NISSAN GT-R 1998 Manual PDF

Manufacturer: NISSAN, Model Year: 1998, Model line: GT-R, Model: NISSAN GT-R 1998Pages: 230, PDF Size: 12.66 MB

Page 71 of 230

TROUBLE DIAGNOSES

DESCRIPTION

CONSULT indicates operation timing of each solenoid such as electrical shift timing and lock-up timing.

Therefore, when there is a definite difference between shift timing detected from shift shock (or engine

speed variation) and the one indicated by CONSULT, mechanical parts other than solenoids and sensors

(including hydraulic circuit) may be malfunctioning. In this case, check the mechanical parts using appli-

cable diagnostic procedures.

Shift schedule (which implies gear position) displayed on CONSULT and that indicated in Service Manual

may differ slightly. This occurs because of the following reasons:

Actual shift schedule has more or less tolerance or allowance.

Shift schedule indicated in Service Manual refers to the point where shifts start, and gear position dis-

played on CONSULT indicates the point where shifts are completed.

Shift solenoid valve A or B (ON/OFF) is displayed on CONSULT at the start of shifting. Gear position

is displayed upon completion of shifting (which is computed by TCM).

To make sure the part No. of ECM-TCM on CONSULT, touch "ENGINE" to verify "C/U PART NUMBER".

