4WD NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2763 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual RFD-60

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

TROUBLE DIAGNOSIS FOR SYSTEM

Differential Lock Position Switch

EDS003B4

CONSULT-II REFERENCE VALUE IN DATA MONITOR MODE

Data are reference value.

DIFFEREN NISSAN NAVARA 2005 Repair Workshop Manual RFD-60

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

TROUBLE DIAGNOSIS FOR SYSTEM

Differential Lock Position Switch

EDS003B4

CONSULT-II REFERENCE VALUE IN DATA MONITOR MODE

Data are reference value.

DIFFEREN](/img/5/57362/w960_57362-2762.png)

RFD-60

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

TROUBLE DIAGNOSIS FOR SYSTEM

Differential Lock Position Switch

EDS003B4

CONSULT-II REFERENCE VALUE IN DATA MONITOR MODE

Data are reference value.

DIFFERENTIAL CONTROL UNIT TERMINALS AND REFERENCE VALUE

Data are reference value and are measured between each terminal and ground.

CAUTION:

When using a circuit tester to measure voltage for inspection, be sure not to extend forcibly any connector terminals.Monitor item [Unit] Content Condition Display value

D-LOCK POS SW [ON/

OFF]Condition of differential

lock position switch

lVehicle stopped

lEngine running

l4WD shift switch: 4LODifferential lock mode

switch: ON

(DIFF LOCK indicator

lamp: ON)ON

Differential lock mode

switch: OFF

(DIFF LOCK indicator

lamp: OFF)OFF

Te r m i n a lWire

colorItem Condition Data (Approx.)

20 BRDifferential lock position

switch

lVehicle stopped

lEngine running

l4WD shift switch: 4LODifferential lock mode switch: ON

(DIFF LOCK indicator lamp: ON)0V

Differential lock mode switch: OFF

(DIFF LOCK indicator lamp: OFF)Battery voltage

Page 2764 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual TROUBLE DIAGNOSIS FOR SYSTEM

RFD-61

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

DIAGNOSTIC PROCEDURE

1.CHECK DIFFERENTIAL LOCK POSITION SWITCH SIGNAL

With CONSULT-II

1. Start eng NISSAN NAVARA 2005 Repair Workshop Manual TROUBLE DIAGNOSIS FOR SYSTEM

RFD-61

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

DIAGNOSTIC PROCEDURE

1.CHECK DIFFERENTIAL LOCK POSITION SWITCH SIGNAL

With CONSULT-II

1. Start eng](/img/5/57362/w960_57362-2763.png)

TROUBLE DIAGNOSIS FOR SYSTEM

RFD-61

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

DIAGNOSTIC PROCEDURE

1.CHECK DIFFERENTIAL LOCK POSITION SWITCH SIGNAL

With CONSULT-II

1. Start engine.

2. Select “DATA MONITOR” mode for “DIFF LOCK” with CONSULT-II.

3. Read out ON/OFF switching action of “D-LOCK POS SW SIG”.

Without CONSULT-II

1. Start engine.

2. Check voltage between differential lock control unit harness

connector terminal and ground.

OK or NG

OK >> GO TO 5.

NG >> GO TO 2.

2.CHECK GROUND CIRCUIT

1. Turn ignition switch “OFF”.

2. Disconnect differential lock position switch harness connector.

3. Check continuity between differential lock position switch har-

ness connector C22 terminal 2 and ground.

Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 3.

NG >> Repair open circuit or short to ground or short to power

in harness or connectors.

Monitor item ConditionDisplay

value

D-LOCK POS

SW SIG

lVehicle stopped

lEngine running

l4WD shift

switch: 4LODifferential lock mode

switch: ON

(DIFF LOCK indicator

lamp: ON)ON

Differential lock mode

switch: OFF

(DIFF LOCK indicator

lamp: OFF)OFF

SDIA2538E

Connector Terminal ConditionVo l ta g e

(Approx.)

M10720 -

Ground

lVehicle stopped

lEngine running

l4WD shift switch:

4LODifferential lock mode

switch: ON

(DIFF LOCK indicator

lamp: ON)0V

Differential lock mode

switch: OFF

(DIFF LOCK indicator

lamp: OFF)Battery

voltage

SDIA2570E

Continuity should exist.

