NISSAN NAVARA 2005 Repair Workshop Manual

Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 971 of 3171

WARNING CHIME

DI-61

C

D

E

F

G

H

I

J

L

MA

B

DI

SYMPTOM CHART

Meter Buzzer Circuit InspectionEKS00L9L

1.CHECK CHIME OPERATION

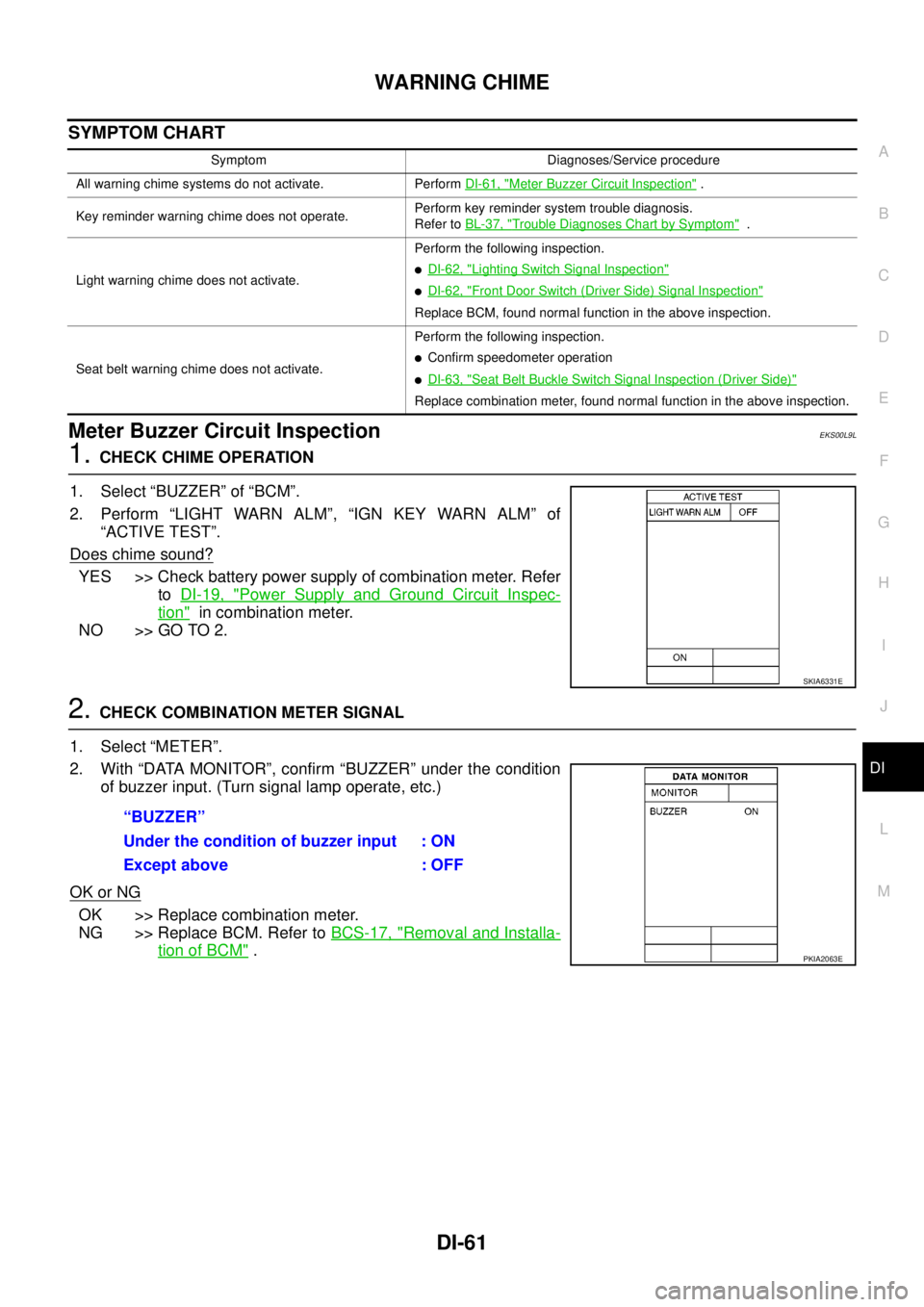

1. Select “BUZZER” of “BCM”.

2. Perform “LIGHT WARN ALM”, “IGN KEY WARN ALM” of

“ACTIVE TEST”.

