NISSAN NAVARA 2005 Repair Workshop Manual

Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 931 of 3171

COMBINATION METERS

DI-21

C

D

E

F

G

H

I

J

L

MA

B

DI

Engine Speed Signal InspectionEKS00PDG

Symptom: Tachometer indication is malfunction.

1.CHECK COMBINATION METER INPUT SIGNAL

1. Start engine and select “METER” on CONSULT-II.

2. Using “TACHO METER” on “DATA MONITOR”, compare the

value of “DATA MONITOR” with tachometer pointer of combina-

tion meter.

OK or NG

OK >> Perform ECM self-diagnosis. Refer toEC-59, "CON-

SULT-II Function (ENGINE)".

NG >> Replace combination meter. (Perform self-diagnosis of

ECM when the value in the monitor indicates 8191.875

rpm. Then repair or replace the malfunction part. Refer

toEC-59, "

CONSULT-II Function (ENGINE)".)

Engine Coolant Temperature Signal InspectionEKS00PDH

Symptom: Water temperature gauge indication is malfunction.

1.CHECK COMBINATION METER INPUT SIGNAL

1. Start engine and select “METER” on CONSULT-II.

2. Using “W TEMP METER” on “DATA MONITOR”, compare the

value of “DATA MONITOR” with water temperature gauge

pointer of combination meter.

OK or NG

OK >> Perform ECM self-diagnosis. Refer toEC-59, "CON-

SULT-II Function (ENGINE)".

NG >> Replace combination meter. (Perform self-diagnosis of ECM when the value in the monitor indi-

cates 215°C. Then repair or replace the malfunction part. Refer toEC-59, "

CONSULT-II Function

(ENGINE)".)

PKIA2090E

Water temperature gauge pointer Reference value of data monitor [°C(°F)]

Hot Approx. 130 (266)

Middle Approx. 70 - 105 (158 - 221)

Cold Approx. 50 (122)

PKIA2091E

Page 932 of 3171

DI-22

COMBINATION METERS

Fuel Level Sensor Signal Inspection

EKS00L8U

Symptom:

lFuel gauge indication is malfunction.

lLow-fuel warning lamp indication is irregular.

NOTE:

The following symptoms are not malfunction.

Fuel level sensor unit

lDepending on vehicle incline or driving circumstance, the fuel level in the tank varies, and the pointer may

fluctuate.

lIf the vehicle is fueled with the ignition switch ON, the pointer moves slowly.

Low-fuel warning lamp

lDepending on vehicle incline or driving circumstance, the fuel in the tank flows and the warning lamp ON

timing may change.

1.CHECK COMBINATION METER INPUT SIGNAL

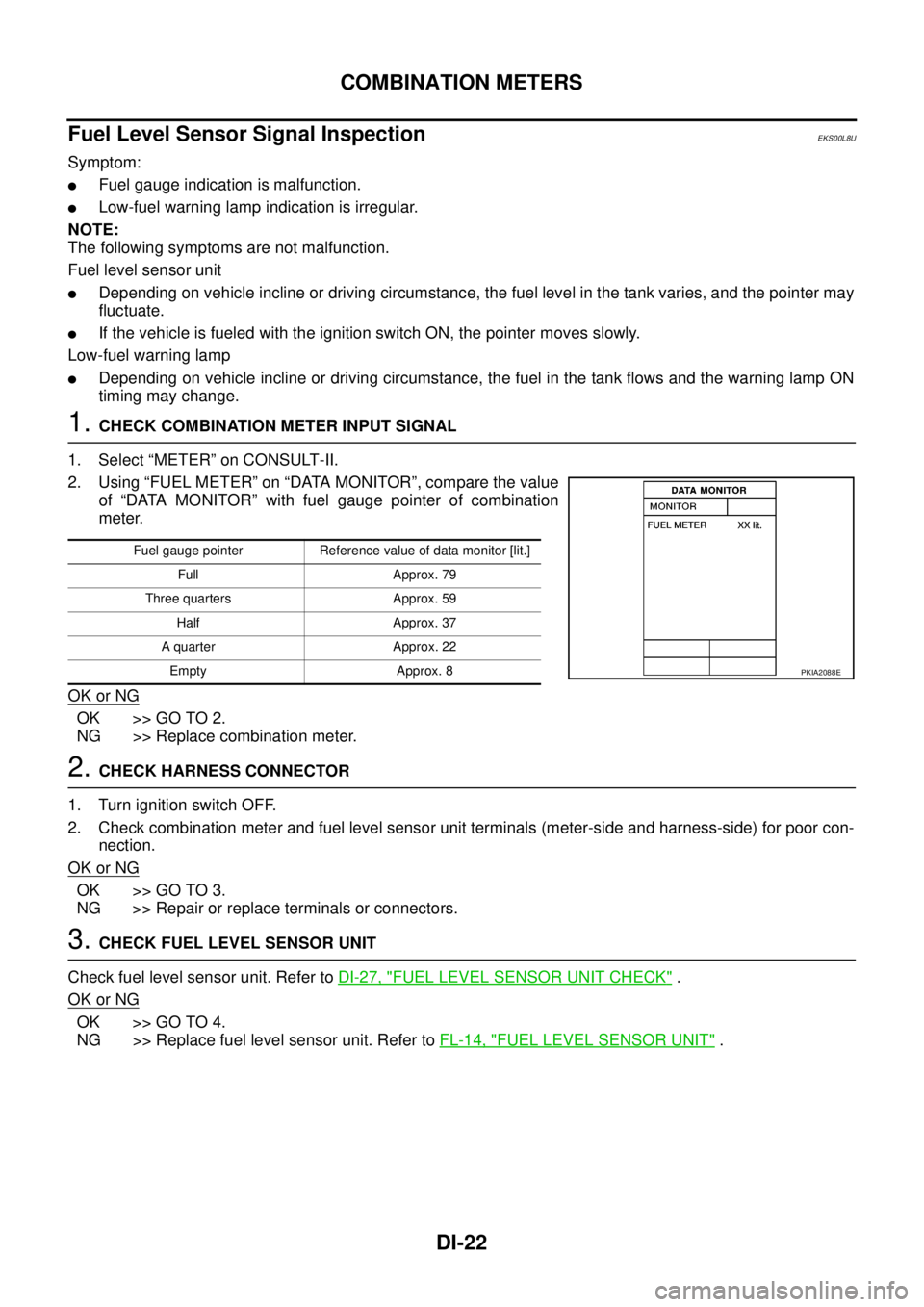

1. Select “METER” on CONSULT-II.

2. Using “FUEL METER” on “DATA MONITOR”, compare the value

of “DATA MONITOR” with fuel gauge pointer of combination

meter.

