NISSAN NAVARA 2005 Repair Workshop Manual

NAVARA 2005

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57362/w960_57362-0.png

NISSAN NAVARA 2005 Repair Workshop Manual

Trending: engine oil, ABS, fuse box diagram, wheelbase, wiper fluid, P1272, Brc

Page 951 of 3171

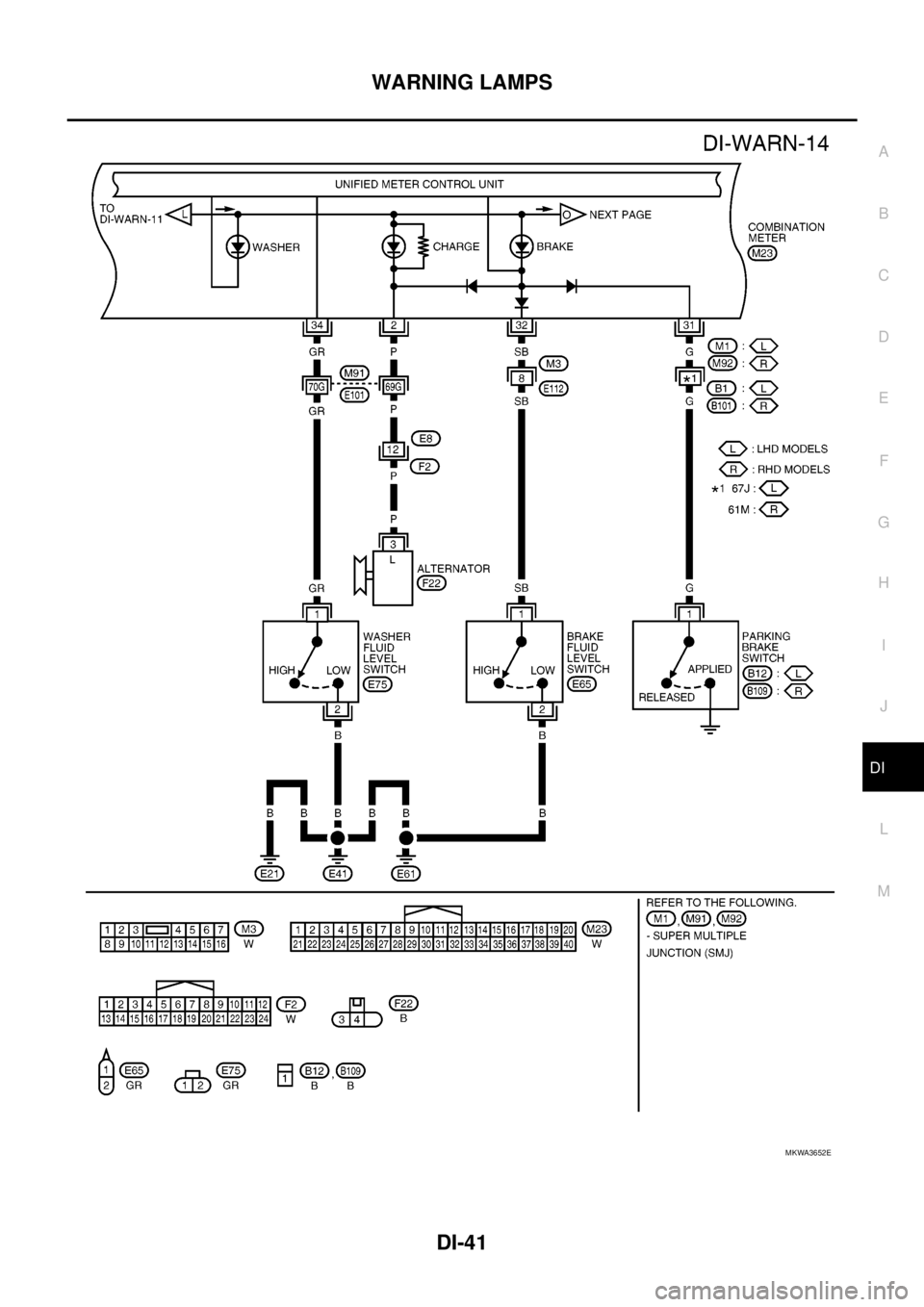

WARNING LAMPS

DI-41

C

D

E

F

G

H

I

J

L

MA

B

DI

MKWA3652E

Page 952 of 3171

DI-42

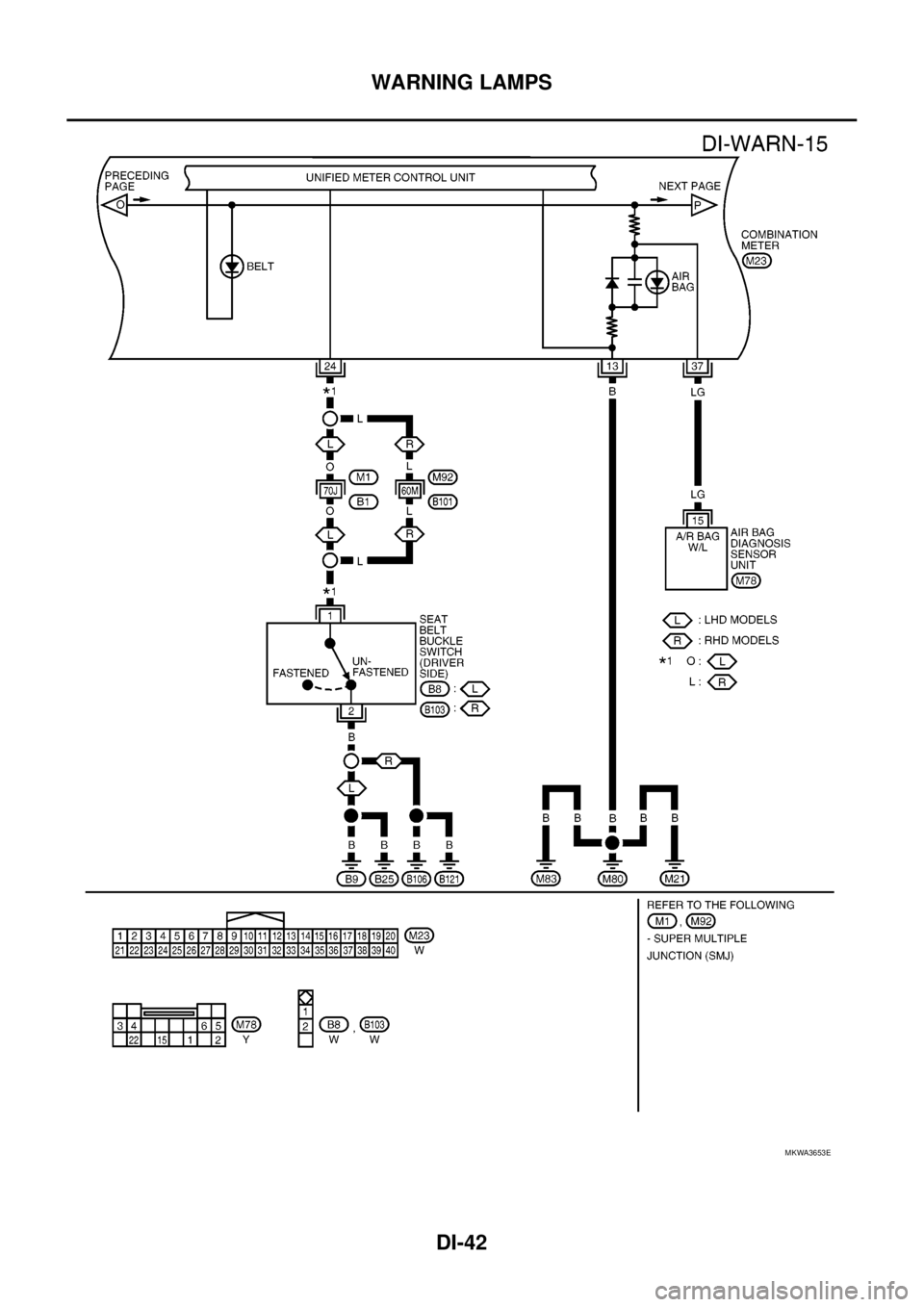