Does chime sound?

YES >> Check battery power supply of combination meter. Refer

toDI-19, "

Power Supply and Ground Circuit Inspec-

tion"in combination meter.

NO >> GO TO 2.

2.CHECK COMBINATION METER SIGNAL

1. Select “METER”.

2. With “DATA MONITOR”, confirm “BUZZER” under the condition

of buzzer input. (Turn signal lamp operate, etc.)

OK or NG

OK >> Replace combination meter.

NG >> Replace BCM. Refer toBCS-17, "

Removal and Installa-

tion of BCM".

Symptom Diagnoses/Service procedure

All warning chime systems do not activate. PerformDI-61, "

Meter Buzzer Circuit Inspection".

Key reminder warning chime does not operate.Perform key reminder system trouble diagnosis.

Refer toBL-37, "

Trouble Diagnoses Chart by Symptom".

Light warning chime does not activate.Perform the following inspection.

lDI-62, "Lighting Switch Signal Inspection"

lDI-62, "Front Door Switch (Driver Side) Signal Inspection"

Replace BCM, found normal function in the above inspection.

Seat belt warning chime does not activate.Perform the following inspection.

lConfirm speedometer operation

lDI-63, "Seat Belt Buckle Switch Signal Inspection (Driver Side)"

Replace combination meter, found normal function in the above inspection.

SKIA6331E

“BUZZER”

