4WD NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2972 of 3171

PRECAUTIONS

TF-5

C

E

F

G

H

I

J

K

L

MA

B

TF

METHODFORADJUSTMENTWITH4WDSHIFTSWITCHAT“2WD”

Select Adjustment Pattern

1. Start engine. Run engine for at least 10 seconds.

2. Check 4WD shift indicator lamp and 4LO indicator lamp.

Pattern A

1. Stay in the below for at least 2 seconds.

lFor A/T models, stop the vehicle and move A/T selector lever to “N” position with the brake pedal

depressed.

lFor M/T models, stop the vehicle and move M/T shift lever to the neutral position with the brake and

clutch pedal depressed.

2. Turn 4WD shift switch to “4LO” position. Stay in "4LO" for at least 2 seconds.

3. Turn ignition switch “OFF”.

4. Start engine.

5. Erase self-diagnosis. Refer toTF-46, "

How to Erase Self-diagnostic Results"(with CONSULT-II) orTF-

51, "ERASE SELF-DIAGNOSIS"(without CONSULT-II).

6. Check 4WD shift indicator lamp and 4LO indicator lamp again. Refer toTF-4, "

CHECK 4WD SHIFT INDI-

CATOR PATTERN".

If 4WD shift indicator lamp and 4LO indicator lamp do not indicate proper pattern, install new transfer con-

trol unit and retry the above check.

Pattern B

1. Stay in the below for at least 2 seconds.

lFor A/T models, stop the vehicle and move A/T selector lever to “N” position with the brake pedal

depressed.

lFor M/T models, stop the vehicle and move M/T shift lever to the neutral position with the brake and

clutch pedal depressed.

2. Turn ignition switch “OFF”.

3. Start engine.

4. Erase self-diagnosis. Refer toTF-46, "

How to Erase Self-diagnostic Results"(with CONSULT-II) orTF-

51, "ERASE SELF-DIAGNOSIS"(without CONSULT-II).

5. Check 4WD shift indicator lamp and 4LO indicator lamp again. Refer toTF-4, "

CHECK 4WD SHIFT INDI-

CATOR PATTERN".

If 4WD shift indicator lamp and 4LO indicator lamp do not indicate proper pattern, install new transfer con-

trol unit and retry the above check.

METHODFORADJUSTMENTWITH4WDSHIFTSWITCHAT“4H”OR“4LO”

1. Start engine. Run the engine for at least 10 seconds.

2. Stay in the below for at least 2 seconds.

lFor A/T models, stop the vehicle and move A/T selector lever to “N” position with the brake pedal

depressed.

lFor M/T models, stop the vehicle and move M/T shift lever to the neutral position with the brake and

clutch pedal depressed.

3. Turn 4WD shift switch to “2WD” position. Stay in "2WD" for at least 2 seconds.

4. Turn ignition switch “OFF”.

5. Start engine.

6. Erase self-diagnosis. Refer toTF-46, "

How to Erase Self-diagnostic Results"(with CONSULT-II) orTF-

51, "ERASE SELF-DIAGNOSIS"(without CONSULT-II).

7. Check 4WD shift indicator lamp and 4LO indicator lamp again. Refer toTF-4, "

CHECK 4WD SHIFT INDI-

CATOR PATTERN".

Indicator lamp condition Refer procedure

When 4WD shift indicator lamp or 4LO indicator lamp is flashing.TF-5, "

Pattern A"

Except for above.TF-5, "Pattern B"

Page 2973 of 3171

TF-6

PRECAUTIONS

If 4WD shift indicator lamp and 4LO indicator lamp do not indicate proper pattern, install new transfer con-

trol unit and retry the above check.

PrecautionsEDS0031B

lBefore connecting or disconnecting the transfer control unit harness connector, turn ignition

switch “OFF” and disconnect the battery cables. Battery voltage is applied to transfer control unit

even if ignition switch is turned “OFF”.

