fuse NISSAN NAVARA 2005 Repair Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 1185 of 3171

DTC P0563 BATTERY VOLTAGE

EC-205

C

D

E

F

G

H

I

J

K

L

MA

EC

7.CHECK ELECTRICAL PARTS DAMAGE

Check the following for damage.

lWiring harness and harness connectors for burn

lFuses for short

OK or NG

OK >>INSPECTION END

NG >> Repair or replace malfunctioning part.

Page 1302 of 3171

EC-322

HEAT UP SWITCH

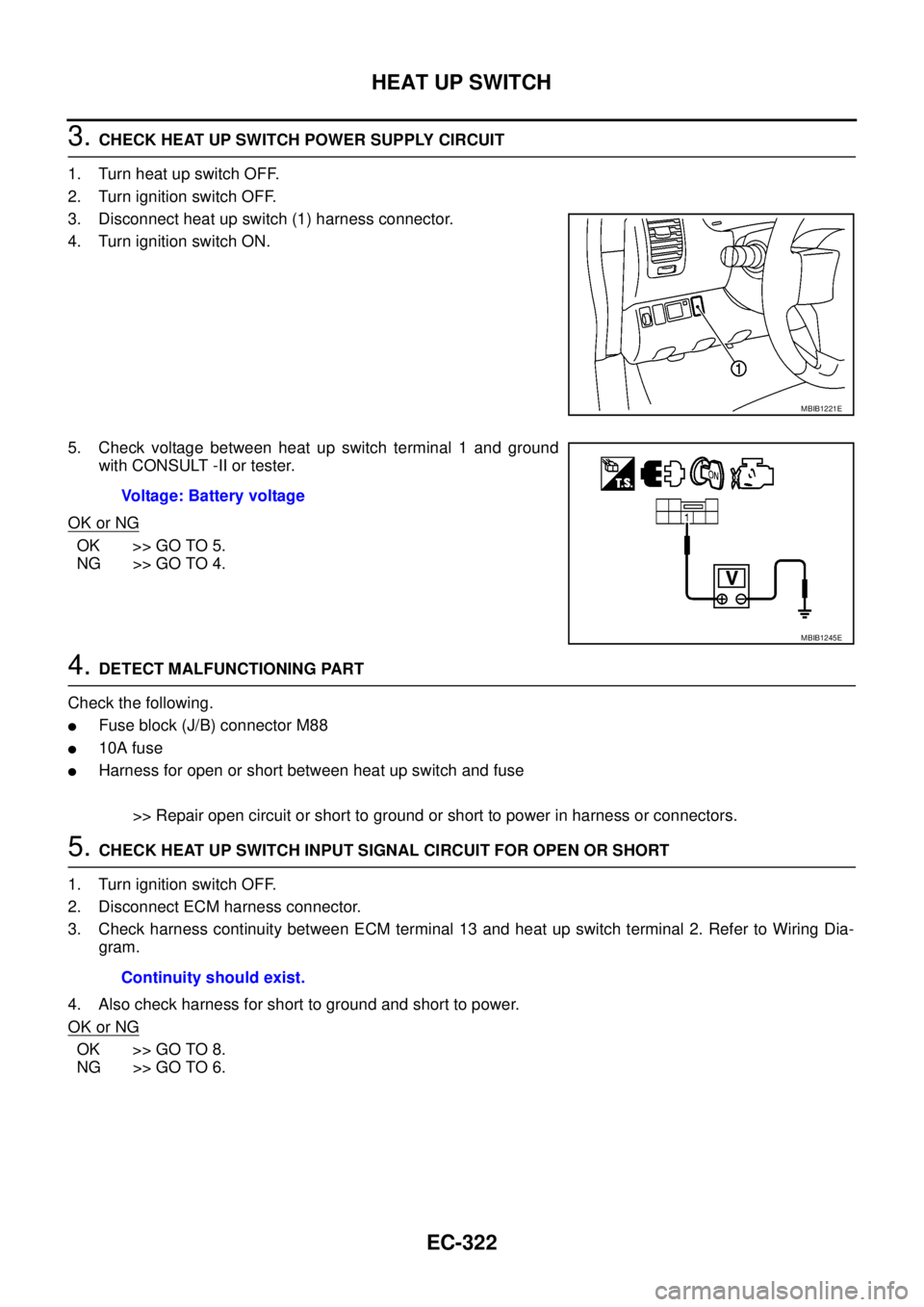

3.CHECK HEAT UP SWITCH POWER SUPPLY CIRCUIT

1. Turn heat up switch OFF.

2. Turn ignition switch OFF.

3. Disconnect heat up switch (1) harness connector.

4. Turn ignition switch ON.

5. Check voltage between heat up switch terminal 1 and ground

with CONSULT -II or tester.

OK or NG

OK >> GO TO 5.

NG >> GO TO 4.

4.DETECT MALFUNCTIONING PART

Check the following.

lFuse block (J/B) connector M88

l10A fuse

lHarness for open or short between heat up switch and fuse

>> Repair open circuit or short to ground or short to power in harness or connectors.

5.CHECK HEAT UP SWITCH INPUT SIGNAL CIRCUIT FOR OPEN OR SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM terminal 13 and heat up switch terminal 2. Refer to Wiring Dia-

gram.

4. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 8.

NG >> GO TO 6.

MBIB1221E

Voltage: Battery voltage

MBIB1245E

Continuity should exist.

