NISSAN LATIO 2009 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2009, Model line: LATIO, Model: NISSAN LATIO 2009Pages: 4331, PDF Size: 58.04 MB

Page 3001 of 4331

PBIC3722E

Page 3002 of 4331

EM

NP

O

5. Check matching mark position of timing chain and each sprocket again.

6. Install the front oil seal to the front cover. Refer to EM-77, " FRONT OIL SEAL : Removal and Installation "

7. Install front cover with the following procedure:

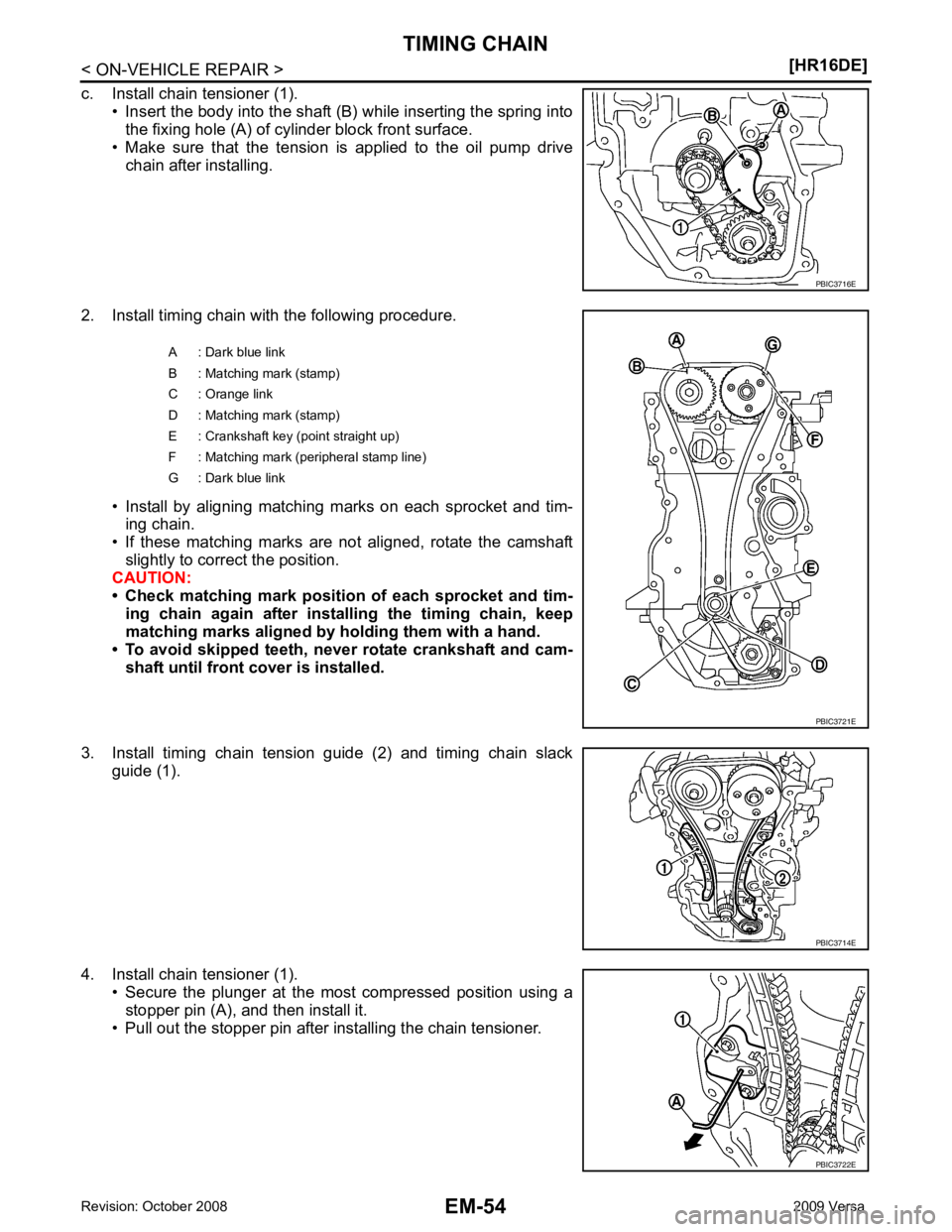

a. Apply a continuous bead of liquid gasket with Tool to front cover as shown.

Use Genuine Silicone RTV Seal ant or equivalent. Refer to

GI-42, " Recommended Chemical Product and Sealant " .

b. Apply a continuous bead of liquid gasket with Tool to front cover as shown.

Use Genuine Silicone RTV Seal ant or equivalent. Refer to

GI-42, " Recommended Chemical Product and Sealant " .

1 : Cylinder head

2 : Cylinder block

3 : Oil pan (upper)

A : Liquid gasket application φ 3.0 - 4.0 mm (0.12 - 0.16 in) dia.

