NISSAN GT-R 1998 Service Manual

Manufacturer: NISSAN, Model Year: 1998, Model line: GT-R, Model: NISSAN GT-R 1998Pages: 230, PDF Size: 12.66 MB

Page 181 of 230

XENON HEADLAMP SYSTEM

Trouble Diagnoses (Cont'd)

DIAGNOSTIC PROCEDURE

I

FUSE, FUSIBLE LINK, AND XENON Fuse, fusible link, or xenon

HEADLAMP RELAY CHECK headlamp relay is faulty.

CONNECTOR CHECK ON THE VEHICLE Harness on the vehicle is

FOR BATTERY VOLTAGE faulty.

With lighting switch ON, check HID control

unit connector on the vehicle for battery

I voltage. I

OK

XENON HEADLAMP BULB REPLACE- Xenon bulb is faulty.

MENT

Replace the xenon headiamp bulb with a

known

good bulb and check for proper

operation.

HID CONTROL UNIT REPLACEMENT HID control unit is faulty.

Install a known good

HID control unit to

I

the xenon headlarnp and check for proper

operation.

NG

XENON HEADLAMP HOUSING ASSEM- OK, BLY REPLACEMENT

Install a known good xenon headlamp

housing assembly to the xenon

headlamp

and check for proper operation.

---

Starter in xenon headlamp

housing (boost circuit) is

faulty. (Xenon

headlamp housing

assembly

is faulty.)

Page 182 of 230

IGNITION KEY-OPERATED ILLUMINATION SYSTEM

Behind combination meter Component Parts Location

Meter control unit

Circuit Diagram

7, . .

& Driver door lock detection switch

T

2 1 r Passenger door SW Rear RH door SW 326

' a

Rear LH door SW

3 - -

Room lamp

IGN SW illumination

TK24 (Brown) TK20 (Brown) TK20 (White) EL-2 178D I 1 J

Meter Control Unit Input/Output Signal

Terminal No.

Specifications I I

Specification

Approx.

OV

Approx. 12V

Approx. OV

Approx. 5V

Approx. 12V

Approx. OV

Approx. 12V

Approx. 12V

Approx. OV

Approx. 12V

Approx. OV

Approx. OV

Approx. 12V

Approx. OV'

Approx. 12V

Measuring condition

Signal name Ignition

Operation or condition

switch

Driver door switch ON (Open)

OFF Driver door switch

signal OFF (Closed)

Driver door lock

sig-

Door is unlocked. (Switch ON)

nal OFF

Door is locked. (Switch OFF)

Battery OFF

-

Open a door. (ON)

Door switch signal

OFF

Close all the doors. (OFF)

Ignition power supply ON

-

Key-in detection Remove

the ignition key.

switch signal OFF

Insert the ignition key.

Ground ON

-

OFF Room lamp switch:

Insert the ignition key. Each door switch

Room lamp, ignition Neutral position ON

(Open)

OFF (Closed)

switch illumination

Remove the ignition key from the

signal

- lamp switch: Close all the doors. key cylinder.

Neutral position

Turn the ignition switch ON.