SDIA3428E

Page 2766 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual TROUBLE DIAGNOSIS FOR SYSTEM

RFD-63

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

COMPONENT INSPECTION

1. Turn ignition switch “OFF”.

2. Disconnect differential lock position s NISSAN NAVARA 2005 Repair Workshop Manual TROUBLE DIAGNOSIS FOR SYSTEM

RFD-63

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

COMPONENT INSPECTION

1. Turn ignition switch “OFF”.

2. Disconnect differential lock position s](/img/5/57362/w960_57362-2765.png)

TROUBLE DIAGNOSIS FOR SYSTEM

RFD-63

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

COMPONENT INSPECTION

1. Turn ignition switch “OFF”.

2. Disconnect differential lock position switch harness connector.

3. Remove differential lock position switch. Refer toRFD-45, "

Location of Electrical Parts".

4. Pull differential lock position switch and check continuity

between differential lock position switch harness connector ter-

minals.

5. If NG, replace differential lock position switch.

Differential Lock Solenoid RelayEDS003B5

CONSULT-II REFERENCE VALUE IN DATA MONITOR MODE

Data are reference value.

DIAGNOSTIC PROCEDURE

1.CHECK DIFFERENTIAL LOCK SOLENOID SYSTEM

Perform self-diagnosis. Refer toRFD-51, "

SELF-DIAG RESULTS MODE".

Is

“RELAY [P1844]”displayed?

YES >> Perform trouble diagnosis for differential lock solenoid. Refer toRFD-64, "Differential Lock Sole-

noid".

NO >> GO TO 2.

2.CHECK DIFFERENTIAL LOCK SOLENOID RELAY SIGNAL

With CONSULT-II

1. Start engine.

2. Select “DATA MONITOR” mode for “DIFF LOCK” with CONSULT-II.

3. Read out ON/OFF switching action of “RELAY ON”.

OK or NG

OK >> GO TO 4.

NG >> GO TO 3.

Terminal Condition Continuity

1-2Pull differential position switch Yes

Release Differential position switch No

SDIA3429E

Monitor item [Unit] Content Condition Display value

RELAY ON [ON/OFF]Operating condition of dif-

ferential lock solenoid

relay (integrated in differ-

ential lock control unit)

lVehicle stopped

lEngine running

l4WD shift switch: 4LODifferential lock mode

switch: ONON

Differential lock mode

switch: OFFOFF

Monitor item ConditionDisplay

value

RELAY ON

lVehicle stopped

lEngine running

l4WD shift

switch: 4LODifferential lock mode

switch: ONON

Differential lock mode

switch: OFFOFF

SDIA2642E

Page 2767 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual RFD-64

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

TROUBLE DIAGNOSIS FOR SYSTEM

3.CHECK DIFFERENTIAL LOCK CONTROL UNIT

Check differential lock control unit input/output signal. Refer toRFD-48, "

Differenti NISSAN NAVARA 2005 Repair Workshop Manual RFD-64

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

TROUBLE DIAGNOSIS FOR SYSTEM

3.CHECK DIFFERENTIAL LOCK CONTROL UNIT

Check differential lock control unit input/output signal. Refer toRFD-48, "

Differenti](/img/5/57362/w960_57362-2766.png)

RFD-64

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

TROUBLE DIAGNOSIS FOR SYSTEM

3.CHECK DIFFERENTIAL LOCK CONTROL UNIT

Check differential lock control unit input/output signal. Refer toRFD-48, "

Differential Lock Control Unit Input/

Output Signal Reference Values".

OK or NG

OK >> GO TO 4.

NG >> Check differential lock control unit pin terminals for damage or loose connection with harness con-

nector. If any item is damaged, repair or replace damaged parts.

4.CHECK DTC

Perform the self-diagnosis, after driving the vehicle for a while.

OK or NG

OK >>INSPECTION END

NG >> Replace differential lock control unit. Refer toRFD-76, "

Removal and Installation".

Differential Lock SolenoidEDS003B6

CONSULT-II REFERENCE VALUE IN DATA MONITOR MODE

Data are reference value.

DIFFERENTIAL LOCK CONTROL UNIT TERMINALS AND REFERENCE VALUE

Data are reference value and are measured between each terminal and ground.