Tool number : WS39930000 ( — )

Page 3003 of 4331

![NISSAN LATIO 2009 Service Repair Manual EM-56< ON-VEHICLE REPAIR >

[HR16DE]

TIMING CHAIN

c. Tighten bolts in the numerical order shown.

d. After all bolts are tightened, retighten them to specified torque in numerical order as shown.

CAUTIO NISSAN LATIO 2009 Service Repair Manual EM-56< ON-VEHICLE REPAIR >

[HR16DE]

TIMING CHAIN

c. Tighten bolts in the numerical order shown.

d. After all bolts are tightened, retighten them to specified torque in numerical order as shown.

CAUTIO](/img/5/57359/w960_57359-3002.png)

EM-56< ON-VEHICLE REPAIR >

[HR16DE]

TIMING CHAIN

c. Tighten bolts in the numerical order shown.

d. After all bolts are tightened, retighten them to specified torque in numerical order as shown.

CAUTION:

Be sure to wipe off any excessive liquid gasket leaking to

surface.

8. Insert crankshaft pulley by aligning with crankshaft key. • When inserting crankshaft pulley with a plastic hamme r, tap on its center portion (not circumference).

CAUTION:

Never damage front oil seal lip section.

9. Tighten crankshaft pulley bolt with the following procedure: • Secure crankshaft pulley with a suitable tool, and tighten crankshaft pulley bolt.

a. Apply new engine oil to thread and seat surfaces of crankshaft pulley bolt.

b. Tighten crankshaft pulley bolt.

c. Put a paint mark (B) on crankshaft pulley, mating with any one of six easy to recognize angle marks (A) on crankshaft bolt flange

(1).

d. Turn another 60 degrees clockwise (angle tightening). • Check the tightening angle with movement of one angle mark.

10. Make sure that crankshaft turns smoothly by rotating by hand clockwise.

11. Installation of the remaining components is in the reverse order of removal.

Inspection INFOID:0000000004784298

INSPECTION AFTER REMOVAL

Timing Chain KBIA3429J

Crankshaft pulley bolt : 35.0 N·m (3.6 kg-m, 26 ft-lb)

