NISSAN GT-R 1998 Repair Manual

Manufacturer: NISSAN, Model Year: 1998, Model line: GT-R, Model: NISSAN GT-R 1998Pages: 230, PDF Size: 12.66 MB

Page 61 of 230

TROUBLE DIAGNOSES

Circuit Diagram (Cont'd)

Data link connector for C0NS;ILT

Engine speed signal -

i? Throttle ~otal controi port&-2 s-2 33 7'' ELM I E - , 10

AT mode SW & '' 19

(2WD)

1- 1 I I Throttle msition sensor

I I Vehicle speed sensor 1

Turbine sensor 38 -

Throttle position SW 2 r I- 16

L TO IGN SW I PNPSW

To starter relay 4-1 34 - 27

A i 26

n I IGN IOA ID OFF 1ND.L AT> I T 22 I Shift CIU

ATN 1 987D

Page 62 of 230

TROUBLE DIAGNOSES

Control Unit Input/Output Signal Specifications

Refer to EC section ("ECM.TCM or ECM Input/Output Signal

Reference Value").

USING CONSULT -

Monitor item Indication value Operating status

Throttle position sensor Approx.

0.4 - 4.OV

Throttle fully - closed to fully-open --

AK fluid temperature sensor I Appro~. 1.5 - 0.5V I A/T fluid: Appro~. 20 - 80°C -- - - --- -

ON Overdrive control switch: OFF

Lever switch

OFF Overdrive control switch: ON

Line pressure

duty 29 - 94% Low

pressure - High pressure

Lock-up duty

4 - 94% Lock-up released - Lock-up engaged

USING CIRCUIT TESTER

Terminal

No.' 1 Condition Specifications

.- Refer to EC section

("ECM-TCM or

5 (39) Engine speed signal - ECM Input/Output Signal Reference

Value*).

Voltage increases gradually in

Throttle position sensor

signal After

engine warm-up, depress accelerator pedal

slowly. response

to throttle position.

Fully-closed throttle

: Approx. 0.5V

Fully-open throttle : Approx. 4.2V

24 (I0) Power source

31 (19) Turn

ignition switch ON. Battery

voltage

Turn ignition switch OFF. Approx.

OV

--

25 (25) 1 Ground 32 (48) Turn ignition switch ON. Approx. OV

Shift control

signal SB1 - - 28 (I4) (Except RB20DE)

Vehicle speed sensor

2 When vehicle is moved at 2 to 3 km/h for more than Voltage varies approx. between OV 29 (40) (vehicle speed

signal in 1 m. and 4.5V intermittently.

speedometer)

*: Each number in parenthesis ( ) shows the terminal No. for TCM (RB25DE).

Page 63 of 230

TROUBLE DIAGNOSES

Control Unit

InputlOutput Signal Specifications

Terminal

No.' Operation

or measurement condition Specifications

Idle switch

(in throttle position switch) After

engine warm-up, release accelerator pedal.

After engine warm-up, depress accelerator

pedal.

PNP switch "1"

(c > is used for M-AT.) Battery voltage

@ Approx.

OV

PNP switch

"2"

<"33 position

(c > is used for M-AT.) Selector lever:

"1"

&?"2 position

Selector lever;

Exce~t

"1"

<"2"> ~osition Battery voltage

gz

A~~rox.

OV

PNP switch

"Dm position Selector

lever:

2" <3*> position

Selector lever: Except

"Y 4'3'5 position

Selector lever;

"Dn

position Battery voltage

Approx. OV

Battery voltage

Neutral signal

(PNP switch

"N-P"

position)

- -- Selector lever: Except "Dm position Approx.

OV

PNP switch

"Rn

position RR Selector lever: "Nn, "P" position

Selector lever: Except

"N", "Pn position

Selector lever:

"Rn

~osition

I Selector lever: Except "Rn position 1 Approx. OV

U" " Approx. OV

Approx. 4.7V

. Batterv voltaae ST

I

After engine warm-up, depress accelerator pedal

partially. (Throttle opening: More than 50%) Battery voltage i% Full

switch

(in throttle position switch)

I After engine warm-up, release accelerator pedal. I Approx. OV

Sensor ground

Throttle position sensor

power -- -- - - - I

-- --- Turn iqnition switch ON. Ao~rox. OV @z!.