WARNING LAMPS

MKWA3653E

Page 953 of 3171

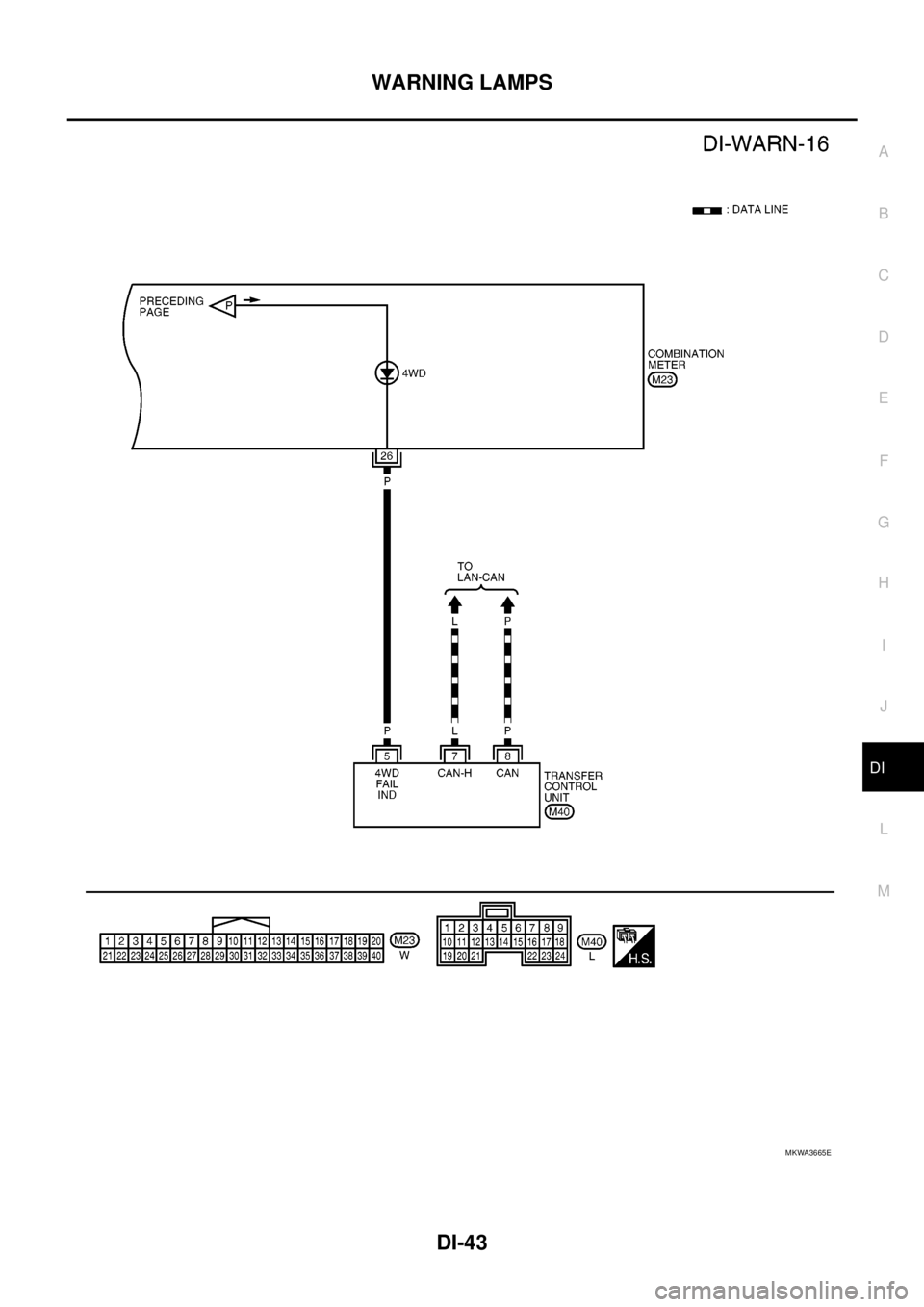

WARNING LAMPS

DI-43

C

D

E

F

G

H

I

J

L

MA

B

DI

MKWA3665E

Page 954 of 3171

DI-44

WARNING LAMPS

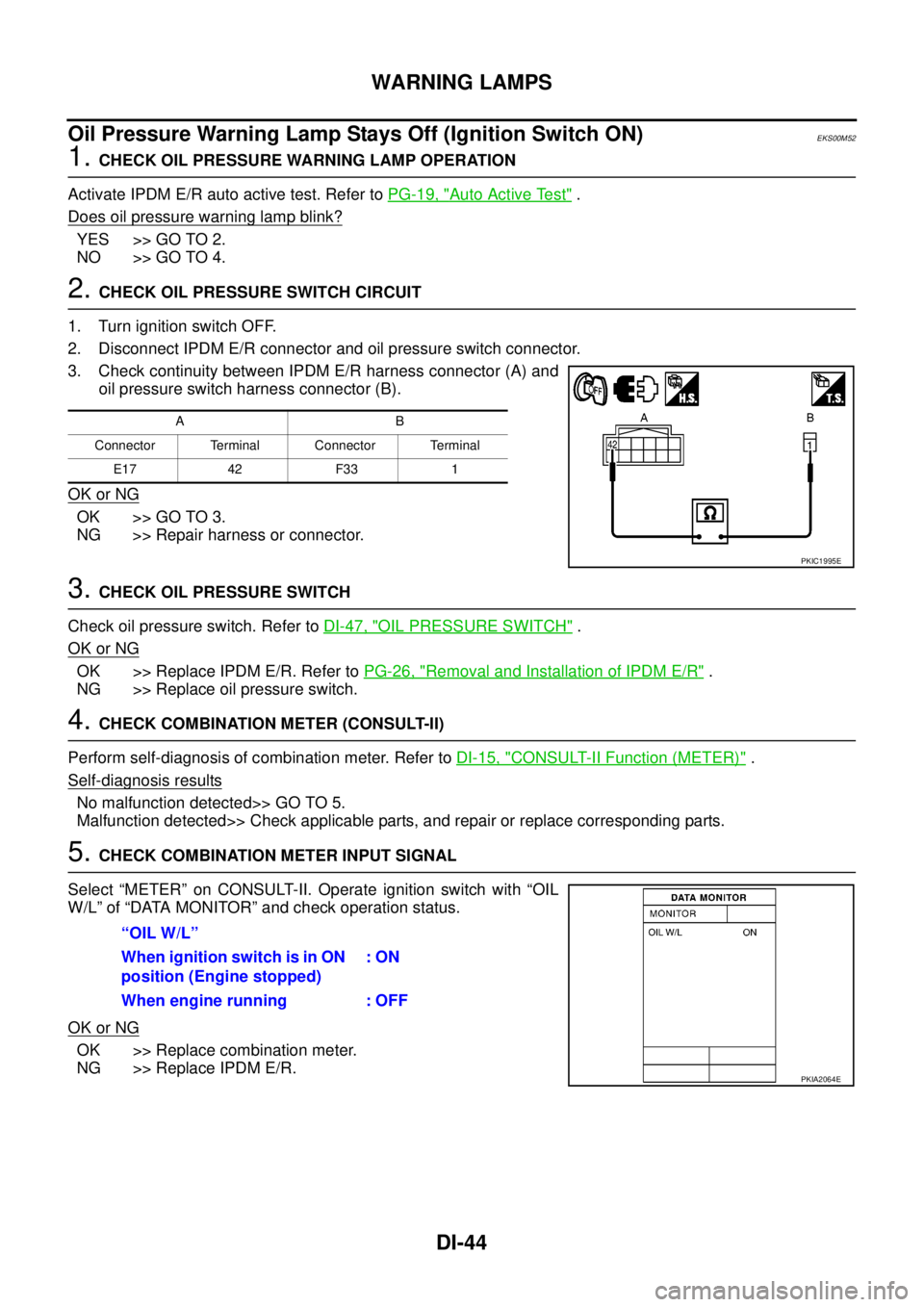

Oil Pressure Warning Lamp Stays Off (Ignition Switch ON)

EKS00M52

1.CHECK OIL PRESSURE WARNING LAMP OPERATION

Activate IPDM E/R auto active test. Refer toPG-19, "

Auto Active Test".

