NISSAN ALMERA TINO 2001 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA TINO, Model: NISSAN ALMERA TINO 2001Pages: 3051, PDF Size: 46.38 MB

Page 2821 of 3051

SMT664D

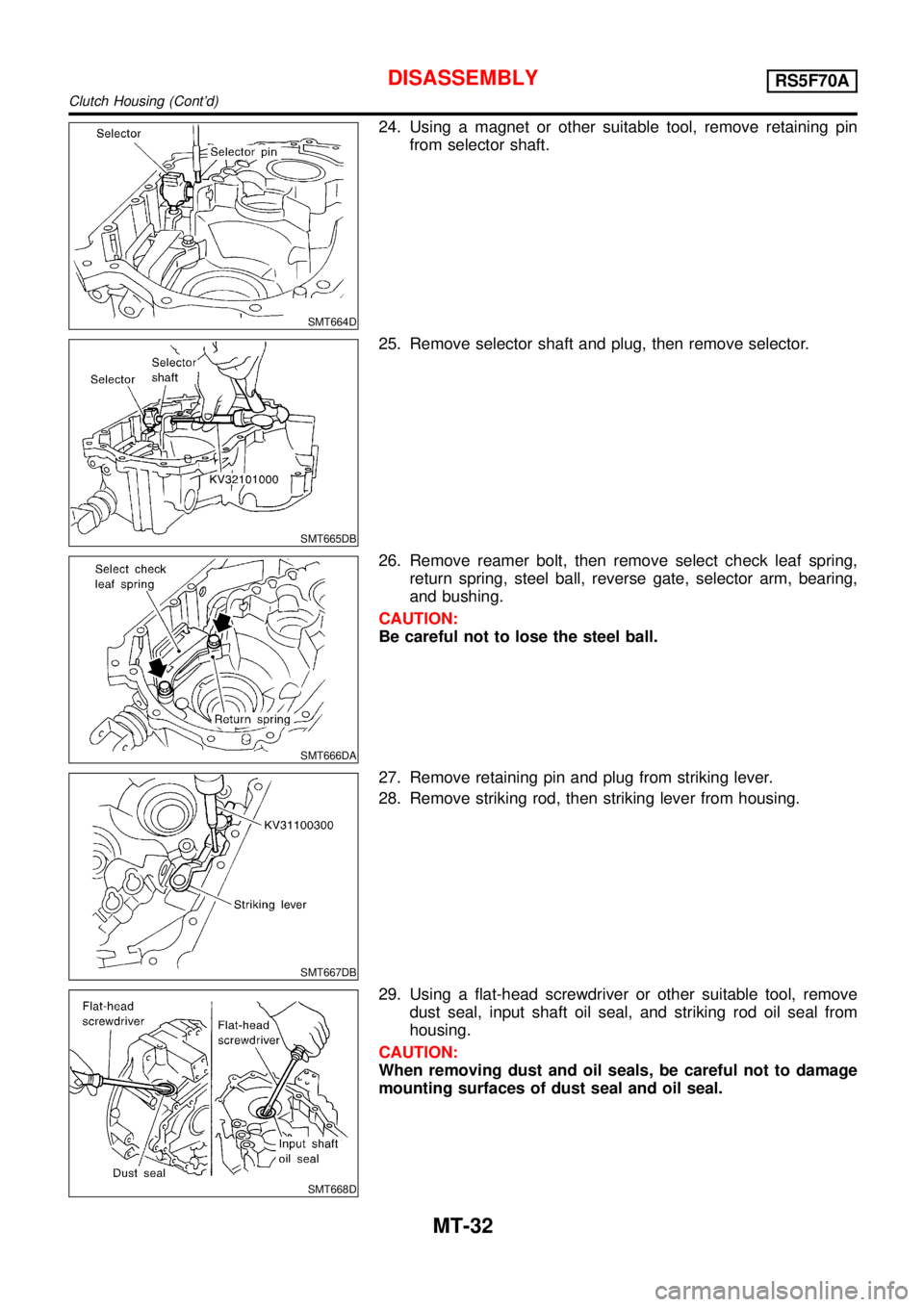

24. Using a magnet or other suitable tool, remove retaining pin

from selector shaft.

SMT665DB

25. Remove selector shaft and plug, then remove selector.

SMT666DA

26. Remove reamer bolt, then remove select check leaf spring,

return spring, steel ball, reverse gate, selector arm, bearing,

and bushing.

CAUTION:

Be careful not to lose the steel ball.

SMT667DB

27. Remove retaining pin and plug from striking lever.

28. Remove striking rod, then striking lever from housing.

SMT668D

29. Using a flat-head screwdriver or other suitable tool, remove

dust seal, input shaft oil seal, and striking rod oil seal from

housing.

CAUTION:

When removing dust and oil seals, be careful not to damage

mounting surfaces of dust seal and oil seal.

DISASSEMBLYRS5F70A

Clutch Housing (Cont’d)

