NISSAN NAVARA 2005 Repair Workshop Manual

Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 981 of 3171

EC-1

ENGINE CONTROL SYSTEM

B ENGINE

CONTENTS

C

D

E

F

G

H

I

J

K

L

M

SECTIONEC

A

EC

ENGINE CONTROL SYSTEM

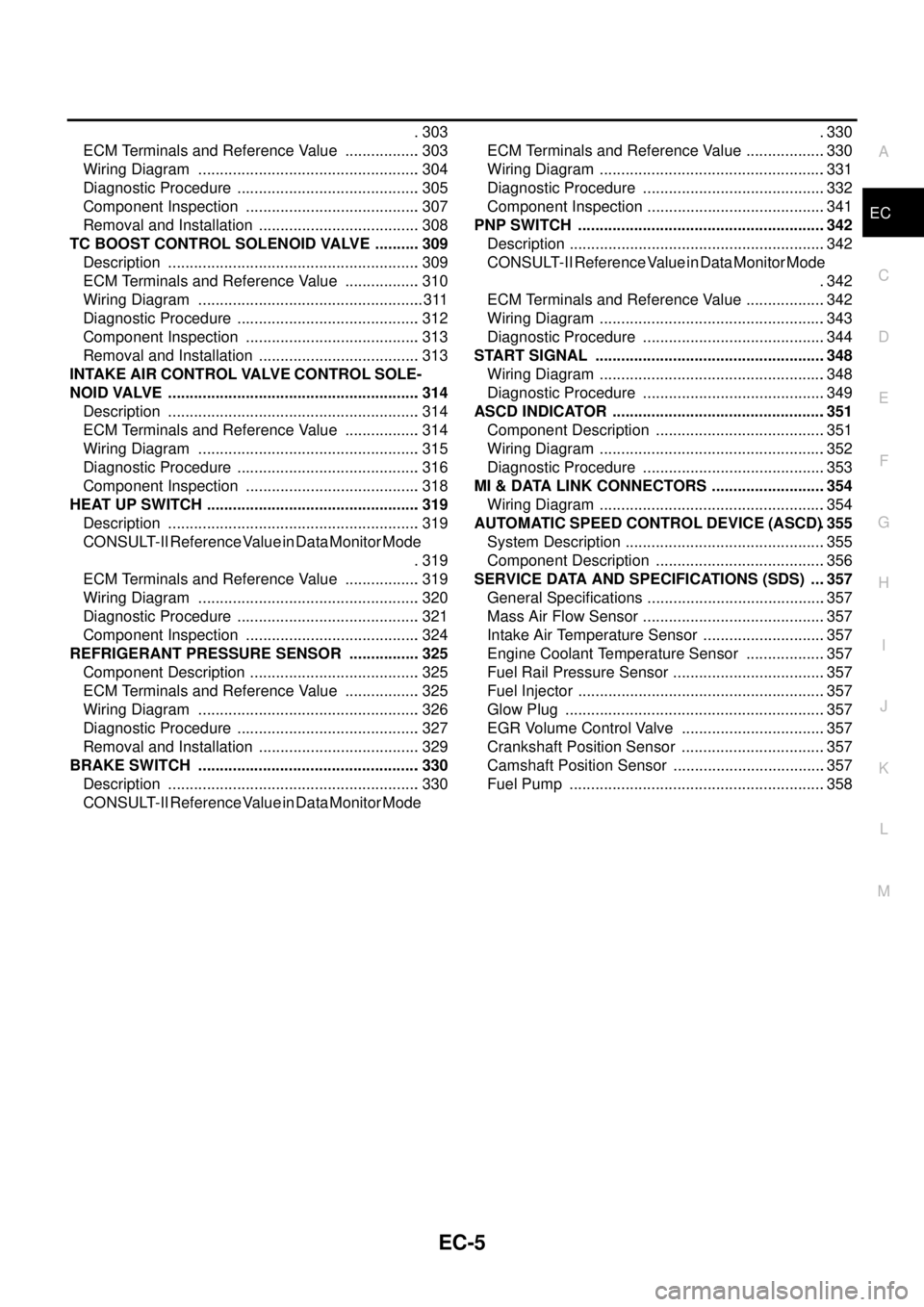

INDEX FOR DTC ........................................................ 6

DTC No. Index ......................................................... 6

Alphabetical Index .................................................... 8

PRECAUTIONS ........................................................ 10

Precautions for Supplemental Restraint System

(SRS)“AIRBAG”and“SEATBELTPRE-TEN-

SIONER” ................................................................ 10

On Board Diagnostic (OBD) System of Engine ...... 10

Precautions ............................................................ 10

Wiring Diagrams and Trouble Diagnosis ................ 13

PREPARATION ......................................................... 14

Special Service Tools ............................................. 14

Commercial Service Tools ...................................... 14

ENGINE CONTROL SYSTEM .................................. 15

System Diagram ..................................................... 15

Vacuum Hose Drawing ........................................... 16

System Chart ......................................................... 18

Fuel Injection Control System ................................ 18

Fuel Injection Timing Control System ..................... 20

Air Conditioning Cut Control ................................... 20

Fuel Cut Control (At No Load & High Engine Speed)... 20

Crankcase Ventilation System ............................... 21

CAN Communication .............................................. 22

BASIC SERVICE PROCEDURE .............................. 23

Fuel Filter ............................................................... 23

Fuel Pump Learning Value Clearing ...................... 24

Injector Adjustment Value Registration .................. 25

ON BOARD DIAGNOSTIC (OBD) SYSTEM ............ 27

DTC Detection Logic .............................................. 27

Diagnostic Trouble Code (DTC) ............................. 27

Freeze Frame Data ................................................ 28

NATS (Nissan Anti-theft System) ........................... 28

Malfunction Indicator (MI) ....................................... 28

Relationship Between MI, DTC, CONSULT-II and

Driving Patterns ...................................................... 31

TROUBLE DIAGNOSIS ............................................ 33

Trouble Diagnosis Introduction ............................... 33

DTC Inspection Priority Chart ................................ 37

Basic Inspection ..................................................... 38

Symptom Matrix Chart ........................................... 42Engine Control Component Parts Location ............ 46