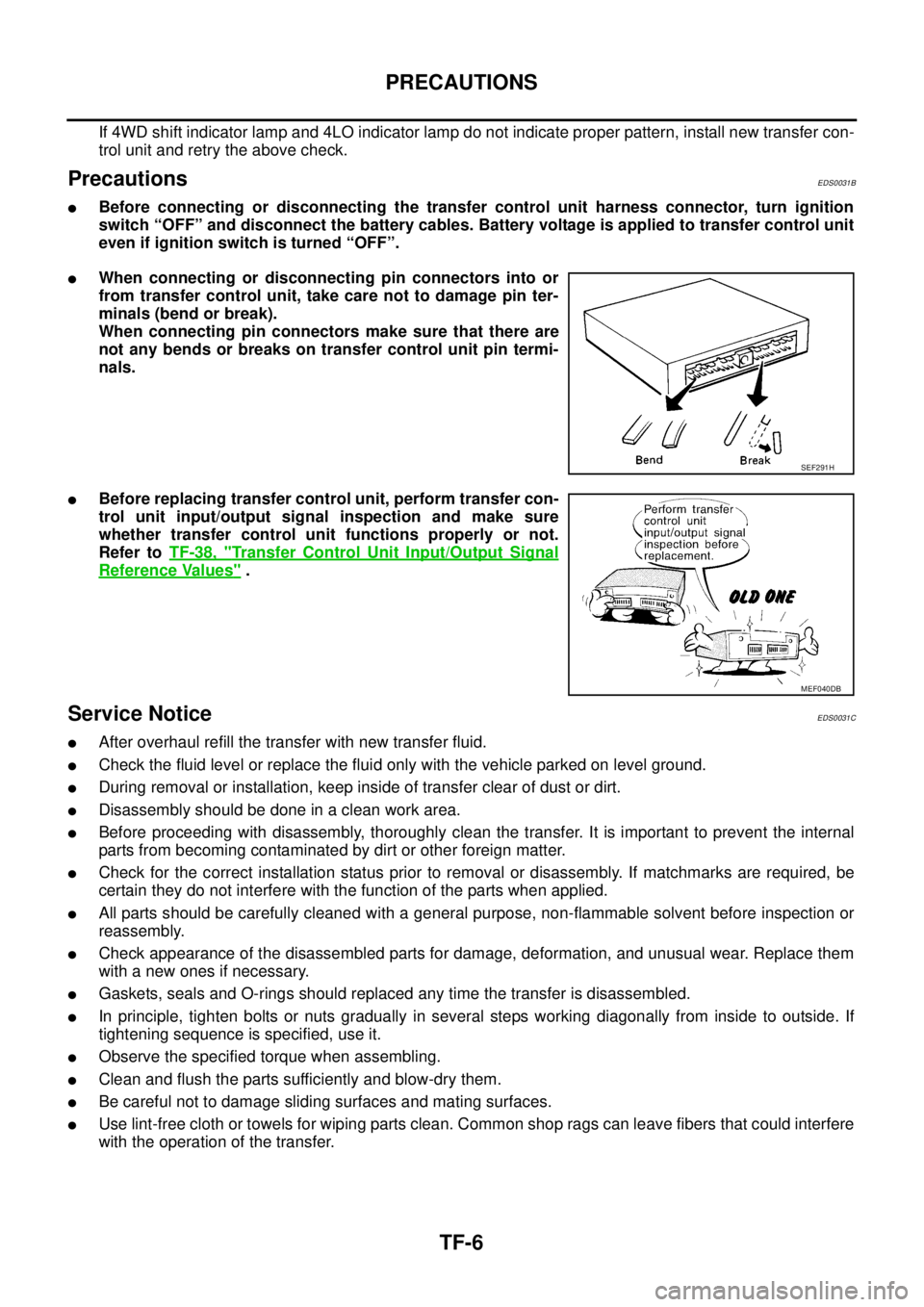

lWhen connecting or disconnecting pin connectors into or

from transfer control unit, take care not to damage pin ter-

minals (bend or break).

When connecting pin connectors make sure that there are

not any bends or breaks on transfer control unit pin termi-

nals.

lBefore replacing transfer control unit, perform transfer con-

trol unit input/output signal inspection and make sure

whether transfer control unit functions properly or not.

Refer toTF-38, "

Transfer Control Unit Input/Output Signal

Reference Values".

Service NoticeEDS0031C

lAfter overhaul refill the transfer with new transfer fluid.

lCheck the fluid level or replace the fluid only with the vehicle parked on level ground.

lDuring removal or installation, keep inside of transfer clear of dust or dirt.

lDisassemblyshouldbedoneinacleanworkarea.

lBefore proceeding with disassembly, thoroughly clean the transfer. It is important to prevent the internal

parts from becoming contaminated by dirt or other foreign matter.

lCheck for the correct installation status prior to removal or disassembly. If matchmarks are required, be

certain they do not interfere with the function of the parts when applied.

lAll parts should be carefully cleaned with a general purpose, non-flammable solvent before inspection or

reassembly.

lCheck appearance of the disassembled parts for damage, deformation, and unusual wear. Replace them

with a new ones if necessary.

lGaskets, seals and O-rings should replaced any time the transfer is disassembled.

lIn principle, tighten bolts or nuts gradually in several steps working diagonally from inside to outside. If

tightening sequence is specified, use it.

lObserve the specified torque when assembling.

lClean and flush the parts sufficiently and blow-dry them.

lBe careful not to damage sliding surfaces and mating surfaces.

lUse lint-free cloth or towels for wiping parts clean. Common shop rags can leave fibers that could interfere

with the operation of the transfer.

