NISSAN LATIO 2009 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2009, Model line: LATIO, Model: NISSAN LATIO 2009Pages: 4331, PDF Size: 58.04 MB

Page 2961 of 4331

Drive Belts " .

Page 2962 of 4331

![NISSAN LATIO 2009 Service Repair Manual DRIVE BELTS

EM-15

< ON-VEHICLE MAINTENANCE >

[HR16DE] C

D E

F

G H

I

J

K L

M A EM

NP

O

• When the lock nut is loosened excessively, the idle

r pulley tilts and the correct tension adju NISSAN LATIO 2009 Service Repair Manual DRIVE BELTS

EM-15

< ON-VEHICLE MAINTENANCE >

[HR16DE] C

D E

F

G H

I

J

K L

M A EM

NP

O

• When the lock nut is loosened excessively, the idle

r pulley tilts and the correct tension adju](/img/5/57359/w960_57359-2961.png)

DRIVE BELTS

EM-15

< ON-VEHICLE MAINTENANCE >

[HR16DE] C

D E

F

G H

I

J

K L

M A EM

NP

O

• When the lock nut is loosened excessively, the idle

r pulley tilts and the correct tension adjust-

ment cannot be performed. Never loo sen it excessively (more than 45 degrees).

• Put a matching mark on the lock nut, and check turning angle with a protractor. Never visually

check the tightening angle.

2. Adjust the belt tension by turning the adjusting bolt. CAUTION:

• When checking immediately after in stallation, first adjust it to the specified value. Then, after

turning crankshaft two turns or more, re-adjust to the specified value to avoid variation in deflec-

tion between pulleys.

• When the tension adjustment is performed, the lo ck nut should be in the condition at step“2”. If

the tension adjustment is performed when the lo ck nut is loosened more than the standard, the

idler pulley tilts and the correct tens ion adjustment cannot be performed.

3. Tighten the idler pulley lock nut.

Removal and Installation INFOID:0000000004784271

REMOVAL 1. Loosen the idler pulley lock nut (A), and then adjust the belt ten- sion by turning the adjusting bolt (B).

2. Remove drive belt.

INSTALLATION 1. Pull the idler pulley in the loosening direction, and then tempo- rarily tighten the idler pulley lock nut (A) to the following torque.

NOTE:

Do not move the lock nut from the tightened position. Proceed to step “2”.

2. Install the drive belt to each pulley. CAUTION:

• Make sure that there is no oil, grease, or coolant, etc. in pulley grooves.

• Make sure that the belt is securely inside the groove on each pulley.

3. Adjust drive belt tension by turning the adjusting bolt. Refer to EM-14, " Tension Adjustment " .

CAUTION: Idler pulley lock nut : 34.8 N·m (3.5 kg-m, 26 ft-lb)