OK or NG

OK >> GO TO 2.

NG >> Replace combination meter.

2.CHECK HARNESS CONNECTOR

1. Turn ignition switch OFF.

2. Check combination meter and fuel level sensor unit terminals (meter-side and harness-side) for poor con-

nection.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace terminals or connectors.

3.CHECK FUEL LEVEL SENSOR UNIT

Check fuel level sensor unit. Refer toDI-27, "

FUEL LEVEL SENSOR UNIT CHECK".

OK or NG

OK >> GO TO 4.

NG >> Replace fuel level sensor unit. Refer toFL-14, "

FUEL LEVEL SENSOR UNIT".

Fuel gauge pointer Reference value of data monitor [lit.]

Full Approx. 79

Three quarters Approx. 59

Half Approx. 37

A quarter Approx. 22

Empty Approx. 8

PKIA2088E

Page 933 of 3171

COMBINATION METERS

DI-23

C

D

E

F

G

H

I

J

L

MA

B

DI

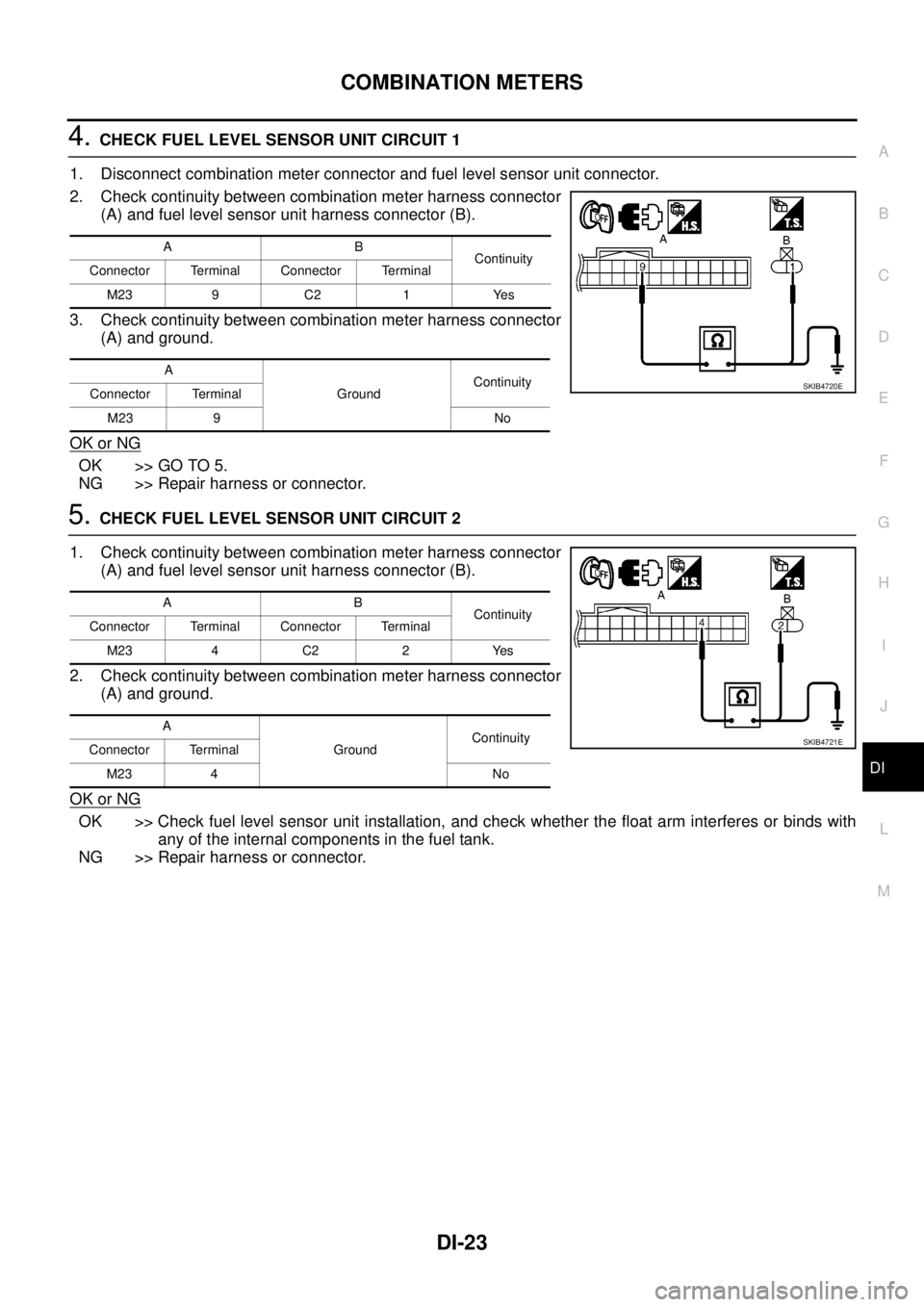

4.CHECK FUEL LEVEL SENSOR UNIT CIRCUIT 1

1. Disconnect combination meter connector and fuel level sensor unit connector.

2. Check continuity between combination meter harness connector

(A) and fuel level sensor unit harness connector (B).