Page 1314 of 3171

EC-334

BRAKE SWITCH

4.DETECT MALFUNCTIONING PART

Check the following.

lFuse block (J/B) connector E103

l10A fuse

lHarness for open or short between stop lamp switch and battery

>> Repair open circuit or short to ground or short to power in harness or connectors.

5.CHECK STOP LAMP SWITCH INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 100 and stop lamp switch terminal 2.

Refer to Wiring Diagram.

3. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 6.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

6.CHECK STOP LAMP SWITCH

Refer toEC-341, "

Component Inspection".

OK or NG

OK >> GO TO 11.

NG >> Replace stop lamp switch.

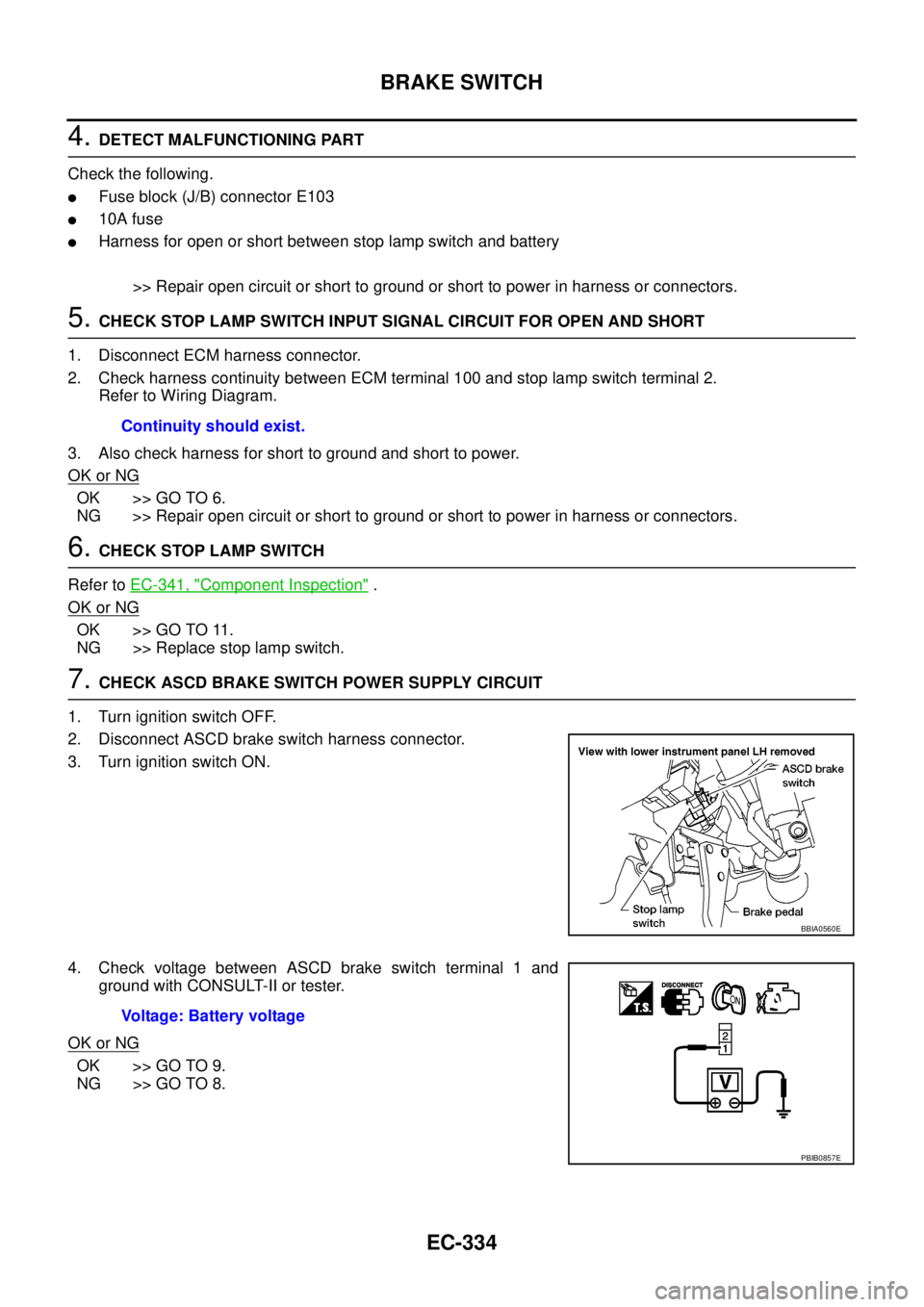

7.CHECK ASCD BRAKE SWITCH POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ASCD brake switch harness connector.

3. Turn ignition switch ON.

4. Check voltage between ASCD brake switch terminal 1 and

ground with CONSULT-II or tester.

OK or NG

OK >> GO TO 9.

NG >> GO TO 8.Continuity should exist.

BBIA0560E

Voltage: Battery voltage

PBIB0857E

Page 1315 of 3171

BRAKE SWITCH

EC-335

C

D

E

F

G

H

I

J

K

L

MA

EC

8.DETECT MALFUNCTIONING PART

Check the following.

lFuse block (J/B) connector E103

l10A fuse

lHarness for open or short between ASCD brake switch and fuse

>> Repair open circuit or short to ground or short to power in harness or connectors.

