NISSAN NAVARA 2005 Repair Workshop Manual

Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 1241 of 3171

DTC P1274 FUEL PUMP

EC-261

C

D

E

F

G

H

I

J

K

L

MA

EC

Diagnostic ProcedureEBS01KK5

1.CHECK ECM OUTPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

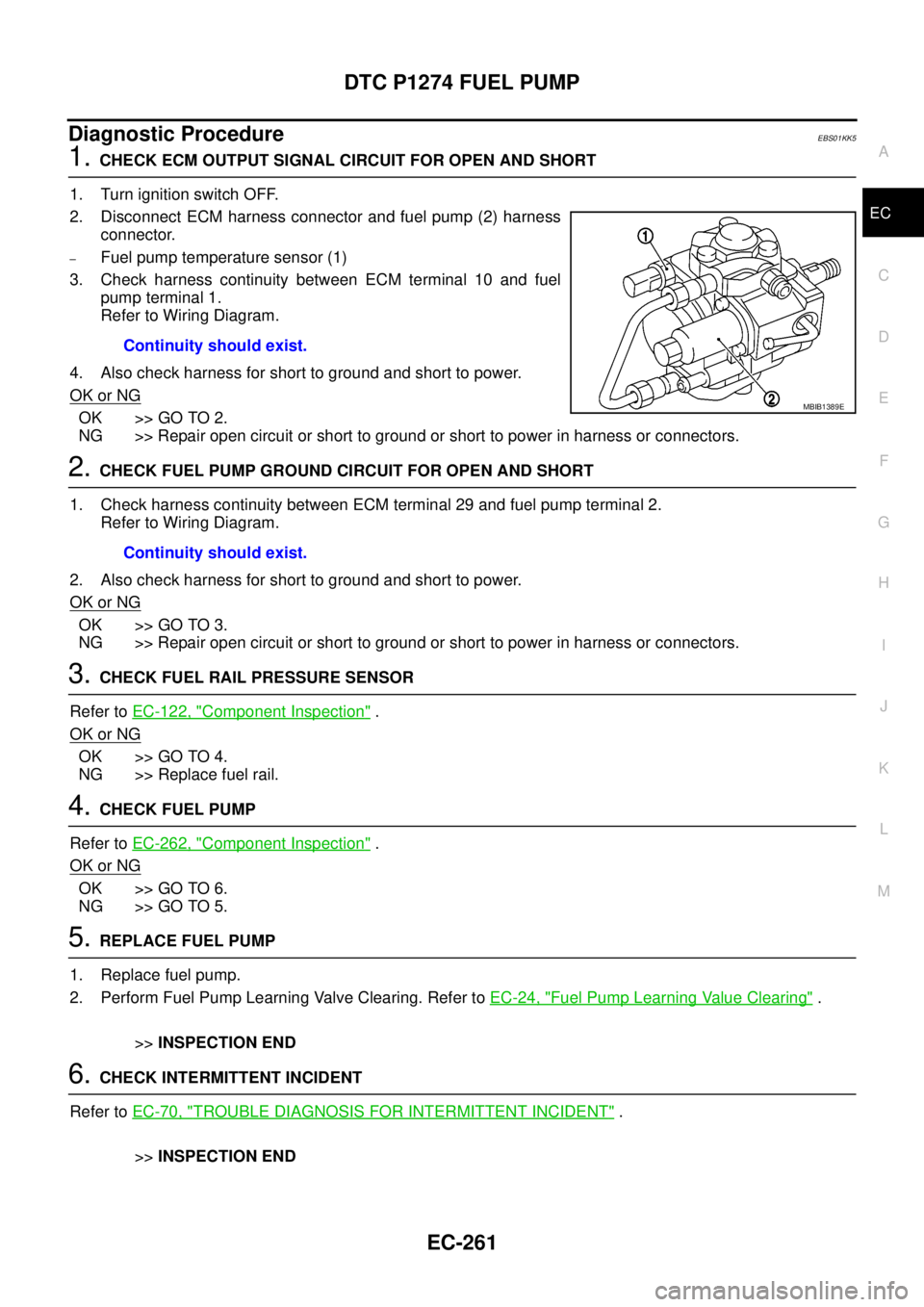

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector and fuel pump (2) harness

connector.