3. Check continuity between combination meter harness connector

(A) and ground.

OK or NG

OK >> GO TO 5.

NG >> Repair harness or connector.

5.CHECK FUEL LEVEL SENSOR UNIT CIRCUIT 2

1. Check continuity between combination meter harness connector

(A) and fuel level sensor unit harness connector (B).

2. Check continuity between combination meter harness connector

(A) and ground.

OK or NG

OK >> Check fuel level sensor unit installation, and check whether the float arm interferes or binds with

any of the internal components in the fuel tank.

NG >> Repair harness or connector.

AB

Continuity

Connector Terminal Connector Terminal

M23 9 C2 1 Yes

A

GroundContinuity

Connector Terminal

M23 9 No

SKIB4720E

AB

Continuity

Connector Terminal Connector Terminal

M23 4 C2 2 Yes

A

GroundContinuity

Connector Terminal

M23 4 No

SKIB4721E

Page 934 of 3171

DI-24

COMBINATION METERS

Ambient Sensor Signal Inspection

EKS00MDQ

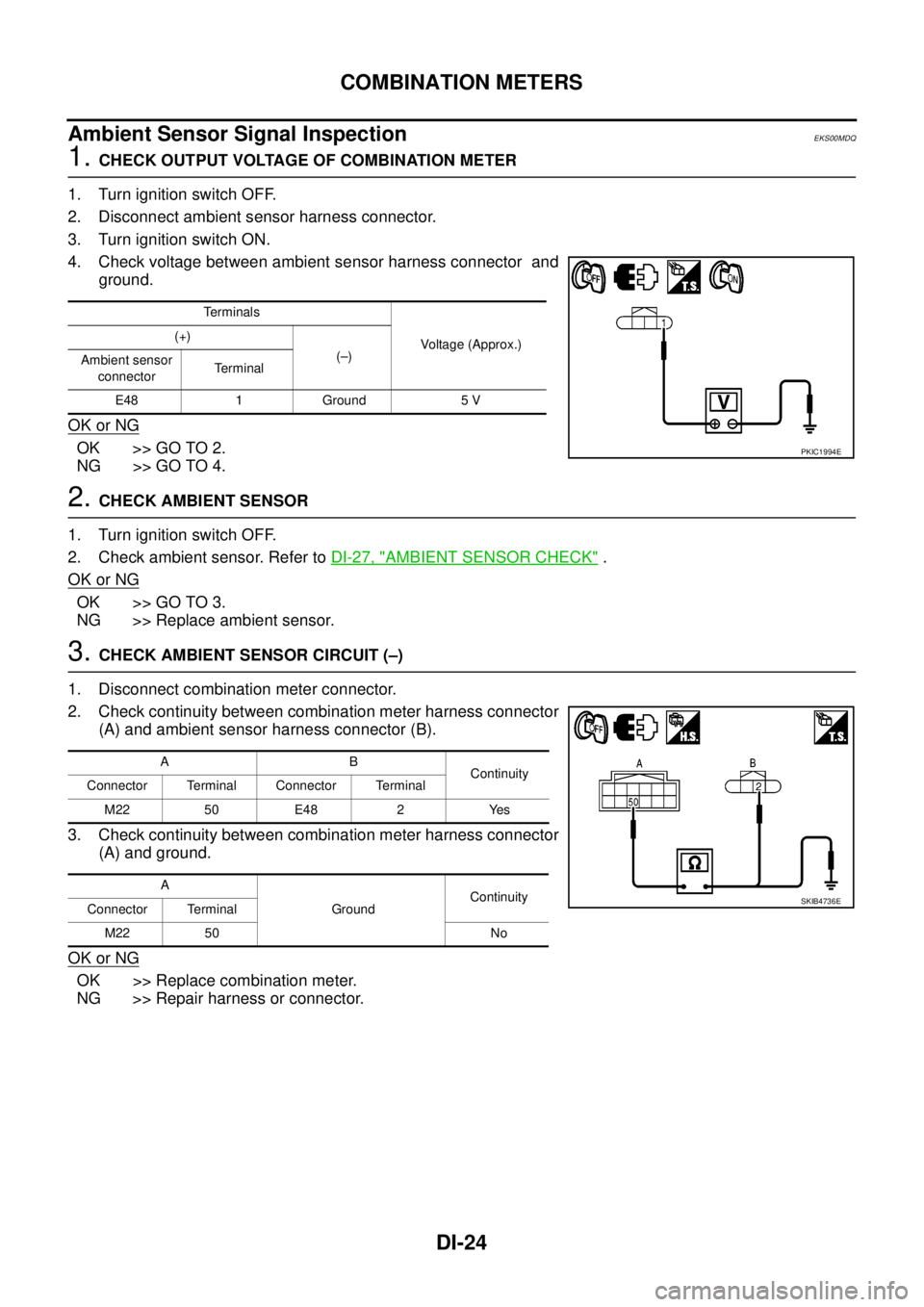

1.CHECK OUTPUT VOLTAGE OF COMBINATION METER

1. Turn ignition switch OFF.

2. Disconnect ambient sensor harness connector.

3. Turn ignition switch ON.

4. Check voltage between ambient sensor harness connector and

ground.

OK or NG

OK >> GO TO 2.

NG >> GO TO 4.

2.CHECK AMBIENT SENSOR

1. Turn ignition switch OFF.

2. Check ambient sensor. Refer toDI-27, "

AMBIENT SENSOR CHECK".

OK or NG

OK >> GO TO 3.

NG >> Replace ambient sensor.

3.CHECK AMBIENT SENSOR CIRCUIT (–)

1. Disconnect combination meter connector.

2. Check continuity between combination meter harness connector

(A) and ambient sensor harness connector (B).

3. Check continuity between combination meter harness connector

(A) and ground.

OK or NG

OK >> Replace combination meter.

NG >> Repair harness or connector.

