start NISSAN NOTE 2016 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 1072 of 3641

![NISSAN NOTE 2016 Service Repair Manual CAMSHAFTEM-71

< REMOVAL AND INSTALLATION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

• Measure the outer diameter of valve lifter using suitable tool (A).

VALVE LIFTER HOLE DIAMETER

Measure the diame NISSAN NOTE 2016 Service Repair Manual CAMSHAFTEM-71

< REMOVAL AND INSTALLATION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

• Measure the outer diameter of valve lifter using suitable tool (A).

VALVE LIFTER HOLE DIAMETER

Measure the diame](/img/5/57363/w960_57363-1071.png)

CAMSHAFTEM-71

< REMOVAL AND INSTALLATION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

• Measure the outer diameter of valve lifter using suitable tool (A).

VALVE LIFTER HOLE DIAMETER

Measure the diameter of valve lifter hole of cylinder head using suit-

able tool (A).

VALVE LIFTER CLEARANCE

• (Valve lifter clearance) = (Valve lifter hole diameter) – (Valve lifter outer diameter)

• If out of the standard, referring to the each standard of

valve lifter outer diameter and valve lifter hole diame-

ter, replace either or both valve lifter and cylinder head.

INSPECTION AFTER INSTALLATION

Inspection of Camshaft Sprocket Oil Groove

CAUTION:

• Perform this inspection only when DTC P0011 or P 0014 is detected in self-diagnostic results of CON-

SULT and it is directed according to insp ection procedure of EC section. Refer to EC-168, "

Diagnosis

Procedure" (P0011) or EC-172, "Diagnosis Procedure" (P0014).

• Check when engine is cold so as to pr event burns from the splashing engine oil.

NOTE:

This section provides the inspection method of oil passage of cam sprocket on the intake side. For oil passage

on the exhaust side, the inspection proc edure must be changed as instructed below:

1. Check engine oil level. Refer to LU-7, "

Inspection".

2. Perform the following procedure so as to prevent the engine from being unintentionally started while checking.

a. Release the fuel pressure. Refer to EC-137, "

Work Procedure".

b. Remove intake manifold. Refer to EM-28, "

Removal and Installation".

Standard : Refer to

EM-117, "

Camshaft".

PBIC3185J

Standard : Refer to EM-117, "Camshaft".

PBIC3184J

Standard : Refer to EM-117, "Camshaft".

· Step 3 : Remove exhaust valve timing control solenoid valve. Refer to EM-60, "Exploded View".

· Step 4 : Crank engine, and then check that engine oil comes out from exhaust valve timing control solenoid

valve hole (A). End crank after checking.

·Step 5 Perform the following inspection if engine oil does not come out from exhaust valve timing control

solenoid valve oil hole of the cylinder head.

• Remove oil filter, and then clean it. Refer to

EM-60, "

Exploded View".

• Clean oil groove between oil strainer and exhaust valve timing control solenoid valve. Refer to

EM-60, "

Exploded View".

·Step 6 : Remove components between exhaust valve timing control solenoid valve and camshaft sprocket

(EXH), and then check each oil groove for clogging.

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 1085 of 3641

![NISSAN NOTE 2016 Service Repair Manual EM-84

< REMOVAL AND INSTALLATION >[HR16DE]

CYLINDER HEAD

5. Using a suitable tool finish valve seat to the specified dimen-

sions. For dimensions, refer to MA-11, "

Fluids and Lubricants".

CAUTION:

W NISSAN NOTE 2016 Service Repair Manual EM-84

< REMOVAL AND INSTALLATION >[HR16DE]

CYLINDER HEAD

5. Using a suitable tool finish valve seat to the specified dimen-

sions. For dimensions, refer to MA-11, "

Fluids and Lubricants".

CAUTION:

W](/img/5/57363/w960_57363-1084.png)

EM-84

< REMOVAL AND INSTALLATION >[HR16DE]

CYLINDER HEAD

5. Using a suitable tool finish valve seat to the specified dimen-

sions. For dimensions, refer to MA-11, "

Fluids and Lubricants".

