NISSAN LATIO 2009 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2009, Model line: LATIO, Model: NISSAN LATIO 2009Pages: 4331, PDF Size: 58.04 MB

Page 3131 of 4331

![NISSAN LATIO 2009 Service Repair Manual EM-184< SERVICE INFORMATION >

[MR18DE]

OIL SEAL

2. Install rear oil seal so that each seal lip is oriented as shown.

• Install rear oil seal with a suitable tool with an outer diameter115 NISSAN LATIO 2009 Service Repair Manual EM-184< SERVICE INFORMATION >

[MR18DE]

OIL SEAL

2. Install rear oil seal so that each seal lip is oriented as shown.

• Install rear oil seal with a suitable tool with an outer diameter115](/img/5/57359/w960_57359-3130.png)

EM-184< SERVICE INFORMATION >

[MR18DE]

OIL SEAL

2. Install rear oil seal so that each seal lip is oriented as shown.

• Install rear oil seal with a suitable tool with an outer diameter115 mm (4.53 in) and inner diameter 90 mm (3.54 in) (A).

CAUTION:

• Be careful not to damage crankshaft and cylinder block.

• Press-fit oil seal straight to avoid causing burrs or tilt-

ing.

• Do not touch grease applied onto oil seal lip.

• Install rear oil seal (1) to the position as shown.

NOTE:

The standard surface of the dimension is the rear end surface of

cylinder block.

3. Installation of the remaining components is in the reverse order of removal. A : Dust seal lip

B : Oil seal lip

: Engine outside

: Engine inside PBIC3485J

PBIC3951E

A : Rear end surface of cylinder block

PBIC3761E

Page 3132 of 4331

EM

NP

O

CYLINDER HEAD

On-Vehicle Service INFOID:0000000004307150

CHECKING COMPRESSION PRESSURE 1. Warm up engine thoroughly. Then, stop it.

2. Release fuel pressure. Refer to EC-574, " Fuel Pressure Check " (Type 1) or

EC-1086, " Fuel Pressure

Check " (Type 2).