Circuit Diagram ....................................................... 50

ECM Harness Connector Terminal Layout ............. 52

ECM Terminals And Reference Value .................... 52

CONSULT-II Function (ENGINE) ............................ 59

CONSULT-II Reference Value in Data Monitor Mode

... 66

Major Sensor Reference Graph in Data Monitor

Mode ....................................................................... 69

TROUBLE DIAGNOSIS FOR INTERMITTENT INCI-

DENT ......................................................................... 70

Description .............................................................. 70

Diagnostic Procedure ............................................. 70

POWER SUPPLY AND GROUND CIRCUIT ............. 71

ECM Terminals and Reference Value ..................... 71

Wiring Diagram ....................................................... 72

Diagnostic Procedure ............................................. 73

Ground Inspection .................................................. 78

DTC U1000 CAN COMMUNICATION LINE .............. 79

Description .............................................................. 79

On Board Diagnosis Logic ...................................... 79

DTC Confirmation Procedure ................................. 79

Wiring Diagram ....................................................... 80

Diagnostic Procedure ............................................. 81

DTC P0016 CKP - CMP CORRELATION ................. 82

On Board Diagnosis Logic ...................................... 82

DTC Confirmation Procedure ................................. 82

Diagnostic Procedure ............................................. 82

DTC P0088 FUEL SYSTEM ...................................... 84

On Board Diagnosis Logic ...................................... 84

DTC Confirmation Procedure ................................. 84

Diagnostic Procedure ............................................. 84

Removal and Installation ........................................ 85

DTC P0089 FUEL PUMP .......................................... 86

On Board Diagnosis Logic ...................................... 86

DTC Confirmation Procedure ................................. 86

Diagnostic Procedure ............................................. 87

Removal and Installation ........................................ 87

DTC P0093 FUEL SYSTEM ...................................... 88

On Board Diagnosis Logic ...................................... 88

Page 982 of 3171

EC-2

DTC Confirmation Procedure ................................. 88

Diagnostic Procedure ............................................. 89

Component Inspection ............................................ 90

Removal and Installation ........................................ 91

DTC P0102, P0103 MAF SENSOR ........................... 92

Component Description .......................................... 92

CONSULT-II Reference Value in Data Monitor Mode

... 92

ECM Terminals and Reference Value ..................... 92

On Board Diagnosis Logic ...................................... 93

DTC Confirmation Procedure ................................. 93

Wiring Diagram ....................................................... 94

Diagnostic Procedure ............................................. 95

Component Inspection ............................................ 96

Removal and Installation ........................................ 97

DTC P0112, P0113 IAT SENSOR ............................. 98

Component Description .......................................... 98

On Board Diagnosis Logic ...................................... 98

DTC Confirmation Procedure ................................. 98

Wiring Diagram .....................................................100

Diagnostic Procedure ...........................................101

Component Inspection ..........................................102

Removal and Installation ......................................102

DTC P0117, P0118 ECT SENSOR ..........................103

Description ............................................................103

On Board Diagnosis Logic ....................................103

DTC Confirmation Procedure ...............................103

Wiring Diagram .....................................................105

Diagnostic Procedure ...........................................106

Component Inspection ..........................................107

Removal and Installation ......................................107

DTC P0122, P0123 APP SENSOR .........................108

Description ............................................................108

CONSULT-II Reference Value in Data Monitor Mode

.108

ECM Terminals and Reference Value ...................108

On Board Diagnosis Logic ....................................109

DTC Confirmation Procedure ...............................109

Wiring Diagram .....................................................110

Diagnostic Procedure ............................................111

Component Inspection ..........................................112

Removal and Installation ......................................112

DTC P0182, P0183 FUEL PUMP TEMPERATURE

SENSOR ..................................................................113

Description ............................................................113

CONSULT-II Reference Value in Data Monitor Mode

.113

ECM Terminals and Reference Value ...................113

On Board Diagnosis Logic ....................................113

DTC Confirmation Procedure ...............................114

Wiring Diagram .....................................................115

Diagnostic Procedure ...........................................116

Removal and Installation ......................................117

DTC P0192, P0193 FRP SENSOR .........................118

Description ............................................................118

CONSULT-II Reference Value in Data Monitor Mode

.118

ECM Terminals and Reference Value ...................118

On Board Diagnosis Logic ....................................118DTC Confirmation Procedure ................................119

