NISSAN LATIO 2009 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2009, Model line: LATIO, Model: NISSAN LATIO 2009Pages: 4331, PDF Size: 58.04 MB

Page 3121 of 4331

![NISSAN LATIO 2009 Service Repair Manual EM-174< SERVICE INFORMATION >

[MR18DE]

CAMSHAFT

2. Measure the camshaft sprocket runout with a dial indicator (A). (Total indicator reading)

• If it exceeds the limit, replace camshaft spro NISSAN LATIO 2009 Service Repair Manual EM-174< SERVICE INFORMATION >

[MR18DE]

CAMSHAFT

2. Measure the camshaft sprocket runout with a dial indicator (A). (Total indicator reading)

• If it exceeds the limit, replace camshaft spro](/img/5/57359/w960_57359-3120.png)

EM-174< SERVICE INFORMATION >

[MR18DE]

CAMSHAFT

2. Measure the camshaft sprocket runout with a dial indicator (A). (Total indicator reading)

• If it exceeds the limit, replace camshaft sprocket.

Valve Lifter

Check if surface of valve lifter has any wear or cracks.

• If anything above is found, replace valve lifter. Refer to EM-178," Valve Clearance " .

Valve Lifter Clearance

VALVE LIFTER OUTER DIAMETER

• Measure the outer diameter of valve lifter with a micrometer (A).

VALVE LIFTER HOLE DIAMETER

Measure the diameter of valve lifter hole of cylinder head with an

inside micrometer (A).

VALVE LIFTER CLEARANCE

• (Valve lifter clearance) = (Valve lifter hole diameter) – (Valve lifter outer diameter)

• If out of the standard, referring to the each standard of va lve lifter outer diameter and valve lifter hole diame-

ter, replace either or both valve lifter and cylinder head.

INSTALLATION

1. Install valve lifters. • Install them in the original positions.

2. Install camshafts. Limit : 0.15 mm (0.0059 in)

PBIC3182J

KBIA0182E

Standard:

Intake : 33.977 - 33.987 mm (1.3377 - 1.3381 in)

Exhaust : 29.977 - 29.987 mm (1.1802 - 1.1806 in) PBIC3185J

Standard:

Intake : 34.000 - 34.021 mm (1.3386 - 1.3394 in)

Exhaust : 30.000 - 30.021 mm (1.1811 - 1.1819 in)

