charging NISSAN NAVARA 2005 Repair Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2597 of 3171

PG-68

HARNESS

Wiring Diagram Codes (Cell Codes)

EKS00LJ9

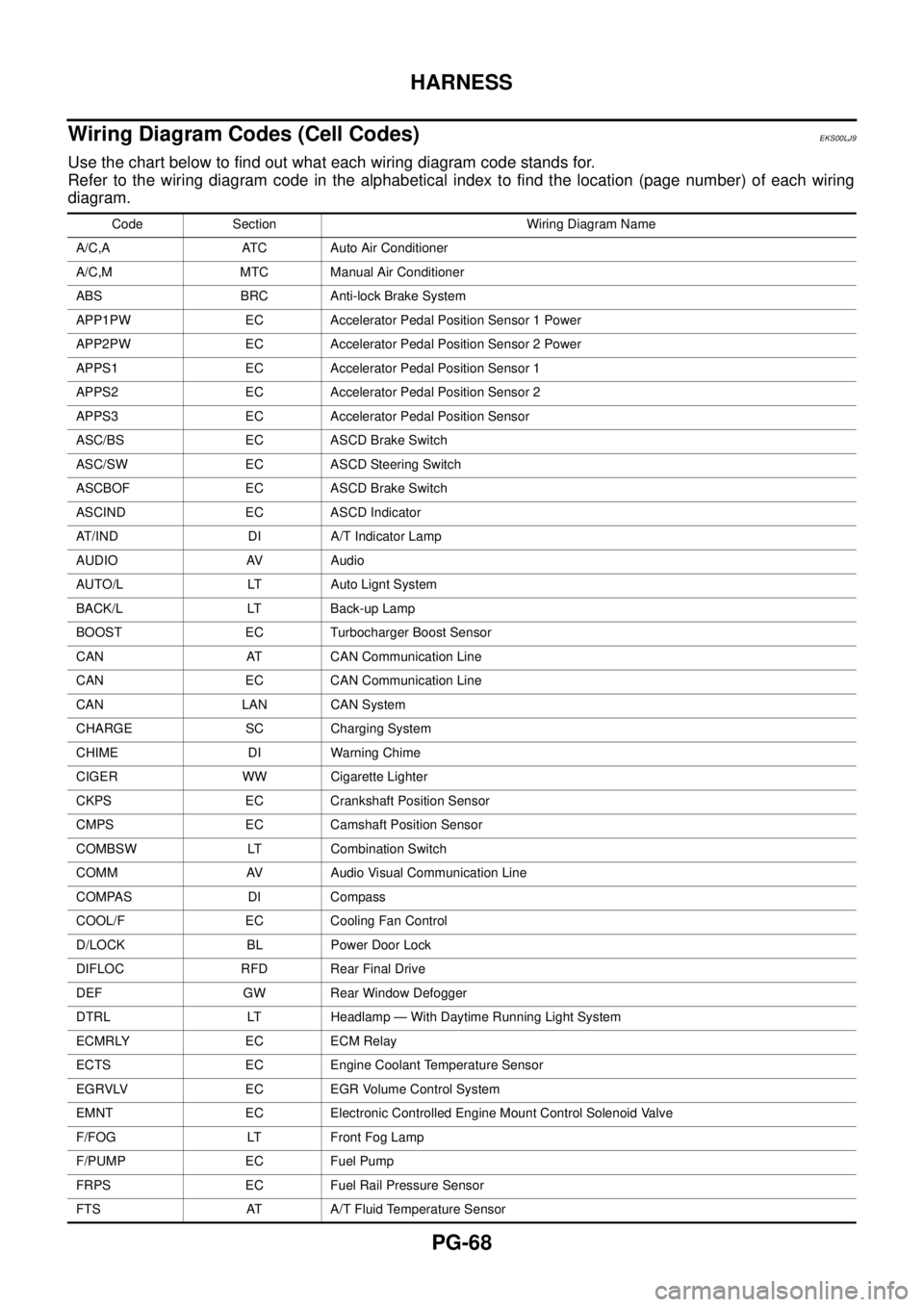

Use the chart below to find out what each wiring diagram code stands for.

Refer to the wiring diagram code in the alphabetical index to find the location (page number) of each wiring

diagram.