SEF291H

MEF040DB

Page 2980 of 3171

4WD SYSTEM

TF-13

C

E

F

G

H

I

J

K

L

MA

B

TF

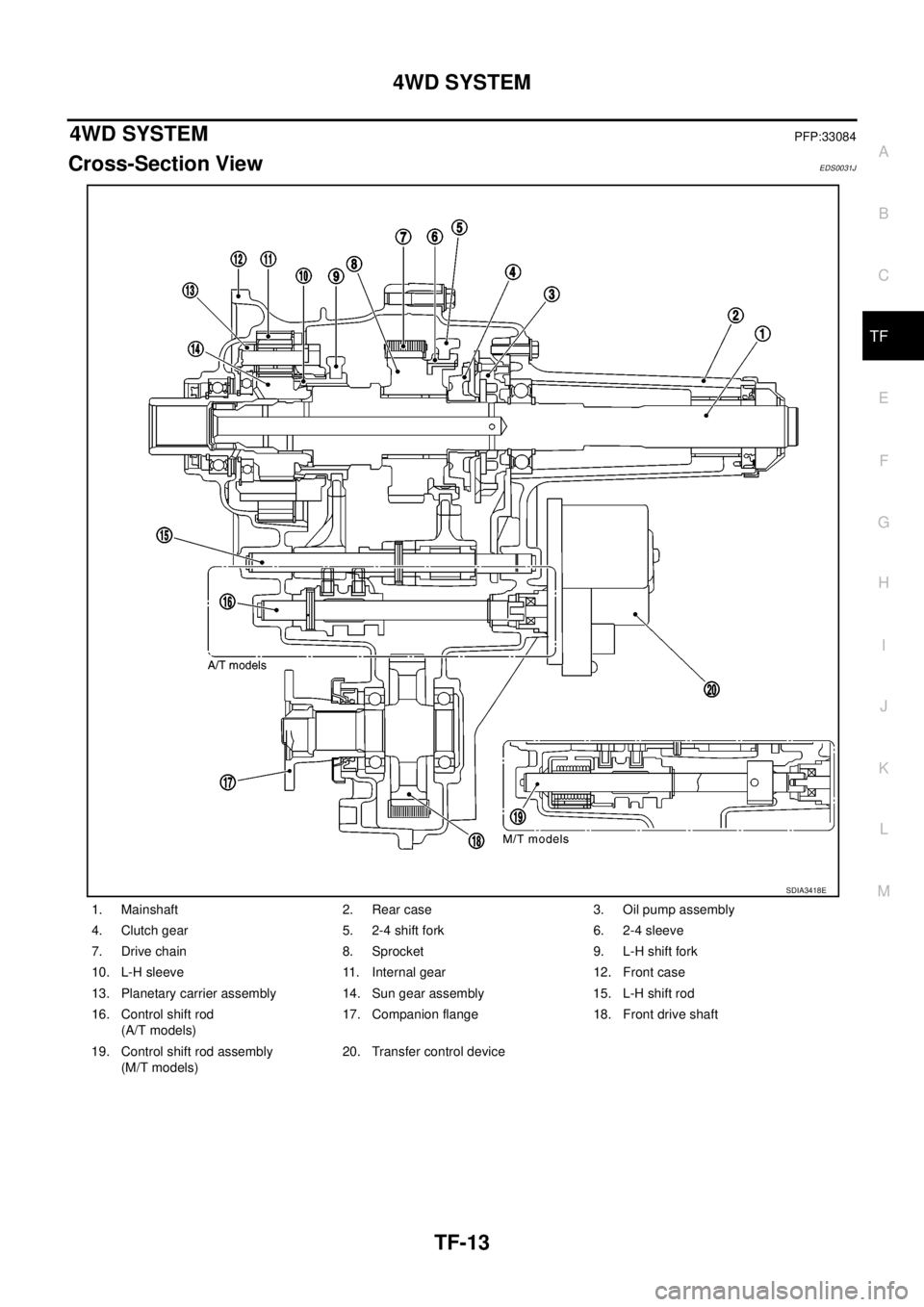

4WD SYSTEMPFP:33084

Cross-Section ViewEDS0031J

1. Mainshaft 2. Rear case 3. Oil pump assembly

4. Clutch gear 5. 2-4 shift fork 6. 2-4 sleeve

7. Drive chain 8. Sprocket 9. L-H shift fork

10. L-H sleeve 11. Internal gear 12. Front case

13. Planetary carrier assembly 14. Sun gear assembly 15. L-H shift rod

16. Control shift rod

(A/T models)17. Companion flange 18. Front drive shaft

19. Control shift rod assembly

(M/T models)20. Transfer control device

SDIA3418E

Page 2981 of 3171

TF-14

4WD SYSTEM

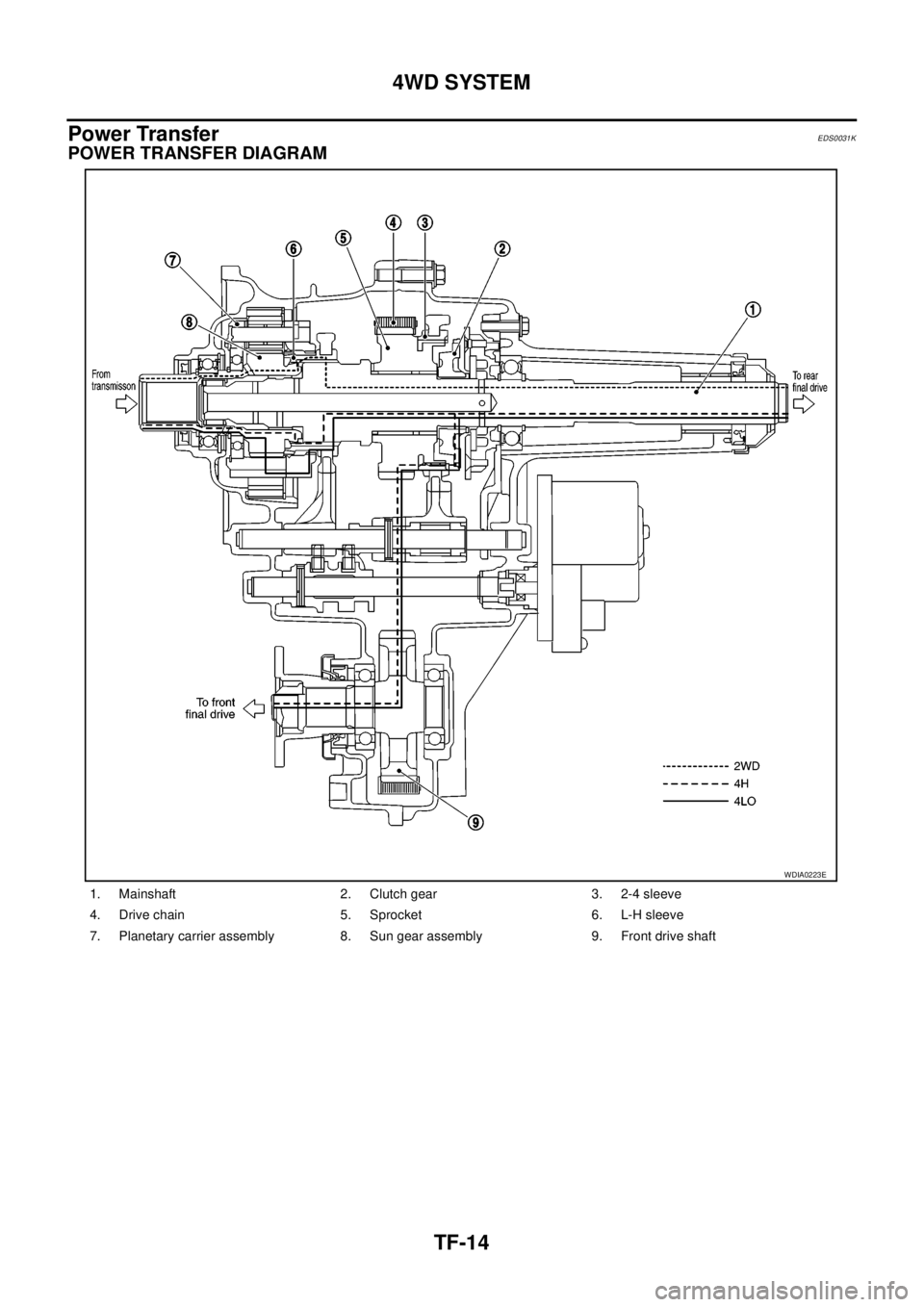

Power Transfer

EDS0031K

POWER TRANSFER DIAGRAM

1. Mainshaft 2. Clutch gear 3. 2-4 sleeve

4. Drive chain 5. Sprocket 6. L-H sleeve

7. Planetary carrier assembly 8. Sun gear assembly 9. Front drive shaft

WDIA0223E

Page 2982 of 3171

4WD SYSTEM

TF-15

C

E

F

G

H

I

J

K

L

MA

B

TF

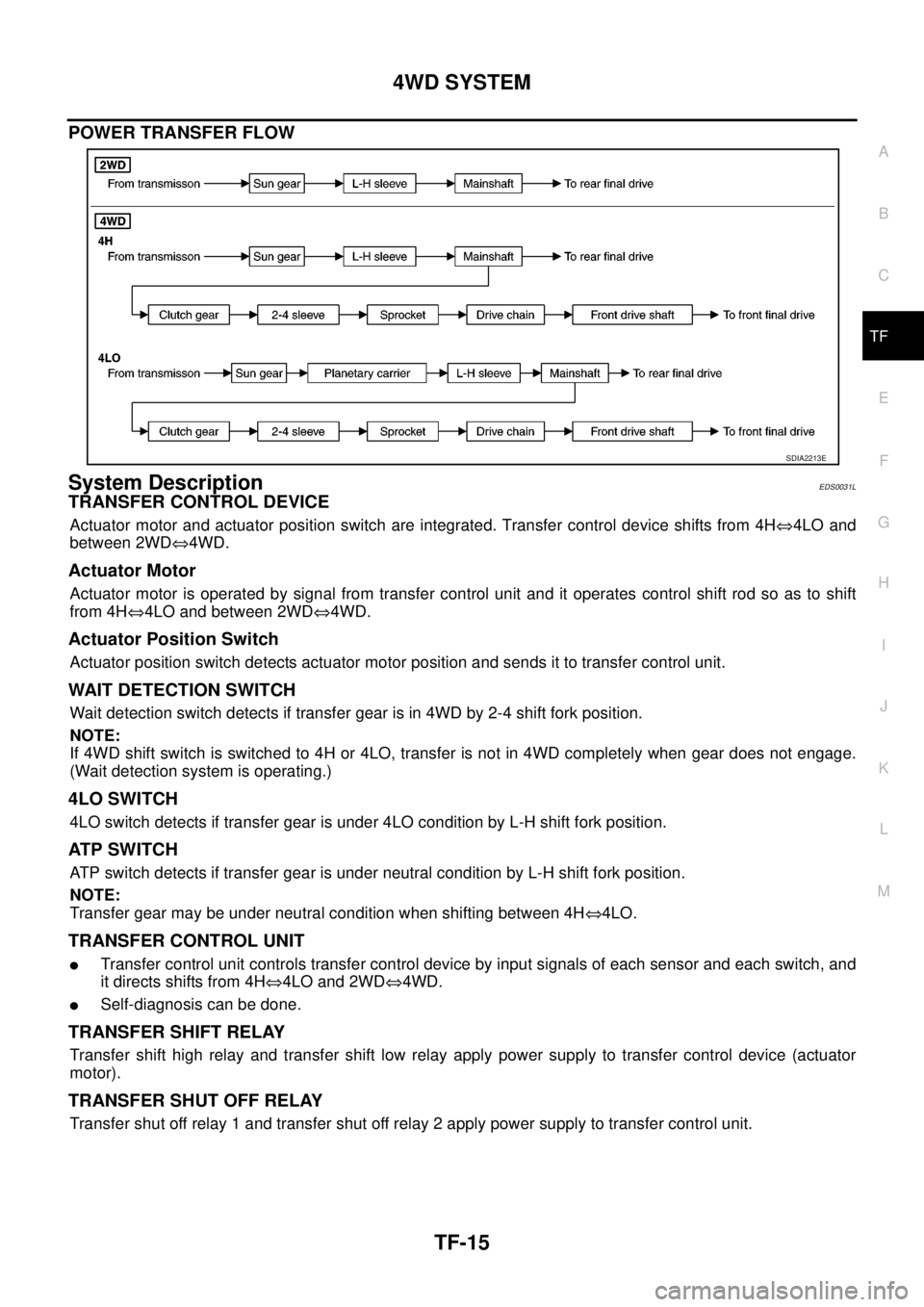

POWER TRANSFER FLOW

System DescriptionEDS0031L

TRANSFER CONTROL DEVICE

Actuator motor and actuator position switch are integrated. Transfer control device shifts from 4HÛ4LO and

between 2WDÛ4WD.

Actuator Motor