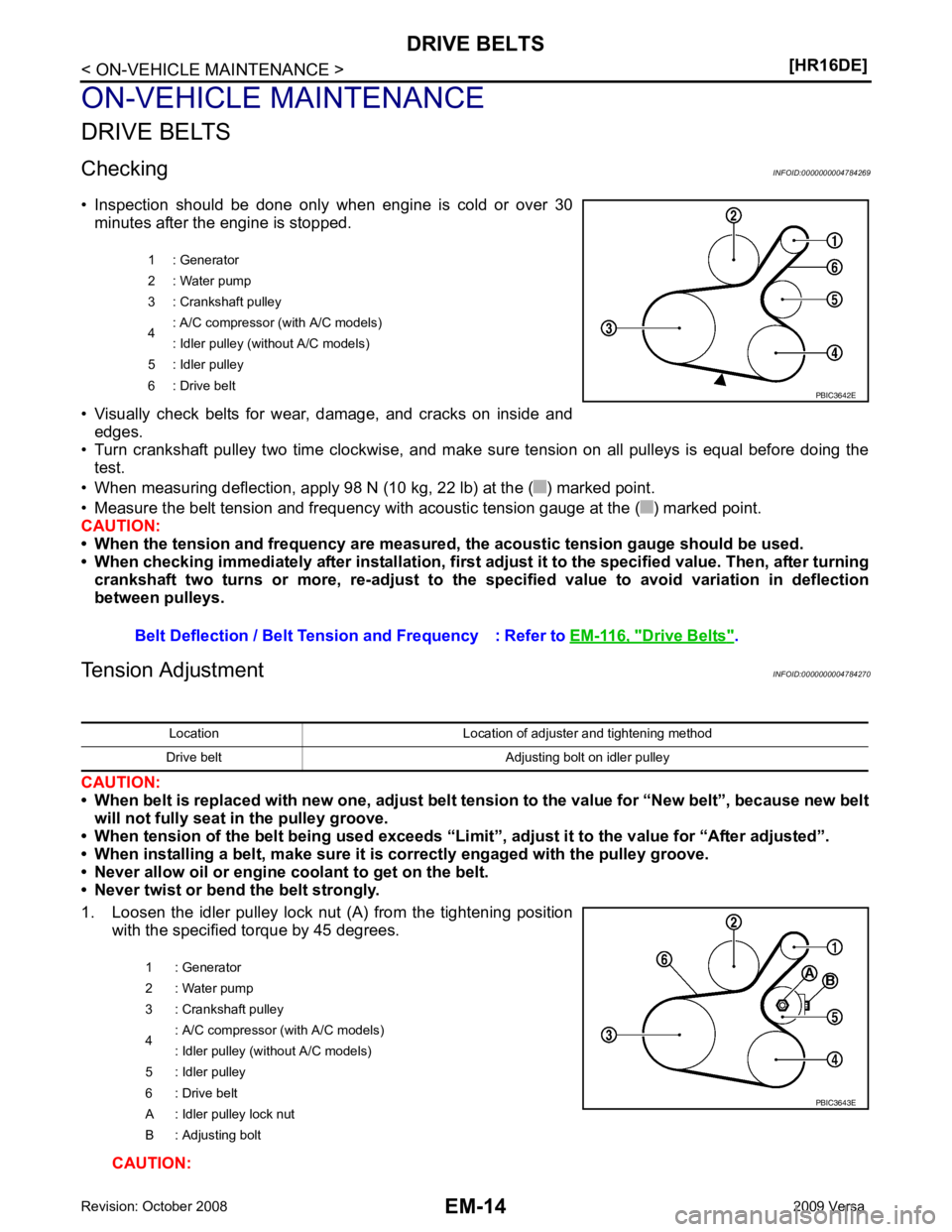

1 : Generator

2 : Water pump

3 : Crankshaft pulley

4 : A/C compressor (with A/C models)

: Idler pulley (without A/C models)

5 : Idler pulley

6 : Drive belt PBIC3643E

1 : Generator

2 : Water pump

3 : Crankshaft pulley

4 : A/C compressor (with A/C models)

: Idler pulley (without A/C models)

5 : Idler pulley

6 : Drive belt

B : Adjusting bolt

Idler pulley lock nut : 4.4 N·m (0.45 kg-m, 39 in-lb)

