4WD NISSAN NAVARA 2005 Repair Owners Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2341 of 3171

MT-24

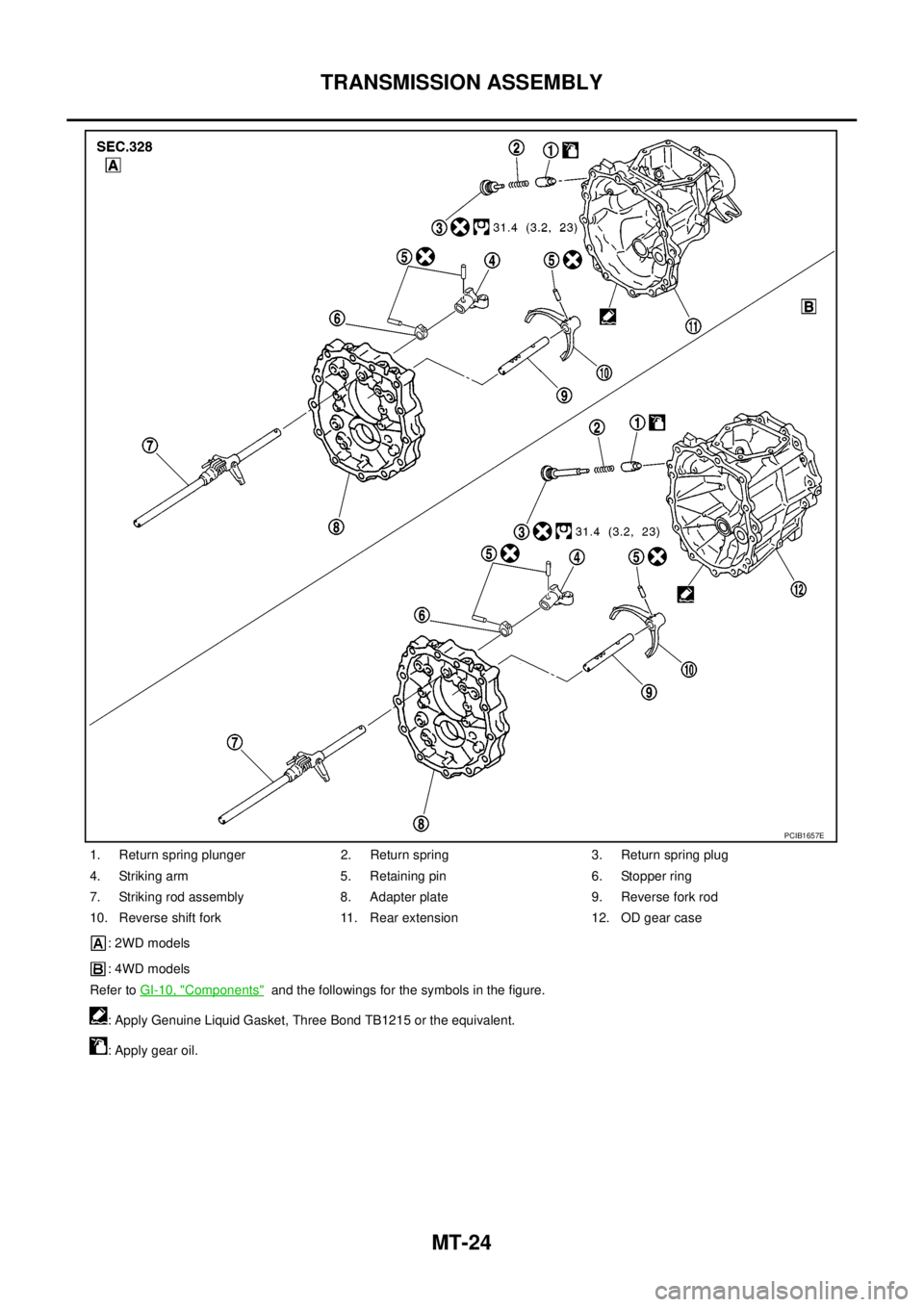

TRANSMISSION ASSEMBLY

1. Return spring plunger 2. Return spring 3. Return spring plug

4. Striking arm 5. Retaining pin 6. Stopper ring

7. Striking rod assembly 8. Adapter plate 9. Reverse fork rod

10. Reverse shift fork 11. Rear extension 12. OD gear case

: 2WD models

: 4WD models

Refer toGI-10, "

Components"and the followings for the symbols in the figure.

: Apply Genuine Liquid Gasket, Three Bond TB1215 or the equivalent.

: Apply gear oil.