Code Section Wiring Diagram Name

A/C,A ATC Auto Air Conditioner

A/C,M MTC Manual Air Conditioner

ABS BRC Anti-lock Brake System

APP1PW EC Accelerator Pedal Position Sensor 1 Power

APP2PW EC Accelerator Pedal Position Sensor 2 Power

APPS1 EC Accelerator Pedal Position Sensor 1

APPS2 EC Accelerator Pedal Position Sensor 2

APPS3 EC Accelerator Pedal Position Sensor

ASC/BS EC ASCD Brake Switch

ASC/SW EC ASCD Steering Switch

ASCBOF EC ASCD Brake Switch

ASCIND EC ASCD Indicator

AT/IND DI A/T Indicator Lamp

AUDIO AV Audio

AUTO/L LT Auto Lignt System

BACK/L LT Back-up Lamp

BOOST EC Turbocharger Boost Sensor

CAN AT CAN Communication Line

CAN EC CAN Communication Line

CAN LAN CAN System

CHARGE SC Charging System

CHIME DI Warning Chime

CIGER WW Cigarette Lighter

CKPS EC Crankshaft Position Sensor

CMPS EC Camshaft Position Sensor

COMBSW LT Combination Switch

COMM AV Audio Visual Communication Line

COMPAS DI Compass

COOL/F EC Cooling Fan Control

D/LOCK BL Power Door Lock

DIFLOC RFD Rear Final Drive

DEF GW Rear Window Defogger

DTRL LT Headlamp — With Daytime Running Light System

ECMRLY EC ECM Relay

ECTS EC Engine Coolant Temperature Sensor

EGRVLV EC EGR Volume Control System

EMNT EC Electronic Controlled Engine Mount Control Solenoid Valve

F/FOG LT Front Fog Lamp

F/PUMP EC Fuel Pump

FRPS EC Fuel Rail Pressure Sensor

FTS AT A/T Fluid Temperature Sensor

Page 2834 of 3171

SC-1

STARTING & CHARGING SYSTEM

K ELECTRICAL

CONTENTS

C

D

E

F

G

H

I

J

L

M

SECTIONSC

A

B

SC

STARTING & CHARGING SYSTEM

PRECAUTIONS .......................................................... 3

Precautions for Supplemental Restraint System

(SRS)“AIRBAG”and“SEATBELTPRE-TEN-

SIONER” .................................................................. 3

Wiring Diagrams and Trouble Diagnosis .................. 3

PREPARATION ........................................................... 4

Special Service Tools ............................................... 4

BATTERY .................................................................... 5

How to Handle Battery ............................................. 5

METHODS OF PREVENTING OVER-DIS-

CHARGE ............................................................... 5

CHECKING ELECTROLYTE LEVEL .................... 5

SPECIFIC GRAVITY CHECK ............................... 6

Battery Test and Charging Chart .............................. 7

CHART I ................................................................ 7

CHART II ............................................................... 8

A: SLOW CHARGE ............................................... 9

B: STANDARD CHARGE .................................... 10

C: QUICK CHARGE ............................................ 12

Removal and Installation ........................................ 13

CHARGING SYSTEM ............................................... 14

System Description ................................................ 14

Wiring Diagram — CHARGE — ............................. 15

Trouble Diagnosis .................................................. 16

DIAGNOSIS PROCEDURE ................................ 16

PRE-DIAGNOSIS INSPECTION ......................... 16

DIAGNOSIS CHART BY SYMPTOM .................. 16

INSPECTION FLOW BY CHARGE WARNING

LAMP .................................................................. 16

CHARGE WARNING LAMP LINE INSPECTION... 17

VOLTAGE DETECTION LINE AND CHARGE

WARNING LAMP INSPECTION ......................... 18

INSPECTION OF INSUFFICIENT ALTERNA-

TOR POWER GENERATION .............................. 20

INSPECTION OF EXCESSIVE ALTERNATOR

POWER GENERATION ...................................... 20

DARK CURRENT INSPECTION ......................... 21

OPERATION PROCEDURE OF CURRENT

MEASUREMENT PROBE FOR CONSULT-II ..... 22

Removal and Installation ........................................ 23REMOVAL ........................................................... 23

INSTALLATION ................................................... 23

Disassembly and Assembly .................................... 23

LHD MODELS ..................................................... 23

RHD MODELS .................................................... 24

Disassembly ........................................................... 24

REAR COVER ..................................................... 24

REAR BEARING ................................................. 24

Inspection ............................................................... 25

ROTOR CHECK .................................................. 25

BRUSH CHECK .................................................. 25

PULLEY CHECK (WITH CLUTCH TYPE) ........... 25

STATOR CHECK ................................................. 25

Assembly ................................................................ 26

RING FITTING IN REAR BEARING .................... 26

REAR COVER INSTALLATION ........................... 26

STARTING SYSTEM ................................................. 27

System Description ................................................. 27

A/T MODELS ....................................................... 27

M/T MODELS ...................................................... 27

Wiring Diagram — START — ................................. 28

A/T MODELS ....................................................... 28

M/T MODELS ...................................................... 29

Trouble Diagnoses ................................................. 30

Removal and Installation ........................................ 31

REMOVAL ........................................................... 31

INSTALLATION ................................................... 31

Disassembly and Assembly .................................... 32

Inspection ............................................................... 32

MAGNETIC SWITCH CHECK ............................. 32

PINION/CLUTCH CHECK ................................... 33

BRUSH CHECK .................................................. 33

YOKE CHECK ..................................................... 34

ARMATURE CHECK ........................................... 35

Assembly ................................................................ 36

PINION PROTRUSION LENGTH ADJUST-

MENT .................................................................. 36

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 37

Battery .................................................................... 37

Page 2838 of 3171

BATTERY

SC-5

C

D

E

F

G

H

I

J

L

MA

B

SC

BATTERYPFP:00011

How to Handle BatteryEKS00MZ7

CAUTION:

lIf it becomes necessary to start the engine with a booster battery and jumper cables, use a 12-volt

booster battery.

lAfter connecting battery cables, ensure that they are tightly clamped to battery terminals for good

contact.

lNever add distilled water through the hole used to check specific gravity.