MT-32

Page 2822 of 3051

SMT669DB

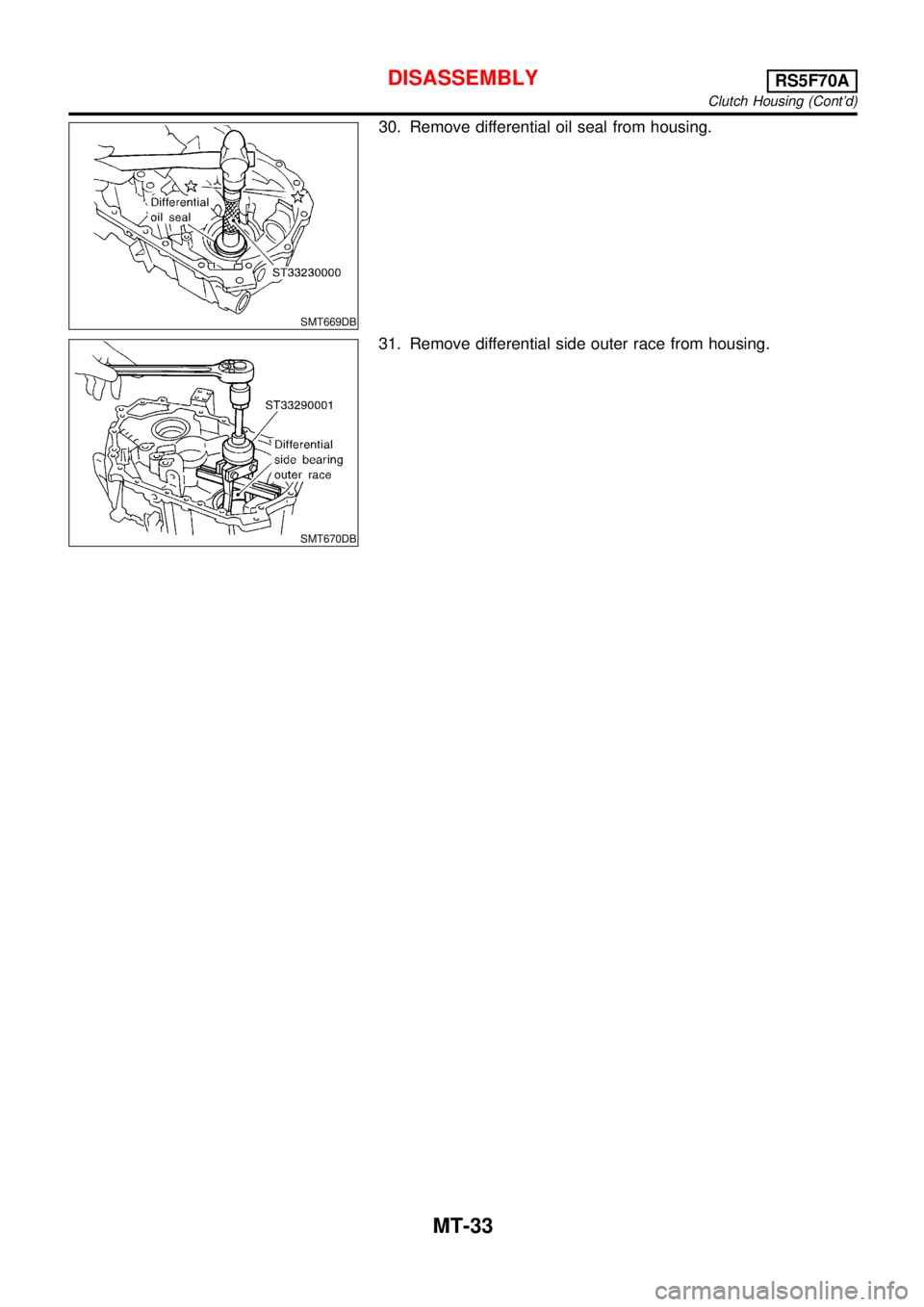

30. Remove differential oil seal from housing.

SMT670DB

31. Remove differential side outer race from housing.

DISASSEMBLYRS5F70A

Clutch Housing (Cont’d)

