NISSAN NAVARA 2005 Repair Workshop Manual

Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 1041 of 3171

TROUBLE DIAGNOSIS

EC-61

C

D

E

F

G

H

I

J

K

L

MA

EC

INSPECTION PROCEDURE

CAUTION:

If CONSULT-II is used with no connection of CONSULT-II CONVERTER, malfunctions might be

detected in self-diagnosis depending on control unit which carry out CAN communication.

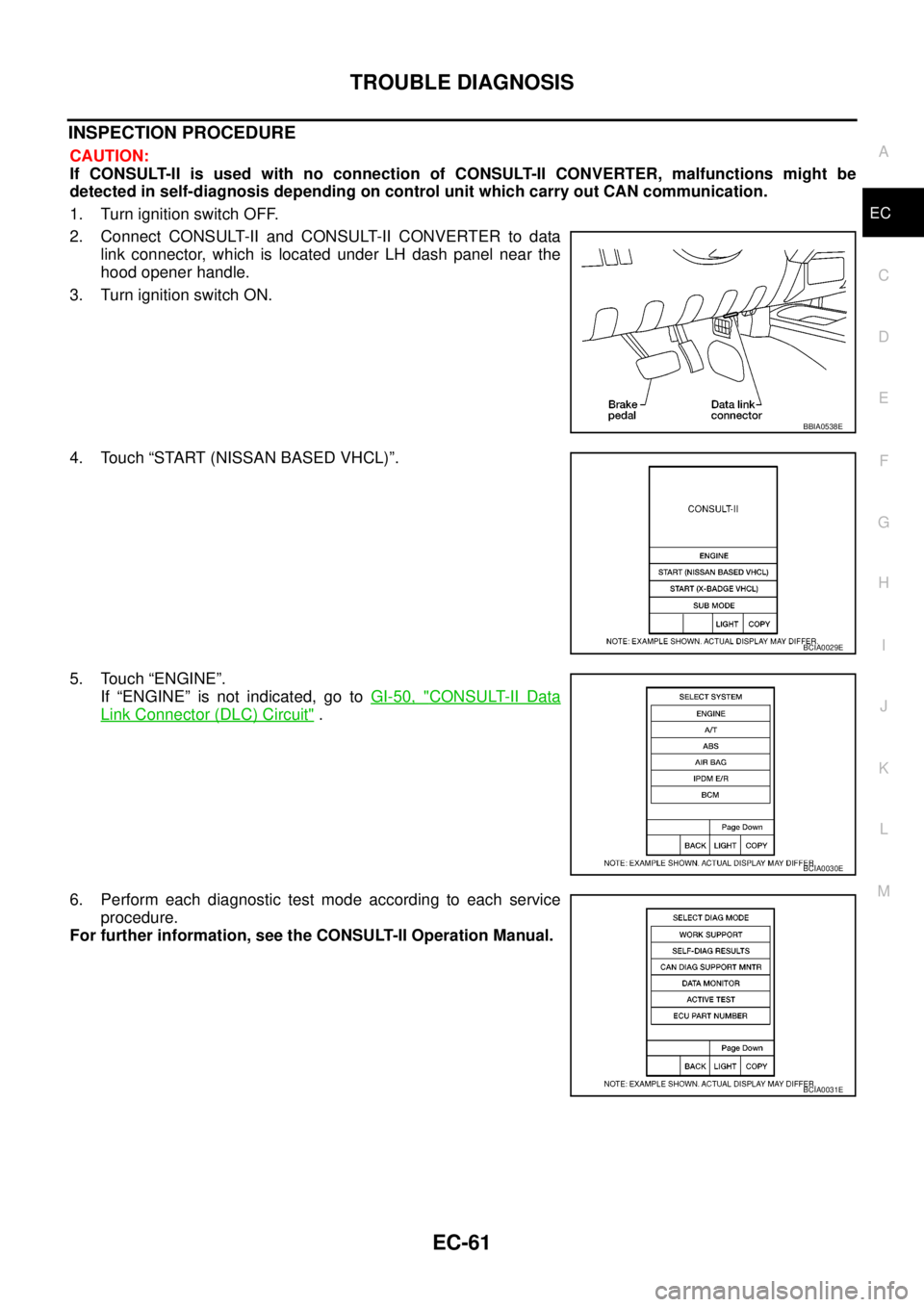

1. Turn ignition switch OFF.

2. Connect CONSULT-II and CONSULT-II CONVERTER to data

link connector, which is located under LH dash panel near the

hood opener handle.