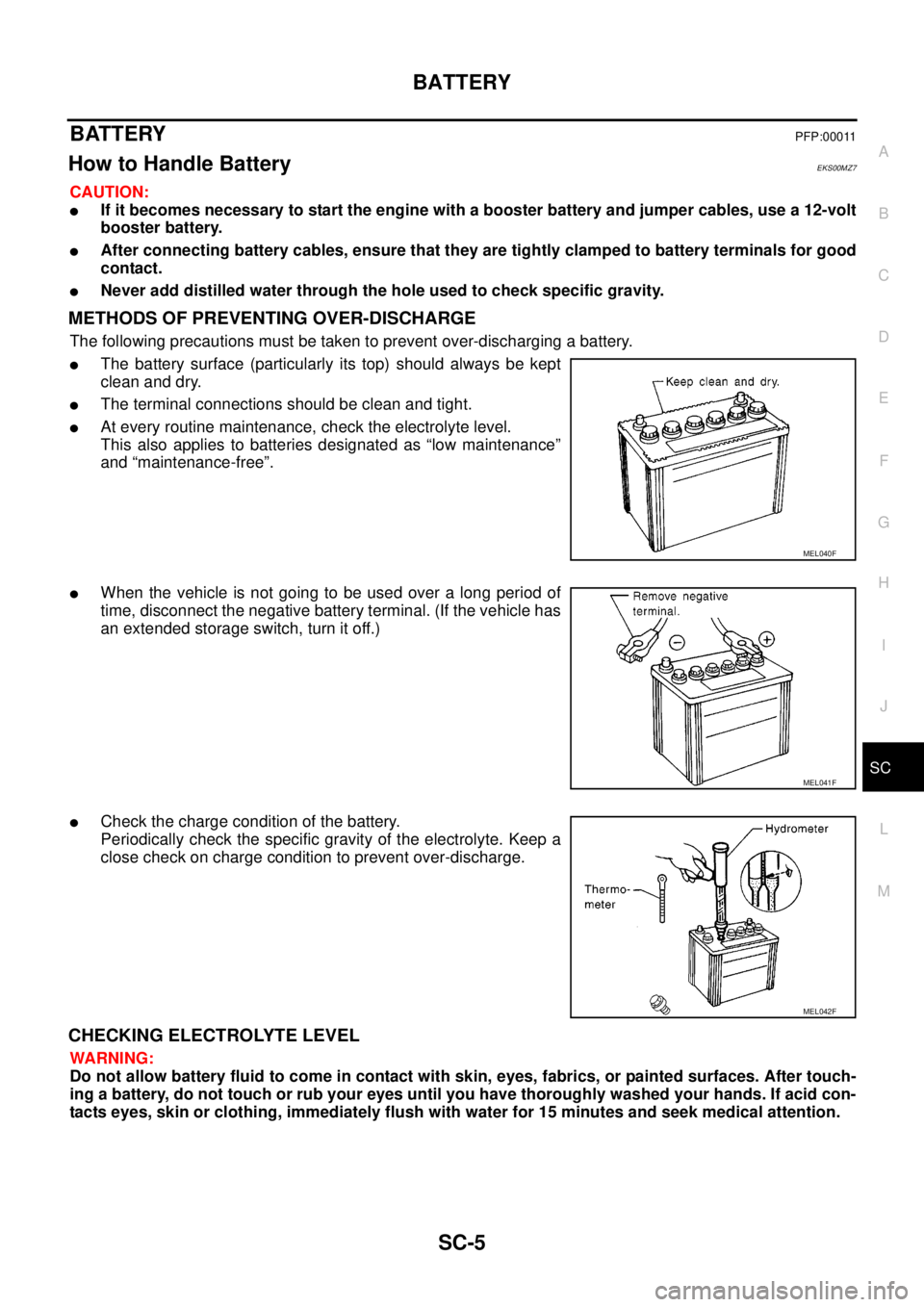

METHODS OF PREVENTING OVER-DISCHARGE

The following precautions must be taken to prevent over-discharging a battery.

lThe battery surface (particularly its top) should always be kept

clean and dry.

lThe terminal connections should be clean and tight.

lAt every routine maintenance, check the electrolyte level.

This also applies to batteries designated as “low maintenance”

and “maintenance-free”.

lWhen the vehicle is not going to be used over a long period of

time, disconnect the negative battery terminal. (If the vehicle has

an extended storage switch, turn it off.)

lCheck the charge condition of the battery.

Periodically check the specific gravity of the electrolyte. Keep a

close check on charge condition to prevent over-discharge.

CHECKING ELECTROLYTE LEVEL

WARNING:

Do not allow battery fluid to come in contact with skin, eyes, fabrics, or painted surfaces. After touch-

ing a battery, do not touch or rub your eyes until you have thoroughly washed your hands. If acid con-

tacts eyes, skin or clothing, immediately flush with water for 15 minutes and seek medical attention.

MEL040F

MEL041F

MEL042F

Page 2839 of 3171

SC-6

BATTERY

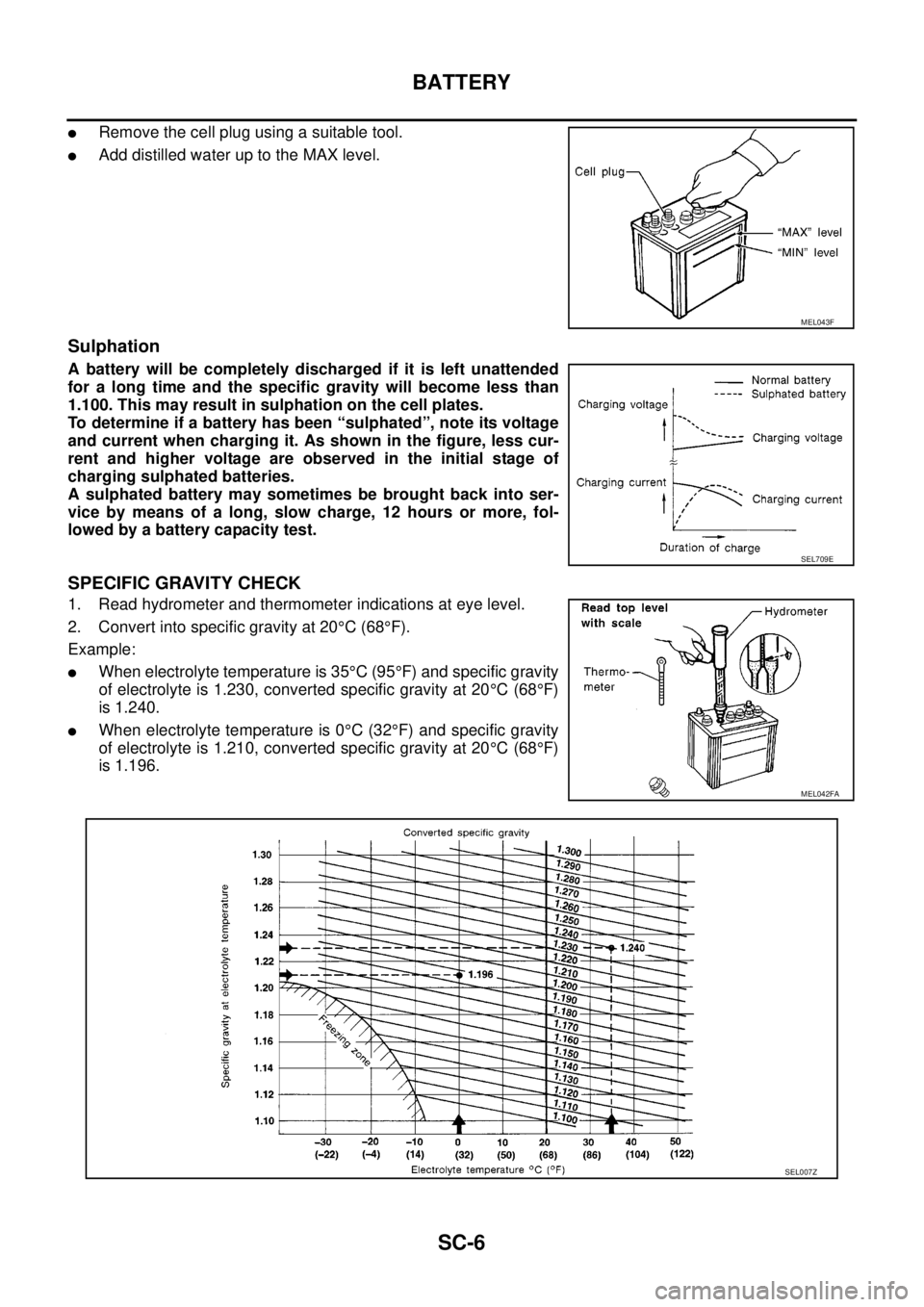

lRemove the cell plug using a suitable tool.

lAdd distilled water up to the MAX level.