PBIC3726E

Page 3004 of 4331

EM

NP

O

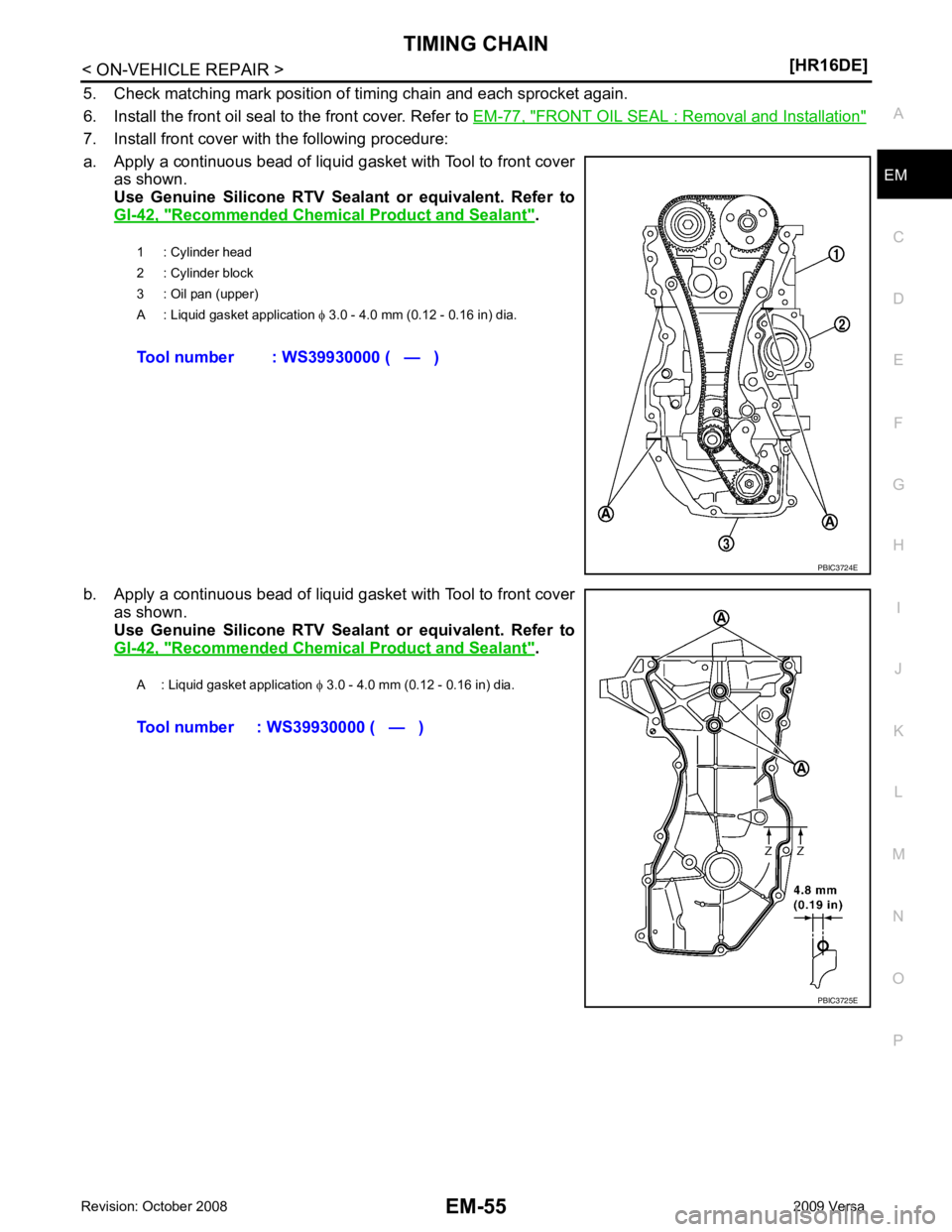

Check for cracks (A) and any excessive wear (B) at link plates and

roller links of timing chain. Replace timing chain as necessary.

INSPECTION AFTER INSTALLATION

Inspection for Leaks • Before starting engine, check oil/fluid levels incl uding engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer to MA-14, " Fluids and Lubricants " .

• Use procedure below to check for fuel leakage.

- Turn ignition switch “ON” (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leak-

age at connection points.

- Start engine. With engine speed increased, check again for fuel leakage at connection points.

• Run engine to check for unusual noise and vibration. NOTE:

If hydraulic pressure inside chain tensioner drops after removal/installation, slack in guide may generate a

pounding noise during and just after the engine start. However, this does not indicate an unusualness. Noise

will stop after hydraulic pressure rises.

• Warm up engine thoroughly to make sure there is no leak age of fuel, or any oil/fluids including engine oil and

engine coolant.

• Bleed air from lines and hoses of applicable lines, such as in cooling system.

• After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to the specified level, if necessary.

Summary of the inspection items:

* Transaxle fluid, power steering fluid, brake fluid, etc.

Page 3005 of 4331

Rotation " .

2. Remove front fender protector (RH). Refer to EI-24, " Removal and Installation " .

3. Drain engine oil. Refer to LU-8, " Draining " .

CAUTION:

Be sure to perform this step when engine is cold.

4. Remove the following parts. • Intake manifold: Refer to EM-28, " Exploded View " .

• Drive belt: Refer to EM-15, " Removal and Installation " .

• Water pump pulley: Refer to CO-20, " Exploded View " .

• Ground cable (RH)