Page 183 of 230

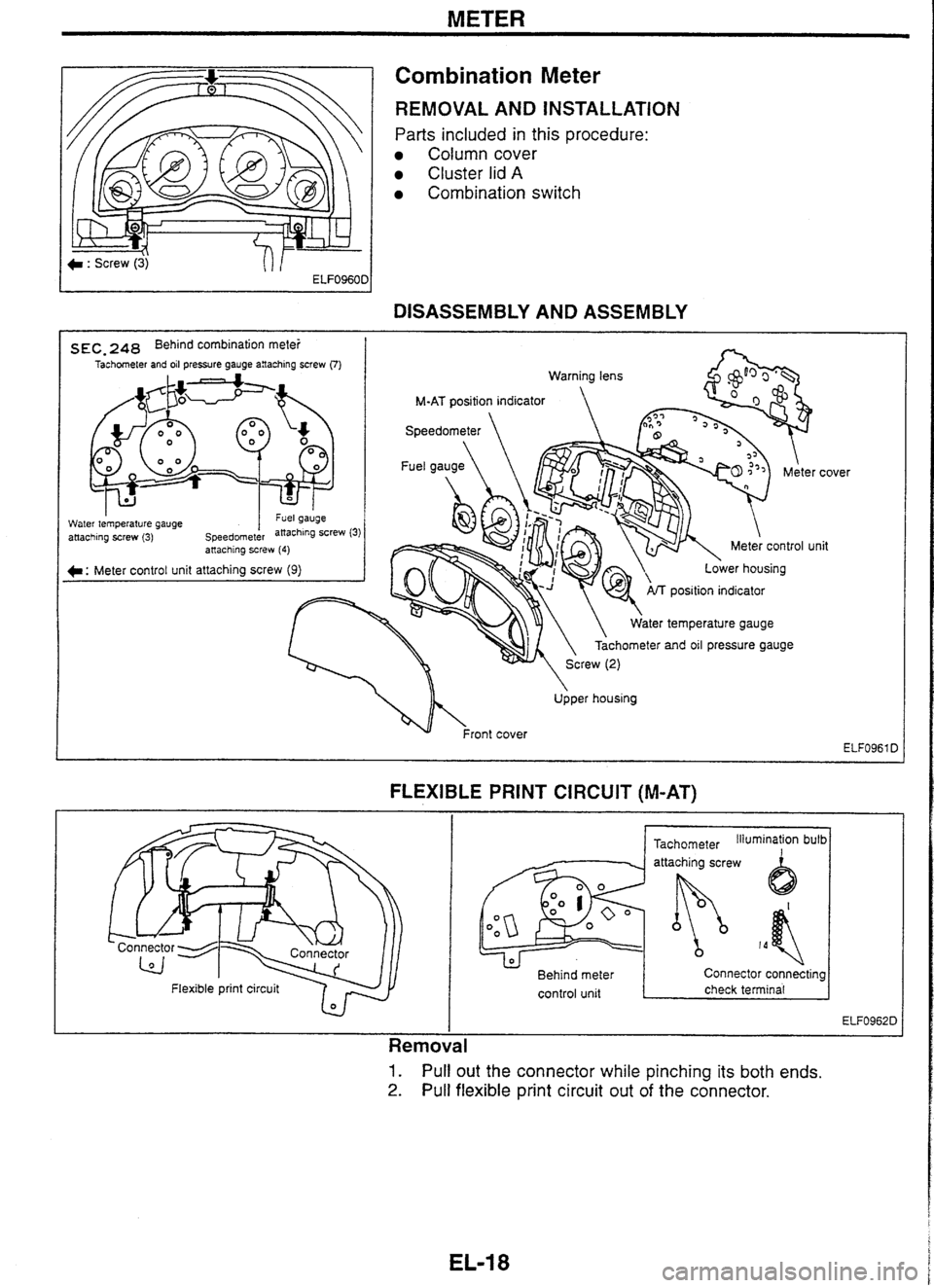

METER

Combination Meter

REMOVAL AND INSTALLATION

Parts included in this procedure:

Column cover

Cluster lid A

Combination switch

-

DISASSEMBLY AND ASSEMBLY

s EC, 248 Behind combination mete! I Tachometer and oil pressure gauge anaching screw (7)

Water tem~erature cauae I "GI yauyc - .. attaching screw (3) speedornet&

position indicator

ater temperature gauge

Tachometer

and oil pressure gauge

. . anaching screw (4)

C: Meter control unit attaching screw (9)

Upper housing cover

lit

FLEXIBLE PRINT CIRCUIT (M-AT)