CAUTION:

When using a valve seat cutter, firmly grip the cutter handle

with both hands. Then, pr ess the contacting surface evenly

around the valve seat to cut in a single attempt. Improper

pressure or cutting several times may result in wavy valve

seat.

6. Using compound, grind to adjust valve fitting.

7. Check again for normal contact. Refer to "VALVE SEAT CONTACT".

VALVE SPRING SQUARENESS

• Set a tri-square (A) along the side of valve spring and rotate spring. Measure the maximum clearance between the top of spring and

tri-square.

• If it exceeds the limit, replace valve spring.

VALVE SPRING DIMENSIONS AND VALVE SPRING PRESSURE LOAD

• Check valve spring pressure with valve spring seat installed at the specified spring height.

CAUTION:

Do not remove valve spring seat from valve spring.

• If the installation load or load with valve open is out of the stan- dard, replace valve spring (with valve spring seat).

INSPECTION AFTER INSTALLATION

• Before starting engine, check oil/fluid levels, incl uding engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer to MA-11, "

Fluids and Lubricants".

• Use procedure below to check for fuel leaks.

• Turn ignition switch ON (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leaks

at connection points.

• Start engine. With engine speed increased, che ck again for fuel leaks at connection points.

• Run engine to check for unusual noise and vibration.

NOTE:

If hydraulic pressure inside timing chain tensioner drops after removal and installation, slack in the guide

may generate a pounding noise during and just after engine start. However, this is normal. Noise will stop

after hydraulic pressure rises.

• Warm up engine thoroughly to make sure there are no l eaks of fuel, exhaust gas, or any oils/fluids including

engine oil and engine coolant.

• Bleed air from passages in lines and hoses, such as in cooling system.

• After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to spec- ified level, if necessary.

• Summary of the inspection items:

SEM934C

(B) : Contact

Limit : Refer to EM-119, "Cylinder head".

PBIC3219J

Standard : Refer to EM-119, "Cylinder head".

SEM113

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1086 of 3641

![NISSAN NOTE 2016 Service Repair Manual CYLINDER HEADEM-85

< REMOVAL AND INSTALLATION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

*Power steering fluid, brake fluid, etc. Item

Before starting engine Engine runningAfter engine stopped

Engine NISSAN NOTE 2016 Service Repair Manual CYLINDER HEADEM-85

< REMOVAL AND INSTALLATION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

*Power steering fluid, brake fluid, etc. Item

Before starting engine Engine runningAfter engine stopped

Engine](/img/5/57363/w960_57363-1085.png)

CYLINDER HEADEM-85

< REMOVAL AND INSTALLATION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

*Power steering fluid, brake fluid, etc. Item

Before starting engine Engine runningAfter engine stopped

Engine coolant LevelLeaks Level

Engine oil LevelLeaks Level

Transmission/

transaxle fluid CVT Models

LeaksLevel/Leaks Leaks

M/T Models Level/Leaks LeaksLevel/Leaks

Other oils and fluids* LevelLeaks Level

Fuel LeaksLeaks Leaks

Exhaust gas —Leaks —

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1088 of 3641

![NISSAN NOTE 2016 Service Repair Manual ENGINE ASSEMBLYEM-87

< UNIT REMOVAL AND INSTALLATION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

CAUTION:

Check that the stud bolt (*2) is tigh

t at the specified torque before tightening the nut (*1) NISSAN NOTE 2016 Service Repair Manual ENGINE ASSEMBLYEM-87

< UNIT REMOVAL AND INSTALLATION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

CAUTION:

Check that the stud bolt (*2) is tigh

t at the specified torque before tightening the nut (*1)](/img/5/57363/w960_57363-1087.png)

ENGINE ASSEMBLYEM-87

< UNIT REMOVAL AND INSTALLATION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

CAUTION:

Check that the stud bolt (*2) is tigh

t at the specified torque before tightening the nut (*1) shown. [Stud

bolt (*2) may be loosened after loosening the nut (*1)]

Removal and InstallationINFOID:0000000012431732

WARNING:

• Position the vehicle on a flat and solid surface.