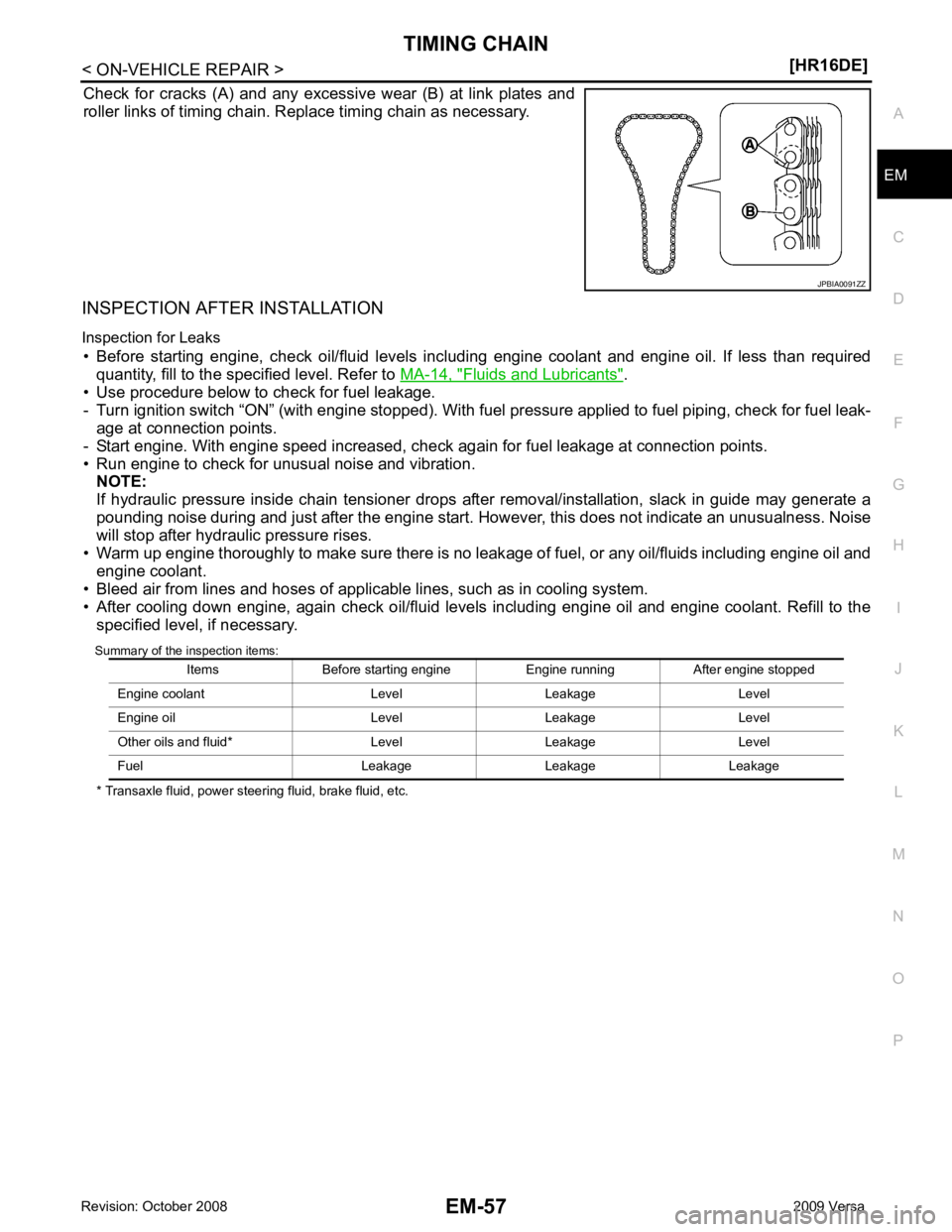

1. Camshaft bracket (No. 2 to 5) 2. Camshaft bracket (No.1) 3. Camshaft sprocket (EXH)

4. Camshaft sprocket (INT) 5. Cylinder head 6. Oil filter (for intake valve timing control)

7. Washer 8. Plug 9. Intake valve timing control solenoid valve

10. O-ring 11. O-ring 12. Camshaf t position sensor (PHASE)

13. Valve lifter 14. Camshaft (INT) 15. Camshaft (EXH)

A. Refer to Installation procedure

Page 3006 of 4331

![NISSAN LATIO 2009 Service Repair Manual CAMSHAFT

EM-59

< ON-VEHICLE REPAIR >

[HR16DE] C

D E

F

G H

I

J

K L

M A EM

NP

O

5. Support the bottom surface of engine using a trans

mission jack, and then remove the engine mounting

bra NISSAN LATIO 2009 Service Repair Manual CAMSHAFT

EM-59

< ON-VEHICLE REPAIR >

[HR16DE] C

D E

F

G H

I

J

K L

M A EM

NP

O

5. Support the bottom surface of engine using a trans

mission jack, and then remove the engine mounting

bra](/img/5/57359/w960_57359-3005.png)

CAMSHAFT

EM-59

< ON-VEHICLE REPAIR >

[HR16DE] C

D E

F

G H

I

J

K L

M A EM

NP

O

5. Support the bottom surface of engine using a trans

mission jack, and then remove the engine mounting

bracket and insulator (RH). Refer to EM-88, " Exploded View " .