I I

- Flexible

print circuit 7 r,

Tachometer Illumination bulb I

Behind meter Connector connecting

control unit

I check terminal I

I

Removal

1. Pull out the connector while pinching its both ends.

2. Pull flexible print circuit out of the connector.

Page 184 of 230

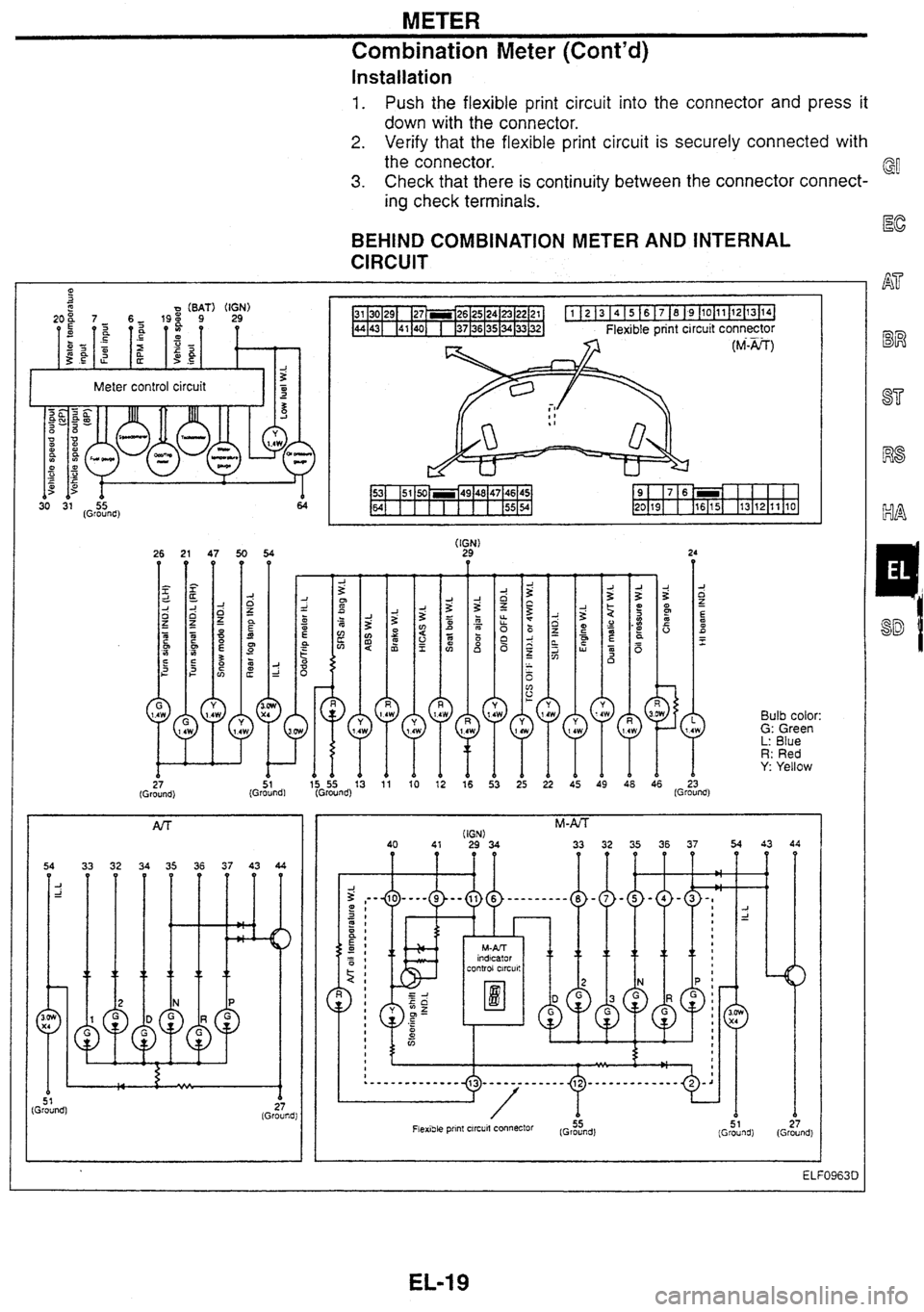

METER

Combination Meter (Cont'd)

Installation

1. Push the flexible print circuit into the connector and press it

down with the connector.