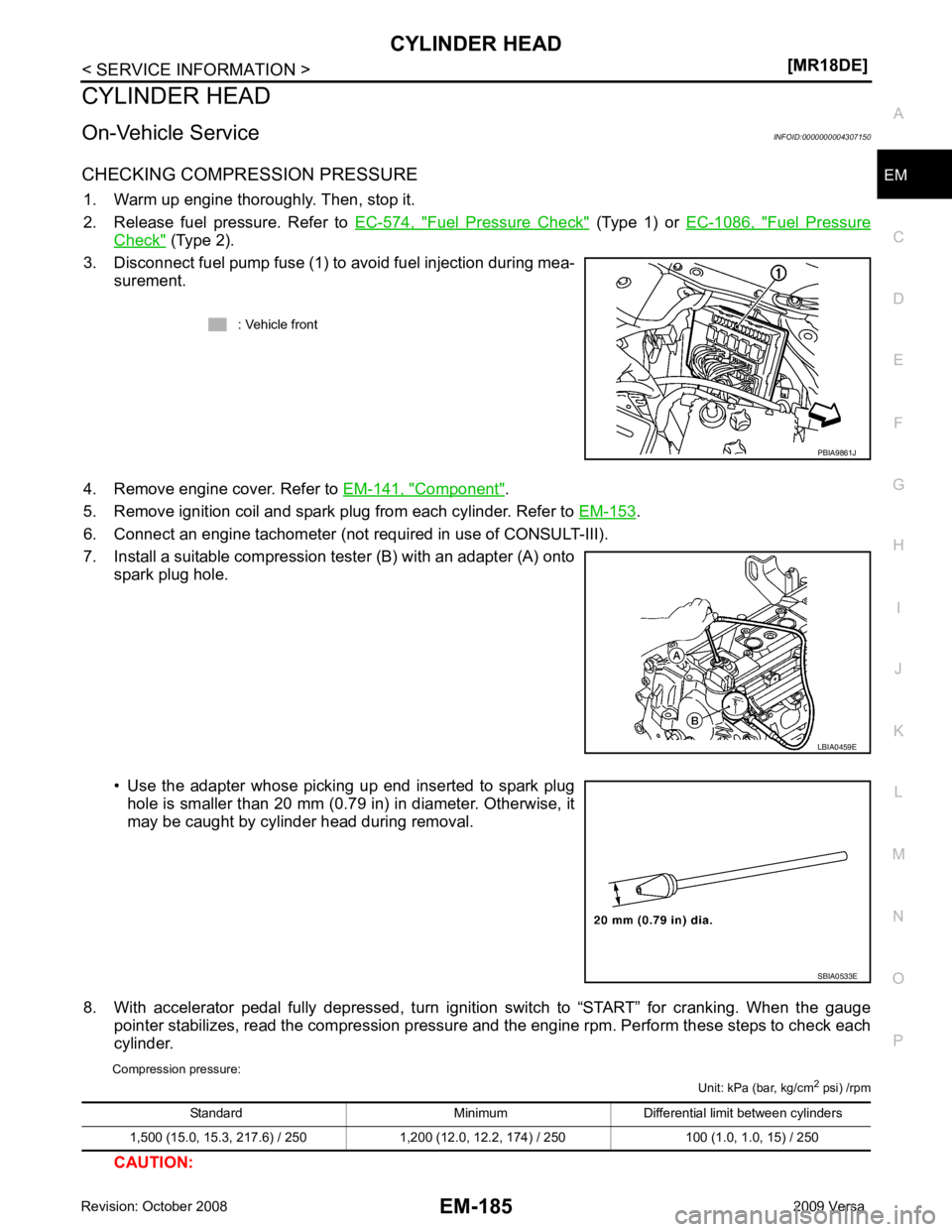

3. Disconnect fuel pump fuse (1) to avoid fuel injection during mea- surement.

4. Remove engine cover. Refer to EM-141, " Component " .

5. Remove ignition coil and spark plug from each cylinder. Refer to EM-153 .

6. Connect an engine tachometer (not required in use of CONSULT-III).

7. Install a suitable compression tester (B) with an adapter (A) onto spark plug hole.

• Use the adapter whose picking up end inserted to spark plug hole is smaller than 20 mm (0.79 in) in diameter. Otherwise, it

may be caught by cylinder head during removal.

8. With accelerator pedal fully depressed, turn ignition switch to “START” for cranking. When the gauge pointer stabilizes, read the compression pressure and the engine rpm. Perform these steps to check each

cylinder.

Compression pressure: Unit: kPa (bar, kg/cm2

psi) /rpm

CAUTION: : Vehicle front

LBIA0459E

SBIA0533E

Page 3133 of 4331

Trouble Diagnosis Introduction "

(Type 1) or

EC-1089, " Trouble Diagnosis Introduction " (Type 2).

Component INFOID:0000000004307151

Removal and Installation INFOID:0000000004307152

REMOVAL

WARNING:

• Put a “CAUTION: FLAMMABLE” sign in the workshop.

• Be sure to work in a well ventilate d area and furnish workshop with a CO

2 fire extinguisher.

• Do not smoke while servicing fuel system. Keep open flames and sparks away from the work area.

1. Release the fuel pressure. Refer to EC-574, " Fuel Pressure Check " (Type 1) or

EC-1086, " Fuel Pressure

Check " (Type 2).

2. Drain engine coolant and engine oil. Refer to CO-35 and

LU-16 .

CAUTION:

• Perform this step when the engine is cold.

• Never spill engine coolant an d engine oil on drive belt.

3. Remove front fender protector (RH). Refer to EI-24 .

1. Cylinder head assembly 2. Cylinder head bolt 3. Cylinder head gasket

A. Refer to EM-186

Page 3134 of 4331

![NISSAN LATIO 2009 Service Repair Manual CYLINDER HEAD

EM-187

< SERVICE INFORMATION >

[MR18DE] C

D E

F

G H

I

J

K L

M A EM

NP

O

4. Remove drive belt. Refer to

EM-136, " Removal and Installation " .

5. Remove the following components and rela NISSAN LATIO 2009 Service Repair Manual CYLINDER HEAD

EM-187

< SERVICE INFORMATION >

[MR18DE] C

D E

F

G H

I

J

K L

M A EM

NP

O

4. Remove drive belt. Refer to

EM-136, " Removal and Installation " .

5. Remove the following components and rela](/img/5/57359/w960_57359-3133.png)

CYLINDER HEAD

EM-187

< SERVICE INFORMATION >

[MR18DE] C

D E

F

G H

I

J

K L

M A EM

NP

O

4. Remove drive belt. Refer to

EM-136, " Removal and Installation " .

5. Remove the following components and related parts. • Exhaust manifold; Refer to EM-144 .

• Intake manifold; Refer to EM-141 .

