4WD NISSAN NAVARA 2005 Repair Manual Online

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2246 of 3171

ILLUMINATION

LT-163

C

D

E

F

G

H

I

J

L

MA

B

LT

lto cigarette lighter (illumination) terminal 1

lto ashtray (illumination) terminal 1

lto headlamp washer switch (illumination) terminal 3

lto headlamp aiming switch (illumination) terminal 3 and

lto NAVI control unit (illumination) terminal 61 (with NAVI).

Ground is supplied

lto hazard switch (illumination) terminal 4

lto 4WD shift switch (illumination) terminal 8 (with 4-wheel drive)

lto front air control (illumination) terminal 9

lto AV switch (illumination) terminal 4 (with NAVI)

lto audio unit (illumination) terminal 28 (with NAVI)

lto DIFF LOCK switch (illumination) terminal 5 (with DIFF LOCK)

lto heated seat switch (driver side) (illumination) terminal 6 (with heated seats) and

lto heated seat switch (passenger side) (illumination) terminal 6 (with heated seats)

lthrough combination meter terminal 22

lthrough combination meter terminal 23

lthrough ground M21, M80 and M83,

lto glove box lamp terminal 2

lto A/T device (illumination) terminal 5 (with A/T)

lto heat up switch (illumination) terminal 6

lto ashtray (illumination) terminal 2

lto headlamp washer switch (illumination) terminal 4 and

lto headlamp aiming switch (illumination) terminal 4

ltrough ground M21, M80 and M83,

lto audio unit (illumination) (1CD and 6CD player)

lthrough case ground of audio unit,

lto cigarette lighter (illumination)

lthrough case ground of cigarette lighter,

lto NAVI control unit (illumination) terminal 1 (with NAVI)

lthrough ground B106 and B121.

With power and ground supplied, illumination lamps illuminate.

CAN Communication System DescriptionEKS00P8W

Refer toLAN-23, "CAN COMMUNICATION".

CAN Communication UnitEKS00P8X

Refer toLAN-30, "CAN Communication Unit".

Page 2282 of 3171

GENERAL MAINTENANCE

MA-7

C

D

E

F

G

H

I

J

K

MA

B

MA

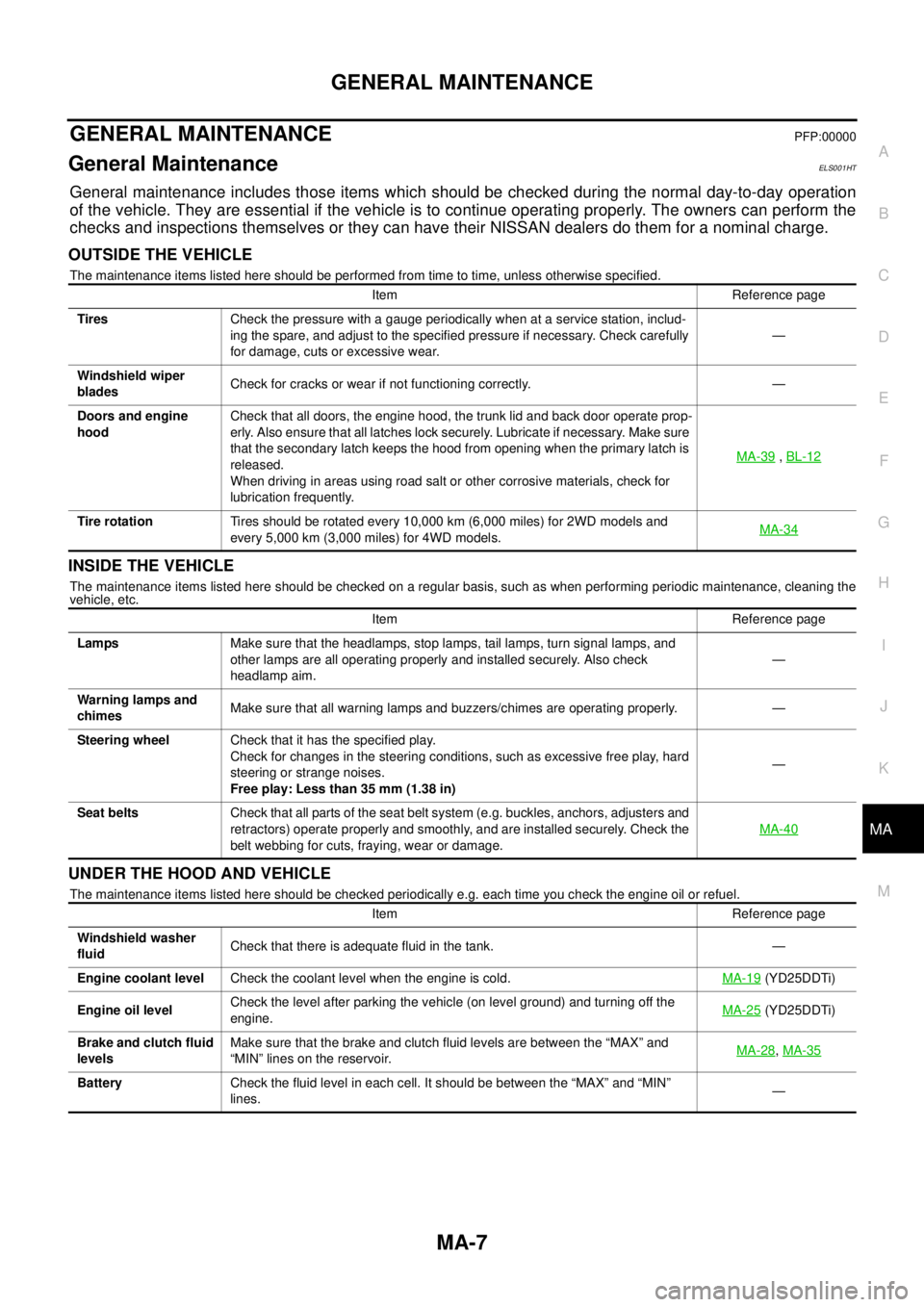

GENERAL MAINTENANCEPFP:00000

General MaintenanceELS001HT

General maintenance includes those items which should be checked during the normal day-to-day operation

of the vehicle. They are essential if the vehicle is to continue operating properly. The owners can perform the

checks and inspections themselves or they can have their NISSAN dealers do them for a nominal charge.

OUTSIDE THE VEHICLE

The maintenance items listed here should be performed from time to time, unless otherwise specified.