Actuator motor is operated by signal from transfer control unit and it operates control shift rod so as to shift

from 4HÛ4LO and between 2WDÛ4WD.

Actuator Position Switch

Actuator position switch detects actuator motor position and sends it to transfer control unit.

WAIT DETECTION SWITCH

Wait detection switch detects if transfer gear is in 4WD by 2-4 shift fork position.

NOTE:

If 4WD shift switch is switched to 4H or 4LO, transfer is not in 4WD completely when gear does not engage.

(Wait detection system is operating.)

4LO SWITCH

4LO switch detects if transfer gear is under 4LO condition by L-H shift fork position.

AT P S W I T C H

ATP switch detects if transfer gear is under neutral condition by L-H shift fork position.

NOTE:

Transfer gear may be under neutral condition when shifting between 4HÛ4LO.

TRANSFER CONTROL UNIT

lTransfer control unit controls transfer control device by input signals of each sensor and each switch, and

itdirectsshiftsfrom4HÛ4LO and 2WDÛ4WD.

lSelf-diagnosis can be done.

TRANSFER SHIFT RELAY

Transfer shift high relay and transfer shift low relay apply power supply to transfer control device (actuator

motor).

TRANSFER SHUT OFF RELAY

Transfer shut off relay 1 and transfer shut off relay 2 apply power supply to transfer control unit.

