4WD NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2627 of 3171

PR-12

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

PFP:00030

General SpecificationsEDS0035N

2WD Models

4WD Models

Snap RingEDS0035O

Model 2S1330

Unit: mm (in)

*Always check with the Parts Department for the latest parts information.

Model 2F S1300 and 3S S1310

Unit: mm (in)

*Always check with the Parts Department for the latest parts information.Applied modelYD25DDTi

6M/T 5A/T

Propeller shaft model 3S S1310

Number of joints3

Coupling method with rear final drive Flange type

Coupling method with transmission Sleeve type

1st Shaft length (Center bearing to spider) 675 mm (26.57 in) 742 mm (29.21 in)

2nd Shaft length (Spider to spider) 897 mm (35.31 in)

Shaft outer diameter 75.64 mm (2.9779 in)

Journal axial play 0.02 mm (0.0008 in) or less

Propeller shaft run out limit 0.6 mm (0.024 in) or less

Propeller shaft joint flex effort 1.96 N·m (0.20 kg-m, 17 in-lb) or less

Applied modelYD25DDTi

Propeller shaft modelFront Rear

2F S1300 2S1330 (aluminum tube)

Number of joints2

Coupling method with front final drive Flange type

Coupling method with transfer Flange type Sleeve type

Shaft length (Spider to spider) 718 mm (28.27 in) 1266.8 mm (35.51 in)

Shaft outer diameter 65 mm (2.56 in) 102.5 mm (2.97 in)

Journal axial play 0.02 mm (0.0008 in) or less

Propeller shaft run out limit 0.6 mm (0.024 in) or less 1.02 mm (0.0402 in) or less

Propeller shaft joint flex effort 1.96 N·m (0.20 kg-m, 17 in-lb) or less 2.26 N·m (0.23 kg-m, 20 in-lb) or less

Thickness Part number* Thickness Part number*

1.600 - 1.638 (0.0630 - 0.0645)

1.549 - 1.588 (0.0610 - 0.0625)37146-7S000

37147-7S0001.524 - 1.562 (0.0600 - 0.0615)

1.499 - 1.537 (0.0590 - 0.0605)37148-7S000

37149-7S000

Thickness Part number* Thickness Part number*

1.45 (0.0571)

1.50 (0.0591)

1.55 (0.0610)

1.60 (0.0630)37146 7F000

37147 7F000

37148 7F000

37149 7F0001.65 (0.0650)

1.70 (0.0669)

1.75 (0.0689)37150 7F000

37151 7F000

37152 7F000

Page 2636 of 3171

STEERING WHEEL

PS-9

C

D

E

F

H

I

J

K

L

MA

B

PS

c. While pulling outer socket slowly in±11 . 5 m m (±0.453 in) range

from neutral position, make sure rack sliding force is within

specification.

d. If rack sliding force is not within specification, overhaul steering

gear assembly.