PCIB1657E

Page 2343 of 3171

MT-26

TRANSMISSION ASSEMBLY

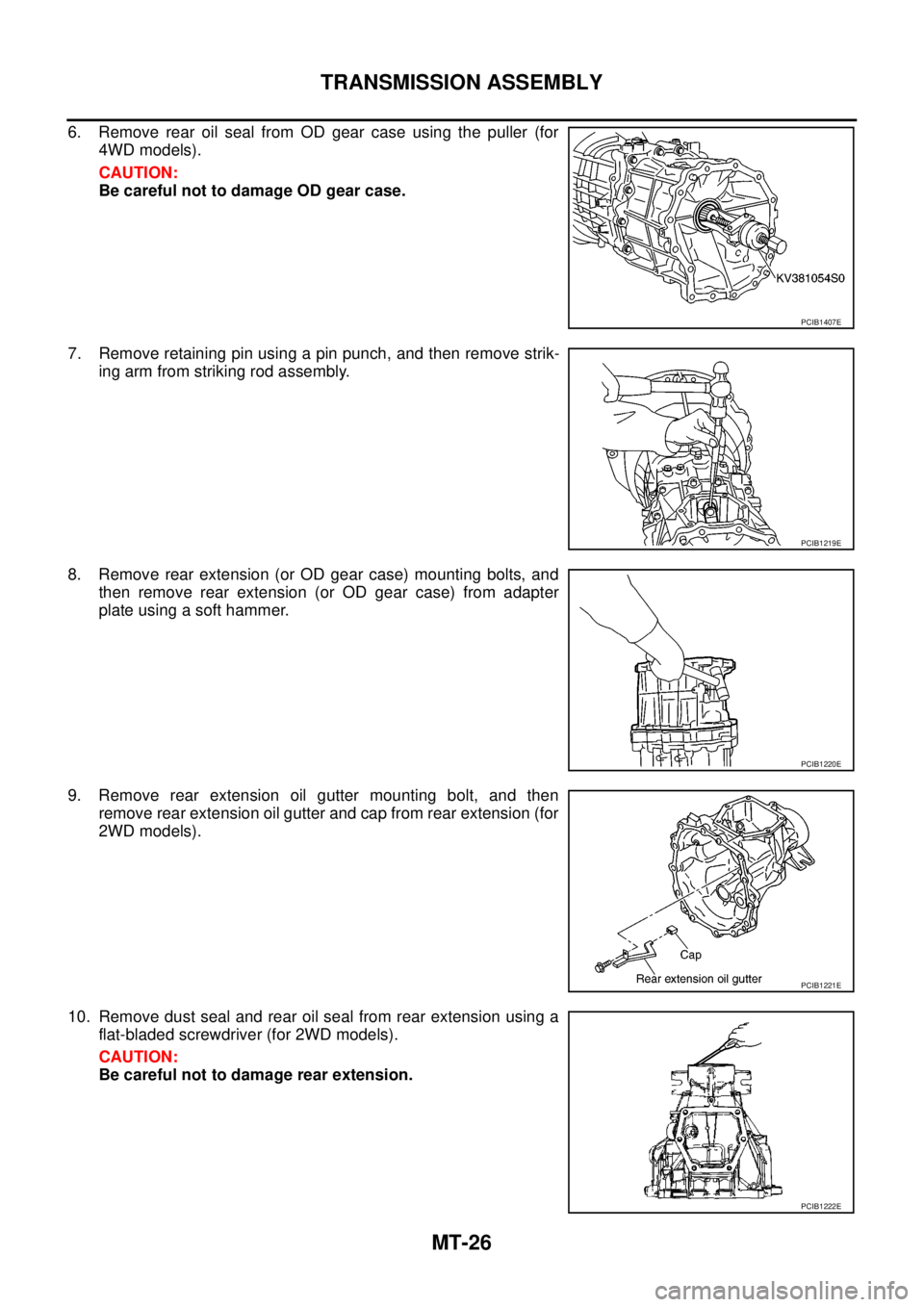

6. Remove rear oil seal from OD gear case using the puller (for

4WD models).

CAUTION:

Be careful not to damage OD gear case.

7. Remove retaining pin using a pin punch, and then remove strik-

ing arm from striking rod assembly.

8. Remove rear extension (or OD gear case) mounting bolts, and

then remove rear extension (or OD gear case) from adapter

plate using a soft hammer.

9. Remove rear extension oil gutter mounting bolt, and then

remove rear extension oil gutter and cap from rear extension (for

2WD models).

10. Remove dust seal and rear oil seal from rear extension using a

flat-bladed screwdriver (for 2WD models).

CAUTION:

Be careful not to damage rear extension.