MT-33

Page 2823 of 3051

SMT759D

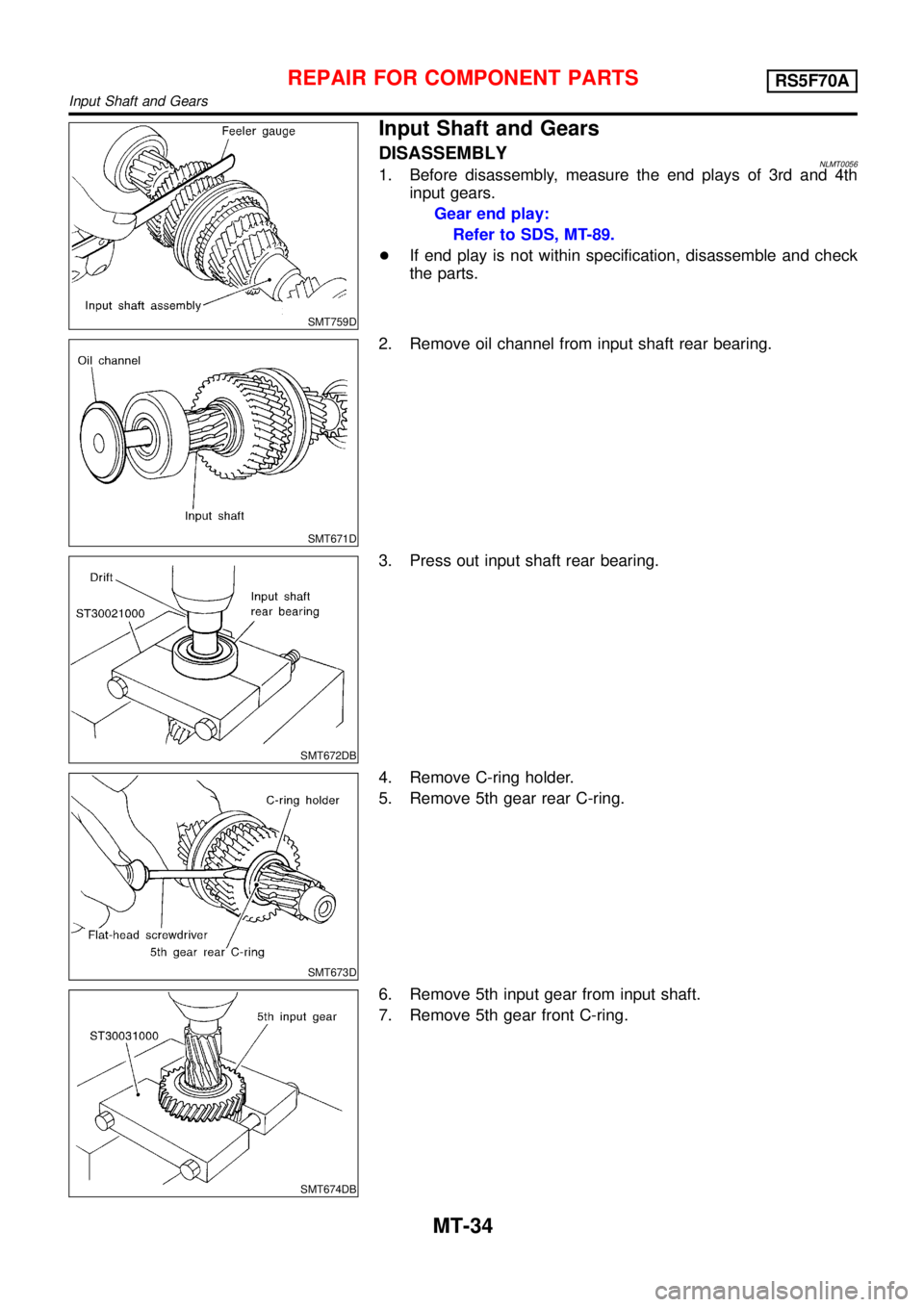

Input Shaft and Gears

DISASSEMBLYNLMT00561. Before disassembly, measure the end plays of 3rd and 4th

input gears.

Gear end play:

Refer to SDS, MT-89.

+If end play is not within specification, disassemble and check

the parts.

SMT671D

2. Remove oil channel from input shaft rear bearing.

SMT672DB

3. Press out input shaft rear bearing.

SMT673D

4. Remove C-ring holder.

5. Remove 5th gear rear C-ring.

SMT674DB

6. Remove 5th input gear from input shaft.

7. Remove 5th gear front C-ring.

REPAIR FOR COMPONENT PARTSRS5F70A

Input Shaft and Gears

MT-34

Page 2824 of 3051

SMT675DB

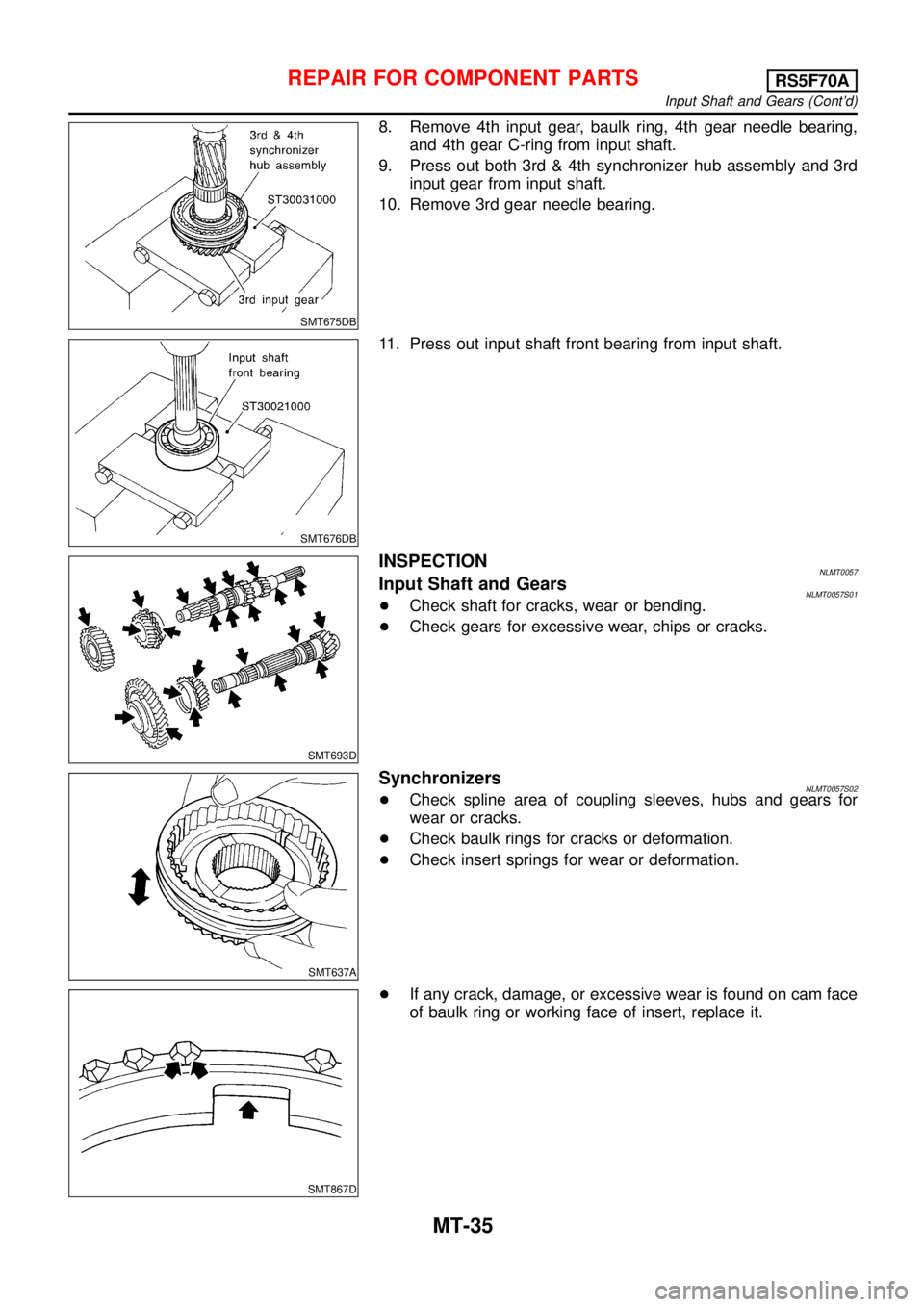

8. Remove 4th input gear, baulk ring, 4th gear needle bearing,

and 4th gear C-ring from input shaft.

9. Press out both 3rd & 4th synchronizer hub assembly and 3rd

input gear from input shaft.

10. Remove 3rd gear needle bearing.

SMT676DB

11. Press out input shaft front bearing from input shaft.

SMT693D

INSPECTIONNLMT0057Input Shaft and GearsNLMT0057S01+Check shaft for cracks, wear or bending.

+Check gears for excessive wear, chips or cracks.