CAUTION:

When using a circuit tester to measure voltage for inspection, be sure not to extend forcibly any connector terminals.Monitor item [Unit] Content Condition Display value

RELAY ON [ON/OFF]Operating condition of dif-

ferential lock solenoid

relay (integrated in differ-

ential lock control unit)

lVehicle stopped

lEngine running

l4WD shift switch: 4LODifferential lock mode

switch: ONON

Differential lock mode

switch: OFFOFF

RELAY MTR [ON/OFF]Control status of differen-

tial lock solenoid relay

(integrated in differential

lock control unit)

lVehicle stopped

lEngine running

l4WD shift switch: 4LODifferential lock mode

switch: ONON

Differential lock mode

switch: OFFOFF

SOL MTR [ON/OFF]Control status of differen-

tial lock solenoid

lVehicle stopped

lEngine running

l4WD shift switch: 4LODifferential lock mode

switch: ONON

Differential lock mode

switch: OFFOFF

Te r m i n a lWire

colorItem Condition Data (Approx.)

11 GR Differential lock solenoid (-)

lVehicle stopped

lEngine running

l4WD shift switch: 4LODifferential lock mode switch: ON 0V

Differential lock mode switch: OFF Battery voltage

12 L Differential lock solenoid (+)

lVehicle stopped

lEngine running

l4WD shift switch: 4LODifferential lock mode switch: ON 0V

Differential lock mode switch: OFF Battery voltage

Page 2768 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual TROUBLE DIAGNOSIS FOR SYSTEM

RFD-65

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

DIAGNOSTIC PROCEDURE

1.CHECK DIFFERENTIAL SOLENOID SIGNAL

With CONSULT-II

1. Start engine.

2. Sele NISSAN NAVARA 2005 Repair Workshop Manual TROUBLE DIAGNOSIS FOR SYSTEM

RFD-65

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

DIAGNOSTIC PROCEDURE

1.CHECK DIFFERENTIAL SOLENOID SIGNAL

With CONSULT-II

1. Start engine.

2. Sele](/img/5/57362/w960_57362-2767.png)

TROUBLE DIAGNOSIS FOR SYSTEM

RFD-65

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

DIAGNOSTIC PROCEDURE

1.CHECK DIFFERENTIAL SOLENOID SIGNAL

With CONSULT-II

1. Start engine.

2. Select “DATA MONITOR” mode for “DIFF LOCK” with CONSULT-II.

3. Read out ON/OFF switching action of “RELAY ON”, “RELAY

MTR”, “SOL MTR”.

Without CONSULT-II

1. Start engine.

2. Check voltage between differential lock control unit harness

connector terminal and ground.

OK or NG

OK >> GO TO 6.

NG >> GO TO 2.

Monitor item ConditionDisplay

value

RELAY ON

lVehicle stopped

lEngine running

l4WD shift

switch: 4LODifferential lock mode

switch: ONON

Differential lock mode

switch: OFFOFF

RELAY MTRDifferential lock mode

switch: ONON

Differential lock mode

switch: OFFOFF

SOL MTRDifferential lock mode

switch: ONON

Differential lock mode

switch: OFFOFF

Connector Terminal ConditionData

(Approx.)

M10711 -

Ground

lVehicle stopped

lEngine running

l4WD shift switch: 4LODifferential

lock mode

switch: ON0V

Differential

lock mode

switch: OFFBattery

voltage

12 -

GroundDifferential

lock mode

switch: ON0V

Differential

lock mode

switch: OFFBattery

voltage

SDIA2539E

SDIA2565E

Page 2803 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual RFD-100

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

PFP:00030

General SpecificationsEDS003BH

Inspection and AdjustmentEDS003BI

PR NISSAN NAVARA 2005 Repair Workshop Manual RFD-100

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

PFP:00030

General SpecificationsEDS003BH

Inspection and AdjustmentEDS003BI

PR](/img/5/57362/w960_57362-2802.png)

RFD-100

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

PFP:00030

General SpecificationsEDS003BH

Inspection and AdjustmentEDS003BI

PRELOAD TORQUE

Unit: N·m (kg-m, in-lb)

BACKLASH

Unit: mm (in)

COMPANION FLANGE RUNOUT

Unit: mm (in) Applied modelYD25DDTi

4WD

5A/T 6M/T

Final drive modelM226

Gear ratio 3.538 3.692

Number of pinion gears 2

Number of teeth (Drive gear / drive pinion) 46/13 48/13

Oil capacity (Approx.)