9.CHECK ASCD BRAKE SWITCH INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 101 and ASCD brake lamp switch terminal 2.

Refer to Wiring Diagram.

3. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 10.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

10.CHECK ASCD BRAKE SWITCH

Refer toEC-341, "

Component Inspection"

OK or NG

OK >> GO TO 11.

NG >> Replace ASCD brake switch.

11 .CHECK INTERMITTENT INCIDENT

Refer toEC-70, "

TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT".

>>INSPECTION END Continuity should exist.

Page 1318 of 3171

EC-338

BRAKE SWITCH

4.DETECT MALFUNCTIONING PART

Check the following.

lFuse block (J/B) connector E103

l10A fuse

lHarness for open or short between stop lamp switch and battery

>> Repair open circuit or short to ground or short to power in harness or connectors.

5.CHECK STOP LAMP SWITCH INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 100 and stop lamp switch terminal 1.

Refer to Wiring Diagram.

3. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 6.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

6.CHECK STOP LAMP SWITCH

Refer toEC-341, "

Component Inspection".

OK or NG

OK >> GO TO 14.

NG >> Replace stop lamp switch.

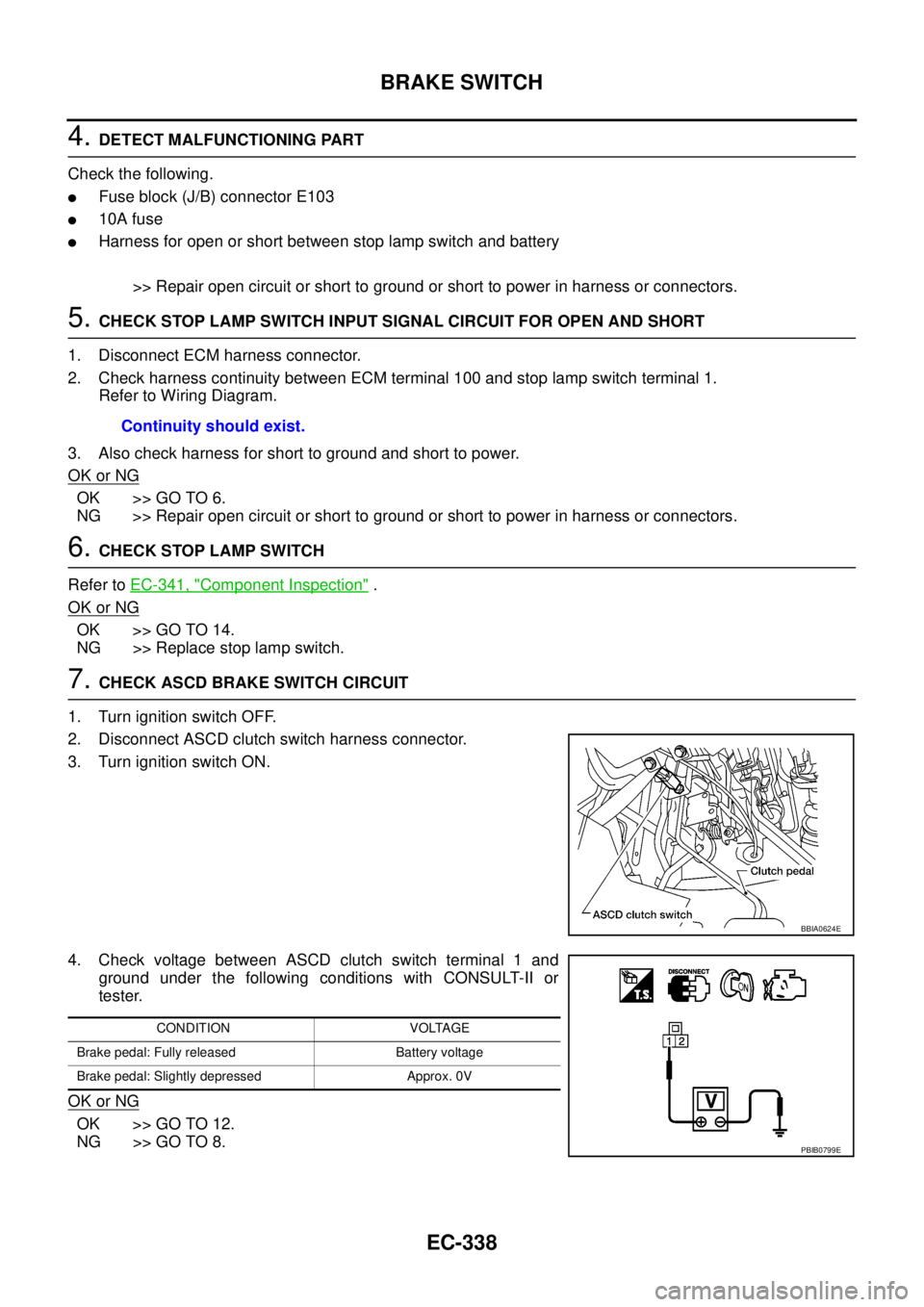

7.CHECK ASCD BRAKE SWITCH CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ASCD clutch switch harness connector.

3. Turn ignition switch ON.

4. Check voltage between ASCD clutch switch terminal 1 and

ground under the following conditions with CONSULT-II or

tester.

OK or NG

OK >> GO TO 12.

NG >> GO TO 8.Continuity should exist.