SMT637A

SynchronizersNLMT0057S02+Check spline area of coupling sleeves, hubs and gears for

wear or cracks.

+Check baulk rings for cracks or deformation.

+Check insert springs for wear or deformation.

SMT867D

+If any crack, damage, or excessive wear is found on cam face

of baulk ring or working face of insert, replace it.

REPAIR FOR COMPONENT PARTSRS5F70A

Input Shaft and Gears (Cont’d)

MT-35

Page 2825 of 3051

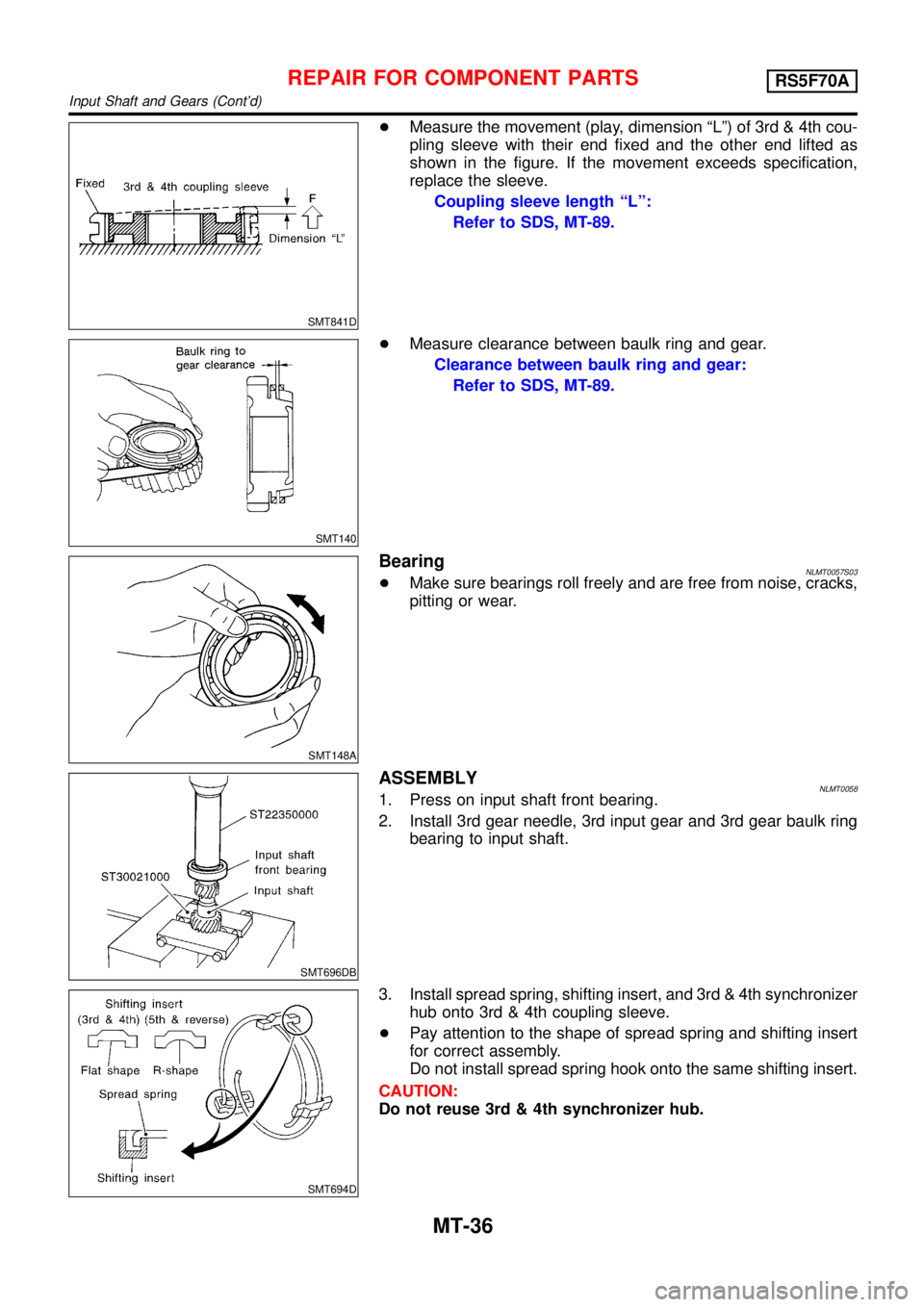

SMT841D

+Measure the movement (play, dimension“L”) of 3rd & 4th cou-

pling sleeve with their end fixed and the other end lifted as

shown in the figure. If the movement exceeds specification,

replace the sleeve.

Coupling sleeve length“L”:

Refer to SDS, MT-89.

SMT140

+Measure clearance between baulk ring and gear.

Clearance between baulk ring and gear:

Refer to SDS, MT-89.

SMT148A

BearingNLMT0057S03+Make sure bearings roll freely and are free from noise, cracks,

pitting or wear.

SMT696DB

ASSEMBLYNLMT00581. Press on input shaft front bearing.

2. Install 3rd gear needle, 3rd input gear and 3rd gear baulk ring

bearing to input shaft.