(temporary tightening) PBIC3643E

Page 2963 of 4331

Page 2964 of 4331

EM

NP

O

AIR CLEANER FILTER

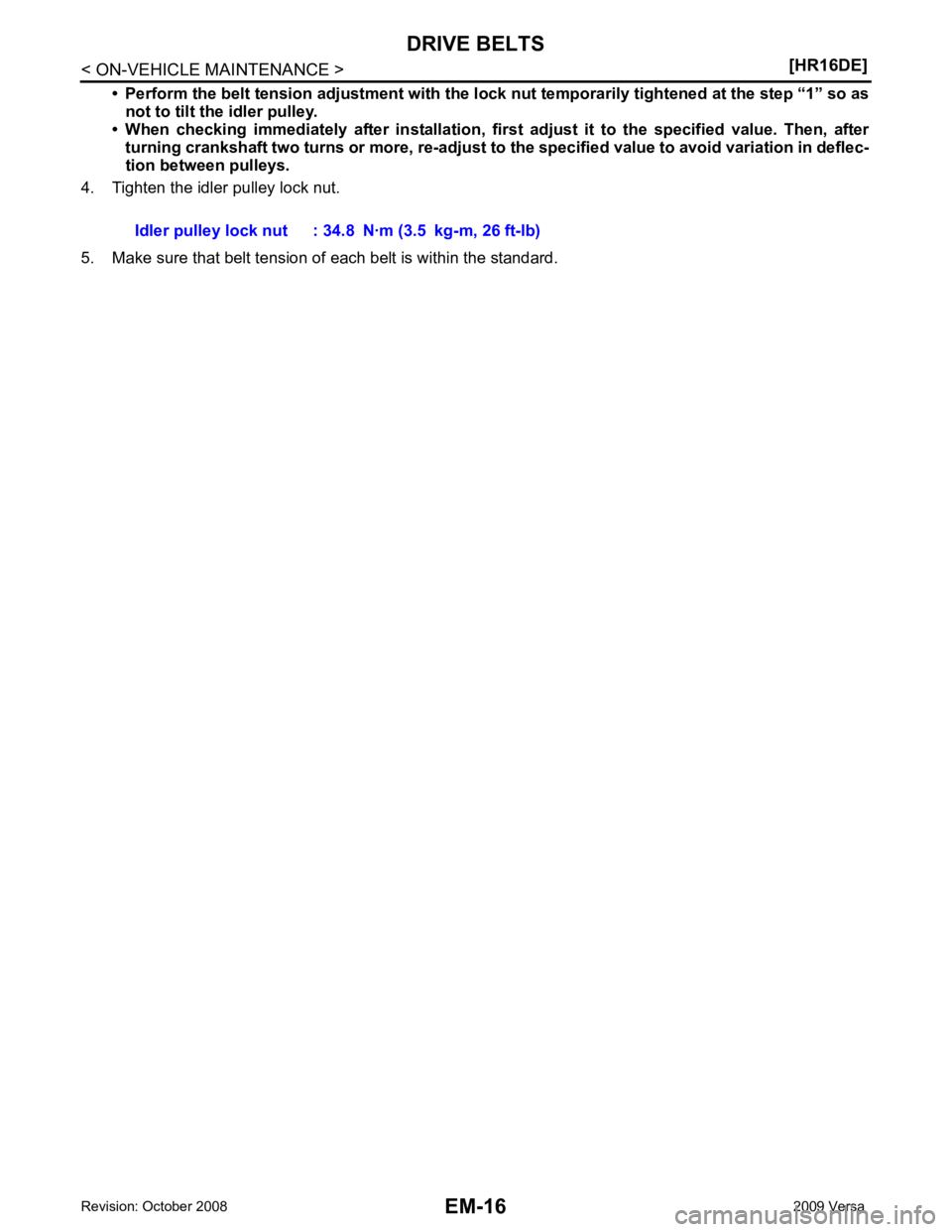

Removal and Installation INFOID:0000000004784272

REMOVAL 1. Push the tabs (A) of both ends of the air cleaner cover (1) into the inside (B).

2. Pull up the air cleaner cover (1) and remove it (C).

3. Remove air cleaner filter (1) and holder (2) assembly from the air cleaner case.

4. Remove the air cleaner filter (1) from the holder (2).

INSPECTION AFTER REMOVAL It is necessary to replace the air cleaner filter at the recommended intervals, more often under dusty driving

conditions. Refer to MA-9, " Introduction of Periodic Maintenance " .

INSTALLATION Installation is in the reverse order of removal.

• Install the air cleaner cover (1) in the direction shown.

• Air cleaner filter (2)