INSIDE THE VEHICLE

The maintenance items listed here should be checked on a regular basis, such as when performing periodic maintenance, cleaning the

vehicle, etc.

UNDER THE HOOD AND VEHICLE

The maintenance items listed here should be checked periodically e.g. each time you check the engine oil or refuel.Item Reference page

TiresCheck the pressure with a gauge periodically when at a service station, includ-

ing the spare, and adjust to the specified pressure if necessary. Check carefully

for damage, cuts or excessive wear.—

Windshield wiper

bladesCheck for cracks or wear if not functioning correctly. —

Doors and engine

hoodCheck that all doors, the engine hood, the trunk lid and back door operate prop-

erly. Also ensure that all latches lock securely. Lubricate if necessary. Make sure

that the secondary latch keeps the hood from opening when the primary latch is

released.

When driving in areas using road salt or other corrosive materials, check for

lubrication frequently.MA-39

,BL-12

Tire rotationTires should be rotated every 10,000 km (6,000 miles) for 2WD models and

every 5,000 km (3,000 miles) for 4WD models.MA-34

Item Reference page

LampsMake sure that the headlamps, stop lamps, tail lamps, turn signal lamps, and

other lamps are all operating properly and installed securely. Also check

headlamp aim.—

Warning lamps and

chimesMake sure that all warning lamps and buzzers/chimes are operating properly. —

Steering wheelCheck that it has the specified play.

Check for changes in the steering conditions, such as excessive free play, hard

steering or strange noises.

Free play: Less than 35 mm (1.38 in)—

Seat beltsCheck that all parts of the seat belt system (e.g. buckles, anchors, adjusters and

retractors) operate properly and smoothly, and are installed securely. Check the

belt webbing for cuts, fraying, wear or damage.MA-40

Item Reference page

Windshield washer

fluidCheck that there is adequate fluid in the tank. —

Engine coolant levelCheck the coolant level when the engine is cold.MA-19

(YD25DDTi)

Engine oil levelCheck the level after parking the vehicle (on level ground) and turning off the

engine.MA-25

(YD25DDTi)

Brake and clutch fluid

levelsMake sure that the brake and clutch fluid levels are between the “MAX” and

“MIN” lines on the reservoir.MA-28

,MA-35

BatteryCheck the fluid level in each cell. It should be between the “MAX” and “MIN”

lines.—

Page 2289 of 3171

MA-14

RECOMMENDED FLUIDS AND LUBRICANTS

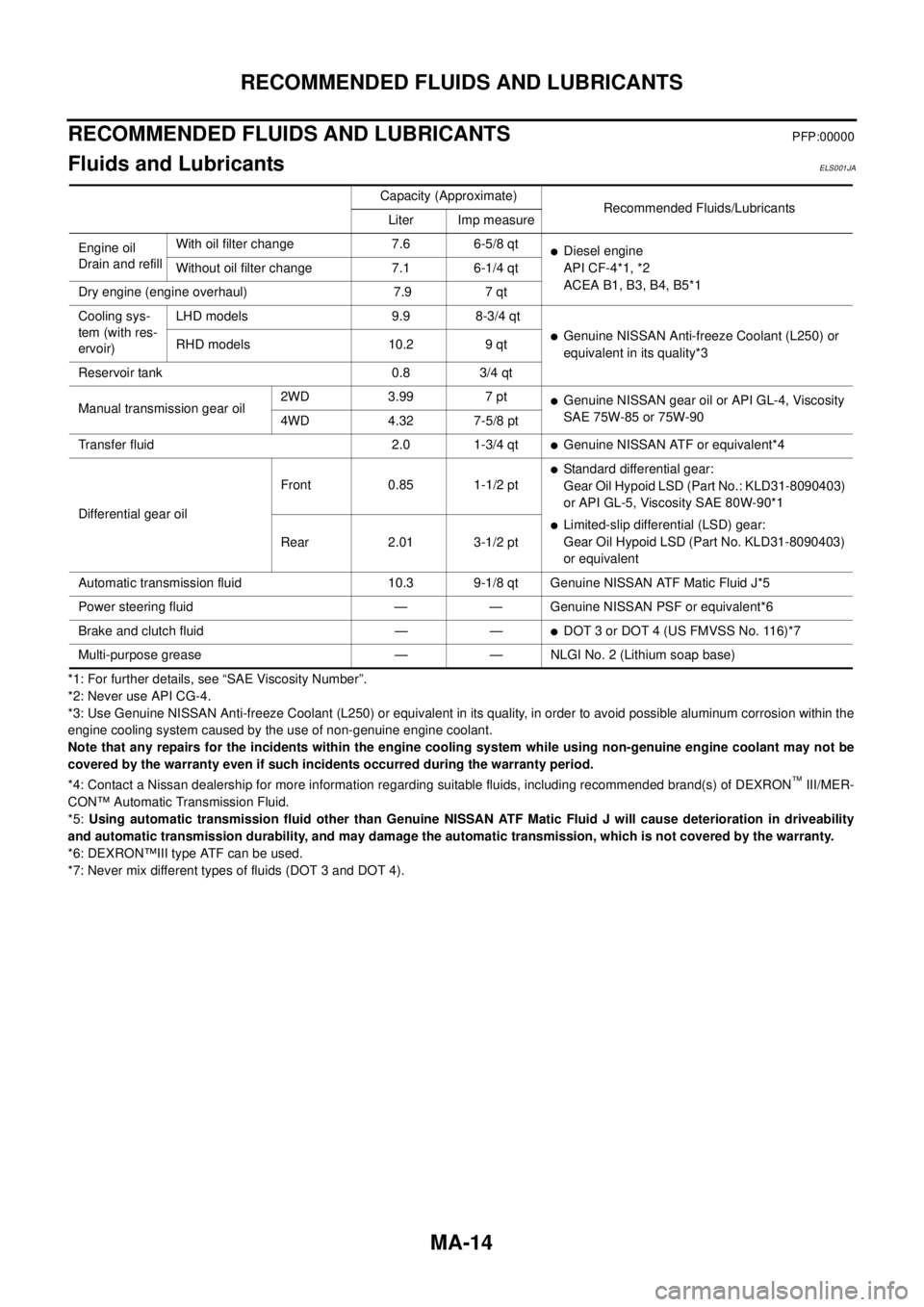

RECOMMENDED FLUIDS AND LUBRICANTS

PFP:00000

Fluids and LubricantsELS001JA

*1: For further details, see “SAE Viscosity Number”.

*2: Never use API CG-4.