SMT694D

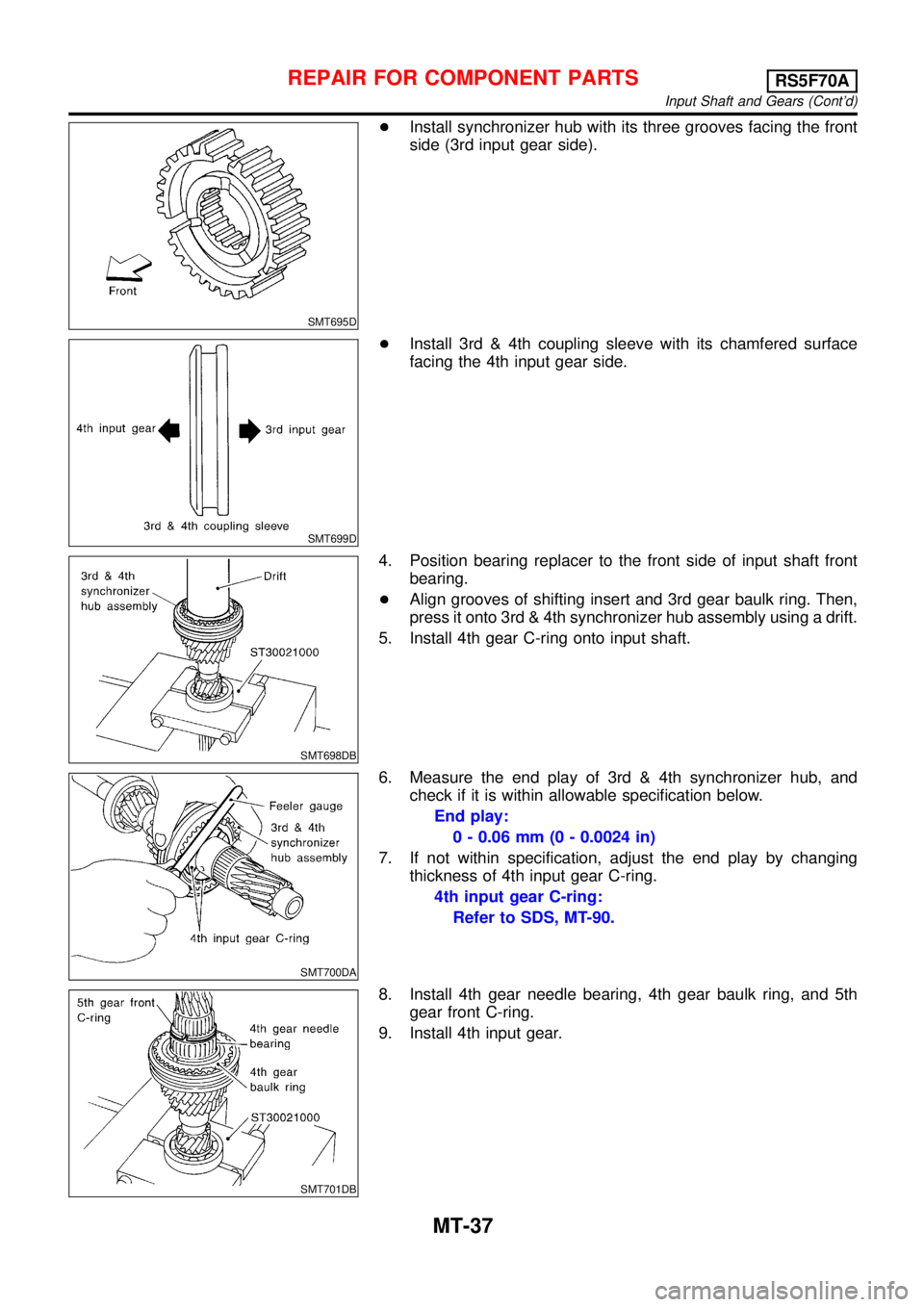

3. Install spread spring, shifting insert, and 3rd & 4th synchronizer

hub onto 3rd & 4th coupling sleeve.

+Pay attention to the shape of spread spring and shifting insert

for correct assembly.

Do not install spread spring hook onto the same shifting insert.

CAUTION:

Do not reuse 3rd & 4th synchronizer hub.

REPAIR FOR COMPONENT PARTSRS5F70A

Input Shaft and Gears (Cont’d)

MT-36

Page 2826 of 3051

SMT695D

+Install synchronizer hub with its three grooves facing the front

side (3rd input gear side).

SMT699D

+Install 3rd & 4th coupling sleeve with its chamfered surface

facing the 4th input gear side.

SMT698DB

4. Position bearing replacer to the front side of input shaft front

bearing.

+Align grooves of shifting insert and 3rd gear baulk ring. Then,

press it onto 3rd & 4th synchronizer hub assembly using a drift.

5. Install 4th gear C-ring onto input shaft.

SMT700DA

6. Measure the end play of 3rd & 4th synchronizer hub, and

check if it is within allowable specification below.

End play:

0 - 0.06 mm (0 - 0.0024 in)

7. If not within specification, adjust the end play by changing

thickness of 4th input gear C-ring.

4th input gear C-ring:

Refer to SDS, MT-90.

SMT701DB

8. Install 4th gear needle bearing, 4th gear baulk ring, and 5th

gear front C-ring.

9. Install 4th input gear.

REPAIR FOR COMPONENT PARTSRS5F70A

Input Shaft and Gears (Cont’d)