Standard: 0.013 - 0.044 mm (0.0005 - 0.0017 in) PBIC3184J

Page 3122 of 4331

EM

NP

O

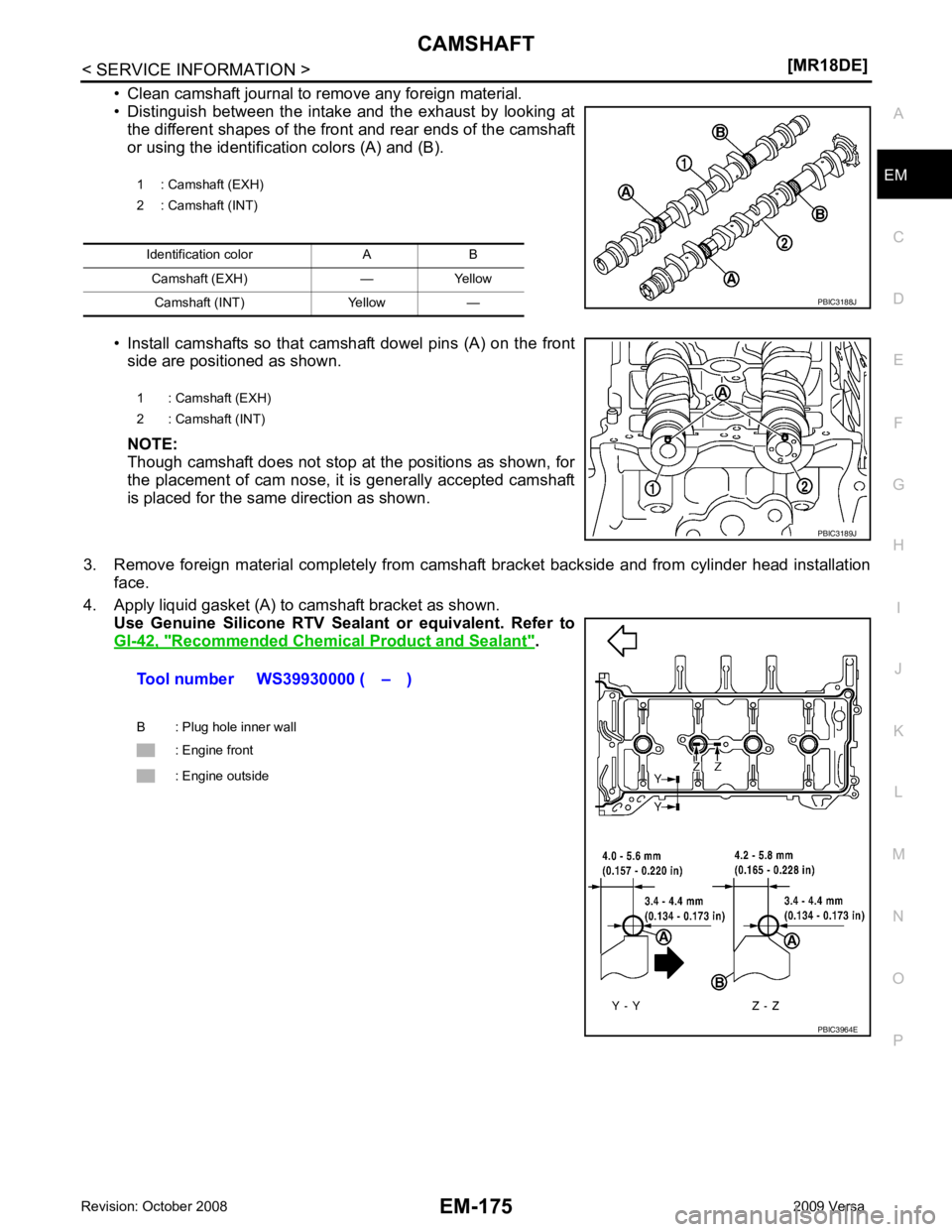

• Clean camshaft journal to remove any foreign material.

• Distinguish between the intake and the exhaust by looking at the different shapes of the front and rear ends of the camshaft

or using the identification colors (A) and (B).

• Install camshafts so that camshaft dowel pins (A) on the front side are positioned as shown.

NOTE:

Though camshaft does not stop at t he positions as shown, for

the placement of cam nose, it is generally accepted camshaft

is placed for the same direction as shown.

3. Remove foreign material completely from camshaft bracket backside and from cylinder head installation face.

4. Apply liquid gasket (A) to camshaft bracket as shown. Use Genuine Silicone RTV Seal ant or equivalent. Refer to

GI-42, " Recommended Chemical Product and Sealant " .

1 : Camshaft (EXH)

2 : Camshaft (INT)

Identification color A BCamshaft (EXH) — YellowCamshaft (INT) Yellow —

Page 3123 of 4331

![NISSAN LATIO 2009 Service Repair Manual EM-176< SERVICE INFORMATION >

[MR18DE]

CAMSHAFT

5. Install camshaft bracket bolts in three stage in numerical order as shown.

• There are two types of bolts. Locate the bolts as shown.

6. T NISSAN LATIO 2009 Service Repair Manual EM-176< SERVICE INFORMATION >

[MR18DE]

CAMSHAFT

5. Install camshaft bracket bolts in three stage in numerical order as shown.

• There are two types of bolts. Locate the bolts as shown.

6. T](/img/5/57359/w960_57359-3122.png)

EM-176< SERVICE INFORMATION >

[MR18DE]

CAMSHAFT

5. Install camshaft bracket bolts in three stage in numerical order as shown.

• There are two types of bolts. Locate the bolts as shown.

6. Tighten all bolts in numerical order in three steps.

7. Install the camshaft sprocket (INT) (2) to the camshaft (INT). NOTE:

Align the matching mark (A) applied during removal. Securely

align the knock pin and the pin hole, and then install them.

8. Tighten camshaft (INT) sprocket bolt. NOTE:

Secure the hexagonal part of camshaft (INT) using wrench to tighten bolt.

9. Turn 67 degrees clockwise (angle tightening) using Tool (B).

CAUTION:

Never judge by visual inspect ion without an angle wrench.