Shift control signal SB2

(Except RB20DE) Turn ignition switch

ON. Turn ignition switch

OFF.

Approx.

4.5 - 5.5V

Approx. OV

EL

Vehicle speed sensor 1

(Output shaft speed sensor) When vehicle

cruises at 30 kwh (Inspected in AC posi-

tion) More

than approx. 1 V

80

(Voltage increases in

resDonse to vehicle

meed.)

Turbine sensor (Except

RB20DE)

When vehicle parks (Inspected in AC position)

When turbine rotates at approx. 1,000

rpm I Approx. 0.1 V

Approx.

OV

rn fluid temperature sensor 5 I A/l fluid temperature: Approx. 20°C Approx. 1.5V

c

3 V) Battery voltage

Approx. OV .- Y .- c a, -

Afr mode switch (POWER)

(Except M-AT)

A/T fluid temperature: Approx. 80°C ,

AIT mode switch: POWER

A/T mode switch: Except POWER - - - - - - -- Shift control signal DB1

(Except RB20DE)

Shift control signal

DB3

(Except RB20DE) Approx. 0.5V

Overdrive control switch

(Except M-AT) Battery voltage

z g 0

Shift

control signal DB2

(Except RB20DE)

A/T mode switch (SNOW)

(Except TCS) Overdrive

control switch: ON (Contact: OFF)

- .= c .- & .&!

- 5

Stop lamp switch Overdrive

control switch:

OFF (Contact: ON)

CONSULT

(RX) signal Approx.

OV

Battery voltage Appro~. OV

Battery voltage

Approx. OV

.z w .- cJ=- T) .g

2

CONSULT (TX) signal

A/l mode switch: SNOW

A/l mode switch: Except SNOW

Depress brake pedal.

' Release brake pedal.

*: Each number in parenthesis ( ) shows the terminal No. for TCM (RB25DE).

AT-1 1

Page 64 of 230

TROUBLE DIAGNOSES

Control Unit InputlOutput Signal Specifications

(Cont'd)

Terminal

No.' Operation

or measurement condition

Specifications

Total control signal

(multiple communication)

(Except

RB20DE) Refer to

EC section

("ECM.TCM or ECM Input1

Output Signal Reference Value").

I I

I Turn ignition swi?ch ON. I Battery voltage

Power supply (Backup)

Line pressure solenoid - - Turn ignition switch OFF. Battery voltage

r After engine

warm-up, depress accelerator pedal

Line pressure solenoid

(dropping resistor circuit) 5

Approx. OV

w

0.

s

Overrun clutch solenoid After engine

wan-up, release accelerator pedal.

After engine warm-up, release accelerator pedal.

After engine warm-up, depress accelerator pedal

fullv. .- >. .- 5

POWER indicator lamp (4AT)

Dual rnatic

AK waming lamp

(M-AT)

Approx. 1.5 - 3.OV

Approx. 4 - 14V

Approx. OV

When POWER indicator lamp is tumed on (W

mode switch: POWER), or dual matic warn-

ing lamp

is turned on

When

overrun clutch solenoid operates

When overrun clutch solenoid does not operate

Approx.

OV

Battery voltage Approx.

OV

When POWER indicator lamp is tumed off (NT

mode switch:Except POWER), or dual matic A/T Battery voltage

I warning lamp is turned off 1

I When vehicle is locked UD I Approx. 8 - 15V Lock-up solenoid I . .

When vehicle is not locked up I Approx. OV

When shift solenoid A operates

(Driving in 'Dln or

"D,")

When

shift solenoid A does not operate

(Driving in

"D," or "D,")

parenthesis

(

Battery voltage

Approx.

OV

Shift solenoid B

) shows the terminal No. for TCM (RB25DE ).