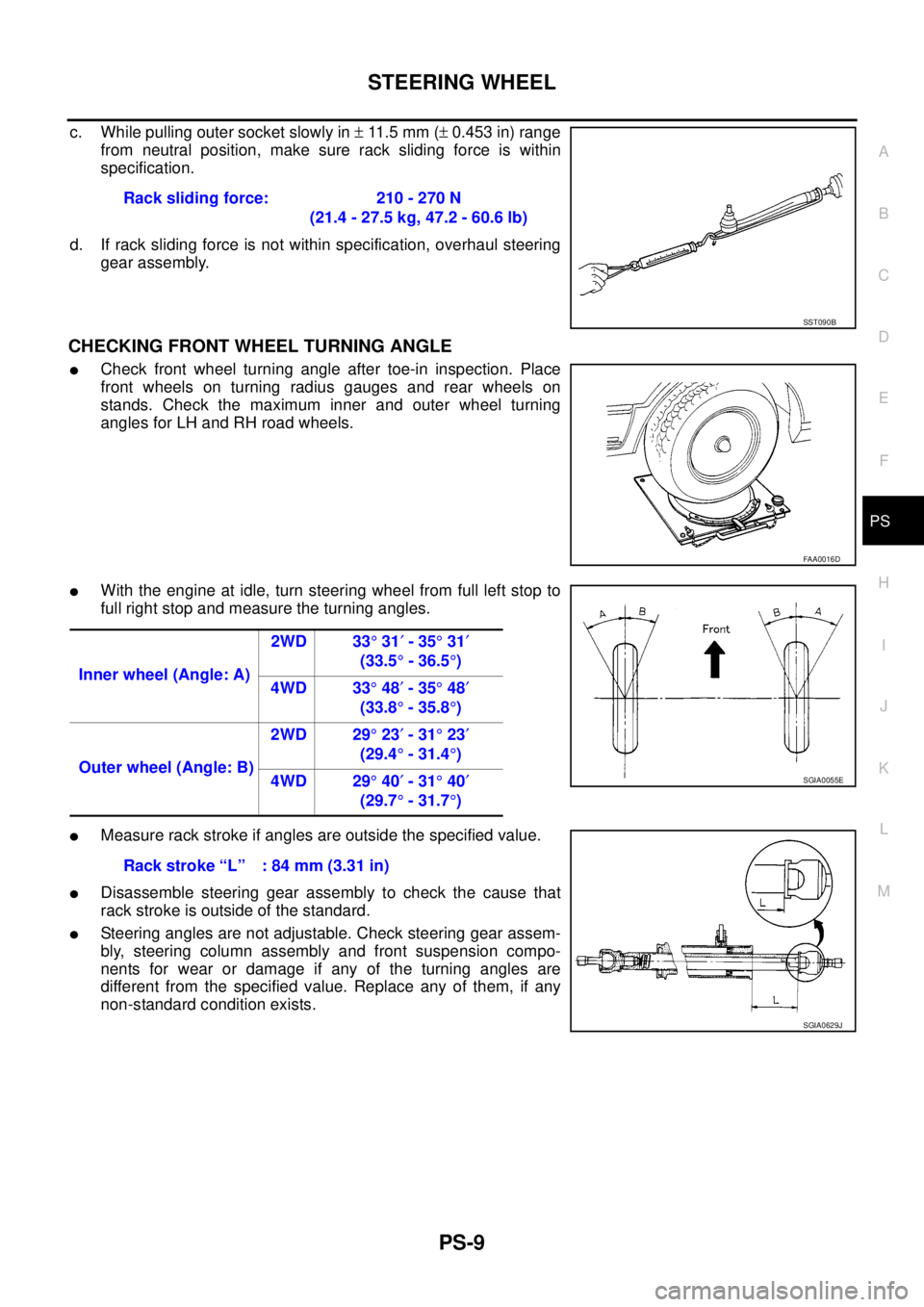

CHECKING FRONT WHEEL TURNING ANGLE

lCheck front wheel turning angle after toe-in inspection. Place

front wheels on turning radius gauges and rear wheels on

stands. Check the maximum inner and outer wheel turning

angles for LH and RH road wheels.

lWith the engine at idle, turn steering wheel from full left stop to

full right stop and measure the turning angles.

lMeasure rack stroke if angles are outside the specified value.

lDisassemble steering gear assembly to check the cause that

rack stroke is outside of the standard.

lSteering angles are not adjustable. Check steering gear assem-

bly, steering column assembly and front suspension compo-

nents for wear or damage if any of the turning angles are

different from the specified value. Replace any of them, if any

non-standard condition exists.Rack sliding force: 210 - 270 N

(21.4 - 27.5 kg, 47.2 - 60.6 lb)

SST090B

FAA0016D

Inner wheel (Angle: A)2WD 33°31¢-35°31¢

(33.5°-36.5°)

4WD 33°48¢-35°48¢

(33.8°-35.8°)

Outer wheel (Angle: B)2WD 29°23¢-31°23¢

(29.4°-31.4°)

4WD 29°40¢-31°40¢

(29.7°-31.7°)

SGIA0055E

Rack stroke “L” : 84 mm (3.31 in)