6. Remove rocker cover. Refer to EM-46, " Exploded View " .

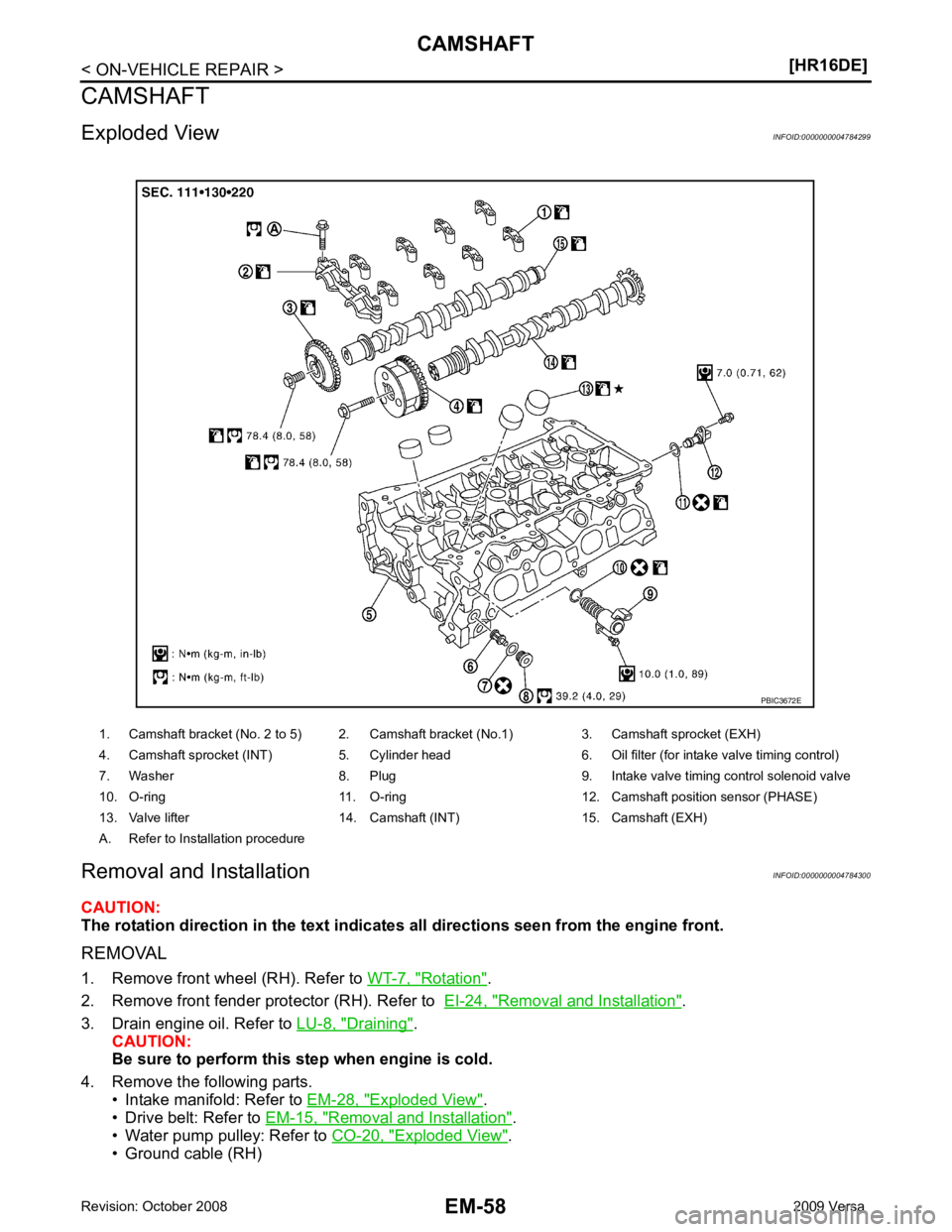

7. Set No. 1 cylinder at TDC of its comp ression stroke with the following procedure:

a. Rotate crankshaft pulley (2) clockwise and align TDC mark (without paint mark) (A) to timing indicator (1) on front cover.

b. Make sure the matching marks on each camshaft sprocket are positioned as shown.

• If not, rotate crankshaft pulley one more turn to align matching marks to the positions.

8. Remove crankshaft pulley with the following procedure:

a. Secure crankshaft pulley (1) using a suitable tool (A).

b. Loosen and pull out crankshaft pulley bolts. CAUTION:

Never remove the bolts as they are used as a supporting

point for the pulley puller.

c. Attach Tool (A) in the M 6 thread hole on crankshaft pulley, and remove crankshaft pulley.

9. Remove front cover with the following procedure: B : White paint mark (Not use for service) PBIC3673E

1 : Camshaft sprocket (EXH)

2 : Camshaft sprocket (INT)

A : Matching mark (stamp)

B : Matching mark (peripheral stamp line) PBIC3872E

PBIC3710E

B : M6 bolt

Tool number : KV11103000 ( — ) PBIC3711E

Page 3007 of 4331

![NISSAN LATIO 2009 Service Repair Manual EM-60< ON-VEHICLE REPAIR >

[HR16DE]

CAMSHAFT

a. Loosen bolts in the reverse of the order shown.

b. Cut liquid gasket by prying the position ( ) shown, and then remove the front cover.

10. Re NISSAN LATIO 2009 Service Repair Manual EM-60< ON-VEHICLE REPAIR >

[HR16DE]

CAMSHAFT

a. Loosen bolts in the reverse of the order shown.

b. Cut liquid gasket by prying the position ( ) shown, and then remove the front cover.

10. Re](/img/5/57359/w960_57359-3006.png)

EM-60< ON-VEHICLE REPAIR >

[HR16DE]

CAMSHAFT

a. Loosen bolts in the reverse of the order shown.

b. Cut liquid gasket by prying the position ( ) shown, and then remove the front cover.

10. Remove camshaft position sensor (PHASE) from rear end of cylinder head. CAUTION:

Handle it carefully and avoid impacts.

11. Remove camshaft sprocket (EXH) (1). CAUTION:

• Hold the camshaft hexagonal part (A), and then secure the

camshaft.