• Fuel tube and fuel injector assembly; Refer to EM-156 .

• Water outlet; Refer to CO-47 .

• Rocker cover; Refer to EM-153 .

• Front cover, timing chain; Refer to EM-160 .

• Camshaft; Refer to EM-170 .

6. Remove cylinder head. • Loosen bolts in reverse order as shown.

• Using TORX socket (size E18), loosen cylinder head bolts.

7. Remove cylinder head gasket.

INSPECTION AFTER REMOVAL

Cylinder Head Bolts Outer Diameter • Cylinder head bolts are tightened by plastic zone tightening method. Whenever the size difference between (d1) and (d2)

exceeds the limit, replac e them with a new one.

• If reduction of outer diameter appear s in a position other than (d2),

use it as (d2) point.

Cylinder Head Distortion NOTE:

When performing this inspection, cylinder block distortion should be also checked. Refer to EM-216, " Inspec-

tion After Disassembly " .

1. Wipe off engine oil and remove water scale (like deposit ), gasket, sealant, carbon, etc. with a scraper.

CAUTION:

Never allow gasket debris to enter passag es for engine oil or engine coolant.

2. At each of several locations on bottom surface of cylinder head, measure the distortion in six di rections using straightedge (A)

and feeler gauge (B).

• If it exceeds the limit, replace cylinder head.

INSTALLATION 1. Install cylinder head gasket.

2. Apply new engine oil to threads and seating surface of bolts. CAUTION: : Engine front

PBIC3206J

Limit [(d1) – (d2)]: 0.15 mm (0.0059 in)

PBIC3994E

Limit: 0.1 mm (0.004 in)

PBIC3207J

Page 3135 of 4331

![NISSAN LATIO 2009 Service Repair Manual EM-188< SERVICE INFORMATION >

[MR18DE]

CYLINDER HEAD

If cylinder head bolts re-used, ch eck their outer diameters before in stallation. Follow the "Cylinder

Head Bolts Outer Diameter" procedure.

3. In NISSAN LATIO 2009 Service Repair Manual EM-188< SERVICE INFORMATION >

[MR18DE]

CYLINDER HEAD

If cylinder head bolts re-used, ch eck their outer diameters before in stallation. Follow the "Cylinder

Head Bolts Outer Diameter" procedure.

3. In](/img/5/57359/w960_57359-3134.png)

EM-188< SERVICE INFORMATION >

[MR18DE]

CYLINDER HEAD

If cylinder head bolts re-used, ch eck their outer diameters before in stallation. Follow the "Cylinder

Head Bolts Outer Diameter" procedure.

3. Install cylinder head, follow the steps below to tighten cylinder head bolts in numerical order as shown.

: Engine front

CAUTION:

Check and confirm the tightening angle by using Tool (A) or

protractor. Never judge by vi sual inspection without the

tool.

4. Installation of the remaining components is in the reverse order of removal.

Component INFOID:0000000004307153

Step a : 40 N·m (4.1 kg-m, 30 ft-lb)

Step b : 100 ° clockwise

Step c : Loosen to 0 N·m in the reverse order of tight- ening.

Step d : 40 N·m (4.1 kg-m, 30 ft-lb)

Step e : 100 ° clockwise

Step f : 100 ° clockwise

Tool number : KV10112100 (BT-8653-A) PBIC3206J

PBIC3208J

PBIC3543J

Page 3136 of 4331

EM

NP

O

Disassembly and Assembly

INFOID:0000000004307154

DISASSEMBLY 1. Remove spark plug using suitable tool.