• Holder (3) PBIC3558J

Page 2965 of 4331

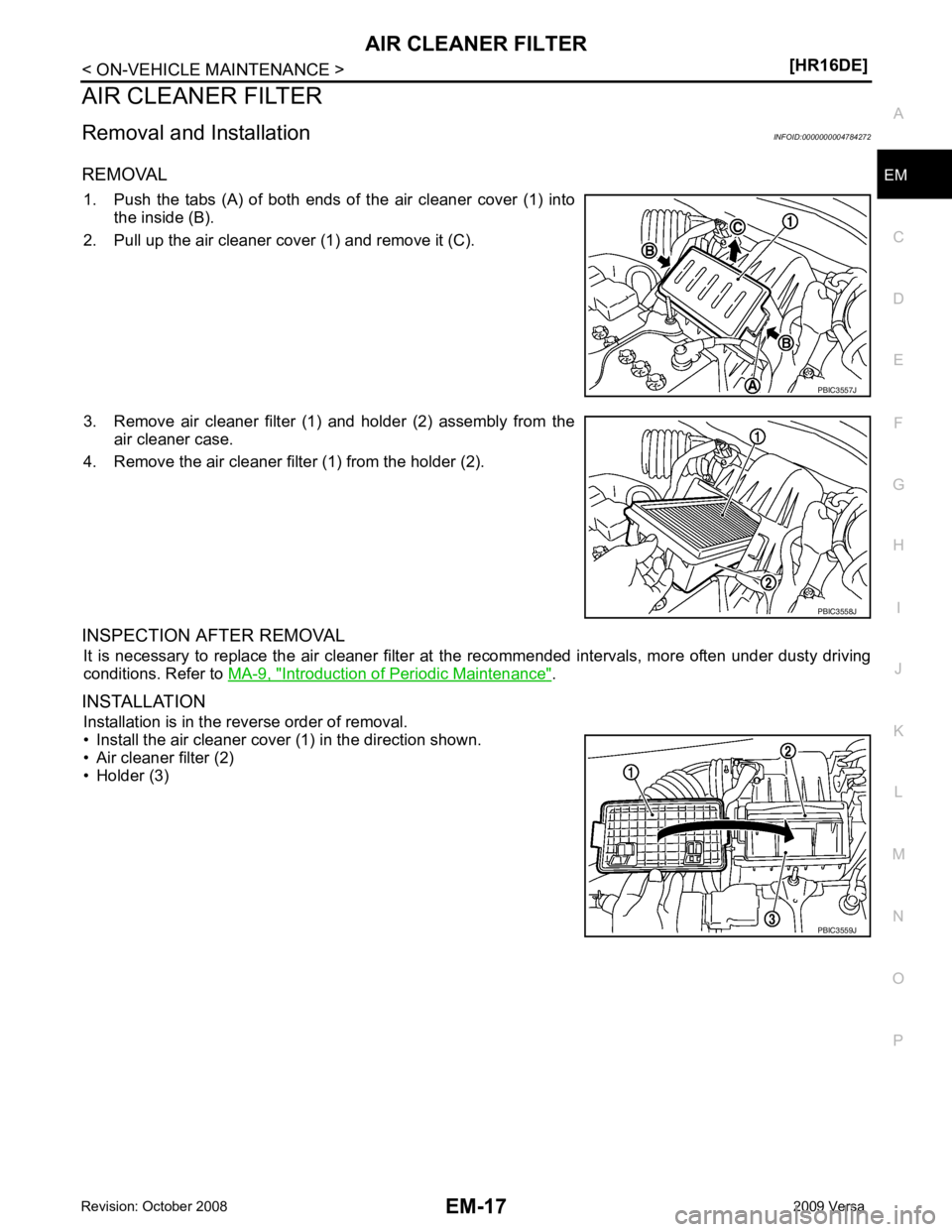

Removal and Installation " .

2. Remove ignition coil. Refer to EM-46, " Removal and Installation " .

3. Remove spark plug with a suitable tool.

INSPECTION AFTER REMOVAL

CAUTION:

• Never drop or shock spark plug.

• Never use a wire brush for cleaning.

• If plug tip is covered with carbon, spark plug cleaner may be used.1. Ignition coil 2. Spark plug

Page 2966 of 4331

EM

NP

O

•

Checking and adjusting plug gap is not required between

change intervals.

INSTALLATION Installation is in the reverse order of removal.

Page 2967 of 4331

Exploded View " .

