NISSAN GT-R 1998 Service Manual

Manufacturer: NISSAN, Model Year: 1998, Model line: GT-R, Model: NISSAN GT-R 1998Pages: 230, PDF Size: 12.66 MB

Page 191 of 230

COMBINATION METER

Combination Meter Input/Output Signal -

Specifications (~ont'd)

Signal name

Vehicle speed signal

(8 pulses)

Body

ground

Ground

I--

Oil pressure sensor

signal Measuring

condi!ion

operation.

Speedometer is in operation.

(Vehicle speed is approx.

40 km~h.)

Specification

Approx.

4.8V or OV

Vehicle speed is approx. 40

ELF0978D

-- - Approx. 2.4V

ON - Approx. OV

- I - I Refer to 'Component Parts Inspection" (EL-28).

J I I Voltage of the upper part of the wave form indicates the value checked with analogue circuit tester.

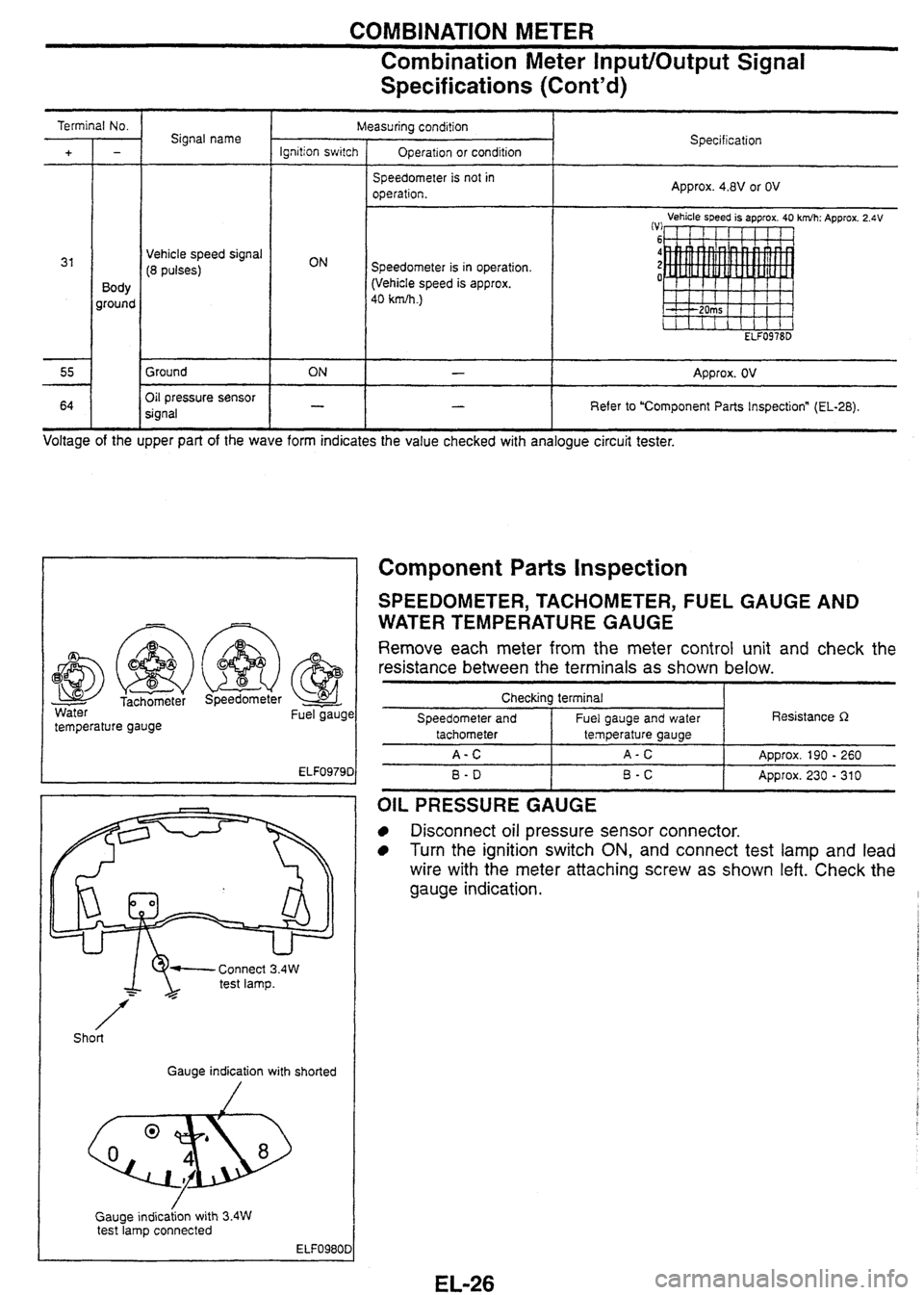

- Water Fuel gaugc

temperature gauge

1 Gauge indication with shorted

Gauge

indicaion with

3.4W test lamp connected

ELF0980D

Component Parts inspection

SPEEDOMETER, TACHOMETER, FUEL GAUGE AND

WATER TEMPERATURE

GAUGE

Remove each meter from the meter control unit and check the

resistance between the terminals as shown below.

Checkina terminal I

Speedometer and I Fuel gauge and water I Resistance R

B-D I B-C I Approx. 230 - 310

tachometer

A-C

OIL PRESSURE GAUGE

Disconnect oil pressure sensor connector.