2. Remove valve lifter. • Identify installation positions, and store them without mixing them up.

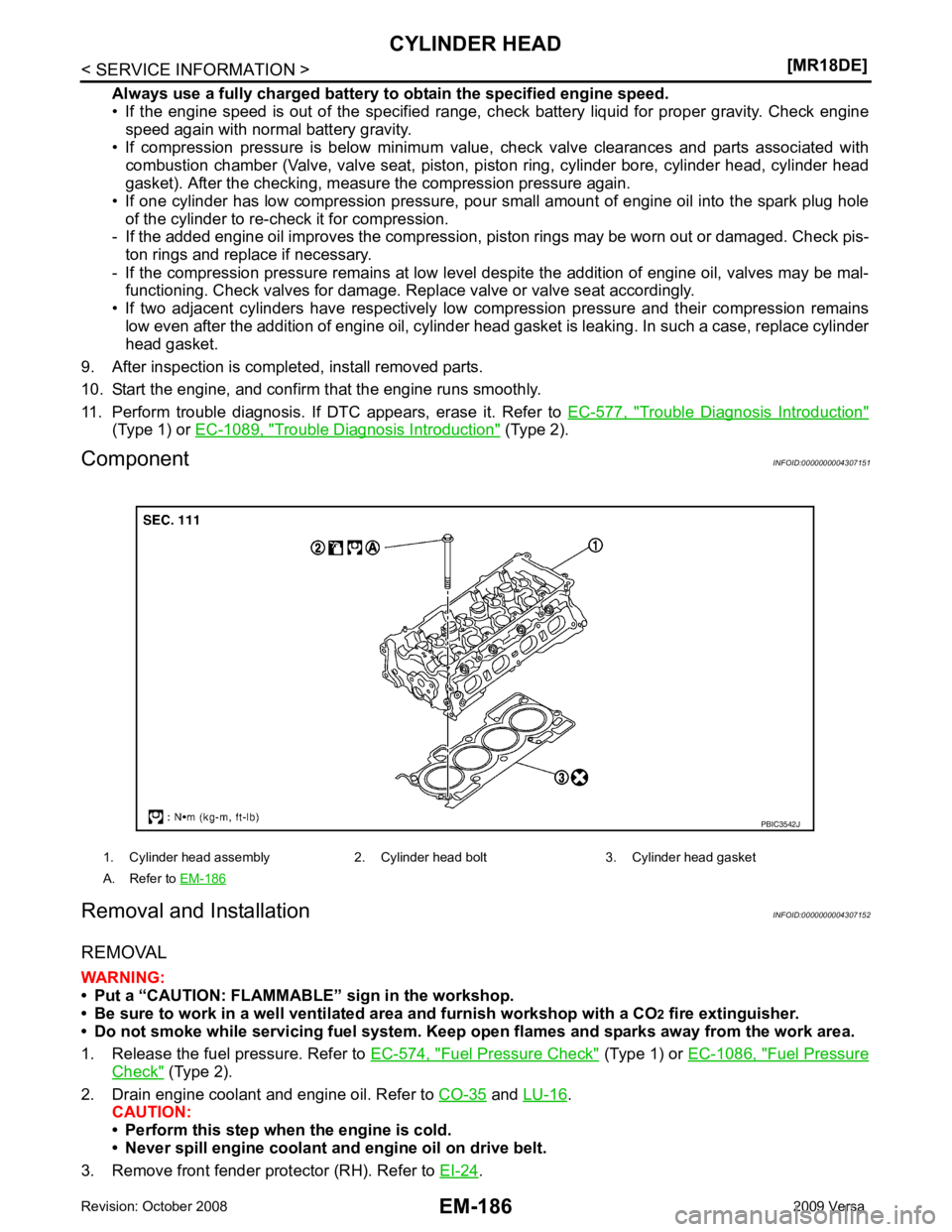

3. Remove valve collet. • Compress valve spring using Tool (A). Remove valve collet

using a suitable magnet hand.

CAUTION:

When working, be careful not to damage valve lifter holes.

4. Remove valve spring retainer and valve spring (with valve spring seat). CAUTION:

Never remove valve spring seat from valve spring.

5. Push valve stem to combustion chamber side, and remove valve. NOTE:

Identify installed positions, and st ore them without mixing them up.

6. Remove valve oil seal using Tool (A).

7. When valve seat must be replaced, refer to EM-190, " Inspection After Disassembly " .

8. When valve guide must be replaced, refer to EM-190, " Inspection After Disassembly " .

ASSEMBLY 1. Install valve guide if removed. Refer to EM-190, " Inspection After Disassembly " .