• Never rotate crankshaft and camshaft separately, so as not to contact valve with pist on in the following steps.

12. Turn the camshaft sprocket (INT) to the most advanced position. CAUTION:

Installation and removal of the camshaft sprocket (INT) must be done in the most advanced posi-

tion for the following reasons. KBIA3429J

PBIC3712E

AWBIA0102ZZ

Page 3008 of 4331

EM

NP

O

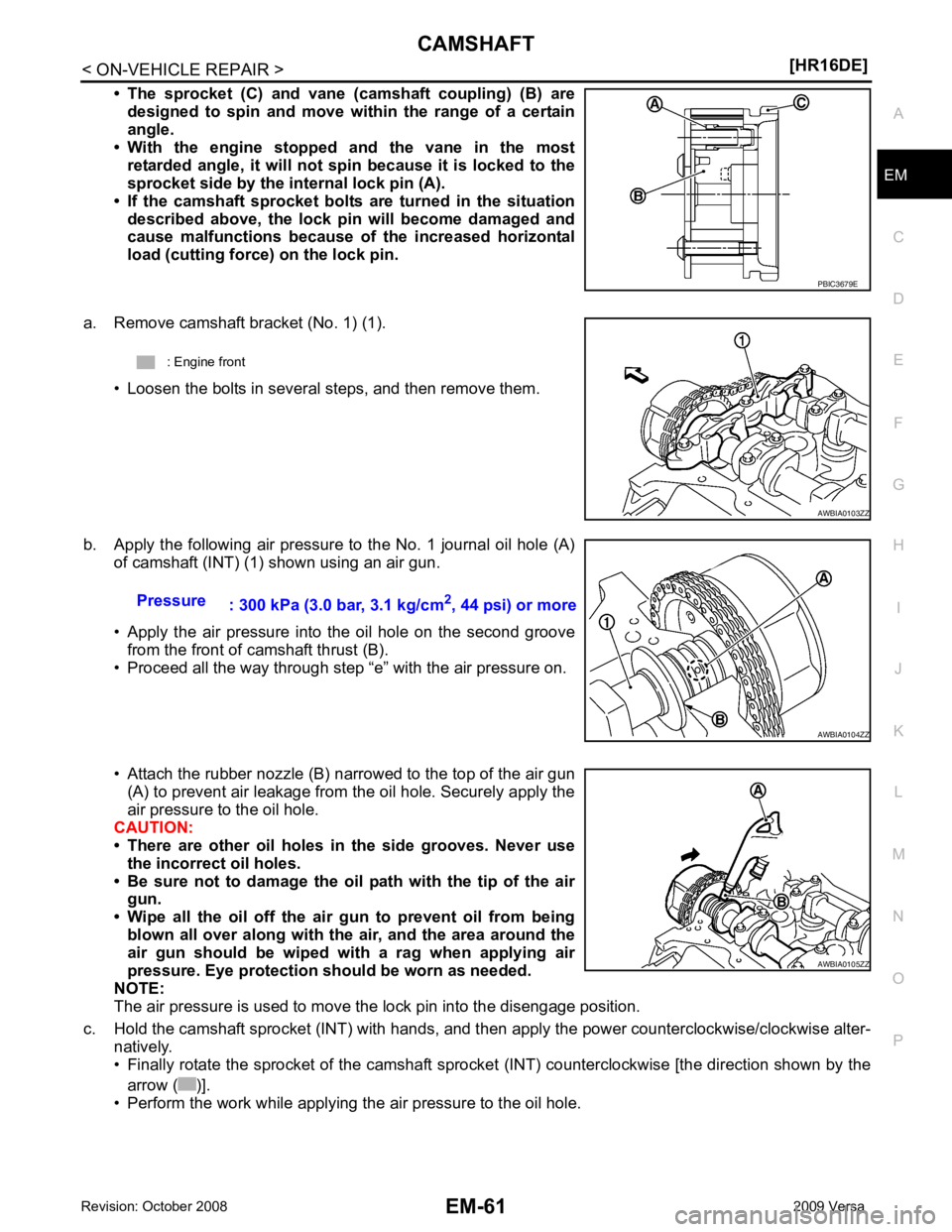

• The sprocket (C) and vane (camshaft coupling) (B) are

designed to spin and move wi thin the range of a certain

angle.

• With the engine stopped and the vane in the most

retarded angle, it will not sp in because it is locked to the

sprocket side by the internal lock pin (A).

• If the camshaft sprocket bolts are turned in the situation

described above, the lock pi n will become damaged and

cause malfunctions because of the increased horizontal

load (cutting force) on the lock pin.

a. Remove camshaft bracket (No. 1) (1). • Loosen the bolts in several steps, and then remove them.

b. Apply the following air pressure to the No. 1 journal oil hole (A) of camshaft (INT) (1) shown using an air gun.