PCIB1407E

PCIB1219E

PCIB1220E

PCIB1221E

PCIB1222E

Page 2380 of 3171

TRANSMISSION ASSEMBLY

MT-63

D

E

F

G

H

I

J

K

L

MA

B

MT

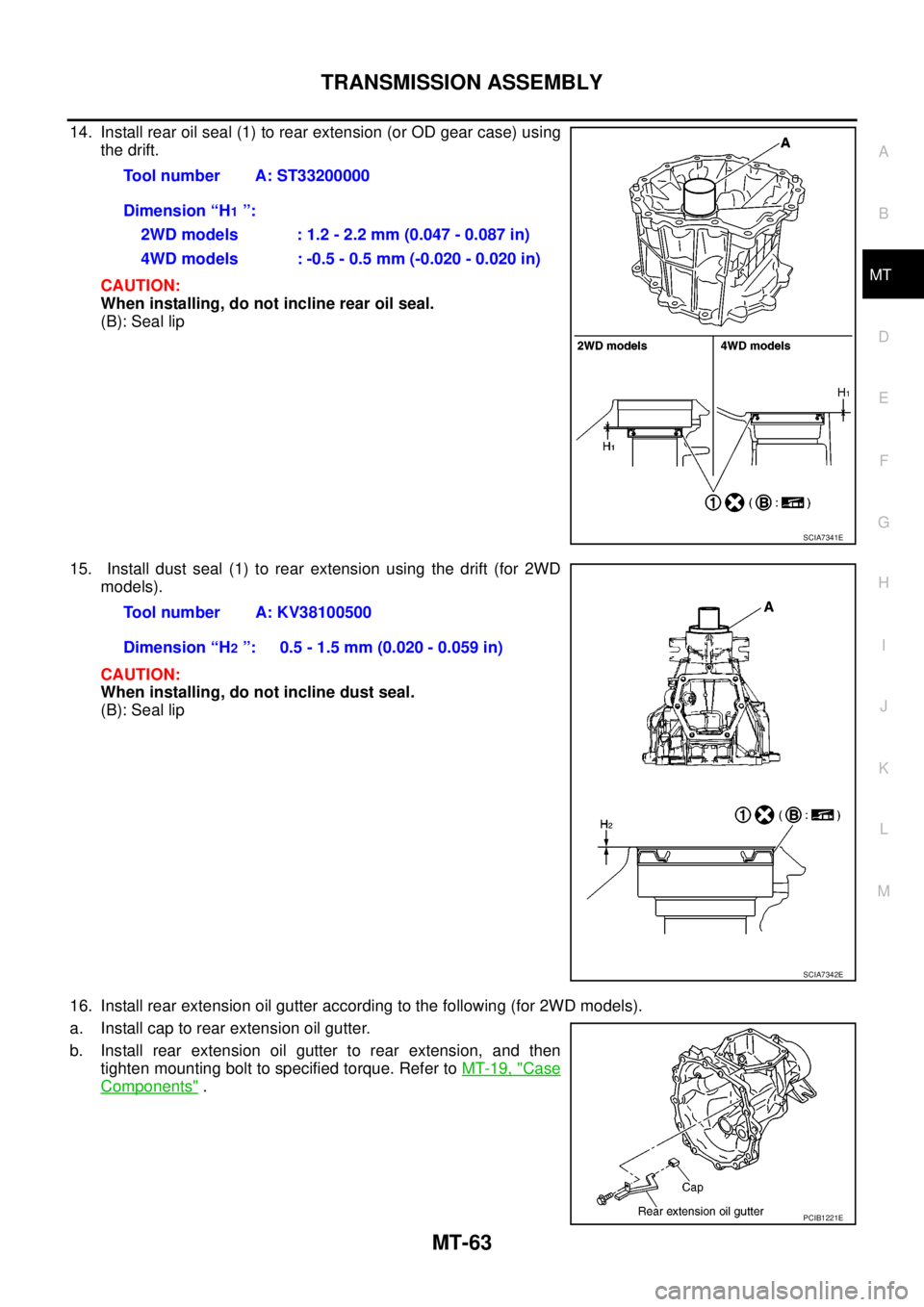

14. Install rear oil seal (1) to rear extension (or OD gear case) using

the drift.

CAUTION:

When installing, do not incline rear oil seal.

(B): Seal lip

15. Install dust seal (1) to rear extension using the drift (for 2WD

models).

CAUTION:

When installing, do not incline dust seal.

(B): Seal lip

16. Install rear extension oil gutter according to the following (for 2WD models).

a. Install cap to rear extension oil gutter.

b. Install rear extension oil gutter to rear extension, and then

tighten mounting bolt to specified torque. Refer toMT-19, "

Case

Components". Tool number A: ST33200000

Dimension “H

1”:

2WD models : 1.2 - 2.2 mm (0.047 - 0.087 in)

4WD models : -0.5 - 0.5 mm (-0.020 - 0.020 in)

SCIA7341E

Tool number A: KV38100500

Dimension “H

2”: 0.5 - 1.5 mm (0.020 - 0.059 in)

SCIA7342E

PCIB1221E

Page 2384 of 3171

SERVICE DATA AND SPECIFICATIONS (SDS)

MT-67

D

E

F

G

H

I

J

K

L

MA

B

MT

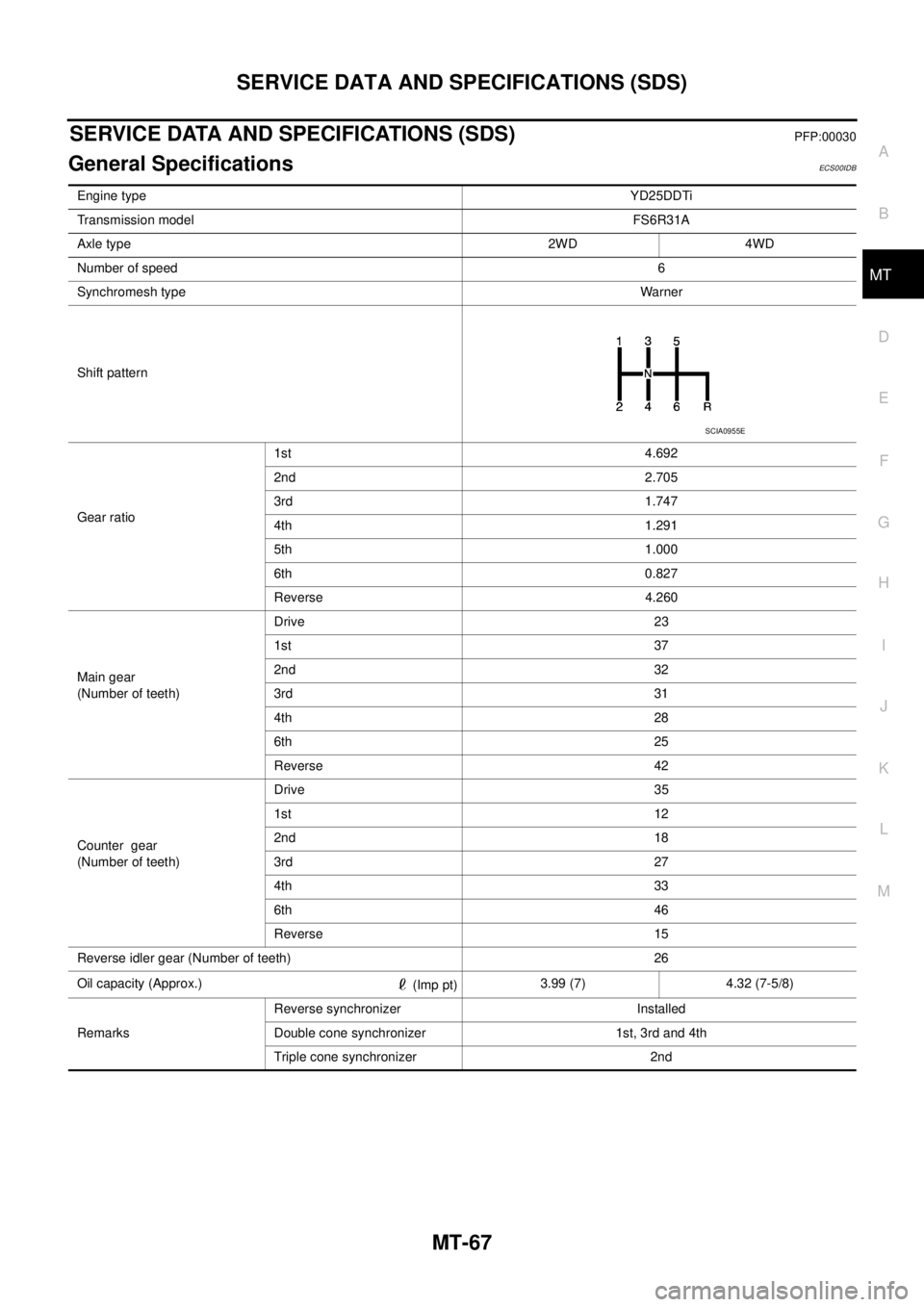

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

General SpecificationsECS00IDB

Engine typeYD25DDTi

Transmission modelFS6R31A

Axle type 2WD 4WD

Number of speed6

Synchromesh typeWarner

Shift pattern

Gear ratio1st 4.692

2nd 2.705

3rd 1.747

4th 1.291

5th 1.000

6th 0.827

Reverse 4.260

Main gear

(Number of teeth)Drive 23

1st 37

2nd 32

3rd 31

4th 28

6th 25

Reverse 42

Counter gear

(Number of teeth)Drive 35

1st 12

2nd 18

3rd 27

4th 33

6th 46

Reverse 15

Reverse idler gear (Number of teeth) 26

Oil capacity (Approx.)