I

*: Each

When shift solenoid B operates

(Driving in 'Dln or

'D,")

When shift solenoid

B does not operate

(Driving in

"D,"

or

"Dd)

number Battery voltage

Approx. OV

Page 65 of 230

TROUBLE DIAGNOSES

Shift Pattern

RB20DE ENGINE (4AX03 model)

"D" position normal mode (Overdrive control switch: ON)

Vehicle speed kmlh

"D" position POWER mode (Overdrive control switch: ON)

- - - --- --- Down-shift

Kickdown

area Vehicle speed

km/h

"D" position SNOW mode (Overdrive control switch: ON I -

I -

-

-

-

Vehicle speed km/h

AT-1 3

ATN 1 988D

Page 66 of 230

TROUBLE DIAGNOSES

Shift Pattern (Cont'd)

RB25DE ENGINE (4AX01 model)

"D" position normal mode

Vehicle speed krnh "D" position SNOW mode

Kickdown area 3

------- Down-shift

10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170 180

Vehicle speed krnh

ATN 1 989C

RB25DET ENGINE (4AX00 model)

"D" ~osition normal mode

Vehicle speed kmfh

Page 67 of 230

TROUBLE DIAGNOSES

Shift Schedule

VEHICLE SPEED WHEN SHIFTING GEARS

RB20DE engine (4AX03 model)

I 1 Vehicle meed km/h

Throttle opening

Full throttle

RB25DE engine (4AX01 model)

Shift pattern

Half throttle

I I Vehicle s~eed km/h

D14D2 I D2*D3 I D34D4 1 D4-1D3 I D3*D2 I D24D1

Normal

Power

Normal

Power

Full throttle 46 - 50

46

- 50

I

Throttle opening Shift pattern

31 - 35

43

- 47

I D2-rD3 I DJdD4 I D4*D3 1 D3*02 1 D24D1

91 - 99

91 - 99

Normal

Power

RB25DET engine (4AX00 model)

62 - 68

84

- 90 149

- 159

149

- 159

50

- 54

50

- 54 I

101 - 109

135

- 143

32

- 36

42

- 46 Half throttle

Throttle opening

VEHICLE SPEED WHEN PERFORMING LOCK-UP

144 - 154

144

- 154

101

- 109

101

- 109

Normal Power

Full throttle

Half throttle

71 - 79

83

- 91

61

- 67

85

- 91

Shift pattern

86 - 94

86

- 94

157

- 167

157

- 167

Vehicle speed krnlh

D14D2 I D2*D3 I D3*D4 I D4*D3 I D3*DZ I D2+D1

Normal

Power

Normal

Power

Closed throttle: Throttle opening

is 118 or below, and idle switch is turned OFF.

Half throttle: Throttle opening is 418.

41 - 45

41

- 45

41

- 45

45

- 51

104

- 112

135

- 143

Engine type

Model No.

