NISSAN NAVARA 2005 Repair Workshop Manual

Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 1071 of 3171

DTC P0093 FUEL SYSTEM

EC-91

C

D

E

F

G

H

I

J

K

L

MA

EC

Removal and InstallationEBS01KDU

FUEL RAIL

Refer toEM-44, "INJECTION TUBE AND FUEL INJECTOR".

FUEL PUMP

Refer toEM-49, "FUEL PUMP".

Page 1072 of 3171

EC-92

DTC P0102, P0103 MAF SENSOR

DTC P0102, P0103 MAF SENSOR

PFP:22680

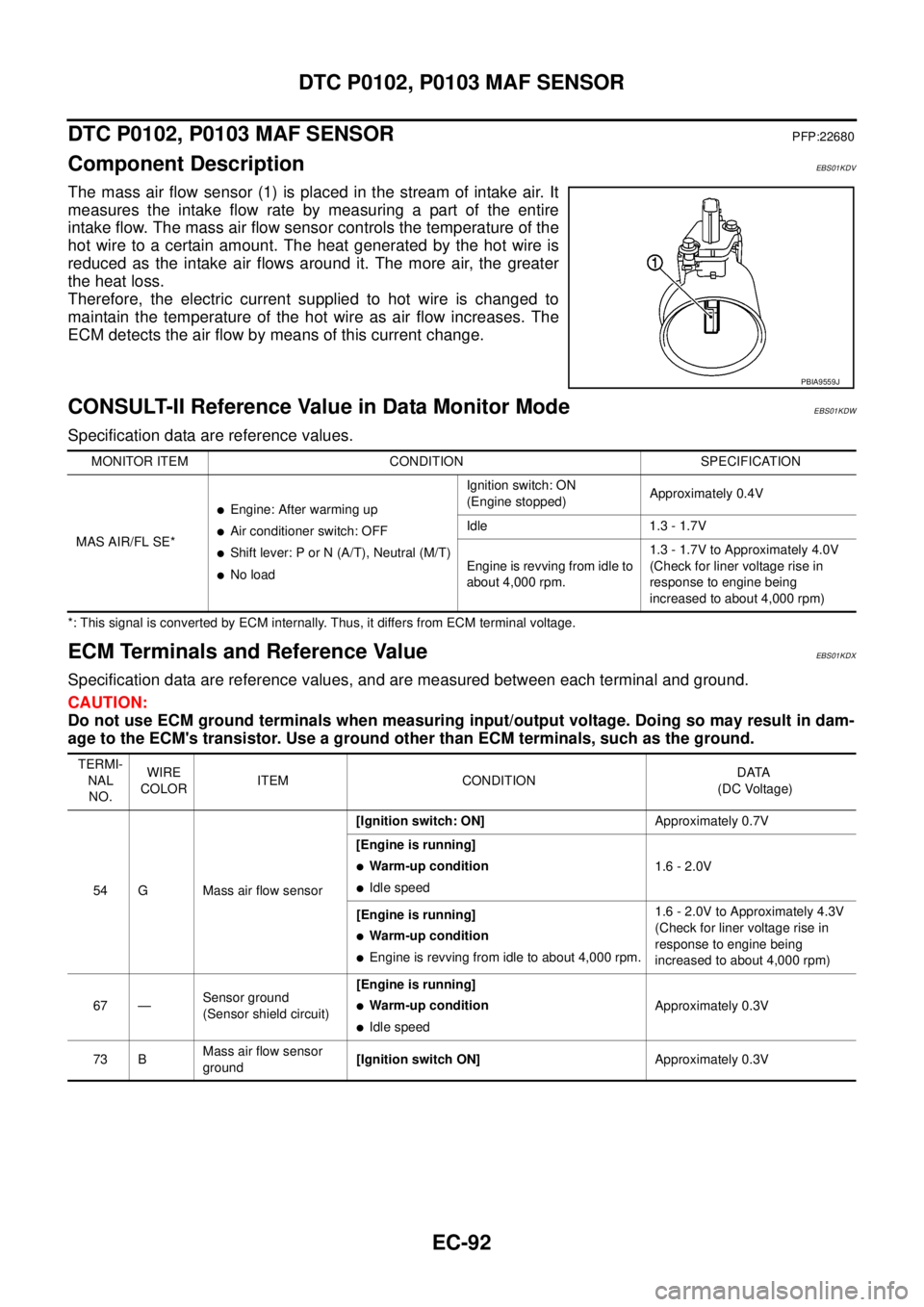

Component DescriptionEBS01KDV

The mass air flow sensor (1) is placed in the stream of intake air. It

measures the intake flow rate by measuring a part of the entire

intake flow. The mass air flow sensor controls the temperature of the

hot wire to a certain amount. The heat generated by the hot wire is

reduced as the intake air flows around it. The more air, the greater

the heat loss.

Therefore, the electric current supplied to hot wire is changed to

maintain the temperature of the hot wire as air flow increases. The

ECM detects the air flow by means of this current change.

CONSULT-II Reference Value in Data Monitor ModeEBS01KDW

Specification data are reference values.

*: This signal is converted by ECM internally. Thus, it differs from ECM terminal voltage.