SGIA0629J

Page 2661 of 3171

PS-34

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

PFP:00030

Steering WheelEGS001LR

Steering AngleEGS001LS

Steering ColumnEGS001LT

Steering Outer Socket and Inner SocketEGS001LU

Steering wheel axial end play 0 mm (0 in)

Steering wheel play 0 - 35 mm (0 - 1.38 in)

Inner wheel

Degree minute (Decimal degree)2WD 33°31¢-35°31¢(33.5°- 36.5°)

4WD 33°48¢-35°48¢(33.8°- 35.8°)

Outer wheel

Degree minute (Decimal degree)2WD 29°23¢-31°23¢(29.4°- 31.4°)

4WD 29°40¢-31°40¢(29.7°- 31.7°)

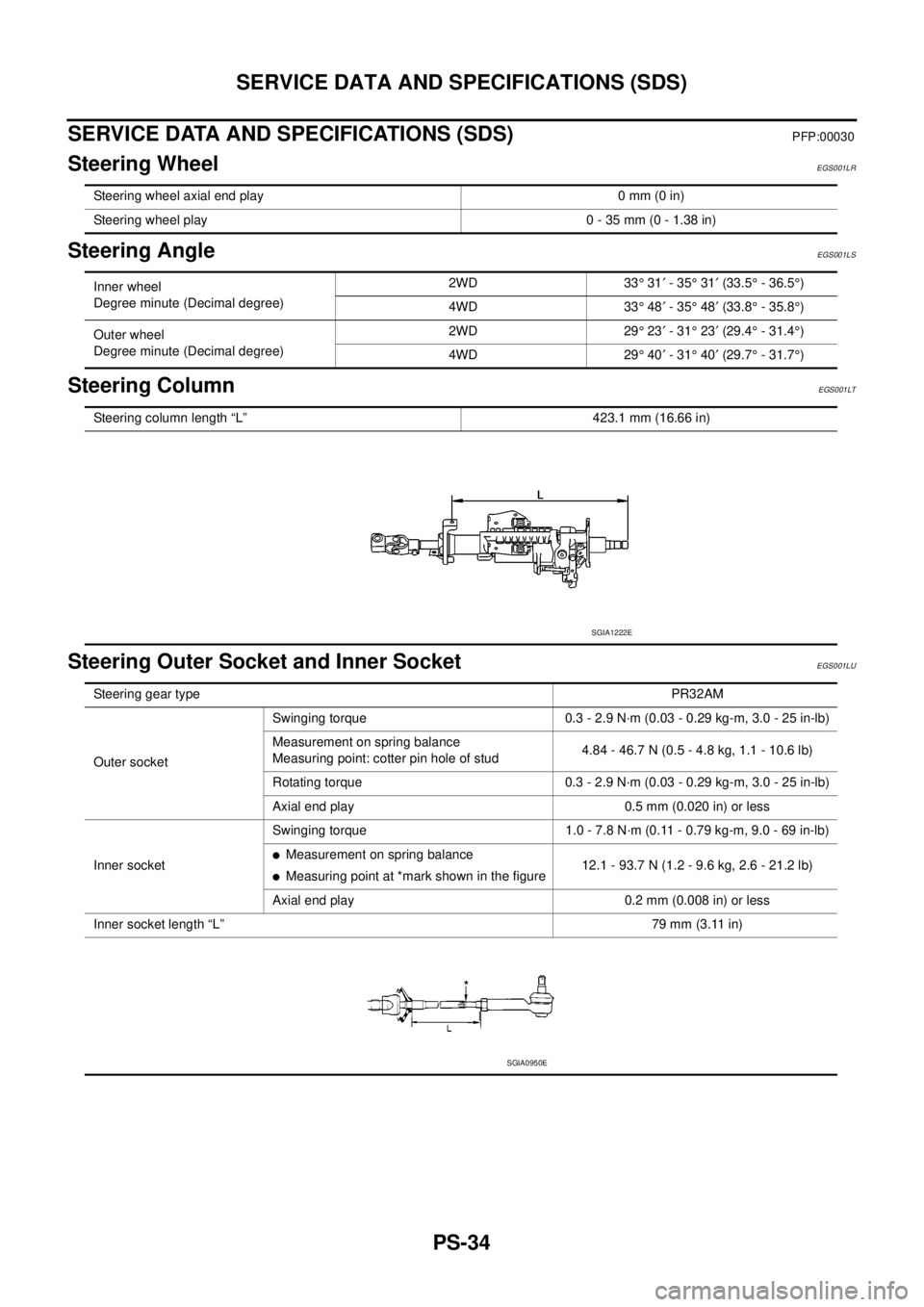

Steering column length “L” 423.1 mm (16.66 in)

SGIA1222E

Steering gear typePR32AM

Outer socketSwinging torque 0.3 - 2.9 N·m (0.03 - 0.29 kg-m, 3.0 - 25 in-lb)

Measurement on spring balance

Measuring point: cotter pin hole of stud4.84 - 46.7 N (0.5 - 4.8 kg, 1.1 - 10.6 lb)

Rotating torque 0.3 - 2.9 N·m (0.03 - 0.29 kg-m, 3.0 - 25 in-lb)

Axial end play 0.5 mm (0.020 in) or less

Inner socketSwinging torque 1.0 - 7.8 N·m (0.11 - 0.79 kg-m, 9.0 - 69 in-lb)

lMeasurement on spring balance

lMeasuring point at *mark shown in the figure12.1 - 93.7 N (1.2 - 9.6 kg, 2.6 - 21.2 lb)

Axial end play 0.2 mm (0.008 in) or less

Inner socket length “L”79 mm (3.11 in)

SGIA0950E

Page 2734 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual SERVICE DATA AND SPECIFICATIONS (SDS)

RFD-31

[WITH LIMITED SLIP DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

General SpecificationsEDS0039A

*: Option

Inspect NISSAN NAVARA 2005 Repair Workshop Manual SERVICE DATA AND SPECIFICATIONS (SDS)

RFD-31

[WITH LIMITED SLIP DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

General SpecificationsEDS0039A

*: Option

Inspect](/img/5/57362/w960_57362-2733.png)

SERVICE DATA AND SPECIFICATIONS (SDS)

RFD-31

[WITH LIMITED SLIP DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

General SpecificationsEDS0039A

*: Option

Inspection and AdjustmentEDS0039B