BBIA0624E

CONDITION VOLTAGE

Brake pedal: Fully released Battery voltage

Brake pedal: Slightly depressed Approx. 0V

PBIB0799E

Page 1319 of 3171

BRAKE SWITCH

EC-339

C

D

E

F

G

H

I

J

K

L

MA

EC

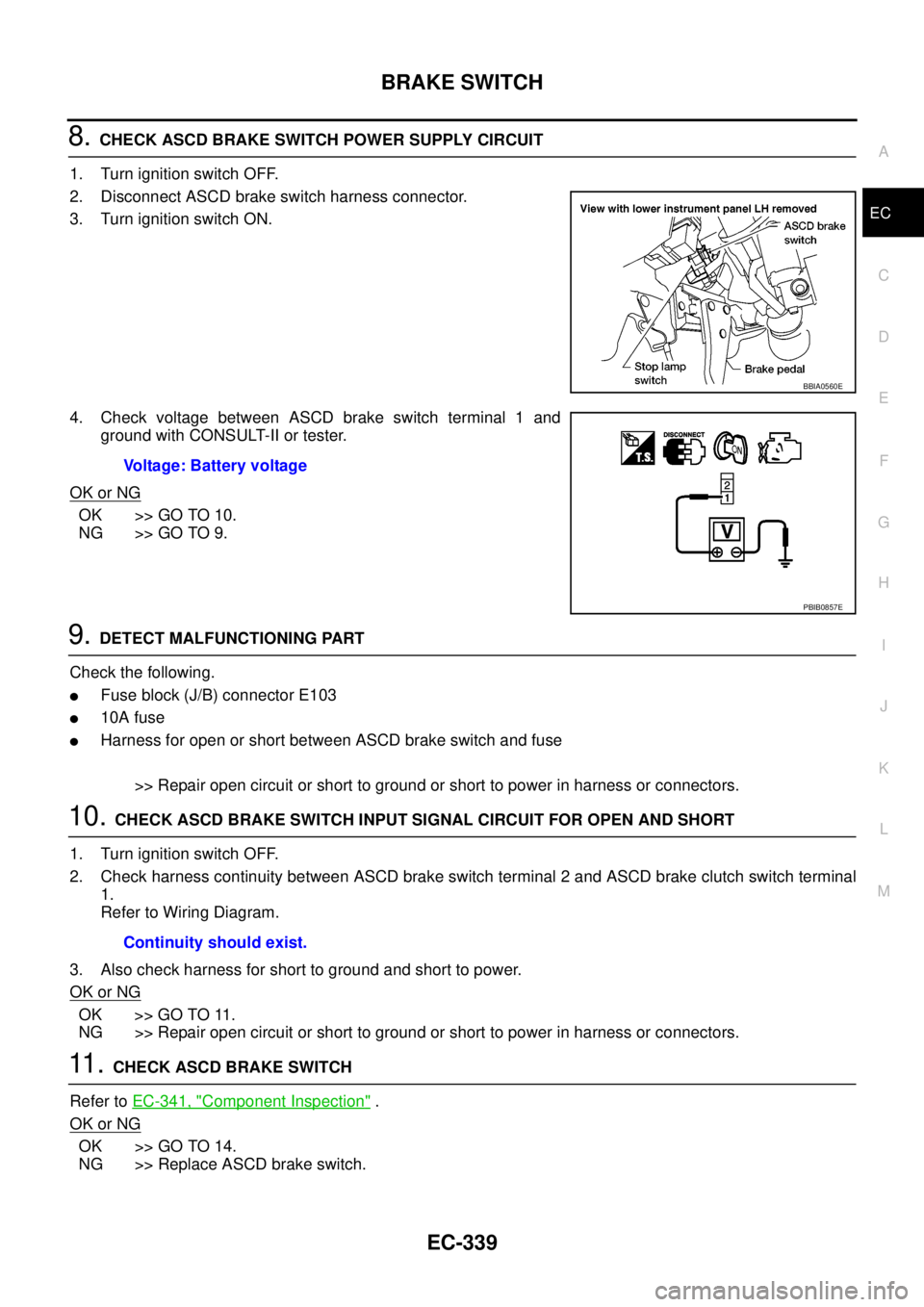

8.CHECK ASCD BRAKE SWITCH POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ASCD brake switch harness connector.

3. Turn ignition switch ON.

4. Check voltage between ASCD brake switch terminal 1 and

ground with CONSULT-II or tester.

OK or NG

OK >> GO TO 10.

NG >> GO TO 9.

9.DETECT MALFUNCTIONING PART

Check the following.

lFuse block (J/B) connector E103

l10A fuse

lHarness for open or short between ASCD brake switch and fuse

>> Repair open circuit or short to ground or short to power in harness or connectors.

10.CHECK ASCD BRAKE SWITCH INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Check harness continuity between ASCD brake switch terminal 2 and ASCD brake clutch switch terminal

1.

Refer to Wiring Diagram.

3. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 11.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

11 .CHECK ASCD BRAKE SWITCH

Refer toEC-341, "

Component Inspection".

OK or NG

OK >> GO TO 14.

NG >> Replace ASCD brake switch.

BBIA0560E

Voltage: Battery voltage

PBIB0857E

Continuity should exist.