• Place chocks at front and back of rear wheels.

• Attach proper slingers and bolts described in PARTS CATALOG if engine is not already equipped.

CAUTION:

• Always be careful to work safely.

• Do not start working until exhaust system and coolant are cool enough.

• If items or work required are not covered by th e engine section, refer to the applicable sections.

• Always use the support poin t specified for lifting.

• Use either 2-pole lift type or separate type lift. If board-on type must be used, support the rear axle

jacking point with a transmission jack or similar to ol before starting work, in preparation for the

backward shift of center of gravity.

• For supporting points for lifting and j acking point at rear axle, refer to GI-29, "

2-Pole Lift".

NOTE:

• When removing components such as hoses, tubes/lines, etc., cap or plug openings to prevent fluid from

spilling.

1. Engine mounting (RH) stay 2. Engine mount (RH) stay 3. Engine mounting insulator (RH)

4. Rear engine mounting bracket 5. Rear torque rod 6. Engine mounting bracket (LH)

7. Mass damper 8. Engine mounting insulator (LH) 9. Engine mounting bracket (LH)

10. Engine mount bracket (LH) A. Front mark B. Transaxle (upper)

C. Transaxle (lower) D. M/T models

AWBIA1587ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1090 of 3641

![NISSAN NOTE 2016 Service Repair Manual ENGINE ASSEMBLYEM-89

< UNIT REMOVAL AND INSTALLATION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

17. Use a suitable jack (A) to securely support the bottom of the

engine and the transaxle assembly.

CAU NISSAN NOTE 2016 Service Repair Manual ENGINE ASSEMBLYEM-89

< UNIT REMOVAL AND INSTALLATION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

17. Use a suitable jack (A) to securely support the bottom of the

engine and the transaxle assembly.

CAU](/img/5/57363/w960_57363-1089.png)

ENGINE ASSEMBLYEM-89

< UNIT REMOVAL AND INSTALLATION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

17. Use a suitable jack (A) to securely support the bottom of the

engine and the transaxle assembly.

CAUTION:

Put a piece of wood or an equivalent as the supporting sur-

face and secure in a stable condition.

18. Remove engine mounting insulator (RH) (1).

19. Remove engine through bolt-securing nut (C).

20. Carefully lower suitable jack, or raise lift to remove the engine and the transaxle assembly. Observe the following cautions:

CAUTION:

• Check that no part interferes with the vehicle side.

• Before and during lifting, always check if any harnesses are left connected.

• During removal, always be careful to prevent the vehic le from falling off the lift due to changes in

the center of gravity.

• If necessary, support the vehicle by setting jack or suitable tool at the rear.

21. Remove starter motor. Refer to STR-31, "

Exploded View".

22. Lift with a hoist and separate the engine from the transaxle assembly. Refer to TM-24, "

Exploded View"

(M/T models) and TM-259, "Exploded View" (CVT models).

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Do not allow engine oil to get on engine mounting insulator. Be careful not to damage engine mount-

ing insulator.

• Check that each mounting insulator is seated properly, and tighten nuts and bolts.

• When installation directions are specified, instal l parts according to the direction marks on them,

referring to the figure of components. Refer to EM-86, "

Exploded View".

• Inspect vehicle alignment and adjust (If necessary). Refer to FSU-8, "

Adjustment".

Engine Mounting Insulator (RH)

• Tighten bolts include spec table showing installation torque for

engine mounting bracket in the numerical order as shown.