PRELOAD TORQUE

Unit: N·m (kg-m, in-lb)

BACKLASH

Unit: mm (in)

COMPANION FLANGE RUNOUT

Unit: mm (in) Applied modelYD25DDTi

2WD 4WD

6M/T 5A/T 6M/T 5A/T

Grade SE, XE SE SE, XE* XE SE

Final drive modelM226

Gear ratio 3.538 3.357 3.692 3.538

Number of pinion gears 2

Number of teeth (Drive gear / drive pinion) 46/13 47/14 48/13 46/13

Oil capacity (Approx.)

(lmp pt)2.01 (3-1/2)

Drive pinion adjustment spacer type Collapsible

ItemSpecification

Gear ratio 3.357 type Gear ratio 3.538 type Gear ratio 3.692 type

To t a l p r e l o a d2.38 - 4.46

(0.25-0.45,21-39)2.34 - 4.34

(0.24 - 0.44, 21 - 38)2.32 - 4.34

(0.24 - 0.44, 21 - 38)

Pinion bearing preload 1.7 - 3.1 (0.18 - 0.31, 15 - 27)

Item Standard

Drive gear to drive pinion gear 0.08 - 0.13 (0.0031 - 0.0051)

Item Runout limit

Companion flange face 0.10 (0.0039) or less

Inner side of companion flange 0.13 (0.0051) or less

Page 2736 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual PRECAUTIONS

RFD-33

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

[WITH ELECTRONIC LOCKING DIFFERENTIAL]PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “A NISSAN NAVARA 2005 Repair Workshop Manual PRECAUTIONS

RFD-33

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

[WITH ELECTRONIC LOCKING DIFFERENTIAL]PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “A](/img/5/57362/w960_57362-2735.png)

PRECAUTIONS

RFD-33

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

[WITH ELECTRONIC LOCKING DIFFERENTIAL]PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EDS003IE

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

Precautions for Differential Case Assembly and Differential Lock Control Unit

Replacement

EDS003AG

lWhen replacing differential case assembly or differential lock control unit, check the DIFF LOCK indicator

pattern and adjustment of the position between differential case assembly and differential lock control unit

if necessary.