Under the condition of buzzer input : ON

Except above : OFF

PKIA2063E

Page 972 of 3171

DI-62

WARNING CHIME

Lighting Switch Signal Inspection

EKS00L9O

1.CHECK BCM INPUT SIGNAL

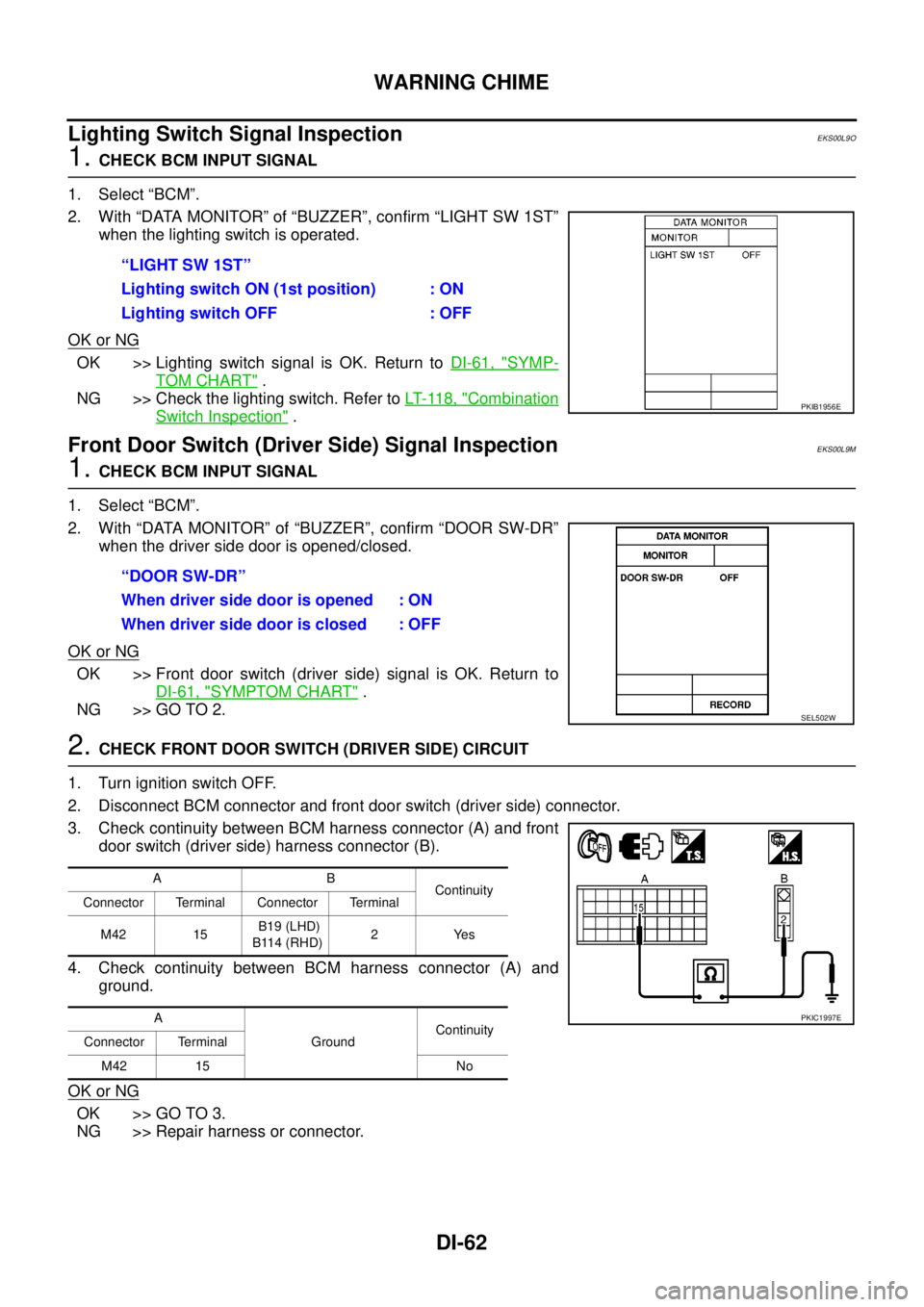

1. Select “BCM”.

2. With “DATA MONITOR” of “BUZZER”, confirm “LIGHT SW 1ST”

whenthelightingswitchisoperated.

OK or NG

OK >> Lighting switch signal is OK. Return toDI-61, "SYMP-

TOM CHART".

NG >> Check the lighting switch. Refer toLT- 11 8 , "

Combination

Switch Inspection".

Front Door Switch (Driver Side) Signal InspectionEKS00L9M

1.CHECK BCM INPUT SIGNAL

1. Select “BCM”.

2. With “DATA MONITOR” of “BUZZER”, confirm “DOOR SW-DR”

when the driver side door is opened/closed.

OK or NG

OK >> Front door switch (driver side) signal is OK. Return to

DI-61, "

SYMPTOM CHART".

NG >> GO TO 2.

2.CHECK FRONT DOOR SWITCH (DRIVER SIDE) CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM connector and front door switch (driver side) connector.

3. Check continuity between BCM harness connector (A) and front

door switch (driver side) harness connector (B).

4. Check continuity between BCM harness connector (A) and

ground.

OK or NG

OK >> GO TO 3.

NG >> Repair harness or connector.“LIGHT SW 1ST”

Lighting switch ON (1st position) : ON

Lighting switch OFF : OFF

PKIB1956E

“DOOR SW-DR”

When driver side door is opened : ON

When driver side door is closed : OFF

SEL502W

AB

Continuity

Connector Terminal Connector Terminal

M42 15B19 (LHD)

B114 (RHD)2Yes

A

GroundContinuity

Connector Terminal

M42 15 No

PKIC1997E

Page 973 of 3171

WARNING CHIME

DI-63

C

D

E

F

G

H

I

J

L

MA

B

DI

3.CHECK FRONT DOOR SWITCH (DRIVER SIDE)

Check front door switch (driver side). Refer toDI-64, "

FRONT DOOR SWITCH (DRIVER SIDE)".

OK or NG

OK >> Replace BCM. Refer toBCS-17, "Removal and Installation of BCM".

NG >> Replace front door switch (driver side).