speed

D4

speed

6-10

6- 10

151

- 161

151

- 161

-

45 - 49

45

- 49

31

- 35

39

- 43

RB20DE

4AX03

31

- 39

- D,

80 - 88

87

- 95

Lock-up OFF kmh

Lock-up

ON km/h

Lock-up

OFF kmlh

96 - 104

96

- 104

RB25DE

4AX01

34

- 42

- Lock-up ON km/h

40 - 44

40 - 44

37 - 43

45

- 51

-

103 - 111

103

- 111

74

- 80

84

- 90

RB25DET

4AX00

-

-

Closed throttle

Half throttle

Closed throttle

Half throttle

Closed throttle

Half throttle

Closed throttle

Half throttle

6-10

6-10

98

- 106

98 - 106

32

- 38

50

- 56

-- --

40 - 44

40

- 44

6-10

6- 10

167

- 177

167

- 177

111

- 119

133

- 141

23

- 31

101

- 109

44

- 52

120

- 128

35

- 43

110

- 118

-- -- -

161 - 171

161

- 171

63

- 71

98

- 106

25

- 33

104

- 112

48

- 56

118

- 126

38

- 46

107

- 115 59

- 67

121

- 129

55

- 63

128 - 136

52

- 60

103

- 111

Page 68 of 230

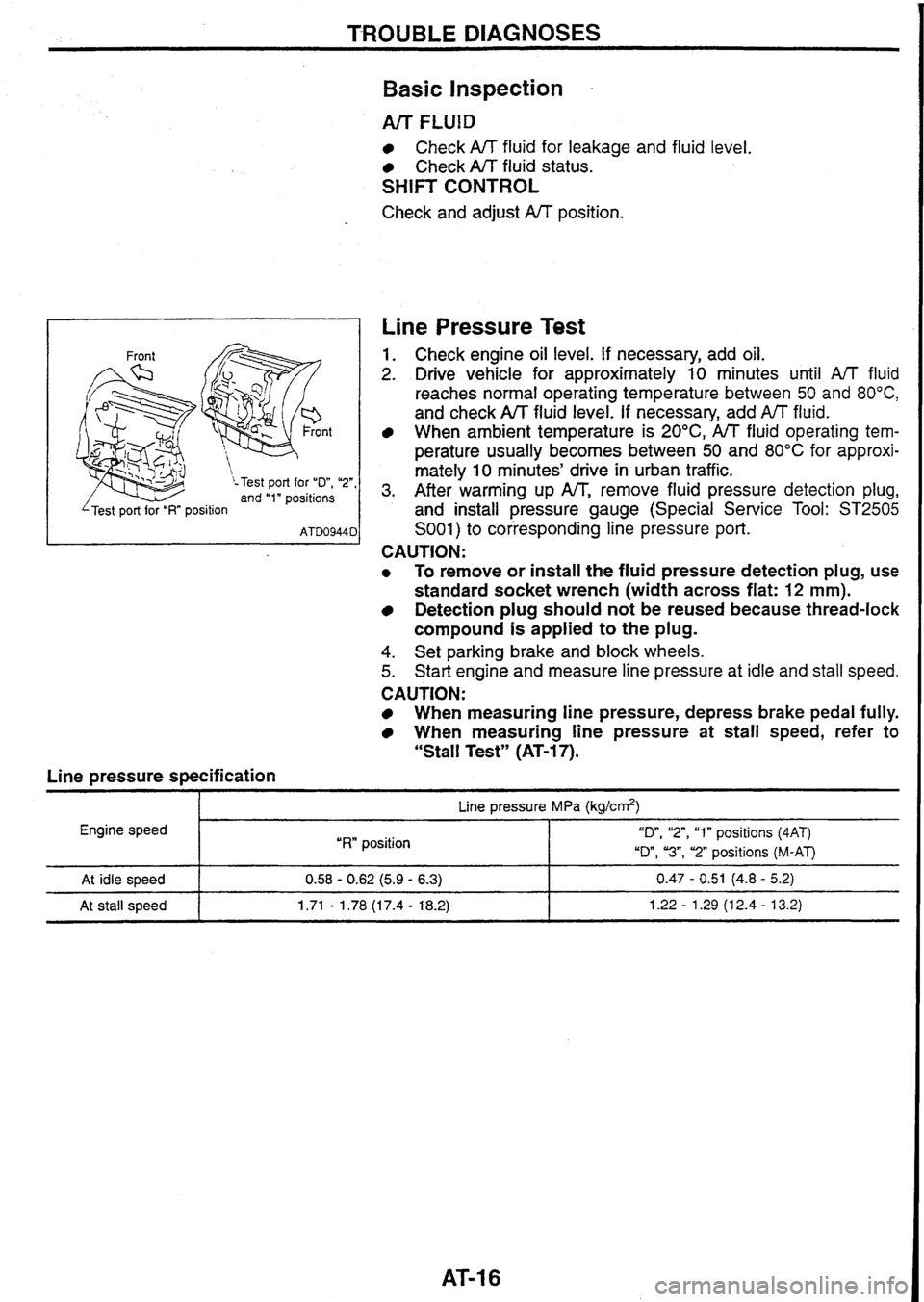

TROUBLE DIAGNOSES

n t

\-Test port for "D", "2", and "1" positions

I 'Test port for "I?" position I

Line pressure specification

Basic Inspection

Arr FLUlD

Check A/T fluid for leakage and fluid level.

Check A/T fluid status.

SHIFT CONTROL

Check and adjust A/T position.

Line Pressure Test

1. Check engine oil level. If necessary, add oil.

2. Drive vehicle for approximately 10 minutes until A/T fluid

reaches normal operating temperature between

50 and 80°C,

and check A/T fluid level. If necessary, add fluid.

When

ambient temperature is 20°C, A/T fluid operating tem-

perature

usually becomes between 50 and 80°C for approxi-

mately

10 minutes' drive in urban traffic.

3. After warming up IW', remove fluid pressure detection plug,

and install pressure gauge (Special Service Tool:

ST2505

S001) to corresponding line pressure port.

CAUTION:

0 To remove or install the fluid pressure detection plug, use

standard socket wrench (width across flat:

12 mm).

Detection plug should not be reused because thread-lock

compound is applied

to the plug.