Wiring Diagram .....................................................120

Diagnostic Procedure ............................................121

Component Inspection ..........................................122

Removal and Installation .......................................122

DTC P0200 FUEL INJECTOR .................................123

On Board Diagnosis Logic ....................................123

DTC Confirmation Procedure ................................123

Diagnostic Procedure ............................................123

DTC P0201 - P0204 FUEL INJECTOR ...................125

Component Description ........................................125

CONSULT-II Reference Value in Data Monitor Mode

.125

ECM Terminals and Reference Value ...................125

On Board Diagnosis Logic ....................................126

DTC Confirmation Procedure ................................127

Wiring Diagram .....................................................128

Diagnostic Procedure ............................................129

Component Inspection ..........................................130

Removal and Installation .......................................131

DTC P0217 ENGINE OVER TEMPERATURE ........132

Description ............................................................132

CONSULT-II Reference Value in Data Monitor Mode

.133

On Board Diagnosis Logic ....................................133

Overall Function Check .........................................133

Wiring Diagram .....................................................135

Diagnostic Procedure ............................................137

Main 12 Causes of Overheating ...........................140

Component Inspection ..........................................141

DTC P0222, P0223 APP SENSOR .........................142

Description ............................................................142

CONSULT-II Reference Value in Data Monitor Mode

.142

ECM Terminals and Reference Value ...................142

On Board Diagnosis Logic ....................................143

DTC Confirmation Procedure ................................143

Wiring Diagram .....................................................144

Diagnostic Procedure ............................................145

Component Inspection ..........................................146

Removal and Installation .......................................146

DTC P0234 TC SYSTEM .........................................147

Description ............................................................147

ECM Terminals and Reference Value ...................147

On Board Diagnosis Logic ....................................148

Overall Function Check .........................................148

Wiring Diagram .....................................................149

Diagnostic Procedure ............................................150

Component Inspection ..........................................152

Removal and Installation .......................................152

DTC P0237, P0238 TC BOOST SENSOR ..............153

Component Description ........................................153

CONSULT-II Reference Value in Data Monitor Mode

.153

ECM Terminals and Reference Value ...................153

On Board Diagnosis Logic ....................................154

DTC Confirmation Procedure ................................154

Wiring Diagram .....................................................155

Diagnostic Procedure ............................................156

Page 983 of 3171

EC-3

C

D

E

F

G

H

I

J

K

L

M

ECA Component Inspection ......................................... 158

Removal and Installation ...................................... 158

DTC P0335 CKP SENSOR ..................................... 159

Description ........................................................... 159

CONSULT-II Reference Value in Data Monitor Mode

. 159

ECM Terminals and Reference Value .................. 159

On Board Diagnosis Logic ................................... 160

DTC Confirmation Procedure ............................... 160

Wiring Diagram .................................................... 161

Diagnostic Procedure ........................................... 162

Component Inspection ......................................... 164

Removal and Installation ...................................... 164

DTC P0336 CKP SENSOR ..................................... 165

Description ........................................................... 165

CONSULT-II Reference Value in Data Monitor Mode

. 165

ECM Terminals and Reference Value .................. 165

On Board Diagnosis Logic ................................... 166

DTC Confirmation Procedure ............................... 166

Wiring Diagram .................................................... 167

Diagnostic Procedure ........................................... 168

Component Inspection ......................................... 170

Removal and Installation ...................................... 170

DTC P0340 CMP SENSOR .................................... 171

Description ........................................................... 171

ECM Terminals and Reference Value .................. 171

On Board Diagnosis Logic ................................... 172

DTC Confirmation Procedure ............................... 172

Wiring Diagram .................................................... 173

Diagnostic Procedure ........................................... 174

Component Inspection ......................................... 175

Removal and Installation ...................................... 176

DTC P0341 CMP SENSOR .................................... 177

Description ........................................................... 177

ECM Terminals and Reference Value .................. 177

On Board Diagnosis Logic ................................... 178

DTC Confirmation Procedure ............................... 178

Wiring Diagram .................................................... 179

Diagnostic Procedure ........................................... 180

Component Inspection ......................................... 182

Removal and Installation ...................................... 182

DTC P0501 ASCD VEHICLE SPEED SENSOR .... 183

Component Description ........................................ 183

On Board Diagnosis Logic ................................... 183

DTC Confirmation Procedure ............................... 183

Diagnostic Procedure ........................................... 184

DTC P0502 ASCD VEHICLE SPEED SENSOR .... 185

Component Description ........................................ 185

On Board Diagnosis Logic ................................... 185

DTC Confirmation Procedure ............................... 185

Diagnostic Procedure ........................................... 186

DTC P0503 ASCD VEHICLE SPEED SENSOR .... 187

Component Description ........................................ 187

On Board Diagnosis Logic ................................... 187

DTC Confirmation Procedure ............................... 187

Diagnostic Procedure ........................................... 188

DTC P0504 ASCD BRAKE SWITCH ..................... 189

Component Description ........................................ 189CONSULT-II Reference Value in Data Monitor Mode

.189

ECM Terminals and Reference Value ...................189

On Board Diagnosis Logic ....................................190

DTC confirmation Procedure ................................190

Wiring Diagram .....................................................192

Diagnostic Procedure ...........................................193

Component Inspection ..........................................202

DTC P0563 BATTERY VOLTAGE ..........................203

On Board Diagnosis Logic ....................................203

DTC Confirmation Procedure ...............................203

Diagnostic Procedure ...........................................203

DTC P0580, P0581 ASCD STEERING SWITCH ....206

Component Description ........................................206

CONSULT-II Reference Value in Data Monitor Mode

.206

ECM Terminals and Reference Value ...................206

On Board Diagnosis Logic ....................................207

DTC Confirmation Procedure ...............................207

Wiring Diagram .....................................................208

Diagnostic Procedure ...........................................209

Component Inspection ..........................................212

DTC P0605 ECM .....................................................213

Description ............................................................213

On Board Diagnosis Logic ....................................213

DTC Confirmation Procedure ...............................213

Diagnostic Procedure ...........................................214

DTC P0606 ECM .....................................................215

Description ............................................................215

On Board Diagnosis Logic ....................................215

DTC Confirmation Procedure ...............................215

Diagnostic Procedure ...........................................216

DTC P0628, P0629 FUEL PUMP ............................217

Description ............................................................217

CONSULT-II Reference Value in Data Monitor Mode

.217

ECM Terminals and Reference Value ...................217

On Board Diagnosis Logic ....................................218

DTC Confirmation Procedure ...............................218

Wiring Diagram .....................................................219

Diagnostic Procedure ...........................................220

Component Inspection ..........................................221

Removal and Installation ......................................221

DTC P0642, P0643 SENSOR POWER SUPPLY ....222

ECM Terminals and Reference Value ...................222

On Board Diagnosis Logic ....................................222

DTC Confirmation Procedure ...............................223

Wiring Diagram .....................................................224

Diagnostic Procedure ...........................................225

DTC P0652, P0653 SENSOR POWER SUPPLY ....227

ECM Terminals and Reference Value ...................227

On Board Diagnosis Logic ....................................228

DTC Confirmation Procedure ...............................228

Wiring Diagram .....................................................229

Diagnostic Procedure ...........................................230

DTC P0686 ECM RELAY ........................................232

ECM Terminals and Reference valve ...................232

On Board Diagnosis Logic ....................................232

DTC Confirmation Procedure ...............................232

Page 984 of 3171

EC-4

Wiring Diagram .....................................................234

Diagnostic Procedure ...........................................235

DTC P1268 - P1271 FUEL INJECTOR ...................237

Component Description ........................................237

CONSULT-II Reference Value in Data Monitor Mode

.237

ECM Terminals and Reference Value ...................237

On Board Diagnosis Logic ....................................238

DTC Confirmation Procedure ...............................239

Wiring Diagram .....................................................240

Diagnostic Procedure ...........................................241

Component Inspection ..........................................243

Removal and Installation ......................................244

DTC P1272 FUEL PUMP ........................................245

Description ............................................................245

CONSULT-II Reference Value in Data Monitor Mode

.245

ECM Terminals and Reference Value ...................245

On Board Diagnosis Logic ....................................246

DTC Confirmation Procedure ...............................246

Wiring Diagram .....................................................248

Diagnostic Procedure ...........................................249

Component Inspection ..........................................250

Removal and Installation ......................................250

DTC P1273 FUEL PUMP ........................................251

Description ............................................................251

CONSULT-II Reference Value in Data Monitor Mode

.251

ECM Terminals and Reference Value ...................251

On Board Diagnosis Logic ....................................252

DTC Confirmation Procedure ...............................252

Wiring Diagram .....................................................254

Diagnostic Procedure ...........................................255

Component Inspection ..........................................257

Removal and Installation ......................................257

DTC P1274 FUEL PUMP ........................................258

Description ............................................................258

CONSULT-II Reference Value in Data Monitor Mode

.258

ECM Terminals and Reference Value ...................258

On Board Diagnosis Logic ....................................259

DTC Confirmation Procedure ...............................259

Wiring Diagram .....................................................260

Diagnostic Procedure ...........................................261

Component Inspection ..........................................262

Removal and Installation ......................................262

DTC P1275 FUEL PUMP ........................................263

Description ............................................................263

CONSULT-II Reference Value in Data Monitor Mode

.263

ECM Terminals and Reference Value ...................263

On Board Diagnosis Logic ....................................264

DTC Confirmation Procedure ...............................264

Wiring Diagram .....................................................266

Diagnostic Procedure ...........................................267

Component Inspection ..........................................268

Removal and Installation ......................................268

DTC P1616 ECM .....................................................269

Description ............................................................269On Board Diagnosis Logic ....................................269