SDIA2213E

Page 2983 of 3171

TF-16

4WD SYSTEM

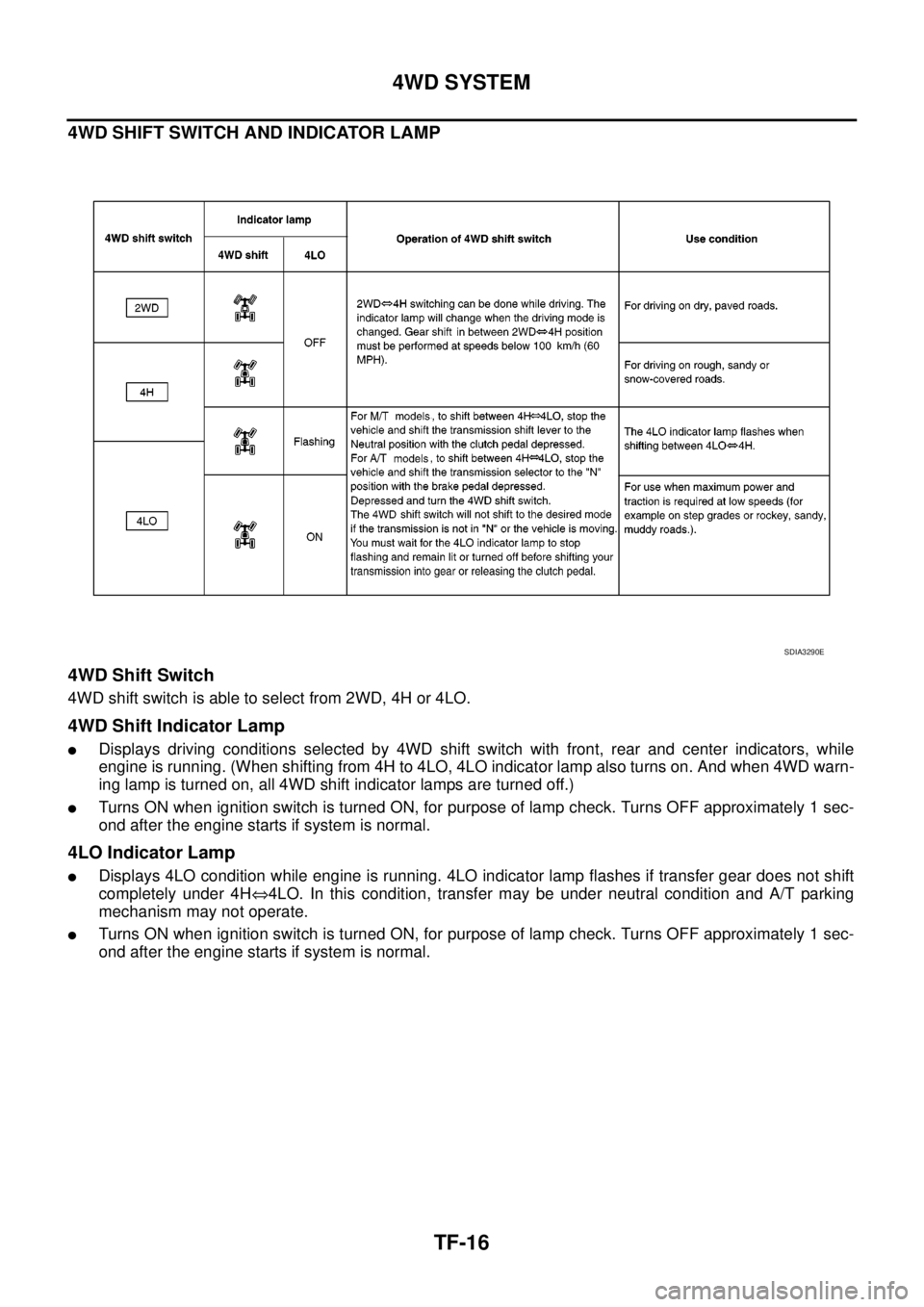

4WD SHIFT SWITCH AND INDICATOR LAMP

4WD Shift Switch

4WD shift switch is able to select from 2WD, 4H or 4LO.

4WD Shift Indicator Lamp

lDisplays driving conditions selected by 4WD shift switch with front, rear and center indicators, while

engine is running. (When shifting from 4H to 4LO, 4LO indicator lamp also turns on. And when 4WD warn-

ing lamp is turned on, all 4WD shift indicator lamps are turned off.)

lTurns ON when ignition switch is turned ON, for purpose of lamp check. Turns OFF approximately 1 sec-

ondaftertheenginestartsifsystemisnormal.

4LO Indicator Lamp

lDisplays 4LO condition while engine is running. 4LO indicator lamp flashes if transfer gear does not shift

completely under 4HÛ4LO. In this condition, transfer may be under neutral condition and A/T parking

mechanism may not operate.

lTurns ON when ignition switch is turned ON, for purpose of lamp check. Turns OFF approximately 1 sec-

ondaftertheenginestartsifsystemisnormal.