Does oil pressure warning lamp blink?

YES >> GO TO 2.

NO >> GO TO 4.

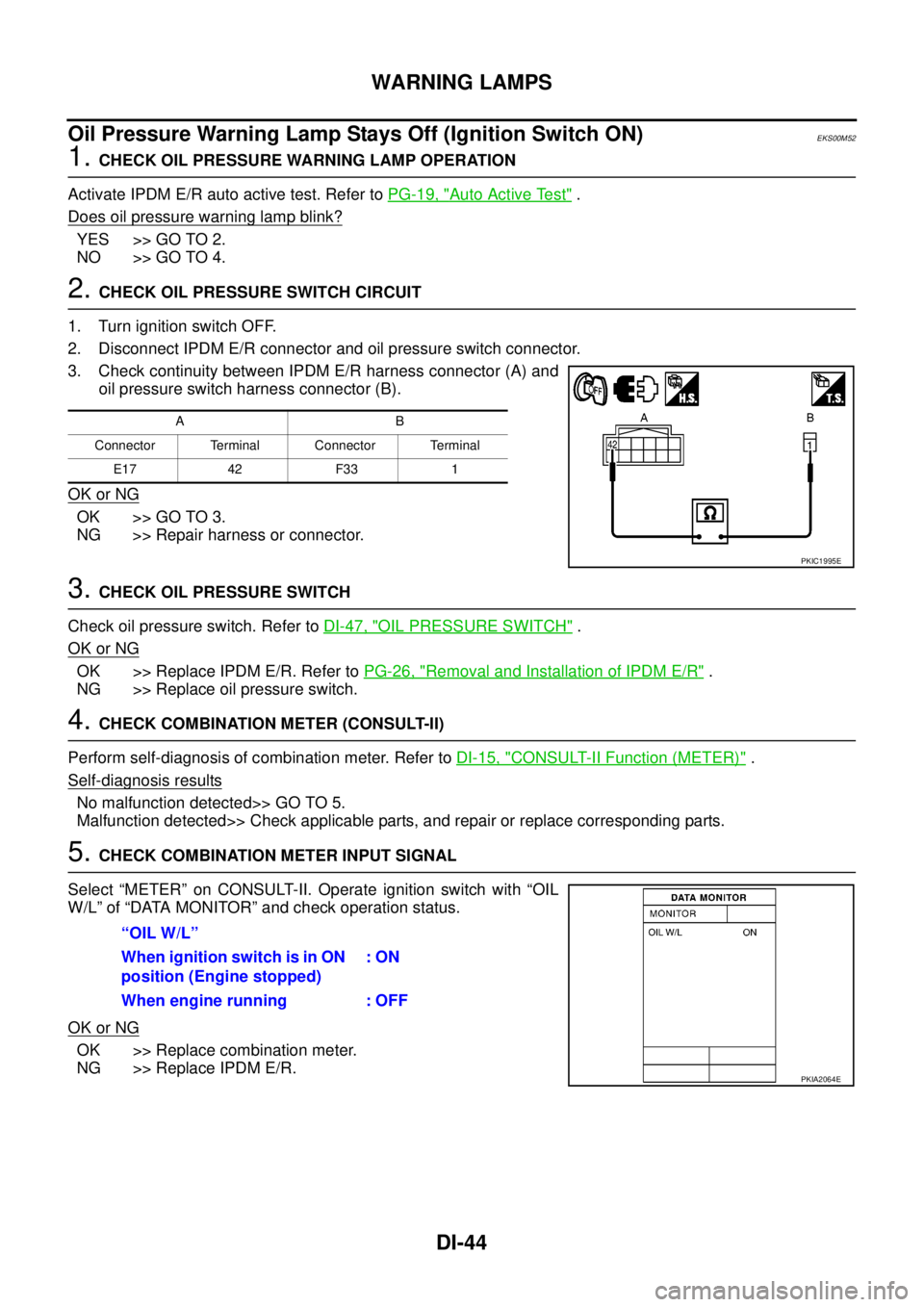

2.CHECK OIL PRESSURE SWITCH CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R connector and oil pressure switch connector.

3. Check continuity between IPDM E/R harness connector (A) and

oil pressure switch harness connector (B).

OK or NG

OK >> GO TO 3.

NG >> Repair harness or connector.

3.CHECK OIL PRESSURE SWITCH

Check oil pressure switch. Refer toDI-47, "

OIL PRESSURE SWITCH".

OK or NG

OK >> Replace IPDM E/R. Refer toPG-26, "Removal and Installation of IPDM E/R".

NG >> Replace oil pressure switch.

4.CHECK COMBINATION METER (CONSULT-II)

Perform self-diagnosis of combination meter. Refer toDI-15, "

CONSULT-II Function (METER)".

Self-diagnosis results

No malfunction detected>> GO TO 5.

Malfunction detected>> Check applicable parts, and repair or replace corresponding parts.

5.CHECK COMBINATION METER INPUT SIGNAL

Select “METER” on CONSULT-II. Operate ignition switch with “OIL

W/L” of “DATA MONITOR” and check operation status.

OK or NG

OK >> Replace combination meter.

NG >> Replace IPDM E/R.

AB

Connector Terminal Connector Terminal

E17 42 F33 1

PKIC1995E

“OIL W/L”

When ignition switch is in ON

position (Engine stopped):ON

When engine running : OFF

PKIA2064E

Page 955 of 3171

WARNING LAMPS

DI-45

C

D

E

F

G

H

I

J

L

MA

B

DI

Oil Pressure Warning Lamp Does Not Turn Off (Oil Pressure Is Normal)EKS00M53

NOTE:

For oil pressure inspection, refer toLU-5, "

ENGINE OIL PRESSURE CHECK".

1.CHECK OIL PRESSURE WARNING LAMP OPERATION

Activate IPDM E/R auto active test. Refer toPG-19, "

Auto Active Test".

Does oil pressure warning lamp blink?

YES >> GO TO 2.

NO >> GO TO 5.