DTC Confirmation Procedure ................................269

Diagnostic Procedure ............................................270

DTC P1622 INJECTOR ADJUSTMENT VALUE .....271

Description ............................................................271

On Board Diagnosis Logic ....................................271

DTC Confirmation Procedure ................................271

Diagnostic Procedure ............................................272

DTC P1623 INJECTOR ADJUSTMENT VALUE .....273

Description ............................................................273

On Board Diagnosis Logic ....................................273

DTC Confirmation Procedure ................................273

Diagnostic Procedure ............................................274

DTC P2135 APP SENSOR ......................................275

Description ............................................................275

CONSULT-II Reference Value in Data Monitor Mode

.275

ECM Terminals and Reference Value ...................275

On Board Diagnosis Logic ....................................276

DTC Confirmation Procedure ................................276

Wiring Diagram .....................................................277

Diagnostic Procedure ............................................278

Component Inspection ..........................................279

Removal and Installation .......................................280

DTC P2146, P2149 FUEL INJECTOR POWER SUP-

PLY ..........................................................................281

Component Description ........................................281

CONSULT-II Reference Value in Data Monitor Mode

.281

ECM Terminals and Reference Value ...................281

On Board Diagnosis Logic ....................................282

DTC Confirmation Procedure ................................283

Wiring Diagram .....................................................284

Diagnostic Procedure ............................................285

DTC P2147, P2148 FUEL INJECTOR CIRCUIT .....286

Component Description ........................................286

CONSULT-II Reference Value in Data Monitor Mode

.286

ECM Terminals and Reference Value ...................286

On Board Diagnosis Logic ....................................287

DTC Confirmation Procedure ................................288

Wiring Diagram .....................................................289

Diagnostic Procedure ............................................290

Component Inspection ..........................................292

Removal and Installation .......................................292

DTC P2228, P2229 BARO SENSOR ......................293

Description ............................................................293

On Board Diagnosis Logic ....................................293

DTC Confirmation Procedure ................................293

Diagnostic Procedure ............................................294

GLOW CONTROL SYSTEM ...................................295

Description ............................................................295

Wiring Diagram .....................................................296

Diagnostic Procedure ............................................297

Component Inspection ..........................................301

Removal and Installation .......................................301

EGR VOLUME CONTROL SYSTEM ......................302

Description ............................................................302

CONSULT-II Reference Value in Data Monitor Mode

Page 985 of 3171

EC-5

C

D

E

F

G

H

I

J

K

L

M

ECA . 303

ECM Terminals and Reference Value .................. 303

Wiring Diagram .................................................... 304

Diagnostic Procedure ........................................... 305

Component Inspection ......................................... 307

Removal and Installation ...................................... 308

TC BOOST CONTROL SOLENOID VALVE ........... 309

Description ........................................................... 309

ECM Terminals and Reference Value .................. 310

Wiring Diagram ..................................................... 311

Diagnostic Procedure ........................................... 312

Component Inspection ......................................... 313

Removal and Installation ...................................... 313

INTAKE AIR CONTROL VALVE CONTROL SOLE-

NOID VALVE ........................................................... 314

Description ........................................................... 314

ECM Terminals and Reference Value .................. 314

Wiring Diagram .................................................... 315

Diagnostic Procedure ........................................... 316

Component Inspection ......................................... 318

HEAT UP SWITCH .................................................. 319

Description ........................................................... 319

CONSULT-II Reference Value in Data Monitor Mode

. 319

ECM Terminals and Reference Value .................. 319

Wiring Diagram .................................................... 320

Diagnostic Procedure ........................................... 321

Component Inspection ......................................... 324

REFRIGERANT PRESSURE SENSOR ................. 325

Component Description ........................................ 325

ECM Terminals and Reference Value .................. 325

Wiring Diagram .................................................... 326

Diagnostic Procedure ........................................... 327

Removal and Installation ...................................... 329

BRAKE SWITCH .................................................... 330

Description ........................................................... 330

CONSULT-II Reference Value in Data Monitor Mode.330

ECM Terminals and Reference Value ...................330

Wiring Diagram .....................................................331

Diagnostic Procedure ...........................................332

Component Inspection ..........................................341

PNP SWITCH ..........................................................342

Description ............................................................342

CONSULT-II Reference Value in Data Monitor Mode

.342

ECM Terminals and Reference Value ...................342

Wiring Diagram .....................................................343

Diagnostic Procedure ...........................................344

START SIGNAL ......................................................348

Wiring Diagram .....................................................348

Diagnostic Procedure ...........................................349

ASCD INDICATOR ..................................................351

Component Description ........................................351

Wiring Diagram .....................................................352

Diagnostic Procedure ...........................................353

MI & DATA LINK CONNECTORS ...........................354

Wiring Diagram .....................................................354

AUTOMATIC SPEED CONTROL DEVICE (ASCD). 355

System Description ...............................................355

Component Description ........................................356

SERVICE DATA AND SPECIFICATIONS (SDS) ....357

General Specifications ..........................................357

Mass Air Flow Sensor ...........................................357

Intake Air Temperature Sensor .............................357

Engine Coolant Temperature Sensor ...................357

Fuel Rail Pressure Sensor ....................................357

Fuel Injector ..........................................................357

Glow Plug .............................................................357

EGR Volume Control Valve ..................................357

Crankshaft Position Sensor ..................................357

Camshaft Position Sensor ....................................357

Fuel Pump ............................................................358

Page 986 of 3171

EC-6

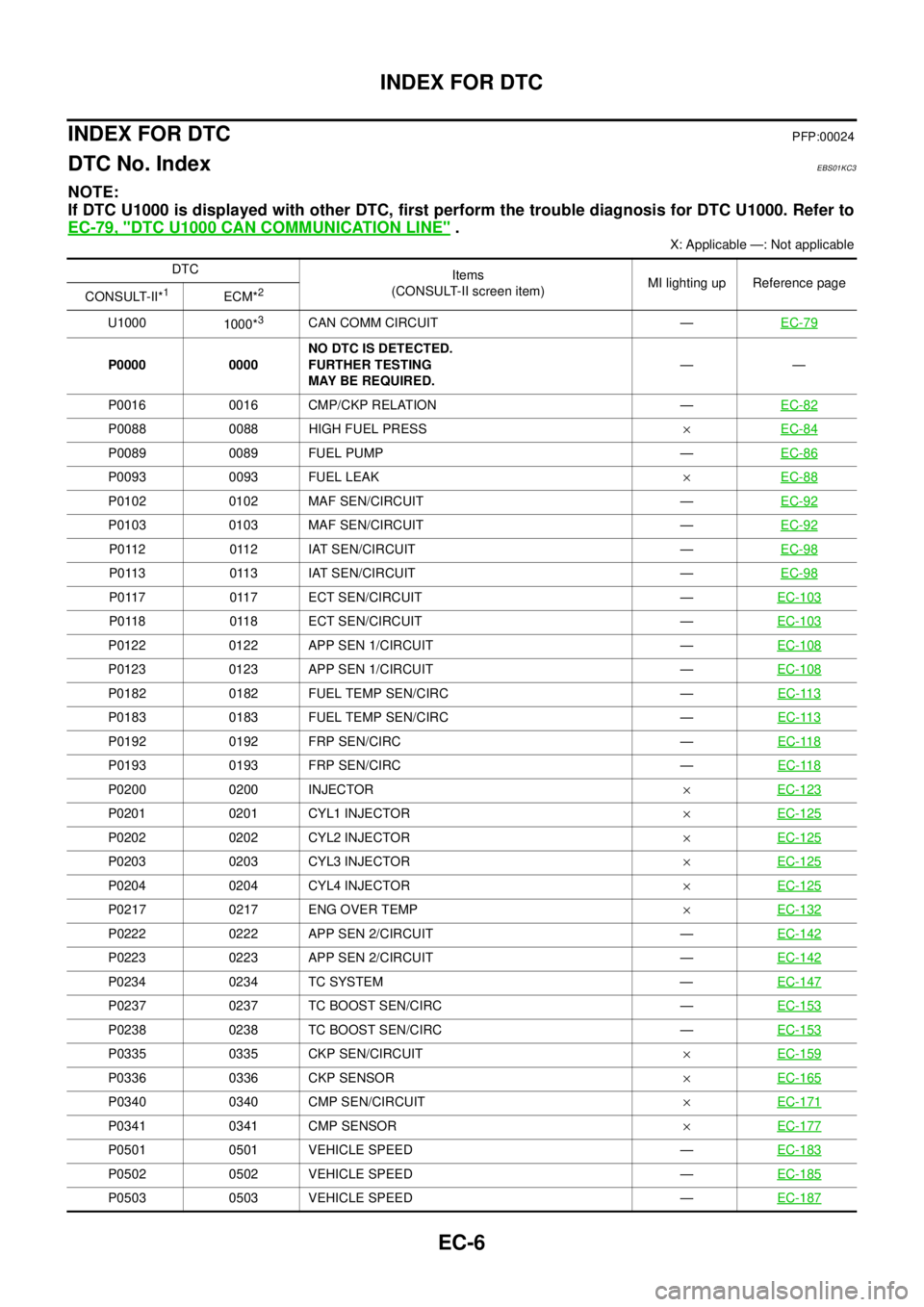

INDEX FOR DTC

INDEX FOR DTC

PFP:00024

DTC No. IndexEBS01KC3

NOTE:

If DTC U1000 is displayed with other DTC, first perform the trouble diagnosis for DTC U1000. Refer to

EC-79, "

DTC U1000 CAN COMMUNICATION LINE".

X: Applicable —: Not applicable

DTC

Items

(CONSULT-II screen item)MI lighting up Reference page

CONSULT-II*

1ECM*2

U1000

1000*3CAN COMM CIRCUIT —EC-79

P0000 0000NO DTC IS DETECTED.