2. Verify that the flexible print circuit is securely connected with

the connector.

3. Check that there is continuity between the connector connect-

ing check terminals.

BEHIND COMBINATION METER AND INTERNAL

CIRCUIT

1 27 (Ground)

2 x

z g2

15 55 13 (Ground)

1 51 (Ground)

5 1 Ground) z I (Ground!

Bulb color: G: Green L: Blue R: Red Y: Yellow

51 27 (Ground)

(Ground)

Page 185 of 230

METER

Triple Meter

REMOVAL AND INSTALLATION

b Screw (2)

DISASSEMBLY AND ASSEMBLY

s EC. 248 Behind triple meter

(373

C : Triple meter attaching screw (5) t

c : Front cover attaching screw (6)

Front

meter

Page 186 of 230

COMBINATION METER

System Description

Speedometer, tachometer, odoltrip meter, fuel gauge, and

water temperature gauge are integrally controlled by the con-

trol circuit in the meter control unit.

Diagnosis function has odoltrip meter segment check, low fuel @

warning lamp check, and continuity check in the meter control

circuit and the meters (speedometer, tachometer, fuel gauge,

and water temperature gauge).

Component Parts Location

Combination meter ABS unit

ID Transfer (4WD) I H side of trunk room

I -unit connector I

/I Diagnosis Function

meter is displayed, turn the ignition switch ACC or

down the odoltrip meter switch, turn the ignition switch

/

ON.

3. Verify that 0000.0 km is displayed on the trip meter.

4. Press the odoltrip meter switch 3 times within 5 seconds.

5. All the odoltrip meter segments light up along with low fuel

warning lamp.

EL-21

SEGMENT CHECK AND LOW FUEL WARNING LAMP

CHECK

Page 187 of 230

COMBINATION METER

Diagnosis Function

(Cont'd)

METER CIRCUIT CHECK

After the segment check, press the odohrip meter switch to

verify that meters operate as shown below. (Low fuel warning

lamp goes off at this point.)

i

ELF0967D I It takes 1 minute for the meters to become stable.

DIAGNOSIS FUNCTION CANCELLATION

Turn the ignition switch ACC or OFF.