(Imp pt)3.99 (7) 4.32 (7-5/8)

RemarksReverse synchronizer Installed

Double cone synchronizer 1st, 3rd and 4th

Triple cone synchronizer 2nd

SCIA0955E

Page 2616 of 3171

PR-1

PROPELLER SHAFT

D DRIVELINE/AXLE

CONTENTS

C

E

F

G

H

I

J

K

L

M

SECTIONPR

A

B

PR

PROPELLER SHAFT

NOISE, VIBRATION, AND HARSHNESS (NVH)

TROUBLESHOOTING ................................................ 2

NVH Troubleshooting Chart ..................................... 2

FRONT PROPELLER SHAFT .................................... 3

On-Vehicle Service ................................................... 3

APPEARANCE AND NOISE INSPECTION .......... 3

PROPELLER SHAFT VIBRATION ........................ 3

Removal and Installation .......................................... 4

COMPONENTS .................................................... 4

REMOVAL ............................................................. 4

INSPECTION ........................................................ 4

INSTALLATION ..................................................... 5

Disassembly and Assembly ..................................... 5

DISASSEMBLY ..................................................... 5

ASSEMBLY ........................................................... 6

REAR PROPELLER SHAFT ...................................... 7On-Vehicle Service ................................................... 7

APPEARANCE AND NOISE INSPECTION .......... 7

PROPELLER SHAFT VIBRATION ........................ 7

Removal and Installation .......................................... 8

COMPONENTS (2WD) ......................................... 8

COMPONENTS (4WD) ......................................... 8

REMOVAL ............................................................. 9

INSPECTION ........................................................ 9

INSTALLATION ................................................... 10

Disassembly and Assembly .................................... 10

DISASSEMBLY ................................................... 10

ASSEMBLY ......................................................... 11

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 12

General Specifications ............................................ 12

Snap Ring ............................................................... 12

Page 2622 of 3171

REAR PROPELLER SHAFT

PR-7

C

E

F

G

H

I

J

K

L

MA

B

PR

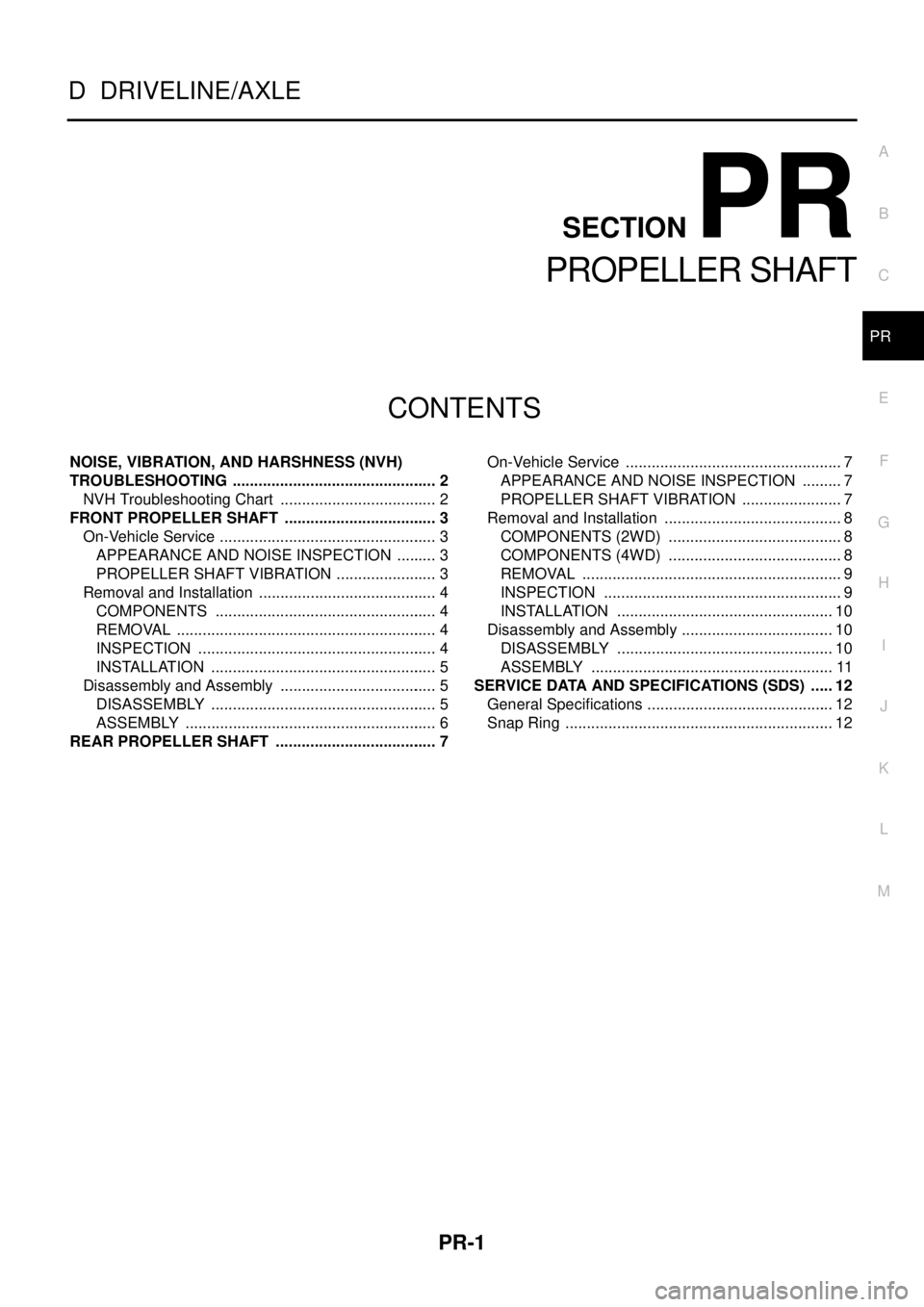

REAR PROPELLER SHAFTPFP:37000

On-Vehicle ServiceEDS002WR

APPEARANCE AND NOISE INSPECTION

lCheck the propeller shaft tube surface for dents or cracks. If damaged, replace the propeller shaft assem-

bly.

lCheck the bearings for noise and damage. Repair or replace the bearings as necessary.