Seat Belt Buckle Switch Signal Inspection (Driver Side)EKS00L9P

1.CHECK OPERATION OF SEAT BELT WARNING LAMP

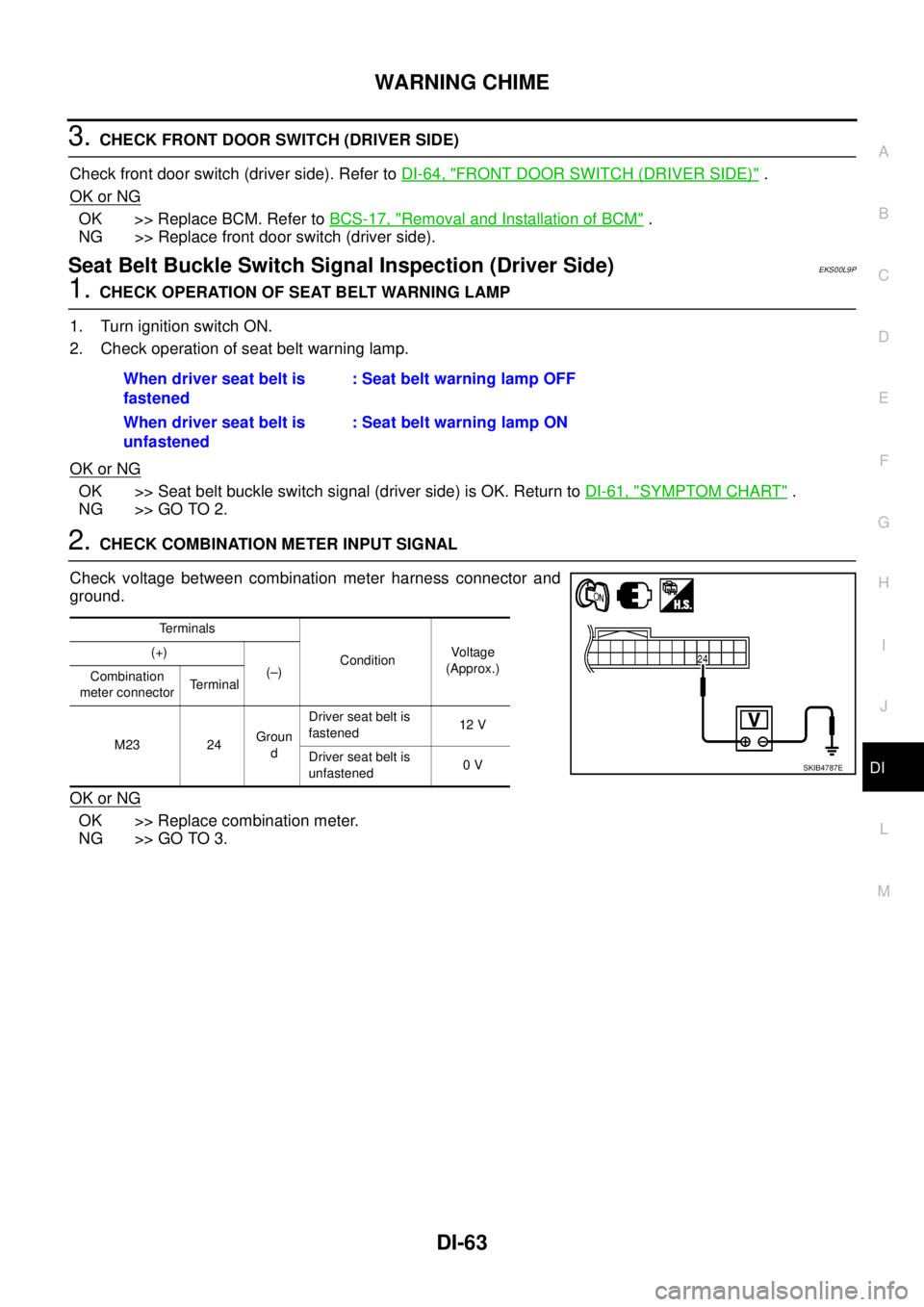

1. Turn ignition switch ON.

2. Check operation of seat belt warning lamp.

OK or NG

OK >> Seat belt buckle switch signal (driver side) is OK. Return toDI-61, "SYMPTOM CHART".

NG >> GO TO 2.

2.CHECK COMBINATION METER INPUT SIGNAL

Check voltage between combination meter harness connector and

ground.

OK or NG

OK >> Replace combination meter.