(lmp pt)2.01 (3-1/2)

Drive pinion adjustment spacer type Collapsible

ItemStandard

Gear ratio: 3.538 type Gear ratio: 3.692 type

Total preload 2.34 - 4.34 (0.24 - 0.44, 21 - 38) 2.32 - 4.34 (0.24 - 0.44, 21 - 38)

Pinion bearing preload 1.7 - 3.1 (0.18 - 0.31, 15 - 27)

Item Standard

Drive gear to drive pinion gear 0.08 - 0.13 (0.0031 - 0.0051)

Item Runout limit

Companion flange face 0.10 (0.0039) or less

Inner side of companion flange 0.13 (0.0051) or less

Page 2816 of 3171

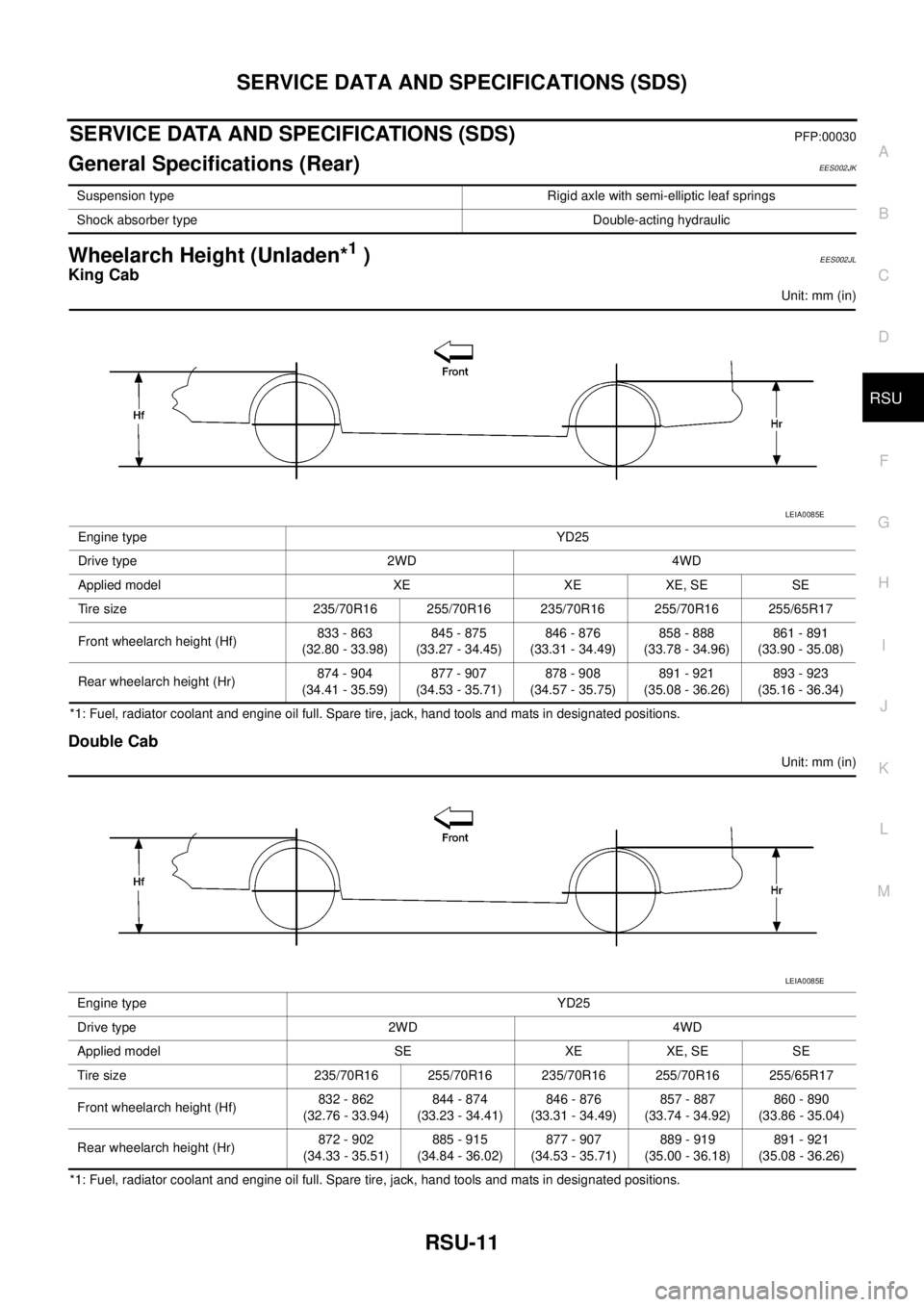

SERVICE DATA AND SPECIFICATIONS (SDS)

RSU-11

C

D

F

G

H

I

J

K

L

MA

B

RSU

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

General Specifications (Rear)EES002JK

Wheelarch Height (Unladen*1)EES002JL

King Cab

Unit: mm (in)

*1: Fuel, radiator coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions.