PROPELLER SHAFT VIBRATION

If a vibration is present at high speed, inspect the propeller shaft runout first.

1. Measure the runout of the propeller shaft tube at several points

by rotating the final drive companion flange with your hands.

For measuring point, refer toPR-7, "

Propeller Shaft Runout

Measuring Point".

2. If the runout exceeds specifications, disconnect the propeller

shaft at the final drive companion flange; then rotate the com-

panion flange 90°,180°and 270°and reconnect the propeller

shaft.

3. Check the runout again. If the runout still exceeds specifications, replace the propeller shaft assembly.

4. After installation, check for vibration by driving vehicle.

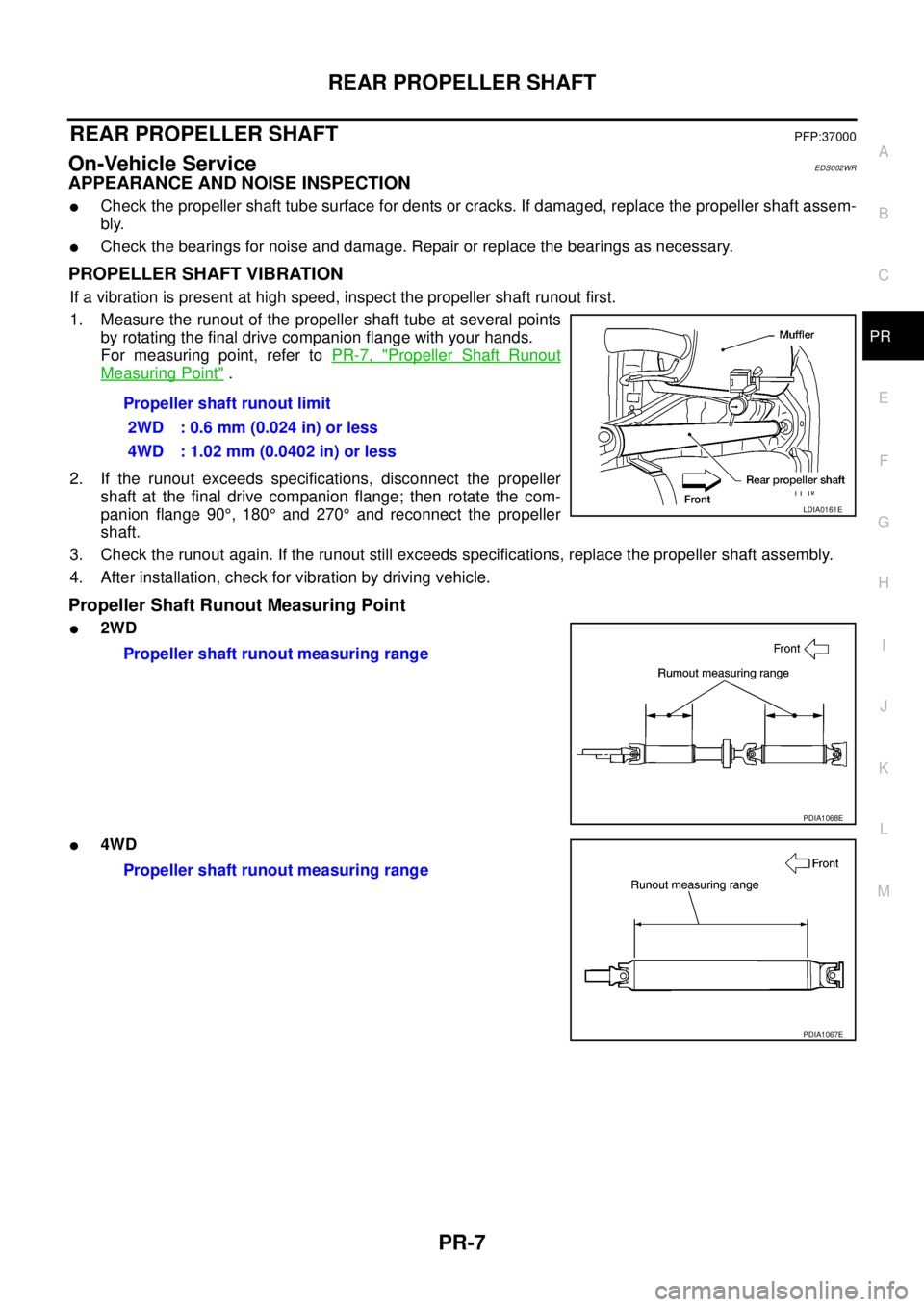

Propeller Shaft Runout Measuring Point

l2WD

l4WDPropeller shaft runout limit

2WD : 0.6 mm (0.024 in) or less

4WD : 1.02 mm (0.0402 in) or less

LDIA0161E

Propeller shaft runout measuring range

PDIA1068E

Propeller shaft runout measuring range

PDIA1067E

Page 2623 of 3171

PR-8

REAR PROPELLER SHAFT

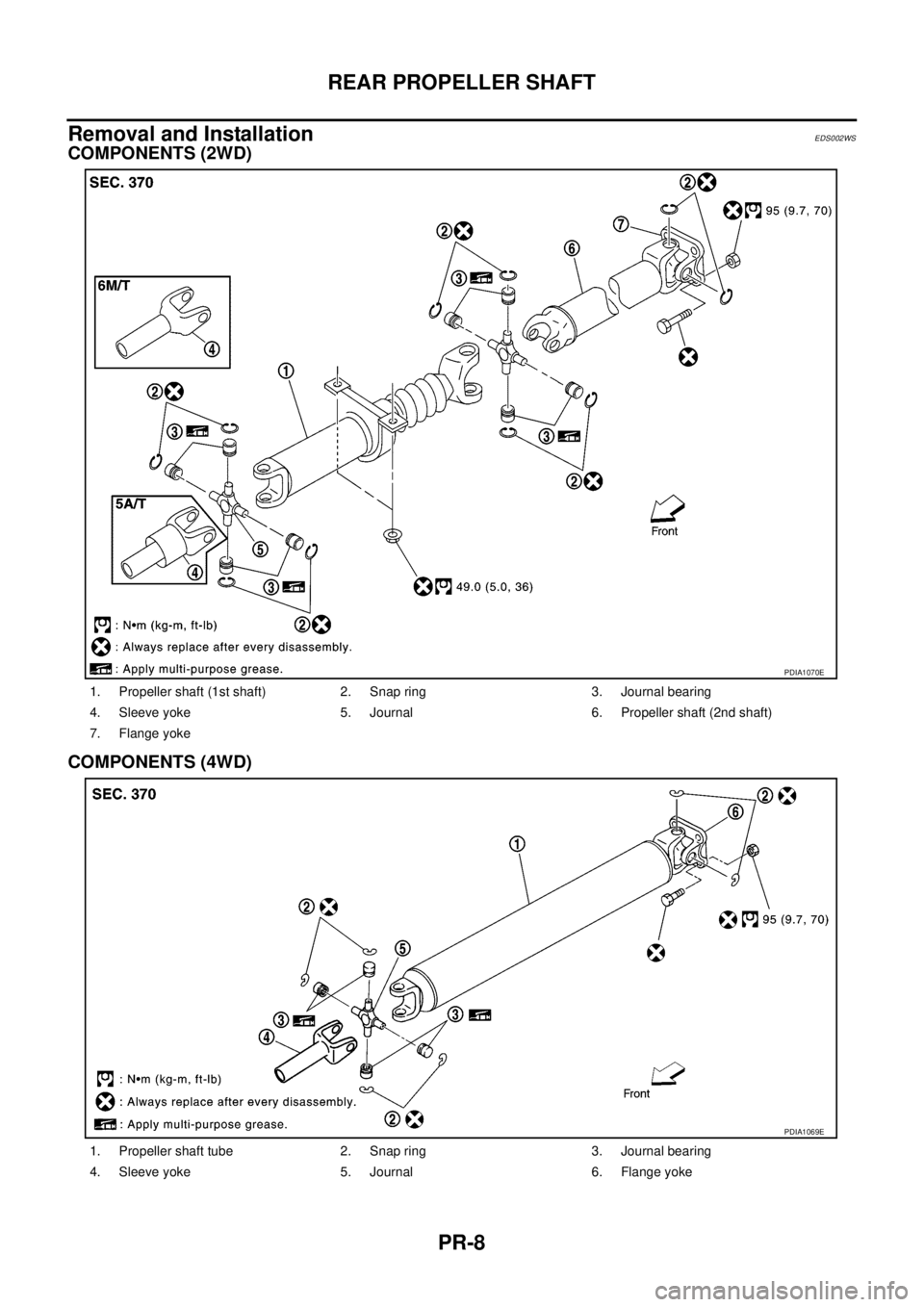

Removal and Installation

EDS002WS

COMPONENTS (2WD)

COMPONENTS (4WD)