CHECK DIFF LOCK INDICATOR LAMP

1. Start engine. Run engine for at least 10 seconds.

2. Turn 4WD shift switch to “4LO” and confirm 4LO indicator lamp is turned on. Refer toTF-16, "

4WD SHIFT

SWITCH AND INDICATOR LAMP".

3. Stop vehicle and turn differential lock mode switch to “ON”.

4. Drive vehicle at 7 km/h (4 MPH) or less.

NOTE:

Differential case assembly must be given a rotation from rear left wheel and rear right wheel.

5. Check if DIFF LOCK indicator lamp flashes to turn on.

6. Check if DIFF LOCK indicator lamp and 4LO indicator lamp are changed properly as follows.

lIf each indication and state is OK, rear final drive assembly and differential lock control unit is working cor-

rectly.

lIf each indication and state is NG, rear final drive assembly and differential lock control unit is not working

correctly. Refer toRFD-34, "

METHOD FOR ADJUSTMENT".

Differential lock mode

switch4LO indicator lamp Vehicle speed (VSS)Differential case assem-

bly stateDIFF LOCK indicator

lamp

ONOFF7 km/h (4 MPH) < VSS

Disengage Flash VSS£7km/h(4MPH)

ON7 km/h (4 MPH) < VSS

VSS£7 km/h (4 MPH) Disengage®Engage Flash®ON

OFFOFF7 km/h (4 MPH) < VSS

Disengage OFF VSS£7km/h(4MPH)

ON7 km/h (4 MPH) < VSS

VSS£7km/h(4MPH)

Page 2746 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual DIFFERENTIAL LOCK SYSTEM

RFD-43

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

System DiagramEDS003AS

COMPONENTS FUNCTION DESCRIPTION

CAN CommunicationEDS003AT

SYSTEM DESCRIPTION

CA NISSAN NAVARA 2005 Repair Workshop Manual DIFFERENTIAL LOCK SYSTEM

RFD-43

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

System DiagramEDS003AS

COMPONENTS FUNCTION DESCRIPTION

CAN CommunicationEDS003AT

SYSTEM DESCRIPTION

CA](/img/5/57362/w960_57362-2745.png)

DIFFERENTIAL LOCK SYSTEM

RFD-43

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

System DiagramEDS003AS

COMPONENTS FUNCTION DESCRIPTION

CAN CommunicationEDS003AT

SYSTEM DESCRIPTION

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent error detection ability. Many elec-

tronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CAN communication, control units are connected with 2

communication lines (CAN H line, CAN L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only.

For details, refer toDI-65, "

CAN Communication Unit".

SDIA2500E

Component parts Function

Differential lock control unit

lControls differential lock solenoid and switches differential lock/unlock.

lAs a fail-safe function, differential lock disengages, if malfunction is detected in differential lock

system.

Differential lock solenoid Controls pressure plate by current from differential lock control unit.

Differential lock position switch Detects that differential is lock or unlock condition.

Differential lock mode switch Able to select differential lock or unlock.

DIFF LOCK indicator lamp Illuminates that differential is in lock or lock standby condition.