MT-37

Page 2827 of 3051

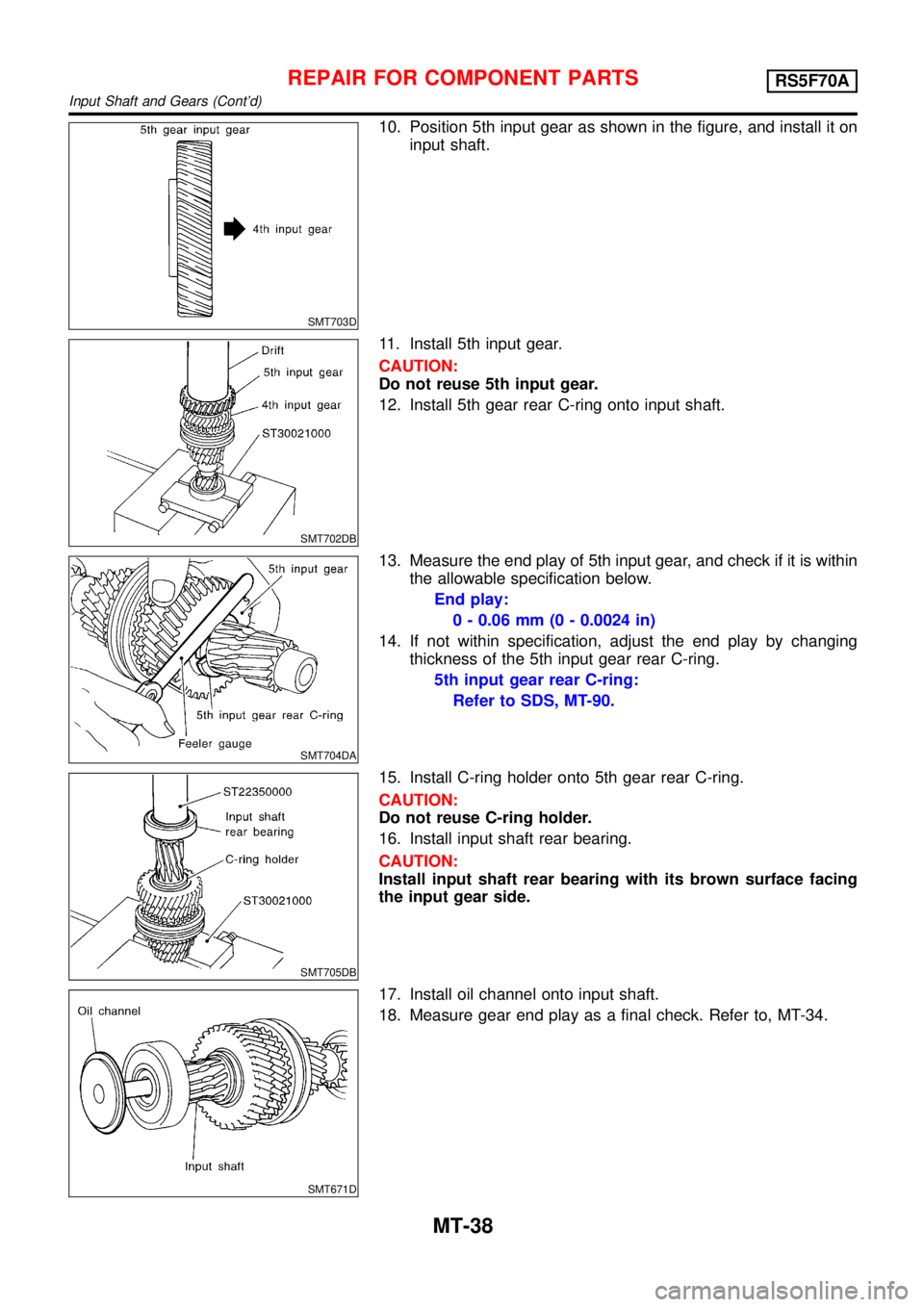

SMT703D

10. Position 5th input gear as shown in the figure, and install it on

input shaft.

SMT702DB

11. Install 5th input gear.

CAUTION:

Do not reuse 5th input gear.

12. Install 5th gear rear C-ring onto input shaft.

SMT704DA

13. Measure the end play of 5th input gear, and check if it is within

the allowable specification below.

End play:

0 - 0.06 mm (0 - 0.0024 in)

14. If not within specification, adjust the end play by changing

thickness of the 5th input gear rear C-ring.

5th input gear rear C-ring:

Refer to SDS, MT-90.

SMT705DB

15. Install C-ring holder onto 5th gear rear C-ring.

CAUTION:

Do not reuse C-ring holder.

16. Install input shaft rear bearing.

CAUTION:

Install input shaft rear bearing with its brown surface facing

the input gear side.

SMT671D

17. Install oil channel onto input shaft.

18. Measure gear end play as a final check. Refer to, MT-34.

REPAIR FOR COMPONENT PARTSRS5F70A

Input Shaft and Gears (Cont’d)