ECM Terminals and Reference ValueEBS01KDX

Specification data are reference values, and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

PBIA9559J

MONITOR ITEM CONDITION SPECIFICATION

MAS AIR/FL SE*

lEngine: After warming up

lAir conditioner switch: OFF

lShift lever: P or N (A/T), Neutral (M/T)

lNo loadIgnition switch: ON

(Engine stopped)Approximately 0.4V

Idle 1.3 - 1.7V

Engine is revving from idle to

about 4,000 rpm.1.3 - 1.7V to Approximately 4.0V

(Check for liner voltage rise in

response to engine being

increased to about 4,000 rpm)

TERMI-

NAL

NO.WIRE

COLORITEM CONDITIONDATA

(DC Voltage)

54 G Mass air flow sensor[Ignition switch: ON]Approximately 0.7V

[Engine is running]

lWarm-up condition

lIdle speed1.6 - 2.0V

[Engine is running]

lWarm-up condition

lEngine is revving from idle to about 4,000 rpm.1.6 - 2.0V to Approximately 4.3V

(Check for liner voltage rise in

response to engine being

increased to about 4,000 rpm)

67 —Sensor ground

(Sensor shield circuit)[Engine is running]

lWarm-up condition

lIdle speedApproximately 0.3V

73 BMass air flow sensor

ground[Ignition switch ON]Approximately 0.3V

Page 1073 of 3171

DTC P0102, P0103 MAF SENSOR

EC-93

C

D

E

F

G

H

I

J

K

L

MA

EC

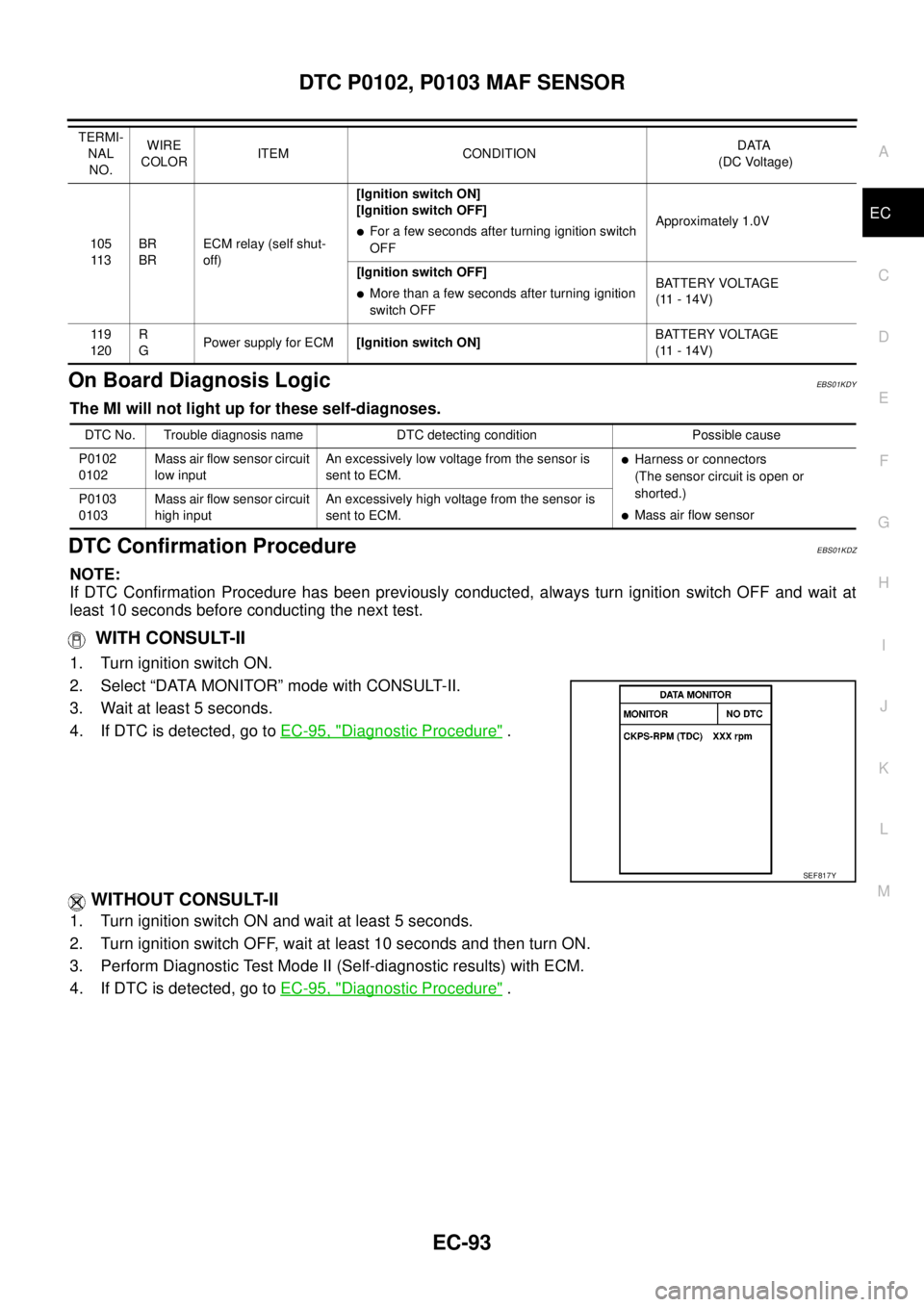

On Board Diagnosis LogicEBS01KDY

The MI will not light up for these self-diagnoses.