1. Propeller shaft (1st shaft) 2. Snap ring 3. Journal bearing

4. Sleeve yoke 5. Journal 6. Propeller shaft (2nd shaft)

7. Flange yoke

PDIA1070E

1. Propeller shaft tube 2. Snap ring 3. Journal bearing

4. Sleeve yoke 5. Journal 6. Flange yoke

PDIA1069E

Page 2624 of 3171

REAR PROPELLER SHAFT

PR-9

C

E

F

G

H

I

J

K

L

MA

B

PR

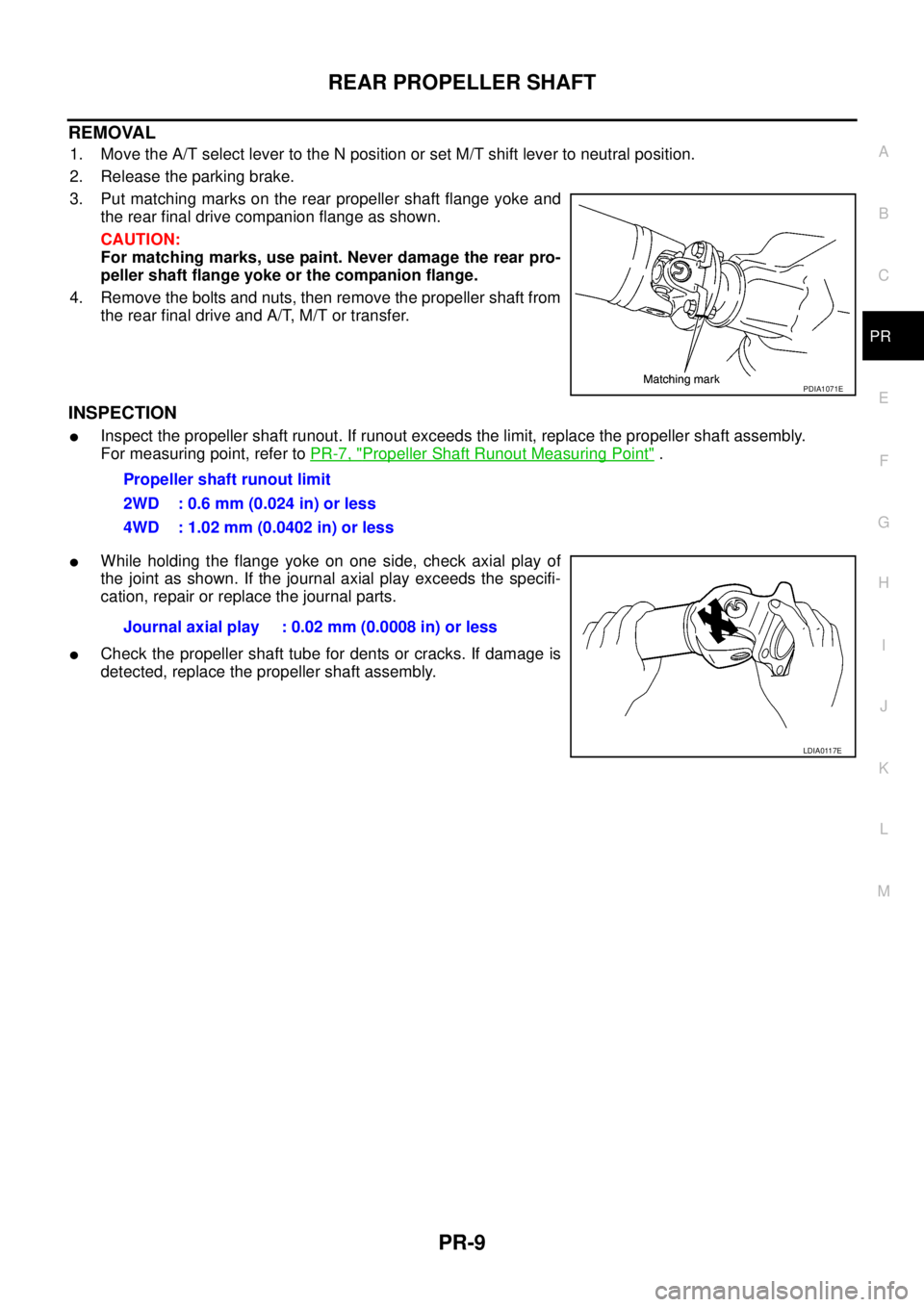

REMOVAL

1. Move the A/T select lever to the N position or set M/T shift lever to neutral position.

2. Release the parking brake.

3. Put matching marks on the rear propeller shaft flange yoke and

the rear final drive companion flange as shown.

CAUTION:

For matching marks, use paint. Never damage the rear pro-

peller shaft flange yoke or the companion flange.

4. Remove the bolts and nuts, then remove the propeller shaft from

the rear final drive and A/T, M/T or transfer.

INSPECTION

lInspect the propeller shaft runout. If runout exceeds the limit, replace the propeller shaft assembly.