3. Turn ignition switch ON.

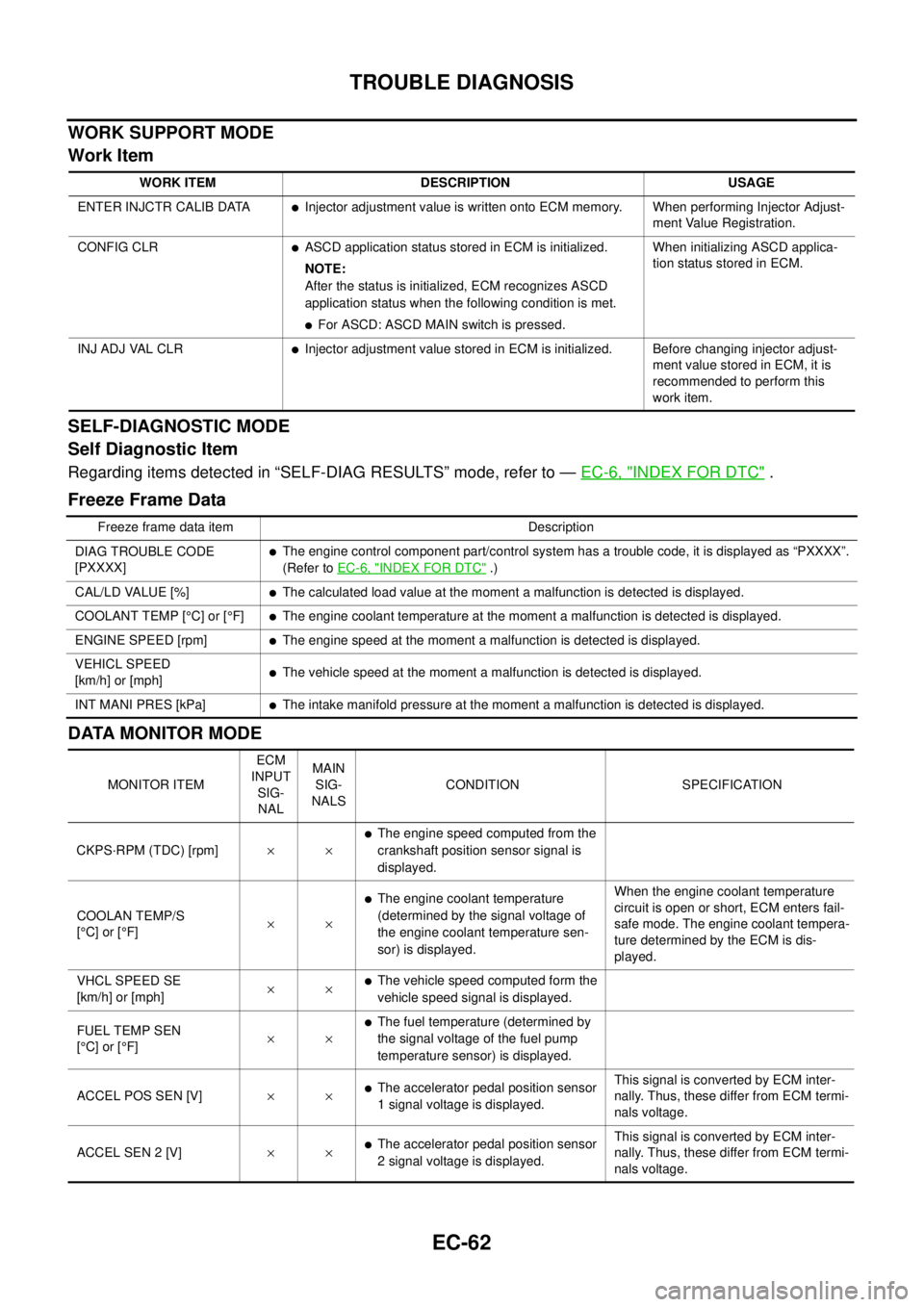

4. Touch “START (NISSAN BASED VHCL)”.

5. Touch “ENGINE”.

If “ENGINE” is not indicated, go toGI-50, "

CONSULT-II Data

Link Connector (DLC) Circuit".

6. Perform each diagnostic test mode according to each service

procedure.

For further information, see the CONSULT-II Operation Manual.

BBIA0538E

BCIA0029E

BCIA0030E

BCIA0031E

Page 1042 of 3171

EC-62

TROUBLE DIAGNOSIS

WORK SUPPORT MODE

Work Item

SELF-DIAGNOSTIC MODE

Self Diagnostic Item

Regarding items detected in “SELF-DIAG RESULTS” mode, refer to —EC-6, "INDEX FOR DTC".

Freeze Frame Data

DATA MONITOR MODE

WORK ITEM DESCRIPTION USAGE

ENTER INJCTR CALIB DATA

lInjector adjustment value is written onto ECM memory. When performing Injector Adjust-

ment Value Registration.

CONFIG CLR

lASCD application status stored in ECM is initialized.

NOTE:

After the status is initialized, ECM recognizes ASCD

application status when the following condition is met.

lFor ASCD: ASCD MAIN switch is pressed.When initializing ASCD applica-

tion status stored in ECM.

INJ ADJ VAL CLR

lInjector adjustment value stored in ECM is initialized. Before changing injector adjust-

ment value stored in ECM, it is

recommended to perform this

work item.

Freeze frame data item Description

DIAG TROUBLE CODE

[PXXXX]

lThe engine control component part/control system has a trouble code, it is displayed as “PXXXX”.

(Refer toEC-6, "

INDEX FOR DTC".)

CAL/LD VALUE [%]

lThe calculated load value at the moment a malfunction is detected is displayed.

COOLANT TEMP [°C] or [°F]

lThe engine coolant temperature at the moment a malfunction is detected is displayed.

ENGINE SPEED [rpm]

lThe engine speed at the moment a malfunction is detected is displayed.

VEHICL SPEED

[km/h] or [mph]

lThe vehicle speed at the moment a malfunction is detected is displayed.

INT MANI PRES [kPa]

lThe intake manifold pressure at the moment a malfunction is detected is displayed.

MONITOR ITEMECM

INPUT

SIG-

NALMAIN

SIG-

NALSCONDITION SPECIFICATION

CKPS·RPM (TDC) [rpm]´´

lThe engine speed computed from the

crankshaft position sensor signal is

displayed.

COOLAN TEMP/S

[°C] or [°F]´´

lThe engine coolant temperature

(determined by the signal voltage of

the engine coolant temperature sen-

sor) is displayed.When the engine coolant temperature

circuit is open or short, ECM enters fail-

safe mode. The engine coolant tempera-

ture determined by the ECM is dis-

played.

VHCL SPEED SE

[km/h] or [mph]´´

lThe vehicle speed computed form the

vehicle speed signal is displayed.

FUEL TEMP SEN

[°C] or [°F]´´

lThe fuel temperature (determined by

the signal voltage of the fuel pump

temperature sensor) is displayed.

ACCEL POS SEN [V]´´

lThe accelerator pedal position sensor

1 signal voltage is displayed.This signal is converted by ECM inter-

nally. Thus, these differ from ECM termi-

nals voltage.

ACCEL SEN 2 [V]´´

lThe accelerator pedal position sensor

2 signal voltage is displayed.This signal is converted by ECM inter-

nally. Thus, these differ from ECM termi-

nals voltage.

Page 1043 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual TROUBLE DIAGNOSIS

EC-63

C

D

E

F

G

H

I

J

K

L

MA

ECACT CR PRESS [MPa]´´

lThe Fuel rail pressure (determined by

the signal voltage of the fuel rail pres-

sure sensor) is displayed.

BATTERY VOLT [V]´´ NISSAN NAVARA 2005 Repair Workshop Manual TROUBLE DIAGNOSIS

EC-63

C

D

E

F

G

H

I

J

K

L

MA

ECACT CR PRESS [MPa]´´

lThe Fuel rail pressure (determined by

the signal voltage of the fuel rail pres-

sure sensor) is displayed.

BATTERY VOLT [V]´´](/img/5/57362/w960_57362-1042.png)

TROUBLE DIAGNOSIS

EC-63

C

D

E

F

G

H

I

J

K

L

MA

ECACT CR PRESS [MPa]´´

lThe Fuel rail pressure (determined by

the signal voltage of the fuel rail pres-

sure sensor) is displayed.

BATTERY VOLT [V]´´

lThe power supply voltage of ECM is

displayed.

P/N POSI SW [ON/OFF]´´

lIndicates [ON/OFF] condition from the

park/neutral position switch signal.

START SIGNAL [ON/OFF]´´

lIndicates [ON/OFF] condition from the

starter signal.

AIR COND SIG [ON/OFF]´´

lIndicates [ON/OFF] condition of the air

conditioner switch as determined by

the air conditioner signal.

BRAKE SW [ON/OFF]´´

lIndicates [ON/OFF] condition from the

stop lamp switch signal.

BRAKE SW2 [ON/OFF]´´

lIndicates [ON/OFF] condition from the

ASCD brake switch and ASCD clutch

switch signal.