: Engine front

M6 bolts [thread length: 57.5 mm (2.264 in)] : 13, 14 and 15

M6 bolts [thread length: 35.00 mm (1.378 in)] : Except the above

Step 1 : 1.96 N·m (0.20 kg-m, 17 in-lb)

Step 2 : 5.88 N·m (0.60 kg-m, 52 in-lb)

Step 3 : 9.5 N·m (0.97 kg-m, 84 in-lb)

1 : Camshaft bracket : Engine front PBIC3176J

PBIC3992J

Camshaft sprocket bolt (INT) : 35.0 N·m (3.6 kg-m, 26 ft-lb)

1 : Camshaft sprocket (INT)

A : Camshaft (INT) hexagonal part

Tool number : KV10112100 (BT-8653-A) PBIC3455J

Page 3124 of 4331

![NISSAN LATIO 2009 Service Repair Manual CAMSHAFT

EM-177

< SERVICE INFORMATION >

[MR18DE] C

D E

F

G H

I

J

K L

M A EM

NP

O

10. Install camshaft sprocket (EXH) (2).

NOTE:

Secure the hexagonal part (A) of camshaft (EXH) using wrench

to tighten NISSAN LATIO 2009 Service Repair Manual CAMSHAFT

EM-177

< SERVICE INFORMATION >

[MR18DE] C

D E

F

G H

I

J

K L

M A EM

NP

O

10. Install camshaft sprocket (EXH) (2).

NOTE:

Secure the hexagonal part (A) of camshaft (EXH) using wrench

to tighten](/img/5/57359/w960_57359-3123.png)

CAMSHAFT

EM-177

< SERVICE INFORMATION >

[MR18DE] C

D E

F

G H

I

J

K L

M A EM

NP

O

10. Install camshaft sprocket (EXH) (2).

NOTE:

Secure the hexagonal part (A) of camshaft (EXH) using wrench

to tighten bolt.

11. Install timing chain and related parts. Refer to EM-160 .

12. Inspect and adjust valve clearance. Refer to EM-178, " Valve Clearance " .

13. Installation of the remaining components is in the reverse order of removal.

INSPECTION AFTER INSTALLATION The following are procedures for chec king fluids leak, lubricates leak.

• Before starting engine, check oil/fluid levels incl uding engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer to GI-42, " Recommended Chemical Product and Sealant " .

• Use procedure below to check for fuel leakage.

- Turn ignition switch “ON” (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leak-

age at connection points.

- Start engine. With engine speed increased, check again for fuel leakage at connection points.

• Run engine to check for unusual noise and vibration. NOTE:

If hydraulic pressure inside timing chain tensioner drops after removal/installation, slack in the guide may

generate a pounding noise during and just after engine start. However, this is normal. Noise will stop after

hydraulic pressure rises.

• Warm up engine thoroughly to make sure there is no leak age of fuel, or any oil/fluids including engine oil and

engine coolant.

• Bleed air from lines and hoses of applicable lines, such as in cooling system.

• After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to the

specified level, if necessary.

Summary of the inspection items:

* Transmission/transaxle/CVT fluid, power steering fluid, brake fluid, etc.

Inspection of Camshaft Sprocket (INT) Oil Groove

CAUTION:

• Perform this inspection only when DTC P0011 is detected in self-diagnostic results of CONSULT-III

and it is directed according to inspect ion procedure of EC section. Refer to EC-638, " Diagnosis Pro-

cedure " (Type 1) or

EC-1153, " Diagnosis Procedure " (Type 2).

• Check when engine is cold so as to pr event burns from the splashing engine oil.

1. Check engine oil level. Refer to LU-16, " Inspection " .

2. Perform the following procedure so as to prevent the engine from being unintentionally started while checking.

a. Remove intake manifold. Refer to EM-141, " Component " .

b. Disconnect ignition coil and in jector harness connectors.

3. Remove intake valve timing control solenoid valve. Refer to EM-160, " Component " .

1 : Camshaft sprocket (INT)

Camshaft sprocket

bolt (EXH) : 88.2 N·m (9.0 kg-m, 65 ft-lb) PBIC3454J

Item Before starting engine Engine running After engine stopped

Engine coolant Level Leakage Level

Engine oil Level Leakage Level

Other oils and fluid* Level Leakage Level

Fuel Leakage Leakage Leakage

Exhaust gases — Leakage —

Page 3125 of 4331

Component " .