Double Cab

Unit: mm (in)

*1: Fuel, radiator coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions.Suspension type Rigid axle with semi-elliptic leaf springs

Shock absorber type Double-acting hydraulic

Engine type YD25

Drive type 2WD 4WD

Applied model XE XE XE, SE SE

Tire size 235/70R16 255/70R16 235/70R16 255/70R16 255/65R17

Front wheelarch height (Hf)833 - 863

(32.80 - 33.98)845 - 875

(33.27 - 34.45)846 - 876

(33.31 - 34.49)858 - 888

(33.78 - 34.96)861 - 891

(33.90 - 35.08)

Rear wheelarch height (Hr)874 - 904

(34.41 - 35.59)877 - 907

(34.53 - 35.71)878 - 908

(34.57 - 35.75)891 - 921

(35.08 - 36.26)893 - 923

(35.16 - 36.34)

LEIA0085E

Engine type YD25

Drive type 2WD 4WD

Applied model SE XE XE, SE SE

Tire size 235/70R16 255/70R16 235/70R16 255/70R16 255/65R17

Front wheelarch height (Hf)832 - 862

(32.76 - 33.94)844 - 874

(33.23 - 34.41)846 - 876

(33.31 - 34.49)857 - 887

(33.74 - 34.92)860 - 890

(33.86 - 35.04)

Rear wheelarch height (Hr)872 - 902

(34.33 - 35.51)885 - 915

(34.84 - 36.02)877 - 907

(34.53 - 35.71)889 - 919

(35.00 - 36.18)891 - 921

(35.08 - 36.26)

LEIA0085E

Page 2968 of 3171

TF-1

TRANSFER

D DRIVELINE/AXLE

CONTENTS

C

E

F

G

H

I

J

K

L

M

SECTIONTF

A

B

TF

TRANSFER

PRECAUTIONS .......................................................... 4

Precautions for Supplemental Restraint System

(SRS)“AIRBAG”and“SEATBELTPRE-TEN-

SIONER” .................................................................. 4

Precautions for Transfer Assembly and Transfer

Control Unit Replacement ........................................ 4

CHECK 4WD SHIFT INDICATOR PATTERN ....... 4

METHOD FOR ADJUSTMENT WITH 4WD

SHIFT SWITCH AT “2WD” .................................... 5

METHOD FOR ADJUSTMENT WITH 4WD

SHIFT SWITCH AT “4H” OR “4LO” ....................... 5

Precautions .............................................................. 6

Service Notice .......................................................... 6

Wiring Diagrams and Trouble Diagnosis .................. 7

PREPARATION ........................................................... 8

Special Service Tools ............................................... 8

Commercial Service Tools ...................................... 10

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING ...............................................11