–Fuel pump temperature sensor (1)

3. Check harness continuity between ECM terminal 10 and fuel

pump terminal 1.

Refer to Wiring Diagram.

4. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 2.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

2.CHECK FUEL PUMP GROUND CIRCUIT FOR OPEN AND SHORT

1. Check harness continuity between ECM terminal 29 and fuel pump terminal 2.

Refer to Wiring Diagram.

2. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 3.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

3.CHECK FUEL RAIL PRESSURE SENSOR

Refer toEC-122, "

Component Inspection".

OK or NG

OK >> GO TO 4.

NG >> Replace fuel rail.

4.CHECK FUEL PUMP

Refer toEC-262, "

Component Inspection".

OK or NG

OK >> GO TO 6.

NG >> GO TO 5.

5.REPLACE FUEL PUMP

1. Replace fuel pump.

2. Perform Fuel Pump Learning Valve Clearing. Refer toEC-24, "

Fuel Pump Learning Value Clearing".

>>INSPECTION END

6.CHECK INTERMITTENT INCIDENT

Refer toEC-70, "

TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT".

>>INSPECTION END Continuity should exist.

MBIB1389E

Continuity should exist.

Page 1242 of 3171

EC-262

DTC P1274 FUEL PUMP

Component Inspection

EBS01KK6

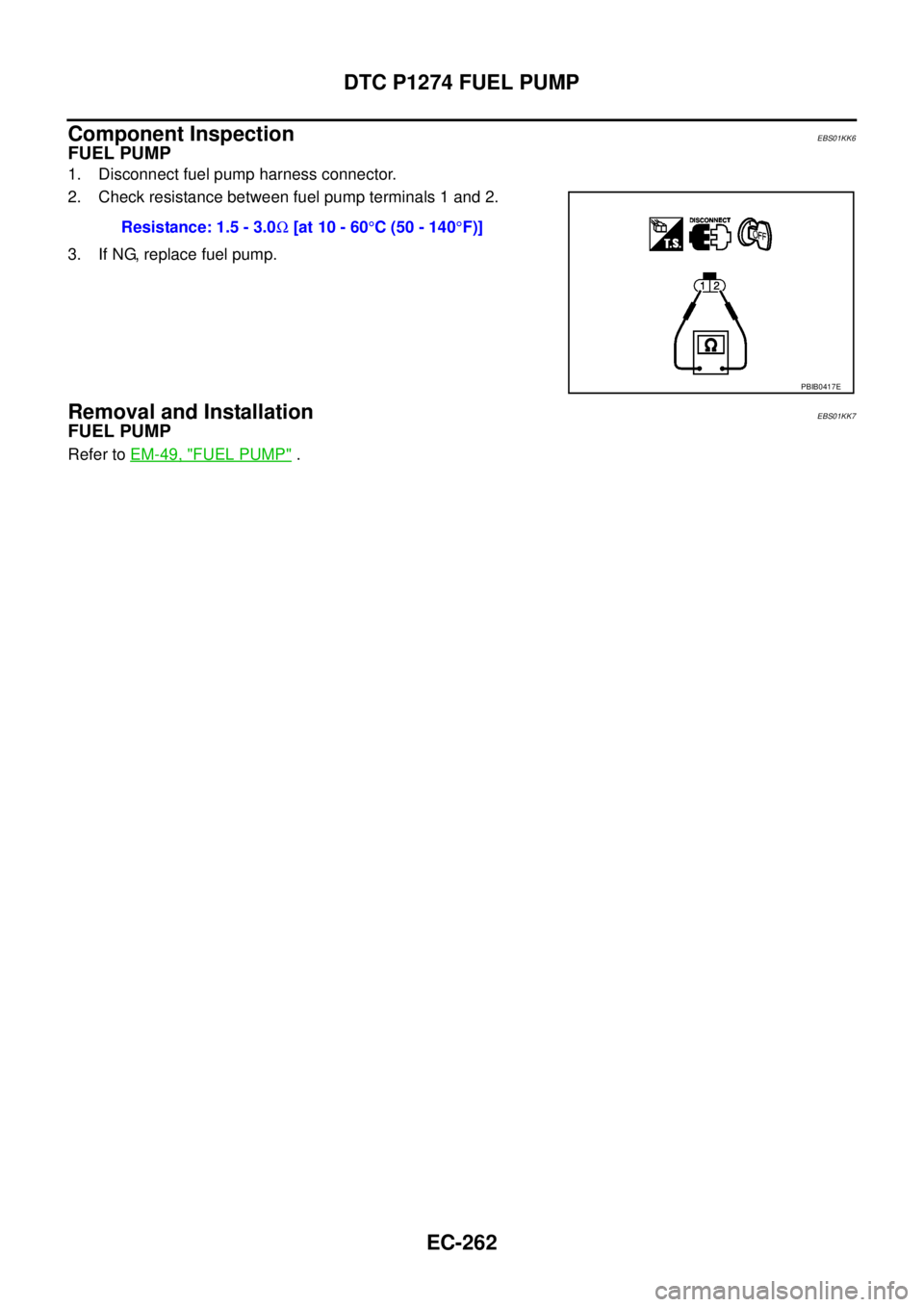

FUEL PUMP

1. Disconnect fuel pump harness connector.

2. Check resistance between fuel pump terminals 1 and 2.

3. If NG, replace fuel pump.

Removal and InstallationEBS01KK7

FUEL PUMP

Refer toEM-49, "FUEL PUMP". Resistance: 1.5 - 3.0W[at 10 - 60°C (50 - 140°F)]

PBIB0417E

Page 1243 of 3171

DTC P1275 FUEL PUMP

EC-263

C

D

E

F

G

H

I

J

K

L

MA

EC

DTC P1275 FUEL PUMPPFP:16700

DescriptionEBS01KK8

To control the amount of the fuel inhalation of the fuel pump, a plunger is built into the fuel pump. When the

amount of the fuel inhalation of fuel increases, the fuel pump raises the fuel exhalation pressure. As a result,

the fuel injection pressure is raised. When the load of the engine increases, the ECM sends a signal to fuel

pump to raise the injection pressure.