Sulphation

A battery will be completely discharged if it is left unattended

for a long time and the specific gravity will become less than

1.100. This may result in sulphation on the cell plates.

To determine if a battery has been “sulphated”, note its voltage

and current when charging it. As shown in the figure, less cur-

rent and higher voltage are observed in the initial stage of

charging sulphated batteries.

A sulphated battery may sometimes be brought back into ser-

vice by means of a long, slow charge, 12 hours or more, fol-

lowed by a battery capacity test.

SPECIFIC GRAVITY CHECK

1. Read hydrometer and thermometer indications at eye level.

2. Convert into specific gravity at 20°C(68°F).

Example:

lWhen electrolyte temperature is 35°C(95°F) and specific gravity

of electrolyte is 1.230, converted specific gravity at 20°C(68°F)

is 1.240.

lWhen electrolyte temperature is 0°C(32°F) and specific gravity

of electrolyte is 1.210, converted specific gravity at 20°C(68°F)

is 1.196.

MEL043F

SEL709E

MEL042FA

SEL007Z

Page 2840 of 3171

BATTERY

SC-7

C

D

E

F

G

H

I

J

L

MA

B

SC

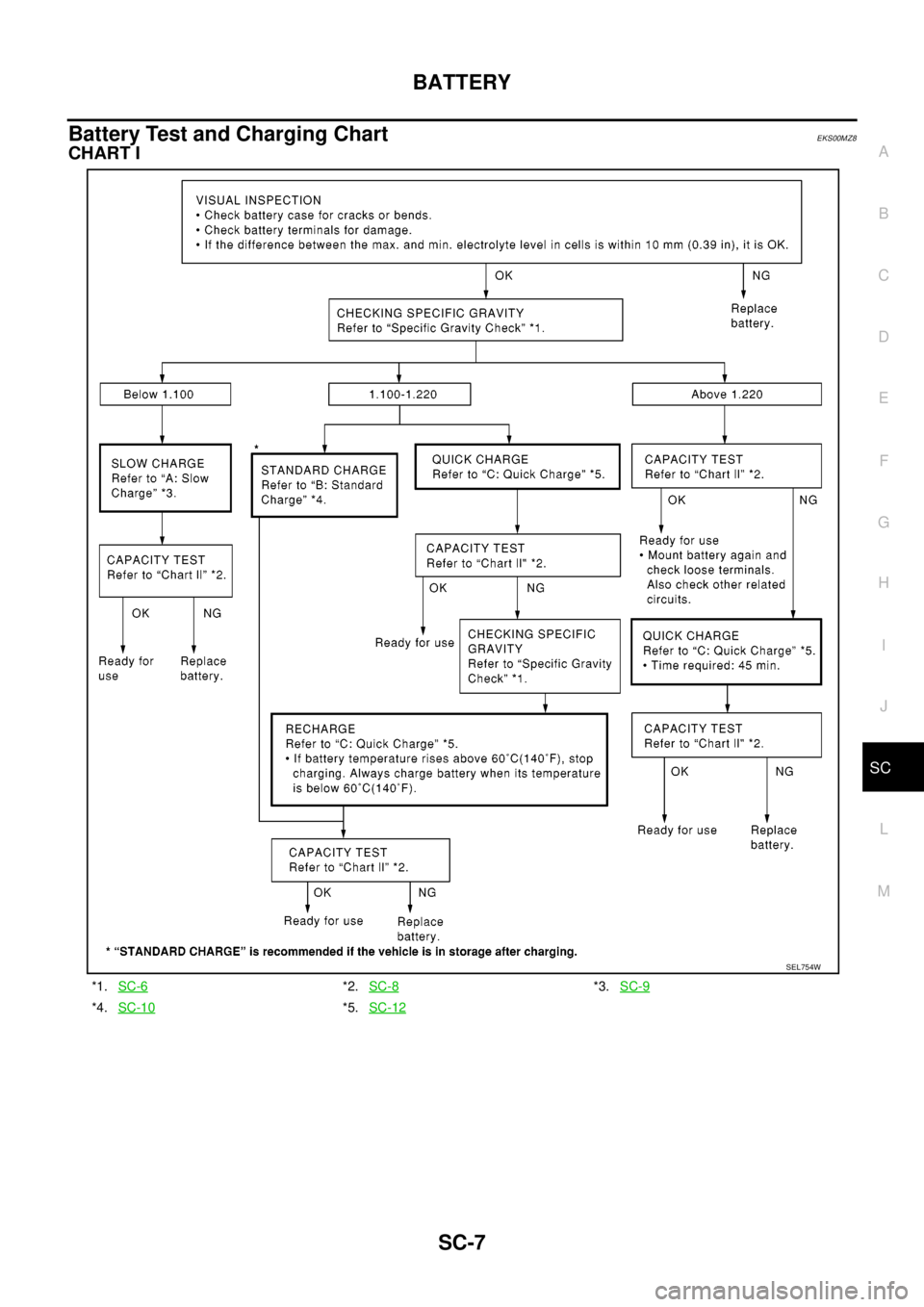

Battery Test and Charging ChartEKS00MZ8

CHART I

*1.SC-6*2.SC-8*3.SC-9

*4.SC-10*5.SC-12

SEL754W

Page 2841 of 3171

SC-8

BATTERY

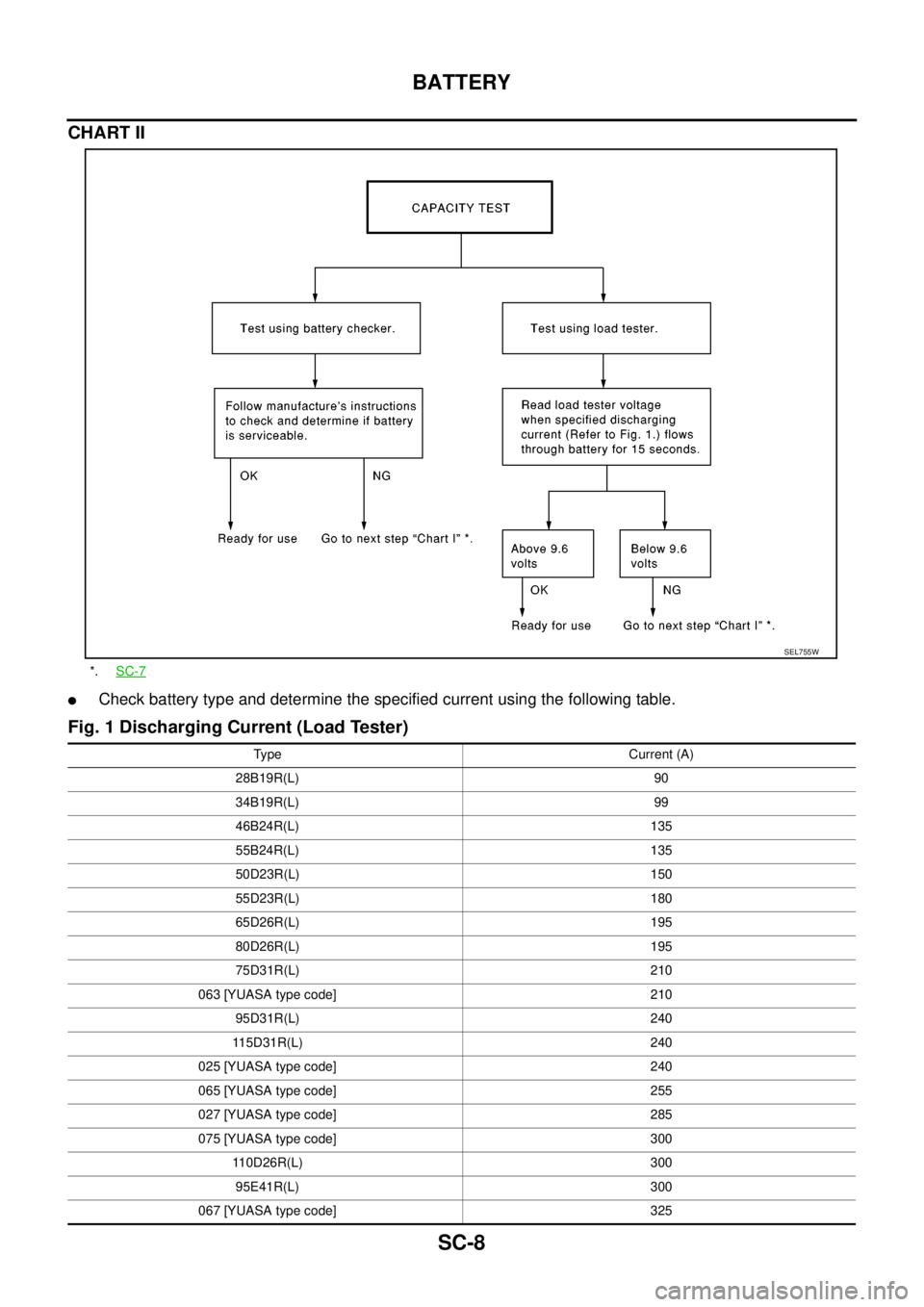

CHART II

lCheck battery type and determine the specified current using the following table.

Fig. 1 Discharging Current (Load Tester)

*.SC-7

SEL755W

Type Current (A)