Page 1329 of 3171

START SIGNAL

EC-349

C

D

E

F

G

H

I

J

K

L

MA

EC

Diagnostic ProcedureEBS01KMX

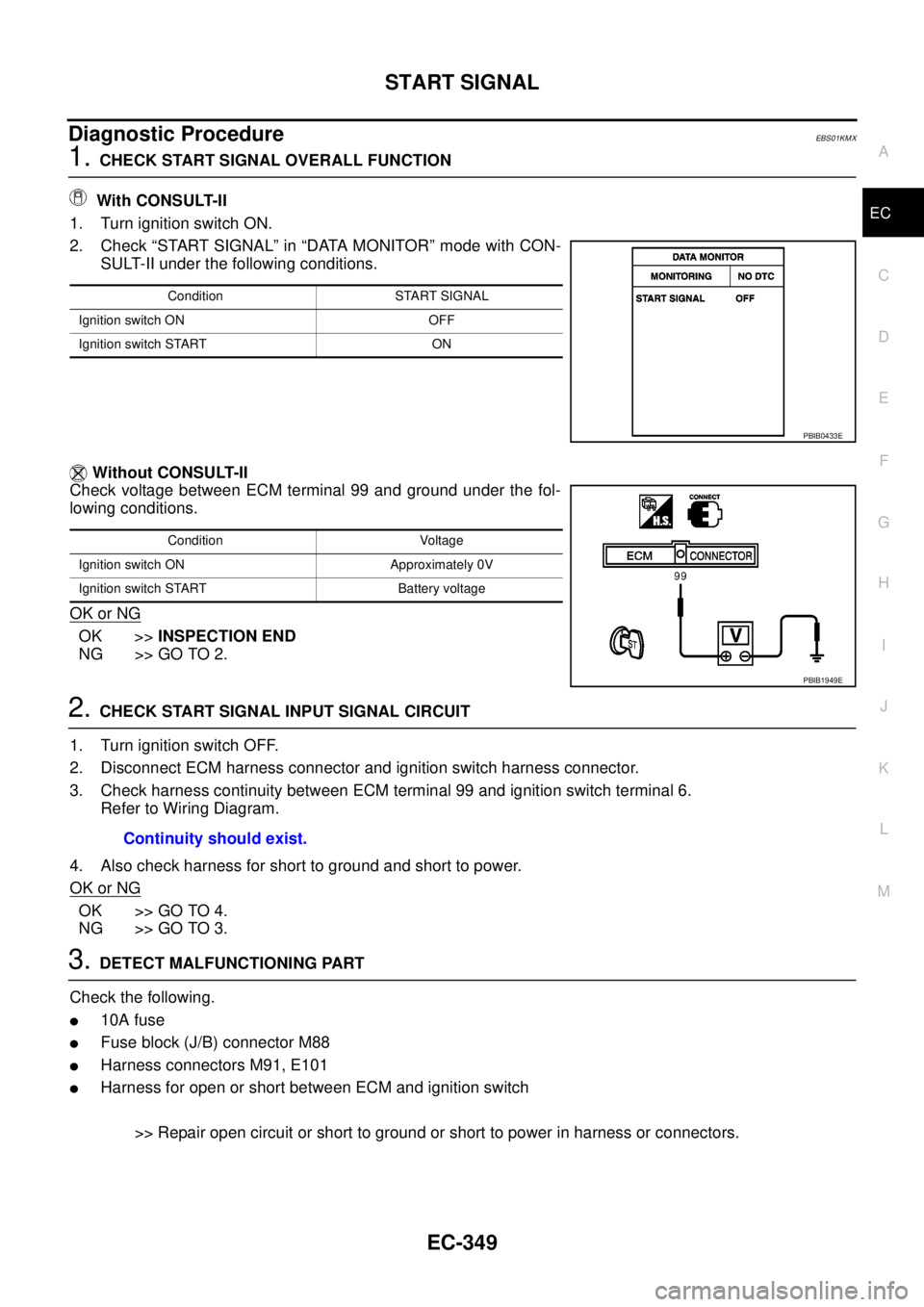

1.CHECK START SIGNAL OVERALL FUNCTION

With CONSULT-II

1. Turn ignition switch ON.

2. Check “START SIGNAL” in “DATA MONITOR” mode with CON-

SULT-II under the following conditions.

Without CONSULT-II

Check voltage between ECM terminal 99 and ground under the fol-

lowing conditions.

OK or NG

OK >>INSPECTION END

NG >> GO TO 2.

2.CHECK START SIGNAL INPUT SIGNAL CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector and ignition switch harness connector.

3. Check harness continuity between ECM terminal 99 and ignition switch terminal 6.

Refer to Wiring Diagram.

4. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 4.

NG >> GO TO 3.

3.DETECT MALFUNCTIONING PART

Check the following.

l10A fuse

lFuse block (J/B) connector M88

lHarness connectors M91, E101

lHarness for open or short between ECM and ignition switch

>> Repair open circuit or short to ground or short to power in harness or connectors.

Condition START SIGNAL

Ignition switch ON OFF

Ignition switch START ON

PBIB0433E

Condition Voltage

Ignition switch ON Approximately 0V

Ignition switch START Battery voltage

PBIB1949E

Continuity should exist.