NG >> GO TO 3.When driver seat belt is

fastened: Seat belt warning lamp OFF

When driver seat belt is

unfastened: Seat belt warning lamp ON

Terminals

ConditionVoltag e

(Approx.) (+)

(–)

Combination

meter connectorTerminal

M23 24Groun

dDriver seat belt is

fastened12 V

Driver seat belt is

unfastened0V

SKIB4787E

Page 974 of 3171

DI-64

WARNING CHIME

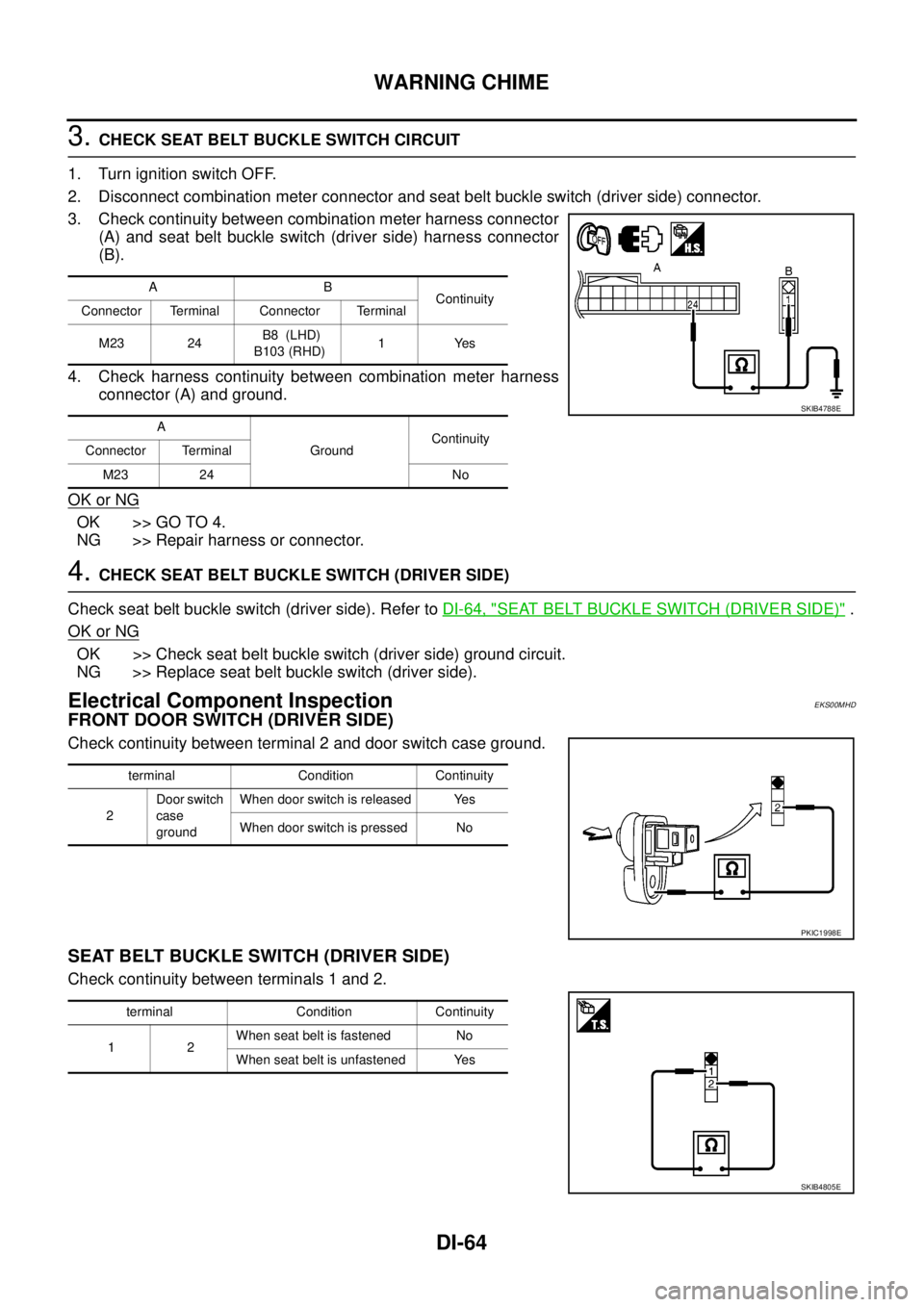

3.CHECK SEAT BELT BUCKLE SWITCH CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect combination meter connector and seat belt buckle switch (driver side) connector.