28B19R(L) 90

34B19R(L) 99

46B24R(L) 135

55B24R(L) 135

50D23R(L) 150

55D23R(L) 180

65D26R(L) 195

80D26R(L) 195

75D31R(L) 210

063 [YUASA type code] 210

95D31R(L) 240

115D31R(L) 240

025 [YUASA type code] 240

065 [YUASA type code] 255

027 [YUASA type code] 285

075 [YUASA type code] 300

110D26R(L) 300

95E41R(L) 300

067 [YUASA type code] 325

Page 2842 of 3171

BATTERY

SC-9

C

D

E

F

G

H

I

J

L

MA

B

SC

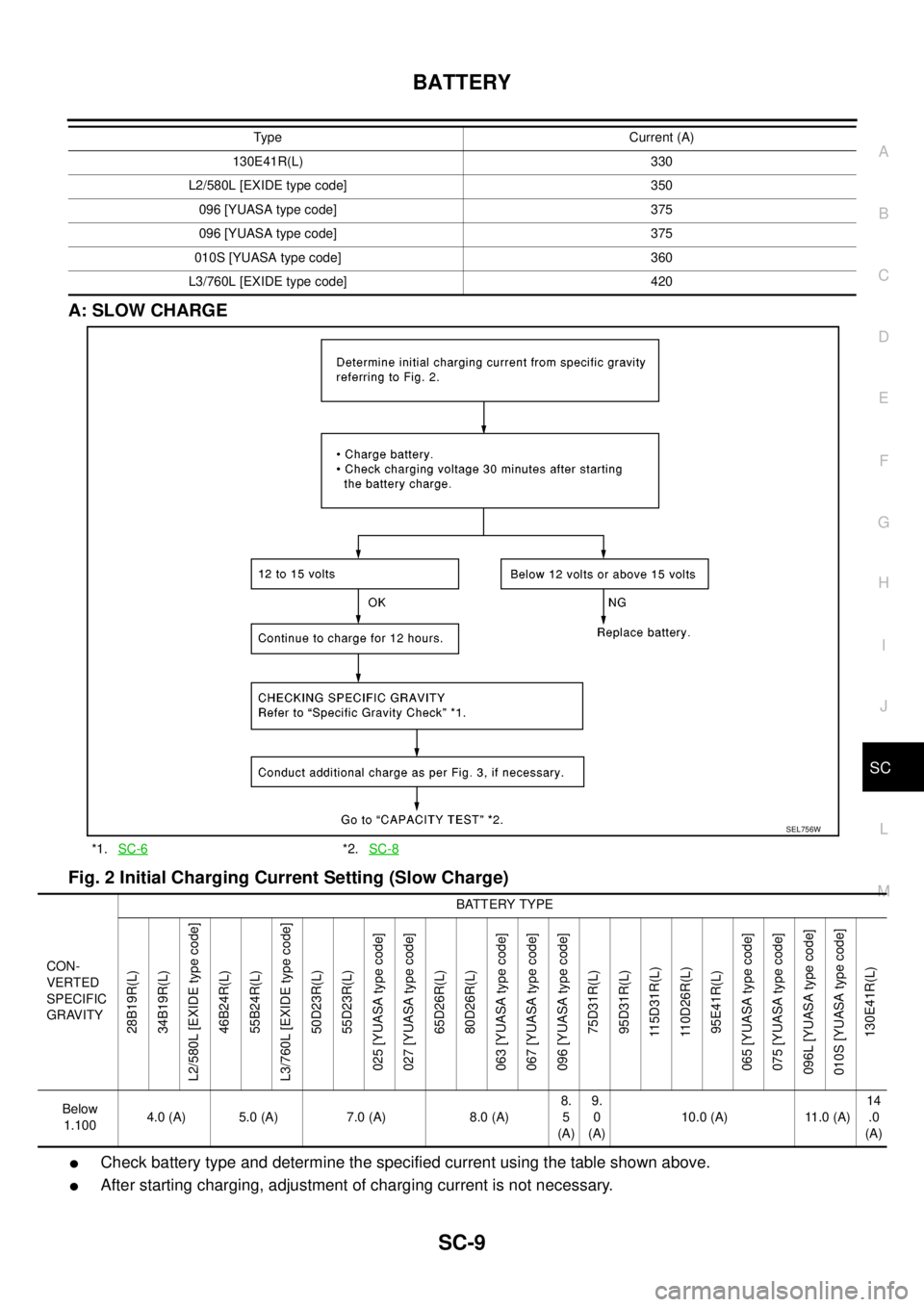

A: SLOW CHARGE

Fig. 2 Initial Charging Current Setting (Slow Charge)

lCheck battery type and determine the specified current using the table shown above.

lAfter starting charging, adjustment of charging current is not necessary.

130E41R(L) 330

L2/580L [EXIDE type code] 350

096 [YUASA type code] 375

096 [YUASA type code] 375

010S [YUASA type code] 360

L3/760L [EXIDE type code] 420Type Current (A)

*1.SC-6*2.SC-8

SEL756W

CON-

VERTED

SPECIFIC

GRAVITYBATTERY TYPE

28B19R(L)

34B19R(L)

L2/580L [EXIDE type code]

46B24R(L)

55B24R(L)

L3/760L [EXIDE type code]