Page 1452 of 3171

EM-70

OIL SEAL

OIL SEAL

PFP:12279

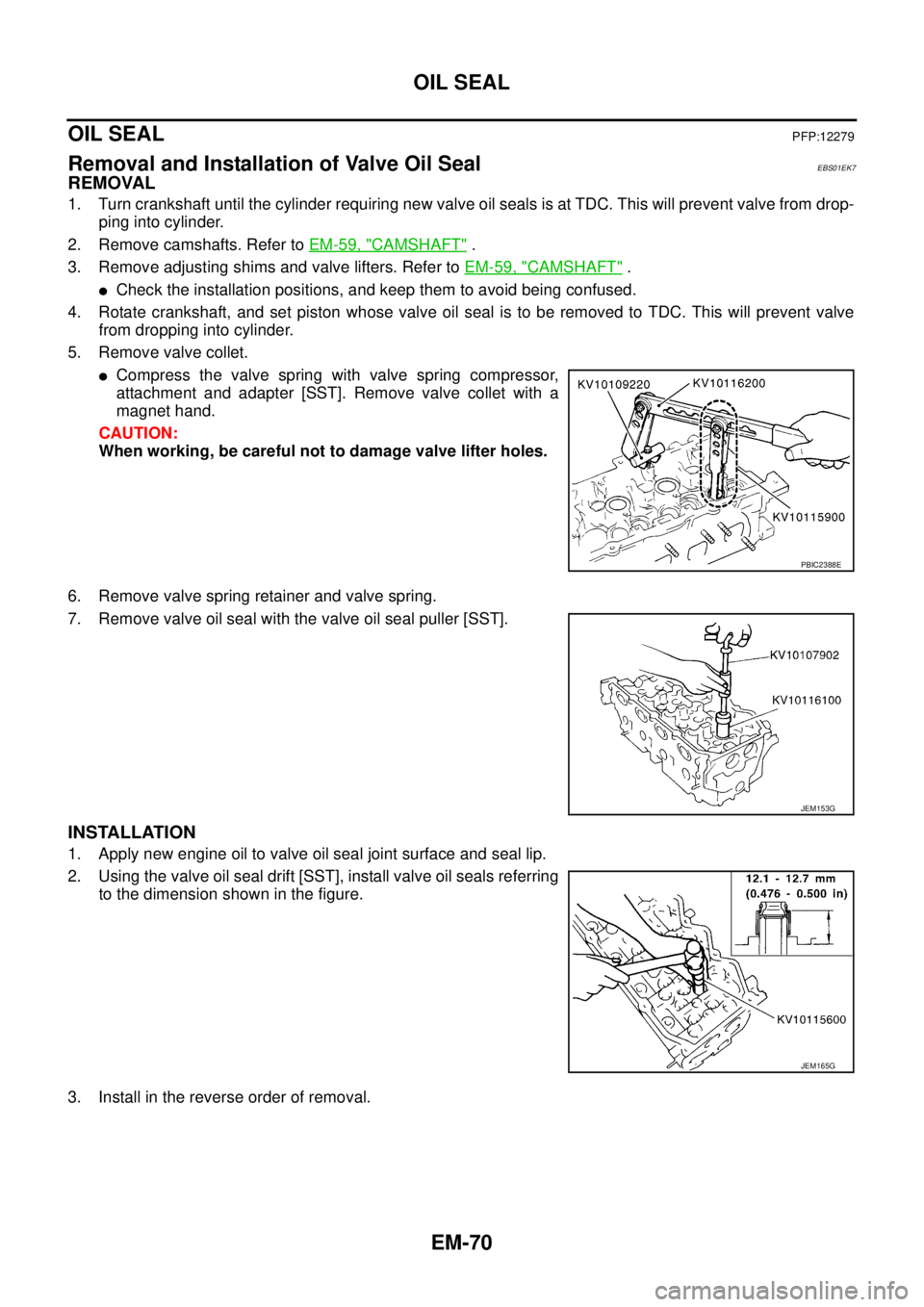

Removal and Installation of Valve Oil SealEBS01EK7

REMOVAL

1. Turn crankshaft until the cylinder requiring new valve oil seals is at TDC. This will prevent valve from drop-

ping into cylinder.

2. Remove camshafts. Refer toEM-59, "

CAMSHAFT".

3. Remove adjusting shims and valve lifters. Refer toEM-59, "

CAMSHAFT".

lCheck the installation positions, and keep them to avoid being confused.

4. Rotate crankshaft, and set piston whose valve oil seal is to be removed to TDC. This will prevent valve

from dropping into cylinder.

5. Remove valve collet.

lCompress the valve spring with valve spring compressor,

attachment and adapter [SST]. Remove valve collet with a

magnet hand.

CAUTION:

When working, be careful not to damage valve lifter holes.

6. Remove valve spring retainer and valve spring.

7. Remove valve oil seal with the valve oil seal puller [SST].

INSTALLATION

1. Apply new engine oil to valve oil seal joint surface and seal lip.

2. Using the valve oil seal drift [SST], install valve oil seals referring

to the dimension shown in the figure.

3. Install in the reverse order of removal.

PBIC2388E

JEM153G

JEM165G

Page 1474 of 3171

EM-92

CYLINDER HEAD

CYLINDER HEAD

PFP:11041

On-Vehicle ServiceEBS01E6A

CHECKING COMPRESSION PRESSURE

1. Warm up engine thoroughly. Then, stop it.

2. Using CONSULT-II, make sure no error codes are indicated for self-diagnosis items. Refer toEC-38,

"Basic Inspection".

lDo not disconnect CONSULT-II until the end of this operation; it will be used to check engine rpm and

for error detection at the end of this operation.