3. Check continuity between combination meter harness connector

(A) and seat belt buckle switch (driver side) harness connector

(B).

4. Check harness continuity between combination meter harness

connector (A) and ground.

OK or NG

OK >> GO TO 4.

NG >> Repair harness or connector.

4.CHECK SEAT BELT BUCKLE SWITCH (DRIVER SIDE)

Check seat belt buckle switch (driver side). Refer toDI-64, "

SEAT BELT BUCKLE SWITCH (DRIVER SIDE)".

OK or NG

OK >> Check seat belt buckle switch (driver side) ground circuit.

NG >> Replace seat belt buckle switch (driver side).

Electrical Component InspectionEKS00MHD

FRONT DOOR SWITCH (DRIVER SIDE)

Check continuity between terminal 2 and door switch case ground.

SEAT BELT BUCKLE SWITCH (DRIVER SIDE)

Check continuity between terminals 1 and 2.

AB

Continuity

Connector Terminal Connector Terminal

M23 24B8 (LHD)

B103 (RHD)1Yes

A

GroundContinuity

Connector Terminal

M23 24 No

SKIB4788E

terminal Condition Continuity

2Door switch

case

groundWhen door switch is released Yes

When door switch is pressed No

PKIC1998E

terminal Condition Continuity

12When seat belt is fastened No

When seat belt is unfastened Yes

SKIB4805E

Page 975 of 3171

CAN COMMUNICATION

DI-65

C

D

E

F

G

H

I

J

L

MA

B

DI

CAN COMMUNICATIONPFP:23710

System DescriptionEKS00MHE

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent error detection ability. Many elec-

tronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CAN communication, control units are connected with 2

communication lines (CAN H line, CAN L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only.

CAN Communication UnitEKS00MHF

Refer toLAN-30, "CAN Communication Unit"in “LAN SYSTEM”.