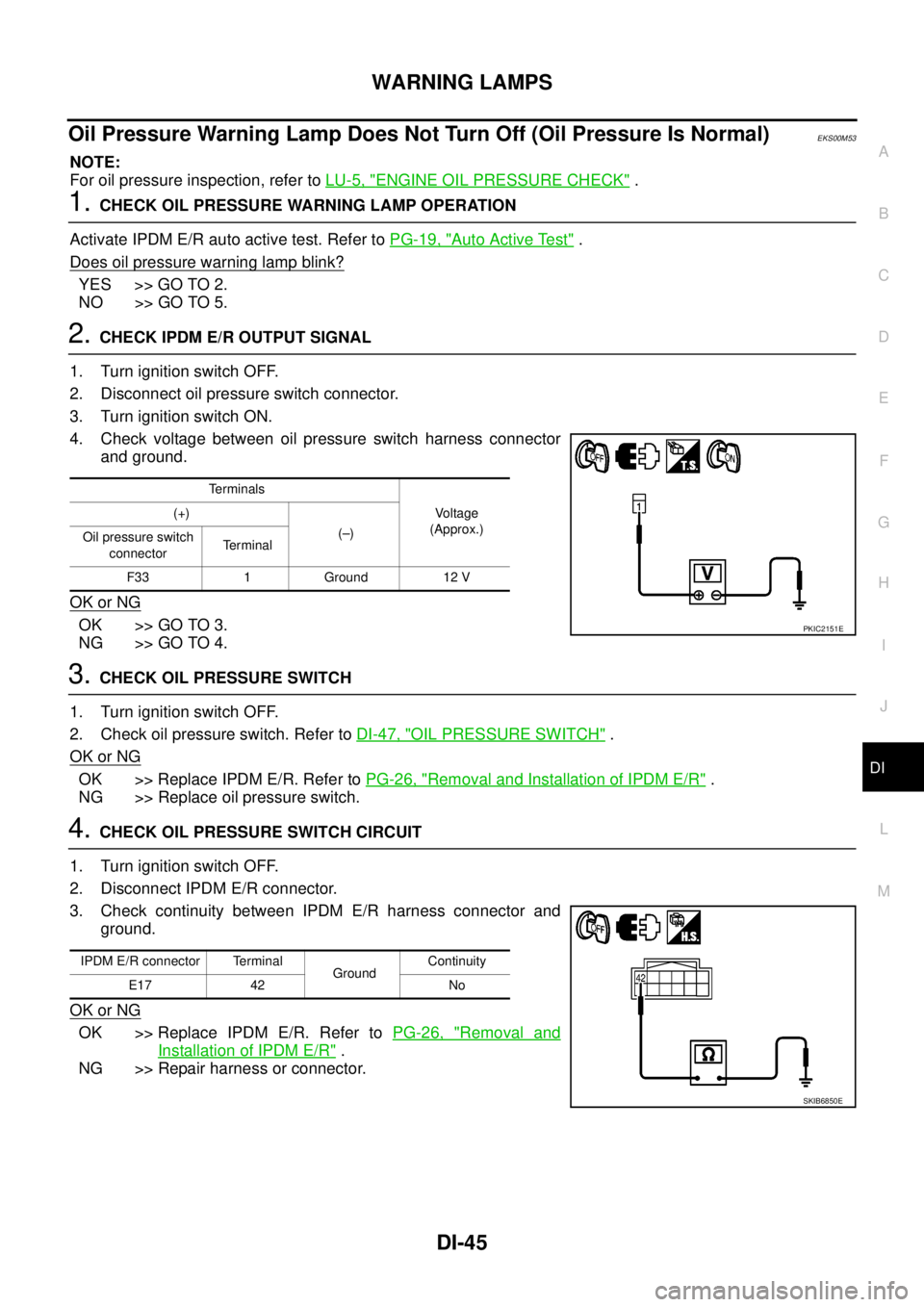

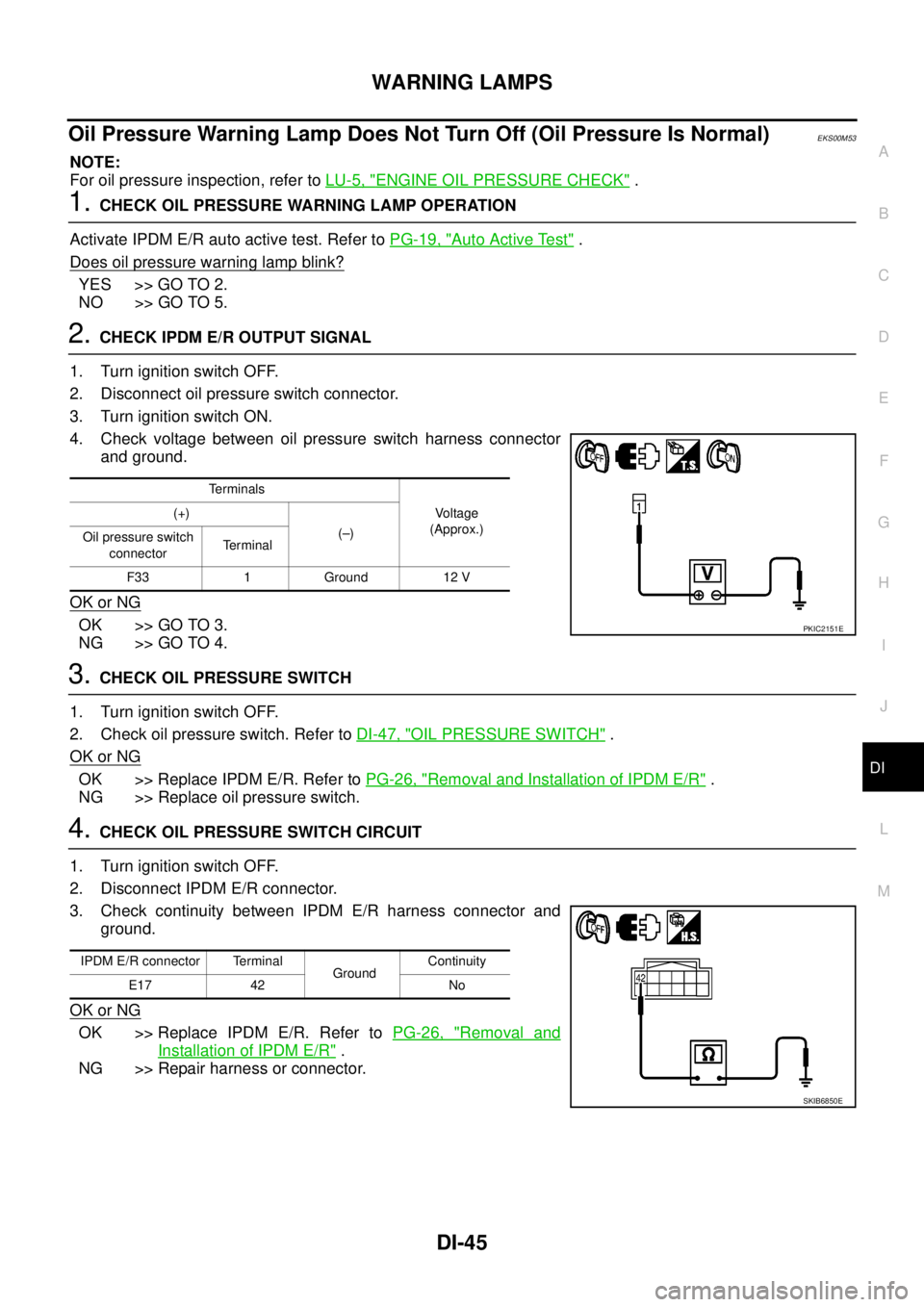

2.CHECK IPDM E/R OUTPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect oil pressure switch connector.

3. Turn ignition switch ON.

4. Check voltage between oil pressure switch harness connector

and ground.

OK or NG

OK >> GO TO 3.

NG >> GO TO 4.

3.CHECK OIL PRESSURE SWITCH

1. Turn ignition switch OFF.

2. Check oil pressure switch. Refer toDI-47, "

OIL PRESSURE SWITCH".

OK or NG

OK >> Replace IPDM E/R. Refer toPG-26, "Removal and Installation of IPDM E/R".

NG >> Replace oil pressure switch.