IGN SW [ON/OFF]´´

lIndicates [ON/OFF] condition from

ignition switch signal.

WARM UP SW [ON/OFF]´

lIndicates [ON/OFF] condition from

heat up switch signal.

MAS AIR/FL SE [V]´´

lThe signal voltage of the mass air flow

sensor is displayed.This signal is converted by ECM inter-

nally. Thus, these differ from ECM termi-

nals voltage.

MAIN INJ WID [msec]´

lIndicates the actual fuel injection pulse

width compensated by ECM according

to the input signals.

PUMP CURRENT [mA]´

lIndicates the fuel pump power supply

current from the ECM.

GLOW RLY [ON/OFF]´

lThe glow relay control condition

(determined by ECM according to the

input signal) is displayed.

COOLING FAN

[LOW/HI/OFF]´

lIndicates the control condition of the

cooling fans (determined by ECM

according to the input signal).

LOW ... Operates at low speed

HI ... Operates at high speed

OFF ... Stopped

EGR VOL CON/V [step]´

lIndicates the EGR volume control

value computed by the ECM accord-

ing to the input signals.

lThe opening becomes larger as the

value increases.

INT/A VOLUME [mg/]

lThe intake air volume computed from

the mass air flow sensor signal is dis-

played.

BARO SEN [kPa]´´

lThe barometric pressure (determined

by the signal voltage from the absolute

pressure sensor built into the ECM) is

displayed. MONITOR ITEMECM

INPUT

SIG-

NALMAIN

SIG-

NALSCONDITION SPECIFICATION

Page 1044 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual EC-64

TROUBLE DIAGNOSIS

NOTE:

Any monitored item that does not match the vehicle being diagnosed is deleted from the display automatically.

ACTIVE TEST MODE

INT/M PRES SE [kPa]

lTurbocharger boost (de NISSAN NAVARA 2005 Repair Workshop Manual EC-64

TROUBLE DIAGNOSIS

NOTE:

Any monitored item that does not match the vehicle being diagnosed is deleted from the display automatically.

ACTIVE TEST MODE

INT/M PRES SE [kPa]

lTurbocharger boost (de](/img/5/57362/w960_57362-1043.png)

EC-64

TROUBLE DIAGNOSIS

NOTE:

Any monitored item that does not match the vehicle being diagnosed is deleted from the display automatically.

ACTIVE TEST MODE

INT/M PRES SE [kPa]

lTurbocharger boost (determined by

the signal voltage from the turbo-

charger boost sensor) is displayed.

CYL COUNT [1/2/3/4]

lThe cylinder being injected is dis-

played.

1 ... Cylinder No.1 is injected.

2 ... Cylinder No.2 is injected.

3 ... Cylinder No.3 is injected.

4 ... Cylinder No.4 is injected.

SET SW

[ON/OFF]´

lIndicates [ON/OFF] condition from

SET/COAST switch signal.

RESUME/ACC SW

[ON/OFF]´

lIndicates [ON/OFF] condition from

RESUME/ACCEL switch signal.

CANCEL SW

[ON/OFF]´

lIndicates [ON/OFF] condition from

CANCEL switch signal.

MAIN SW

[ON/OFF]´

lIndicates [ON/OFF] condition from

MAIN switch signal.

ASCD APPLY [YES/NO]

lDisplaying ASCD application status

stored in ECM.

VDC APPLY [YES/NO]

lDisplaying ESP application status

stored in ECM.

AC PRESS SEN [V]

lThe signal voltage from the refrigerant

pressure sensor is displayed.

Voltage [V]

Voltage, frequency, duty cycle or pulse

width measured by the probe.Only “#” is displayed if item is unable to

be measured.

Figures with “#”s are temporary ones.

They are the same figures as an actual

piece of data which was just previously

measured. [Hz] or [%] Frequency

[msec],[Hz]or[%]

DUTY-HI

DUTY-LOW

PLS WIDTH-HI

PLS WIDTH-LOWMONITOR ITEMECM

INPUT

SIG-

NALMAIN

SIG-

NALSCONDITION SPECIFICATION

TEST ITEM CONDITION JUDGEMENT CHECK ITEM (REMEDY)

POWER BAL-

ANCE

lEngine: After warming up, idle the

engine.

lA/C switch: OFF

lShift lever: P or N (A/T), Neutral

(M/T)

lCut off each injector signal one at

a time using CONSULT-IIEngine runs rough or dies.

lHarness and connectors

lCompression

lFuel injector

COOLING FAN *

lIgnition switch: ON

lOperate the cooling fan at LOW,

HI speed and turn OFF using

CONSULT-II.Cooling fan moves at LOW, HI

speed and stops.lHarness and connector

lCooling fan motor

lCooling fan relay

ENG COOLANT

TEMP

lEngine: Return to the original

trouble condition

lChange the engine coolant tem-

perature using CONSULT-II.If trouble symptom disappears, see

CHECK ITEM.

lHarness and connectors

lEngine coolant temperature sen-

sor

lFuel injector

Page 1045 of 3171

TROUBLE DIAGNOSIS

EC-65

C

D

E

F

G

H

I

J

K

L

MA

EC

*: Leaving cooling fan OFF with CONSULT-II while engine is running may cause the engine to overheat.