INSPECTION AFTER INSTALLATION

PBIC3223J

(2) : Engine mounting insulator (LH)

(A) : Engine front side

(B) : Transaxle side

JSBIA1223ZZ

: Front

JPBIA2809ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1091 of 3641

![NISSAN NOTE 2016 Service Repair Manual EM-90

< UNIT REMOVAL AND INSTALLATION >[HR16DE]

ENGINE ASSEMBLY

• Before starting engine, check oil/fluid levels incl

uding engine coolant and engine oil. If less than required

quantity, fill to the NISSAN NOTE 2016 Service Repair Manual EM-90

< UNIT REMOVAL AND INSTALLATION >[HR16DE]

ENGINE ASSEMBLY

• Before starting engine, check oil/fluid levels incl

uding engine coolant and engine oil. If less than required

quantity, fill to the](/img/5/57363/w960_57363-1090.png)

EM-90

< UNIT REMOVAL AND INSTALLATION >[HR16DE]

ENGINE ASSEMBLY

• Before starting engine, check oil/fluid levels incl

uding engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer to MA-11, "

Fluids and Lubricants".

• Use procedure below to check for fuel leaks.

• Turn ignition switch ON (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leaks

at connection points.

• Start engine. With engine speed increased, che ck again for fuel leaks at connection points.

• Run engine to check for unusual noise and vibration. NOTE:

If hydraulic pressure inside timing chain tensioner drops after removal and installation, slack in the guide

may generate a pounding noise during and just after engine start. However, this is normal. Noise will stop

after hydraulic pressure rises.

• Warm up engine thoroughly to make sure there are no l eaks of fuel, exhaust gas, or any oils/fluids including

engine oil and engine coolant.

• Bleed air from passages in lines and hoses, such as in cooling system.

• After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to spec- ified level, if necessary.

• Summary of the inspection items:

*Power steering fluid, brake fluid, etc. Item

Before starting engine Engine runningAfter engine stopped

Engine coolant LevelLeaks Level

Engine oil LevelLeaks Level

Transmission/

transaxle fluid CVT Models

LeaksLevel/Leaks Leaks

M/T Models Level/Leaks LeaksLevel/Leaks

Other oils and fluids* LevelLeaks Level

Fuel LeaksLeaksLeaks

Exhaust gas —Leaks —

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1132 of 3641

EC-5

C

DE

F

G H

I

J

K L

M

EC A

N

O P

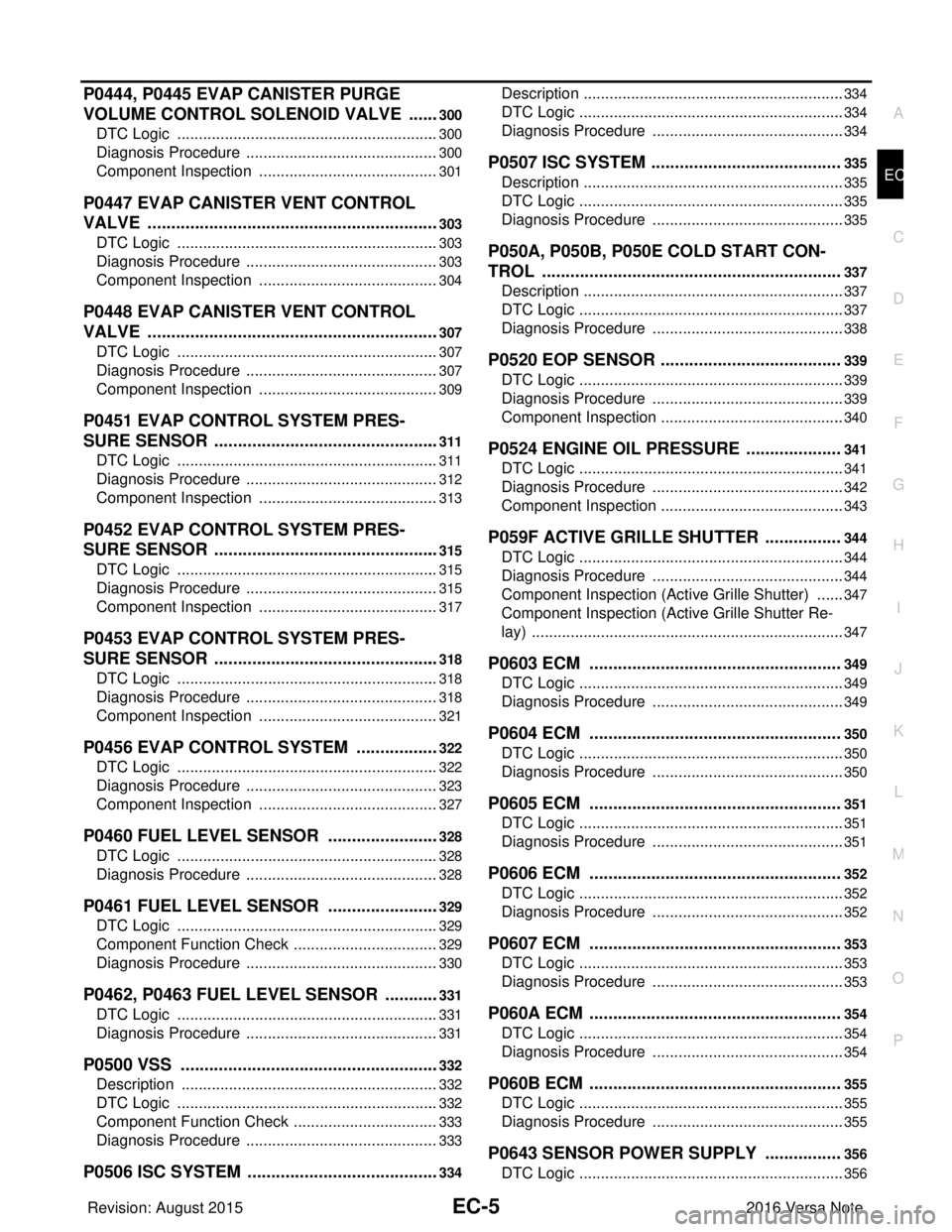

P0444, P0445 EVAP CANISTER PURGE

VOLUME CONTROL SOLENOID VALVE ..... ..

300

DTC Logic ........................................................... ..300

Diagnosis Procedure .............................................300

Component Inspection ..........................................301

P0447 EVAP CANISTER VENT CONTROL

VALVE ..............................................................

303

DTC Logic ........................................................... ..303

Diagnosis Procedure .............................................303

Component Inspection ..........................................304

P0448 EVAP CANISTER VENT CONTROL

VALVE ..............................................................

307

DTC Logic ........................................................... ..307

Diagnosis Procedure .............................................307

Component Inspection ..........................................309

P0451 EVAP CONTROL SYSTEM PRES-

SURE SENSOR ................................................

311

DTC Logic ........................................................... ..311

Diagnosis Procedure .............................................312

Component Inspection ..........................................313

P0452 EVAP CONTROL SYSTEM PRES-

SURE SENSOR ................................................

315

DTC Logic ........................................................... ..315

Diagnosis Procedure .............................................315

Component Inspection ..........................................317

P0453 EVAP CONTROL SYSTEM PRES-

SURE SENSOR ................................................

318

DTC Logic ........................................................... ..318

Diagnosis Procedure .............................................318

Component Inspection ..........................................321

P0456 EVAP CONTROL SYSTEM ..................322

DTC Logic ........................................................... ..322

Diagnosis Procedure .............................................323

Component Inspection ..........................................327

P0460 FUEL LEVEL SENSOR ........................328

DTC Logic ........................................................... ..328

Diagnosis Procedure .............................................328

P0461 FUEL LEVEL SENSOR ........................329

DTC Logic ........................................................... ..329

Component Function Check ..................................329

Diagnosis Procedure .............................................330

P0462, P0463 FUEL LEVEL SENSOR ............331

DTC Logic ........................................................... ..331

Diagnosis Procedure .............................................331

P0500 VSS .......................................................332

Description .......................................................... ..332

DTC Logic .............................................................332

Component Function Check ..................................333

Diagnosis Procedure .............................................333

P0506 ISC SYSTEM .........................................334

Description ........................................................... ..334

DTC Logic ..............................................................334

Diagnosis Procedure .............................................334

P0507 ISC SYSTEM ........................................335

Description .............................................................335

DTC Logic ..............................................................335

Diagnosis Procedure .............................................335

P050A, P050B, P050E COLD START CON-

TROL ...............................................................