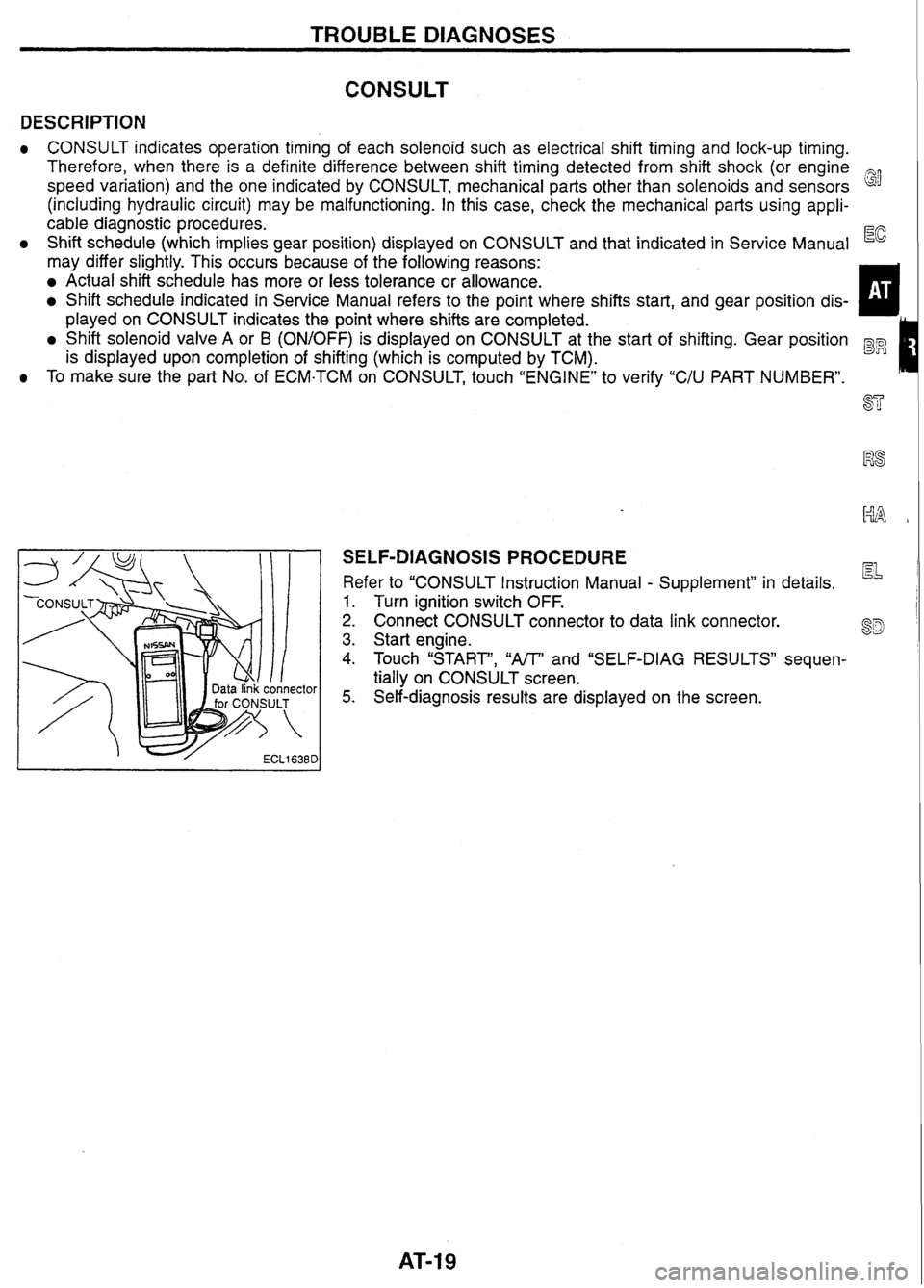

SELF-DIAGNOSIS PROCEDURE

Refer to "CONSULT Instruction Manual - Supplement" in details.

1. Turn ignition switch OFF.

2. Connect CONSULT connector to data link connector.

3. Start engine.

4. Touch "START', "NT and "SELF-DIAG RESULTS" sequen-

tially on CONSULT screen.

5. Self-diagnosis results are displayed on the screen.

Page 72 of 230

TROUBLE DIAGNOSES

CONSULT (Cont'd)

SELF-DIAGNOSTIC RESULTS MODE

Diagnostic item 1 Diagnostic item is detected when ... Inspection item - -- -

I TCM does not receive vehicle speed sensor 1 signal due to

open circuit, etc.

TCM receives improper signal during driving. After ignition switch is turned ON, vehicle speed sensor 2 receives improper signal until vehicle starts to run.

VHCL

SPEED

SEN.A/T Vehicle

speed sensor 1 circuit

TCM does not receive vehicle speed sensor 2 signal due to

open circuit, etc.

TCM receives improper signal during driving.

VHCL

SPEED

SEN.MTR Vehicle

speed sensor 2 circuit

TCM detects

folfowing conditions during driving (Except N and

P positions). 0 Excessively high throttle position sensor signal voltage Excessive1 low throttle position sensor signal voltage with idle

switch OF; or full switch ON

THROTTLE

POSl

SEN

Throttle position sensor circuit

SHIFT SOLENOIDN A

SHIFT SOLENOIDN B Shift

solenoid A circuit

Shift solenoid

B circuit

Overrun clutch solenoid circuit

TIC

CLUTCH SOW

I

OVERRUN CLUTCH SN

Lock-up solenoid circuit Specified voltage is not applied to solenoid due to open and/or

short circuit.

LINE

PRESSURE SN

I Line pressure solenoid circuit

0 Excessively low supply voltage to TCM during driving

Excessively high si nal voltage of AIT fluid temperature sensor

(excessively low d fluid temperature) during driving This message is displayed only when malfunction occurs with ignition switch ON, and does not have memory func-

tion.

fluid temperature sensor circuit,

TCM power supply circuit, or

throttle position sensor power sup-

ply circuit

BATT/FLUID

TEMP SEN

ENGINE SPEED SIG

I Excessively low engine speed during driving Engine speed

signal circuit

Turbine sensor circuit

TURBINE

SENSOR

(Except

RB20DE)

SHIFT SOLENOIDN C

(Except

RB20DE)

TCM does not receive input shaft speed sensor signal due to

open circuit,

etc.