NVH Troubleshooting Chart .................................... 11

TRANSFER FLUID ................................................... 12

Replacement .......................................................... 12

DRAINING ........................................................... 12

FILLING ............................................................... 12

Inspection ............................................................... 12

FLUID LEAKAGE AND FLUID LEVEL ................ 12

4WD SYSTEM .......................................................... 13

Cross-Section View ................................................ 13

Power Transfer ....................................................... 14

POWER TRANSFER DIAGRAM ........................ 14

POWER TRANSFER FLOW ............................... 15

System Description ................................................ 15

TRANSFER CONTROL DEVICE ........................ 15

WAIT DETECTION SWITCH .............................. 15

4LO SWITCH ...................................................... 15

ATP SWITCH ...................................................... 15

TRANSFER CONTROL UNIT ............................. 15

TRANSFER SHIFT RELAY ................................. 15

TRANSFER SHUT OFF RELAY ......................... 15

4WD SHIFT SWITCH AND INDICATOR LAMP... 164WD WARNING LAMP ....................................... 17

ATP WARNING LAMP (A/T MODELS) ................ 17

System Diagram ..................................................... 18

COMPONENTS FUNCTION ............................... 18

CAN Communication .............................................. 19

SYSTEM DESCRIPTION .................................... 19

TROUBLE DIAGNOSIS ............................................ 20

How to Perform Trouble Diagnosis ......................... 20

BASIC CONCEPT ............................................... 20

Location of Electrical Parts ..................................... 21

A/T MODELS ....................................................... 21

M/T MODELS ...................................................... 22

Circuit Diagram ....................................................... 23

A/T MODELS ....................................................... 23

M/T MODELS ...................................................... 24

Wiring Diagram — T/F — ....................................... 25

A/T MODELS ....................................................... 25

M/T MODELS ...................................................... 31

Trouble Diagnosis Chart for Symptoms .................. 38

Transfer Control Unit Input/Output Signal Refer-

ence Values ............................................................ 38

TRANSFER CONTROL UNIT INSPECTION

TABLE ................................................................. 38

CONSULT-II Function (ALL MODE AWD/4WD) ..... 44

FUNCTION .......................................................... 44

CONSULT-II SETTING PROCEDURE ................ 44

SELF-DIAG RESULT MODE ............................... 45

DATA MONITOR MODE ...................................... 47

Self-Diagnostic Procedure ...................................... 49

SELF-DIAGNOSTIC PROCEDURE (WITH

CONSULT-II) ....................................................... 49

SELF-DIAGNOSTIC PROCEDURE (WITHOUT

CONSULT-II) ....................................................... 49

ERASE SELF-DIAGNOSIS ................................. 51

TROUBLE DIAGNOSIS FOR SYSTEM .................... 52

Power Supply Circuit For Transfer Control Unit ...... 52

CONSULT-II REFERENCE VALUE IN DATA

MONITOR MODE ................................................ 52

TRANSFER CONTROL UNIT TERMINALS AND

REFERENCE VALUE .......................................... 52

Page 2969 of 3171

TF-2

DIAGNOSTIC PROCEDURE .............................. 53

COMPONENT INSPECTION .............................. 54

Transfer Control Unit .............................................. 54

DIAGNOSTIC PROCEDURE .............................. 54

Output Shaft Revolution Signal (TCM) ................... 55