ABS actuator and electric unit

(control unit)Transmits the following signals via CAN communication to differential lock control unit.

lVehicle speed signal

Transfer control unitTransmits the following signal via CAN communication to differential lock control unit.

l4WD shift switch signal

Page 2751 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual RFD-48

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

TROUBLE DIAGNOSIS

Trouble Diagnosis Chart for Symptoms

EDS003AY

If DIFF LOCK indicator lamp does not turn ON after engine start, perform self-diagnosis. R NISSAN NAVARA 2005 Repair Workshop Manual RFD-48

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

TROUBLE DIAGNOSIS

Trouble Diagnosis Chart for Symptoms

EDS003AY

If DIFF LOCK indicator lamp does not turn ON after engine start, perform self-diagnosis. R](/img/5/57362/w960_57362-2750.png)

RFD-48

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

TROUBLE DIAGNOSIS

Trouble Diagnosis Chart for Symptoms

EDS003AY

If DIFF LOCK indicator lamp does not turn ON after engine start, perform self-diagnosis. Refer toRFD-51, "SELF-DIAG RESULTSMODE".

Differential Lock Control Unit Input/Output Signal Reference ValuesEDS003AZ

DIFFERENTIAL LOCK CONTROL UNIT INSPECTION TABLE

Specifications with CONSULT-II

Symptom Condition Check itemReference

page

DIFF LOCK indicator lamp does not turn ON.

(DIFF LOCK indicator lamp check)Ignition switch: ONCAN communication line

RFD-70

Power supply and ground for differential

lock control unit

Combination meter

DIFF LOCK indicator lamp does not change.

lEngine running

lDifferential lock mode

switch: ONCombination meter

RFD-73Differential lock mode switch

CAN communication line

DIFF LOCK indicator lamp sometimes flashes.

lEngine running

lDifferential lock mode

switch: ONCombination meter

RFD-74Differential lock mode switch

Differential lock position switch

Differential inner parts

Monitor item [Unit] Content Condition Display value

BATTERY VOLT [V]Power supply voltage for

differential lock control unitIgnition switch: ON Battery voltage

4WD MODE [2H/4H/

4Lo]Condition of 4WD shift

switch4WD shift switch

(Engine running)2WD 2H

4H 4H

4LO 4Lo

VHCL S/SEN-R [km/h]

or [mph]Wheel speed

(Rear wheel right)Vehicle stopped 0 km/h (0 mph)

Vehicle running

CAUTION:

Check air pressure of tire under standard condition.Approximately

equal to the indi-

cation on speed-

ometer (Inside of

±10%)

VHCL S/SEN-L [km/h] or

[mph]Wheel speed

(Rear wheel left)Vehicle stopped 0 km/h (0 mph)

Vehicle running

CAUTION:

Check air pressure of tire under standard condition.Approximately

equal to the indi-

cation on speed-

ometer (Inside of

±10%)

VHCL S/SEN-RL [km/h]

or [mph]Wheel speed

(Average value of rear

wheel right and left)Vehicle stopped 0 km/h (0 mph)

Vehicle running

CAUTION:

Check air pressure of tire under standard condition.Approximately

equal to the indi-

cation on speed-

ometer (Inside of

±10%)

D-LOCK SW SIG [ON/

OFF]Condition of differential

lock mode switchDifferential lock mode switch: ON ON

Differential lock mode switch: OFF OFF

D-LOCK SIG [ON/OFF]Control status of differen-

tial lock

lVehicle stopped

lEngine running

l4WD shift switch: 4LODifferential lock mode

switch: ONON

Differential lock mode

switch: OFFOFF

Page 2752 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual TROUBLE DIAGNOSIS

RFD-49

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

Specifications Between Differential Lock Control Unit Terminals

DIFFERENTIAL LOCK CONTROL UNIT TERMINAL CONNE NISSAN NAVARA 2005 Repair Workshop Manual TROUBLE DIAGNOSIS

RFD-49

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

Specifications Between Differential Lock Control Unit Terminals

DIFFERENTIAL LOCK CONTROL UNIT TERMINAL CONNE](/img/5/57362/w960_57362-2751.png)