Turn the ignition switch ON, and connect test lamp and lead

wire with the meter attaching screw as shown left. Check the

gauge indication.

temperature gauge

A-C

ADD~OX.

190 - 260

Page 192 of 230

COMBINATION METER

Component Parts Inspection (Cont'd)

Fuel gauge unit harness

connector

Lower side

<

I

I

I

(Full) Lead switch

harness connector

on fuel gauge unit

h L Upper side

Harness connec:or on lead sw~lch

With fuel

T/f Without fuel

Lower side

(Empty)

FUEL GAUGE UNIT

Remove fuel gauge unit from the vehicle.

Check the gauge resistance on the gauge with the fuel gauge

at Empty and then Full.

SD

LEAD SWITCH

Remove fuel gauge unit from the vehicle.

Check continuity between terminals on the lead switches in the

tank.

Terminal No.

1-3

Termina! No. I Condition I Continuity

Float position

Full

Empty

THERMAL

TRANSMITER

Resistance R

Approx. 6 max.

Approx. 80 min.

5 - 7 6-7

0 When the engine has warmed up to approx. 80°C, measure

resistance between thermal transmitter and body ground.

Specification: Approx. 76 - 90Q

There is no continuity when approx. 26 of fuel is left in the sub fuel tank.

With fuel

Without fuel Yes

No

Page 193 of 230

COMBINATION METER

Component Parts Inspection (Cont'd)