0 TCM receives improper signal during driving.

0 TCM does not receive shift solenoid A pressure detection switch

signal due to open

andfor short circuit. Shift solenoid A pressure

detection

switch circuit

MANUAL MODE SW

(Except

RB20DE)

TCM does not receive proper manual mode switch signal due to

open and/or short circuit. Manual

mode switch circuit

ENGINE BRAKE

C/U'1

(Except

RB20DE)

Shift control unit does not operate properly due to open and/or

short circuit of each

input/output signal wire.

Malfunction occurs in shift control unit. Each

signal wire circuit connected

to shift control unit

'INITIAL START*

Power supply to TCM is shut down, and self-diagnostic memory

function is canceled due to battery removal, etc.

CONTROL UNIT (RAM)

I Malfunction is detected in TCM memory (RAM) function.

CONTROL

UNIT

(ROM)

I Malfunction is detected in TCM memory (ROM) function.

'1 : Indicates shift control unit.

DATA MONITOR PROCEDURE

Refer to "CONSULT Instruction Manual - Supplement" and "CON-

SULT Service Manual

- Supplement" in details.

1. Turn ignition switch OFF.

2. Connect CONSULT connector to data link connector.

3. Turn ignition switch ON.

4. Touch "START', ''AT and "DATA MONITOR" sequentially on

CONSULT screen.

Page 73 of 230

![NISSAN GT-R 1998 Manual PDF

TROUBLE DIAGNOSES

CONSULT (Contd)

DATA MONITOR MODE (M)

1 I Monitor item

I

tem Display ECU

input Main

signals

-

Description Remarks

signals

VHCUS

SE.AT

[kmlh] or [mph]

I-

Vehicl NISSAN GT-R 1998 Manual PDF

TROUBLE DIAGNOSES

CONSULT (Contd)

DATA MONITOR MODE (M)

1 I Monitor item

I

tem Display ECU

input Main

signals

-

Description Remarks

signals

VHCUS

SE.AT

[kmlh] or [mph]

I-

Vehicl](/img/5/57354/w960_57354-72.png)

TROUBLE DIAGNOSES

CONSULT (Cont'd)

DATA MONITOR MODE (M)

1 I Monitor item

I

tem Display ECU

input Main

signals

-

Description Remarks

signals

VHCUS

SE.A'T

[kmlh] or [mph]

I-

Vehicle speed computed from When

racing engine in "Nn or "P" signal of revolution sensor is position

with vehicle stationary,

displayed. CONSULT

data may not indicate

0 kmlh (0 mph).

Vehicle speed computed from Vehicle

speed display may not be

signal of vehicle speed sensor accurate under approx. 10 kmlh

is displayed. (6 mph). It may not indicate 0

kmlh (0 mph) when vehicle is sta-

tionary.

Throttle position sensor signal

voltage is displayed.

AlT fluid temperature sensor

signal voltage is displayed.

Signal voltage lowers as fluid

temperature rises.

Source voltage of TCM is dis-

played.

Engine speed, computed from Engine speed display

may not be

engine speed signal, is

dis- accurate under approx. 800 rpm.

played. It

may not indicate

0 rpm even

when engine is not running.

Turbine revolution computed Error

may occur under approx.

from signal of turbine revolution 800 rpm and will not indicate

0

sensor is displayed. rpm even if engine is not running.

ONIOFF state computed from

signal of overdrive control SW

is displayed.

ONIOFF state computed from

signal of PIN position SW is

displayed.

ONIOFF state computed from

signal of

R position SW is dis-

played.

ONIOFF state computed from

signal of D position SW is dis-

played.

ONIOFF status, computed from

signal of 2 position SW, is dis-

played.

signal of

1 position SW, is dis-

displayed. ASCD is mounted.