Terminals

Voltage (Approx.) (+)

(–)

Ambient sensor

connectorTerminal

E48 1 Ground 5 V

PKIC1994E

AB

Continuity

Connector Terminal Connector Terminal

M22 50 E48 2 Yes

A

GroundContinuity

Connector Terminal

M22 50 No

SKIB4736E

Page 935 of 3171

COMBINATION METERS

DI-25

C

D

E

F

G

H

I

J

L

MA

B

DI

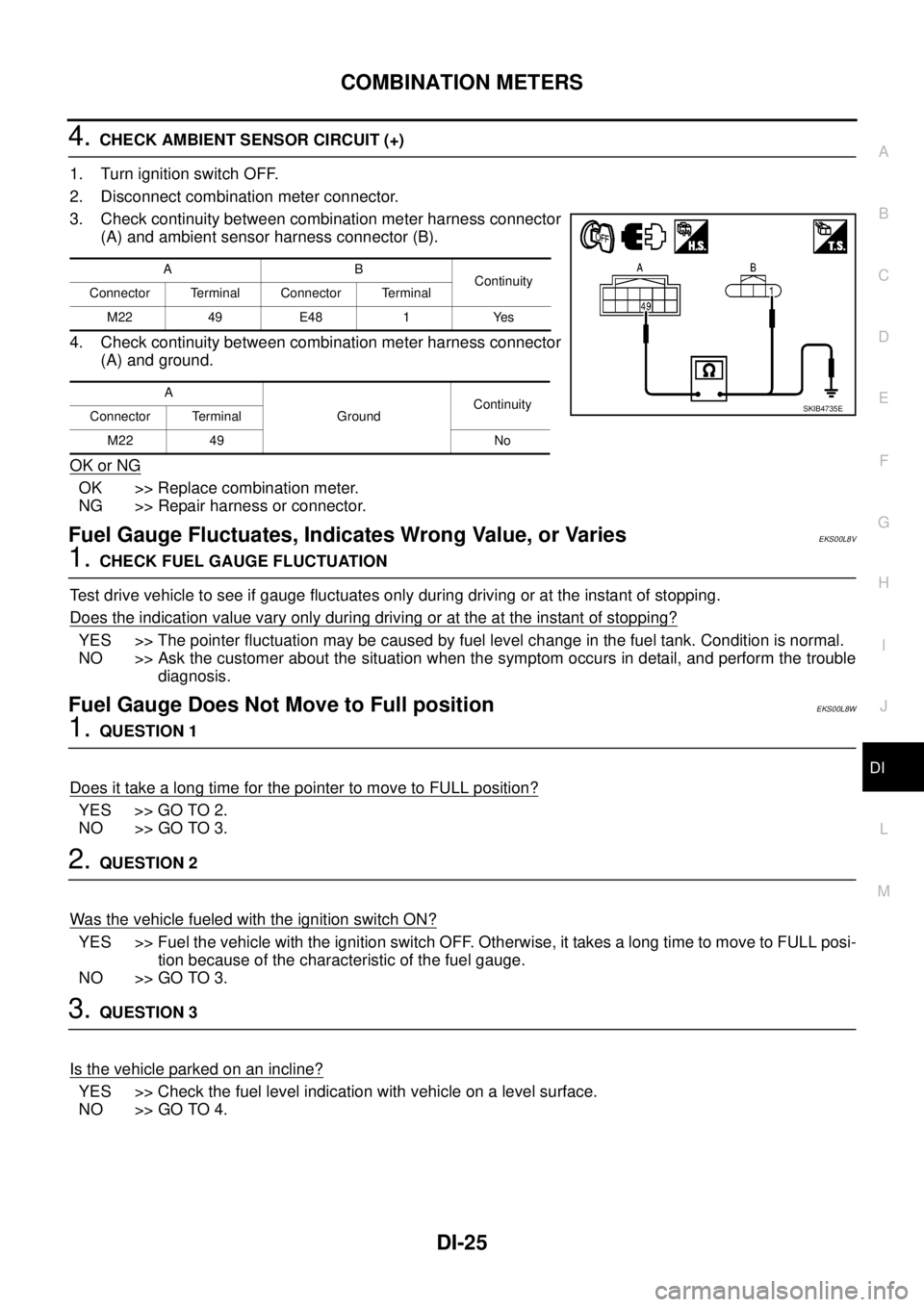

4.CHECK AMBIENT SENSOR CIRCUIT (+)

1. Turn ignition switch OFF.

2. Disconnect combination meter connector.

3. Check continuity between combination meter harness connector

(A) and ambient sensor harness connector (B).

4. Check continuity between combination meter harness connector

(A) and ground.

OK or NG

OK >> Replace combination meter.

NG >> Repair harness or connector.

Fuel Gauge Fluctuates, Indicates Wrong Value, or VariesEKS00L8V

1.CHECK FUEL GAUGE FLUCTUATION

Test drive vehicle to see if gauge fluctuates only during driving or at the instant of stopping.

Does the indication value vary only during driving or at the at the instant of stopping?

YES >> The pointer fluctuation may be caused by fuel level change in the fuel tank. Condition is normal.

NO >> Ask the customer about the situation when the symptom occurs in detail, and perform the trouble

diagnosis.

Fuel Gauge Does Not Move to Full positionEKS00L8W

1.QUESTION 1

Does it take a long time for the pointer to move to FULL position?

YES >> GO TO 2.

NO >> GO TO 3.

2.QUESTION 2

Was the vehicle fueled with the ignition switch ON?

YES >> Fuel the vehicle with the ignition switch OFF. Otherwise, it takes a long time to move to FULL posi-

tion because of the characteristic of the fuel gauge.

NO >> GO TO 3.

3.QUESTION 3

Isthevehicleparkedonanincline?

YES >> Check the fuel level indication with vehicle on a level surface.

NO >> GO TO 4.