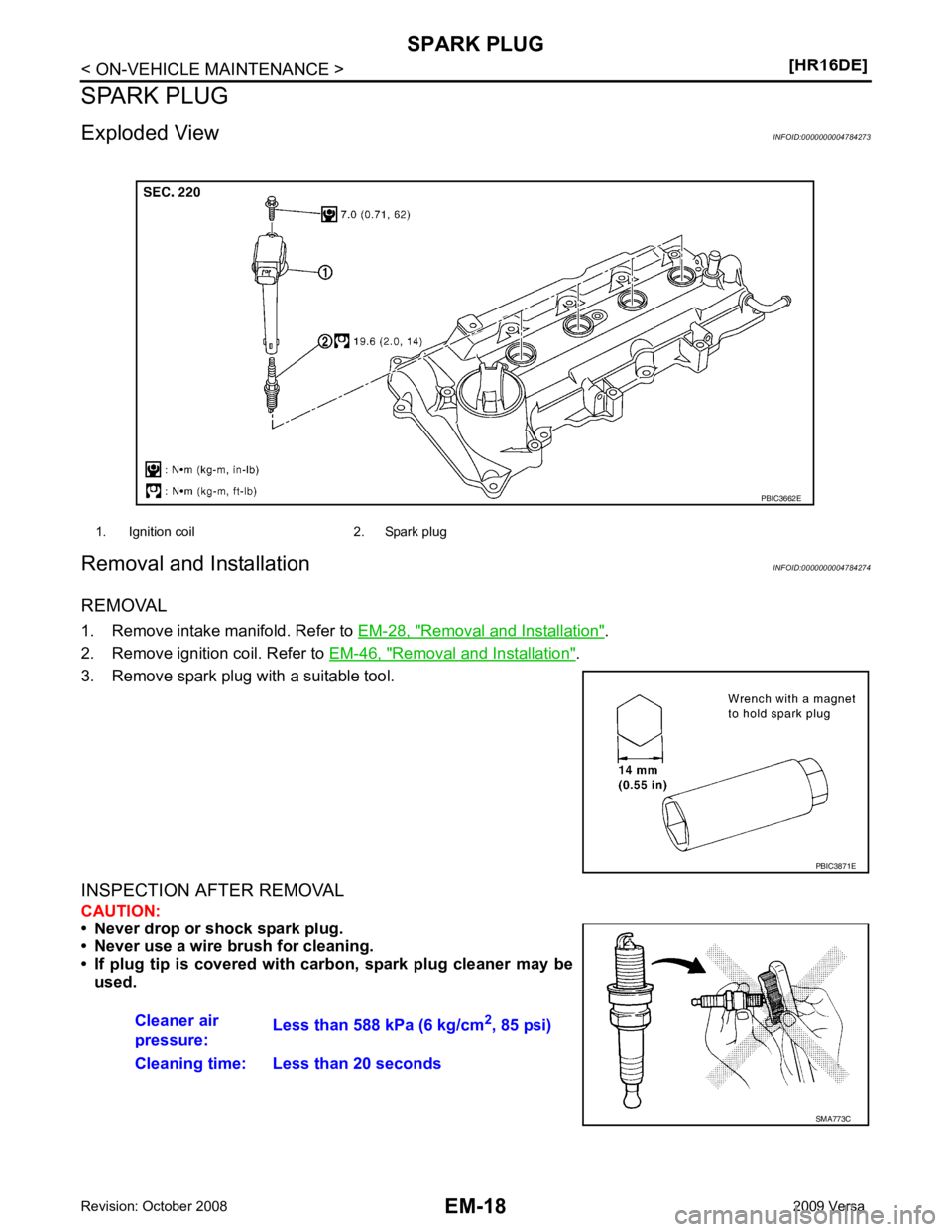

2. Measure the valve clearance with the following procedure:

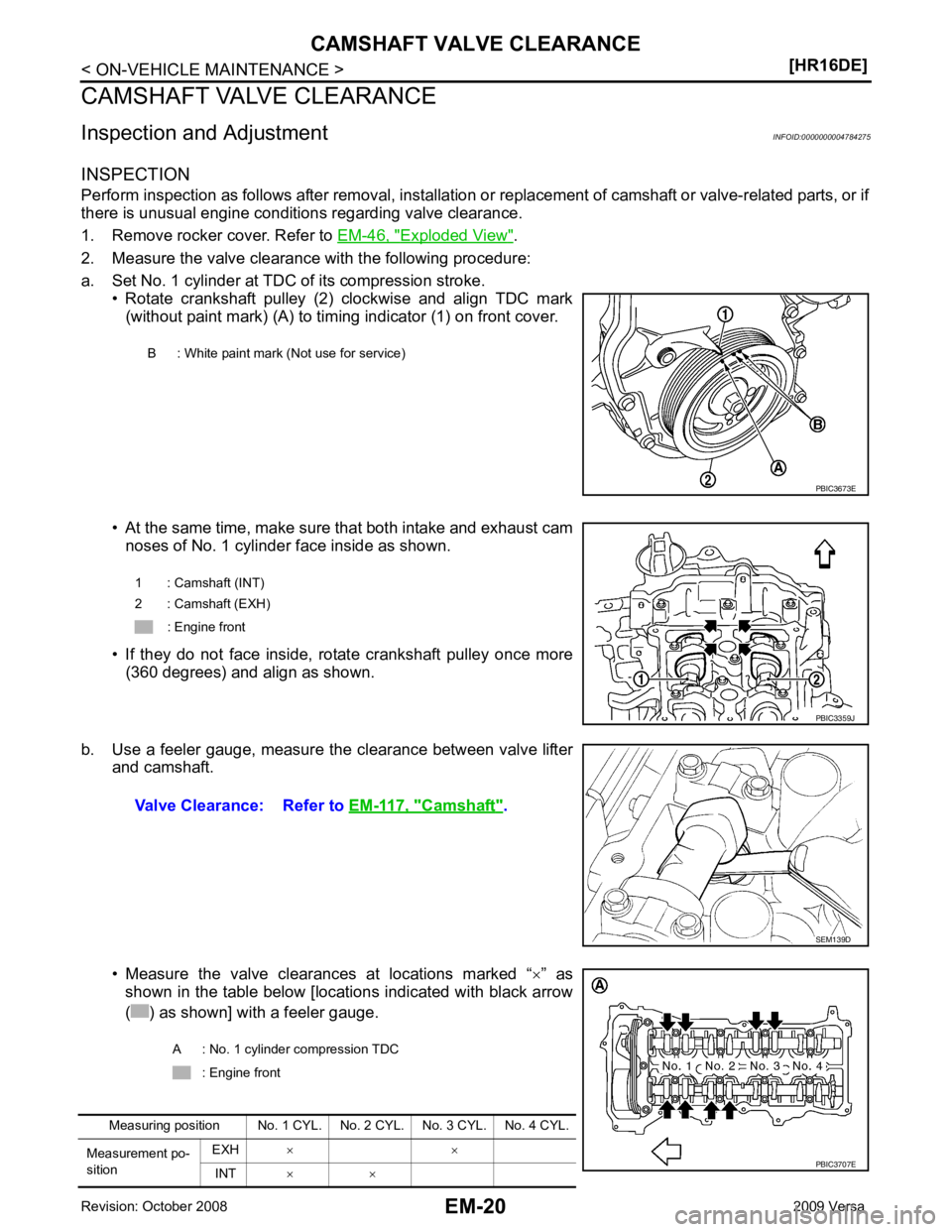

a. Set No. 1 cylinder at TDC of its compression stroke. • Rotate crankshaft pulley (2) clockwise and align TDC mark(without paint mark) (A) to timing indicator (1) on front cover.

• At the same time, make sure that both intake and exhaust cam noses of No. 1 cylinder face inside as shown.

• If they do not face inside, rotate crankshaft pulley once more (360 degrees) and align as shown.

b. Use a feeler gauge, measure the clearance between valve lifter and camshaft.

• Measure the valve clearances at locations marked “ ×” as

shown in the table below [locations indicated with black arrow

( ) as shown] with a feeler gauge. B : White paint mark (Not use for service)

Camshaft " .

Page 2968 of 4331

![NISSAN LATIO 2009 Service Repair Manual CAMSHAFT VALVE CLEARANCE

EM-21

< ON-VEHICLE MAINTENANCE >

[HR16DE] C

D E

F

G H

I

J

K L

M A EM

NP

O

c. Rotate crankshaft pulley (2) one revolution (360 degrees) and

align TDC mark (without pain NISSAN LATIO 2009 Service Repair Manual CAMSHAFT VALVE CLEARANCE

EM-21

< ON-VEHICLE MAINTENANCE >

[HR16DE] C

D E

F

G H

I

J

K L

M A EM

NP

O

c. Rotate crankshaft pulley (2) one revolution (360 degrees) and

align TDC mark (without pain](/img/5/57359/w960_57359-2967.png)

CAMSHAFT VALVE CLEARANCE

EM-21

< ON-VEHICLE MAINTENANCE >

[HR16DE] C

D E

F

G H

I

J

K L

M A EM

NP

O

c. Rotate crankshaft pulley (2) one revolution (360 degrees) and

align TDC mark (without paint mark) (A) to timing indicator (1) on

front cover.

• Measure the valve clearance at locations marked “ ×” as shown

in the table below [locations indicated with black arrow ( ) as

shown] with a feeler gauge.