*3: Use Genuine NISSAN Anti-freeze Coolant (L250) or equivalent in its quality, in order to avoid possible aluminum corrosion within the

engine cooling system caused by the use of non-genuine engine coolant.

Note that any repairs for the incidents within the engine cooling system while using non-genuine engine coolant may not be

covered by the warranty even if such incidents occurred during the warranty period.

*4: Contact a Nissan dealership for more information regarding suitable fluids, including recommended brand(s) of DEXRON

™III/MER-

CON™ Automatic Transmission Fluid.

*5:Using automatic transmission fluid other than Genuine NISSAN ATF Matic Fluid J will cause deterioration in driveability

and automatic transmission durability, and may damage the automatic transmission, which is not covered by the warranty.

*6: DEXRON™III type ATF can be used.

*7: Never mix different types of fluids (DOT 3 and DOT 4).Capacity (Approximate)

Recommended Fluids/Lubricants

Liter Imp measure

Engine oil

Drain and refillWith oil filter change 7.6 6-5/8 qt

lDiesel engine

API CF-4*1, *2

ACEA B1, B3, B4, B5*1 Without oil filter change 7.1 6-1/4 qt

Dry engine (engine overhaul) 7.9 7 qt

Cooling sys-

tem (with res-

ervoir)LHD models 9.9 8-3/4 qt

lGenuine NISSAN Anti-freeze Coolant (L250) or

equivalent in its quality*3 RHD models 10.2 9 qt

Reservoir tank 0.8 3/4 qt

Manual transmission gear oil2WD 3.99 7 pt

lGenuine NISSAN gear oil or API GL-4, Viscosity

SAE 75W-85 or 75W-90

4WD 4.32 7-5/8 pt

Transfer fluid 2.0 1-3/4 qt

lGenuine NISSAN ATF or equivalent*4

Differential gear oilFront 0.85 1-1/2 pt

lStandard differential gear:

Gear Oil Hypoid LSD (Part No.: KLD31-8090403)

or API GL-5, Viscosity SAE 80W-90*1

lLimited-slip differential (LSD) gear:

Gear Oil Hypoid LSD (Part No. KLD31-8090403)

or equivalent Rear 2.01 3-1/2 pt

Automatic transmission fluid 10.3 9-1/8 qt Genuine NISSAN ATF Matic Fluid J*5

Power steering fluid — — Genuine NISSAN PSF or equivalent*6

Brake and clutch fluid — —

lDOT 3 or DOT 4 (US FMVSS No. 116)*7

Multi-purpose grease — — NLGI No. 2 (Lithium soap base)

Page 2304 of 3171

CHASSIS AND BODY MAINTENANCE

MA-29

C

D

E

F

G

H

I

J

K

MA

B

MA

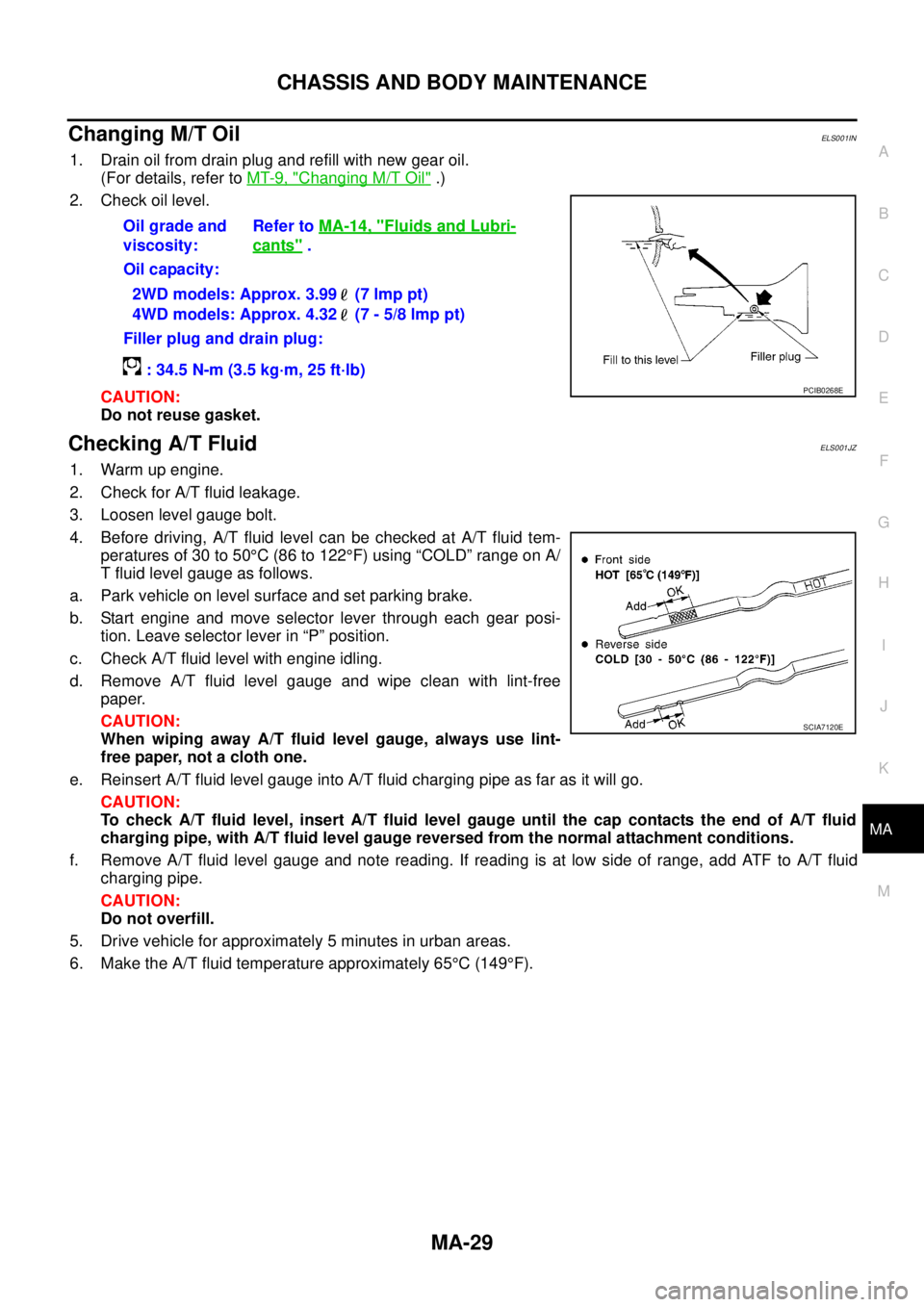

Changing M/T OilELS001IN

1. Drain oil from drain plug and refill with new gear oil.

(For details, refer toMT-9, "

Changing M/T Oil".)