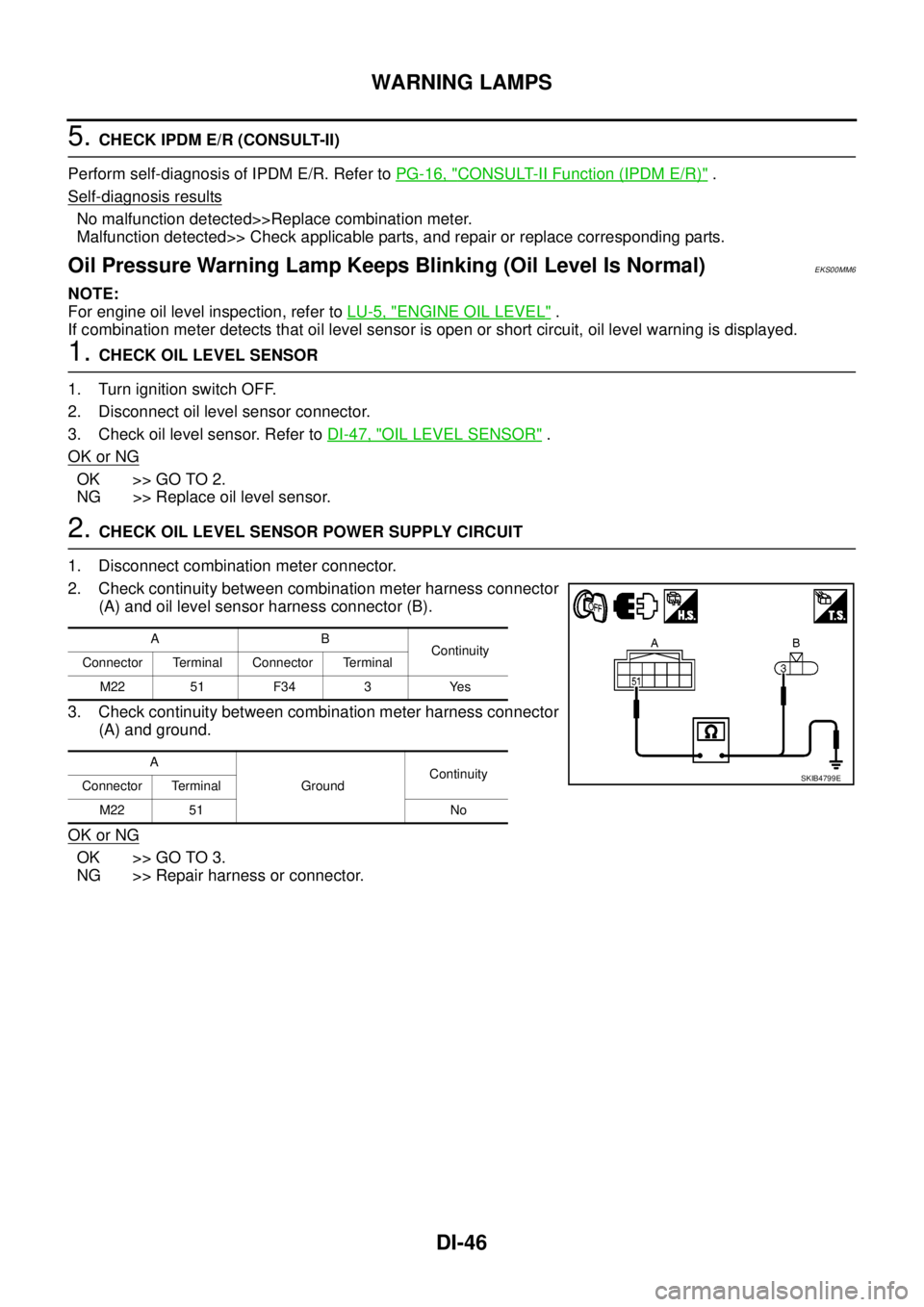

4.CHECK OIL PRESSURE SWITCH CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R connector.

3. Check continuity between IPDM E/R harness connector and

ground.

OK or NG

OK >> Replace IPDM E/R. Refer toPG-26, "Removal and

Installation of IPDM E/R".

NG >> Repair harness or connector.

Terminals

Vo l ta g e

(Approx.) (+)

(–)

Oil pressure switch

connectorTerminal

F33 1 Ground 12 V

PKIC2151E

IPDM E/R connector Terminal

GroundContinuity

E17 42 No

SKIB6850E

Page 956 of 3171

DI-46

WARNING LAMPS

5.CHECK IPDM E/R (CONSULT-II)

Perform self-diagnosis of IPDM E/R. Refer toPG-16, "

CONSULT-II Function (IPDM E/R)".

Self-diagnosis results

No malfunction detected>>Replace combination meter.

Malfunction detected>> Check applicable parts, and repair or replace corresponding parts.

Oil Pressure Warning Lamp Keeps Blinking (Oil Level Is Normal)EKS00MM6

NOTE:

For engine oil level inspection, refer toLU-5, "

ENGINE OIL LEVEL".

If combination meter detects that oil level sensor is open or short circuit, oil level warning is displayed.

1.CHECK OIL LEVEL SENSOR

1. Turn ignition switch OFF.

2. Disconnect oil level sensor connector.

3. Check oil level sensor. Refer toDI-47, "

OIL LEVEL SENSOR".

OK or NG

OK >> GO TO 2.

NG >> Replace oil level sensor.