ON

... Cruising state

OFF ... Normal running state

Vehicle

speed sensor

1 (All) (Revolution sensor)

Vehicle speed sensor

2 (Meter) VHCUS SE,MTR

[kmk] or

[rnph]

Throttle position sensor

ITHRTLPOS SEN

I ,

AT fluid temperature sensor

PI

FLUID TEMP SE

Battery voltage

A

Engine speed ENGINE SPEED

[rpml

Turbine revolution sensor

TURBINE REV

[rpml

I

Overdrive control switch

OVERDRIVE SW

[ONIOFFJ

I

PIN position switch

PIN POSI SW

[ONlOFF]

R position switch

R POSITION SW

[OWOFF]

I

2 position switch

1

2 POSITION SW

[ONIOFF]

I

D position switch

1 position switch 1 POSITION SW

[ONIOFF]

I

D POSITION SW

[ON/OFF] X

ASCD OD cut signal

ASCD.OD CUT

[ONIOFF]

X

ASCD cruise signal

Status of ASCD OD release

signal is displayed.

ON

... OD released

OFF ... OD not released

ONIOFF status, computed from

signal of

kickdown SW, is dis-

played.

ONIOFF status, computed from

signal of HOLD shift SW, is dis-

played.

ONIOFF status, computed from

signal of closed throttle position

SW, is displayed.

ONIOFF status, computed from

signal of wide open throttle

position SW, is displayed.

ASCD.CRUISE

[ONIOFF]

This

is displayed even when no

ASCD is mounted.

This is displayed even when no

kickdown switch is equipped.

Kickdown

switch

KICKDOWN

SW

[ONIOFq

Wide open throttle position switch X .

X A/T mode switch

t

WIO THRUP-SW

[ONIOFq POWERSHIFT SW

[ONIOFF]

Closed

throttle position switch

, CLOSED THUSW

[ONIOFF]

Page 74 of 230

TROUBLE

CONSU (Cont'd)

I Monitor item

Display input

signals Main

signals

-

Description Remarks

Indicates check signal (reen-

trant signal) status for TCM

control signal output.

ONIOFF

status of shift solenoid is not

changed when thermal insula-

tion or short-circuit occurs in

these valves.

Shift solenoid A SHlFT

SN A

Shift solenoid

B [ONIOFF]

OVRRUNIC SN

- [ONOFF]

Overrun

clutch solenoid

OVRRUN/C SN2

- [ONIOFF]

HOLD SW

[ONIOFFI

X

MANU MODE SW

[ONIOFFJ

NONM MODESW

[ONIOFF]

UP SW

[ONOFF]

X

DOWN SW

[ON/OFFl X

NON SHlFT SW - [ONlOFF]

Overrun

clutch solenoid

2 (Excep

RB20DE)

HOLD!SNOW

switch

A/T mode switch - SNOW mode

1 Gate side contact in mznual

mode switch

Manual

mode switch (Except

RB20DE)

- Non-gate side contact in

manual mode switch

UP (+) side contact in manual

mode switch

Non-manual

mode switch (Excepi

RB20DE)

UP switch (Except

RB20DE)

DOWN (-) side contact in

manual mode switch

DOWN

switch (Except

RB20DE)

Non-shift switch (Except

RB20DE)

Brake switch

I Stop lamp switch

BRAKE SW

[OWOFF] I

Shift solenoid A pressure detec-

tion switch

Gear position data used for

computation by TCM, is dis-

played.

Selector lever position data, A specific value used for control

used for computation by TCM, is

displayed if fail-safe is

acti-

is displayed. vated

due to error.

Vehicle speed data, used for

computation by TCM, is dis-

played.

- -- Shift solenoid valve A (P switch)

(Except

RB20DE) SHlFT

SN A

Gear position

- --- - - Selector lever position SLCT

LVR POSl

I -

VEHICLE

SPEED

[kmlh] or [mph]

I -

Vehicle speed

THROTTLE POSl

Throttle position data, used for A specific value used for control

computation by TCM, is

dis- is displayed if fail-safe is acti-

played. vated due to error.