FURTHER TESTING

MAY BE REQUIRED.——

P0016 0016 CMP/CKP RELATION —EC-82

P0088 0088 HIGH FUEL PRESS´EC-84

P0089 0089 FUEL PUMP —EC-86

P0093 0093 FUEL LEAK´EC-88

P0102 0102 MAF SEN/CIRCUIT —EC-92

P0103 0103 MAF SEN/CIRCUIT —EC-92

P0112 0112 IAT SEN/CIRCUIT —EC-98

P0113 0113 IAT SEN/CIRCUIT —EC-98

P0117 0117 ECT SEN/CIRCUIT —EC-103

P0118 0118 ECT SEN/CIRCUIT —EC-103

P0122 0122 APP SEN 1/CIRCUIT —EC-108

P0123 0123 APP SEN 1/CIRCUIT —EC-108

P0182 0182 FUEL TEMP SEN/CIRC —EC-113

P0183 0183 FUEL TEMP SEN/CIRC —EC-113

P0192 0192 FRP SEN/CIRC —EC-118

P0193 0193 FRP SEN/CIRC —EC-118

P0200 0200 INJECTOR´EC-123

P0201 0201 CYL1 INJECTOR´EC-125

P0202 0202 CYL2 INJECTOR´EC-125

P0203 0203 CYL3 INJECTOR´EC-125

P0204 0204 CYL4 INJECTOR´EC-125

P0217 0217 ENG OVER TEMP´EC-132

P0222 0222 APP SEN 2/CIRCUIT —EC-142

P0223 0223 APP SEN 2/CIRCUIT —EC-142

P0234 0234 TC SYSTEM —EC-147

P0237 0237 TC BOOST SEN/CIRC —EC-153

P0238 0238 TC BOOST SEN/CIRC —EC-153

P0335 0335 CKP SEN/CIRCUIT´EC-159

P0336 0336 CKP SENSOR´EC-165

P0340 0340 CMP SEN/CIRCUIT´EC-171

P0341 0341 CMP SENSOR´EC-177

P0501 0501 VEHICLE SPEED —EC-183

P0502 0502 VEHICLE SPEED —EC-185

P0503 0503 VEHICLE SPEED —EC-187

Page 987 of 3171

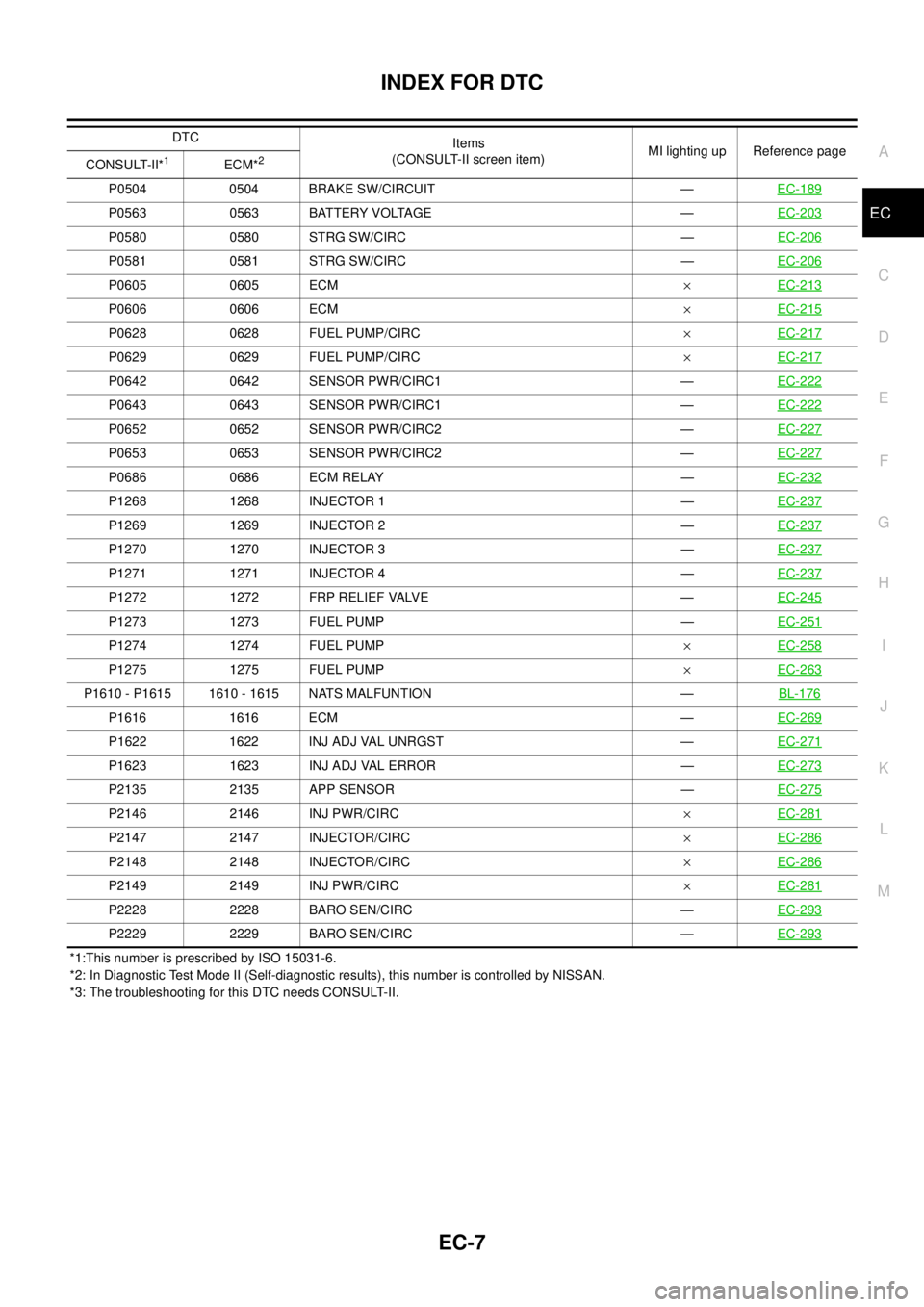

INDEX FOR DTC

EC-7

C

D

E

F

G

H

I

J

K

L

MA

EC

*1:This number is prescribed by ISO 15031-6.

*2: In Diagnostic Test Mode II (Self-diagnostic results), this number is controlled by NISSAN.

*3: The troubleshooting for this DTC needs CONSULT-II.P0504 0504 BRAKE SW/CIRCUIT —EC-189