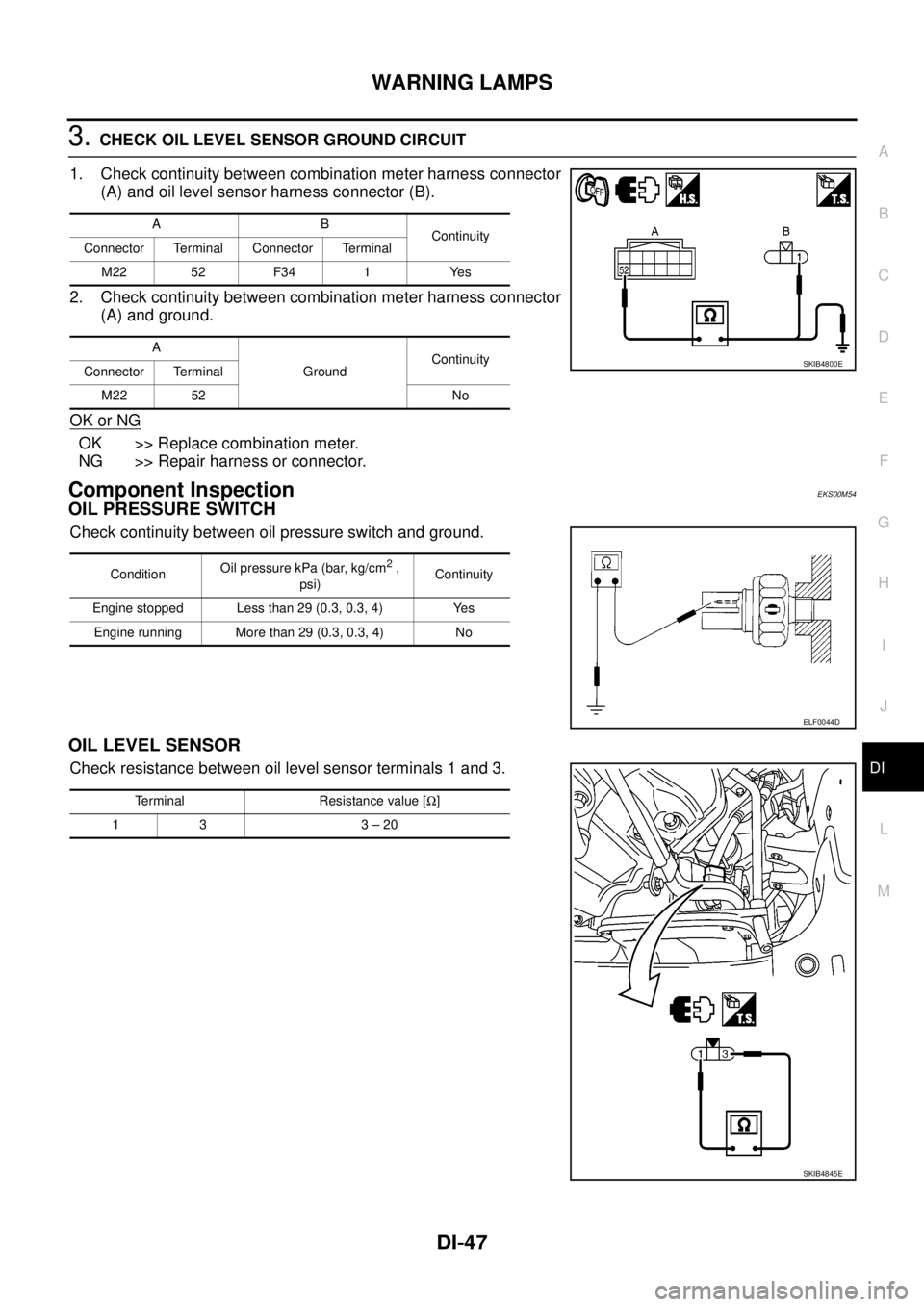

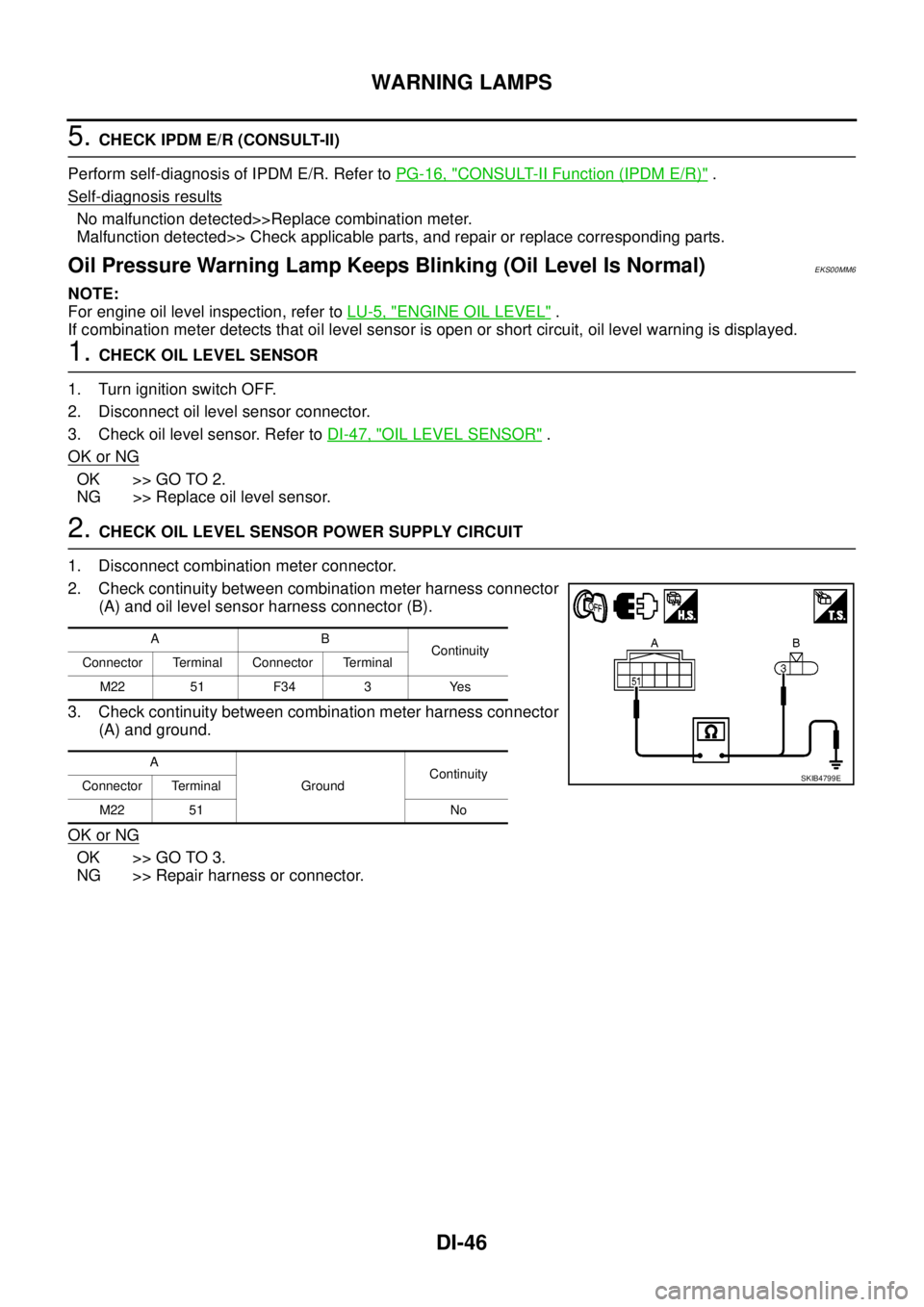

2.CHECK OIL LEVEL SENSOR POWER SUPPLY CIRCUIT

1. Disconnect combination meter connector.

2. Check continuity between combination meter harness connector

(A) and oil level sensor harness connector (B).

3. Check continuity between combination meter harness connector

(A) and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair harness or connector.

AB

Continuity

Connector Terminal Connector Terminal

M22 51 F34 3 Yes

A

GroundContinuity

Connector Terminal

M22 51 No

SKIB4799E

Page 957 of 3171

WARNING LAMPS

DI-47

C

D

E

F

G

H

I

J

L

MA

B

DI

3.CHECK OIL LEVEL SENSOR GROUND CIRCUIT

1. Check continuity between combination meter harness connector

(A) and oil level sensor harness connector (B).

2. Check continuity between combination meter harness connector

(A) and ground.

OK or NG

OK >> Replace combination meter.

NG >> Repair harness or connector.

Component InspectionEKS00M54

OIL PRESSURE SWITCH

Check continuity between oil pressure switch and ground.

OIL LEVEL SENSOR

Check resistance between oil level sensor terminals 1 and 3.

AB

Continuity

Connector Terminal Connector Terminal

M22 52 F34 1 Yes

A

GroundContinuity

Connector Terminal

M22 52 No

SKIB4800E

ConditionOil pressure kPa (bar, kg/cm2,

psi)Continuity

Engine stopped Less than 29 (0.3, 0.3, 4) Yes

Engine running More than 29 (0.3, 0.3, 4) No

ELF0044D

Terminal Resistance value [W]

