NISSAN GT-R 1998 Workshop Manual

Manufacturer: NISSAN, Model Year: 1998, Model line: GT-R, Model: NISSAN GT-R 1998Pages: 230, PDF Size: 12.66 MB

Page 51 of 230

TROUBLE DIAGNOSES

ECM (-TCM) Input/Output Signal Reference

Terminal No.

108

- NOTE:

Signal name

CM.TCM, TCS/ABS

tegrated control signal

dultiplex communica-

&DE.m,

B25DETj

attery power supply

ijector drive signal

3attery voltage When cranking: Approx.

10.5V

Value (Cont'd)

(v) 50 40 30 20 10

0

At idle: &Wry voltage

A:

idle

Approx. 2V

rariable

air intake con-

:ol solenoid valve con- switch ON: Battery voltage (Solenoid valve

rot signal

RB20DE (UB), At idle: Approx. 0.2

- 0.3V (Solenoid valve ON) At

approx. 2,000

rpm

t

3B25DEI ' .

-urbo pressure control iO1enOid valve Battery voltage (Solenoid valve OFF)

iianal

4ir jet swirl sole- Coolant temperature below approx. 70°C: Approx.

0.9V (Solenoid valve ON)

'Oid Coolant temperature approx. 70°C and above: Battery

RB20DE (VB)] voltage (Solenold valve OFF)

[RB20DE (UB), RB25DEl

Air conditioner OFF: Battery voltage

Air conditioner ON: Battery voltage Approx.

10V

(After approx.

15 sec.)

Zanister

purge control

~alve

control signal

M 30 20 10 0

(Waveform indicates when air conditioner is

ON.)

[RB20DETJ

Air conditioner OFF: Battery voltage

Air conditioner ON: Battery voltage

4 Approx. 1OV

(After approx. 15 sec.) Slightly lower than battery voltage

t At

approx. 3,650 rpm and above [RB2ODE (UB)]

At approx. 3,500 rpm and above [RB25Dq : Battery voltage (Solenotd valve OFF)

t [When engine raced suddenly: Approx. 0.3V (Solenoid

valve ON)]

t Coolant temperature approx. 70°C and above, and

driving at approx. 3,300 rpm and above [MTT] Coolant temperature approx. 70°C and above, and

driving at approx. 3,000 rpm and above [A/T1 : Approx. 0.9V (Solenoid valve ON)

Approx.

9V

Approx. 9V

I (Waveform indicates when air conditioner is ON.)

tester.

Page 52 of 230

TROUBLE DIAGNOSES

ECM (.TCM) InputlOutput Signal Reference

Value (Cont'd)

I Signal name

No. At

idle 7 At approx. 2,000 rpm

Control unit power sup-

ply (Counter-electromo-

live current feedback

circuit)

Fuel pump terminal

voltage control output

1 signal

IRB25DETI

Variable valve timing ,- control signal Battery voltage

Ignition switch at START: Approx.

OV During approx. 30 sec. after engine started with cool-

ant temperature 50°C or above: Approx. OV At idle: Approx. 1 OV

Battery voltage (Solenoid valve OFF)

Approx.

0.3V

Approx. OV

I t [With driving wheels lifted and gear in D position:

Approx. 0.45V (Solenoid valve ON)] AT

Approx. 0.3V (At approx. 2,800 rpm and above: Battery voltage) 1 I I

NOTE: Above voltages are measured values obtained by analogue circuit tester. BR

Page 53 of 230

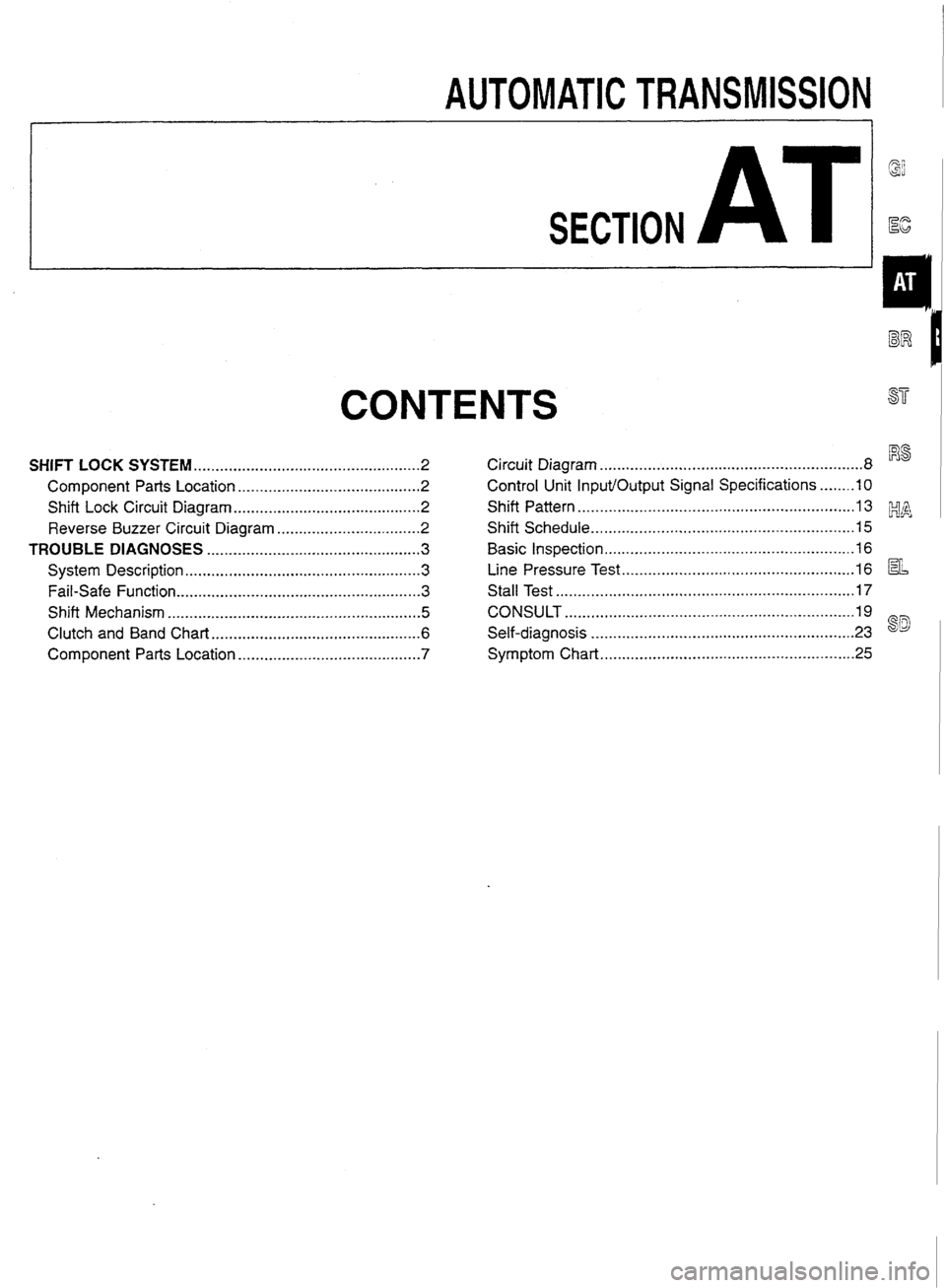

AUTOMATIC TRANSMISSION

SECTION

AT

CONTENTS

SHIFT LOCK SYSTEM .................................................... 2

Component Parts Location .......................................... 2

Shift Lock Circuit Diagram ........................................... 2

Reverse Buzzer Circuit Diagram ................................. 2

TROUBLE DIAGNOSES ................................................. 3

System Description .................................................... ..3

Fail-safe Function ...................................................... ..3

................... Shift Mechanism ............. .........,,.............. .5

Clutch and Band Chart ................................................ 6

Component Parts Location .......................................... 7

........................................................... Circuit Diagram .8

Control Unit Input/Output Signal Specifications ....... .I0

Shift Pattern .............................................................. 1 3

............................................................ Shift Schedule 15

....................................................... Basic Inspection. -16

Line Pressure Test ..................................................... 16

................................................................... Stall Test 17

.................................................................. CONSULT 9

.......................................................... Self-diagnosis ..23

Symptom Chart. ........................................................ -25

Page 54 of 230

SHIFT LOCK SYSTEM

Component Parts Location

Control device pJ/ I '-#I

Park position

Key interlock cable

Shift Lock Circuit Diagram

I AfT device connector

Brake SW connector

4AT M-AT

Terminal No. in parenthesis is used for M-AT. AfT device AT01 O57C

6 (2)