Throttle

position

- - Control value of line pressure

solenoid valve, computed by

TCM from each input signal, is

displayed.

Control value of torque con-

verter clutch solenoid valve,

computed by TCM from each

input signal, is displayed.

Line

pressure duty LINE

PRES

DTY I

-- Torque converter clutch soienoid

valve duty TCC

SN DUTY I

Shift solenoid valve A .-control value of shift solenoid Control value

of solenoid is dis-

valve A, computed by TCM played even

if solenoid circuit is

from each input signal, is

dis- disconnected.

. - played. The

"OFF signal is displayed if

Control value of shift solenoid solenoid circuit is shorted.

Shift solenoid valve El SHIFT SN B I valve 6, computed by TCM

from each input signal, is dis-

played.

Control value of overrun clutch

solenoid valve computed by

TCM from each input signal is I OVERRUNIC SN I Overrun clutch solenoid valve

displayed.

D Control status of TCM power

>OWER

SFT

LMP

Power shift lamp

shift lamp

-- - Voltage

- Pulse

X: Applicable

-: Not applicable

Page 75 of 230

TROUBLE DIAGNOSES

Self-diagnosis

DESCRIPTION

If malfunction should occur in electrical systems, turning ignition switch ON lights M mode switch POWER

indicator lamp

(M-AT Dual matic AfT warning lamp) for 2 seconds, and then flashes the indicator lamp for 8 Gc

seconds. If malfunction does not occur, A/T mode switch POWER indicator lamp (M-AT Dual matic A/T warn-

ing lamp) is turned on for

2 seconds upon turning ignition switch ON. To locate and display the malfunction-

ing part, output the trouble information memory and flash

A/T mode switch POWER indicator lamp (M-AT Dual

matic

A/T warning lamp) by inputting self-diagnostic startup signal.

SELF-DIAGNOSIS PROCEDURE

1. Warm up engine.

2. Repeat ON-OFF cycles of ignition switch for more than once, and turn it OFF at last.

3. Move A/T mode switch to AUTO, and turn overdrive control switch to O/D ON.

4. Turn ignition switch ON with selector lever in "Pn position, and ensure POWER indicator lamp is turned on

for

2 seconds.

5. Turn ignition switch OFF.

6. Move selector lever to "D" position.

7. Turn overdrive control switch O/D OFF.

8. Turn ignition switch ON.

9. Move selector lever to "2" position.

10. Turn overdrive control switch OID ON.

11. Move selector lever to "I" position.

12. Turn overdrive control switch O/D OFF.

13. Depress accelerator pedal fully, and release it.

14. Read flashing status of POWER indicator lamp to complete self-diagnosis procedures.

M-AT

1. Warm up engine.

2. Repeat ON-OFF cycles of ignition switch for more than once, and turn it OFF at last.

3. Turn ignition switch ON with selector lever in "P" position, and ensure dual matic PJT warning lamp is turned

on for

2 seconds.

4. Turn ignition switch OFF.

5. Depress brake pedal, release accelerator pedal, and then move selector lever to "D" position.

6. Turn ignition switch ON.

7. Release brake pedal, and move selector lever to "3" position.

8. While depressing brake pedal with left foot, depress accelerator pedal fully with right foot, and move

selector lever to

"2" position.

9. Read dual matic A/T warning lamp indication to complete self-diagnosis procedures.

Page 76 of 230

TROUBLE DIAGNOSES

Self-diagnosis (Cont'd)

\ I1 // \ 11 // =-I= or =mj= // 11 \ // 11 \

1, = 2.5 sec. t, = 2.0 sec. t, = 1.0 sec.

RB20DE 10 judgement flashes.

Stan signal Malfunctioning unit and circuit I

Except RBPODE 13 judgement flashes.

signal Malfunctioning unit and circuit I

POWER INDICATOR LAMP OR DUAL MATIC A/T

WARNING LAMP INDICATION

If malfunction occurs in electrical system, indicator lamp stays on

longer at corresponding circuit.