2. Install valve seat if removed. Refer to EM-190, " Inspection After Disassembly " .

1. Valve collet 2. Valve spring retainer 3. Valve spring (EXH) (with valve spring

seat)

4. Valve oil seal 5. Valve guide (EXH) 6. Valve seat (EXH)

7. Valve (EXH) 8. Valve (INT) 9. Valve seat (INT)

10. Cylinder head 11. Valve guide (INT) 12. Spark plug

13. Valve spring (INT ) (with valve spring

seat)

A. Refer to EM-190 B. Refer to

EM-190

Page 3137 of 4331

![NISSAN LATIO 2009 Service Repair Manual EM-190< SERVICE INFORMATION >

[MR18DE]

CYLINDER HEAD

3. Install valve oil seal. • Install with a valve oil seal using Tool (A) to match dimensionas shown.

NOTE:

Dimension (H) is height NISSAN LATIO 2009 Service Repair Manual EM-190< SERVICE INFORMATION >

[MR18DE]

CYLINDER HEAD

3. Install valve oil seal. • Install with a valve oil seal using Tool (A) to match dimensionas shown.

NOTE:

Dimension (H) is height](/img/5/57359/w960_57359-3136.png)

EM-190< SERVICE INFORMATION >

[MR18DE]

CYLINDER HEAD

3. Install valve oil seal. • Install with a valve oil seal using Tool (A) to match dimensionas shown.

NOTE:

Dimension (H) is height that measured before installing valve

spring (with valve spring seat).

4. Install valve. • Install larger diameter to intake side.

5. Install valve spring (with valve spring seat). • Install smaller pitch (valve spring seat side) to cylinder head

side (B).

• Confirm identification color (A) of valve spring.

6. Install valve spring retainer.

7. Install valve collet. • Compress valve spring using Tool (A). Install valve collet with a magnet hand.

CAUTION:

When working, be careful not to damage valve lifter holes.

• Tap valve stem edge lightly with a plastic hammer after instal- lation to check its installed condition.

8. Install valve lifter. • Install it in the original position.

9. Install spark plug using suitable tool.

Inspection After Disassembly INFOID:0000000004307155

VALVE DIMENSIONS

• Check dimensions of each valve. For dimensions, refer to EM-227, " Standard and Limit " .

• If dimensions are out of the standard, replace valve.

VALVE GUIDE CLEARANCE

Valve Stem Diameter Tool number : KV10115600 (J-38958)

Height (H) : 15.1 - 15.7 mm (0.594 - 0.618 in) PBIC3211J

1 : Valve spring seat (Do not remove from valve spring.)

Intake : White

Exhaust : Orange PBIC3462J

Tool number : KV101092S0 (J-26336 B)

PBIC3209J

Page 3138 of 4331

![NISSAN LATIO 2009 Service Repair Manual CYLINDER HEAD

EM-191

< SERVICE INFORMATION >

[MR18DE] C

D E

F

G H

I

J

K L

M A EM

NP

O

Measure the diameter of valv

e stem with a micrometer (A).

Valve Guide Inner Diameter Measure the inner diameter o NISSAN LATIO 2009 Service Repair Manual CYLINDER HEAD

EM-191

< SERVICE INFORMATION >

[MR18DE] C

D E

F

G H

I

J

K L

M A EM

NP

O

Measure the diameter of valv

e stem with a micrometer (A).

Valve Guide Inner Diameter Measure the inner diameter o](/img/5/57359/w960_57359-3137.png)

CYLINDER HEAD

EM-191

< SERVICE INFORMATION >

[MR18DE] C

D E

F

G H

I

J

K L

M A EM

NP

O

Measure the diameter of valv

e stem with a micrometer (A).

Valve Guide Inner Diameter Measure the inner diameter of valve guide with a bore gauge.

Valve Guide Clearance (Valve guide clearance) = (Valve guide inner diameter) – (Valve stem diameter).

• If it exceeds the limit, replace valve guide and/or valve.

VALVE GUIDE REPLACEMENT When valve guide is removed, replace with oversized [0.2 mm (0.008 in)] valve guide.

1. To remove valve guide, heat cylinder head to 110 ° to 130 °C

(230 ° to 266 °F) by soaking in heated oil (A).

2. Drive out valve guide using suitable tools. WARNING:

Cylinder head contai ns heat, when workin g, wear protective

equipment to avoid getting burned. Standard

Intake : 5.465 - 5.480 mm (0.2152 - 0.2157 in)

Exhaust : 5.455 - 5.470 mm (0.2148 - 0.2154 in) PBIC3213J

Standard

: 5.500 - 5.518 mm (0.2165 - 0.2172 in)

Valve guide clearance:

Standard Intake : 0.020 - 0.053 mm (0.0008 - 0.0021 in)

Exhaust : 0.030 - 0.063 mm (0.0012 - 0.0025 in)

Limit : 0.1 mm (0.004 in) PBIC3214J

SEM931C

Page 3139 of 4331

![NISSAN LATIO 2009 Service Repair Manual EM-192< SERVICE INFORMATION >

[MR18DE]