$5 - 5

IOA / 2j nI1 - (6)

Brake SW

Reverse Buzzer Circuit Diagram

Shift lock solenoid

Park position SW ~-

Connectors

1 1 )29m [ I]l~a!!b-ll1ll1 36 , &- 551 l\li I i I1 I I I I! I TK 20 pins (Wh~te)

TK 24 pins (Brown) TK 20 pins (Brown) AT01 056D

# 12

b

-

#ll PNP SW 36 Reverse lamp 29

# 28 9

1 1 Meter C/U 155 4 (with

integrated buzzer) ,

Page 55 of 230

TROUBLE DIAGNOSES

System Description

Vehicle with RB20DE and RB25DET engine has TCM integrated into ECM. Vehicle with RB25DE engine has

TCM and ECM separately.

Fail-safe Function @ When malfunction occurs in each sensor and solenoid, the fail-safe functions below enable vehicle to be

driven.

VEHICLE SPEED SENSOR 1 (Output shaft speed sensor)

Inputs a signal from vehicle speed sensor in speedometer. EG

THROTTLE POSITION SENSOR

Detects throttle opening by idle switch and full switch, and controls line pressure as follows. I 1 I Idle switch

-

--

I

--

ON OFF I Minimum oil pressure I 0/8 ST

I

OFF OFF

Full switch

ON Maximum oil pressure

PNP SWITCH

When the multiple PNP switch signals are input to TCM and ECM-TCM, the priority of selector lever position I28

becomes as follows by internal TCM determination.

4AT D, N, R, 2, 1 I%$ M-AT D, N, R, 3, 2

Because the hydraulic circuit of the control valve is switched by manual valve according to the selector lever

position, however, actual operating condition of vehicle becomes as follows.

EL

I N I "N" and other position signals I N

Line pressure

218

P

R

- - -- pp - pp - -

4AT I D I "D" and other position signals I Dl*DP*Dd

Throttle opening I

418 BR

Running status

Actual lever position

1 "2 and other position signals I 21 ~22

PNP switch input signal

"P and other position signals

"R" and other position signals

--

r"2 and "1" 21 ~22

P 83

R

I 2 1 "2" and other position signals / 21 42

M -AT

3

L

1

P

R

N

D

"1" and other position signals

"P" and other position signals

"R" and other position signals

"N" and other position signals

"D" and other position signals

I

l,++l2

P

R

N

D1t;.D2c*D3

"3 and other position signals

"3" and "2" position signals

3, -3,-3-3,

3, +3, +3,

Page 56 of 230

TROUBLE DIAGNOSES

Fail-safe Function (Cont'd)

SHIFT SOLENOID A, B

When a malfunctioning signal of solenoid is input to TCM and ECM-TCM, the gear is shifted as follows.

Normal Abnormal solenoid A Abnormal solenoid B Abnormal solenoid A/B Shift positions A B Gears A B Gears A I3 Gears A 8 Gears

0 0 1 st o-+x 03x - - - -

-- 0: Solenoid ON X: Solenoid OFF -: Abnormal

LINE PRESSURE SOLENOID

When a malfunctioning signal of solenoid is input to TCM and ECM-TCM, the line pressure solenoid is turned

OFF, and the line pressure is set to maximum oil pressure.

LOCK-UP SOLENOID

When a malfunctioning signal of solenoid is input to TCM and ECM.TCM, the lock-up solenoid is turned OFF,

and the lock-up

is released.

OVERRUN CLUTCH SOLENOID

When a malfunctioning signal of solenoid is input to TCM and ECM-TCM, the overrun clutch solenoid is turned

OFF, and the overrun clutch is engaged to apply the engine brake during deceleration.

MANUAL MODE SWITCH (M-AT)

When a malfunctioning signal of manual mode switch is input to TCM and ECM.TCM, the gear is controlled

with normal "D" position.

SHIFT CONTROL UNIT (Except RB20DE)

When a malfunction occurs in the shift control unit, the shift solenoid NB are turned OFF, and the gear posi-

tion

is controlled with 3rd speed.