P0563 0563 BATTERY VOLTAGE —EC-203

P0580 0580 STRG SW/CIRC —EC-206

P0581 0581 STRG SW/CIRC —EC-206

P0605 0605 ECM´EC-213

P0606 0606 ECM´EC-215

P0628 0628 FUEL PUMP/CIRC´EC-217

P0629 0629 FUEL PUMP/CIRC´EC-217

P0642 0642 SENSOR PWR/CIRC1 —EC-222

P0643 0643 SENSOR PWR/CIRC1 —EC-222

P0652 0652 SENSOR PWR/CIRC2 —EC-227

P0653 0653 SENSOR PWR/CIRC2 —EC-227

P0686 0686 ECM RELAY —EC-232

P1268 1268 INJECTOR 1 —EC-237

P1269 1269 INJECTOR 2 —EC-237

P1270 1270 INJECTOR 3 —EC-237

P1271 1271 INJECTOR 4 —EC-237

P1272 1272 FRP RELIEF VALVE —EC-245

P1273 1273 FUEL PUMP —EC-251

P1274 1274 FUEL PUMP´EC-258

P1275 1275 FUEL PUMP´EC-263

P1610 - P1615 1610 - 1615 NATS MALFUNTION —BL-176

P1616 1616 ECM —EC-269