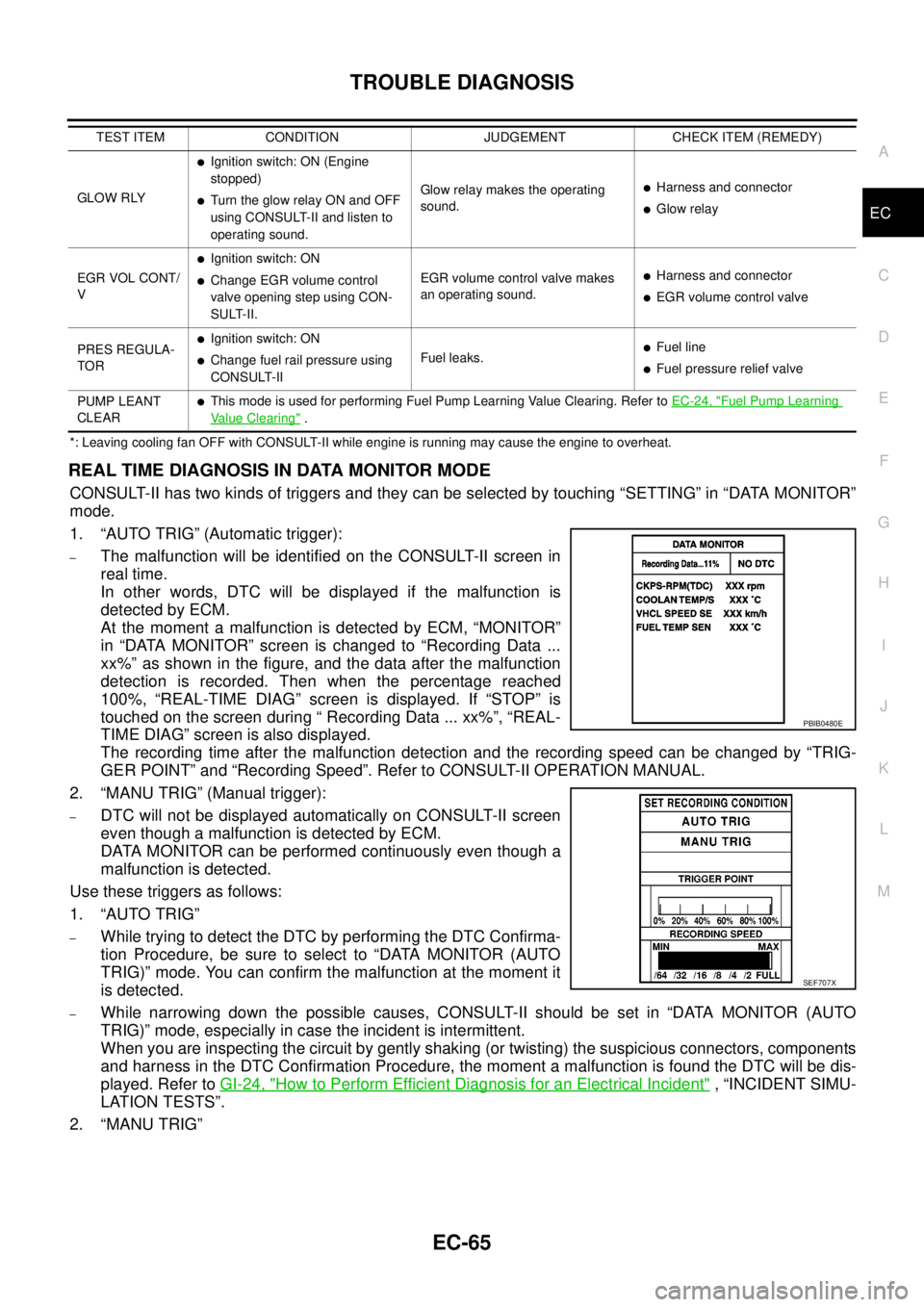

REAL TIME DIAGNOSIS IN DATA MONITOR MODE

CONSULT-II has two kinds of triggers and they can be selected by touching “SETTING” in “DATA MONITOR”

mode.

1. “AUTO TRIG” (Automatic trigger):

–The malfunction will be identified on the CONSULT-II screen in

real time.

In other words, DTC will be displayed if the malfunction is

detected by ECM.

At the moment a malfunction is detected by ECM, “MONITOR”

in “DATA MONITOR” screen is changed to “Recording Data ...

xx%” as shown in the figure, and the data after the malfunction

detection is recorded. Then when the percentage reached

100%, “REAL-TIME DIAG” screen is displayed. If “STOP” is

touched on the screen during “ Recording Data ... xx%”, “REAL-

TIME DIAG” screen is also displayed.

The recording time after the malfunction detection and the recording speed can be changed by “TRIG-

GER POINT” and “Recording Speed”. Refer to CONSULT-II OPERATION MANUAL.

2. “MANU TRIG” (Manual trigger):

–DTC will not be displayed automatically on CONSULT-II screen

even though a malfunction is detected by ECM.

DATA MONITOR can be performed continuously even though a

malfunction is detected.

Use these triggers as follows:

1. “AUTO TRIG”

–While trying to detect the DTC by performing the DTC Confirma-

tion Procedure, be sure to select to “DATA MONITOR (AUTO

TRIG)” mode. You can confirm the malfunction at the moment it

is detected.

–While narrowing down the possible causes, CONSULT-II should be set in “DATA MONITOR (AUTO

TRIG)” mode, especially in case the incident is intermittent.

When you are inspecting the circuit by gently shaking (or twisting) the suspicious connectors, components

and harness in the DTC Confirmation Procedure, the moment a malfunction is found the DTC will be dis-

played. Refer toGI-24, "

How to Perform Efficient Diagnosis for an Electrical Incident", “INCIDENT SIMU-

LATION TESTS”.

2. “MANU TRIG”

GLOW RLY

lIgnition switch: ON (Engine

stopped)

lTurn the glow relay ON and OFF

using CONSULT-II and listen to

operating sound.Glow relay makes the operating

sound.lHarness and connector

lGlow relay

EGR VOL CONT/

V

lIgnition switch: ON

lChange EGR volume control

valve opening step using CON-

SULT-II.EGR volume control valve makes

an operating sound.lHarness and connector

lEGR volume control valve

PRES REGULA-

TOR

lIgnition switch: ON

lChange fuel rail pressure using

CONSULT-IIFuel leaks.lFuel line

lFuel pressure relief valve

PUMP LEANT

CLEAR

lThis mode is used for performing Fuel Pump Learning Value Clearing. Refer toEC-24, "Fuel Pump Learning

Value Clearing". TEST ITEM CONDITION JUDGEMENT CHECK ITEM (REMEDY)