SDIA3290E

Page 2984 of 3171

4WD SYSTEM

TF-17

C

E

F

G

H

I

J

K

L

MA

B

TF

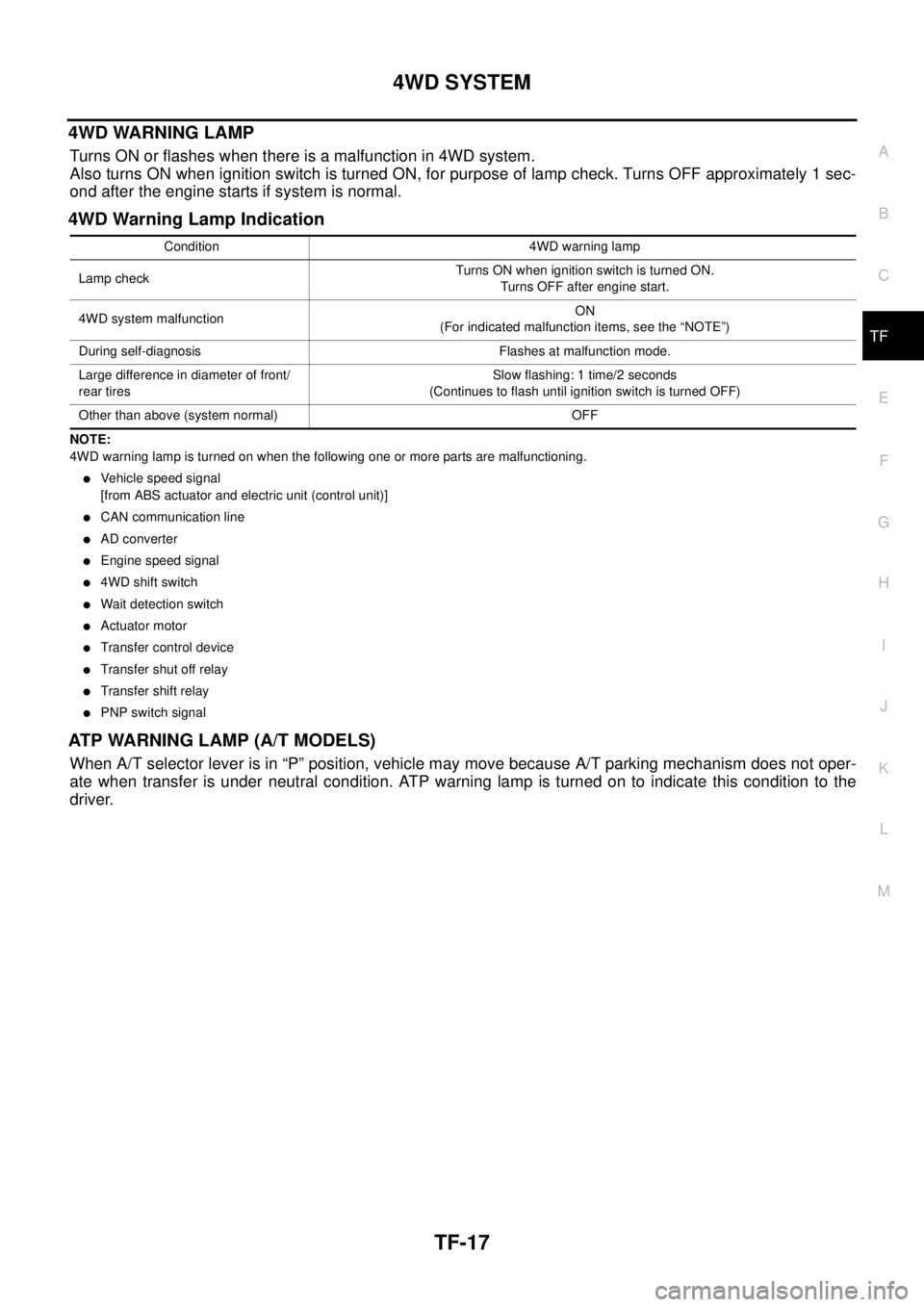

4WD WARNING LAMP

Turns ON or flashes when there is a malfunction in 4WD system.

Also turns ON when ignition switch is turned ON, for purpose of lamp check. Turns OFF approximately 1 sec-

ond after the engine starts if system is normal.

4WD Warning Lamp Indication

NOTE:

4WD warning lamp is turned on when the following one or more parts are malfunctioning.

lVehicle speed signal

[from ABS actuator and electric unit (control unit)]

lCAN communication line

lAD converter

lEngine speed signal

l4WD shift switch

lWait detection switch

lActuator motor

lTransfer control device

lTransfer shut off relay

lTransfer shift relay

lPNP switch signal

ATP WARNING LAMP (A/T MODELS)

When A/T selector lever is in “P” position, vehicle may move because A/T parking mechanism does not oper-

ate when transfer is under neutral condition. ATP warning lamp is turned on to indicate this condition to the

driver.

Condition 4WD warning lamp

Lamp checkTurns ON when ignition switch is turned ON.

Turns OFF after engine start.

4WD system malfunctionON

(For indicated malfunction items, see the “NOTE”)

During self-diagnosis Flashes at malfunction mode.

Large difference in diameter of front/

rear tiresSlow flashing: 1 time/2 seconds

(Continues to flash until ignition switch is turned OFF)

Other than above (system normal) OFF

Page 2985 of 3171

TF-18

4WD SYSTEM

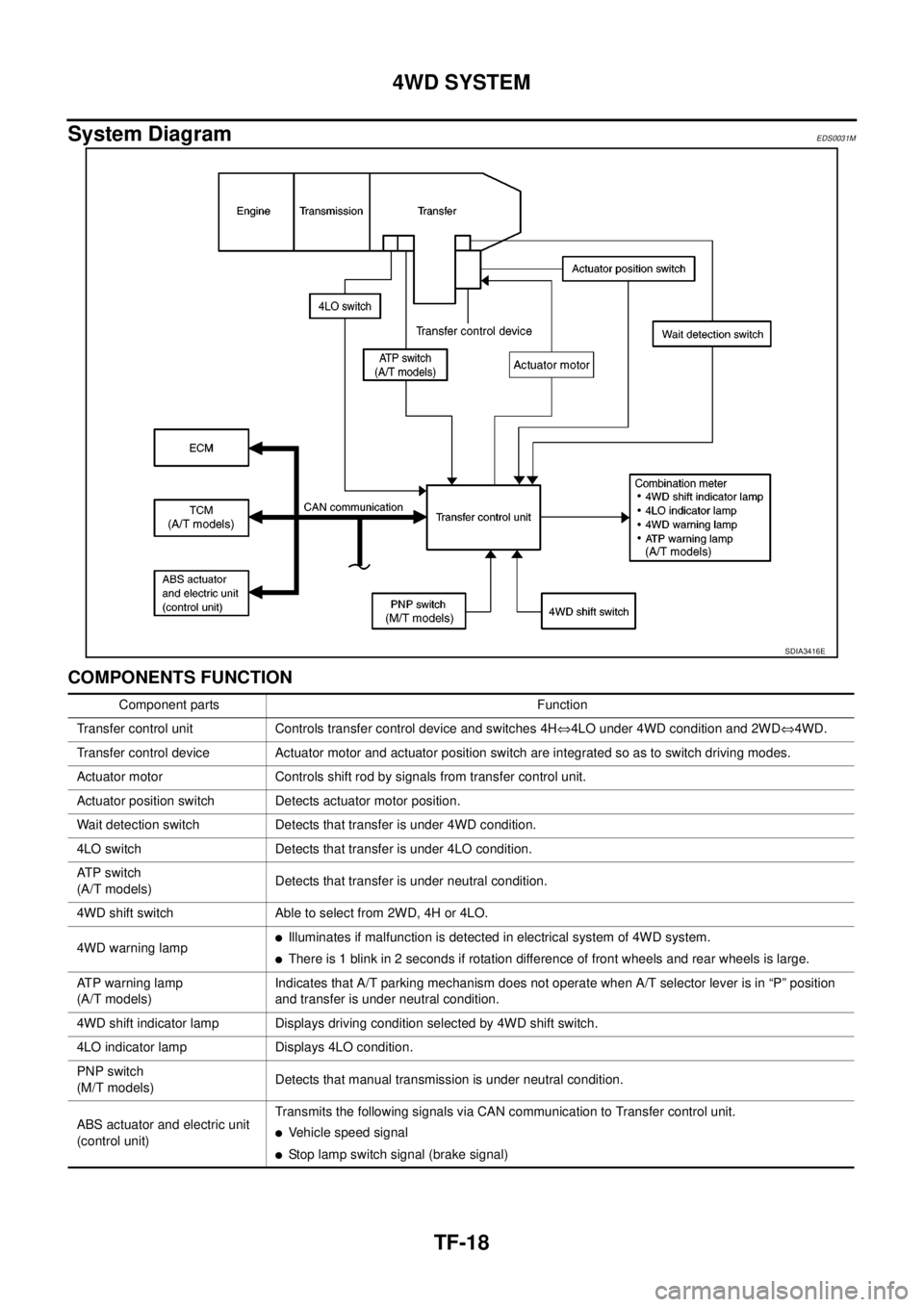

System Diagram

EDS0031M

COMPONENTS FUNCTION

SDIA3416E

Component parts Function

Transfer control unit Controls transfer control device and switches 4HÛ4LO under 4WD condition and 2WDÛ4WD.