DTC Confirmation ProcedureEBS01KDZ

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

WITH CONSULT-II

1. Turn ignition switch ON.

2. Select “DATA MONITOR” mode with CONSULT-II.

3. Wait at least 5 seconds.

4. If DTC is detected, go toEC-95, "

Diagnostic Procedure".

WITHOUT CONSULT-II

1. Turn ignition switch ON and wait at least 5 seconds.

2. Turn ignition switch OFF, wait at least 10 seconds and then turn ON.

3. Perform Diagnostic Test Mode II (Self-diagnostic results) with ECM.

4. If DTC is detected, go toEC-95, "

Diagnostic Procedure".

105

11 3BR

BRECM relay (self shut-

off)[Ignition switch ON]

[Ignition switch OFF]lFor a few seconds after turning ignition switch

OFFApproximately 1.0V

[Ignition switch OFF]

lMore than a few seconds after turning ignition

switch OFFBATTERY VOLTAGE

(11 - 14V)

11 9

120R

GPower supply for ECM[Ignition switch ON]BATTERY VOLTAGE

(11 - 14V) TERMI-

NAL

NO.WIRE

COLORITEM CONDITIONDATA

(DC Voltage)

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0102

0102Mass air flow sensor circuit

low inputAn excessively low voltage from the sensor is

sent to ECM.

lHarness or connectors

(The sensor circuit is open or

shorted.)

lMass air flow sensor P0103

0103Mass air flow sensor circuit

high inputAn excessively high voltage from the sensor is

sent to ECM.