TROUBLE DIAGNOSIS

RFD-49

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

Specifications Between Differential Lock Control Unit Terminals

DIFFERENTIAL LOCK CONTROL UNIT TERMINAL CONNECTOR LAYOUT

Data are reference value and are measured between each terminal and ground.RELAY ON [ON/OFF]Operating condition of dif-

ferential lock solenoid

relay (integrated in differ-

ential lock control unit)

lVehicle stopped

lEngine running

l4WD shift switch: 4LODifferential lock mode

switch: ONON

Differential lock mode

switch: OFFOFF

RELAY MTR [ON/OFF]Control status of differen-

tial lock solenoid relay

(integrated in differential

lock control unit)

lVehicle stopped

lEngine running

l4WD shift switch: 4LODifferential lock mode

switch: ONON

Differential lock mode

switch: OFFOFF

SOL MTR [ON/OFF]Control status of differen-

tial lock solenoid

lVehicle stopped

lEngine running

l4WD shift switch: 4LODifferential lock mode

switch: ONON

Differential lock mode

switch: OFFOFF

IND MTR [ON/OFF]Control status of DIFF

LOCK indicator lampDIFF LOCK indicator lamp: ON ON

DIFF LOCK indicator lamp: OFF OFF

D-LOCK POS SW [ON/

OFF]Condition of differential

lock position switch

lVehicle stopped

lEngine running

l4WD shift switch: 4LODifferential lock mode

switch: ON

(DIFF LOCK indicator

lamp: ON)ON

Differential lock mode

switch: OFF

(DIFF LOCK indicator

lamp: OFF)OFF Monitor item [Unit] Content Condition Display value

SDIA2573E

TerminalWire

colorItem Condition Data (Approx.)

1 O Power supplyIgnition switch: ON Battery voltage

Ignition switch: OFF 0V

2 O Power supplyIgnition switch: ON Battery voltage

Ignition switch: OFF 0V

3 B Ground Always 0V

4 P CAN-L – –

5 L CAN-H – –

9YDifferential lock mode switch

(ON)Ignition switch: ONDifferential lock mode switch: ON Battery voltage

Differential lock mode switch: OFF 0V

10 B Ground Always 0V

Page 2753 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual RFD-50

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

TROUBLE DIAGNOSIS

CAUTION:

When using a circuit tester to measure voltage for inspection, be sure not to extend forcibly any connector terminals.

CONSULT- NISSAN NAVARA 2005 Repair Workshop Manual RFD-50

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

TROUBLE DIAGNOSIS

CAUTION:

When using a circuit tester to measure voltage for inspection, be sure not to extend forcibly any connector terminals.

CONSULT-](/img/5/57362/w960_57362-2752.png)

RFD-50

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

TROUBLE DIAGNOSIS

CAUTION:

When using a circuit tester to measure voltage for inspection, be sure not to extend forcibly any connector terminals.

CONSULT-II Function (DIFF LOCK)EDS003B0

FUNCTION

CONSULT-II can display each diagnostic item using the diagnostic test modes shown following.

CONSULT-II SETTING PROCEDURE

CAUTION:

If CONSULT-II is used with no connection of CONSULT-II CONVERTER, malfunctions might be

detected in self-diagnosis depending on control unit which carries out CAN communication.

NOTE:

For details, refer to the separate “CONSULT-II Operations Manual”.

1. Turn ignition switch “OFF”.

2. Connect CONSULT-II and CONSULT-II CONVERTER to data

link connector on vehicle.

3. Turn ignition switch “ON”.

11 GR Differential lock solenoid (-)

lVehicle stopped

lEngine running

l4WD shift switch: 4LODifferential lock mode switch: ON 0V

Differential lock mode switch: OFF Battery voltage

12 L Differential lock solenoid (+)

lVehicle stopped

lEngine running

l4WD shift switch: 4LODifferential lock mode switch: ON 0V

Differential lock mode switch: OFF Battery voltage

13 G K-LINE (CONSULT-II signal) – –

15 RPower supply

(Memory back-up)Ignition switch: ON Battery voltage

Ignition switch: OFF Battery voltage

20 BRDifferential lock position

switch

lVehicle stopped

lEngine running

l4WD shift switch: 4LODifferential lock mode switch: ON

(DIFF LOCK indicator lamp: ON)0V

Differential lock mode switch: OFF

(DIFF LOCK indicator lamp: OFF)Battery voltage

21 SB DIFF LOCK indicator lamp Ignition switch: ONDIFF LOCK indicator lamp: ON 0V

DIFF LOCK indicator lamp: OFF Battery voltage

22 GDifferential lock mode switch

(OFF)Ignition switch: ONDifferential lock mode switch: ON 0V

Differential lock mode switch: OFF Battery voltage Te r m i n a lWire

colorItem Condition Data (Approx.)