2. Check oil level.

CAUTION:

Do not reuse gasket.

Checking A/T FluidELS001JZ

1. Warm up engine.

2. Check for A/T fluid leakage.

3. Loosen level gauge bolt.

4. Before driving, A/T fluid level can be checked at A/T fluid tem-

peraturesof30to50°C(86to122°F) using “COLD” range on A/

T fluid level gauge as follows.

a. Park vehicle on level surface and set parking brake.

b. Start engine and move selector lever through each gear posi-

tion. Leave selector lever in “P” position.

c. Check A/T fluid level with engine idling.

d. Remove A/T fluid level gauge and wipe clean with lint-free

paper.

CAUTION:

When wiping away A/T fluid level gauge, always use lint-

free paper, not a cloth one.

e. Reinsert A/T fluid level gauge into A/T fluid charging pipe as far as it will go.

CAUTION:

To check A/T fluid level, insert A/T fluid level gauge until the cap contacts the end of A/T fluid

charging pipe, with A/T fluid level gauge reversed from the normal attachment conditions.

f. Remove A/T fluid level gauge and note reading. If reading is at low side of range, add ATF to A/T fluid

charging pipe.

CAUTION:

Do not overfill.

5. Drive vehicle for approximately 5 minutes in urban areas.

6. Make the A/T fluid temperature approximately 65°C(149°F). Oil grade and

viscosity:Refer toMA-14, "

Fluids and Lubri-

cants".

Oil capacity:

2WD models: Approx. 3.99 (7 lmp pt)

4WD models: Approx. 4.32 (7 - 5/8 lmp pt)

Filler plug and drain plug:

: 34.5 N-m (3.5 kg·m, 25 ft·lb)

PCIB0268E

SCIA7120E

Page 2326 of 3171

M/T OIL

MT-9

D

E

F

G

H

I

J

K

L

MA

B

MT

M/T OILPFP:KLD20

Changing M/T OilECS00ID3

DRAINING

1. Start engine and let it run to warm up transmission.

2. Stop engine. Remove drain plug and gasket and then drain oil.

3. Set a gasket on drain plug and install it to transmission case. Tighten drain plug to the specified torque.

Refer toMT-19, "

Case Components".

CAUTION:

Do no reuse gasket.

FILLING

1. Remove filler plug and gasket. Fill with new oil until oil level reaches the specified limit near filler plug

mounting hole.

2. After refilling oil, check oil level. Set a gasket to filler plug, then install it to transmission case. Tighten filler

plug to the specified torque. Refer toMT-19, "

Case Components".

CAUTION:

Do no reuse gasket.

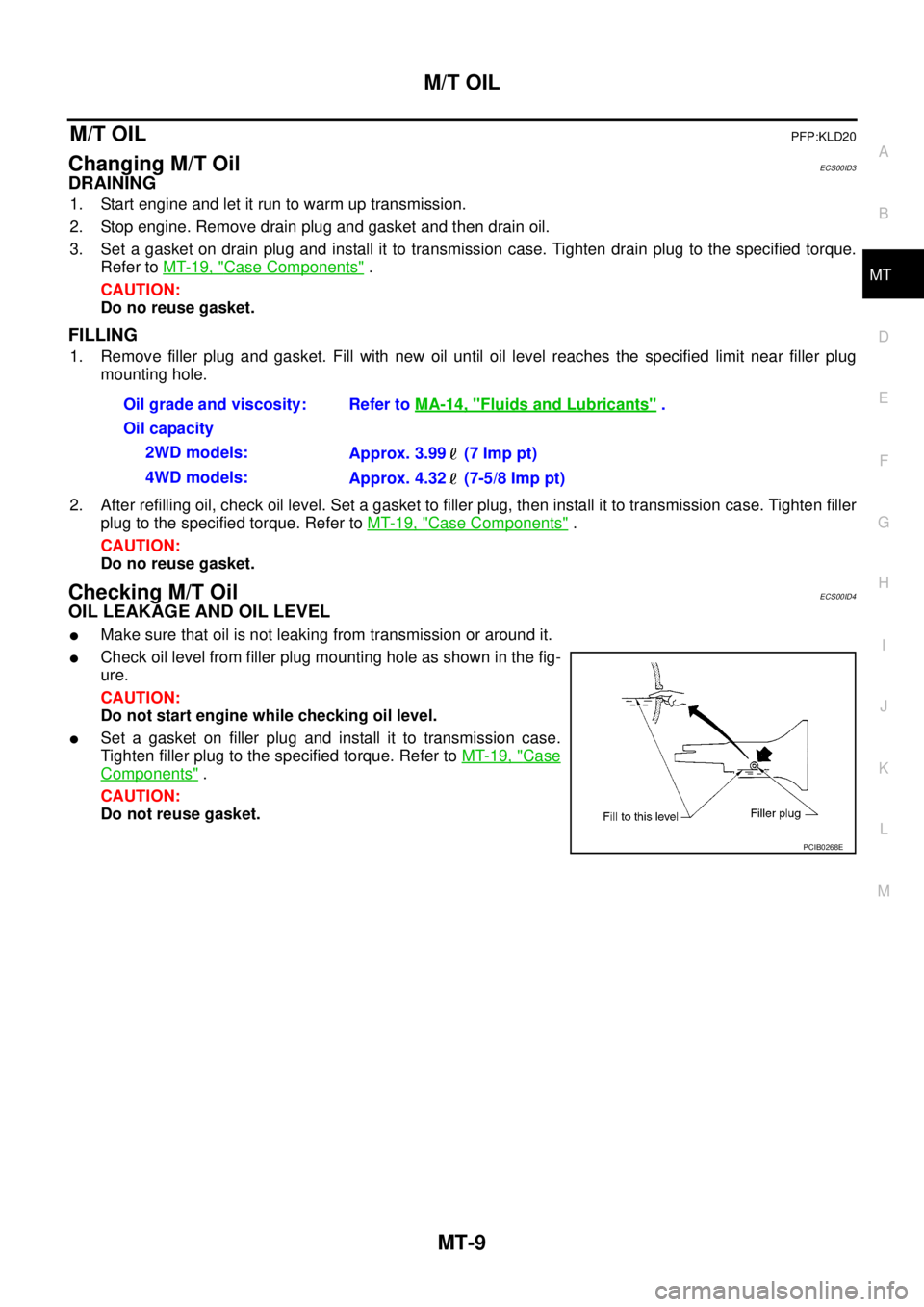

Checking M/T OilECS00ID4

OIL LEAKAGE AND OIL LEVEL

lMake sure that oil is not leaking from transmission or around it.

lCheck oil level from filler plug mounting hole as shown in the fig-

ure.