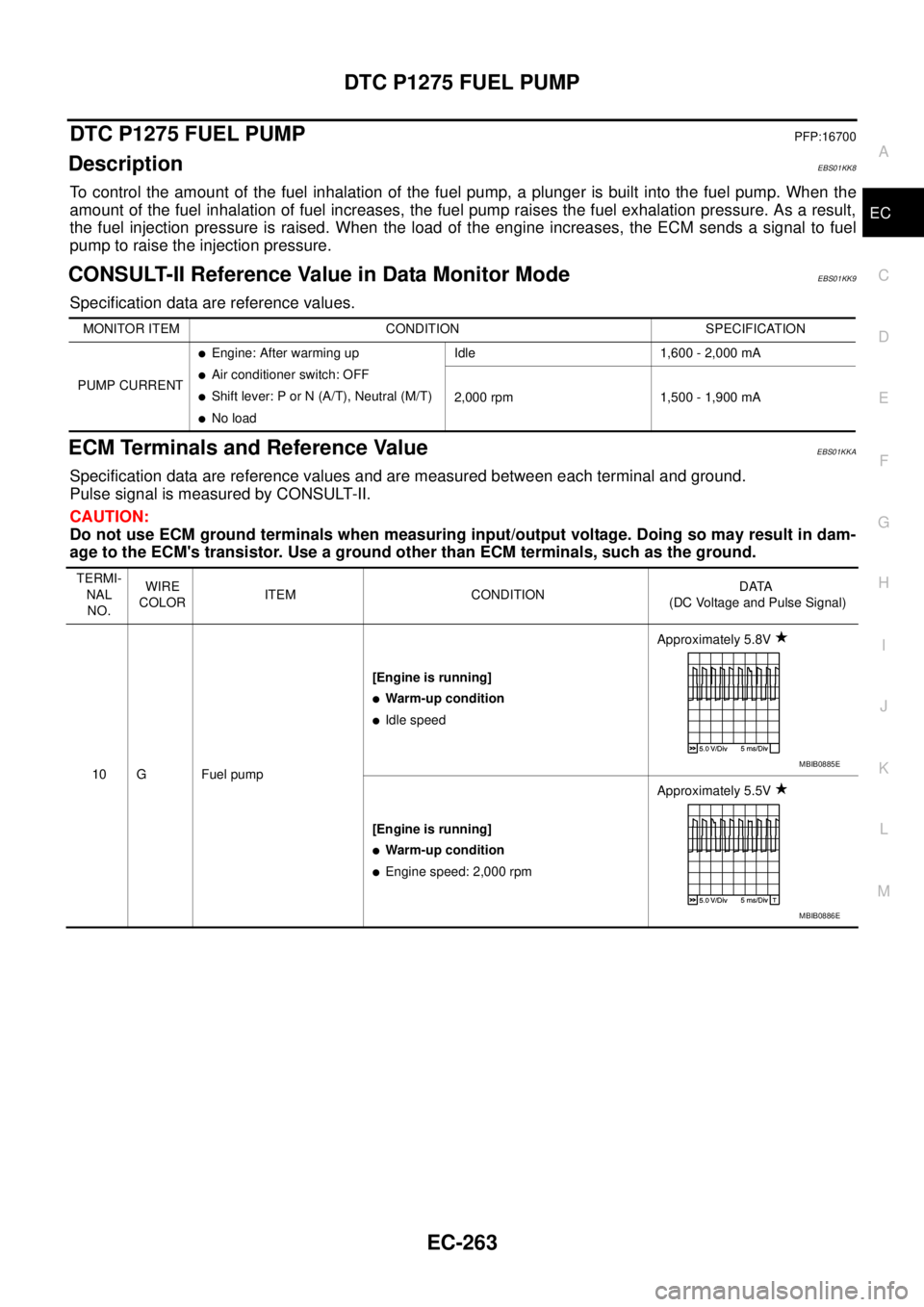

CONSULT-II Reference Value in Data Monitor ModeEBS01KK9

Specification data are reference values.

ECM Terminals and Reference ValueEBS01KKA

Specification data are reference values and are measured between each terminal and ground.

Pulse signal is measured by CONSULT-II.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

MONITOR ITEM CONDITION SPECIFICATION

PUMP CURRENT

lEngine: After warming up

lAir conditioner switch: OFF

lShift lever: P or N (A/T), Neutral (M/T)

lNo loadIdle 1,600 - 2,000 mA

2,000 rpm 1,500 - 1,900 mA

TERMI-

NAL

NO.WIRE

COLORITEM CONDITIONDATA

(DC Voltage and Pulse Signal)

10 G Fuel pump[Engine is running]

lWarm-up condition

lIdle speedApproximately 5.8V

[Engine is running]

lWarm-up condition

lEngine speed: 2,000 rpmApproximately 5.5V

MBIB0885E

MBIB0886E

Page 1244 of 3171

EC-264

DTC P1275 FUEL PUMP

: Average voltage for pulse signal (Actual pulse signal can be confirmed by oscilloscope.)

On Board Diagnosis LogicEBS01KKB

NOTE:

If DTC P1275 is displayed with DTC P0652 or P0653, first perform the trouble diagnosis for DTC P0652

or P0653. Refer toEC-227, "

DTC P0652, P0653 SENSOR POWER SUPPLY".

DTC Confirmation ProcedureEBS01KKC

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

WITH CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Select “DATA MONITOR” mode with CONSULT-II.

3. Keep engine speed more than 2,000 rpm for at least 60 sec-

onds.

4. If DTC is detected, go toEC-267, "

Diagnostic Procedure".

WITHOUT CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Keep engine speed more than 2,000 rpm for at least 60 seconds.

