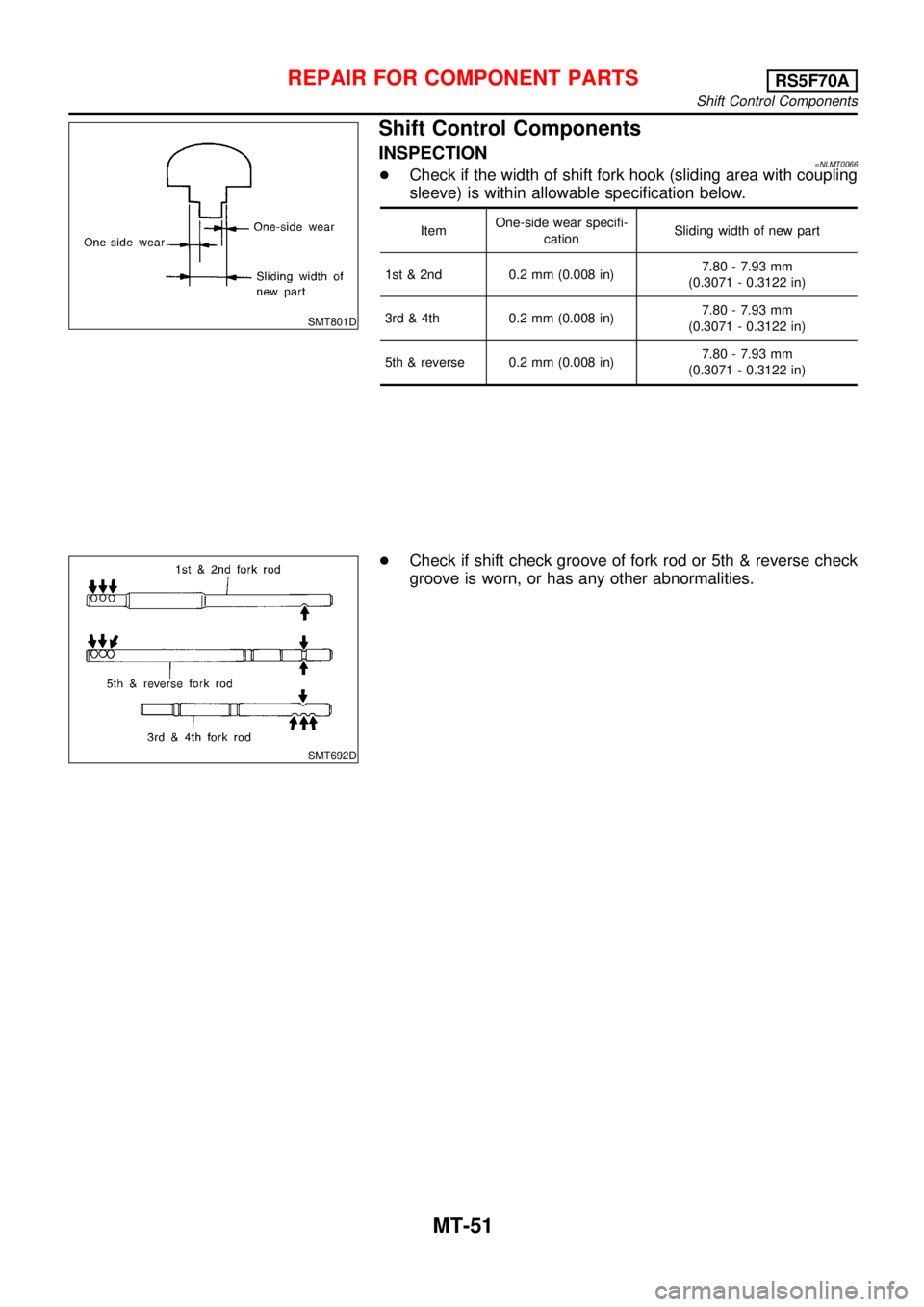

SMT801D

Shift Control Components

INSPECTION=NLMT0066+Check if the width of shift fork hook (sliding area with coupling

sleeve) is within allowable specification below.

ItemOne-side wear specifi-

cationSliding width of new part

1st & 2nd 0.2 mm (0.008 in)7.80 - 7.93 mm

(0.3071 - 0.3122 in)

3rd & 4th 0.2 mm (0.008 in)7.80 - 7.93 mm

(0.3071 - 0.3122 in)

5th & reverse 0.2 mm (0.008 in)7.80 - 7.93 mm

(0.3071 - 0.3122 in)

SMT692D

+Check if shift check groove of fork rod or 5th & reverse check

groove is worn, or has any other abnormalities.

REPAIR FOR COMPONENT PARTSRS5F70A

Shift Control Components

MT-51