AB

Continuity

Connector Terminal Connector Terminal

M22 49 E48 1 Yes

A

GroundContinuity

Connector Terminal

M22 49 No

SKIB4735E

Page 936 of 3171

DI-26

COMBINATION METERS

4.QUESTION 4

During driving, does the fuel gauge pointer move gradually toward EMPTY position?

YES >> Check the fuel level sensor unit. Refer toDI-27, "FUEL LEVEL SENSOR UNIT CHECK".

NO >> The float arm may interfere or bind with any of the components in the fuel tank.

DTC [U1000] CAN Communication CircuitEKS00L8X

Symptom: Displays “CAN COMM CIRC [U1000]” at the self-diagnosis result for combination meter.

1.CHECK CAN COMMUNICATION

1. Select “SELF-DIAG RESULTS” mode for “METER” with CONSULT-II.

2. Print out CONSULT-II screen.

>> Go to “LAN SYSTEM”. Refer toLAN-3, "

Precautions When Using CONSULT-II".

DTC [B2205] Vehicle Speed CircuitEKS00L8Y

Symptom: Displays “VEHICLE SPEED CIRC [B2205]” at the self-diagnosis result for combination meter.

Perform the ABS actuator and electric unit (control unit) self-diagnosis, and repair or replace malfunctioning

parts. Refer toBRC-17, "

CONSULT- II Functions".

Page 937 of 3171

COMBINATION METERS

DI-27

C

D

E

F

G

H

I

J

L

MA

B

DI

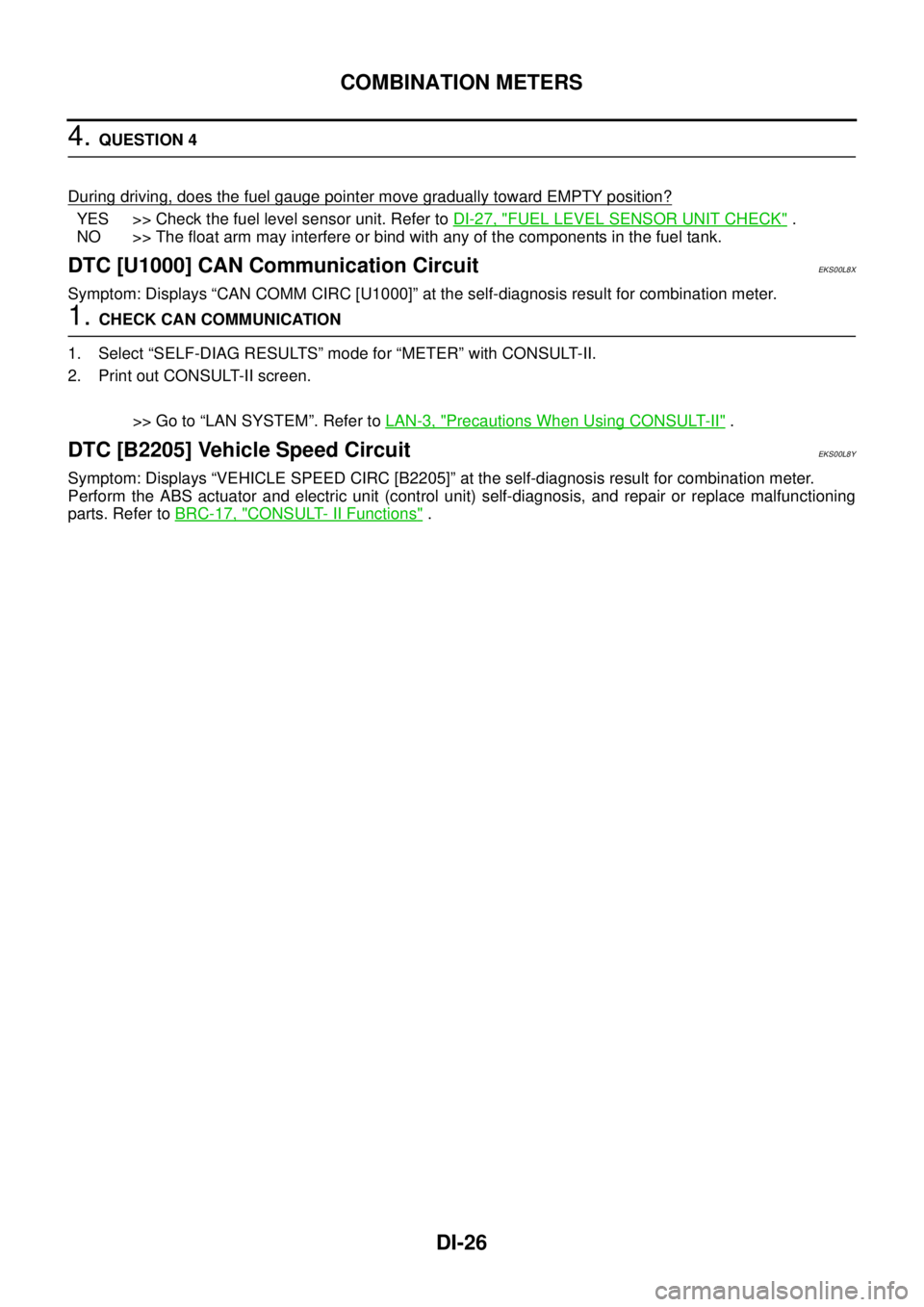

Electrical Components InspectionEKS00L8Z

FUEL LEVEL SENSOR UNIT CHECK

For removal, refer toFL-14, "FUEL LEVEL SENSOR UNIT".

Check Fuel Level Sensor Unit

Check resistance between terminals 1 and 2.

*1 and *2: When float rod is in contact with stopper.

AMBIENT SENSOR CHECK

Check resistance between terminals 1 and 2.