3. Turn ignition switch OFF, wait at least 10 seconds and then turn ON.

4. Perform Diagnostic Test Mode II (Self-diagnostic results) with ECM.

29 B Fuel pump[Engine is running]

lWarm-up condition

lIdle speed0.5 - 1.0V

[Engine is running]

lWarm-up condition

lEngine speed: 2,000 rpm0.5 - 1.0V TERMI-

NAL

NO.WIRE

COLORITEM CONDITIONDATA

(DC Voltage and Pulse Signal)

MBIB0887E

MBIB0888E

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P1275

1275Fuel pump exchangeFuel pressure is too much higher than the target

value.

lHarness or connectors

(The fuel pump circuit is open or

shorted.)

lFuel pump

lFuel rail pressure sensor

SEF817Y

Page 1245 of 3171

DTC P1275 FUEL PUMP

EC-265

C

D

E

F

G

H

I

J

K

L

MA

EC

5. If DTC is detected, go toEC-267, "Diagnostic Procedure".

Page 1246 of 3171

EC-266

DTC P1275 FUEL PUMP

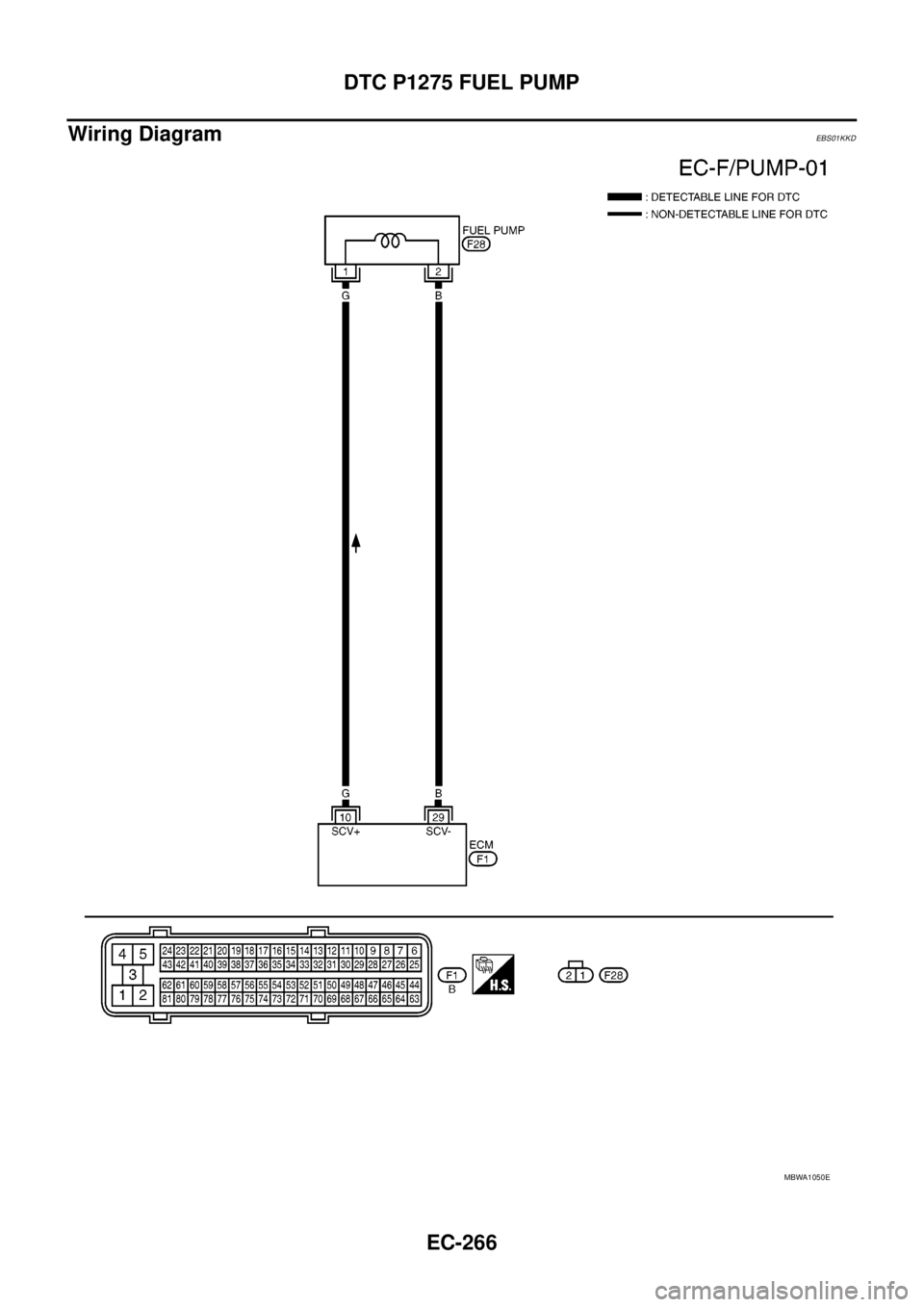

Wiring Diagram

EBS01KKD

MBWA1050E

Page 1247 of 3171

DTC P1275 FUEL PUMP

EC-267

C

D

E

F

G

H

I

J

K

L

MA

EC

Diagnostic ProcedureEBS01KKE

1.CHECK ECM OUTPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector and fuel pump (2) harness

connectors.