MT-38

Page 2828 of 3051

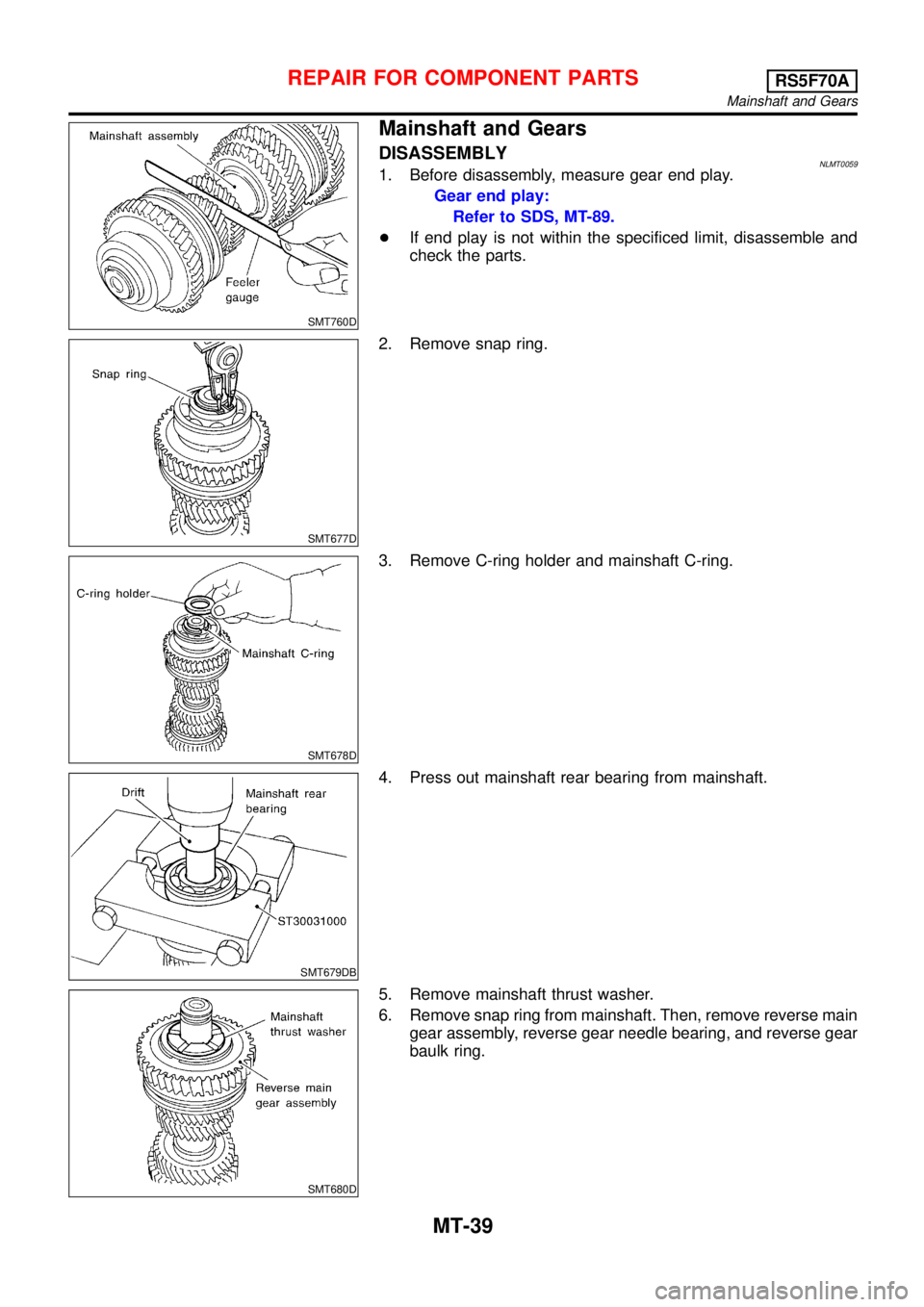

SMT760D

Mainshaft and Gears

DISASSEMBLYNLMT00591. Before disassembly, measure gear end play.

Gear end play:

Refer to SDS, MT-89.

+If end play is not within the specificed limit, disassemble and

check the parts.

SMT677D

2. Remove snap ring.

SMT678D

3. Remove C-ring holder and mainshaft C-ring.

SMT679DB

4. Press out mainshaft rear bearing from mainshaft.

SMT680D

5. Remove mainshaft thrust washer.

6. Remove snap ring from mainshaft. Then, remove reverse main

gear assembly, reverse gear needle bearing, and reverse gear

baulk ring.

REPAIR FOR COMPONENT PARTSRS5F70A

Mainshaft and Gears

MT-39

Page 2829 of 3051

SMT681DB

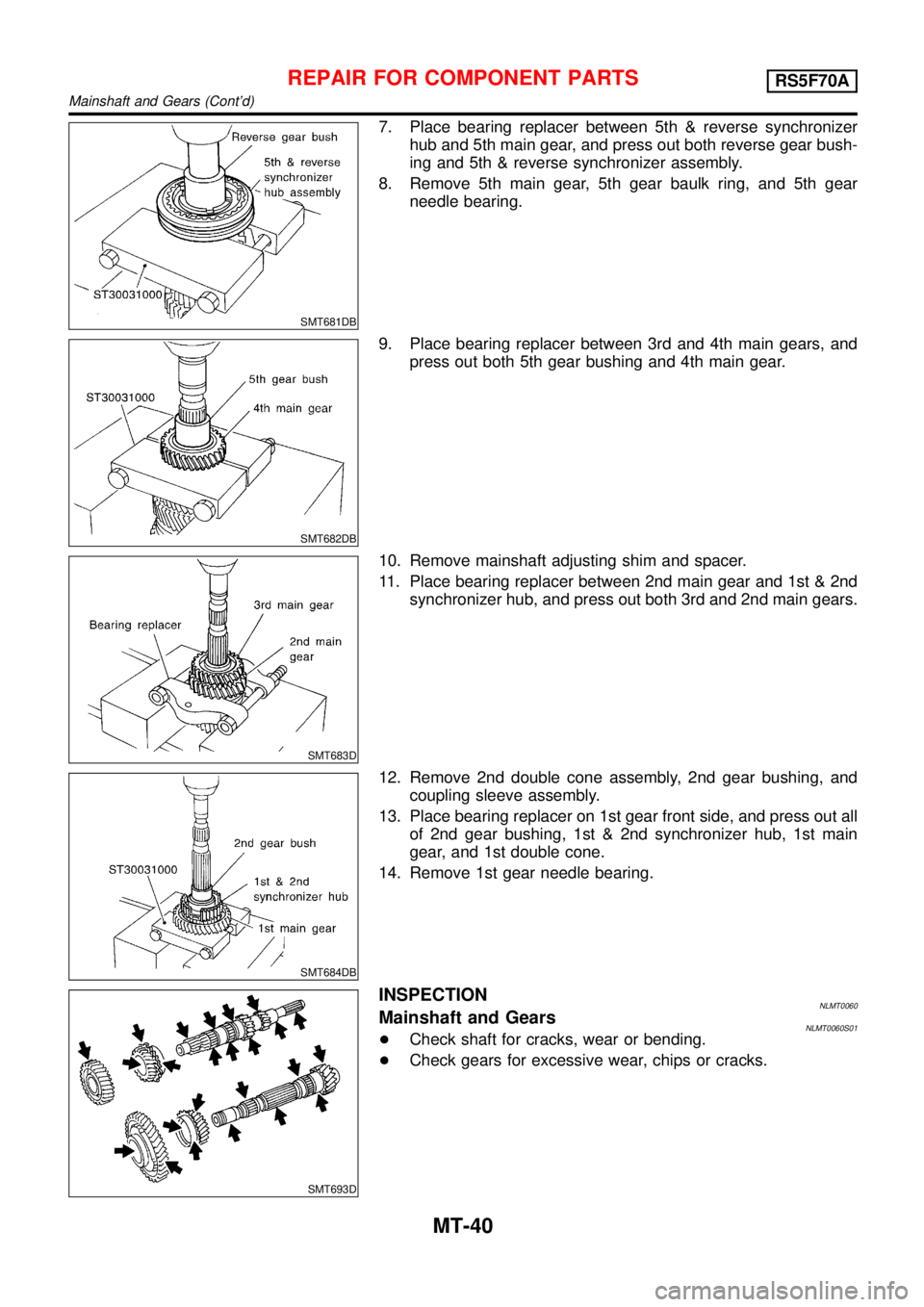

7. Place bearing replacer between 5th & reverse synchronizer

hub and 5th main gear, and press out both reverse gear bush-

ing and 5th & reverse synchronizer assembly.