Diagnostic test mode FunctionReference

page

Self-diagnostic results

lSelf-diagnostic results can be read and erased quickly.RFD-51

Data monitorlInput/Output data in the differential lock control unit can be read.RFD-53

CAN diagnostic support monitorlThe results of transmit/receive diagnosis of CAN communication can be read.LAN-15

BDIA0013E

Page 2756 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual TROUBLE DIAGNOSIS

RFD-53

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

DATA MONITOR MODE

Operation Procedure

1. Perform “CONSULT-II SETTING PROCEDURE”. Refer toRFD-50, "CONSULT NISSAN NAVARA 2005 Repair Workshop Manual TROUBLE DIAGNOSIS

RFD-53

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

DATA MONITOR MODE

Operation Procedure

1. Perform “CONSULT-II SETTING PROCEDURE”. Refer toRFD-50, "CONSULT](/img/5/57362/w960_57362-2755.png)

TROUBLE DIAGNOSIS

RFD-53

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

DATA MONITOR MODE

Operation Procedure

1. Perform “CONSULT-II SETTING PROCEDURE”. Refer toRFD-50, "CONSULT-II SETTING PROCE-

DURE".

2. Touch “DATA MONITOR”.

3. Select from “SELECT MONITOR ITEM”, screen of data monitor mode is displayed.

NOTE:

When malfunction is detected, CONSULT-II performs REAL-TIME DIAGNOSIS.

Also, any malfunction detected while in this mode will be displayed at real time.

Display Item List

´: Standard –: Not applicable

Monitor item (Unit)SELECT MONITOR ITEM

Remarks

ECU INPUT

SIGNALSMAIN

SIGNALSSELECTION

FROM MENU

BATTERY VOLT [V]´´´Power supply voltage for differential lock

control unit.

4WD MODE [2H/4H/4Lo]´´´4WD shift switch signal status via CAN

communication line is displayed.

VHCL S/SEN-R [km/h] or [mph]´–´Wheel speed calculated by rear wheel

sensor right signal is displayed.

VHCL S/SEN-L [km/h] or [mph]´–´Wheel speed calculated by rear wheel

sensor left signal is displayed.

VHCL S/SEN-RL [km/h] or [mph]´´´Average value between wheel speed cal-

culated by rear wheel sensor right signal

and rear wheel sensor left signal is dis-

played.

D-LOCK SW SIG [ON/OFF]´´´Condition of differential lock mode switch

is displayed.

D-LOCK SIG [ON/OFF]´´´Control status of differential lock is dis-

played.

RELAY ON [ON/OFF]´´´Operating condition of differential lock

solenoid relay is displayed (integrated in

differential lock control unit).

RELAY MTR [ON/OFF]´´´Control status of differential lock solenoid

relay is displayed (integrated in differential

lock control unit).

SOL MTR [ON/OFF]´´´Control status of differential lock solenoid

is displayed.

IND MTR [ON/OFF]´´´Control status of DIFF LOCK indicator

lamp is displayed.

D-LOCK POS SW [ON/OFF]´´´Condition of differential lock position switch

is displayed.

Voltage [V] – –´The value measured by the voltage probe

is displayed.

Frequency [Hz] – –´

The value measured by the pulse probe is

displayed. DUTY-HI (high) [%] – –´

DUTY-LOW (low) [%] – –´

PLS WIDTH-HI [msec] – –´

PLS WIDTH-LOW [msec] – –´