Meter-related Circuit Diagram

I I TO oil pressure W.L

Page 188 of 230

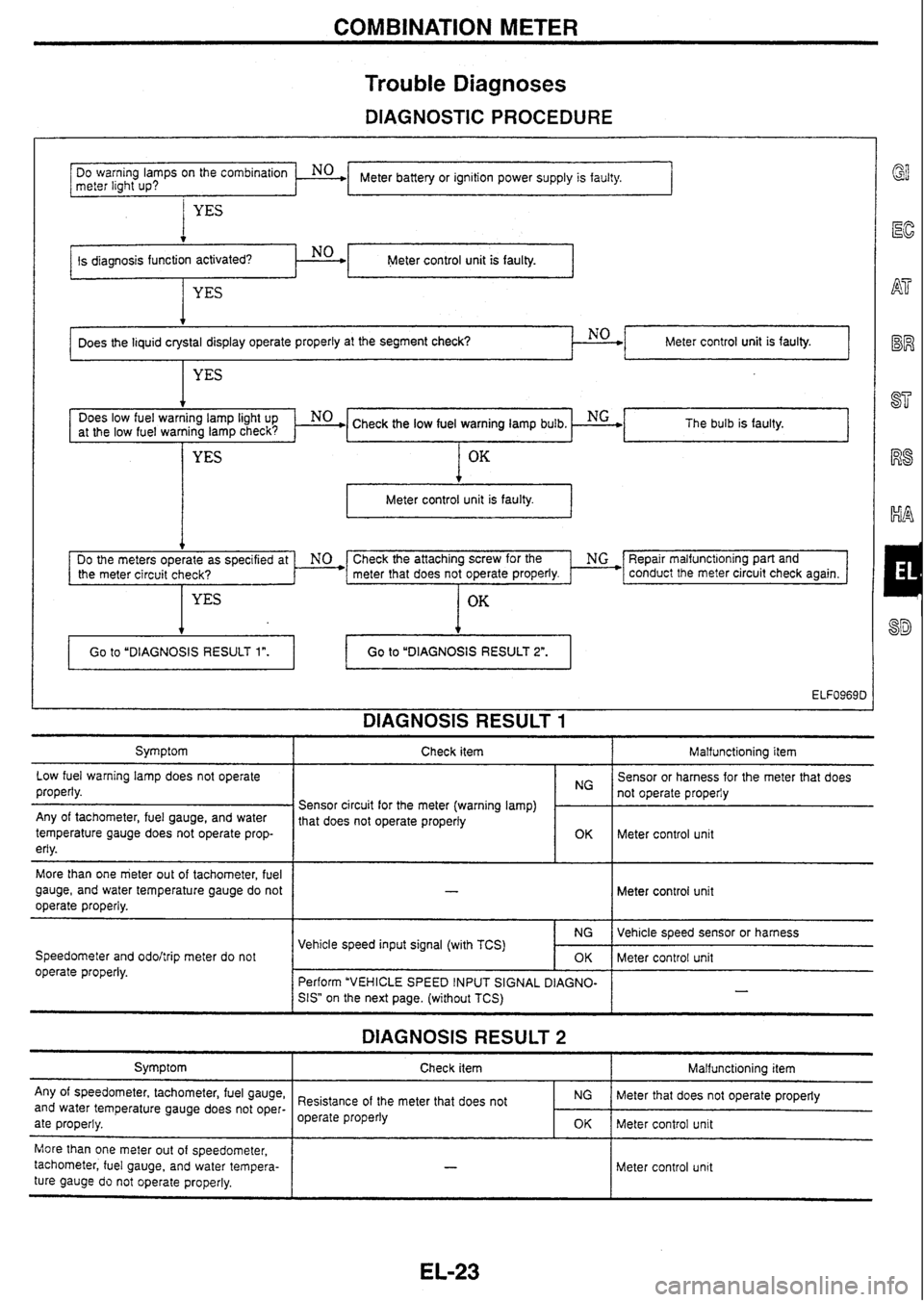

COMBINATION METER

Trouble

Diagnoses

DIAGNOSTIC PROCEDURE

I YES

Meter control unit is faulty.

Meter battery or ignition power supply is faulty.

DO

warning

lamps

on

the

meter light

up?

. No .

at the low fuel warning lamp check? The bulb

is faulty.

t

Meter control unit is faulty. I

Does the liquid crystal display operate properly at the segment check? NO

Check the attaching screw for the ' NG *F3epair malfunct~oning part and

the meter circuit check? meter that

does not operate properly. * conduct the meter circuit check again.

OK

Meter control unit is faulty.

YES

DIAGNOSIS RESULT 1

4

Symptom I Check item I Malfunctioning item

Go

to "DIAGNOSIS RESULT

1".

Low fuel warning lamp does not operate

properly. Go to

"DIAGNOSIS RESULT

2".

Any of tachometer, fuel gauge, and water

temperature gauge does not operate prop-

erly.

More than one meter out of tachometer, fuel

gauge, and water temperature gauge do not

operate properly.