DIAGNOSTIC PROCEDURE .............................. 55

Vehicle Speed Sensor (ABS) .................................. 55

DIAGNOSTIC PROCEDURE .............................. 55

4LO Switch ............................................................. 56

CONSULT-II REFERENCE VALUE IN DATA

MONITOR MODE ................................................ 56

TRANSFER CONTROL UNIT TERMINALS AND

REFERENCE VALUE .......................................... 56

DIAGNOSTIC PROCEDURE .............................. 57

COMPONENT INSPECTION .............................. 59

4WD Shift Switch .................................................... 59

CONSULT-II REFERENCE VALUE IN DATA

MONITOR MODE ................................................ 59

TRANSFER CONTROL UNIT TERMINALS AND

REFERENCE VALUE .......................................... 59

DIAGNOSTIC PROCEDURE .............................. 60

COMPONENT INSPECTION .............................. 62

Wait Detection Switch ............................................. 63

CONSULT-II REFERENCE VALUE IN DATA

MONITOR MODE ................................................ 63

TRANSFER CONTROL UNIT TERMINALS AND

REFERENCE VALUE .......................................... 63

DIAGNOSTIC PROCEDURE .............................. 64

COMPONENT INSPECTION .............................. 66

PNP Switch Signal (TCM) ...................................... 66

DIAGNOSTIC PROCEDURE .............................. 66

Actuator Motor ........................................................ 67

CONSULT-II REFERENCE VALUE IN DATA

MONITOR MODE ................................................ 67

TRANSFER CONTROL UNIT TERMINALS AND

REFERENCE VALUE .......................................... 67

DIAGNOSTIC PROCEDURE .............................. 68

COMPONENT INSPECTION .............................. 74

Actuator Position Switch ......................................... 75

CONSULT-II REFERENCE VALUE IN DATA

MONITOR MODE ................................................ 75

TRANSFER CONTROL UNIT TERMINALS AND

REFERENCE VALUE .......................................... 75

DIAGNOSTIC PROCEDURE .............................. 76

Transfer Control Device .......................................... 78

CONSULT-II REFERENCE VALUE IN DATA

MONITOR MODE ................................................ 78

TRANSFER CONTROL UNIT TERMINALS AND

REFERENCE VALUE .......................................... 78

DIAGNOSTIC PROCEDURE .............................. 79

Engine Speed Signal (ECM) ................................... 81

DIAGNOSTIC PROCEDURE .............................. 81

CAN Communication Line ...................................... 82

DIAGNOSTIC PROCEDURE .............................. 82

ATP Switch ............................................................. 82

CONSULT-II REFERENCE VALUE IN DATA

MONITOR MODE ................................................ 82

TRANSFER CONTROL UNIT TERMINALS ANDREFERENCE VALUE .......................................... 82

DIAGNOSTIC PROCEDURE ............................... 83

COMPONENT INSPECTION ............................... 85

Park/Neutral Position Switch ................................... 85

TRANSFER CONTROL UNIT TERMINALS AND

REFERENCE VALUE .......................................... 85

DIAGNOSTIC PROCEDURE ............................... 85

COMPONENT INSPECTION ............................... 87

TROUBLE DIAGNOSIS FOR SYMPTOMS .............. 88

4WD Shift Indicator Lamp and 4LO Indicator Lamp

Do Not Turn ON ...................................................... 88

SYMPTOM: .......................................................... 88

DIAGNOSTIC PROCEDURE ............................... 89

4WD Warning Lamp Does Not Turn ON ................. 91

SYMPTOM: .......................................................... 91

DIAGNOSTIC PROCEDURE ............................... 92

4WD Shift Indicator Lamp or 4LO Indicator Lamp

Does Not Change ................................................... 94

SYMPTOM: .......................................................... 94