Transfer control device Actuator motor and actuator position switch are integrated so as to switch driving modes.

Actuator motor Controls shift rod by signals from transfer control unit.

Actuator position switch Detects actuator motor position.

Wait detection switch Detects that transfer is under 4WD condition.

4LO switch Detects that transfer is under 4LO condition.

AT P s w i t c h

(A/T models)Detects that transfer is under neutral condition.

4WD shift switch Able to select from 2WD, 4H or 4LO.

4WD warning lamp

lIlluminates if malfunction is detected in electrical system of 4WD system.

lThere is 1 blink in 2 seconds if rotation difference of front wheels and rear wheels is large.

ATP warning lamp

(A/T models)Indicates that A/T parking mechanism does not operate when A/T selector lever is in “P” position

and transfer is under neutral condition.

4WD shift indicator lamp Displays driving condition selected by 4WD shift switch.

4LO indicator lamp Displays 4LO condition.

PNP switch

(M/T models)Detects that manual transmission is under neutral condition.

ABS actuator and electric unit

(control unit)Transmits the following signals via CAN communication to Transfer control unit.

lVehicle speed signal

lStop lamp switch signal (brake signal)

Page 2986 of 3171

4WD SYSTEM

TF-19

C

E

F

G

H

I

J

K

L

MA

B

TF

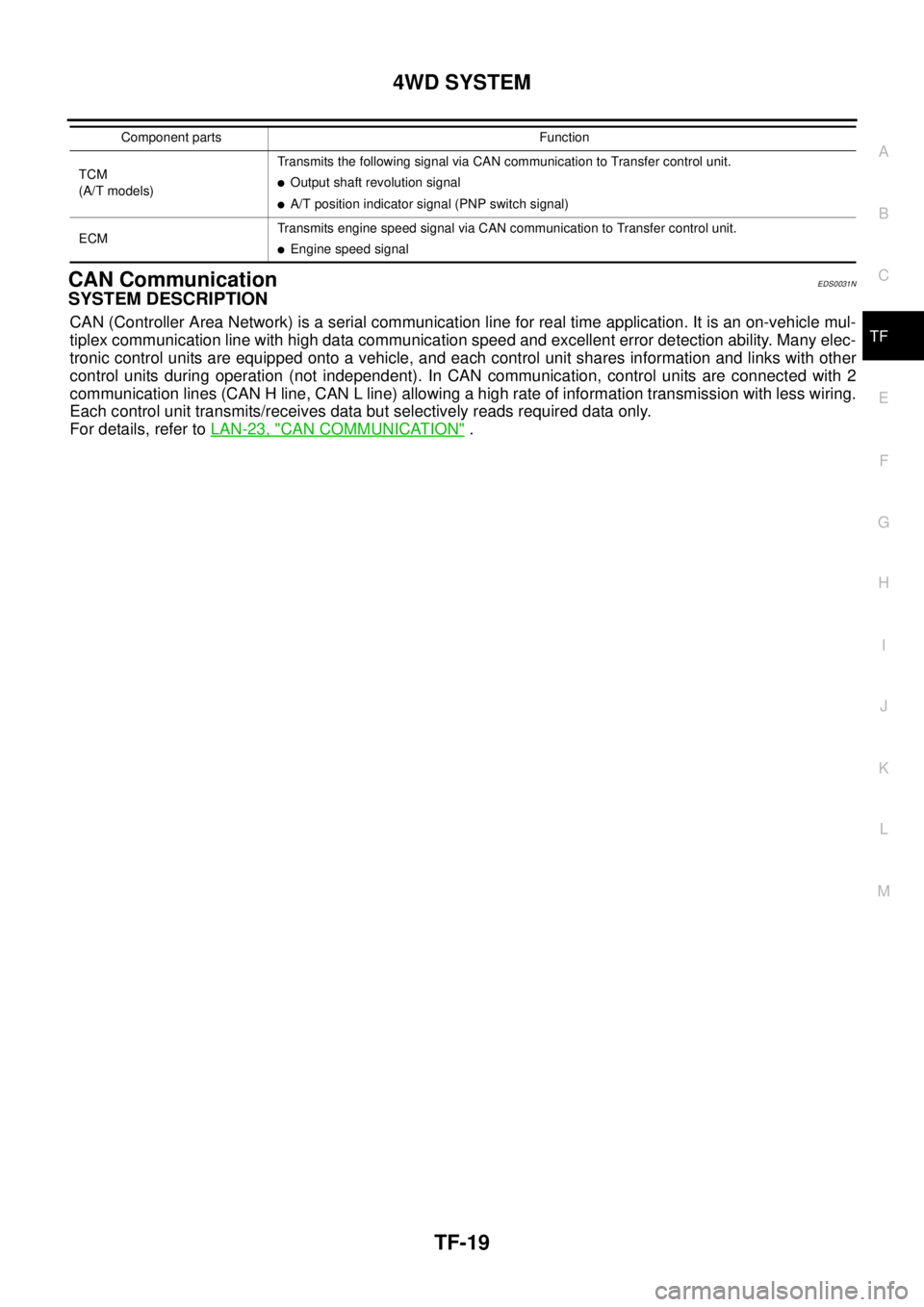

CAN CommunicationEDS0031N

SYSTEM DESCRIPTION

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent error detection ability. Many elec-

tronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CAN communication, control units are connected with 2

communication lines (CAN H line, CAN L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only.

For details, refer toLAN-23, "

CAN COMMUNICATION".