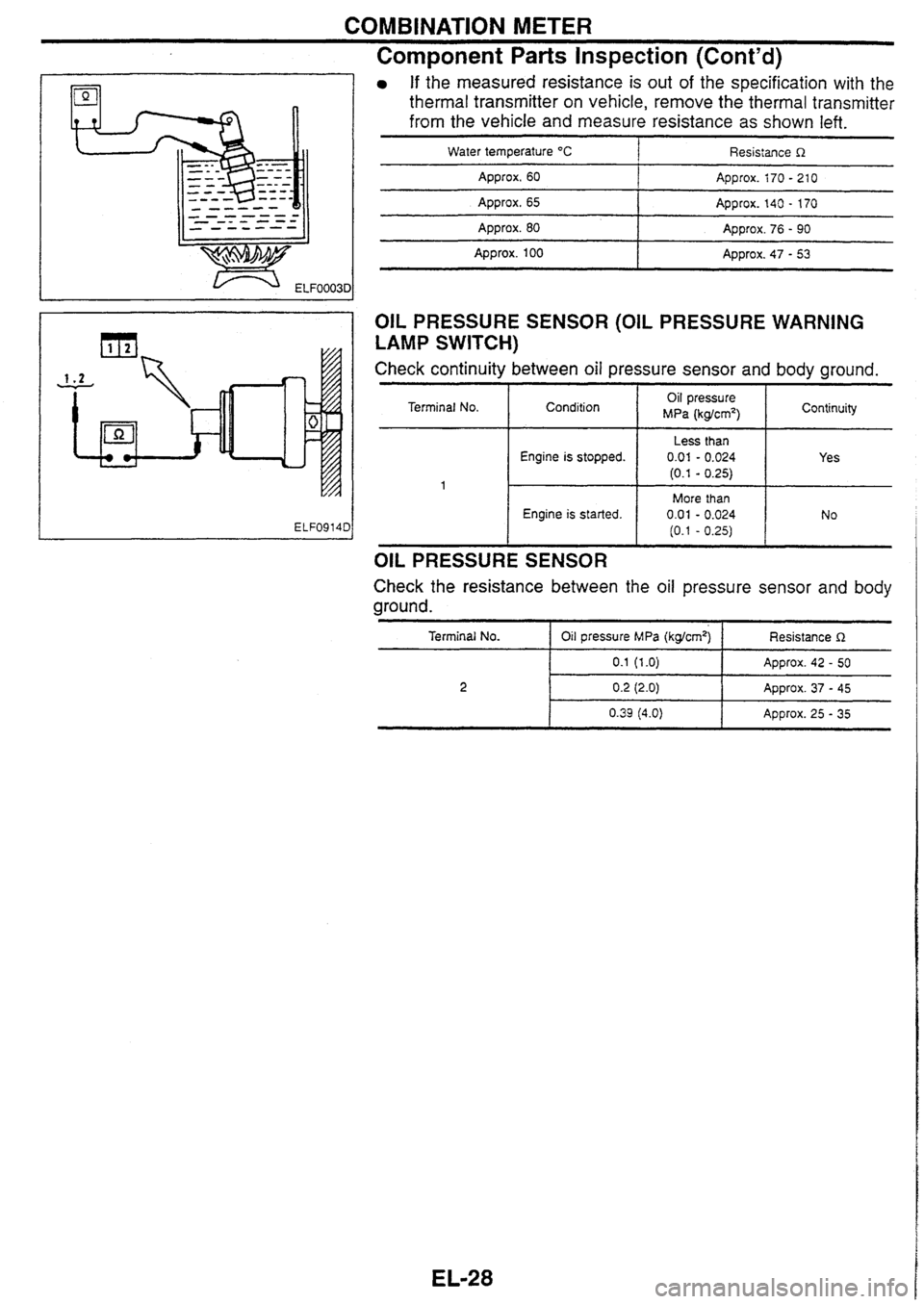

If the measured resistance is out of the specification with the

thermal transmitter on vehicle, remove the thermal transmitter

from the vehicle and measure resistance as

shown left.

Water temperature "C 1 Resistance R

Approx. 60 I Approx. i70 - 21 0

Approx. 65 I Approx. 140 - 170

Approx. 80 I Approx. 76 - 90

I

- - -- Appro~. 100 Approx. 47 - 53

OIL PRESSURE SENSOR (OIL PRESSURE WARNING

LAMP SWITCH)

Check continuity between oil pressure sensor and body ground.

Terminal No.

OIL PRESSURE SENSOR

Engine is stopped.

Engine is started.

Check the resistance between the oil pressure sensor and body

ground.

Condition

Terminal No.

I Oil pressure MPa (kgkmq-1 Resistance R

Oil pressure

MPa (kg/cm2) 1 Continuity

Less than

0.01 - 0.024

(0.1 - 0.25)

More than 0.01 - 0.024

(0.1 - 0.25)