3. Disconnect the battery cable from the negative terminal.

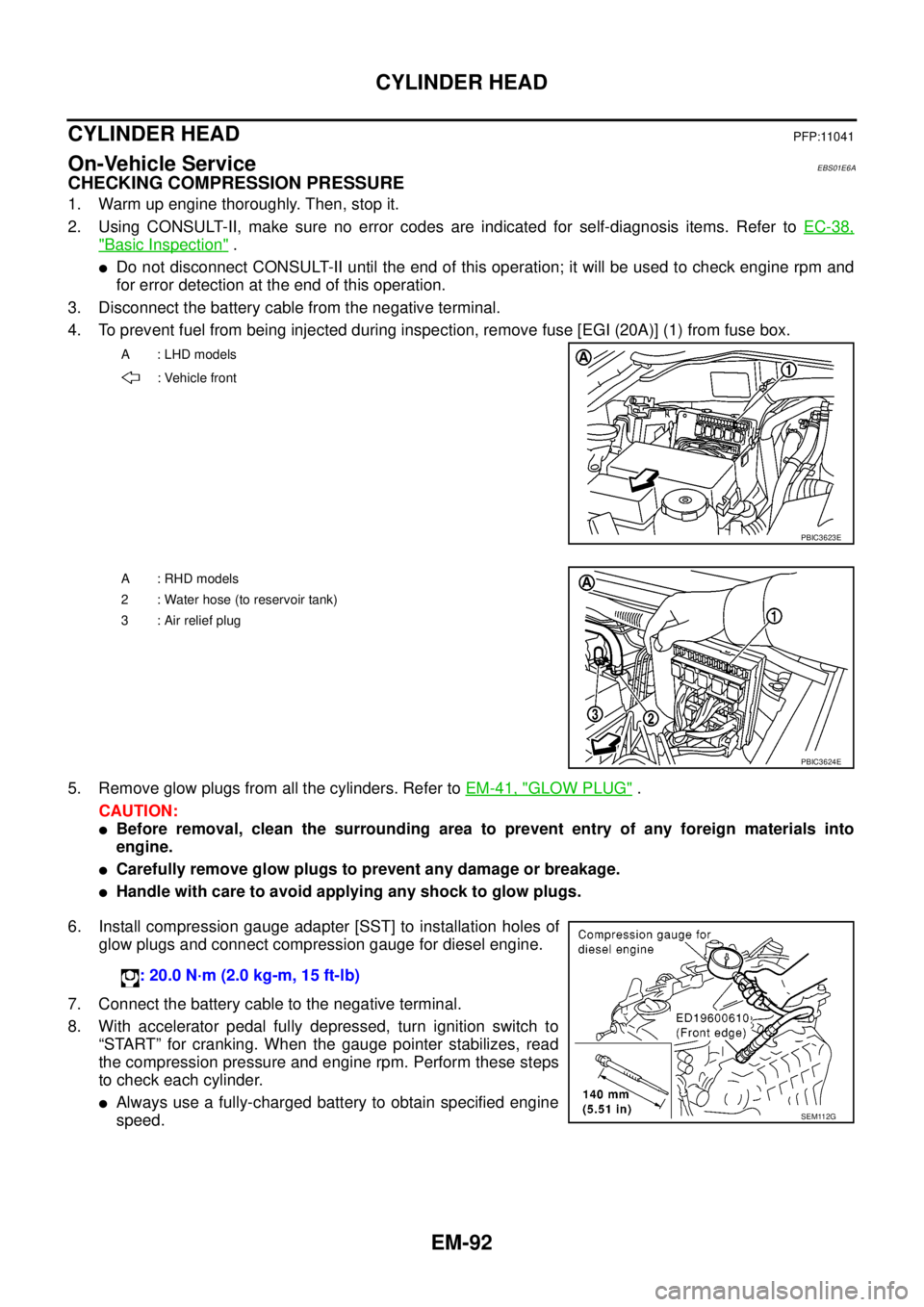

4. To prevent fuel from being injected during inspection, remove fuse [EGI (20A)] (1) from fuse box.

5. Remove glow plugs from all the cylinders. Refer toEM-41, "

GLOW PLUG".

CAUTION:

lBefore removal, clean the surrounding area to prevent entry of any foreign materials into

engine.

lCarefully remove glow plugs to prevent any damage or breakage.

lHandle with care to avoid applying any shock to glow plugs.

6. Install compression gauge adapter [SST] to installation holes of

glow plugs and connect compression gauge for diesel engine.

7. Connect the battery cable to the negative terminal.

8. With accelerator pedal fully depressed, turn ignition switch to

“START” for cranking. When the gauge pointer stabilizes, read

the compression pressure and engine rpm. Perform these steps

to check each cylinder.

lAlways use a fully-charged battery to obtain specified engine

speed.

A : LHD models

: Vehicle front

PBIC3623E

A : RHD models

2 : Water hose (to reservoir tank)

3:Airreliefplug

PBIC3624E

: 20.0 N·m (2.0 kg-m, 15 ft-lb)

SEM112G

Page 1475 of 3171

CYLINDER HEAD

EM-93

C

D

E

F

G

H

I

J

K

L

MA

EM

Compression pressure

Unit: kPa (bar, kg/cm2, psi)/rpm

lWhen engine rpm is out of the specified range, check the specific gravity of battery liquid. Measure

again under corrected conditions.

lIf engine rpm exceeds the limit, check valve clearance and combustion chamber components (valves,

valve seats, cylinder head gaskets, piston rings, pistons, cylinder bores, cylinder block upper and lower

surfaces) and measure again.

lIf compression pressure is low in some cylinders, apply engine oil from glow plug installation hole. Then

check pressure again.