13 3–20

SKIB4845E

Page 958 of 3171

DI-48

A/T INDICATOR

A/T INDICATOR

PFP:24814

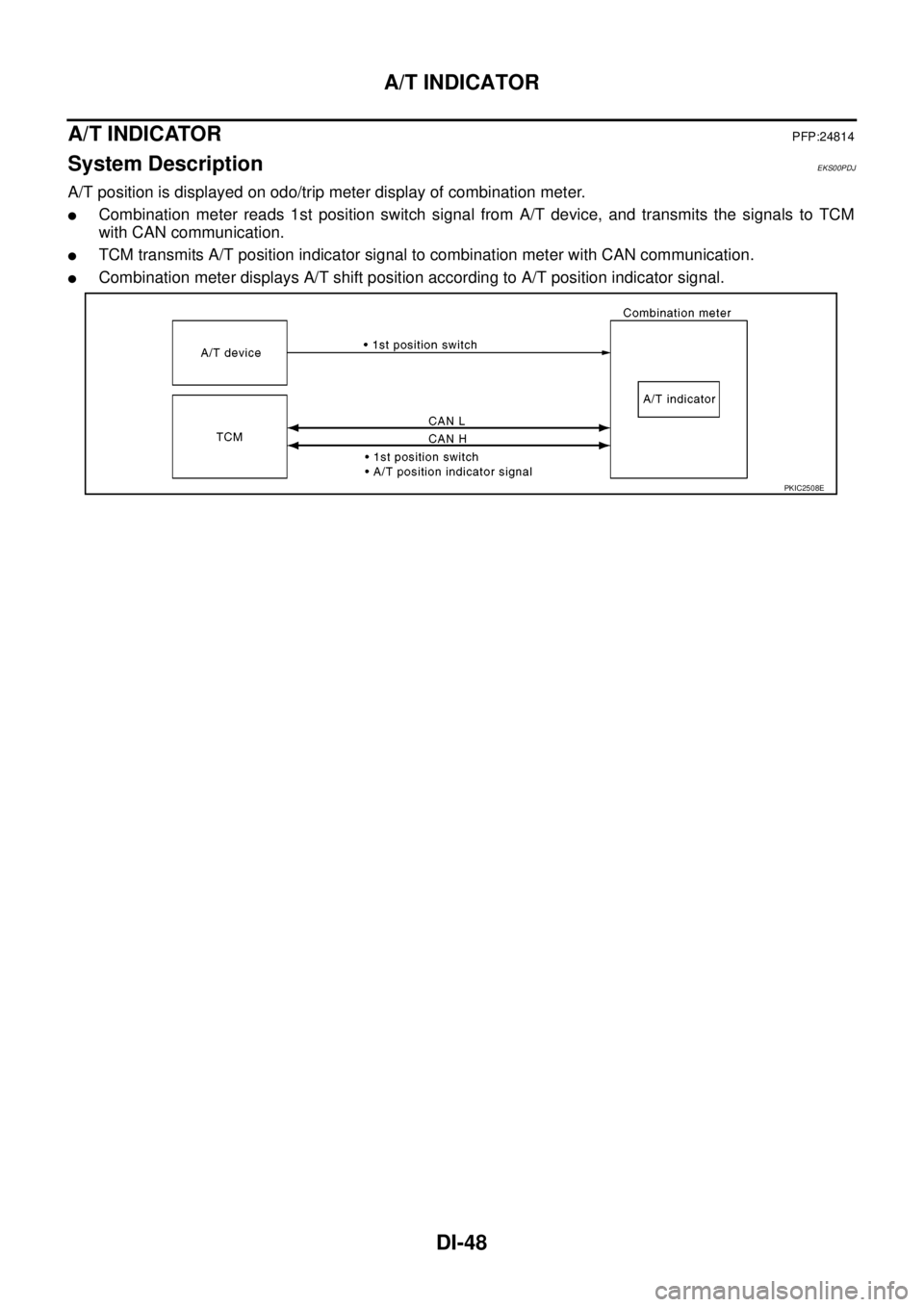

System DescriptionEKS00PDJ

A/T position is displayed on odo/trip meter display of combination meter.

lCombination meter reads 1st position switch signal from A/T device, and transmits the signals to TCM

with CAN communication.

lTCM transmits A/T position indicator signal to combination meter with CAN communication.

lCombination meter displays A/T shift position according to A/T position indicator signal.

PKIC2508E

Page 959 of 3171

A/T INDICATOR

DI-49

C

D

E

F

G

H

I

J

L

MA

B

DI

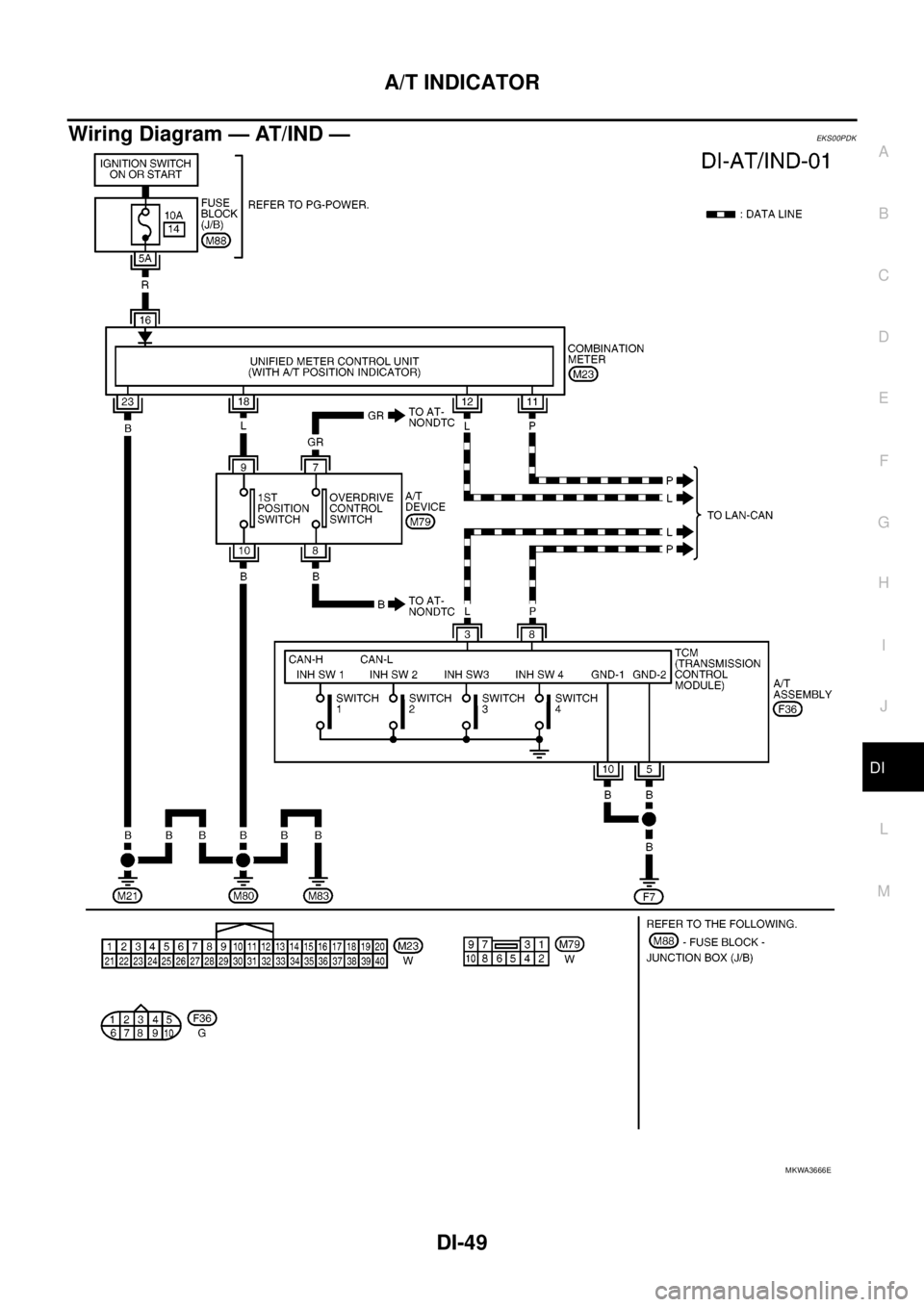

Wiring Diagram — AT/IND —EKS00PDK

MKWA3666E

Page 960 of 3171

DI-50

A/T INDICATOR

A/T Indicator Does Not Illuminate

EKS00PDL

1.CHECK SEGMENT OF A/T INDICATOR

Perform self-diagnosis mode of combination meter. Refer toDI-13, "

Self-Diagnosis Mode of Combination

Meter".

Are all segments displayed?

YES >> GO TO 2.

NO >> Replace combination meter.

2.CHECK COMBINATION METER (CONSULT-II)

Perform self-diagnosis of combination meter. Refer toDI-15, "

CONSULT-II Function (METER)".

OK or NG

OK >> GO TO 3.

NG >> Check applicable part, and repair or replace corresponding parts.