50D23R(L)

55D23R(L)

025 [YUASA type code]

027 [YUASA type code]

65D26R(L)

80D26R(L)

063 [YUASA type code]

067 [YUASA type code]

096 [YUASA type code]

75D31R(L)

95D31R(L)

115D31R(L)

110D26R(L)

95E41R(L)

065 [YUASA type code]

075 [YUASA type code]

096L [YUASA type code]

010S [YUASA type code]

130E41R(L)

Below

1.1004.0(A) 5.0(A) 7.0(A) 8.0(A)8.

5

(A)9.

0

(A)10.0 (A) 11.0 (A)14

.0

(A)

Page 2843 of 3171

SC-10

BATTERY

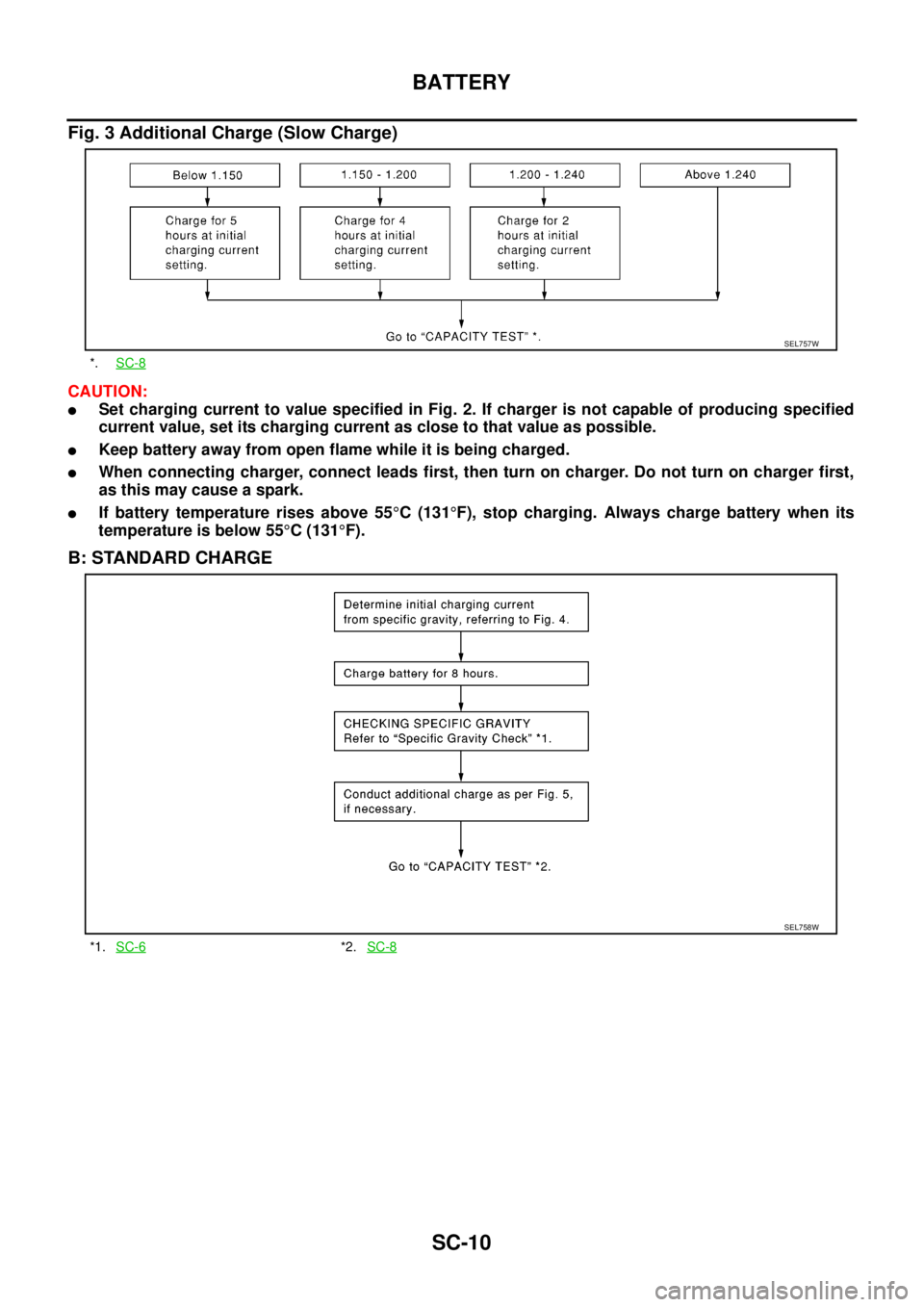

Fig. 3 Additional Charge (Slow Charge)

CAUTION:

lSet charging current to value specified in Fig. 2. If charger is not capable of producing specified

current value, set its charging current as close to that value as possible.

lKeep battery away from open flame while it is being charged.

lWhen connecting charger, connect leads first, then turn on charger. Do not turn on charger first,

as this may cause a spark.

lIf battery temperature rises above 55°C(131°F), stop charging. Always charge battery when its

temperature is below 55°C(131°F).