CYLINDER HEAD

3. Ream cylinder head valve guide hole using suitable tool (A).

4. Heat cylinder head to 110 ° to 130 °C (230 ° to 266 °F) by soaking

in heated NISSAN LATIO 2009 Service Repair Manual EM-192< SERVICE INFORMATION >

[MR18DE]

CYLINDER HEAD

3. Ream cylinder head valve guide hole using suitable tool (A).

4. Heat cylinder head to 110 ° to 130 °C (230 ° to 266 °F) by soaking

in heated](/img/5/57359/w960_57359-3138.png)

EM-192< SERVICE INFORMATION >

[MR18DE]

CYLINDER HEAD

3. Ream cylinder head valve guide hole using suitable tool (A).

4. Heat cylinder head to 110 ° to 130 °C (230 ° to 266 °F) by soaking

in heated oil (A).

5. Press valve guide (1) from camshaft side to dimensions as shown.

WARNING:

Cylinder head contains heat, when working, wear protective

equipment to avoid getting burned.

6. Apply reamer finish to valve guide using suitable tool (A).

VALVE SEAT CONTACT

• After confirming that the dimensions of valve guides and valves are within specifications, perform this proce-

dure.

• Apply prussian blue (or white lead) onto contacting surfac e of valve seat to check the condition of the valve

contact on the surface. Valve guide hole diameter (for service parts):

: 9.675 - 9.696 mm (0.3809 - 0.3817 in) PBIC3215J

PBIC3214J

2 : Cylinder head

Projection (H) : 13.35 - 13.65 mm (0.526 - 0.537 in) PBIC3217J

Standard

: 5.500 - 5.518 mm (0.2165 - 0.2172 in) PBIC3215J

Page 3140 of 4331

![NISSAN LATIO 2009 Service Repair Manual CYLINDER HEAD

EM-193

< SERVICE INFORMATION >

[MR18DE] C

D E

F

G H

I

J

K L

M A EM

NP

O

• Check if the contact area band is continuous all around the circum-

ference.

• If not, grind to adjust valve NISSAN LATIO 2009 Service Repair Manual CYLINDER HEAD

EM-193

< SERVICE INFORMATION >

[MR18DE] C

D E

F

G H

I

J

K L

M A EM

NP

O

• Check if the contact area band is continuous all around the circum-

ference.

• If not, grind to adjust valve](/img/5/57359/w960_57359-3139.png)

CYLINDER HEAD

EM-193

< SERVICE INFORMATION >

[MR18DE] C

D E

F

G H

I

J

K L

M A EM

NP

O

• Check if the contact area band is continuous all around the circum-

ference.

• If not, grind to adjust valve fitti ng and check again. If the contacting

surface still has NG conditions even after the re-check, replace

valve seat.

VALVE SEAT REPLACEMENT When valve seat is removed, replace with oversized [0.5 mm (0.020 in)] valve seat.

1. Bore out old seat until it collapses. Boring shoul d not continue beyond the bottom face of the seat recess

in cylinder head. Set the machine depth stop to ensure this. Refer to EM-227, " Standard and Limit " .

2. Ream cylinder head (1) recess diameter for service valve seat.

• Be sure to ream in circles concentric to the valve guide center.This will enable valve seat to fit correctly.

3. Heat cylinder head to 110 ° to 130 °C (230 ° to 266 °F) by soaking

in heated oil (A).

4. Provide valve seats cooled well with dry ic e. Press-fit valve seat into cylinder head.

WARNING:

• Never touch cold valve seats directly.

• Cylinder head contains heat, wh en working, wear protective equipment to avoid getting burned.

5. Using valve seat cutter set or valve seat grinder, finish valve seat to the specified dimensions. For dimensions, refer to EM-227, " Standard and Limit " .

CAUTION:

When using valve seat cutter, firmly grip the cutter handle

with both hands. Then, press on the contacting surface all

around the circumference to cu t in a single drive. Improper

pressure on the cutter or cutting many different times may

result in staged valve seat.

6. Using compound, grind to adjust valve fitting.

7. Check again for normal contact. SBIA0322E

2 : Valve seat

Oversize [0.5 mm (0.020 in)] Intake : 35.200 - 35.227 mm (1.3858 - 1.3869 in)

Exhaust : 29.200 - 29.227 mm (1.1496 - 1.1507 in) PBIC3218J

PBIC3214J

SEM934C