–Fuel pump temperature sensor (1)

3. Check harness continuity between ECM terminal 10 and fuel

pump terminal 1.

Refer to Wiring Diagram.

4. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 2.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

2.CHECK FUEL PUMP GROUND CIRCUIT FOR OPEN AND SHORT

1. Check harness continuity between ECM terminal 29 and fuel pump terminal 2.

Refer to Wiring Diagram.

2. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 3.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

3.CHECK FUEL RAIL PRESSURE SENSOR

Refer toEC-122, "

Component Inspection".

OK or NG

OK >> GO TO 4.

NG >> Replace fuel rail.

4.CHECK FUEL PUMP

Refer toEC-268, "

Component Inspection".

OK or NG

OK >> GO TO 6.

NG >> GO TO 5.

5.REPLACE FUEL PUMP

1. Replace fuel pump.

2. Perform Fuel Pump Learning Valve Clearing. Refer toEC-24, "

Fuel Pump Learning Value Clearing".

>>INSPECTION END

6.CHECK INTERMITTENT INCIDENT

Refer toEC-70, "

TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT".

>>INSPECTION END Continuity should exist.

MBIB1389E

Continuity should exist.

Page 1248 of 3171

EC-268

DTC P1275 FUEL PUMP

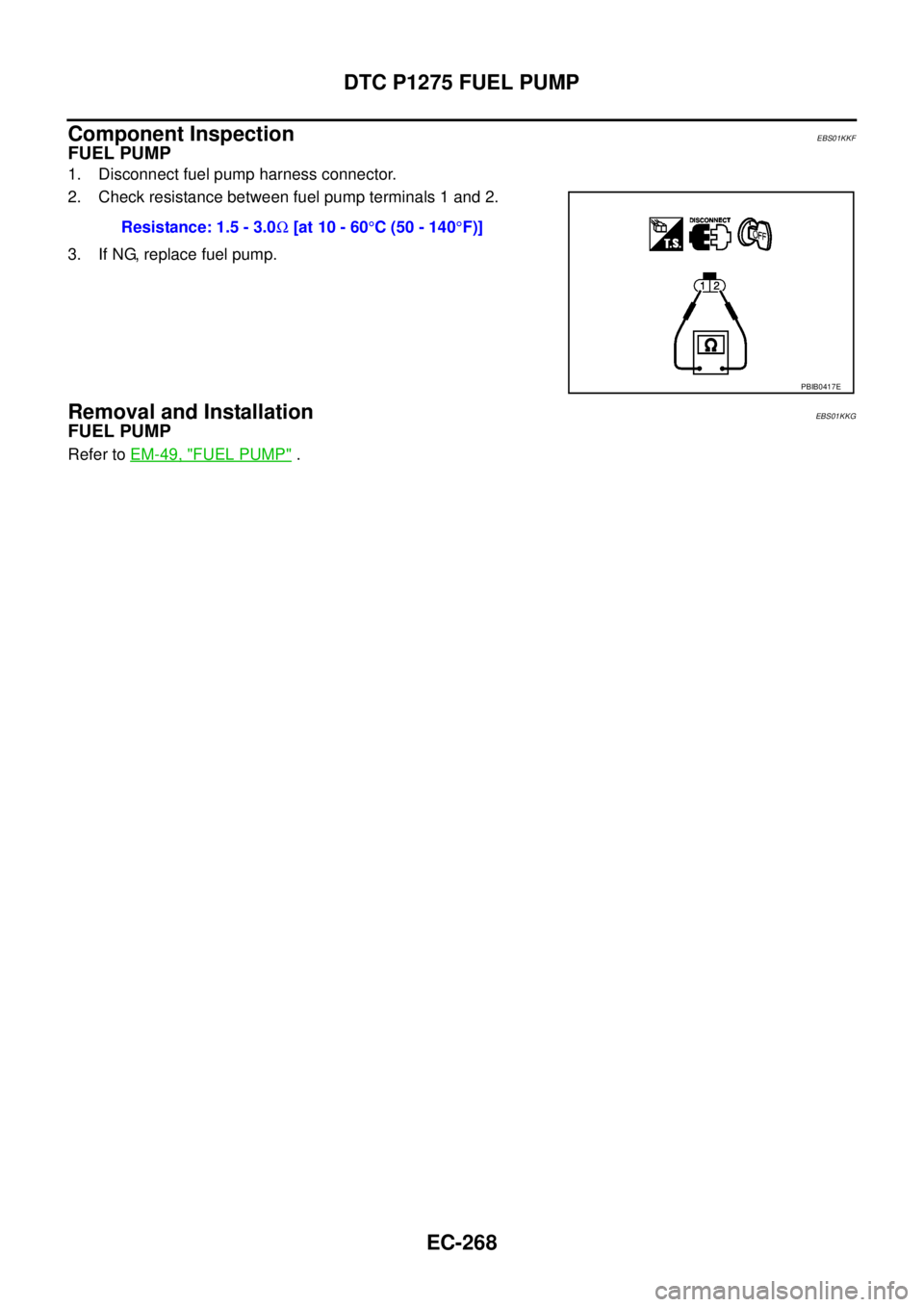

Component Inspection

EBS01KKF

FUEL PUMP

1. Disconnect fuel pump harness connector.

2. Check resistance between fuel pump terminals 1 and 2.

3. If NG, replace fuel pump.

Removal and InstallationEBS01KKG

FUEL PUMP

Refer toEM-49, "FUEL PUMP". Resistance: 1.5 - 3.0W[at 10 - 60°C (50 - 140°F)]