4. Set parking brake and block wheels.

5. Start engine and measure line pressure at idle and stall speed.

CAUTION:

When measuring line pressure, depress brake pedal fully.

When measuring line pressure at stall speed, refer to

"Stall Test" (AT-17).

I p- Line pressure MPa (kg/crn2)

Engine speed

I "RW position "On, 'Z", "1" positions (4AT)

"Dm,

"3", "2" positions (M-AT)

At idle speed

At stall speed 0.58 - 0.62 (5.9 - 6.3) 0.47 - 0.51 (4.8 - 5.2)

1.71

- 1.78 (1 7.4 - 18.2) 1.22 - 1.29 (1 2.4 - 13.2)

Page 69 of 230

TROUBLE DIAGNOSES

Line Pressure Test (Cont'd)

JUDGEMENT OF LINE PRESSURE TEST

At idle

speed

At stall

speed Judgement

Line pressure is low in all

positions.

Line pressure is low in par-

ticular position.

Line pressure is

high.

Line pressure increase is

poorer than that measured at

idle speed.

Line pressure increases but

does not reach specification.

Line pressure is low in par-

ticular position. Possible

causes

Pressure supply system malfunction or low oil pump output

Examples:

0 Oil pump wear

Control piston damage

Pressure regulator valve or plug sticking, and weak spring

Fluid pressure leakage between oil strainer and pressure regulator valve through oil Eg

Pump

Low idle speed

After line pressure is supplied from manual valve, fluid pressure may leak between devices

or circuits of corresponding position.

1

Malfunctions of sensors or pressure regulation function. El

Examples:

Misadjustment of throttle position sensor

PJT fluid temperature sensor damaged ST

Poor operation of line pressure solenoid (stuck with OFF status, clogged filter, or open

harness)

Pressure modifier valve sticking F%

Pressure regulator valve or plug sticking

Malfunctions of sensors or pressure regulation function

Examples:

EILA

Misadjustment of throttle position sensor

TCM, ECM.TCM damaged la

Poor operation of line pressure solenoid (stuck or shorted with ON status)

Pressure regulator valve and plug sticking

Pressure modifier valve sticking

sf$

Pilot valve sticking and pilot filter clogged

Malfunctions of pressure supply system, sensors, or pressure regulation function

Examples:

Misadjustment of throttle position sensor

Control piston damage

Poor operation of line pressure solenoid, and filter sticking or clogged

Pressure regulator valve and plug sticking

Pressure modifier valve sticking

Pilot valve sticking and pilot filter clogged

After line pressure is supplied from manual valve, fluid pressure

may leak between devices

or circuits of corresponding position.