0.2 (2.0) Approx. 37 - 45

Yes

No

Page 194 of 230

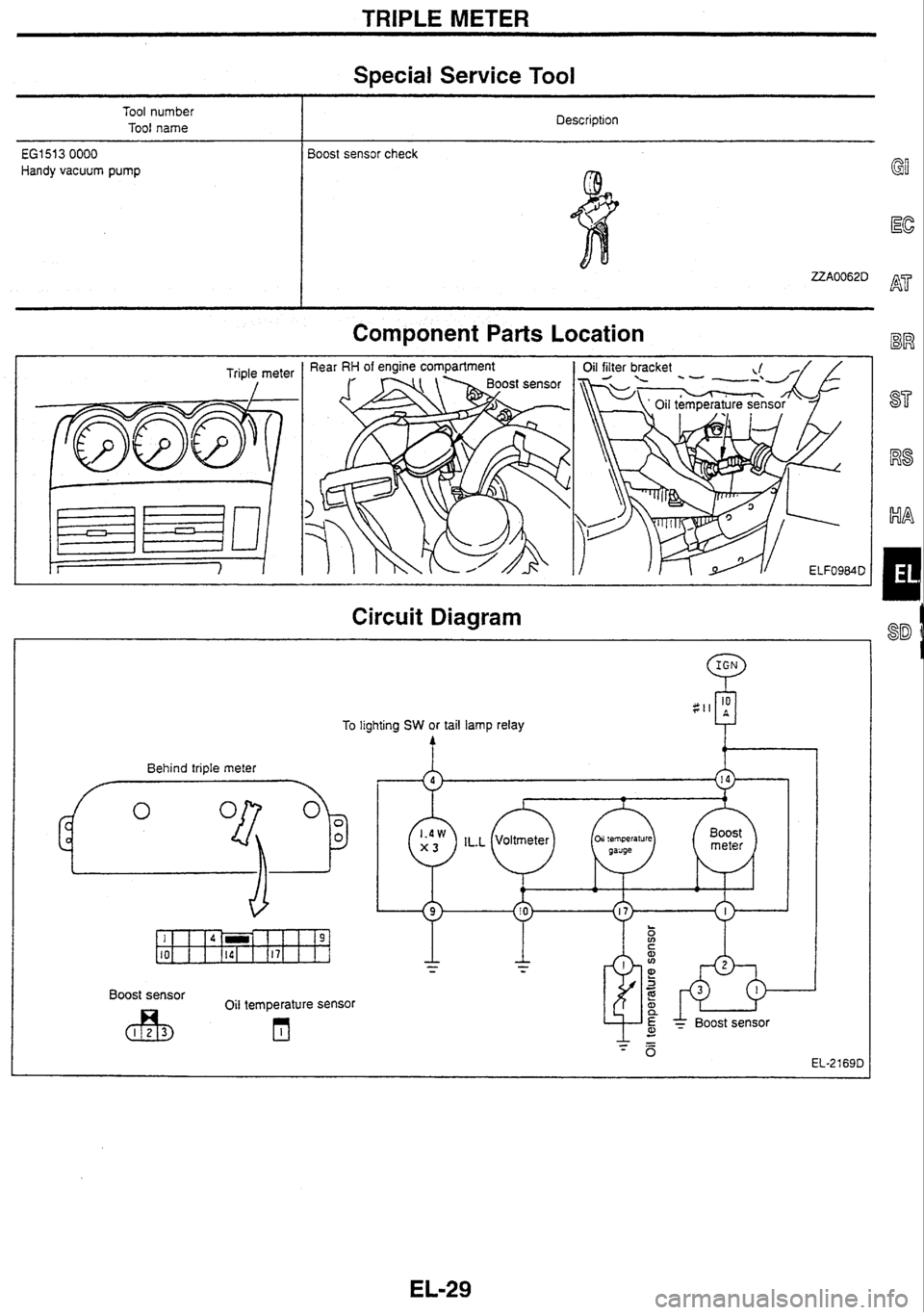

TRIPLE METER

Special Service Tool

Tool number

Tool name Description

i

€GI 51 3 0000 Boost sensor

check

Handy vacuum pump

Component Parts Location

Triple meter

I

Circuit Diagram

Behind triple meter

h

To lighting SW or tail lamp relay

Boost sensor

Oil temperature sensor

* BOOS^ sensor

Page 195 of 230

TRIPLE METER

Triple Meter InputlOutput Signal Specifications

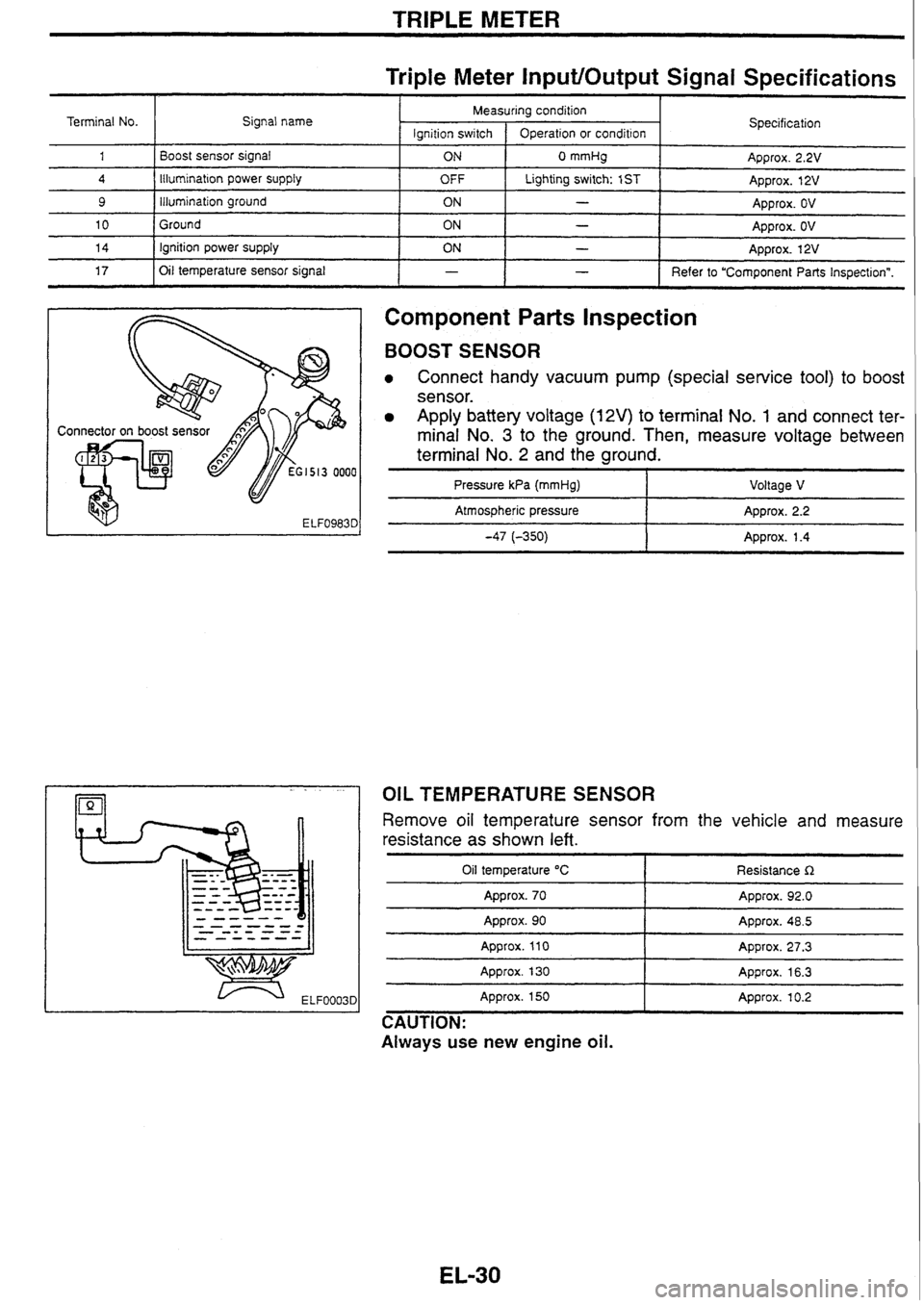

Component

Parts Inspection

Terminal No.

1

4

9

10

14

17

BOOST SENSOR

Connect handy vacuum pump (special service tool) to boost

sensor.

Apply battery voltage (12V) to terminal No. 1 and connect ter-

minal No.

3 to the ground. Then, measure voltage between

terminal No.

2 and the ground.

I I - I Refer to "Component Parts Inspectionn.

Signal

name

Boost sensor signal

Illumination

power

supply

illumination ground

Ground ignition power supply

Oil temperature sensor signal

Pressure

kPa (mmHg) I Voltage V

I

- pp Atmospheric pressure Approx. 2.2

-47 (-350) 1 Approx. 1.4

-

Specification

Approx. 2.2V

Approx. 12V

Approx. OV

Approx.

OV

Approx. 12V

Measuring condition

OIL TEMPERATURE SENSOR

lgnition

switch

ON

OFF

ON

ON

ON

Remove oil temperature sensor from the vehicle and measure

resistance as shown

left.

Operation or condition

0 mmHg

Lighting switch: 1

ST

-

-

-

Oil temperature "C

Approx. 70

-- - - --

Resistance R

Approx. 92.0

Approx. 90

Approx.

110

Approx. 130 - -- Appro~. 48.5

Approx. 27.3

Approx. 16.3

Approx. 150

Approx. 10.2

CAUTION:

Always use new engine

oil.

Page 196 of 230

IGNITION KEY WARNING BUZZER AND LIGHT WARNING BUZZER

I Behind combination meter

Meter control unit Component Parts Location

J

Circuit Diagram

Meter Control Unit

InputlOutput Signal

Specifications

Terminal No.