Flashing

order

t5 1 Overrun clutch solenoid

1

2

3

4

5

7 1 Lock-up solenoid

Malfunctioning

unit and circuit

Vehicle speed sensor

1

Vehicle speed sensor 2

Throttle position sensor

Shift solenoid

A

Shift solenoid B

I

W fluid temperature sensor, TCM power supply, or throttle posi-

tion sensor power supply

RB20DE

9 1 Engine speed

signal Except

RB20DE

10 1 Line

pressure solenoid I Turbine sensor

I - I Line pressure solenoid

12 1 - I Total control signal

When indicator lamp repeats flashing in 4 Hz, the following malfunctions

may exist: (Insufficient memory backup

powerflCM repiacement1Battery

has been disconnected for prolonged

periodllow battery power)

13

No flashes

HOW TO ERASE SELF-DIAGNOSTIC RESULTS

To facilitate cause investigation of malfunction that is less likely to

reappear, the TCM always stores self-diagnostic results during cus-

tomer operation. This memory cannot be erased even if ignition

switch

is turned ON and OFF repeatedly. To erase the seif-diag-

nostic

results, turn ignition switch

OFF after self-diagnosis has

been performed, or use

"ERASE" function of CONSULT.

- - - - Shift control unit

PNP switch, idle

switch/full switch

Overdrive control switch Stop lamp switch

Page 77 of 230

TROUBLE DIAGNOSES

Symptom Chart

Sharp shock in Engine brake

applied

Shifting

Malfunctions

Slip

(Racing)

hifting

.- erator pedal

Shifting

Shifting

inspection item

Fluid level and status

Control linkage

PNP switch (short/open circuit)

Throttle ~osition sensor (installed)

I Vehicle weed sensor

I Enaine meed sensor

A/T fluid temperature sensor

Engine idle speed

Line

Dressure

Control valve assembly

Shift solenoid

A

Shift solenoid B

Line pressure solenoid

Lock-up solenoid

Overrun clutch solenoid

Accumulator N-D

Accumulator

1-2

Accumulator 2-3

Accumulator 3-4 (N-R) Ignition coil and starter motor

Overdrive control switch

I AfT mode switch (AUTO)

Torque converter

1 Oil pump

I Reverse clutch

I High clutch

I Forward clutch

I Forward one-wav clutch

I Overrun ciutch

1 Low one-wav clutch

I Low reverse brake

Brake. band (including servo)

Parking linkage

Page 78 of 230

Symptom Chart (Cont'd)

Greater noise

Malfunctions

Inspection item No shifting

I Shifting I

Fluid level

and status 11

Control linkage

-

(I) C 0 .- c. .- (I) 0 a

v

-CU

n - 1

PNP switch

(shortlopen

circuit)

Throttle position sensor (installed)

2 2

Vehicle speed sensor

I Engine speed sensor -

-T

L o 1 Control valve assembly .- - -- Shift solenoid A 4 3

. ' Shift solenoid 6 4 cut I1

--, Line pressure solenoid .- 5 -t Lock-up solenoid ?

6 Overrun clutch solenoid 3

Accumulator N-D

1 Accumulator 1-2 I 1-

Accumulator 2-3

Accumulator 3-4 (N-R)

Ignition coil and starter motor

I Overdrive control switch I 1-

A/T mode switch (AUTO)

A/T mode switch (POWER) I - I Ail mode switch (SNOW) I

I Torque converter I I

1 Oil pump I I -- - - Reverse clutch 0 -

'g High clutch a 4 6

%I Forward clutch I I - .- a Forward one-way clutch -

$ Overrun clutch a, 8

Low one-way clutch

O Low reverse brake 7

Brake band (including servo) 7

Parking linkage

Page 79 of 230

TROUBLE DIAGNOSES

Symptom Chart (Cont'd)

xi - - ([I C V) a, C .- cn C W

t 0 .- .L 2 a, - 8 0 ([I L 0 0 Q

& 0 a, a, Q V)