3. If out of standard, perform adjustment procedure.

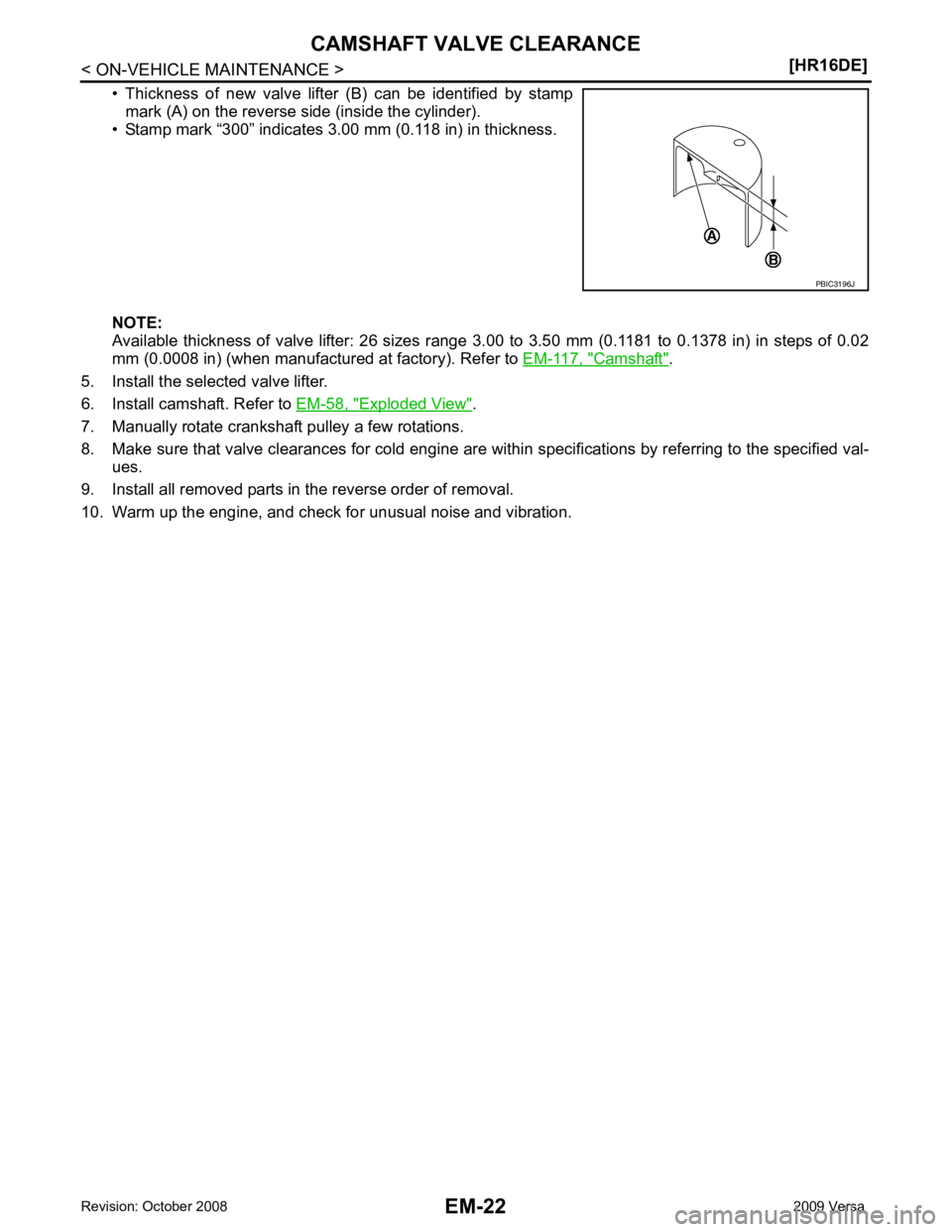

ADJUSTMENT • Perform adjustment depending on selected head thickness of valve lifter.

1. Remove camshaft. Refer to EM-58, " Exploded View " .

2. Remove valve lifters at the loca tions that are out of the standard.

3. Measure the center thickness of the removed valve lifters with a micrometer (A).

4. Use the equation below to calculate valve lifter thickness for replacement. B : White paint mark (Not use for service) PBIC3673E

A : No. 4 cylinder compression TDC

: Engine front

Measuring position No. 1 CYL. No . 2 CYL. No. 3 CYL. No. 4 CYL.

Measurement

point EXH

× ×

INT × × PBIC3708E

PBIC3195J

Valve lifter thickness calculation: t = t

1 + (C 1– C 2)

t = Valve lifter thickness to be replaced

t 1

= Removed valve lifter thickness

C 1

= Measured valve clearance

C 2

= Standard valve clearance:

Intake : 0.30 mm (0.012 in)

Exhaust : 0.33 mm (0.013 in)

Page 2969 of 4331

Camshaft " .

5. Install the selected valve lifter.

6. Install camshaft. Refer to EM-58, " Exploded View " .

7. Manually rotate crankshaft pulley a few rotations.

8. Make sure that valve clearances for cold engine are wit hin specifications by referring to the specified val-

ues.