6. Crank engine, and then make sure that engine oil comes out from intake valve timing control solenoid valve hole (A). End cranking after checking.

• Check engine oil leakage by oil amount adhered to the shop cloth inserted into the oil hole.

WARNING:

• Be careful not to touch rotating parts (drive be lts, idler pulley, and crankshaft pulley, etc.).

• Prevent splashing by using a shop cloth so as to prevent the worker from injury from engine oil

and so as to prevent engi ne oil contamination.

CAUTION:

• Do not perform cranking without installing right engine mount bracket, right engine mount insu-

lator, and right torque rod.

• Prevent splashing by using a shop cloth so as to prevent engine oil from being splashed to

engine and vehicle. Especially, be careful not to apply engine oil to rubber parts of drive belts,

engine mounting insulator, etc. Wipe engi ne oil off immediately if it is splashed.

7. Perform the following inspection if engine oil does not come out from intake valve timing control solenoid valve oil hole of the cylinder head.

• Remove oil filter (for intake valve timing control), and then clean it. Refer to EM-199, " Component " .

• Clean oil groove between oil strainer and intake valve timing control solenoid valve. Refer to LU-15 .

8. Remove components between intake valve timing c ontrol solenoid valve and camshaft sprocket (INT),

and then check each oil groove for clogging.

• Clean oil groove if necessary. Refer to LU-15 .

9. Installation of the remaining components is in the reverse order of removal

Valve Clearance INFOID:0000000004307146

INSPECTION

Perform inspection as follows after removal, installation or replacement of camshaft or valve-related parts, or if

there is unusual engine conditions regarding valve clearance.