SEF817Y

Page 1074 of 3171

EC-94

DTC P0102, P0103 MAF SENSOR

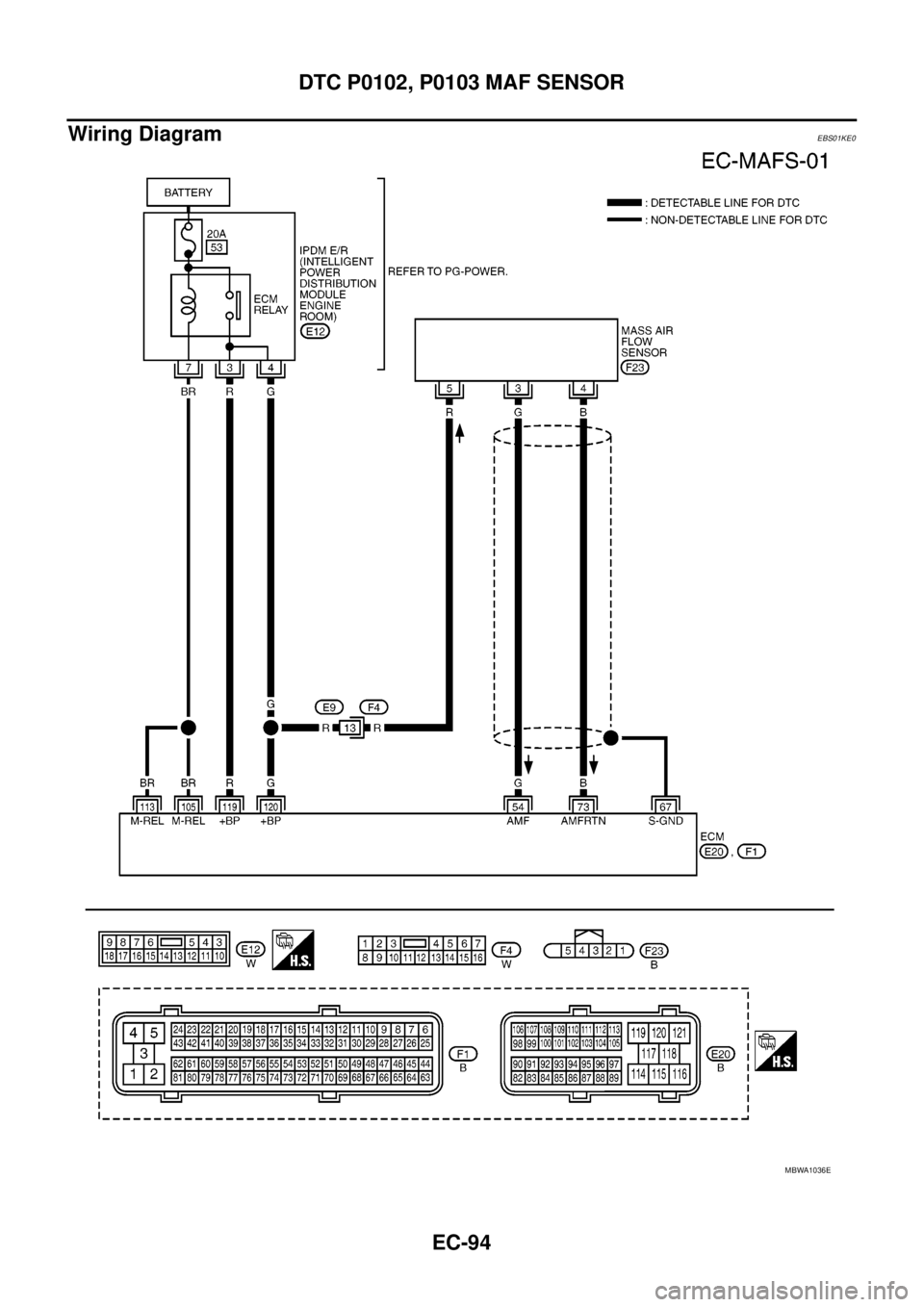

Wiring Diagram

EBS01KE0

MBWA1036E

Page 1075 of 3171

DTC P0102, P0103 MAF SENSOR

EC-95

C

D

E

F

G

H

I

J

K

L

MA

EC

Diagnostic ProcedureEBS01KE1

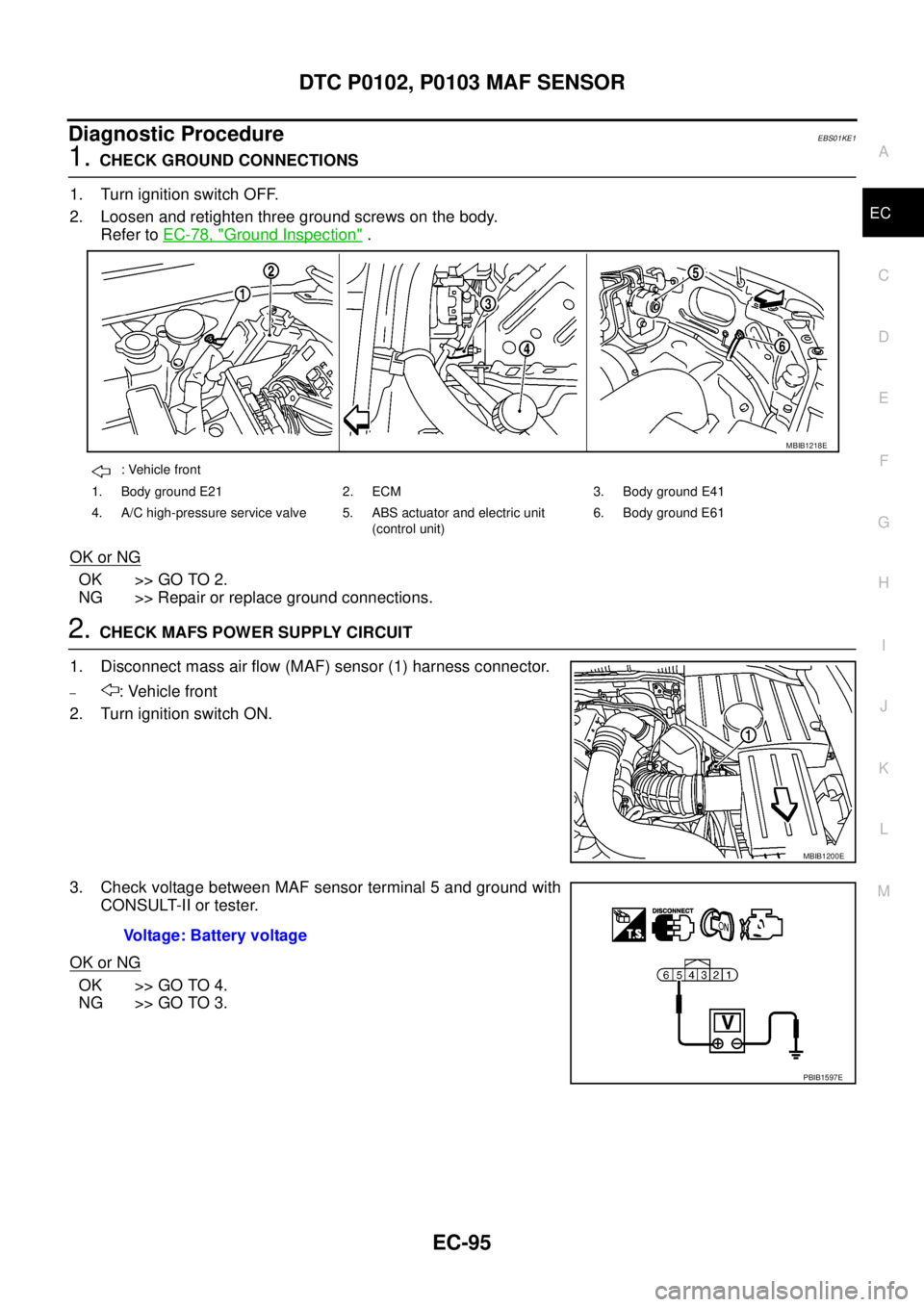

1.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Loosen and retighten three ground screws on the body.

Refer toEC-78, "

Ground Inspection".

OK or NG

OK >> GO TO 2.

NG >> Repair or replace ground connections.