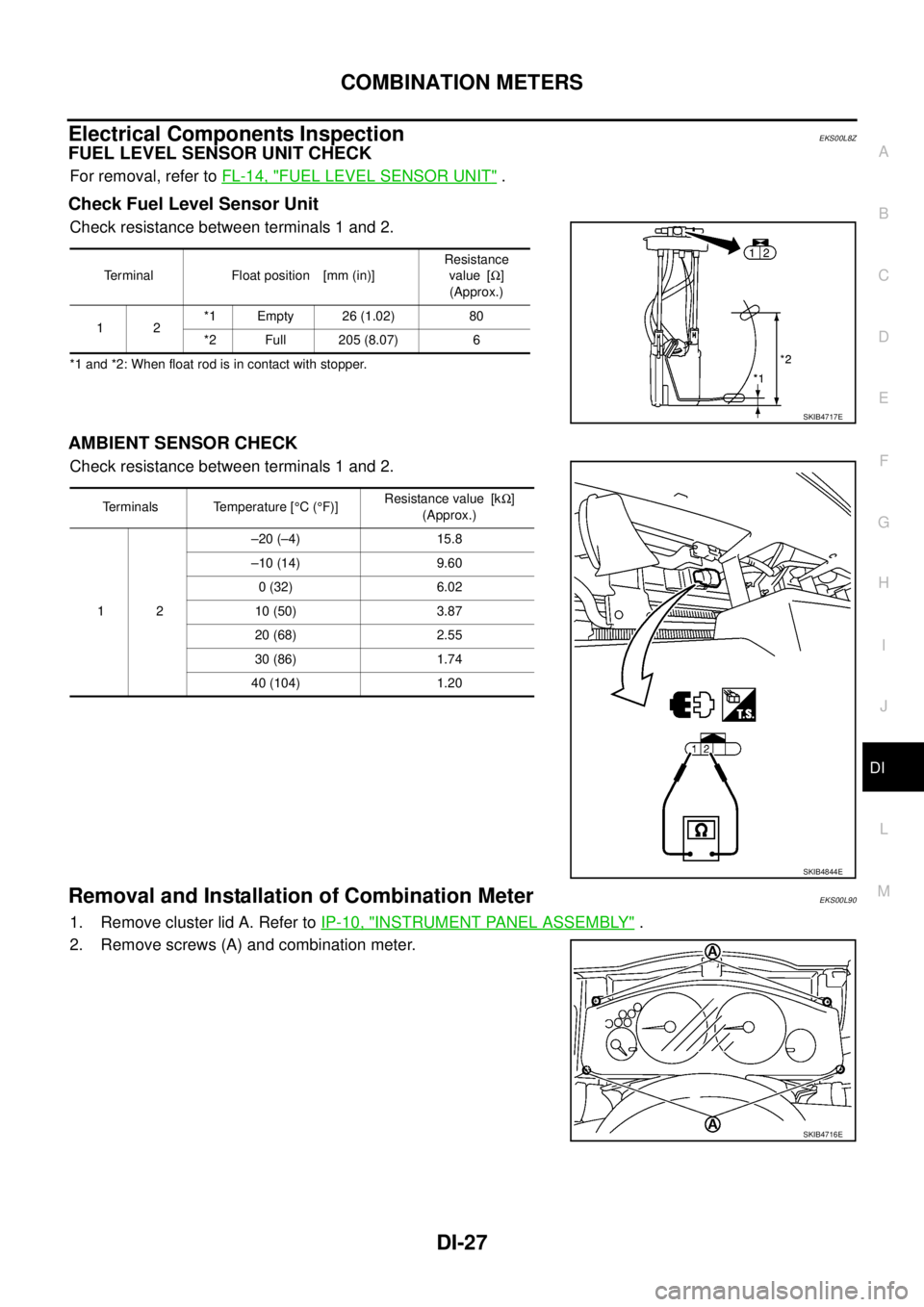

Removal and Installation of Combination MeterEKS00L90

1. Remove cluster lid A. Refer toIP-10, "INSTRUMENT PANEL ASSEMBLY".

2. Remove screws (A) and combination meter.

Terminal Float position [mm (in)]Resistance

value [W]

(Approx.)

12*1 Empty 26 (1.02) 80

*2 Full 205 (8.07) 6

SKIB4717E

Terminals Temperature [°C(°F)]Resistance value [kW]

(Approx.)