1. Remove rocker cover. Refer to EM-153 .

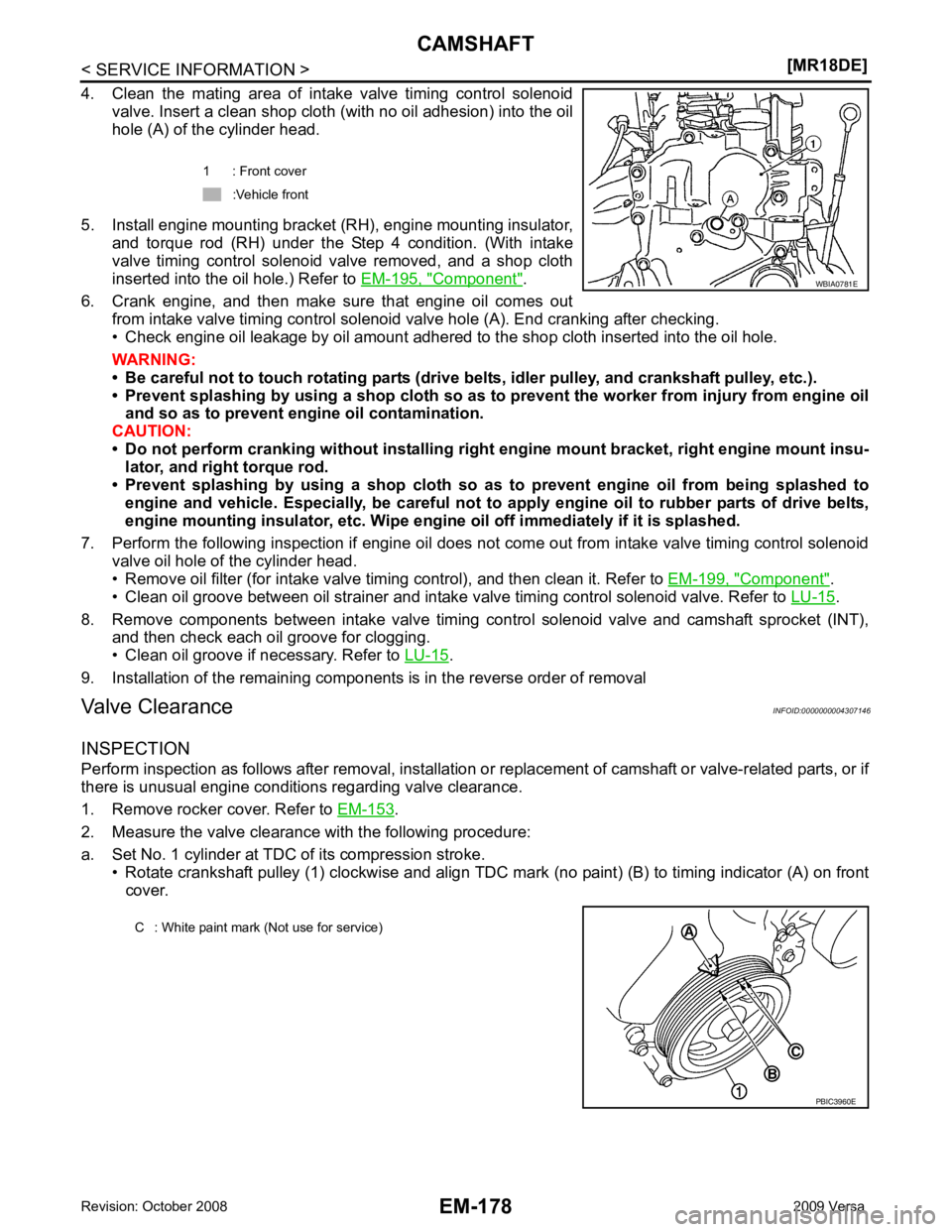

2. Measure the valve clearance with the following procedure:

a. Set No. 1 cylinder at TDC of its compression stroke. • Rotate crankshaft pulley (1) clockwise and align TDC mark (no paint) (B) to timing indicator (A) on front

cover. 1 : Front cover

:Vehicle front

Page 3126 of 4331

![NISSAN LATIO 2009 Service Repair Manual CAMSHAFT

EM-179

< SERVICE INFORMATION >

[MR18DE] C

D E

F

G H

I

J

K L

M A EM

NP

O

• At the same time, make sure that both intake and exhaust cam

noses of No. 1 cylinder face inside ( ) as shown.

• NISSAN LATIO 2009 Service Repair Manual CAMSHAFT

EM-179

< SERVICE INFORMATION >

[MR18DE] C

D E

F

G H

I

J

K L

M A EM

NP

O

• At the same time, make sure that both intake and exhaust cam

noses of No. 1 cylinder face inside ( ) as shown.

•](/img/5/57359/w960_57359-3125.png)

CAMSHAFT

EM-179

< SERVICE INFORMATION >

[MR18DE] C

D E

F

G H

I

J

K L

M A EM

NP

O

• At the same time, make sure that both intake and exhaust cam

noses of No. 1 cylinder face inside ( ) as shown.

• If they do not face inside, rotate crankshaft pulley once more (360 degrees) and align as shown.

b. Use a feeler gauge, measure the clearance between valve lifter and camshaft.

Valve clearance: Unit: mm (in)

*: Approximately 80 °C (176 °F)

• By referring to the figure, measure the valve clearances at locations marked × as shown in the table below [locations indi-

cated with black arrow ( )] with a feeler gauge.

• No. 1 cylinder compression TDC

c. Set No.4 cylinder at TDC of its compression stroke. 1 : Camshaft (INT)

2 : Camshaft (EXH)

: Engine front PBIC3359J

PBIC3192J

Cold Hot * (reference data)

Intake 0.26 - 0.34 (0.010 - 0.013) 0.304 - 0.416 (0.012 - 0.016)

Exhaust 0.29 - 0.37 (0.011 - 0.015) 0.308 - 0.432 (0.012 - 0.017) Measuring position No. 1 CYL. No. 2 CYL. No. 3 CYL. No. 4 CYL.

No. 1 cylinder at

compression TDC EXH

× ×

INT × ×

A : Exhaust side

B : No.1 cylinder

C : No.2 cylinder

D : No.3 cylinder

E : No.4 cylinder

F : Intake side

: Engine front PBIC3193J

Page 3127 of 4331

![NISSAN LATIO 2009 Service Repair Manual EM-180< SERVICE INFORMATION >

[MR18DE]

CAMSHAFT

• Rotate crankshaft pulley (1) one revolution (360 degrees) and align TDC mark (no paint) (B) to timing indicator (A) on front

cover.