Page 976 of 3171

DI-66

COMPASS

COMPASS

PFP:24835

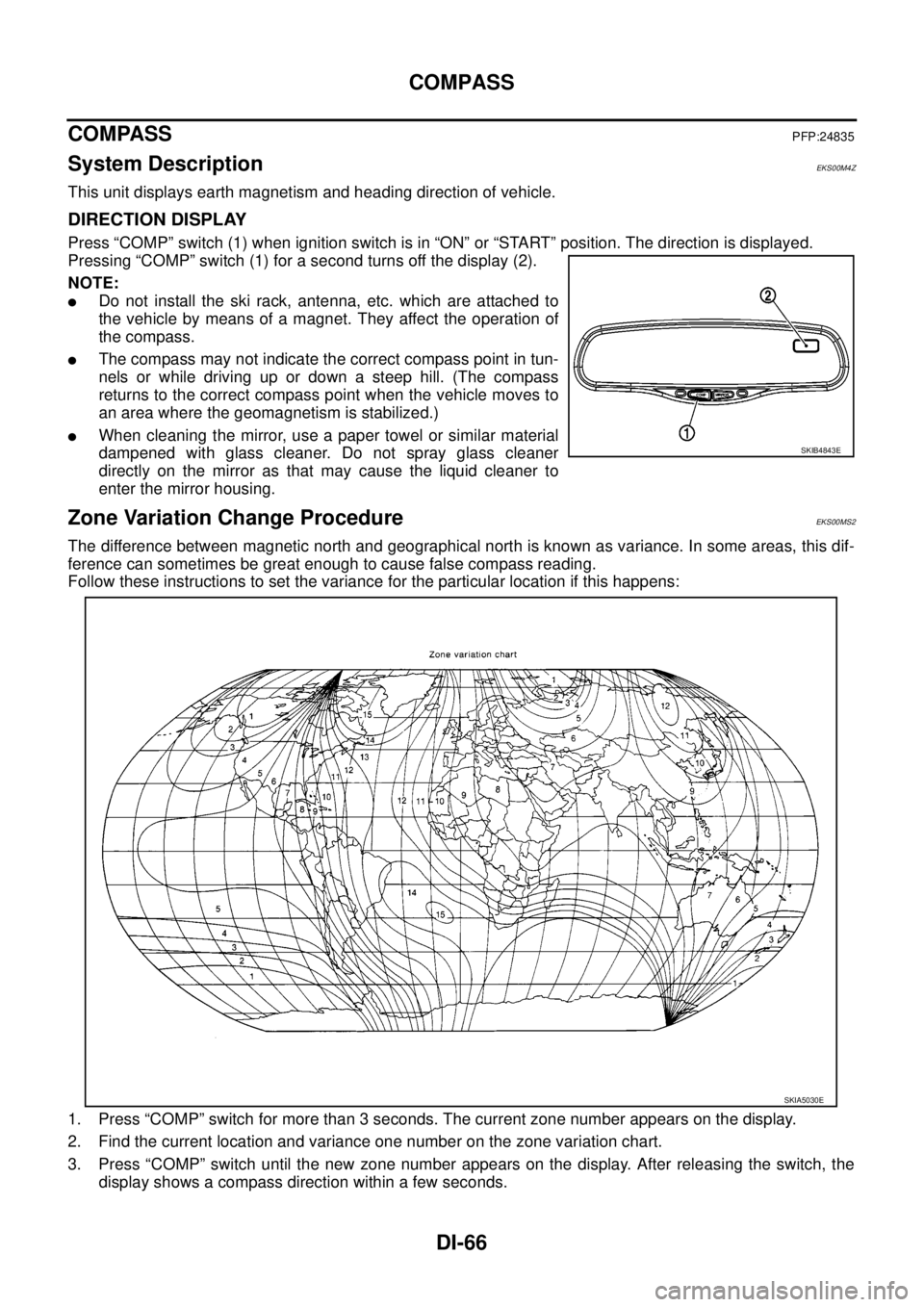

System DescriptionEKS00M4Z

This unit displays earth magnetism and heading direction of vehicle.

DIRECTION DISPLAY

Press “COMP” switch (1) when ignition switch is in “ON” or “START” position. The direction is displayed.

Pressing “COMP” switch (1) for a second turns off the display (2).

NOTE:

lDo not install the ski rack, antenna, etc. which are attached to

the vehicle by means of a magnet. They affect the operation of

the compass.

lThe compass may not indicate the correct compass point in tun-

nels or while driving up or down a steep hill. (The compass

returns to the correct compass point when the vehicle moves to

an area where the geomagnetism is stabilized.)

lWhen cleaning the mirror, use a paper towel or similar material

dampened with glass cleaner. Do not spray glass cleaner

directly on the mirror as that may cause the liquid cleaner to

enter the mirror housing.

Zone Variation Change ProcedureEKS00MS2

The difference between magnetic north and geographical north is known as variance. In some areas, this dif-

ference can sometimes be great enough to cause false compass reading.

Follow these instructions to set the variance for the particular location if this happens:

1. Press “COMP” switch for more than 3 seconds. The current zone number appears on the display.

2. Find the current location and variance one number on the zone variation chart.

3. Press “COMP” switch until the new zone number appears on the display. After releasing the switch, the

display shows a compass direction within a few seconds.

SKIB4843E

SKIA5030E

Page 977 of 3171

COMPASS

DI-67

C

D

E

F

G

H

I

J

L

MA

B

DI

Correction Functions of the Compass DisplayEKS00MS3

AUTOMATIC CORRECTION

The compass display is equipped with automatic correction function. If the direction is not shown correctly,

perform manual correction procedure set out below.

MANUAL CORRECTION PROCEDURE

When the display reads “C” or “CAL”, calibrate the compass by driving the vehicle in 3 complete circles at less

than8km/h(5MPH).

The compass can be calibrated by driving the vehicle on everyday route. The compass is calibrated once it

has tracked 3 complete circles.

In places where the terrestrial magnetism is extremely disturbed, the initial correction procedure may start

automatically.