CAUTION:

Do not start engine while checking oil level.

lSet a gasket on filler plug and install it to transmission case.

Tighten filler plug to the specified torque. Refer toMT-19, "

Case

Components".

CAUTION:

Do not reuse gasket.Oil grade and viscosity: Refer toMA-14, "

Fluids and Lubricants".

Oil capacity

2WD models:

Approx. 3.99 (7 Imp pt)

4WD models:

Approx. 4.32 (7-5/8 Imp pt)

PCIB0268E

Page 2327 of 3171

MT-10

REAR OIL SEAL

REAR OIL SEAL

PFP:33140

Removal and InstallationECS00ID5

REMOVAL

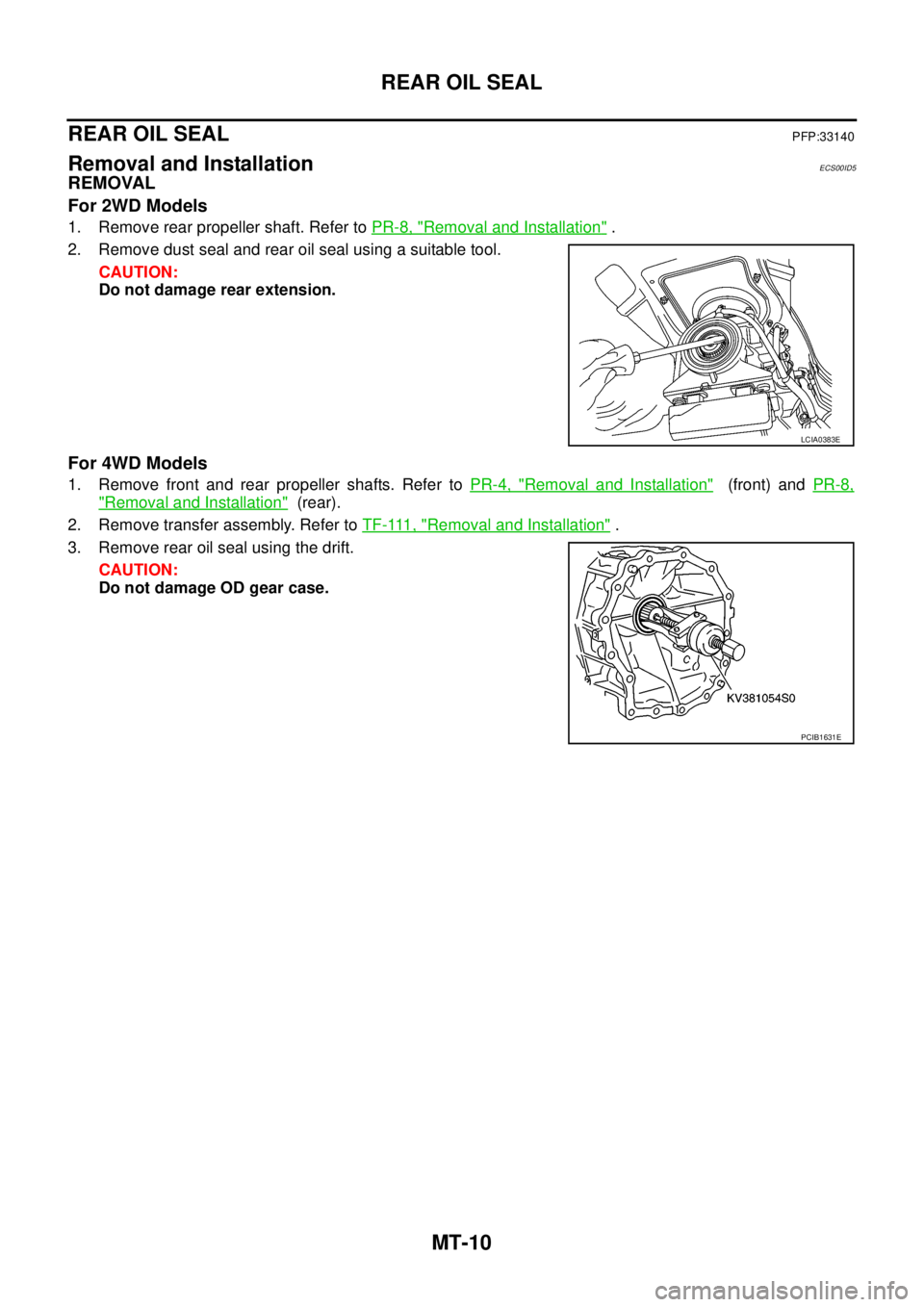

For 2WD Models

1. Remove rear propeller shaft. Refer toPR-8, "Removal and Installation".

2. Remove dust seal and rear oil seal using a suitable tool.

CAUTION:

Do not damage rear extension.

For 4WD Models

1. Remove front and rear propeller shafts. Refer toPR-4, "Removal and Installation"(front) andPR-8,

"Removal and Installation"(rear).

2. Remove transfer assembly. Refer toTF-111, "

Removal and Installation".

3. Remove rear oil seal using the drift.

CAUTION:

Do not damage OD gear case.