• NISSAN LATIO 2009 Service Repair Manual EM-180< SERVICE INFORMATION >

[MR18DE]

CAMSHAFT

• Rotate crankshaft pulley (1) one revolution (360 degrees) and align TDC mark (no paint) (B) to timing indicator (A) on front

cover.

•](/img/5/57359/w960_57359-3126.png)

EM-180< SERVICE INFORMATION >

[MR18DE]

CAMSHAFT

• Rotate crankshaft pulley (1) one revolution (360 degrees) and align TDC mark (no paint) (B) to timing indicator (A) on front

cover.

• By referring to the figure, measure the valve clearance at loca- tions marked × as shown in the table below [locations indi-

cated with black arrow ( )] with a feeler gauge.

• No. 4 cylinder compression TDC

3. If out of standard, perform adjustment.

ADJUSTMENT

• Perform adjustment depending on selected head thickness of valve lifter.

1. Remove camshaft. Refer to EM-170, " Removal and Installation " .

2. Remove valve lifters at the locations that are out of the standard.

3. Measure the center thickness of the removed valve lifters with a micrometer (A).

4. Use the equation below to calculate valve lifter thickness for replacement. C : White paint mark (Not use for service) PBIC3960E

Measuring position No. 1 CYL. No. 2 CYL. No. 3 CYL. No. 4 CYL.

No. 4 cylinder at

compression TDC EXH

× ×

INT × ×

A : Exhaust side

B : No.1 cylinder

C : No.2 cylinder

D : No.3 cylinder

E : No.4 cylinder

F : Intake side

: Engine front PBIC3194J

PBIC3195J

Valve lifter thickness calculation: t = t

1 + (C 1 – C 2)

t = Valve lifter thickness to be replaced

t 1

= Removed valve lifter thickness

C 1

= Measured valve clearance

C 2

= Standard valve clearance:

Page 3128 of 4331

![NISSAN LATIO 2009 Service Repair Manual CAMSHAFT

EM-181

< SERVICE INFORMATION >

[MR18DE] C

D E

F

G H

I

J

K L

M A EM

NP

O

• Thickness of new valve lifter (B) can be identified by stamp

mark (A) on the reverse side (inside the cyl NISSAN LATIO 2009 Service Repair Manual CAMSHAFT

EM-181

< SERVICE INFORMATION >

[MR18DE] C

D E

F

G H

I

J

K L

M A EM

NP

O

• Thickness of new valve lifter (B) can be identified by stamp

mark (A) on the reverse side (inside the cyl](/img/5/57359/w960_57359-3127.png)

CAMSHAFT

EM-181

< SERVICE INFORMATION >

[MR18DE] C

D E

F

G H

I

J

K L

M A EM

NP

O

• Thickness of new valve lifter (B) can be identified by stamp

mark (A) on the reverse side (inside the cylinder).

Stamp mark “302” indicates 3.02 mm (0.1189 in) in thickness.

NOTE:

Available thickness of valve lifter: 26 sizes range 3.00 to 3.50 mm (0.1181 to 0.1378 in) in steps of 0.02

mm (0.0008 in) (when manufactured at factory). Refer to EM-227, " Standard and Limit " .

5. Install the selected valve lifter.

6. Install camshaft. Refer to EM-170, " Removal and Installation " .

7. Install timing chain and related parts. Refer to EM-160 .

8. Manually rotate crankshaft pulley a few rotations.

9. Make sure that the valve cl earances is within the standard.

10. Installation of the remaining components is in the reverse order of removal. Intake : 0.30 mm (0.012 in)

Exhaust : 0.33 mm (0.013 in) PBIC3196J

Page 3129 of 4331

![NISSAN LATIO 2009 Service Repair Manual EM-182< SERVICE INFORMATION >

[MR18DE]

OIL SEAL

OIL SEAL

Removal and Installation of Valve Oil Seal INFOID:0000000004307147

REMOVAL

1. Remove camshafts. Refer to EM-170, " Component " .

2. Remove va NISSAN LATIO 2009 Service Repair Manual EM-182< SERVICE INFORMATION >

[MR18DE]

OIL SEAL

OIL SEAL

Removal and Installation of Valve Oil Seal INFOID:0000000004307147

REMOVAL

1. Remove camshafts. Refer to EM-170, " Component " .

2. Remove va](/img/5/57359/w960_57359-3128.png)

EM-182< SERVICE INFORMATION >

[MR18DE]

OIL SEAL

OIL SEAL

Removal and Installation of Valve Oil Seal INFOID:0000000004307147

REMOVAL

1. Remove camshafts. Refer to EM-170, " Component " .

2. Remove valve lifters. Refer to EM-170 .

3. Rotate crankshaft, and set piston whose valve oil seal is to be removed to TDC. This will prevent valve from dropping into cylinder.