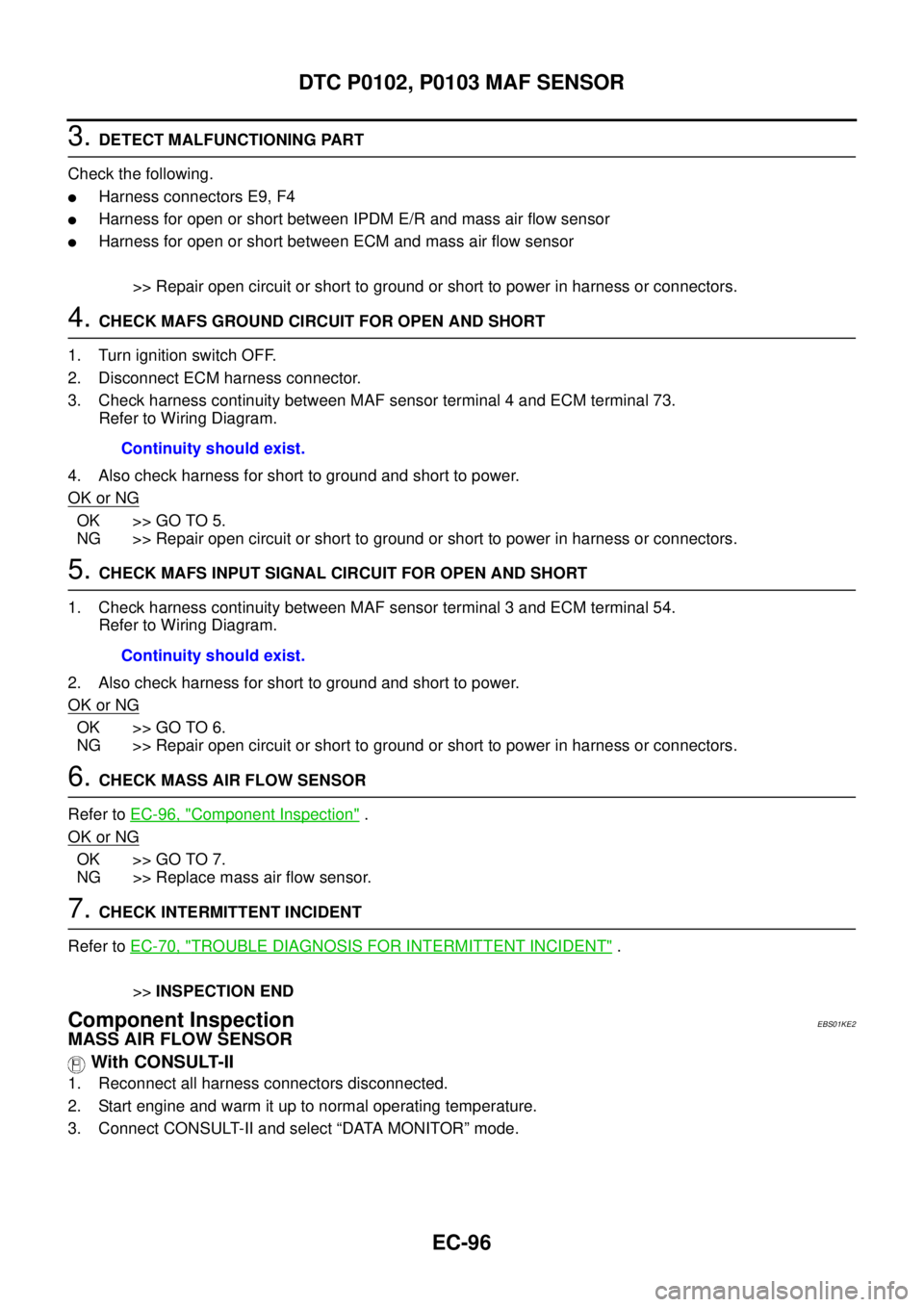

2.CHECK MAFS POWER SUPPLY CIRCUIT

1. Disconnect mass air flow (MAF) sensor (1) harness connector.

–: Vehicle front

2. Turn ignition switch ON.

3. Check voltage between MAF sensor terminal 5 and ground with

CONSULT-II or tester.

OK or NG

OK >> GO TO 4.

NG >> GO TO 3.

: Vehicle front

1. Body ground E21 2. ECM 3. Body ground E41

4. A/C high-pressure service valve 5. ABS actuator and electric unit

(control unit)6. Body ground E61

MBIB1218E

MBIB1200E

Voltage: Battery voltage

PBIB1597E

Page 1076 of 3171

EC-96

DTC P0102, P0103 MAF SENSOR

3.DETECT MALFUNCTIONING PART

Check the following.

lHarness connectors E9, F4

lHarness for open or short between IPDM E/R and mass air flow sensor

lHarness for open or short between ECM and mass air flow sensor

>> Repair open circuit or short to ground or short to power in harness or connectors.

4.CHECK MAFS GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check harness continuity between MAF sensor terminal 4 and ECM terminal 73.

Refer to Wiring Diagram.

4. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 5.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

5.CHECK MAFS INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Check harness continuity between MAF sensor terminal 3 and ECM terminal 54.

Refer to Wiring Diagram.

2. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 6.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

6.CHECK MASS AIR FLOW SENSOR

Refer toEC-96, "

Component Inspection".

OK or NG

OK >> GO TO 7.

NG >> Replace mass air flow sensor.

7.CHECK INTERMITTENT INCIDENT

Refer toEC-70, "

TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT".

>>INSPECTION END

Component InspectionEBS01KE2

MASS AIR FLOW SENSOR

With CONSULT-II

1. Reconnect all harness connectors disconnected.

2. Start engine and warm it up to normal operating temperature.

3. Connect CONSULT-II and select “DATA MONITOR” mode.Continuity should exist.

Continuity should exist.