12–20 (–4) 15.8

–10 (14) 9.60

0 (32) 6.02

10 (50) 3.87

20 (68) 2.55

30 (86) 1.74

40 (104) 1.20

SKIB4844E

SKIB4716E

Page 938 of 3171

DI-28

WARNING LAMPS

WARNING LAMPS

PFP:24814

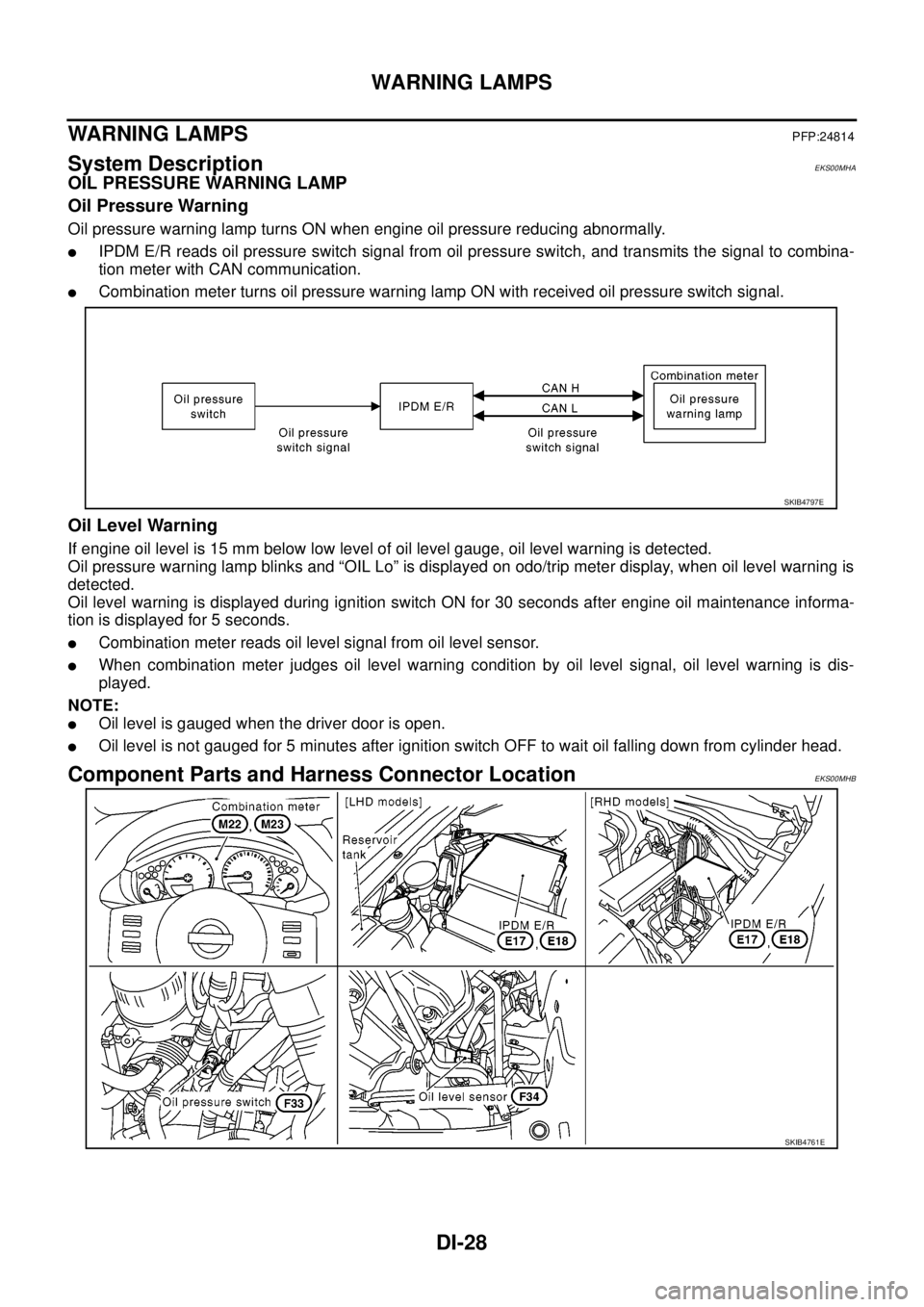

System DescriptionEKS00MHA

OIL PRESSURE WARNING LAMP

Oil Pressure Warning

Oil pressure warning lamp turns ON when engine oil pressure reducing abnormally.

lIPDM E/R reads oil pressure switch signal from oil pressure switch, and transmits the signal to combina-

tion meter with CAN communication.

lCombination meter turns oil pressure warning lamp ON with received oil pressure switch signal.

Oil Level Warning

If engine oil level is 15 mm below low level of oil level gauge, oil level warning is detected.

Oil pressure warning lamp blinks and “OIL Lo” is displayed on odo/trip meter display, when oil level warning is

detected.

Oil level warning is displayed during ignition switch ON for 30 seconds after engine oil maintenance informa-

tion is displayed for 5 seconds.

lCombination meter reads oil level signal from oil level sensor.

lWhen combination meter judges oil level warning condition by oil level signal, oil level warning is dis-

played.

NOTE:

lOil level is gauged when the driver door is open.

lOil level is not gauged for 5 minutes after ignition switch OFF to wait oil falling down from cylinder head.