Speedometer and

odohrip meter do not

operate properly. Sensor

or harness for the meter that does

Sensor circuit for the meter (warning lamp)

1 1: 1 not operate properiy

1 that does not operate properly

~ Meter control unit

Meter control unit

DIAGNOSIS RESULT 2

Symptom

Any of speedometer, tachometer, fuel gauge,

and water temperature gauge does not oper-

ate properly. Vehicle

speed sensor or harness

Meter control unit

-

Vehicle speed input signal (with TCS)

Check item

I Malfunctioning item

NG

OK

Perform "VEHICLE SPEED INPUT SIGNAL

DIAGNO-

SIS"

on the next page. (without TCS)

More than one meter out of speedometer,

tachometer, fuel gauge, and water tempera-

ture gauge

do not operate properly. Resistance

of the meter that does not

operate properly

Meter control unit

NG

OK

- -

Meter that does not operate properly

Meter control unit

Page 189 of 230

COMBINATION METER

Trouble Diagnoses (Cont'd)

VEHICLE SPEED INPUT SIGNAL DIAGNOSIS

I Connector

WARNING LAMP CHECK Does ABS warning lamp remain ON with

ignition switch ON?

ABS I

Perform ABS self-diagnosis

and check faulty circuit.

Refer to

BR section ("ABS

SYSTEMn).

Continuity exists.

Terminal No. 19 and ground:

No continuity

. -- I I

HARNESS CHECK ' Disconnect ABS control unit connector

(TK24)

and meter connector (TK20

Brown).

Terminals No. 19 - 24:

OK

El f

Meter control unit connector on vehicle

NG+'

I - = 'ELF0970D

El

@EM

Meter control unit connector on vehicle rn

rm-1 ffee

1

L / - - -

ELFo971D -

ABS control unit to meter

harness is faulty.

Meter control unit

is faulty. VEHICLE SPEED INPUT SIGNAL

CHECK 1 Connect meter connector (TK20 Brown). Terminal No. 19 and around:

'2

" Approx. 9V

OK

r9 v

VEHICLE SPEED INPUT SIGNAL

CHECK 2 Connect ABS control unit connector

(TK24).

Start the engine and drive the vehicle. Terminal No. 19 and ground:

Specification

Refer to "Combination Meter InpuffOutput

Signal Specificationsn on the next page.

OK

Meter control unit is faulty.

5' Pelform ABS self-diagnosis and check faulty circuit.

Refer to BR section ("ABS

SYSTEMn).

Page 190 of 230

COMBINATION METER

Combination Meter

InputlOutput Signal

Specifications

Terminal No. Measuring condition

Signal name

Ignition switch Operation or condition

Disconnect ECM connector. Approx.

8 - 10V

At 2.000 rprn: Approx. 3.OV

IVI

15

10

5 0

ELF0973D

Tachometer drive

signal

Engine is idling or running at

!,000 rpm. RB25DET

At ~dling: Approx. 7.2V At 2.000 rprn: Approx. 72V

(VI

(VI ST

15 I5 10 10

5 5

0 0

RS

ELF0974D RA

Refer to "Component Parts Inspection" (EL-27).

Approx. 12V I

-uel gauge signal

OFF With TCS

Vehicle speed: Approx. 40 km

(VI

15 10 5 0 -5 -1 0 -1 5

A Veh~cle Speed Approx 60 kmh

Body

lrounc

Speedometer is in operation.

Vehicle speed is approx.

10 kmh.)

Vehicle speed is approx.

i0 kmh.)

e speed

inpi

Without

TCS Vehcle speed: Approx. 40 k

IV!

15 10 5 0

h Vehicle speed: Approx. 60 kmh (V) 15 10

5

0

ELF0376D

-

-

;peedometer is not in opera-

on.

hermal

transmitte

iignal Refer

to "Component Parts Inspection"

(EL-27)

gnition power sup

'IY Approx. 12V

Approx. 4.8V or OV

Vehicle speed is approx. 40 kwh: Approx. 2.4V (Vi d!!!!!!!!!] ,

rehicle speed sign 2 pulses) ipeedometer

is in operation.

Vehicle speed is approx.

0 kmm.)

Voltage the

part

of the indicates the value checked with an )gue circuit tester