Page 1077 of 3171

DTC P0102, P0103 MAF SENSOR

EC-97

C

D

E

F

G

H

I

J

K

L

MA

EC

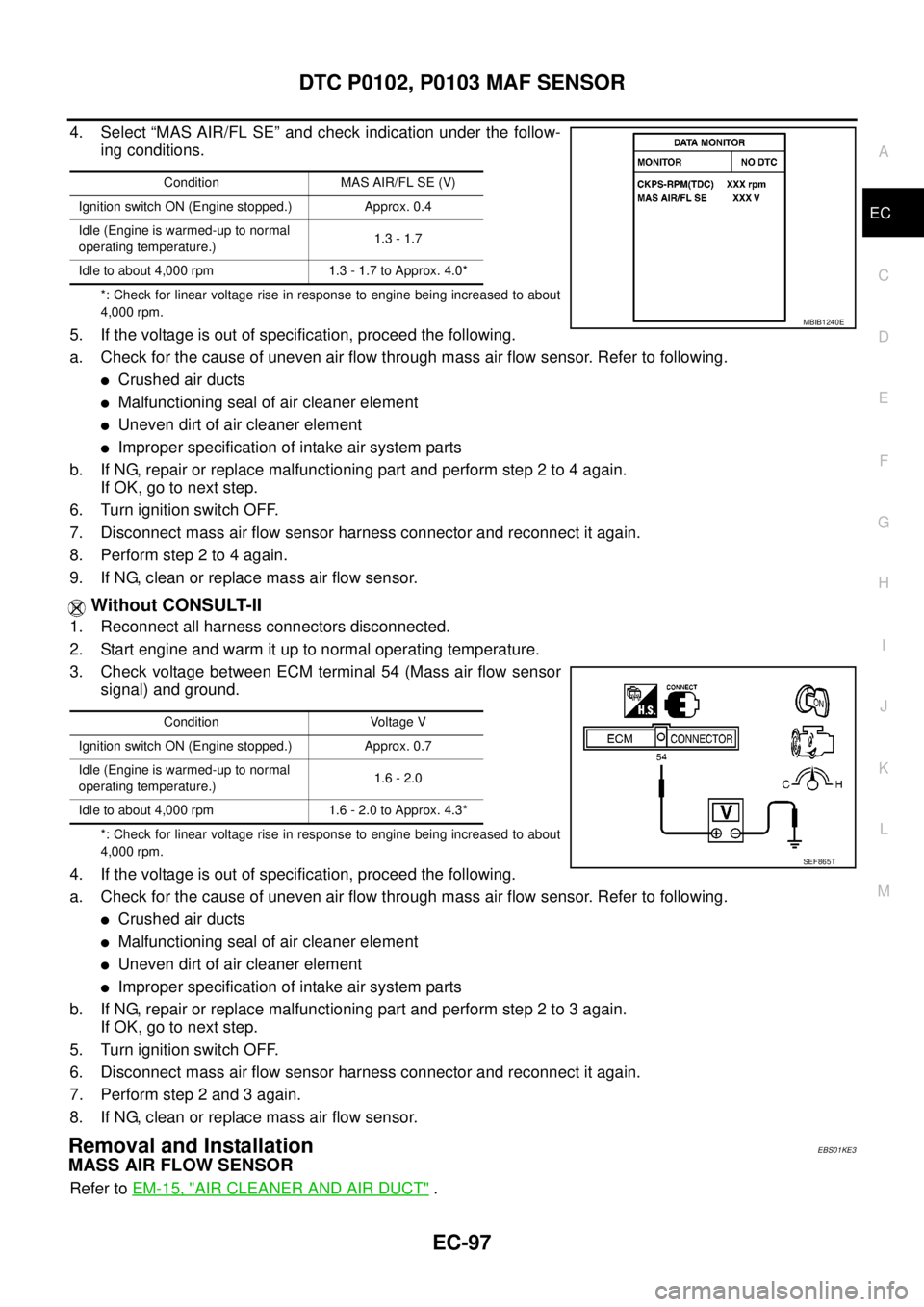

4. Select “MAS AIR/FL SE” and check indication under the follow-

ing conditions.

*: Check for linear voltage rise in response to engine being increased to about

4,000 rpm.

5. If the voltage is out of specification, proceed the following.

a. Check for the cause of uneven air flow through mass air flow sensor. Refer to following.

lCrushed air ducts

lMalfunctioning seal of air cleaner element

lUneven dirt of air cleaner element

lImproper specification of intake air system parts

b. If NG, repair or replace malfunctioning part and perform step 2 to 4 again.

IfOK,gotonextstep.

6. Turn ignition switch OFF.

7. Disconnect mass air flow sensor harness connector and reconnect it again.

8. Performstep2to4again.

9. If NG, clean or replace mass air flow sensor.

Without CONSULT-II

1. Reconnect all harness connectors disconnected.

2. Start engine and warm it up to normal operating temperature.

3. Check voltage between ECM terminal 54 (Mass air flow sensor

signal) and ground.

*: Check for linear voltage rise in response to engine being increased to about

4,000 rpm.

4. If the voltage is out of specification, proceed the following.

a. Check for the cause of uneven air flow through mass air flow sensor. Refer to following.

lCrushed air ducts

lMalfunctioning seal of air cleaner element

lUneven dirt of air cleaner element

lImproper specification of intake air system parts

b. If NG, repair or replace malfunctioning part and perform step 2 to 3 again.

IfOK,gotonextstep.

5. Turn ignition switch OFF.

6. Disconnect mass air flow sensor harness connector and reconnect it again.

7. Perform step 2 and 3 again.

8. If NG, clean or replace mass air flow sensor.

Removal and InstallationEBS01KE3

MASS AIR FLOW SENSOR

Refer toEM-15, "AIR CLEANER AND AIR DUCT".