For measuring point, refer toPR-7, "

Propeller Shaft Runout Measuring Point".

lWhile holding the flange yoke on one side, check axial play of

the joint as shown. If the journal axial play exceeds the specifi-

cation, repair or replace the journal parts.

lCheck the propeller shaft tube for dents or cracks. If damage is

detected, replace the propeller shaft assembly.

PDIA1071E

Propeller shaft runout limit

2WD : 0.6 mm (0.024 in) or less

4WD : 1.02 mm (0.0402 in) or less

Journal axial play : 0.02 mm (0.0008 in) or less

LDIA0117E

Page 2625 of 3171

PR-10

REAR PROPELLER SHAFT

INSTALLATION

Installation is in the reverse order of removal.

lAfter installation, check for vibration by driving the vehicle. Refer toPR-2, "NVH Troubleshooting Chart".

CAUTION:

Do not reuse the bolts and nuts. Always install new ones.

Disassembly and AssemblyEDS002WT

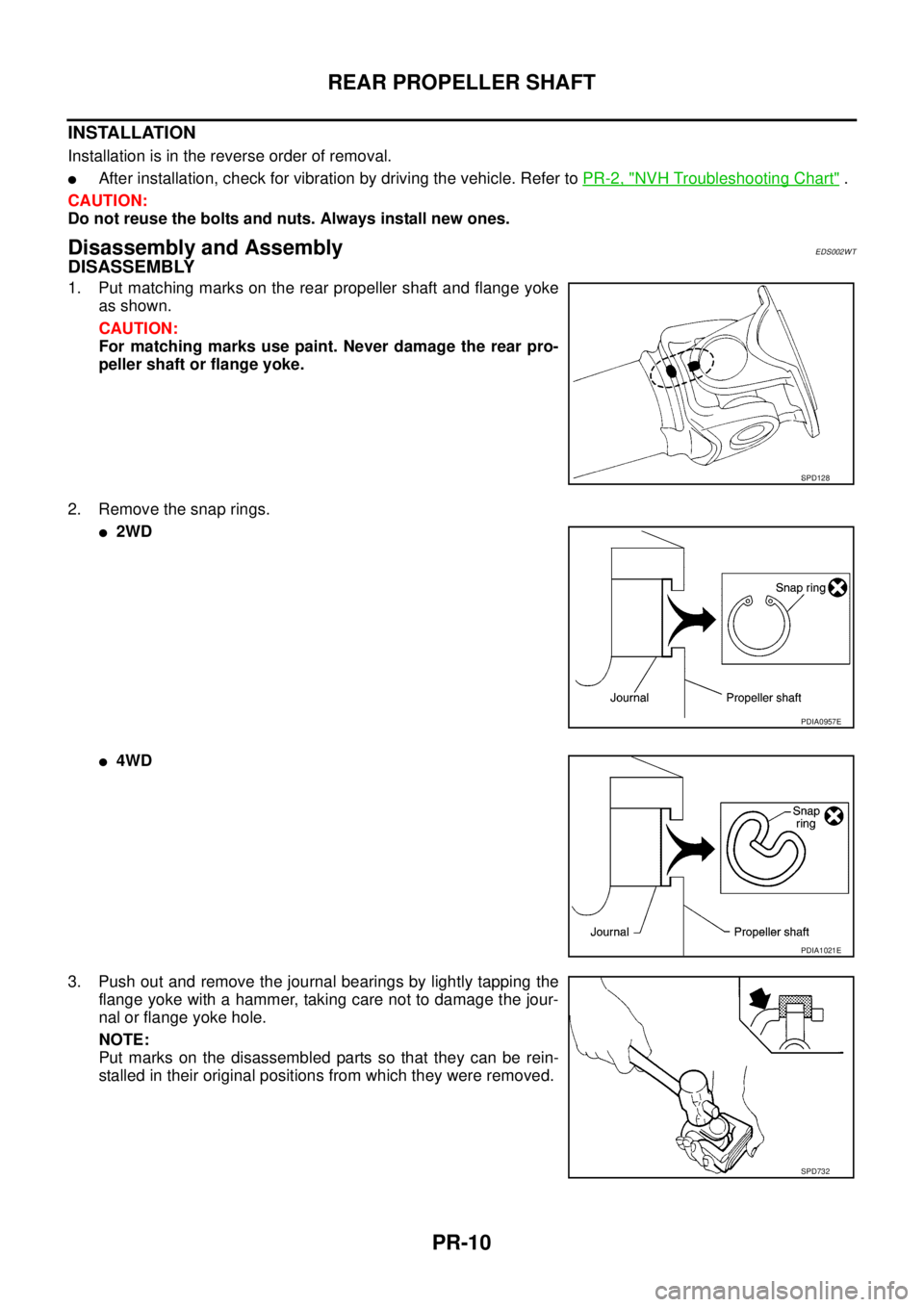

DISASSEMBLY

1. Put matching marks on the rear propeller shaft and flange yoke

as shown.