TURBINE SENSOR (Except RB20DE)

Controlled by vehicle speed sensor 1 in the same way without turbine sensor

Page 57 of 230

TROUBLE DIAGNOSES

Shift Mechanism

1 Turbine sensor 1

tine pressure solenoid I 1

Shift solenoid B

Full switch

ECM-TCM

(All side) (RB20DE, RB25DET) or TCM (RB25DE) p-

ECM.TCM (Engine side) * I

(RB20DE. RB25DET) or Venrle speed sensor 2

ECM (RB25DE) ,

1 (RB25DET)

POWER ~nd~calor lamp @AT;

( POWER (Except M-AT) ] 1 SNOW I

Shift control unit

(Except RB20DE)

Overdrive control switch

I

O/D OFF

indicator lamp

Steering shift main switch

- ATN 1983D

Page 58 of 230

TROUBLE DIAGNOSES

Clutch and Band Chart

U0.C

(Low one-

way

clutchl L&R/B

(Low and

reverse

brake)

F/O C

(Forward

clutch)

.

Remarks

PARK POSI-

TION

REVERSE POSITION

O/C

(Overrun

clutch)

*I@

'I@

'18

@

NEUTRAL

POSITION

*"

c'utch)

0

0

WC

clutch)

(Reverse

0

P

R

N

Automatic shift

0

0

FIC

(For-

ward

clutch)

0

0

0

69

0

Band servo

'4

2 Automatic shift

1 st

2nd

-3rd 4th

1 st

1. Locked in 1st

-

4th apply

0

2nd apply

0

'263

*3@

2nd

I st

2nd

0

0

0

DUAL MATIC M-ATx

3rd release

0

8

0

0

0

--

fi In Band servo I FI0.C / UOC I L&WB I

(Reverse clutch) FIC (For- WC (High

ward

clutch) clutch)

PARK POSI-

TION

REVERSE POSITION

NEUTRAL POSITION

@ 0 . . Automatic shift

0 '269 8 - -

-38 8 0

@

G3 0 Automatic shift

10 I I Automatic shift

I I I I I I I

:ch is being set in "OFF position. (D, shift is inhibited.) '2: oil pressure is applied to both 2nd "apply" side and 3rd "releasen side of band servo piston. However, brake band does not contract because oil pressure area on the "releasen side is greater than that on the "apply" side. '3: Oil pressure is applied to 4th "apply" side in condition '2 above, and brake band contracts. '4: A/T will not shift to 4th when overdrive control switch is set in "OFF position.

* 1 : O~erate when control

swil

0: Operates. a: Operates

during "progressive" acceleration.

@: Operates but does not affect power transmission. @: Operates when throttle opening is less than specification, but does not affect engine brake. fi: O~erates when throttle opening is less than specification, activating engine brake.

Page 59 of 230

![NISSAN GT-R 1998 Workshop Manual

TROUBLE DIAGNOSES

Component Parts Location

[M-AT (Except TCS)]

Control valve uppe:

Line pressure

solenoid Shift solenoid A

Shift solenoid B Overrun clutch

solenoid

Steering switch relay I NISSAN GT-R 1998 Workshop Manual

TROUBLE DIAGNOSES

Component Parts Location

[M-AT (Except TCS)]

Control valve uppe:

Line pressure

solenoid Shift solenoid A

Shift solenoid B Overrun clutch

solenoid

Steering switch relay I](/img/5/57354/w960_57354-58.png)

TROUBLE DIAGNOSES

Component Parts Location

[M-AT (Except TCS)]

Control valve uppe:

Line pressure

solenoid Shift solenoid A

Shift solenoid B Overrun clutch

solenoid

Steering switch relay I Ql Shift control unit (Except RB20DE) ?

ATN 1 985D

AT-?

Page 60 of 230

TROUBLE DIAGNOSES

Circuit Diagram

1 Data link connector for CONSULT

I I Vehicle speed sensor 1 I I (Output shaft speed sensor)

Turbine sensor (Exceot RB20DE)

Shifi CRI (M-AT)

65 10 Steering shifl SW (M-AT)

Steering shift main SW

1

Manual mode SW I

Terminal No. in parenthesis ( ) of throttle position sensor and throttle posit~on switch 1s used for RB25DET.

AT-8