Condition MAS AIR/FL SE (V)

Ignition switch ON (Engine stopped.) Approx. 0.4

Idle (Engine is warmed-up to normal

operating temperature.)1.3 - 1.7

Idle to about 4,000 rpm 1.3 - 1.7 to Approx. 4.0*

MBIB1240E

Condition Voltage V

Ignition switch ON (Engine stopped.) Approx. 0.7

Idle (Engine is warmed-up to normal

operating temperature.)1.6 - 2.0

Idle to about 4,000 rpm 1.6 - 2.0 to Approx. 4.3*

SEF865T

Page 1078 of 3171

EC-98

DTC P0112, P0113 IAT SENSOR

DTC P0112, P0113 IAT SENSOR

PFP:22630

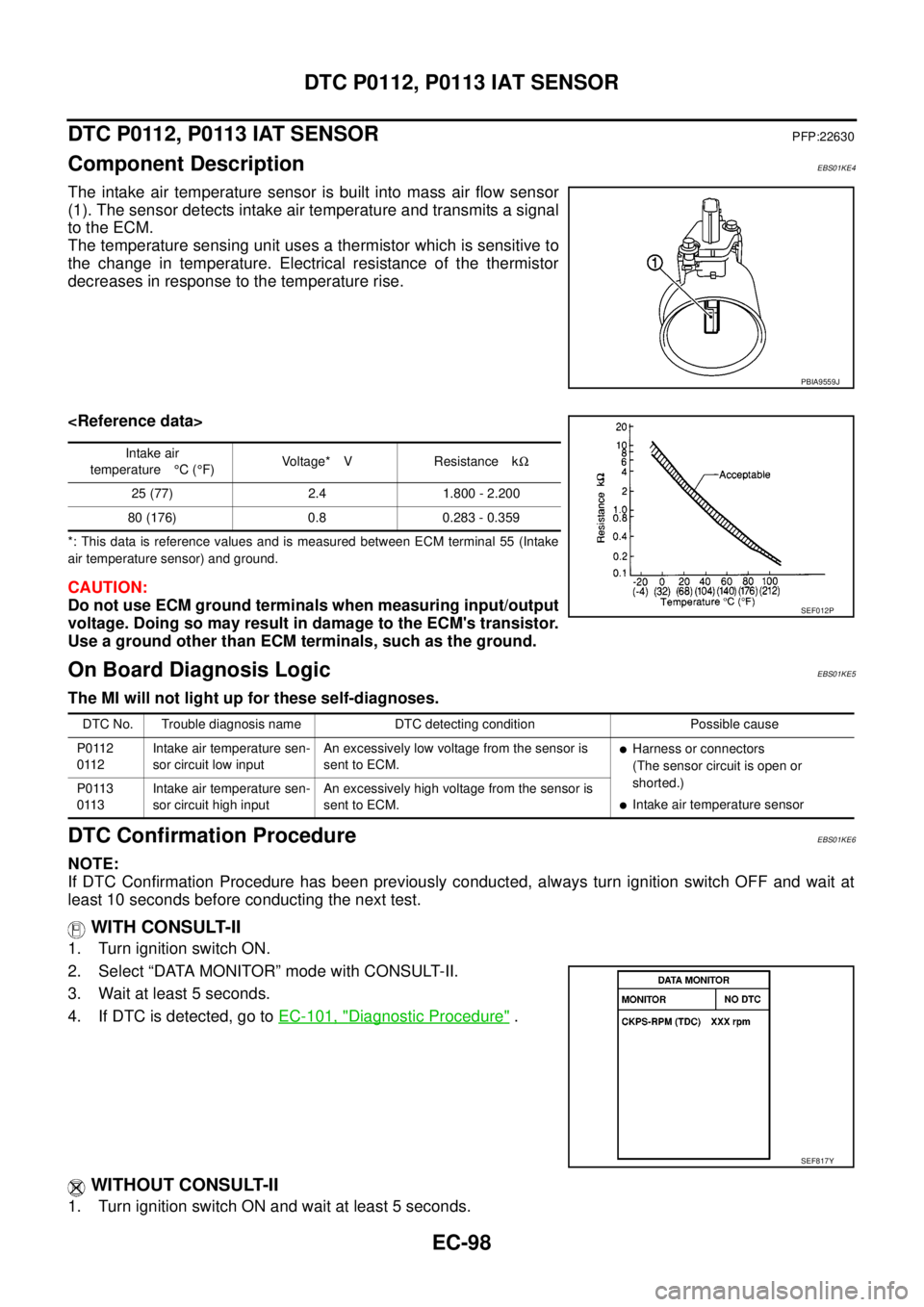

Component DescriptionEBS01KE4

The intake air temperature sensor is built into mass air flow sensor

(1). The sensor detects intake air temperature and transmits a signal

to the ECM.

The temperature sensing unit uses a thermistor which is sensitive to

the change in temperature. Electrical resistance of the thermistor

decreases in response to the temperature rise.

*: This data is reference values and is measured between ECM terminal 55 (Intake

air temperature sensor) and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output

voltage. Doing so may result in damage to the ECM's transistor.

Use a ground other than ECM terminals, such as the ground.

On Board Diagnosis LogicEBS01KE5

The MI will not light up for these self-diagnoses.