DIAGNOSTIC PROCEDURE ............................... 95

ATP Warning Lamp Does Not Turn ON .................. 96

SYMPTOM: .......................................................... 96

DIAGNOSTIC PROCEDURE ............................... 96

4WD Shift Indicator Lamp Repeats Flashing .......... 98

SYMPTOM: .......................................................... 98

DIAGNOSTIC PROCEDURE ............................... 98

4WD Warning Lamp Flashes Slowly ....................... 99

SYMPTOM: .......................................................... 99

DIAGNOSTIC PROCEDURE ............................... 99

TRANSFER CONTROL UNIT .................................100

Removal and Installation .......................................100

REMOVAL ..........................................................100

INSTALLATION ..................................................100

FRONT OIL SEAL ...................................................101

Removal and Installation .......................................101

REMOVAL ..........................................................101

INSTALLATION ..................................................102

REAR OIL SEAL .....................................................103

Removal and Installation .......................................103

REMOVAL ..........................................................103

INSTALLATION ..................................................103

TRANSFER CONTROL DEVICE ............................105

Removal and Installation .......................................105

REMOVAL ..........................................................105

INSTALLATION ..................................................105

AIR BREATHER HOSE ...........................................107

Removal and Installation .......................................107

A/T MODELS .....................................................107

M/T MODELS .....................................................109

TRANSFER ASSEMBLY ......................................... 111

Removal and Installation ....................................... 111

REMOVAL .......................................................... 111

INSTALLATION ..................................................112

Disassembly and Assembly ..................................112

COMPONENTS .................................................112

DISASSEMBLY ..................................................114

INSPECTION AFTER DISASSEMBLY ..............119

ASSEMBLY ........................................................120

Page 2971 of 3171

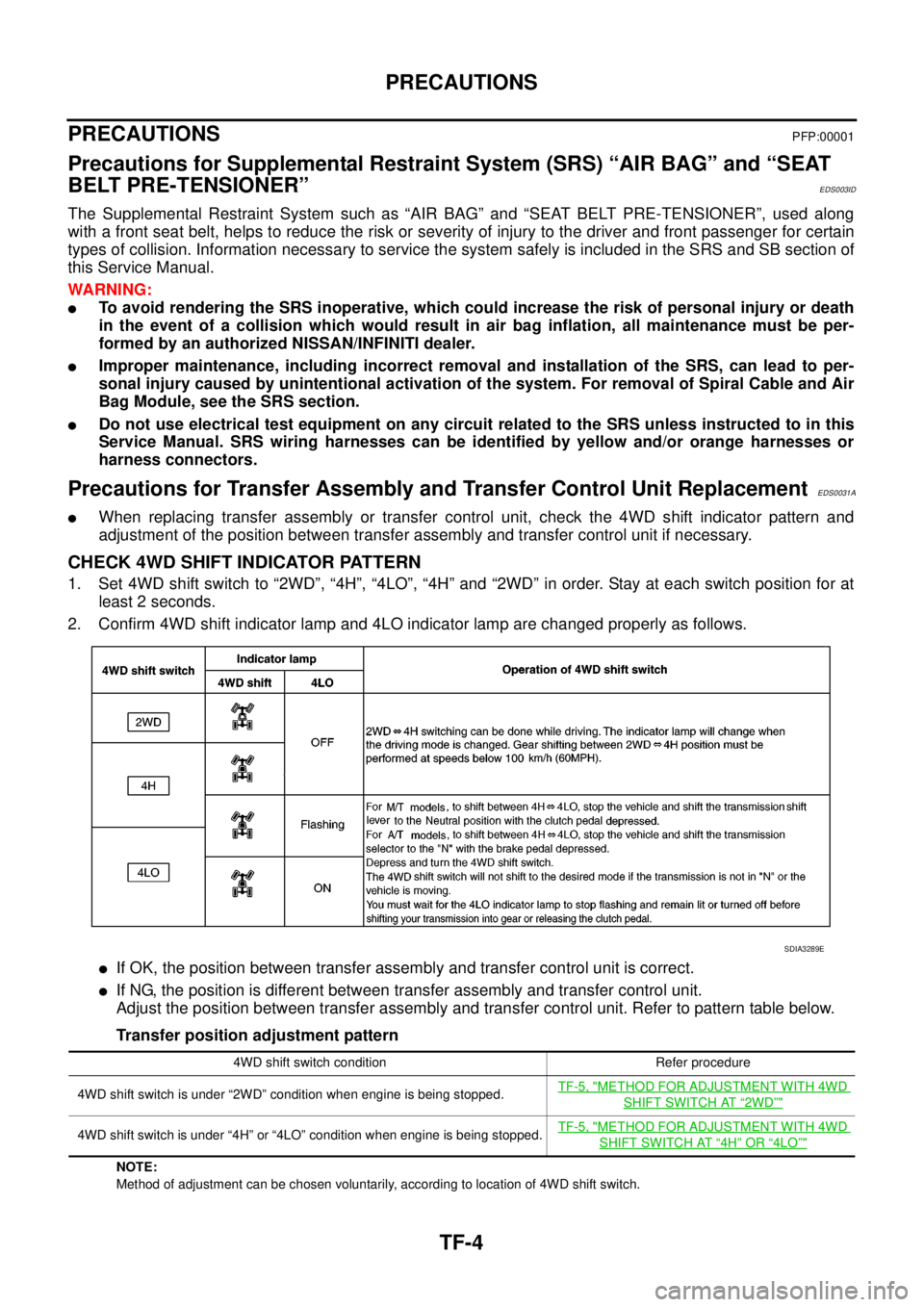

TF-4

PRECAUTIONS

PRECAUTIONS

PFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EDS003ID

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

Precautions for Transfer Assembly and Transfer Control Unit ReplacementEDS0031A

lWhen replacing transfer assembly or transfer control unit, check the 4WD shift indicator pattern and

adjustment of the position between transfer assembly and transfer control unit if necessary.

CHECK 4WD SHIFT INDICATOR PATTERN

1. Set 4WD shift switch to “2WD”, “4H”, “4LO”, “4H” and “2WD” in order. Stay at each switch position for at

least 2 seconds.

2. Confirm 4WD shift indicator lamp and 4LO indicator lamp are changed properly as follows.

lIf OK, the position between transfer assembly and transfer control unit is correct.

lIf NG, the position is different between transfer assembly and transfer control unit.

Adjust the position between transfer assembly and transfer control unit. Refer to pattern table below.

Transfer position adjustment pattern

NOTE:

Method of adjustment can be chosen voluntarily, according to location of 4WD shift switch.

SDIA3289E

4WD shift switch condition Refer procedure

4WD shift switch is under “2WD” condition when engine is being stopped.TF-5, "

METHOD FOR ADJUSTMENT WITH 4WD

SHIFT SWITCH AT“2WD”"

4WD shift switch is under “4H” or “4LO” condition when engine is being stopped.TF-5, "METHOD FOR ADJUSTMENT WITH 4WD

SHIFT SWITCH AT“4H”OR“4LO”"