LCIA0383E

PCIB1631E

Page 2328 of 3171

REAR OIL SEAL

MT-11

D

E

F

G

H

I

J

K

L

MA

B

MT

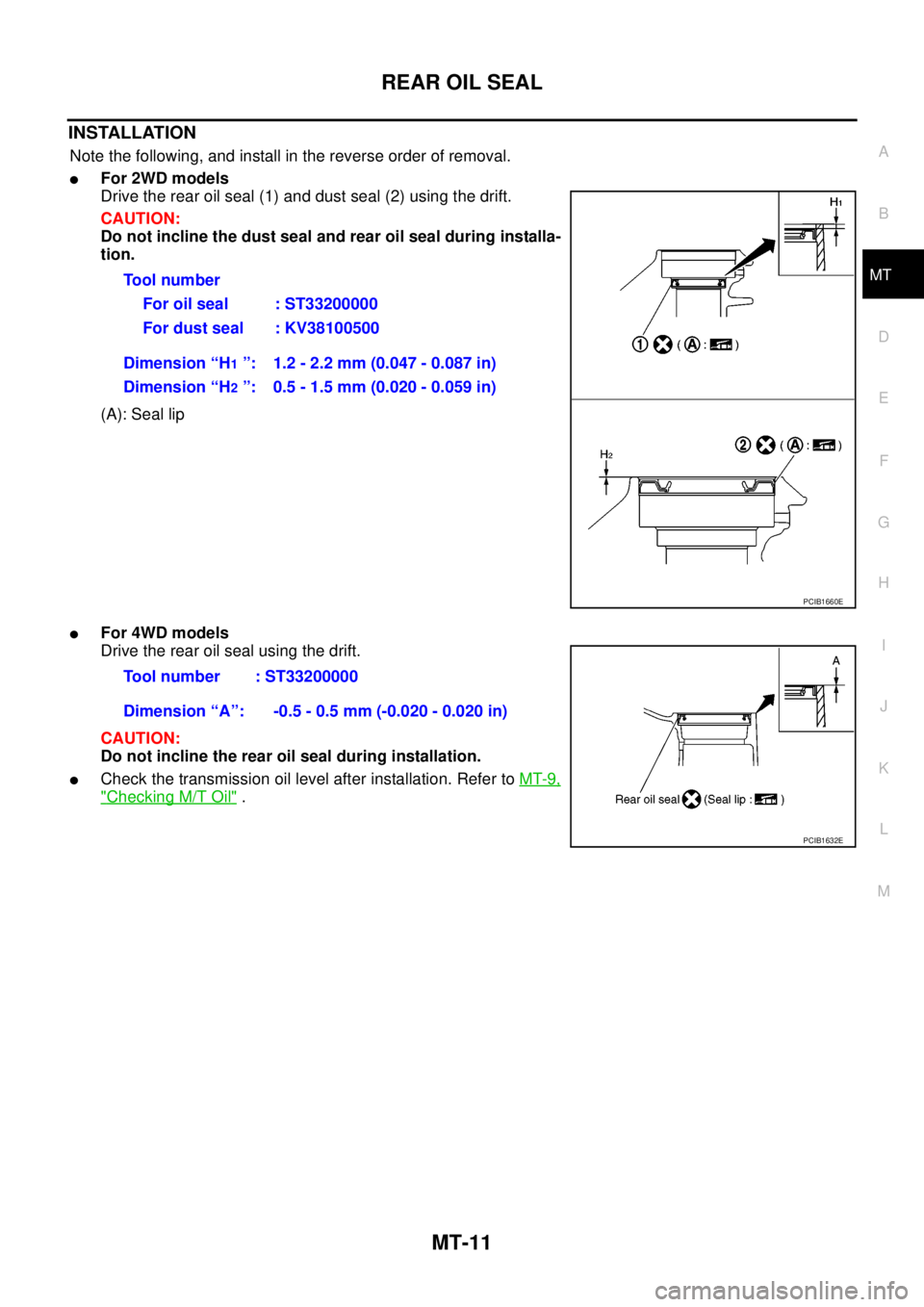

INSTALLATION

Note the following, and install in the reverse order of removal.

lFor 2WD models

Drive the rear oil seal (1) and dust seal (2) using the drift.

CAUTION:

Do not incline the dust seal and rear oil seal during installa-

tion.

(A): Seal lip

lFor 4WD models

Drive the rear oil seal using the drift.

CAUTION:

Do not incline the rear oil seal during installation.

lCheck the transmission oil level after installation. Refer toMT-9,

"Checking M/T Oil". Tool number

For oil seal : ST33200000

For dust seal : KV38100500

Dimension “H

1”: 1.2 - 2.2 mm (0.047 - 0.087 in)

Dimension “H

2”: 0.5 - 1.5 mm (0.020 - 0.059 in)

PCIB1660E

Tool number : ST33200000

Dimension “A”: -0.5 - 0.5 mm (-0.020 - 0.020 in)