Driver door switch signal

Signal

name

OFF Measuring condition

Ignition switch

I Measuring method Specification

Driver door switch

29

ON (Open)

OFF (Closed)

42

Approx. OV

Approx. 12V

Ignition power supply

54

55

Key-in detection switch

signal 1 OFF

ON

Lighting switch signal

Ground Approx. 12V

Remove

the ignition key.

Insert the ignition key. Approx. OV

Approx. 12V

Approx. 12V

Approx. OV

Approx. OV

I

OFF

ON Lighting

switch: 1 ST ON

OFF

-

Page 197 of 230

FRONT WIPER

Front wiper amplifier

Component Parts Location

Circuit Diagram

Front wiper motor Front wiper and washer

SW

Washer motor

---------------- HI

EL-17040

Front Wiper InpWOutput Signal Specifications

Terminal No.

Signal name 1 Measuring condition. I

Wiper motor position detection

signal

1 Specification

Wiper switch: LO position

Ignition switch

(Reference)

I

Operation

Wiper motor LO signal

4 Wiper motor HI signal

Wiper switch

6

ON

OFF

.

Lo

7 1 Washer operation detection signal I ON

8 I Ignition power supply I ON I - I Approx. 12V

Approx. 12V

ADDIOX. OV

-

Wiper switch

I

Washer motor is in operation. I I

I - Ground

Approx.

OV

I Washer motor is not in operation. OFF

HI

. .

Approx. OV

ON

Approx.

12V

Approx. 12V

Approx. OV

Page 198 of 230

REAR WIPER

Component

Parts Location

Rear of suspension tower (RH)

Circuit Diagram

IGN :

Q

Rear washer motor

B Rear wiper motor I-

Washer motor operation

detection signal I

1 Rear wiper and washer SW

Intermittent position de!ection signal I ~SHIOFFI 111~~ INTI - ON IWIW~

I * Wiper motor operation signal

Rear Wiper Amplifier InputlOutput Signal

Specifications

Measuring condition

lanition

switch

/ O~eration

Terminal No.

Signal name Specification

Washer motor operation detection

signal

Wiper operation signal

Ground

Intermittent position detection signal

I ON I Wiper switch

Wlper

motor operation signal ON

ON

ON

ACC power

supply

I I I (Reference)

INT . Other than INT

Washer

motor is in operation.

Washer motor is not in operation.

Wiper motor is in operation.

Wiper motor is not

in operation.

-

Approx. OV

ARD~OX. 12V Approx.

OV

Approx.

12V

Approx. OV

Approx.

12V

AD~rox. OV

. .