8. Remove 5th main gear, 5th gear baulk ring, and 5th gear

needle bearing.

SMT682DB

9. Place bearing replacer between 3rd and 4th main gears, and

press out both 5th gear bushing and 4th main gear.

SMT683D

10. Remove mainshaft adjusting shim and spacer.

11. Place bearing replacer between 2nd main gear and 1st & 2nd

synchronizer hub, and press out both 3rd and 2nd main gears.

SMT684DB

12. Remove 2nd double cone assembly, 2nd gear bushing, and

coupling sleeve assembly.

13. Place bearing replacer on 1st gear front side, and press out all

of 2nd gear bushing, 1st & 2nd synchronizer hub, 1st main

gear, and 1st double cone.

14. Remove 1st gear needle bearing.

SMT693D

INSPECTIONNLMT0060Mainshaft and GearsNLMT0060S01+Check shaft for cracks, wear or bending.

+Check gears for excessive wear, chips or cracks.

REPAIR FOR COMPONENT PARTSRS5F70A

Mainshaft and Gears (Cont’d)

MT-40

Page 2830 of 3051

SMT637A

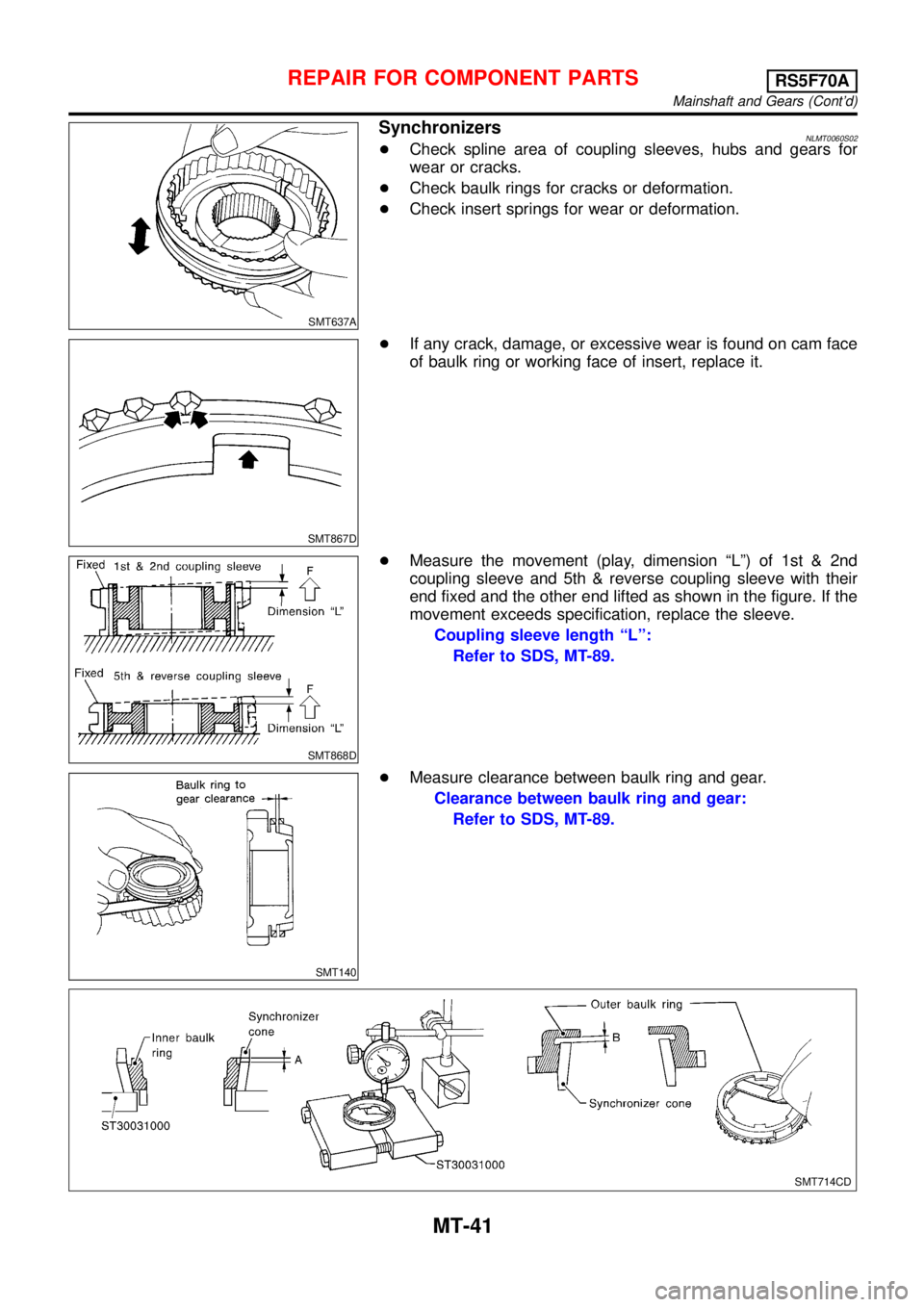

SynchronizersNLMT0060S02+Check spline area of coupling sleeves, hubs and gears for

wear or cracks.

+Check baulk rings for cracks or deformation.

+Check insert springs for wear or deformation.

SMT867D

+If any crack, damage, or excessive wear is found on cam face

of baulk ring or working face of insert, replace it.

SMT868D

+Measure the movement (play, dimension“L”)of1st&2nd

coupling sleeve and 5th & reverse coupling sleeve with their

end fixed and the other end lifted as shown in the figure. If the

movement exceeds specification, replace the sleeve.

Coupling sleeve length“L”:

Refer to SDS, MT-89.

SMT140

+Measure clearance between baulk ring and gear.

Clearance between baulk ring and gear:

Refer to SDS, MT-89.

SMT714CD

REPAIR FOR COMPONENT PARTSRS5F70A

Mainshaft and Gears (Cont’d)

MT-41