PBIB0480E

SEF707X

Page 1046 of 3171

EC-66

TROUBLE DIAGNOSIS

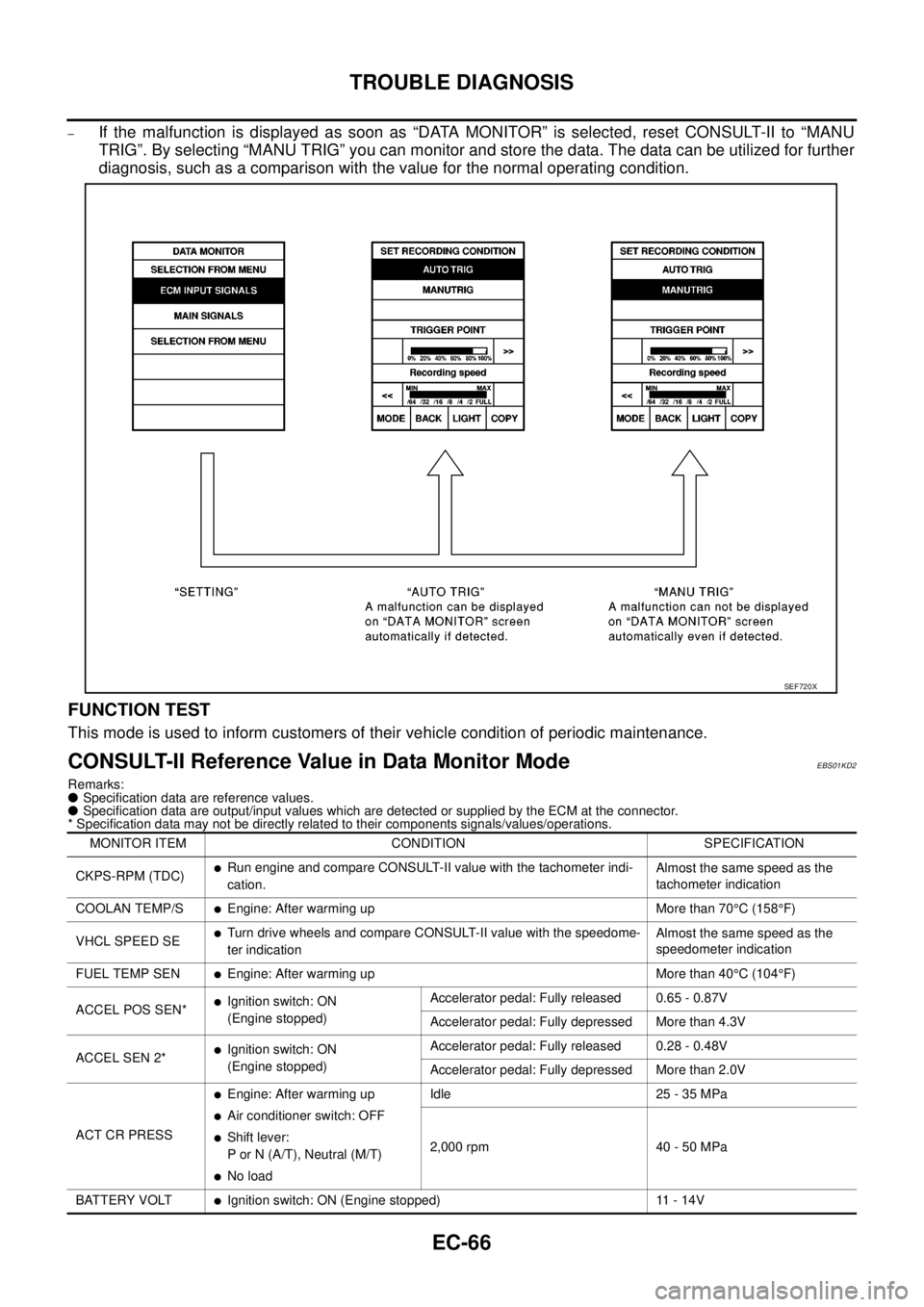

–If the malfunction is displayed as soon as “DATA MONITOR” is selected, reset CONSULT-II to “MANU

TRIG”. By selecting “MANU TRIG” you can monitor and store the data. The data can be utilized for further

diagnosis, such as a comparison with the value for the normal operating condition.

FUNCTION TEST

This mode is used to inform customers of their vehicle condition of periodic maintenance.

CONSULT-II Reference Value in Data Monitor ModeEBS01KD2

Remarks:

lSpecification data are reference values.

lSpecification data are output/input values which are detected or supplied by the ECM at the connector.

* Specification data may not be directly related to their components signals/values/operations.

SEF720X

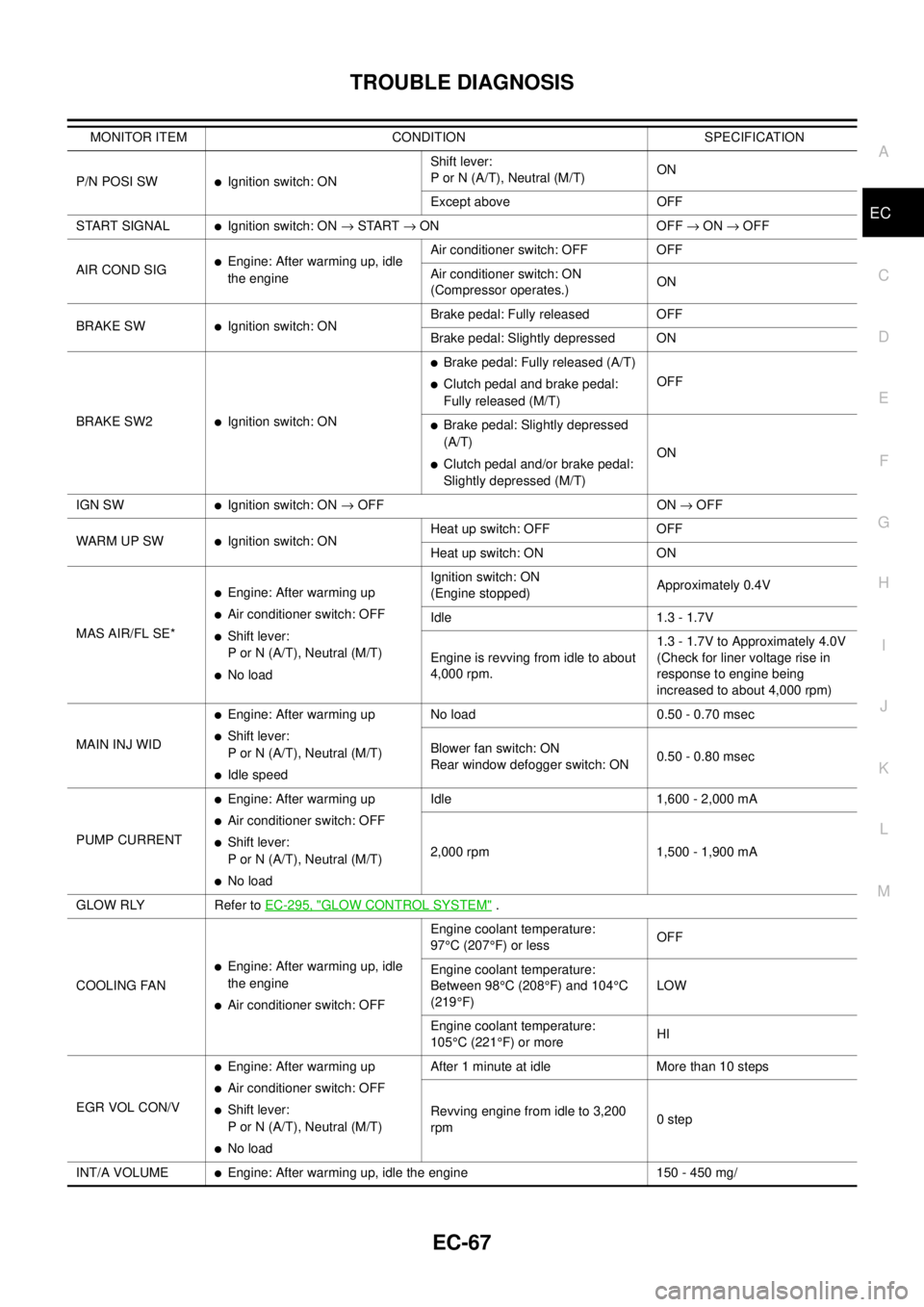

MONITOR ITEM CONDITION SPECIFICATION

CKPS-RPM (TDC)

lRun engine and compare CONSULT-II value with the tachometer indi-

cation.Almost the same speed as the

tachometer indication

COOLAN TEMP/S

lEngine: After warming up More than 70°C(158°F)