Component Parts and Harness Connector LocationEKS00MHB

SKIB4797E

SKIB4761E

Page 939 of 3171

WARNING LAMPS

DI-29

C

D

E

F

G

H

I

J

L

MA

B

DI

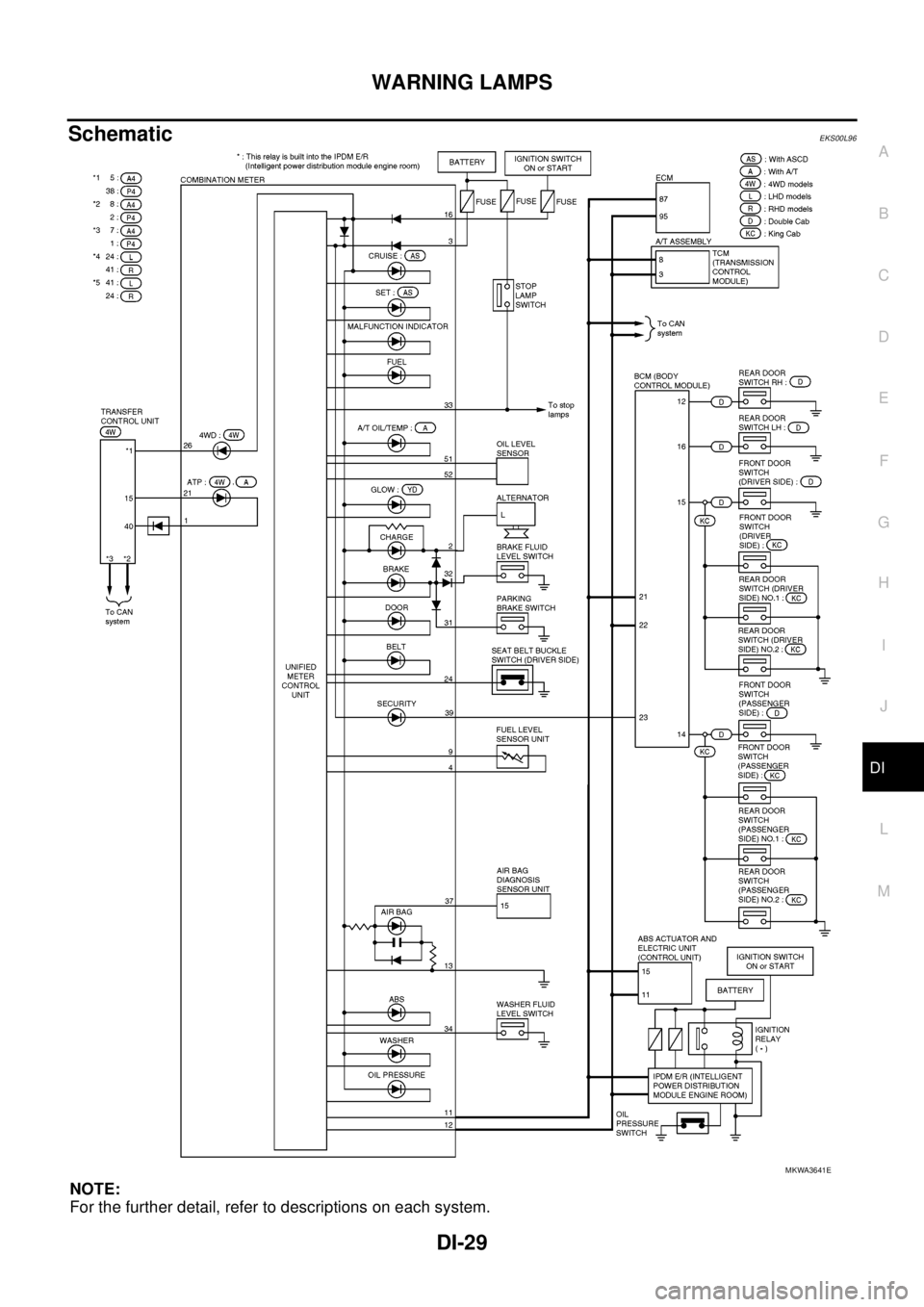

SchematicEKS00L96

NOTE:

For the further detail, refer to descriptions on each system.

MKWA3641E

Page 940 of 3171

DI-30

WARNING LAMPS

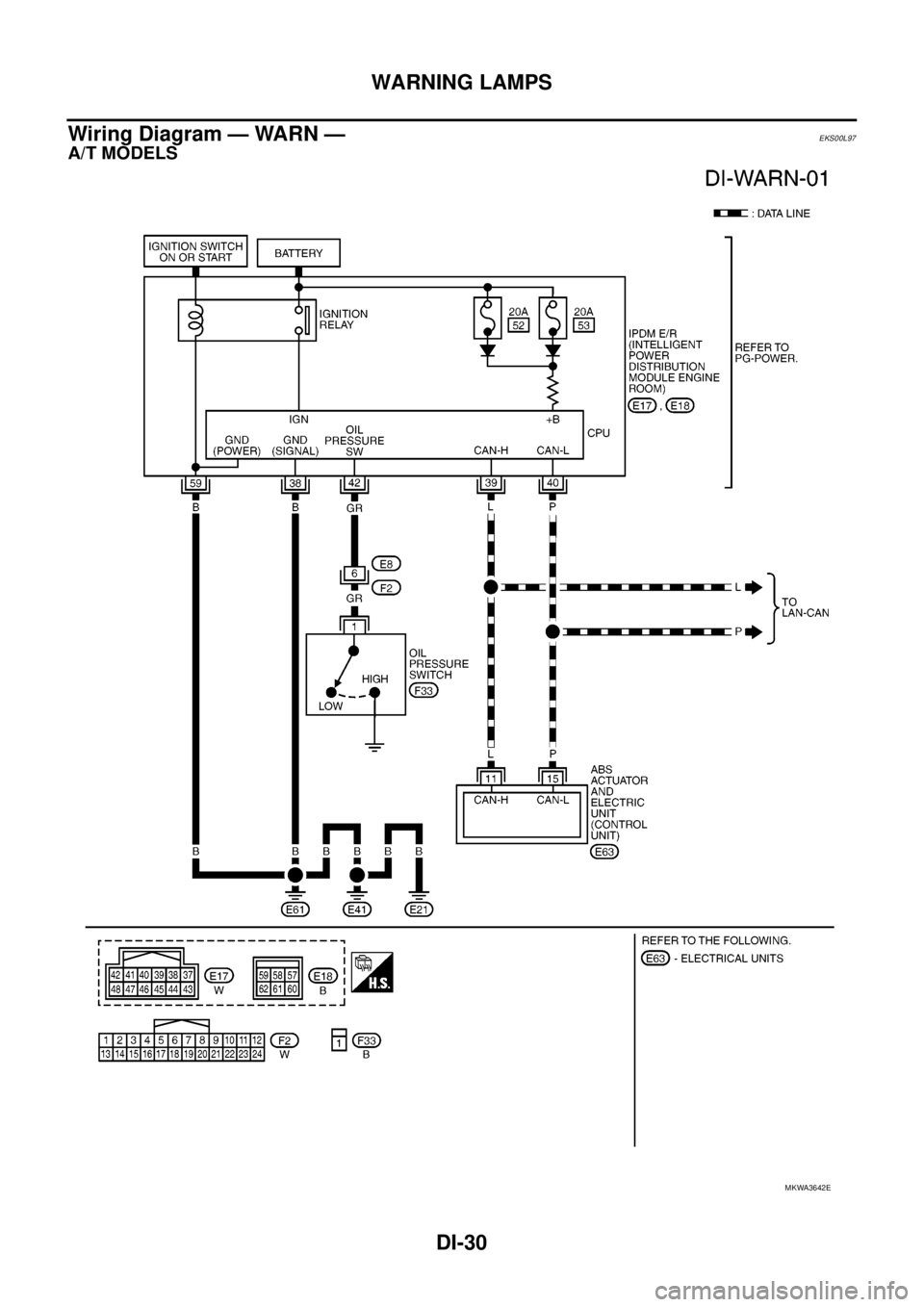

Wiring Diagram — WARN —

EKS00L97

A/T MODELS

MKWA3642E