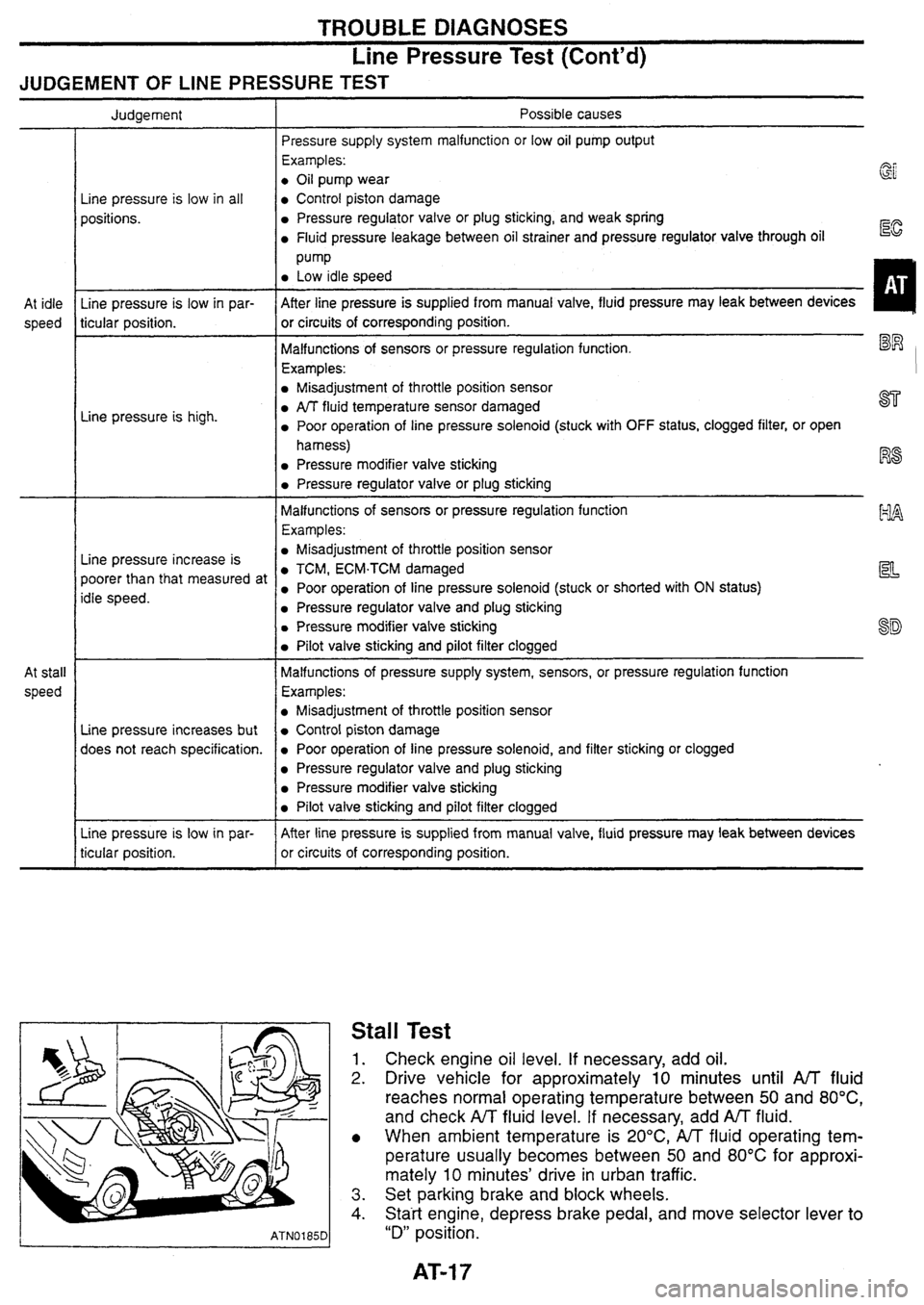

Stall Test

1. Check engine oil level. If necessary, add oil.

2. Drive vehicle for approximately 10 minutes until A/T fluid

reaches normal operating temperature between

50 and 80°C,

and check A/T fluid level. If necessary, add AfT fluid.

When ambient temperature is

20°C,

A/T fluid operating tem-

perature usually becomes between 50 and

80°C for approxi-

mately

10 minutes' drive in urban traffic.

3. Set parking brake and block wheels.

4. Statt engine, depress brake pedal, and move selector lever to

"D" position.

Page 70 of 230

TROUBLE DIAGNOSES

Stall Test (Cont'd)

JUDGEMENT OF STALL SPEED

5. Depress accelerator pedal gradually while depressing brake

pedal.

6. Read stall speed quickly, and immediately release accelerator

pedal.

CAUTION: Do not

depress accelerator pedal for more than 5 seconds

when testing.

7. Move selector lever to "N" position.

8. Cool down fluid.

CAUTION:

Run engine at idle

for at least one minute.

Specification:

RB20DE 2,300 - 2,500 rpm

RB25DE 2,350 - 2,550 rpm

RB25DET 2,920 - 3,170 rpm

7 Lever position

Stall

speed status Possible causes

Forward

clutch

Forward one-way clutch

Low one-way clutch

Engine and torque converter one-way clutch

7-

0

Line pressure circuit (line pressure drop), forward clutch, low one-way clutch

and forward one-way clutch

Line pressure circuit (line pressure drop), reverse clutch and forward clutch

Forward clutch, low one-way clutch, forward one-way clutch, reverse clutch

and forward clutch

Line pressure circuit (line pressure drop), forward clutch, low one-way clutch,

forward one-way clutch, reverse clutch and

forward clutch

Clutches and brake are normal except high clutch, brake band, and overrun

It

I

0

0 0 Low & reverse brake

Reverse clutch

0: Within stall speed specification

H: Higher than stall speed specification

L: Lower than stall speed specification

0 0 0 clutch. (However, status of high clutch, brake band, and overrun clutch cannc

be confirmed by stall test.)