VHCL SPEED SE

lTurn drive wheels and compare CONSULT-II value with the speedome-

ter indicationAlmost the same speed as the

speedometer indication

FUEL TEMP SEN

lEngine: After warming up More than 40°C(104°F)

ACCEL POS SEN*

lIgnition switch: ON

(Engine stopped)Accelerator pedal: Fully released 0.65 - 0.87V

Accelerator pedal: Fully depressed More than 4.3V

ACCEL SEN 2*

lIgnition switch: ON

(Engine stopped)Accelerator pedal: Fully released 0.28 - 0.48V

Accelerator pedal: Fully depressed More than 2.0V

ACT CR PRESS

lEngine: After warming up

lAir conditioner switch: OFF

lShift lever:

P or N (A/T), Neutral (M/T)

lNo loadIdle 25 - 35 MPa

2,000 rpm 40 - 50 MPa

BATTERY VOLT

lIgnition switch: ON (Engine stopped) 11 - 14V

Page 1047 of 3171

TROUBLE DIAGNOSIS

EC-67

C

D

E

F

G

H

I

J

K

L

MA

EC

P/N POSI SWlIgnition switch: ONShift lever:

P or N (A/T), Neutral (M/T)ON

Except above OFF

START SIGNAL

lIgnition switch: ON®START®ON OFF®ON®OFF

AIRCONDSIG

lEngine: After warming up, idle

the engineAir conditioner switch: OFF OFF

Air conditioner switch: ON

(Compressor operates.)ON

BRAKE SW

lIgnition switch: ONBrake pedal: Fully released OFF

Brake pedal: Slightly depressed ON

BRAKE SW2

lIgnition switch: ON

lBrake pedal: Fully released (A/T)

lClutch pedal and brake pedal:

Fully released (M/T)OFF

lBrake pedal: Slightly depressed

(A/T)

lClutch pedal and/or brake pedal:

Slightly depressed (M/T)ON

IGN SW

lIgnition switch: ON®OFF ON®OFF

WARM UP SW

lIgnition switch: ONHeat up switch: OFF OFF

Heat up switch: ON ON

MAS AIR/FL SE*

lEngine: After warming up

lAir conditioner switch: OFF

lShift lever:

P or N (A/T), Neutral (M/T)

lNo loadIgnition switch: ON

(Engine stopped)Approximately 0.4V

Idle 1.3 - 1.7V

Engine is revving from idle to about

4,000 rpm.1.3 - 1.7V to Approximately 4.0V

(Check for liner voltage rise in

response to engine being

increased to about 4,000 rpm)

MAIN INJ WID

lEngine: After warming up

lShift lever:

P or N (A/T), Neutral (M/T)

lIdle speedNo load 0.50 - 0.70 msec

Blower fan switch: ON

Rear window defogger switch: ON0.50 - 0.80 msec

PUMP CURRENT

lEngine: After warming up

lAir conditioner switch: OFF

lShift lever:

P or N (A/T), Neutral (M/T)

lNo loadIdle 1,600 - 2,000 mA

2,000 rpm 1,500 - 1,900 mA

GLOW RLY Refer toEC-295, "

GLOW CONTROL SYSTEM".

COOLING FAN

lEngine: After warming up, idle

the engine

lAir conditioner switch: OFFEngine coolant temperature:

97°C (207°F) or lessOFF

Engine coolant temperature:

Between 98°C(208°F) and 104°C

(219°F)LOW

Engine coolant temperature:

105°C(221°F) or moreHI

EGR VOL CON/V

lEngine: After warming up

lAir conditioner switch: OFF

lShift lever:

P or N (A/T), Neutral (M/T)

lNo loadAfter 1 minute at idle More than 10 steps

Revving engine from idle to 3,200

rpm0step

INT/A VOLUME

lEngine: After warming up, idle the engine 150 - 450 mg/ MONITOR ITEM CONDITION SPECIFICATION