CAUTION:

When rotating crankshaft, be careful to avo id scarring front cover with timing chain.

4. Remove valve collet. • Compress valve spring using Tool (A). Remove valve collet

with a suitable magnet hand (B).

CAUTION:

When working, be careful not to damage valve lifter holes.

5. Remove valve spring retainer, valve spring and valve spring seat.

6. Remove valve oil seal using Tool (A).

INSTALLATION

1. Apply new engine oil to valve oil seal joint surface and seal lip.

2. Press in valve oil seal to the height (H) shown using Tool (A).

3. Installation of the remaining components is in the reverse order of removal.

Removal and Installation of Front Oil Seal INFOID:0000000004307148

REMOVAL

1. Remove the following parts. • Front fender protector (RH); Refer to EI-24 .

Tool number : KV101092S0 (J-26336-B)

PBIC3727E

Tool number :KV10107902 (J-38959)

PBIC3728E

Height (H) : 15.1 - 15.7 mm (0.594 - 0.618 in)

Tool number : KV10115600 (J-38958) PBIC3211J

Page 3130 of 4331

![NISSAN LATIO 2009 Service Repair Manual OIL SEAL

EM-183

< SERVICE INFORMATION >

[MR18DE] C

D E

F

G H

I

J

K L

M A EM

NP

O

• Drive belt; Refer to

EM-136, " Component " .

• Crankshaft pulley; Refer to EM-160, " Component " .

2. Remove fr NISSAN LATIO 2009 Service Repair Manual OIL SEAL

EM-183

< SERVICE INFORMATION >

[MR18DE] C

D E

F

G H

I

J

K L

M A EM

NP

O

• Drive belt; Refer to

EM-136, " Component " .

• Crankshaft pulley; Refer to EM-160, " Component " .

2. Remove fr](/img/5/57359/w960_57359-3129.png)

OIL SEAL

EM-183

< SERVICE INFORMATION >

[MR18DE] C

D E

F

G H

I

J

K L

M A EM

NP

O

• Drive belt; Refer to

EM-136, " Component " .

• Crankshaft pulley; Refer to EM-160, " Component " .

2. Remove front oil seal using a suitable tool. CAUTION:

Be careful not to damage front cover and crankshaft.

INSTALLATION 1. Apply new engine oil to new front oil seal joint surface and seal lip.

2. Install front oil seal so that each seal lip is oriented as shown.

• Install front oil seal (2) using a suitable tool with outer diameter57 mm (2.24 in) and inner diameter 45 mm (1.77 in) (A) to the

dimension as shown.

CAUTION:

• Be careful not to damage front cover and crankshaft.

• Press-fit oil seal straight to avoid causing burrs or tilting.

• Do not touch grease applied on oil seal lip.

3. Installation of the remaining components is in the reverse order of removal.

Removal and Installation of Rear Oil Seal INFOID:0000000004307149

REMOVAL 1. Remove transaxle assembly. Refer to MT-58 (M/T models),

AT-232 (A/T models),

CVT-182 or

CVT-354 (CVT models).

2. Remove clutch cover and clutch disk (M/T models). Refer to CL-15 .

3. Remove drive plate (A/T or CVT models) or flywheel (M/T models). Refer to EM-199, " Component " .

4. Remove rear oil seal with a suitable tool. CAUTION:

Be careful not to damage crankshaft and cylinder block.

INSTALLATION 1. Apply the liquid gasket lightly to entire outside area of new rear oil seal. Use Genuine Silicone RTV Seal ant or equivalent. Refer to GI-42, " Recommended Chemical Prod-

uct and Sealant " .

A : Dust seal lip

B : Oil seal lip

: Engine front

: Engine rear PBIC3485J

1 : Front cover

: Engine front

Within 0.3 mm (0.012 in) toward engine front

Within 0.5 mm (0.020 in) toward engine rear PBIC3729E