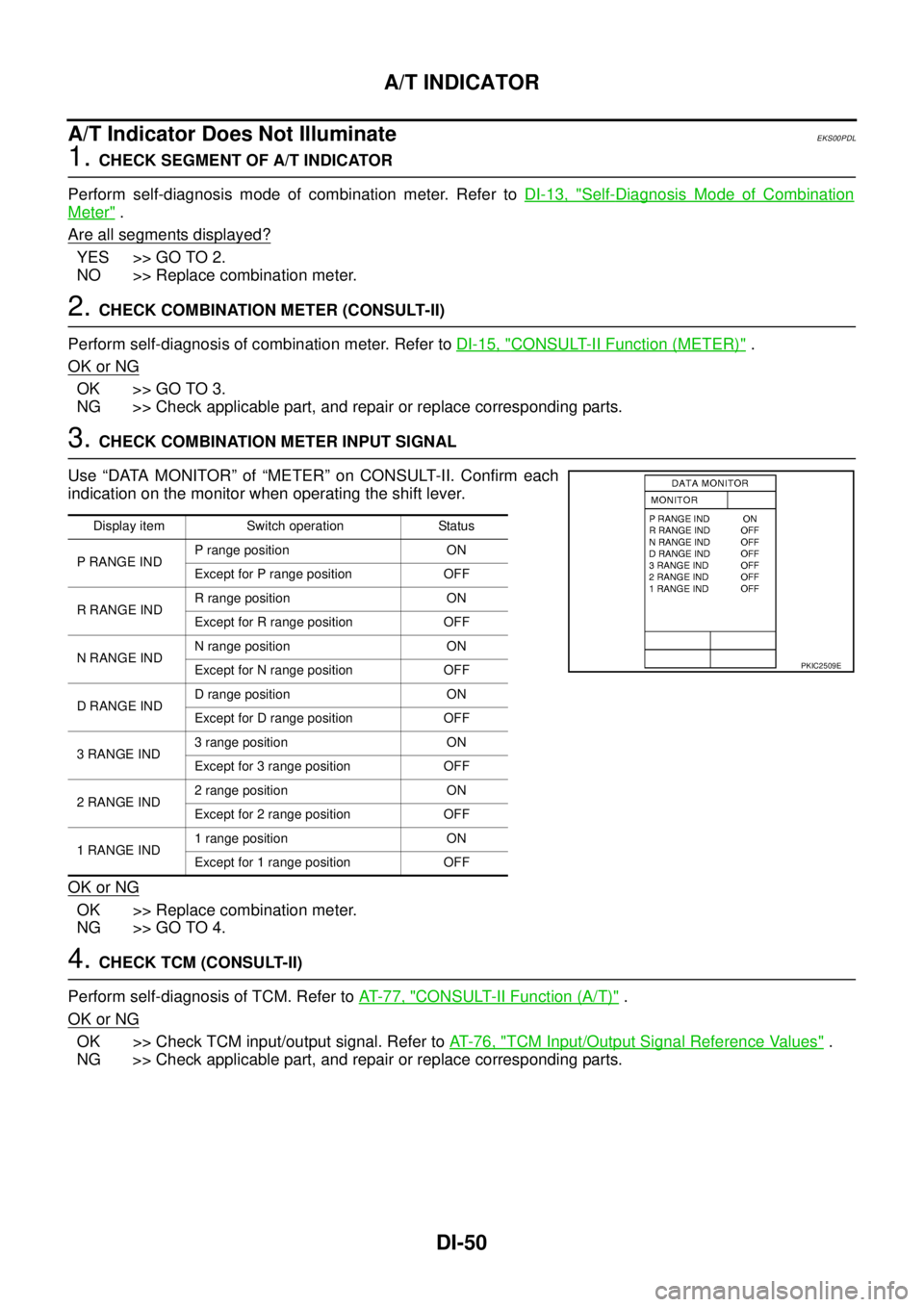

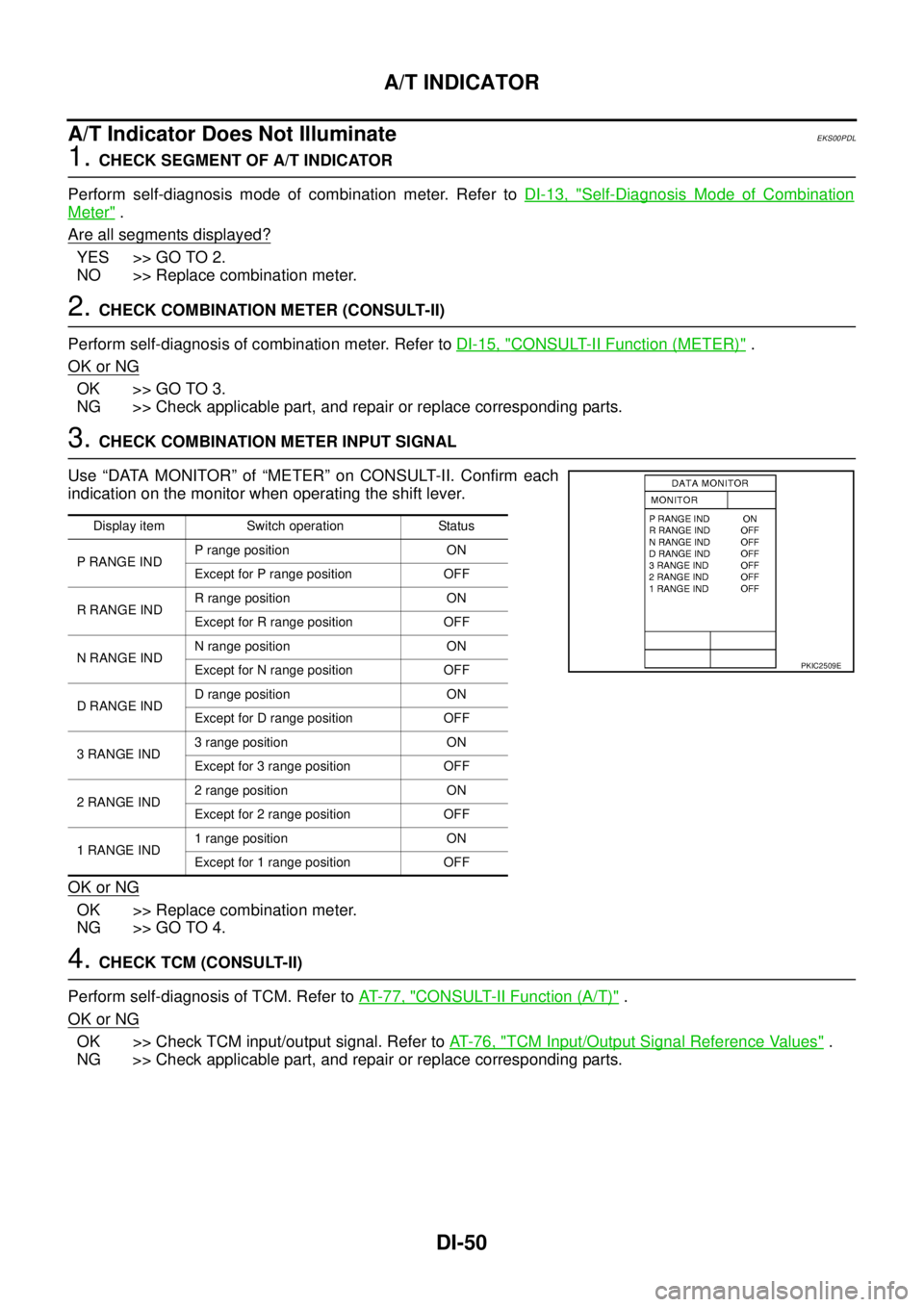

3.CHECK COMBINATION METER INPUT SIGNAL

Use “DATA MONITOR” of “METER” on CONSULT-II. Confirm each

indication on the monitor when operating the shift lever.

OK or NG

OK >> Replace combination meter.

NG >> GO TO 4.

4.CHECK TCM (CONSULT-II)

Perform self-diagnosis of TCM. Refer toAT-77, "

CONSULT-II Function (A/T)".

OK or NG

OK >> Check TCM input/output signal. Refer toAT-76, "TCM Input/Output Signal Reference Values".

NG >> Check applicable part, and repair or replace corresponding parts.

Display item Switch operation Status

P RANGE INDP range position ON

Except for P range position OFF

RRANGEINDR range position ON

Except for R range position OFF

NRANGEINDN range position ON

Except for N range position OFF

DRANGEINDD range position ON

Except for D range position OFF

3RANGEIND3 range position ON

Except for 3 range position OFF

2RANGEIND2 range position ON

Except for 2 range position OFF

1RANGEIND1 range position ON

Except for 1 range position OFF

PKIC2509E

Trending: trailer, body, service schedule, automatic transmission fluid, spare tire, power steering fluid, Timing chain