Page 1048 of 3171

EC-68

TROUBLE DIAGNOSIS

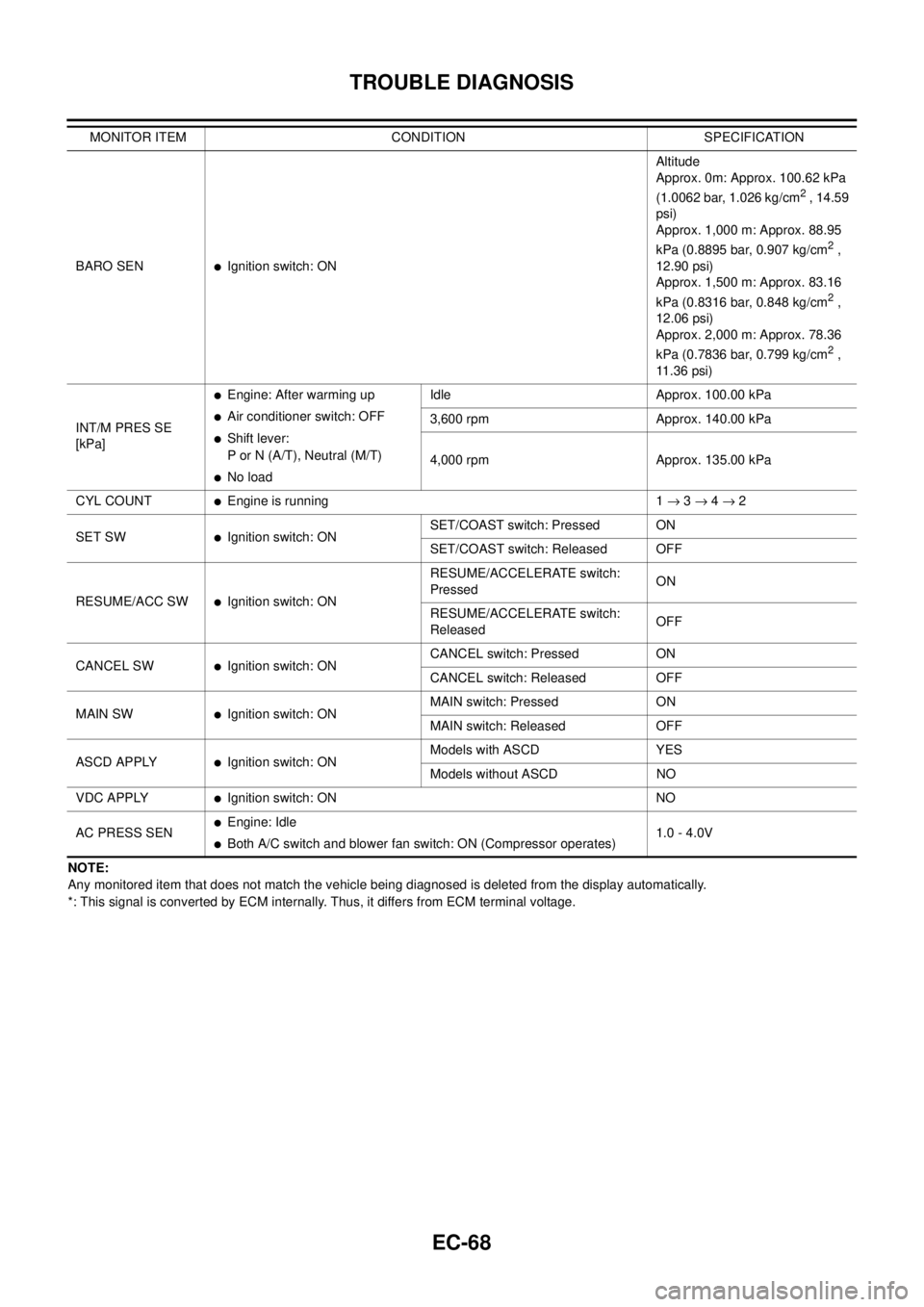

NOTE:

Any monitored item that does not match the vehicle being diagnosed is deleted from the display automatically.

*: This signal is converted by ECM internally. Thus, it differs from ECM terminal voltage.BARO SEN

lIgnition switch: ONAltitude

Approx. 0m: Approx. 100.62 kPa

(1.0062 bar, 1.026 kg/cm

2, 14.59

psi)

Approx. 1,000 m: Approx. 88.95

kPa (0.8895 bar, 0.907 kg/cm

2,

12.90 psi)

Approx. 1,500 m: Approx. 83.16

kPa (0.8316 bar, 0.848 kg/cm

2,

12.06 psi)

Approx. 2,000 m: Approx. 78.36

kPa (0.7836 bar, 0.799 kg/cm

2,

11 . 3 6 p s i )

INT/M PRES SE

[kPa]

lEngine: After warming up

lAir conditioner switch: OFF

lShift lever:

P or N (A/T), Neutral (M/T)

lNo loadIdle Approx. 100.00 kPa

3,600 rpm Approx. 140.00 kPa

4,000 rpm Approx. 135.00 kPa

CYL COUNT

lEngine is running 1®3®4®2

SET SW

lIgnition switch: ONSET/COAST switch: Pressed ON

SET/COAST switch: Released OFF

RESUME/ACC SW

lIgnition switch: ONRESUME/ACCELERATE switch:

PressedON

RESUME/ACCELERATE switch:

ReleasedOFF

CANCEL SW

lIgnition switch: ONCANCEL switch: Pressed ON

CANCEL switch: Released OFF

MAIN SW

lIgnition switch: ONMAIN switch: Pressed ON

MAIN switch: Released OFF

ASCD APPLY

lIgnition switch: ONModels with ASCD YES

Models without ASCD NO

VDC APPLY

lIgnition switch: ON NO

AC PRESS SEN

lEngine: Idle

lBoth A/C switch and blower fan switch: ON (Compressor operates)1.0 - 4.0V MONITOR ITEM CONDITION SPECIFICATION

Page 1049 of 3171

TROUBLE DIAGNOSIS

EC-69

C

D

E

F

G

H

I

J

K

L

MA

EC

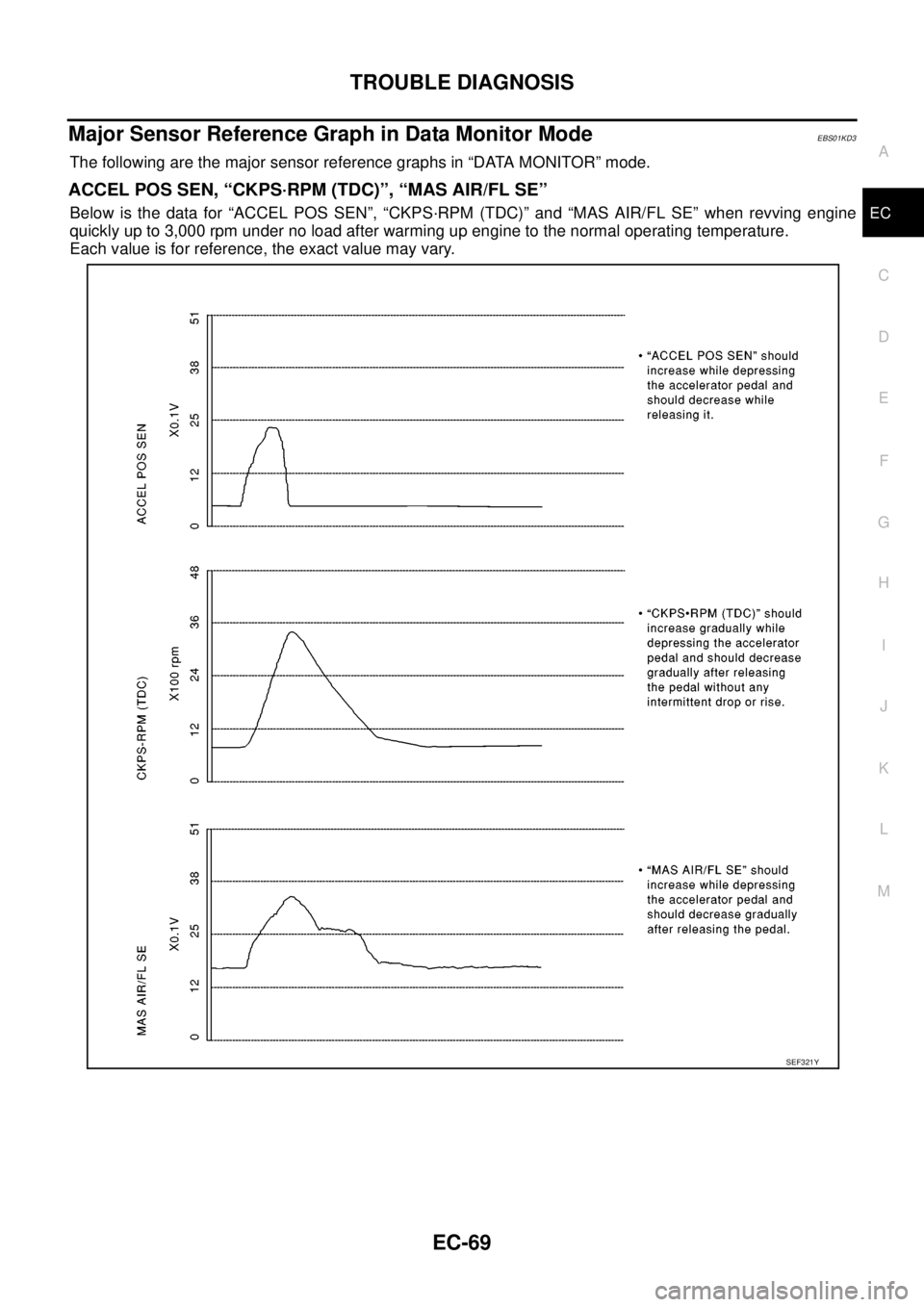

Major Sensor Reference Graph in Data Monitor ModeEBS01KD3

The following are the major sensor reference graphs in “DATA MONITOR” mode.