CAUTION:

For matching marks use paint. Never damage the rear pro-

peller shaft or flange yoke.

2. Remove the snap rings.

l2WD

l4WD

3. Push out and remove the journal bearings by lightly tapping the

flange yoke with a hammer, taking care not to damage the jour-

nal or flange yoke hole.

NOTE:

Put marks on the disassembled parts so that they can be rein-

stalled in their original positions from which they were removed.

SPD128

PDIA0957E

PDIA1021E

SPD732

Page 2626 of 3171

REAR PROPELLER SHAFT

PR-11

C

E

F

G

H

I

J

K

L

MA

B

PR

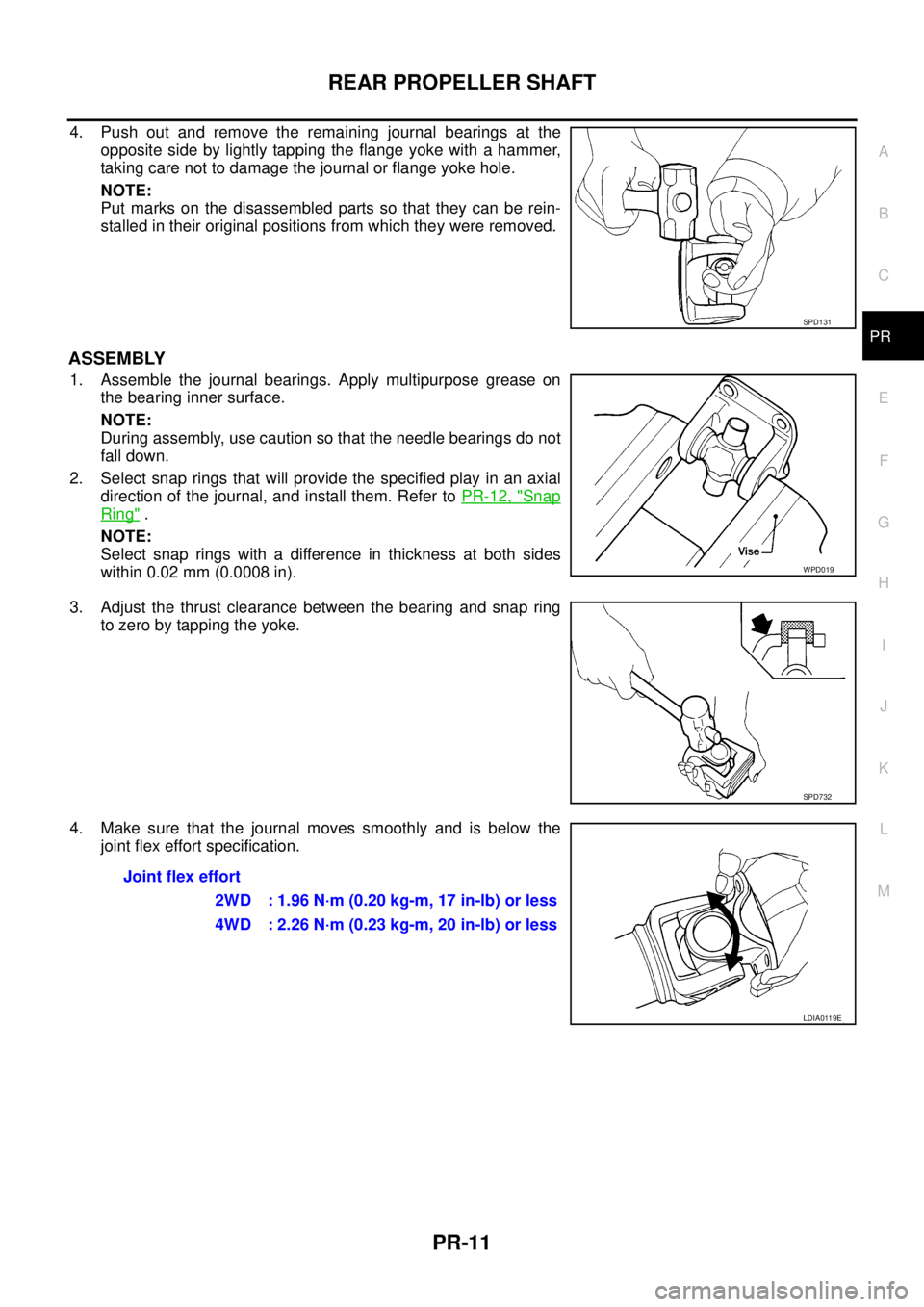

4. Push out and remove the remaining journal bearings at the

opposite side by lightly tapping the flange yoke with a hammer,

taking care not to damage the journal or flange yoke hole.

NOTE:

Put marks on the disassembled parts so that they can be rein-

stalled in their original positions from which they were removed.

ASSEMBLY

1. Assemble the journal bearings. Apply multipurpose grease on

the bearing inner surface.

NOTE:

During assembly, use caution so that the needle bearings do not

fall down.

2. Select snap rings that will provide the specified play in an axial

direction of the journal, and install them. Refer toPR-12, "

Snap

Ring".

NOTE:

Select snap rings with a difference in thickness at both sides

within 0.02 mm (0.0008 in).

3. Adjust the thrust clearance between the bearing and snap ring

to zero by tapping the yoke.

4. Make sure that the journal moves smoothly and is below the

joint flex effort specification.

SPD131

WPD019

SPD732

Joint flex effort

2WD : 1.96 N·m (0.20 kg-m, 17 in-lb) or less

4WD : 2.26 N·m (0.23 kg-m, 20 in-lb) or less

LDIA0119E