DTC Confirmation ProcedureEBS01KE6

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

WITH CONSULT-II

1. Turn ignition switch ON.

2. Select “DATA MONITOR” mode with CONSULT-II.

3. Wait at least 5 seconds.

4. If DTC is detected, go toEC-101, "

Diagnostic Procedure".

WITHOUT CONSULT-II

1. Turn ignition switch ON and wait at least 5 seconds.

PBIA9559J

Intake air

temperature°C(°F)Voltage* V Resistance kW

25 (77) 2.4 1.800 - 2.200

80 (176) 0.8 0.283 - 0.359

SEF012P

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0112

0112Intake air temperature sen-

sor circuit low inputAn excessively low voltage from the sensor is

sent to ECM.

lHarness or connectors

(The sensor circuit is open or

shorted.)

lIntake air temperature sensor P0113

0113Intake air temperature sen-

sor circuit high inputAn excessively high voltage from the sensor is

sent to ECM.

SEF817Y

Page 1079 of 3171

DTC P0112, P0113 IAT SENSOR

EC-99

C

D

E

F

G

H

I

J

K

L

MA

EC

2. Turn ignition switch OFF, wait at least 10 seconds and then turn ON.

3. Perform Diagnostic Test Mode II (Self-diagnostic results) with ECM.

4. If DTC is detected, go toEC-101, "

Diagnostic Procedure".

Page 1080 of 3171

EC-100

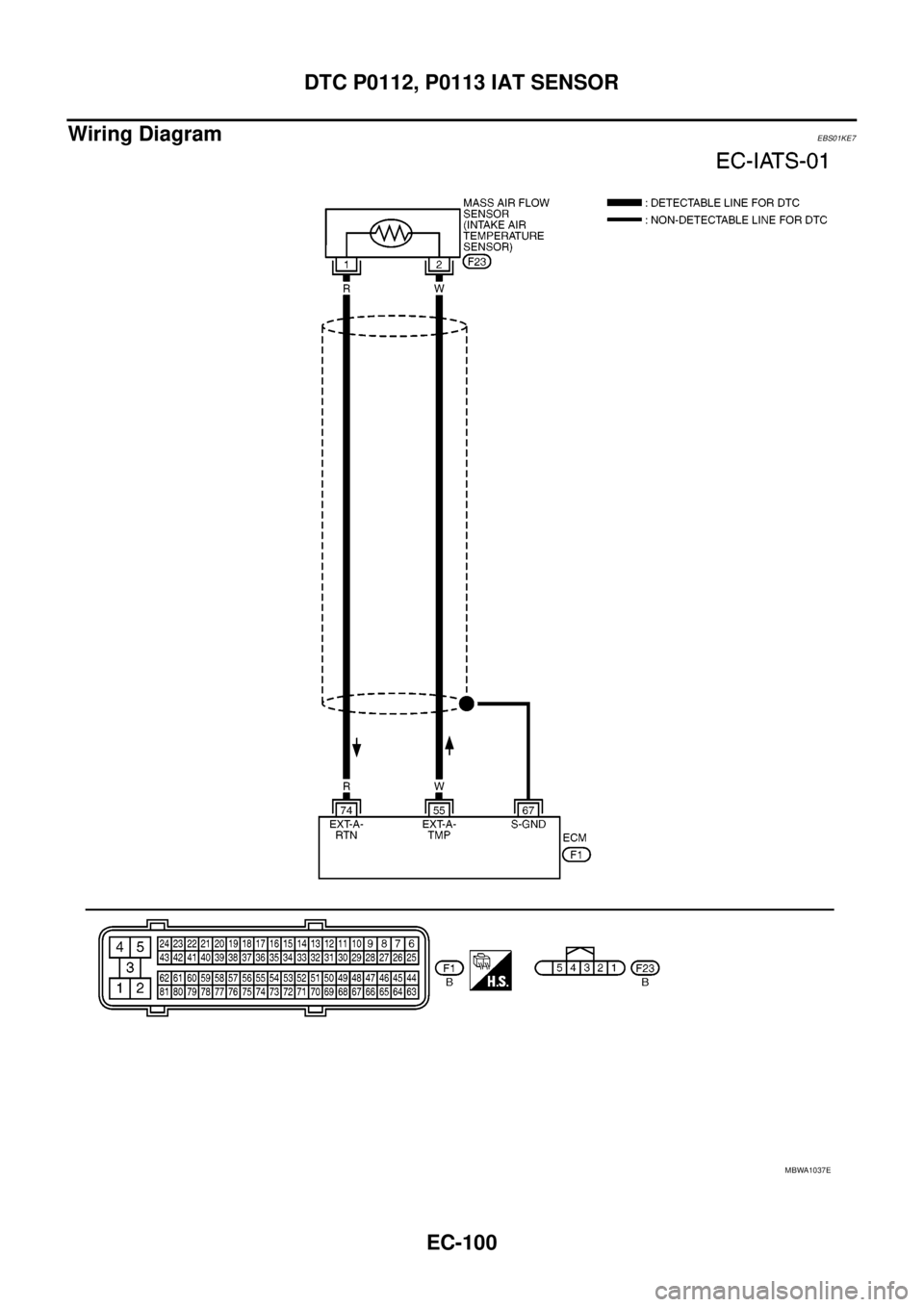

DTC P0112, P0113 IAT SENSOR

Wiring Diagram

EBS01KE7

MBWA1037E