Page 978 of 3171

DI-68

COMPASS

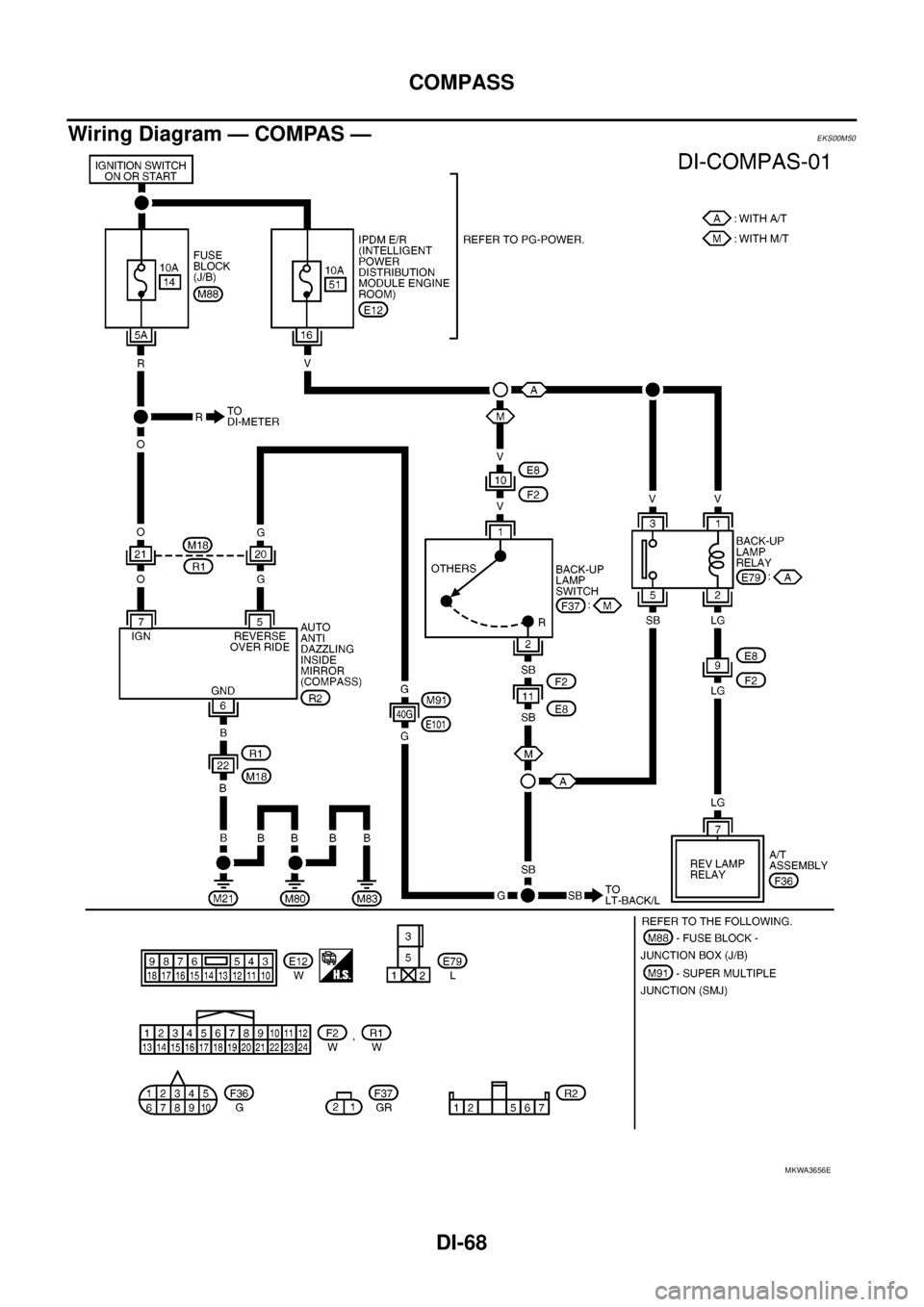

Wiring Diagram — COMPAS —

EKS00M50

MKWA3656E

Page 979 of 3171

COMPASS

DI-69

C

D

E

F

G

H

I

J

L

MA

B

DI

Removal and Installation of CompassEKS00M51

Refer toGW-46, "Removal and Installation".

Page 980 of 3171

DI-70

COMPASS