• Apply the air pressure into the oil hole on the second groove from the front of camshaft thrust (B).

• Proceed all the way through step “e” with the air pressure on.

• Attach the rubber nozzle (B) narrowed to the top of the air gun (A) to prevent air leakage from the oil hole. Securely apply the

air pressure to the oil hole.

CAUTION:

• There are other oil holes in the side grooves. Never use

the incorrect oil holes.

• Be sure not to damage the oil path with the tip of the air

gun.

• Wipe all the oil off the air gun to prevent oil from being blown all over along with the air, and the area around the

air gun should be wiped wi th a rag when applying air

pressure. Eye protection should be worn as needed.

NOTE:

The air pressure is used to move the lock pin into the disengage position.

c. Hold the camshaft sprocket (INT) with hands, and then apply the power counterclockwise/clockwise alter-

natively.

• Finally rotate the sprocket of the camshaft sprocke t (INT) counterclockwise [the direction shown by the

arrow ( )].

• Perform the work while applying the air pressure to the oil hole. AWBIA0105ZZ

Page 3009 of 4331

Page 3010 of 4331

EM

NP

O

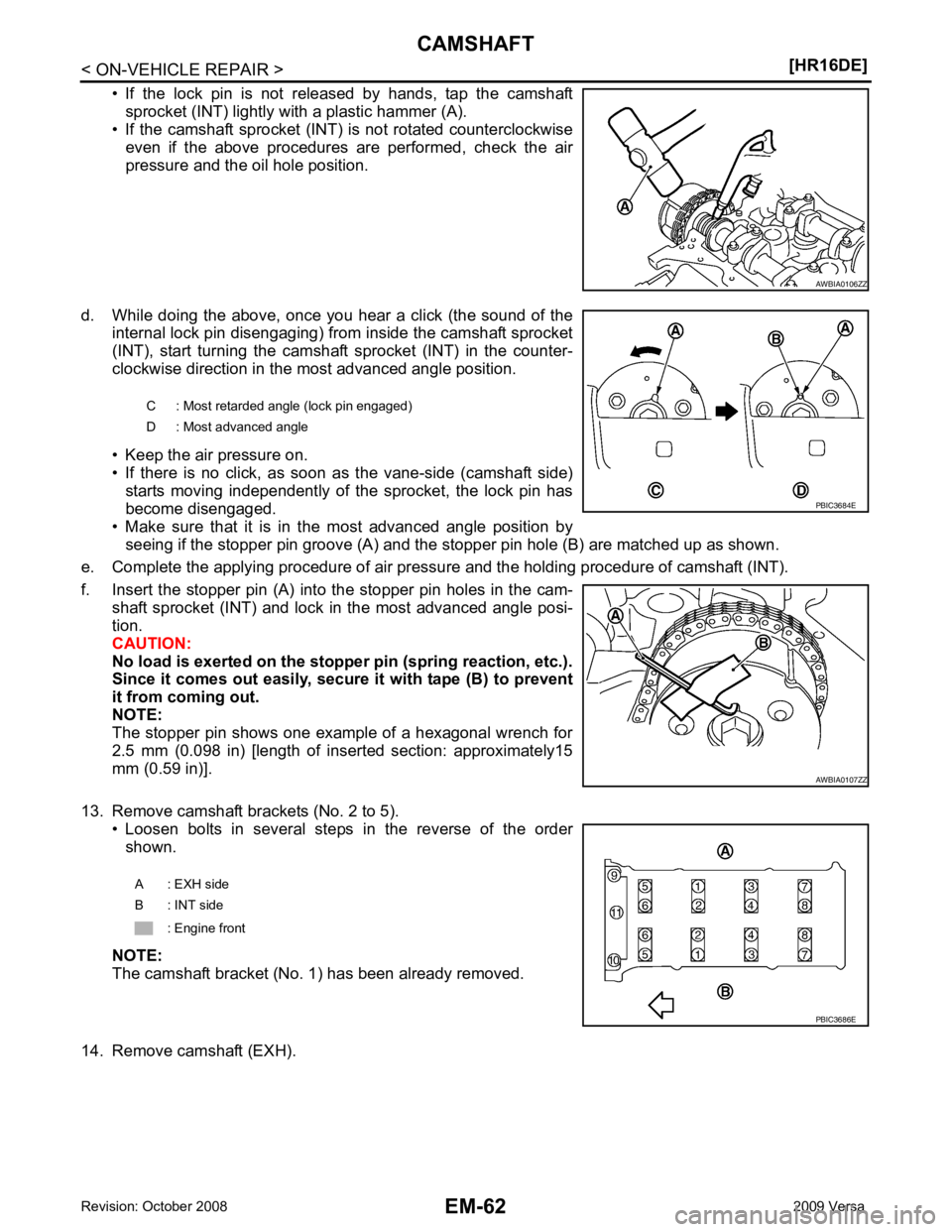

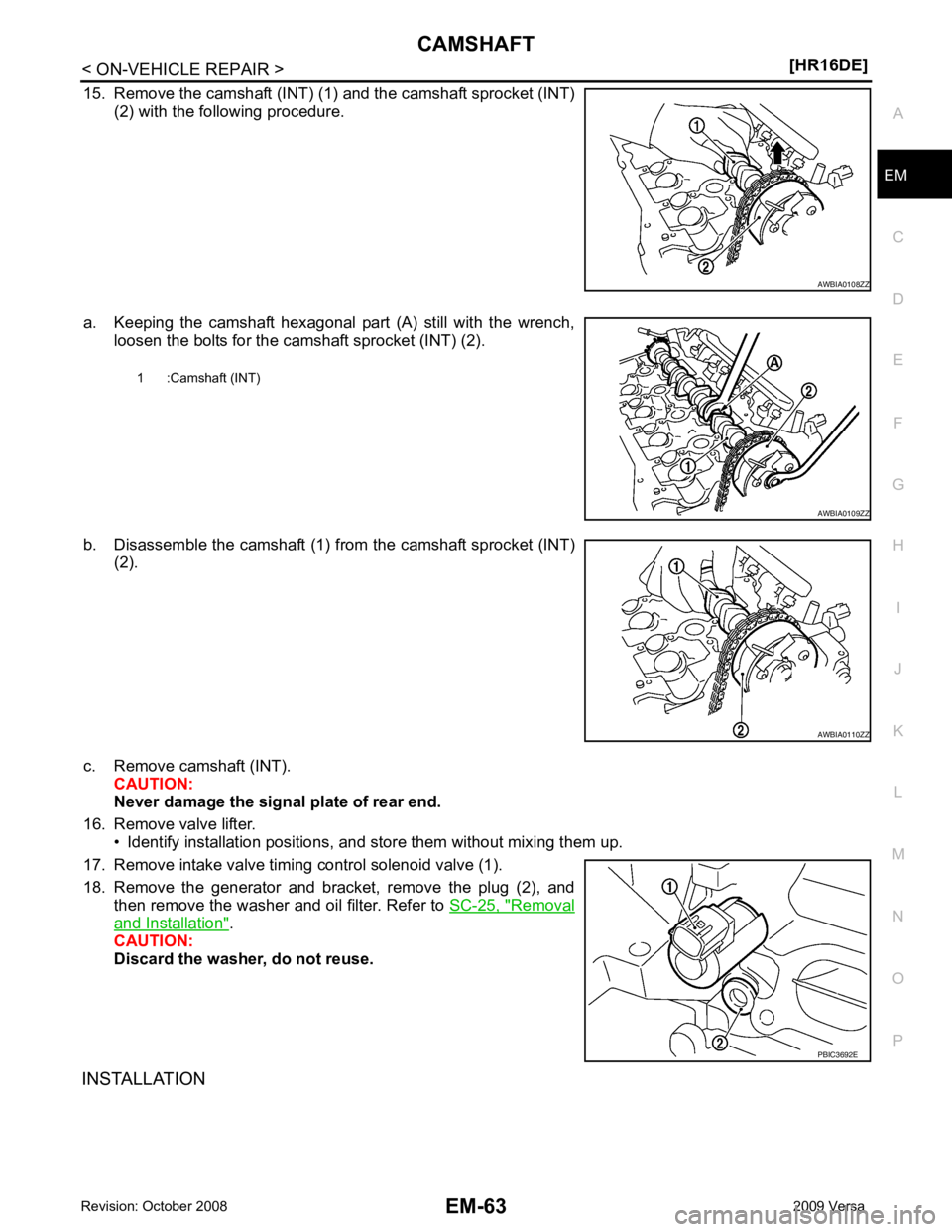

15. Remove the camshaft (INT) (1) and the camshaft sprocket (INT)

(2) with the following procedure.

a. Keeping the camshaft hexagonal part (A) still with the wrench, loosen the bolts for the camshaft sprocket (INT) (2).

b. Disassemble the camshaft (1) from the camshaft sprocket (INT) (2).

c. Remove camshaft (INT). CAUTION:

Never damage the signal plate of rear end.

16. Remove valve lifter. • Identify installation positions, and store them without mixing them up.

17. Remove intake valve timing control solenoid valve (1).

18. Remove the generator and bracket, remove the plug (2), and then remove the washer and oil filter. Refer to SC-25, " Removal

and Installation " .

CAUTION:

Discard the washer, do not reuse.

INSTALLATION AWBIA0110ZZ

PBIC3692E