ACCEL POS SEN, “CKPS·RPM (TDC)”, “MAS AIR/FL SE”

Below is the data for “ACCEL POS SEN”, “CKPS·RPM (TDC)” and “MAS AIR/FL SE” when revving engine

quickly up to 3,000 rpm under no load after warming up engine to the normal operating temperature.

Each value is for reference, the exact value may vary.

SEF321Y

Page 1050 of 3171

EC-70

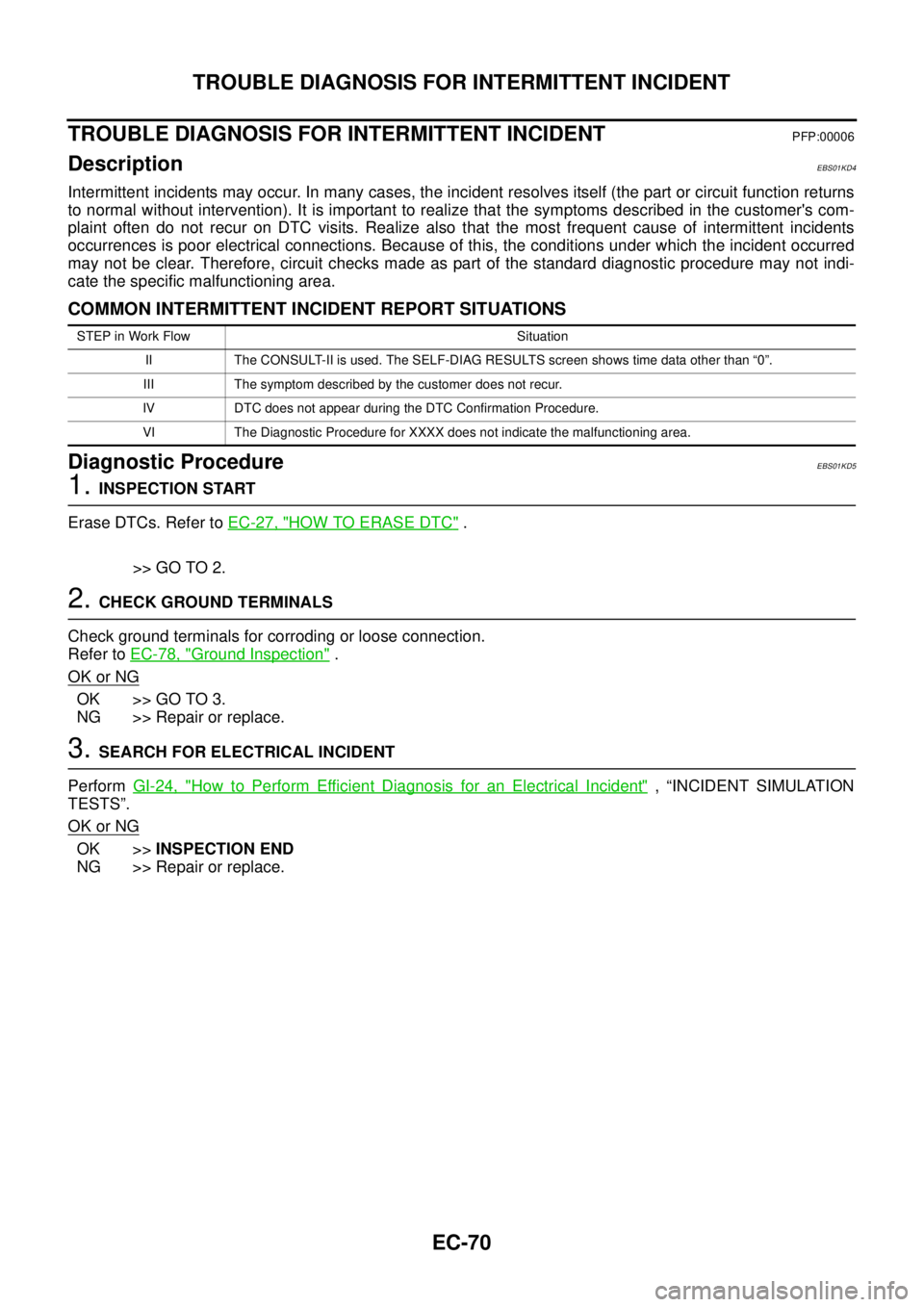

TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT

TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT

PFP:00006

DescriptionEBS01KD4

Intermittent incidents may occur. In many cases, the incident resolves itself (the part or circuit function returns

to normal without intervention). It is important to realize that the symptoms described in the customer's com-

plaint often do not recur on DTC visits. Realize also that the most frequent cause of intermittent incidents

occurrences is poor electrical connections. Because of this, the conditions under which the incident occurred

may not be clear. Therefore, circuit checks made as part of the standard diagnostic procedure may not indi-

cate the specific malfunctioning area.

COMMON INTERMITTENT INCIDENT REPORT SITUATIONS

Diagnostic ProcedureEBS01KD5

1.INSPECTION START

Erase DTCs. Refer toEC-27, "

HOW TO ERASE DTC".

>> GO TO 2.

2.CHECK GROUND TERMINALS

Check ground terminals for corroding or loose connection.

Refer toEC-78, "

Ground Inspection".

OK or NG

OK >> GO TO 3.

NG >> Repair or replace.

3.SEARCH FOR ELECTRICAL INCIDENT

PerformGI-24, "

How to Perform Efficient Diagnosis for an Electrical Incident", “INCIDENT SIMULATION

TESTS”.

OK or NG

OK >>INSPECTION END

NG >> Repair or replace.

STEP in Work Flow Situation

II The CONSULT-II is used. The SELF-DIAG RESULTS screen shows time data other than “0”.

III The symptom described by the customer does not recur.

IV DTC does not appear during the DTC Confirmation Procedure.

VI The Diagnostic Procedure for XXXX does not indicate the malfunctioning area.