PBIB0417E

Page 1249 of 3171

DTC P1616 ECM

EC-269

C

D

E

F

G

H

I

J

K

L

MA

EC

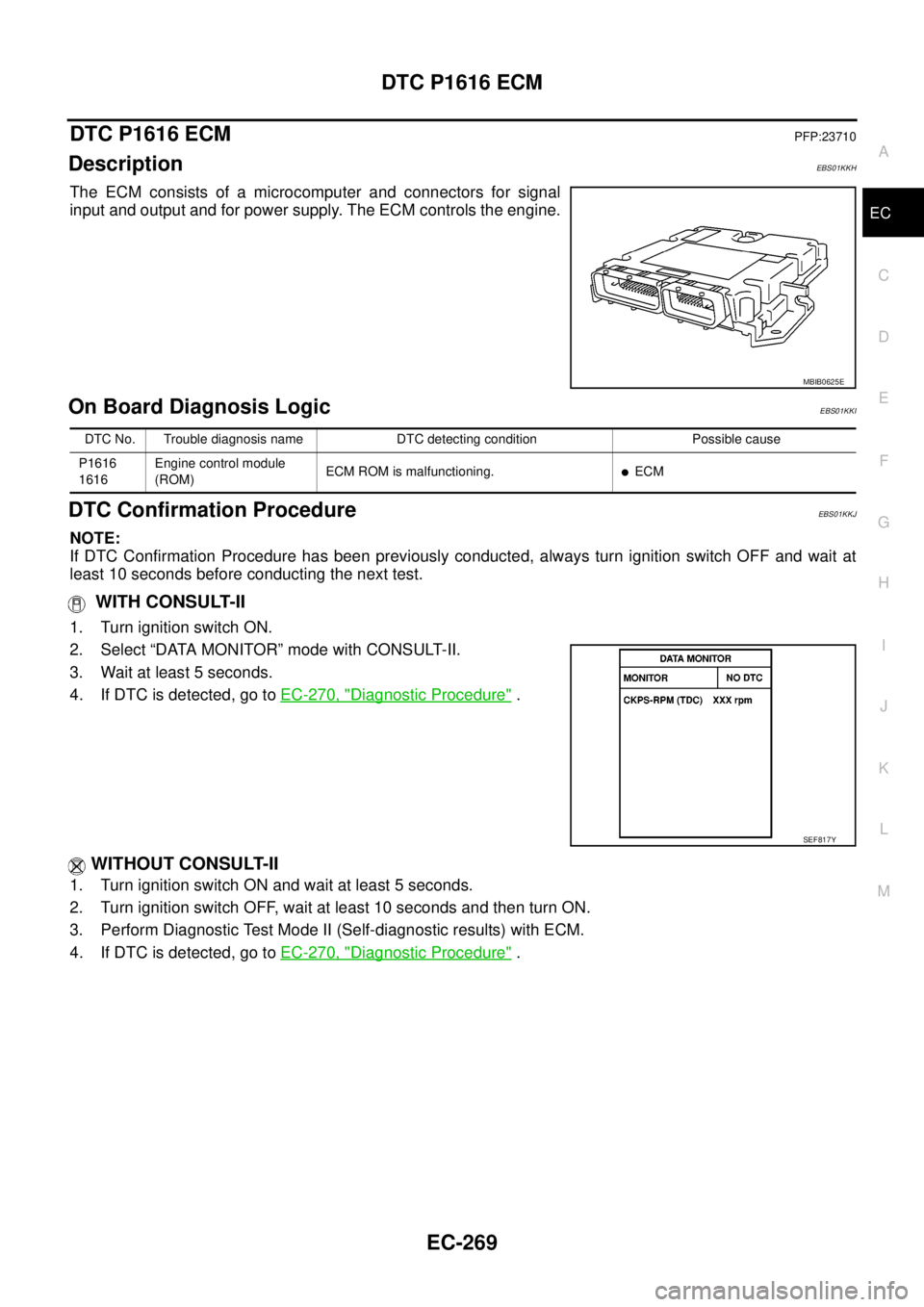

DTC P1616 ECMPFP:23710

DescriptionEBS01KKH

The ECM consists of a microcomputer and connectors for signal

input and output and for power supply. The ECM controls the engine.

On Board Diagnosis LogicEBS01KKI

DTC Confirmation ProcedureEBS01KKJ

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

WITH CONSULT-II

1. Turn ignition switch ON.

2. Select “DATA MONITOR” mode with CONSULT-II.

3. Wait at least 5 seconds.

4. If DTC is detected, go toEC-270, "

Diagnostic Procedure".

WITHOUT CONSULT-II

1. Turn ignition switch ON and wait at least 5 seconds.

2. Turn ignition switch OFF, wait at least 10 seconds and then turn ON.

3. Perform Diagnostic Test Mode II (Self-diagnostic results) with ECM.

4. If DTC is detected, go toEC-270, "

Diagnostic Procedure".

MBIB0625E

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P1616

1616Engine control module