P1622 1622 INJ ADJ VAL UNRGST —EC-271

P1623 1623 INJ ADJ VAL ERROR —EC-273

P2135 2135 APP SENSOR —EC-275

P2146 2146 INJ PWR/CIRC´EC-281

P2147 2147 INJECTOR/CIRC´EC-286

P2148 2148 INJECTOR/CIRC´EC-286

P2149 2149 INJ PWR/CIRC´EC-281

P2228 2228 BARO SEN/CIRC —EC-293

P2229 2229 BARO SEN/CIRC —EC-293

DTC

Items

(CONSULT-II screen item)MI lighting up Reference page

CONSULT-II*

1ECM*2

Page 988 of 3171

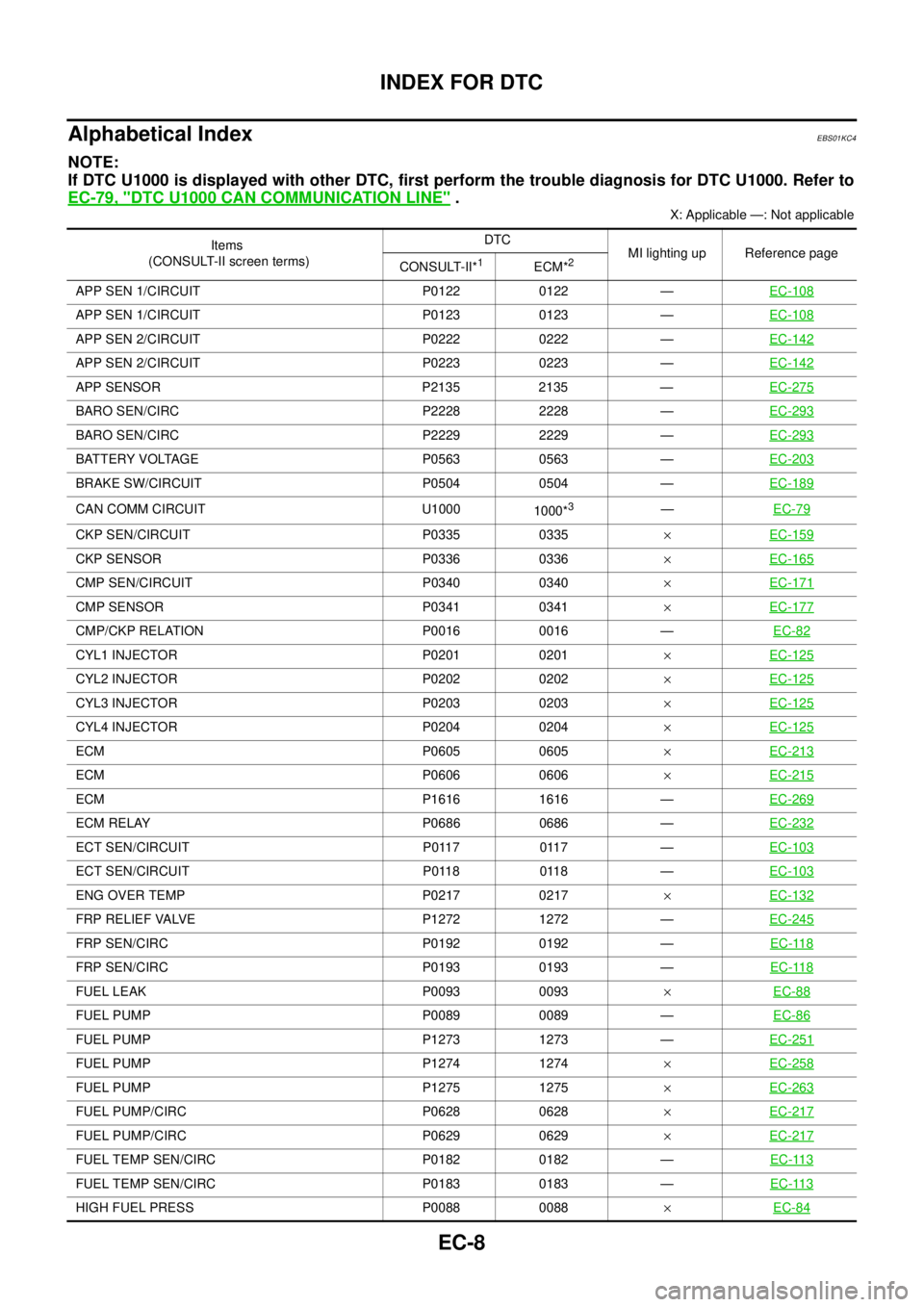

EC-8

INDEX FOR DTC

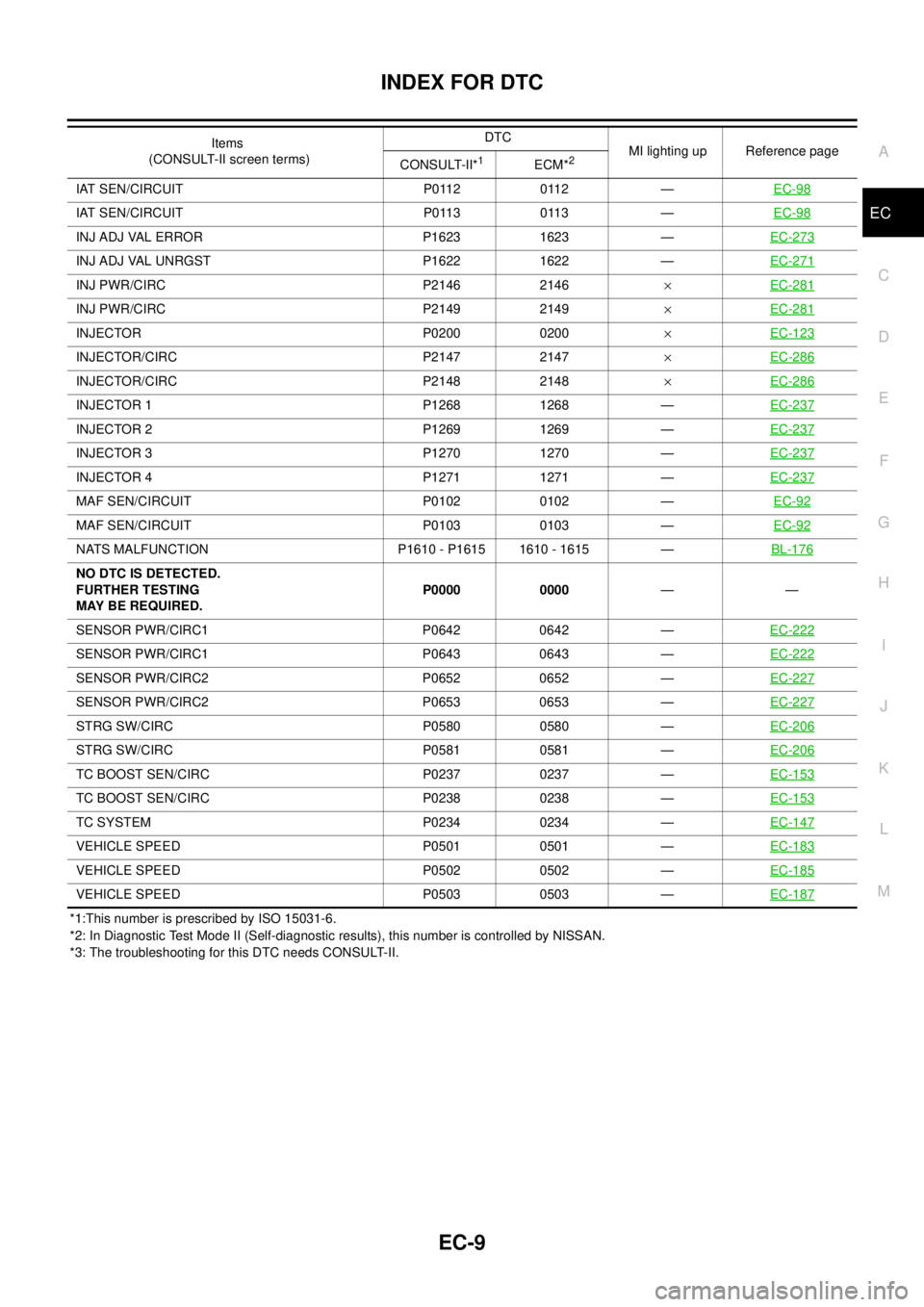

Alphabetical Index

EBS01KC4

NOTE:

If DTC U1000 is displayed with other DTC, first perform the trouble diagnosis for DTC U1000. Refer to

EC-79, "

DTC U1000 CAN COMMUNICATION LINE".