PCIB1632E

Page 2334 of 3171

TRANSMISSION ASSEMBLY

MT-17

D

E

F

G

H

I

J

K

L

MA

B

MT

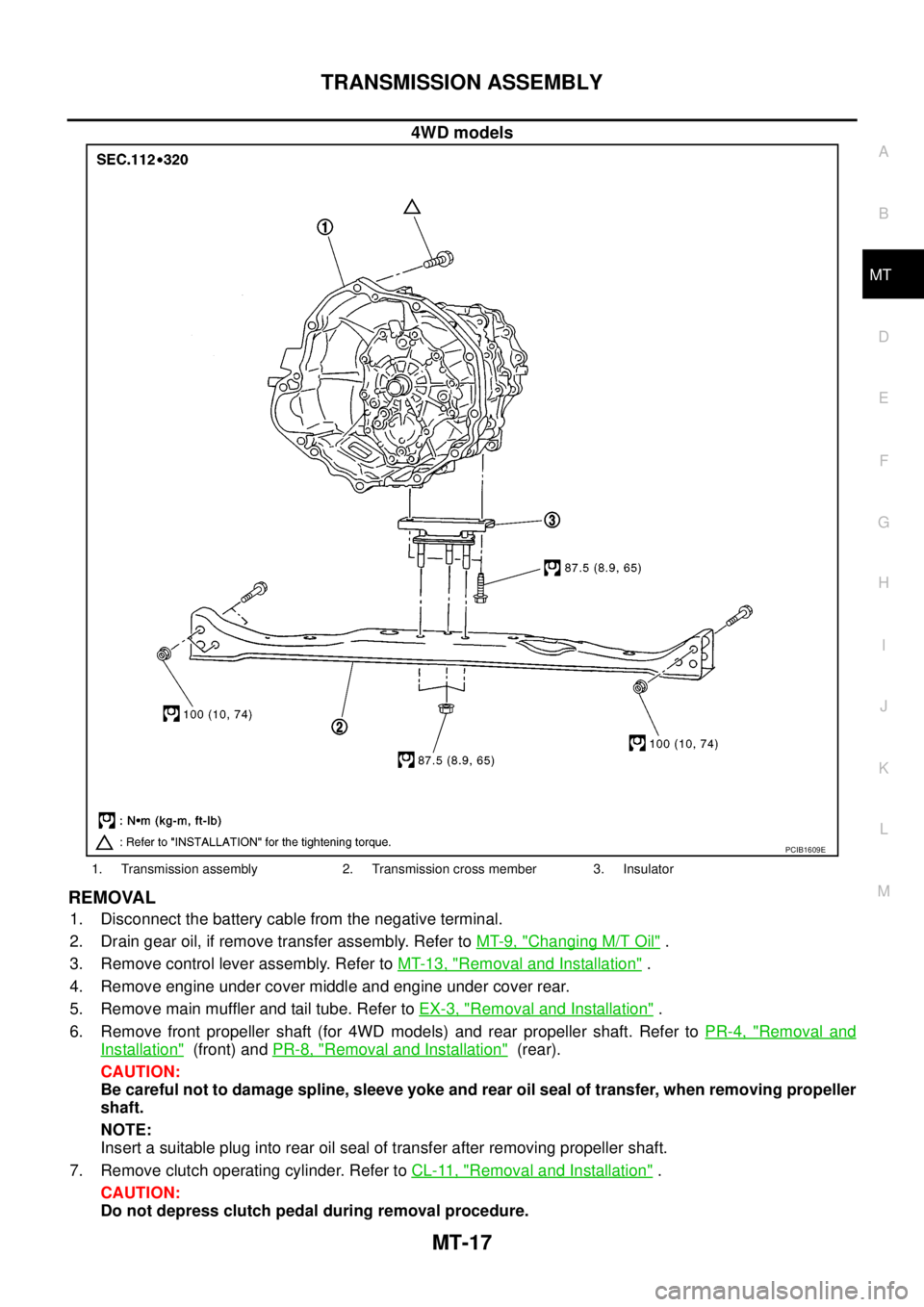

4WD models

REMOVAL

1. Disconnect the battery cable from the negative terminal.

2. Drain gear oil, if remove transfer assembly. Refer toMT-9, "

Changing M/T Oil".

3. Remove control lever assembly. Refer toMT-13, "

Removal and Installation".

4. Remove engine under cover middle and engine under cover rear.

5. Remove main muffler and tail tube. Refer toEX-3, "

Removal and Installation".

6. Remove front propeller shaft (for 4WD models) and rear propeller shaft. Refer toPR-4, "

Removal and

Installation"(front) andPR-8, "Removal and Installation"(rear).

CAUTION:

Be careful not to damage spline, sleeve yoke and rear oil seal of transfer, when removing propeller

shaft.

NOTE:

Insert a suitable plug into rear oil seal of transfer after removing propeller shaft.

7. Remove clutch operating cylinder. Refer toCL-11, "

Removal and Installation".

CAUTION:

Do not depress clutch pedal during removal procedure.

PCIB1609E

1. Transmission assembly 2. Transmission cross member 3. Insulator

Page 2335 of 3171

MT-18

TRANSMISSION ASSEMBLY

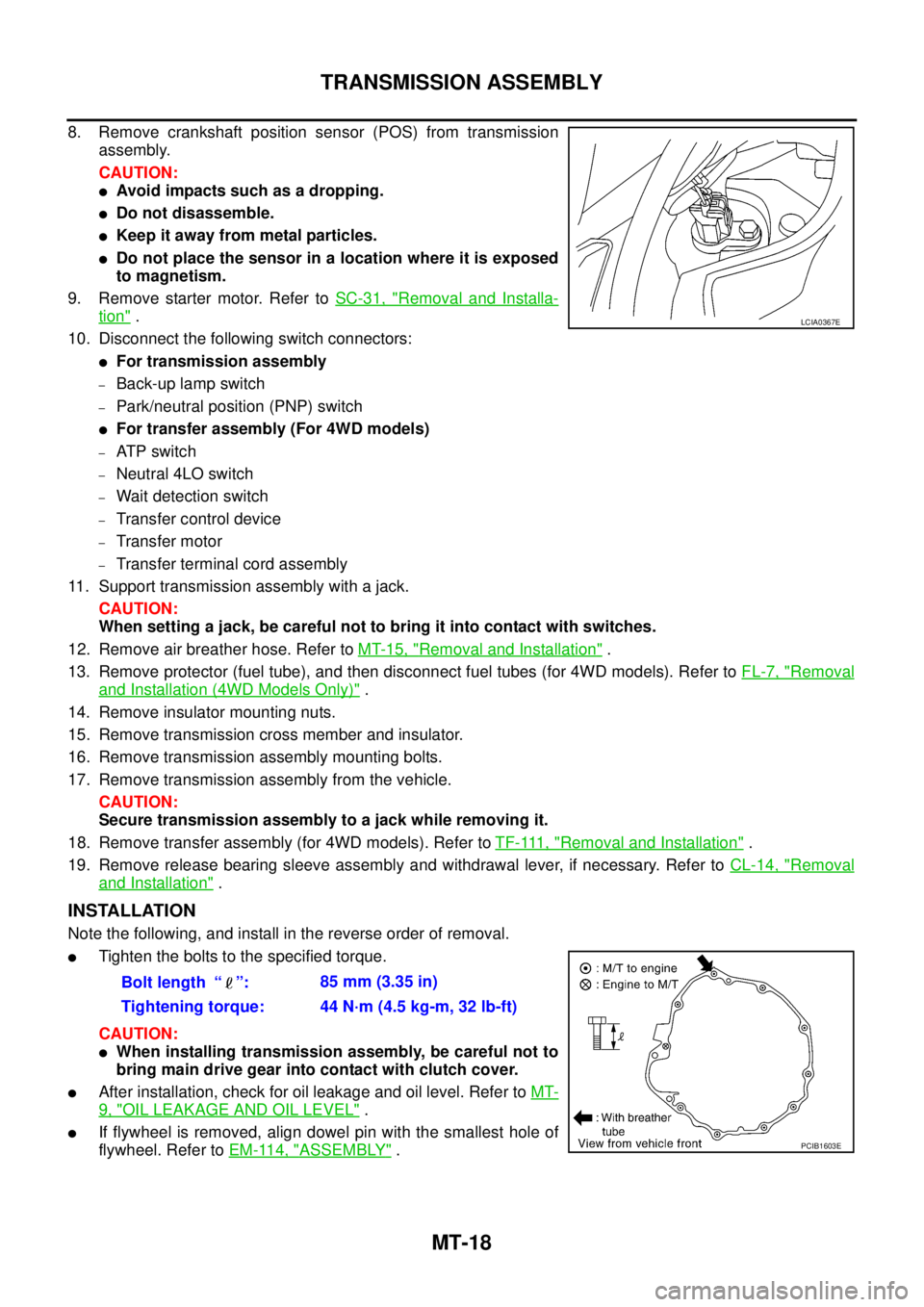

8. Remove crankshaft position sensor (POS) from transmission

assembly.

CAUTION:

lAvoid impacts such as a dropping.

lDo not disassemble.

lKeep it away from metal particles.

lDo not place the sensor in a location where it is exposed

to magnetism.