(ROM)ECM ROM is malfunctioning.

lECM

SEF817Y

Page 1250 of 3171

EC-270

DTC P1616 ECM

Diagnostic Procedure

EBS01KKK

1.INSPECTION START

With CONSULT-II

1. Turn ignition switch ON.

2. Select “SELF DIAG RESULTS” mode with CONSULT-II.

3. Touch “ERASE”.

4. PerformEC-269, "

DTC Confirmation Procedure",again.

5. Is DTC P1616 displayed again?

Without CONSULT-II

1. Turn ignition switch ON.

2. Erase the Diagnostic Test Mode II (Self-diagnostic results) memory. Refer toEC-27

.

3. PerformEC-269, "

DTC Confirmation Procedure",again.

4. Is DTC 1616 displayed again?

Ye s o r N o

Yes >>GOTO2.

No >>INSPECTION END

2.REPLACE ECM

1. Replace ECM.

2. Perform initialization of NATS system and registration of all NATS ignition key IDs. Refer toBL-172, "

ECM

Re-communicating Function".

3. Perform Fuel Pump Learning Value Clearing. Refer toEC-24, "

Fuel Pump Learning Value Clearing".

4. Perform Injector Adjustment Value Registration. Refer toEC-25, "

Injector Adjustment Value Registration".

>>INSPECTION END