X: Applicable —: Not applicable

Items

(CONSULT-II screen terms)DTC

MI lighting up Reference page

CONSULT-II*

1ECM*2

APP SEN 1/CIRCUIT P0122 0122 —EC-108

APP SEN 1/CIRCUIT P0123 0123 —EC-108

APP SEN 2/CIRCUIT P0222 0222 —EC-142

APP SEN 2/CIRCUIT P0223 0223 —EC-142

APP SENSOR P2135 2135 —EC-275

BARO SEN/CIRC P2228 2228 —EC-293

BARO SEN/CIRC P2229 2229 —EC-293

BATTERY VOLTAGE P0563 0563 —EC-203

BRAKE SW/CIRCUIT P0504 0504 —EC-189

CAN COMM CIRCUIT U1000

1000*3—EC-79

CKP SEN/CIRCUIT P0335 0335´EC-159

CKP SENSOR P0336 0336´EC-165

CMP SEN/CIRCUIT P0340 0340´EC-171

CMP SENSOR P0341 0341´EC-177

CMP/CKP RELATION P0016 0016 —EC-82

CYL1 INJECTOR P0201 0201´EC-125

CYL2 INJECTOR P0202 0202´EC-125

CYL3 INJECTOR P0203 0203´EC-125

CYL4 INJECTOR P0204 0204´EC-125

ECM P0605 0605´EC-213

ECM P0606 0606´EC-215

ECM P1616 1616 —EC-269

ECM RELAY P0686 0686 —EC-232

ECT SEN/CIRCUIT P0117 0117 —EC-103

ECT SEN/CIRCUIT P0118 0118 —EC-103

ENG OVER TEMP P0217 0217´EC-132

FRP RELIEF VALVE P1272 1272 —EC-245

FRP SEN/CIRC P0192 0192 —EC-118

FRP SEN/CIRC P0193 0193 —EC-118

FUEL LEAK P0093 0093´EC-88

FUEL PUMP P0089 0089 —EC-86

FUEL PUMP P1273 1273 —EC-251

FUEL PUMP P1274 1274´EC-258

FUEL PUMP P1275 1275´EC-263

FUEL PUMP/CIRC P0628 0628´EC-217

FUEL PUMP/CIRC P0629 0629´EC-217

FUEL TEMP SEN/CIRC P0182 0182 —EC-113

FUEL TEMP SEN/CIRC P0183 0183 —EC-113

HIGH FUEL PRESS P0088 0088´EC-84

Page 989 of 3171

INDEX FOR DTC

EC-9

C

D

E

F

G

H

I

J

K

L

MA

EC

*1:This number is prescribed by ISO 15031-6.

*2: In Diagnostic Test Mode II (Self-diagnostic results), this number is controlled by NISSAN.

*3: The troubleshooting for this DTC needs CONSULT-II.IAT SEN/CIRCUIT P0112 0112 —EC-98

IAT SEN/CIRCUIT P0113 0113 —EC-98

INJ ADJ VAL ERROR P1623 1623 —EC-273

INJ ADJ VAL UNRGST P1622 1622 —EC-271

INJ PWR/CIRC P2146 2146´EC-281

INJ PWR/CIRC P2149 2149´EC-281

INJECTOR P0200 0200´EC-123

INJECTOR/CIRC P2147 2147´EC-286

INJECTOR/CIRC P2148 2148´EC-286

INJECTOR 1 P1268 1268 —EC-237

INJECTOR 2 P1269 1269 —EC-237

INJECTOR 3 P1270 1270 —EC-237

INJECTOR 4 P1271 1271 —EC-237

MAF SEN/CIRCUIT P0102 0102 —EC-92

MAF SEN/CIRCUIT P0103 0103 —EC-92

NATS MALFUNCTION P1610 - P1615 1610 - 1615 —BL-176

NO DTC IS DETECTED.

FURTHER TESTING

MAY BE REQUIRED.P0000 0000——

SENSOR PWR/CIRC1 P0642 0642 —EC-222

SENSOR PWR/CIRC1 P0643 0643 —EC-222

SENSOR PWR/CIRC2 P0652 0652 —EC-227

SENSOR PWR/CIRC2 P0653 0653 —EC-227

STRG SW/CIRC P0580 0580 —EC-206

STRG SW/CIRC P0581 0581 —EC-206

TC BOOST SEN/CIRC P0237 0237 —EC-153

TC BOOST SEN/CIRC P0238 0238 —EC-153

TC SYSTEM P0234 0234 —EC-147

VEHICLE SPEED P0501 0501 —EC-183

VEHICLE SPEED P0502 0502 —EC-185

VEHICLE SPEED P0503 0503 —EC-187

Items

(CONSULT-II screen terms)DTC

MI lighting up Reference page

CONSULT-II*

1ECM*2

Page 990 of 3171

EC-10

PRECAUTIONS

PRECAUTIONS

PFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EBS01KC5

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

On Board Diagnostic (OBD) System of EngineEBS01KC6

The ECM has an on board diagnostic system. It will light up the malfunction indicator (MI) to warn the driver of

a malfunction causing emission deterioration.

CAUTION:

lBe sure to turn the ignition switch OFF and disconnect the battery negative cable before any

repair or inspection work. The open/short circuit of related switches, sensors, solenoid valves,

etc. will cause the MI to light up.

lBe sure to connect and lock the connectors securely after work. A loose (unlocked) connector will

cause the MI to light up due to the open circuit. (Be sure the connector is free from water, grease,

dirt, bent terminals, etc.)

lCertain systems and components, especially those related to OBD, may use a new style slide-

locking type harness connector. For description and how to disconnect, refer toPG-75, "

HAR-

NESS CONNECTOR".

lBe sure to route and secure the harnesses properly after work. The interference of the harness

with a bracket, etc. may cause the MI to light up due to the short circuit.

lBe sure to connect rubber tubes properly after work. A misconnected or disconnected rubber tube

may cause the MI to light up due to the malfunction of the fuel system, etc.

lBe sure to erase the unnecessary malfunction information (repairs completed) from the ECM

before returning the vehicle to the customer.

PrecautionsEBS01KC7

lAlways use a 12 volt battery as power source.

lDo not attempt to disconnect battery cables while engine is

running.

lBefore connecting or disconnecting the ECM harness con-

nector, turn ignition switch OFF and disconnect battery

negative cable. Failure to do so may damage the ECM

because battery voltage is applied to ECM even if ignition

switch is turned off.

lBefore removing parts, turn ignition switch OFF and then

disconnect battery negative cable.

SEF289H