B: STANDARD CHARGE

*.SC-8

SEL757W

*1.SC-6*2.SC-8

SEL758W

Page 2844 of 3171

BATTERY

SC-11

C

D

E

F

G

H

I

J

L

MA

B

SC

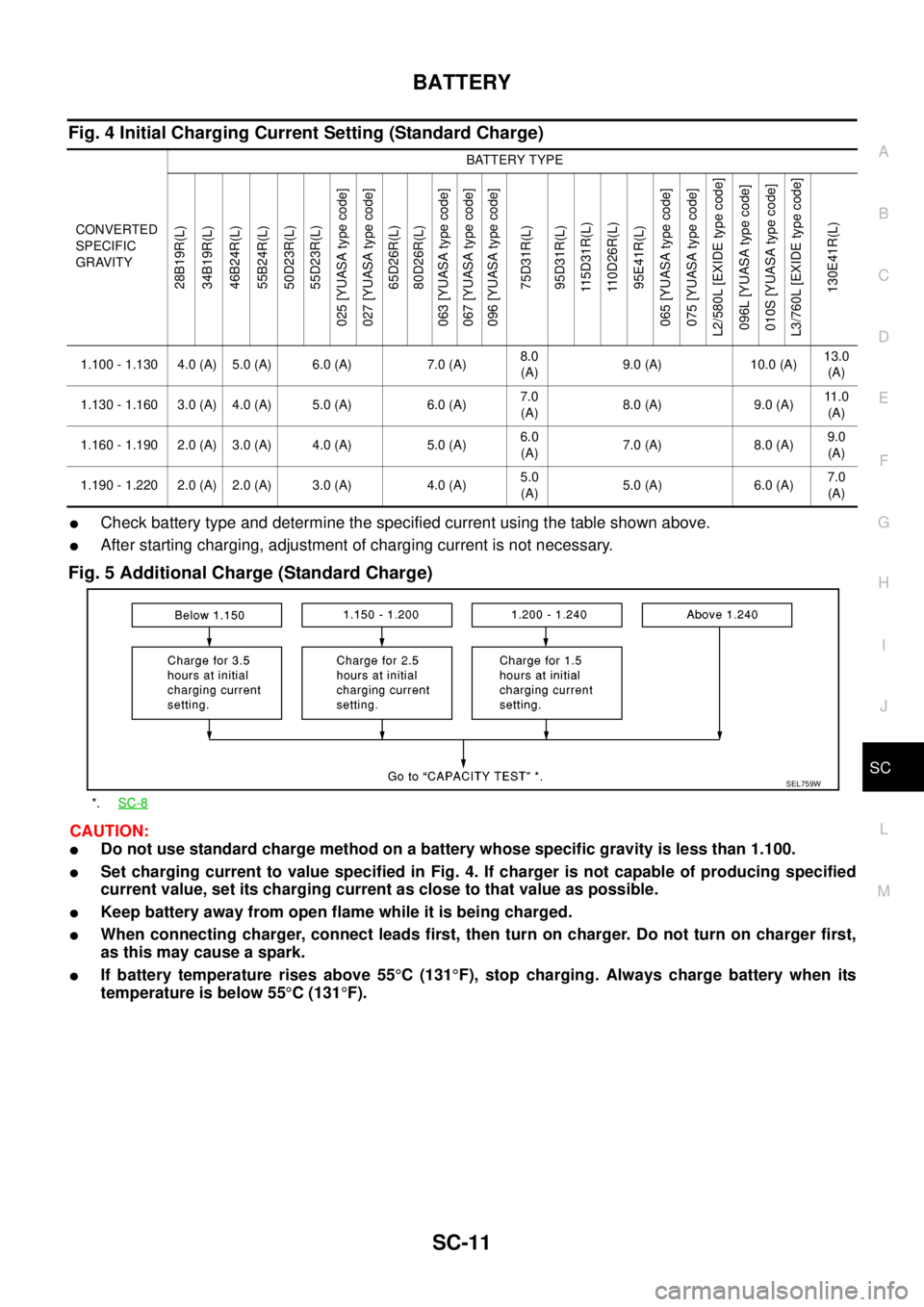

Fig. 4 Initial Charging Current Setting (Standard Charge)

lCheck battery type and determine the specified current using the table shown above.

lAfter starting charging, adjustment of charging current is not necessary.

Fig. 5 Additional Charge (Standard Charge)

CAUTION:

lDo not use standard charge method on a battery whose specific gravity is less than 1.100.

lSet charging current to value specified in Fig. 4. If charger is not capable of producing specified

current value, set its charging current as close to that value as possible.

lKeep battery away from open flame while it is being charged.

lWhen connecting charger, connect leads first, then turn on charger. Do not turn on charger first,

as this may cause a spark.

lIf battery temperature rises above 55°C(131°F), stop charging. Always charge battery when its

temperature is below 55°C(131°F).