9. Install all removed parts in the reverse order of removal.

10. Warm up the engine, and check for unusual noise and vibration.

Page 2970 of 4331

EM

NP

O

COMPRESSION PRESSURE

Inspection INFOID:0000000004784276

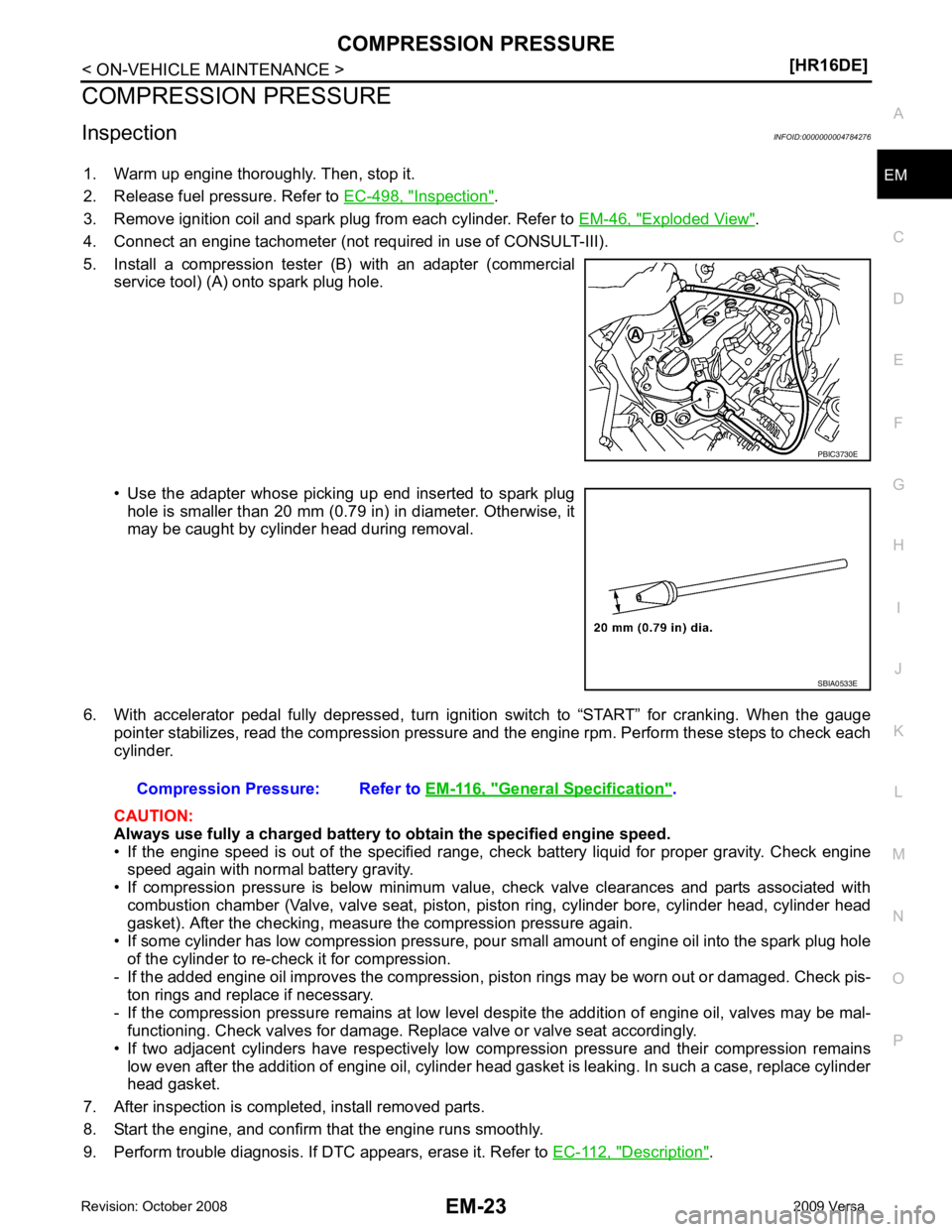

1. Warm up engine thoroughly. Then, stop it.

2. Release fuel pressure. Refer to EC-498, " Inspection " .

3. Remove ignition coil and spark plug from each cylinder. Refer to EM-46, " Exploded View " .

4. Connect an engine tachometer (not required in use of CONSULT-III).

5. Install a compression tester (B) with an adapter (commercial service tool) (A) onto spark plug hole.

• Use the adapter whose picking up end inserted to spark plug hole is smaller than 20 mm (0.79 in) in diameter. Otherwise, it

may be caught by cylinder head during removal.

6. With accelerator pedal fully depressed, turn ignition switch to “START” for cranking. When the gauge pointer stabilizes, read the compression pressure and the engine rpm. Perform these steps to check each

cylinder.

CAUTION:

Always use fully a charged battery to obtain the specified engine speed.

• If the engine speed is out of the specified range, c heck battery liquid for proper gravity. Check engine

speed again with normal battery gravity.

• If compression pressure is below minimum value, check valve clearances and parts associated with combustion chamber (Valve, valve seat, piston, pi ston ring, cylinder bore, cylinder head, cylinder head

gasket). After the checking, measure the compression pressure again.

• If some cylinder has low compression pressure, pour small amount of engine oil into the spark plug hole

of the cylinder to re-check it for compression.

- If the added engine oil improves the compression, piston rings may be worn out or damaged. Check pis-

ton rings and replace if necessary.

- If the compression pressure remains at low level despite the addition of engine oil, valves may be mal- functioning. Check valves for damage. Replace valve or valve seat accordingly.

• If two adjacent cylinders have respectively low compression pressure and their compression remains low even after the addition of engine oil, cylinder head gasket is leaking. In such a case, replace cylinder

head gasket.

7. After inspection is completed, install removed parts.

8. Start the engine, and confirm that the engine runs smoothly.

9. Perform trouble diagnosis. If DTC appears, erase it. Refer to EC-112, " Description " . SBIA0533E

General Specification " .