TCM

(A/T models)Transmits the following signal via CAN communication to Transfer control unit.lOutput shaft revolution signal

lA/T position indicator signal (PNP switch signal)

ECMTransmits engine speed signal via CAN communication to Transfer control unit.

lEngine speed signal Component parts Function

Page 3005 of 3171

TF-38

TROUBLE DIAGNOSIS

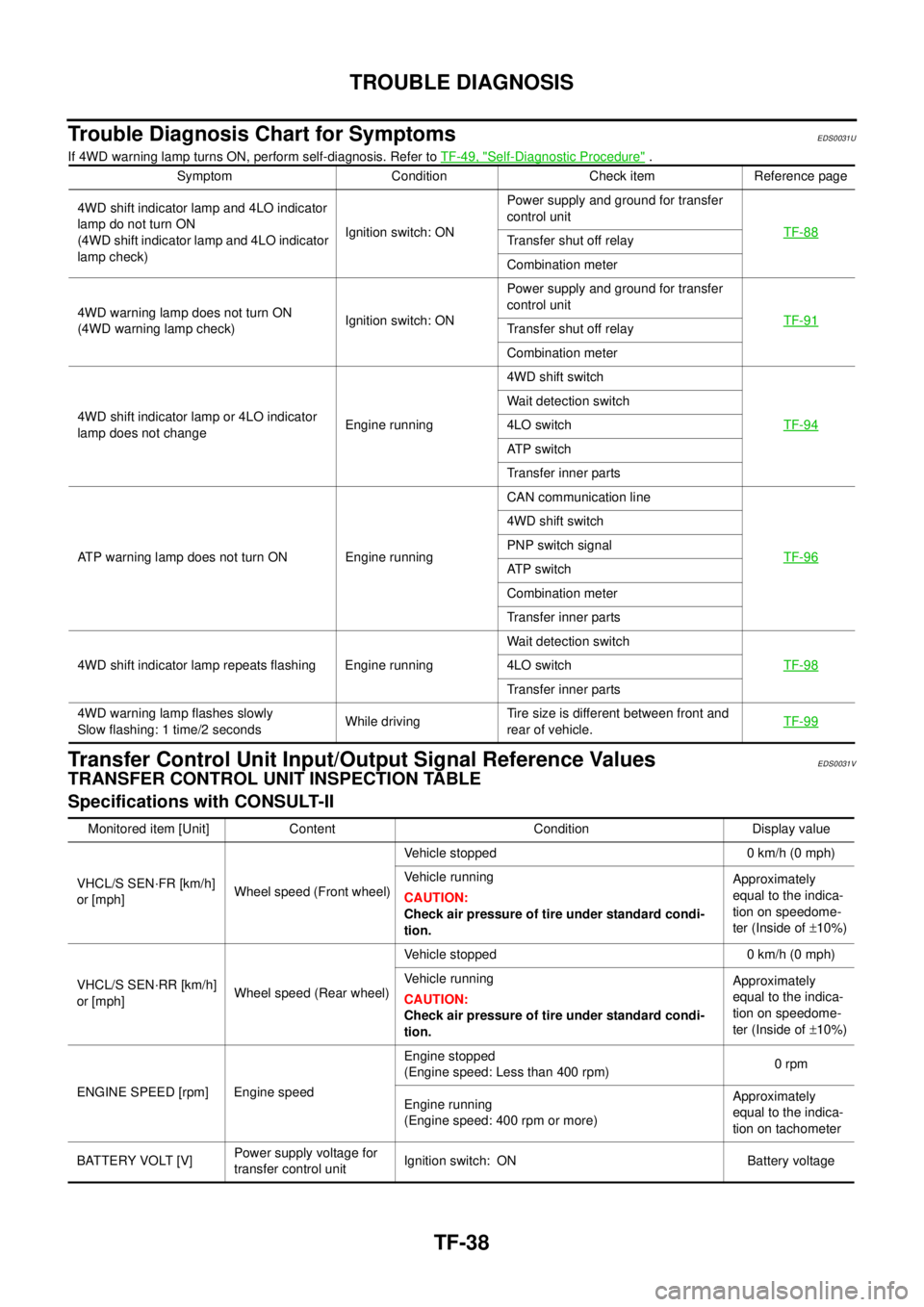

Trouble Diagnosis Chart for Symptoms

EDS0031U

If 4WD warning lamp turns ON, perform self-diagnosis. Refer toTF-49, "Self-Diagnostic Procedure".

Transfer Control Unit Input/Output Signal Reference ValuesEDS0031V

TRANSFER CONTROL UNIT INSPECTION TABLE

Specifications with CONSULT-II

Symptom Condition Check item Reference page

4WD shift indicator lamp and 4LO indicator

lamp do not turn ON

(4WD shift indicator lamp and 4LO indicator

lamp check)Ignition switch: ONPower supply and ground for transfer

control unit

TF-88

Transfer shut off relay

Combination meter

4WD warning lamp does not turn ON

(4WD warning lamp check)Ignition switch: ONPower supply and ground for transfer

control unit

TF-91

Transfer shut off relay

Combination meter

4WD shift indicator lamp or 4LO indicator

lamp does not changeEngine running4WD shift switch

TF-94

Wait detection switch

4LO switch

AT P s w i t c h

Transfer inner parts

ATP warning lamp does not turn ON Engine runningCAN communication line

TF-96

4WD shift switch

PNP switch signal

AT P s w i t c h

Combination meter

Transfer inner parts

4WD shift indicator lamp repeats flashing Engine runningWait detection switch

TF-98

4LO switch

Transfer inner parts

4WD warning lamp flashes slowly

Slow flashing: 1 time/2 secondsWhile drivingTire size is different between front and

rear of vehicle.TF-99

Monitored item [Unit] Content Condition Display value

VHCL/S SEN·FR [km/h]

or [mph]Wheel speed (Front wheel)Vehicle stopped 0 km/h (0 mph)

Vehicle running

CAUTION:

Check air pressure of tire under standard condi-

tion.Approximately

equal to the indica-

tion on speedome-

ter (Inside of±10%)

VHCL/S SEN·RR [km/h]

or [mph]Wheel speed (Rear wheel)Vehicle stopped 0 km/h (0 mph)

Vehicle running

CAUTION:

Check air pressure of tire under standard condi-

tion.Approximately

equal to the indica-

tion on speedome-

ter (Inside of±10%)

ENGINE SPEED [rpm] Engine speedEngine stopped

(Engine speed: Less than 400 rpm)0rpm

Engine running

(Engine speed: 400 rpm or more)Approximately

equal to the indica-

tion on tachometer

BATTERY VOLT [V]Power supply voltage for

transfer control unitIgnition switch: ON Battery voltage