Approx. 12V 1 I ON -

Page 199 of 230

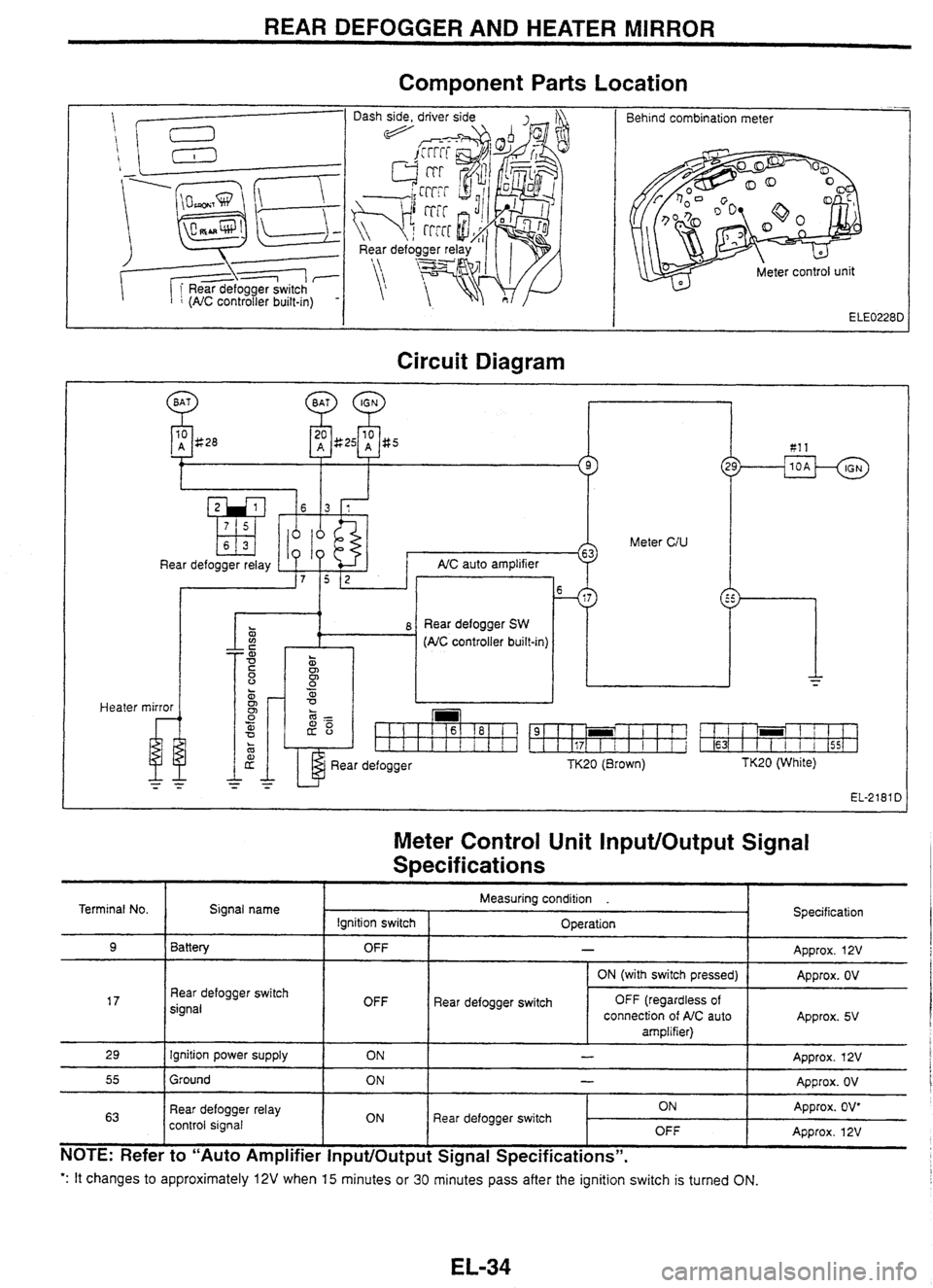

REAR DEFOGGER AND HEATER MIRROR

Component

Parts Location

-- Behind combination meter

Circuit Diagram

Heater

10 A g28 81 1

Meter CIU

Rear defogger relay AIC auto ampl~f~er

. 0

z i 8 Rear defogger SW a (AC controller built-m)

mirror

u

Rear defogger TK20 (Brown) TK20 (White)

EL-2181 D

Meter Control Unit InputlOutput Signal

S~ecif ications

': It changes to approximately 12V when 15 minutes or 30 minutes pass after the ignition switch is turned ON.

Terminal No.

9

17

29

55

63

NOTE: Refer to "Auto Amplifier InputlOutput Signal Specifications".

Signal name

Battery

Rear defogger switch

signal

Ignition power supply

Ground

Rear defogger relay

control signal Specification

Approx.

12V

Approx. OV

Approx. 5V

Approx. 12V

Approx. OV

Approx. OV*

Approx. 12V

Measuring condition .

Ignition switch OFF

OFF ON

ON

ON Operation

-

Rear

defogger switch ON (with switch

pressed)

OFF (regardless of

connection of AIC auto

amplifier)

-

-

Rear defogger switch ON OFF

Page 200 of 230

WIPER DEICER

Component

Parts Location

Wiper deicer switch I

/ I Wiper deicer switch

Circuit Diagram

m

Wiper deicer relay

Wiper deicer Wiper deicer

SW (Timer

built-in) lighting

Wiper

Deicer Switch InputlOutput Signal

Specifications

Terminal No. Signal name

Indicator power supply Measuring

condition .

Ignition switch I Operation Specification

Wiper deicer switch

2

3

OFF

ON

4

- Approx. OV

Approx. 12V

lllumination ground

Ground

5

1 Approx. 12V lgn~tion power supply

6

OFF

ON

Wiper deicer relay control

signal

I ON 1 Wiper deicer switch

ON

*: When

the wiper deicer is activated (approx. 15 minutes).

Illumination power supply

-- -

- - - - - -

ON

OFF

- Approx. OV

Approx. OV

Approx. OV'

Approx. 12V

OFF Lighting

switch: 1ST -- - Approx. 12V