9. Remove starter motor. Refer toSC-31, "

Removal and Installa-

tion".

10. Disconnect the following switch connectors:

lFor transmission assembly

–Back-up lamp switch

–Park/neutral position (PNP) switch

lFor transfer assembly (For 4WD models)

–AT P s w i t c h

–Neutral 4LO switch

–Wait detection switch

–Transfer control device

–Transfer motor

–Transfer terminal cord assembly

11. Support transmission assembly with a jack.

CAUTION:

When setting a jack, be careful not to bring it into contact with switches.

12. Remove air breather hose. Refer toMT-15, "

Removal and Installation".

13. Remove protector (fuel tube), and then disconnect fuel tubes (for 4WD models). Refer toFL-7, "

Removal

and Installation (4WD Models Only)".

14. Remove insulator mounting nuts.

15. Remove transmission cross member and insulator.

16. Remove transmission assembly mounting bolts.

17. Remove transmission assembly from the vehicle.

CAUTION:

Secure transmission assembly to a jack while removing it.

18. Remove transfer assembly (for 4WD models). Refer toTF-111, "

Removal and Installation".

19. Remove release bearing sleeve assembly and withdrawal lever, if necessary. Refer toCL-14, "

Removal

and Installation".

INSTALLATION

Note the following, and install in the reverse order of removal.

lTighten the bolts to the specified torque.

CAUTION:

lWhen installing transmission assembly, be careful not to

bring main drive gear into contact with clutch cover.

lAfter installation, check for oil leakage and oil level. Refer toMT-

9, "OIL LEAKAGE AND OIL LEVEL".

lIf flywheel is removed, align dowel pin with the smallest hole of

flywheel. Refer toEM-114, "

ASSEMBLY".

LCIA0367E

Bolt length “ ”:85 mm (3.35 in)

Tightening torque: 44 N·m (4.5 kg-m, 32 lb-ft)

PCIB1603E

Page 2337 of 3171

MT-20

TRANSMISSION ASSEMBLY

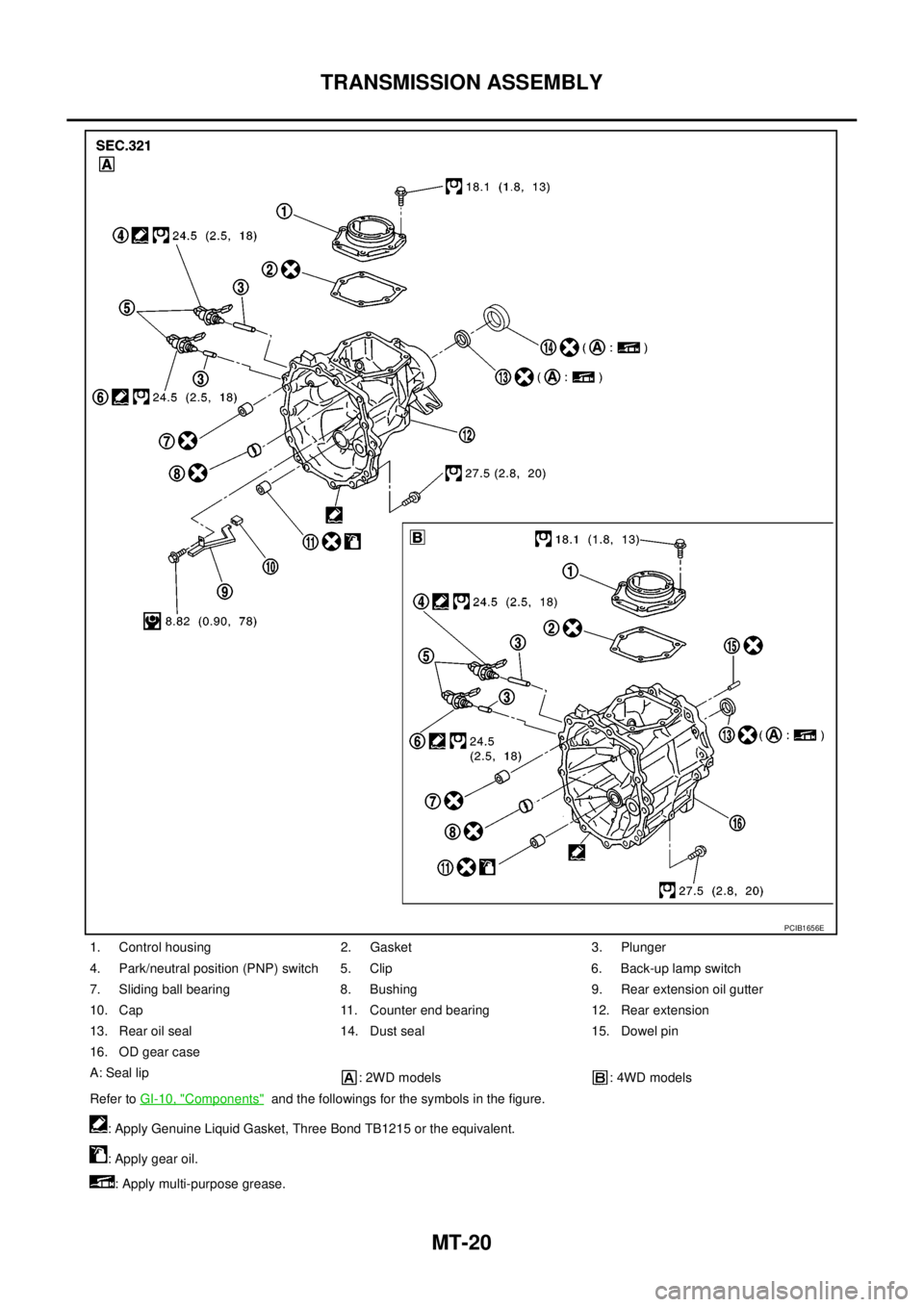

1. Control housing 2. Gasket 3. Plunger

4. Park/neutral position (PNP) switch 5. Clip 6. Back-up lamp switch

7. Sliding ball bearing 8. Bushing 9. Rear extension oil gutter

10. Cap 11. Counter end bearing 12. Rear extension

13. Rear oil seal 14. Dust seal 15. Dowel pin

16. OD gear case

A: Seal lip

: 2WD models : 4WD models

Refer toGI-10, "

Components"and the followings for the symbols in the figure.

: Apply Genuine Liquid Gasket, Three Bond TB1215 or the equivalent.

: Apply gear oil.

: Apply multi-purpose grease.

PCIB1656E