CONVERTED

SPECIFIC

GRAVITYBATTERY TYPE

28B19R(L)

34B19R(L)

46B24R(L)

55B24R(L)

50D23R(L)

55D23R(L)

025 [YUASA type code]

027 [YUASA type code]

65D26R(L)

80D26R(L)

063 [YUASA type code]

067 [YUASA type code]

096 [YUASA type code]

75D31R(L)

95D31R(L)

115D31R(L)

110D26R(L)

95E41R(L)

065 [YUASA type code]

075 [YUASA type code]

L2/580L [EXIDE type code]

096L [YUASA type code]

010S [YUASA type code]

L3/760L [EXIDE type code]

130E41R(L)

1.100 - 1.130 4.0 (A) 5.0 (A) 6.0 (A) 7.0 (A)8.0

(A)9.0 (A) 10.0 (A)13.0

(A)

1.130 - 1.160 3.0 (A) 4.0 (A) 5.0 (A) 6.0 (A)7.0

(A)8.0(A) 9.0(A)11 . 0

(A)

1.160 - 1.190 2.0 (A) 3.0 (A) 4.0 (A) 5.0 (A)6.0

(A)7.0(A) 8.0(A)9.0

(A)

1.190 - 1.220 2.0 (A) 2.0 (A) 3.0 (A) 4.0 (A)5.0

(A)5.0(A) 6.0(A)7.0

(A)

*.SC-8

SEL759W

Page 2845 of 3171

SC-12

BATTERY

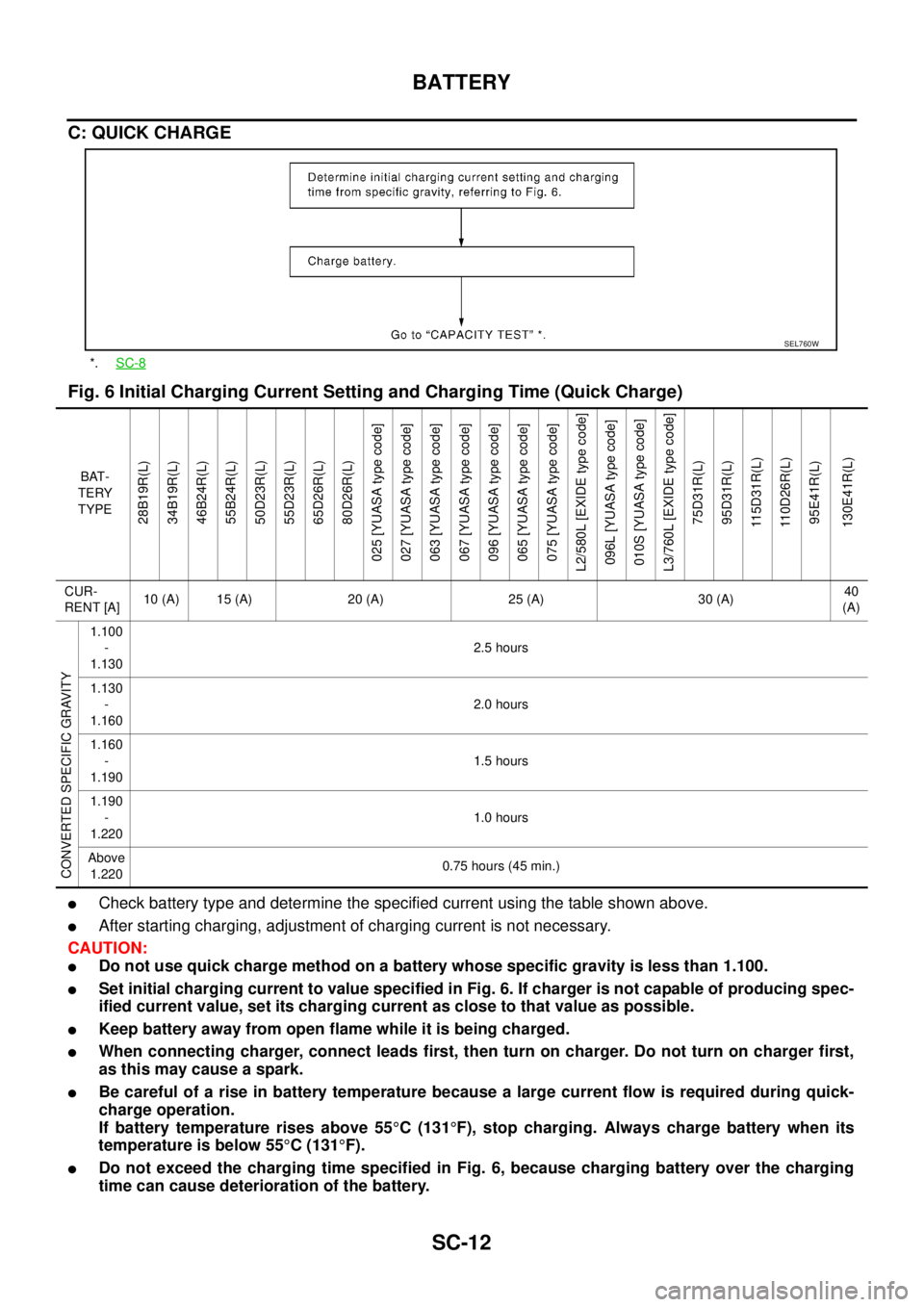

C: QUICK CHARGE

Fig. 6 Initial Charging Current Setting and Charging Time (Quick Charge)

lCheck battery type and determine the specified current using the table shown above.

lAfter starting charging, adjustment of charging current is not necessary.

CAUTION:

lDo not use quick charge method on a battery whose specific gravity is less than 1.100.

lSet initial charging current to value specified in Fig. 6. If charger is not capable of producing spec-

ified current value, set its charging current as close to that value as possible.

lKeep battery away from open flame while it is being charged.

lWhen connecting charger, connect leads first, then turn on charger. Do not turn on charger first,

as this may cause a spark.

lBe careful of a rise in battery temperature because a large current flow is required during quick-

charge operation.

If battery temperature rises above 55°C(131°F), stop charging. Always charge battery when its

temperature is below 55°C(131°F).

lDo not exceed the charging time specified in Fig. 6, because charging battery over the charging

time can cause deterioration of the battery.

*.SC-8

SEL760W

BAT-

TERY

TYPE

28B19R(L)

34B19R(L)

46B24R(L)

55B24R(L)

50D23R(L)

55D23R(L)

65D26R(L)

80D26R(L)

025 [YUASA type code]

027 [YUASA type code]

063 [YUASA type code]

067 [YUASA type code]

096 [YUASA type code]

065 [YUASA type code]

075 [YUASA type code]

L2/580L [EXIDE type code]

096L [YUASA type code]

010S [YUASA type code]

L3/760L [EXIDE type code]

75D31R(L)

95D31R(L)

115D31R(L)

110D26R(L)

95E41R(L)

130E41R(L)

CUR-

RENT [A]10 (A) 15 (A) 20 (A) 25 (A) 30 (A)40

(A)

CONVERTED SPECIFIC GRAVITY

1.100

-

1.1302.5 hours

1.130

-

1.1602.0 hours

1.160

-

1.1901.5 hours

1.190

-

1.2201.0 hours

Above

1.2200.75 hours (45 min.)