–If compression pressure becomes normal after applying engine oil, piston ring may be worn or dam-

aged. Check piston ring for malfunction. If any, replace piston ring.

–If compression pressure is still low after applying engine oil, valve may be malfunctioning. Check valve

for malfunction. If contact malfunction is found, replace valve or valve seat.

lIf compression pressure in adjacent two cylinders is low after applying engine oil, pressure may be

leaking from gasket. In this case, replace cylinder head gasket.

9. Complete this operation as follows:

a. Turn the ignition switch to “OFF”.

b. Disconnect the battery cable from the negative terminal.

c. Install glow plug and install all the parts removed in step 4.

d. Install fuse [EGI (20A)].

e. Connect the battery cable to the negative terminal.

f. Using CONSULT-II make sure no DTC is indicated for items of self-diagnosis.

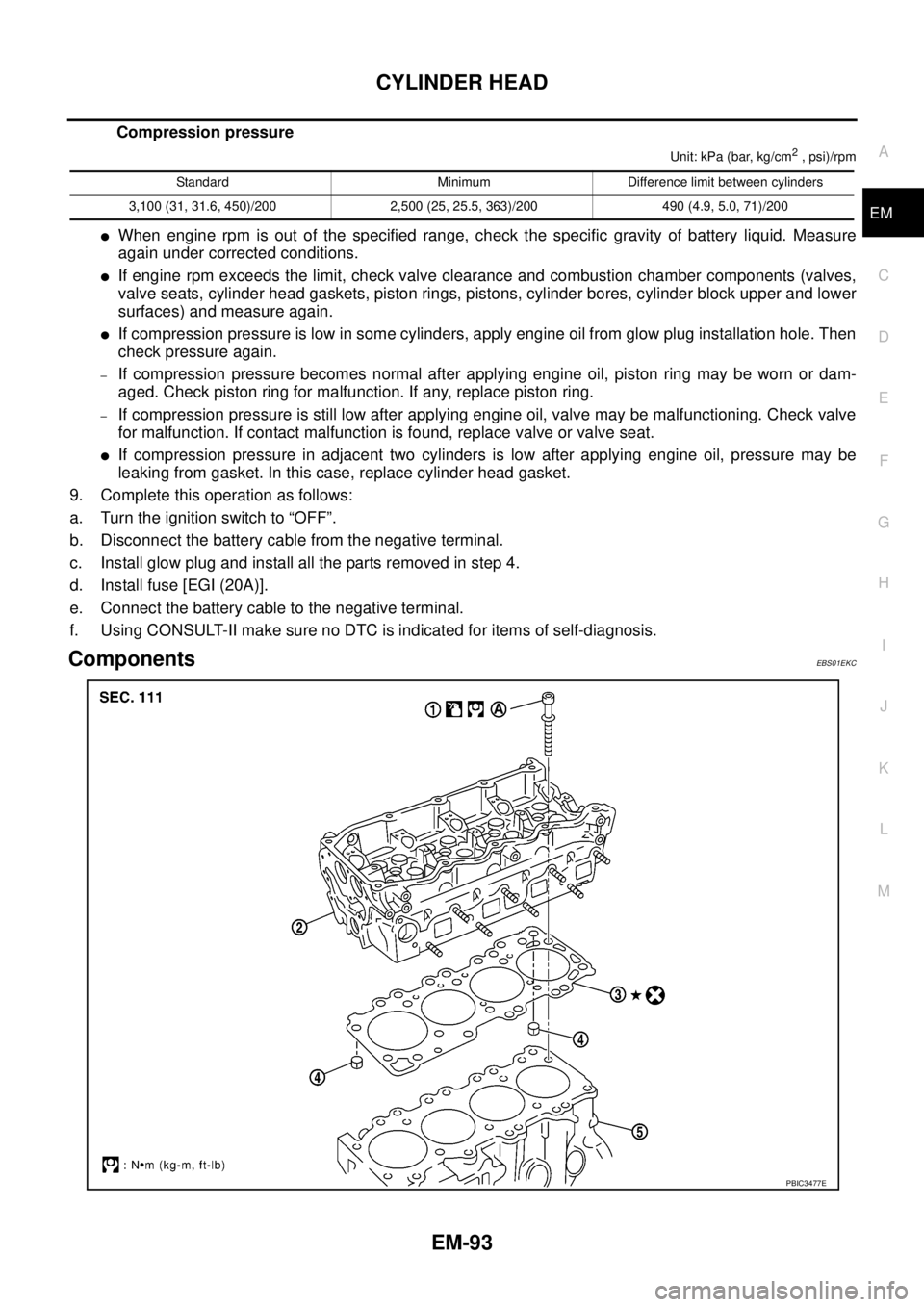

ComponentsEBS01EKC

Standard Minimum Difference limit between cylinders

3,100 (31, 31.6, 450)/200 2,500 (25, 25.5, 363)/200 490 (4.9, 5.0, 71)/200

PBIC3477E