5 E .- X

i! L a

zl -I - 1 -

- 2 -

-

-

-

-

-

5 - 3 - 4 -

-

-

-

-

-

-

-

-

-

-

-

-

I1 - 0 - 6 - 7 -

-

-

-

-

9 - 8 -

-

vj c 0 .- - .- V) 0 n

Q 7J C ([I

t C .- r ([I c. V) c. 0 C V) a 0 7J 0, C .- 0 C W -

- 2 - 3 -

-

- -

-

1 -

-

-

-

- - a +- ([I a a, 2 0 c. 0 C V) a, 0 u a, - 0 2

8 - 1 -

-

-

-

-

-

-

-

2 - 3 -

-

-

-

-

-

-

-

-

-

-

- I

i

g

- 4 -

-

-

-

-

-

-

B- ; 2 to a =? - 0,

2 5.j c 2.z 2 a0 - 0- z & 5 0 gE V) V)o C 02 .s nu 5 ng %-([I C O c --t .- V) a V) r aa ([I z gz a, a- c 50 -6 s

6 $2

11

2

I

I

Malfunctions

Inspection item

I I I Fluid level and status I I Control linkage 2

PNP switch (shortfopen circuit) 1 I I I Throttle position sensor (installed) 111213

Vehicle speed sensor

214

Engine speed sensor L -

AIT fluid temperature sensor

Engine idle weed

Line pressure

Control valve assembly

Shift solenoid A 3

3

Shift solenoid B 4 4

Line pressure solenoid

Lock-up solenoid

Overrun clutch solenoid

u I I I -

Accumulator N-D I I 1 I Accumulator 1-2

Accumulator 2-3 I Accumulator 3-4 (N-R)

Ignition coil and starter motor

Overdrive control switch

Torque converter

tg Reverse clutch .- High clutch

2 Forward clutch C .- a Forward one-way clutch -.

$ Overrun clutch 0, 8

? Low one-way clutch 3= O Low reverse brake 9

Brake band (including servo)

Parking linkage

Page 80 of 230

BRAKE SYSTEM

SECTION B R

CONTENTS

ANTI-LOCK BRAKE SYSTEM ........................................ 2

Fail-safe Function ........................................................ 2

System Diagram .......................................................... 2

Circuit Diagram ............................................................ 3

Component Parts Location .......................................... 4

Control Unit Input/Output Signal Specifications .......... 5

Precautions for Trouble Diagnosis ..... ......................... 7

Basic Inspection ........................................................... 7

CONSULT

.................................................................... 8

Self-diagnosis ...... .. . .. .. .... . . .. . . .. .. .. . . . ..... . .. . . .... .. .. . . ... .. . . -14

TCSIABS SYSTEM ........................................................ 17

System Description.

.. ............................... .................. 17

System Diagram

..................... . .................................. 1 8

Component Parts Location ........................................ 19

Circuit Diagram .......................................................... 20

Control Unit InpuVOutput Signal Specifications .. ...... 21

Precautions for Trouble Diagnosis

............................ 26

Basic Inspection.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -26

CONSULT for TCS/ABS Control Unit Control

System

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -27

Self-diagnosis for TCSfABS Control Unit Control

System

. . . . . . . . . . .. . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ... . -34

CONSULT for Throttle Control Unit Control

System

. ... ... . .... . . . .. . . . .. . ... . . ... . .. . . . . . . .. . . . ... ... . . .. . . .. . . . .. . . . . .. -37

Self-diagnosis for Throttle Control Unit Control

System

. .. . . . . . . .. ... . .. . . . .. .. .. . . . . . . .. .. . . . ... . . . . . . . .. . . .. . . .. . . . . . . ... . . -41