337

Description .............................................................337

DTC Logic ..............................................................337

Diagnosis Procedure .............................................338

P0520 EOP SENSOR ......................................339

DTC Logic ..............................................................339

Diagnosis Procedure .............................................339

Component Inspection ...........................................340

P0524 ENGINE OIL PRESSURE ....................341

DTC Logic ..............................................................341

Diagnosis Procedure .............................................342

Component Inspection ...........................................343

P059F ACTIVE GRILLE SHUTTER ................344

DTC Logic ..............................................................344

Diagnosis Procedure .............................................344

Component Inspection (Active Grille Shutter) .......347

Component Inspection (Active Grille Shutter Re-

lay) ....................................................................... ..

347

P0603 ECM .....................................................349

DTC Logic ..............................................................349

Diagnosis Procedure .............................................349

P0604 ECM .....................................................350

DTC Logic ..............................................................350

Diagnosis Procedure .............................................350

P0605 ECM .....................................................351

DTC Logic ..............................................................351

Diagnosis Procedure .............................................351

P0606 ECM .....................................................352

DTC Logic ..............................................................352

Diagnosis Procedure .............................................352

P0607 ECM .....................................................353

DTC Logic ..............................................................353

Diagnosis Procedure .............................................353

P060A ECM .....................................................354

DTC Logic ..............................................................354

Diagnosis Procedure .............................................354

P060B ECM .....................................................355

DTC Logic ..............................................................355

Diagnosis Procedure .............................................355

P0643 SENSOR POWER SUPPLY ................356

DTC Logic ..............................................................356

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1136 of 3641

![NISSAN NOTE 2016 Service Repair Manual PRECAUTIONSEC-9

< PRECAUTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

General PrecautionsINFOID:0000000012431266

•

Always use a 12 volt battery as power source.

• Do not attempt to disconnect ba NISSAN NOTE 2016 Service Repair Manual PRECAUTIONSEC-9

< PRECAUTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

General PrecautionsINFOID:0000000012431266

•

Always use a 12 volt battery as power source.

• Do not attempt to disconnect ba](/img/5/57363/w960_57363-1135.png)

PRECAUTIONSEC-9

< PRECAUTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

General PrecautionsINFOID:0000000012431266

•

Always use a 12 volt battery as power source.

• Do not attempt to disconnect battery cables while engine is

running.

• Before connecting or disc onnecting the ECM harness con-

nector, turn ignition switch OFF and disconnect negative bat-

tery cable. Failure to do so may damage the ECM because

battery voltage is applied to ECM even if ignition switch is

turned OFF.

• Before removing parts, turn ig nition switch OFF and then dis-

connect battery ground cable.

• Do not disassemble ECM.

• If a battery cable is disconnected, the memory will return to

the ECM value.

The ECM will now start to self-c ontrol at its initial value. So,

engine operation can vary slight ly in this case. However, this

is not an indication of a malf unction. Do not replace parts

because of a slight variation.

• If the battery is disconnected, the following emission-related

diagnostic information will be lost within 24 hours.

- Diagnostic trouble codes

- 1st trip diagnostic trouble codes

- Freeze frame data

- 1st trip freeze frame data

- System readiness test (SRT) codes

- Test values

• When connecting or disconnecting pin connectors into or

from ECM, take care not to damage pin terminals (bend or

break).

Make sure that there are not any bends or breaks on ECM pin

terminal, when connecting pin connectors.

• Securely connect ECM harness connectors.

A poor connection can cause an extremely high (surge) volt-

age to develop in coil and cond enser, thus resulting in dam-

age to ICs.

• Keep engine control system harness at least 10 cm (4 in) away

from adjacent harness, to prevent engine control system mal-

functions due to receiving externa l noise, degraded operation

of ICs, etc.

• Keep engine control system parts and harness dry.

• Before replacing ECM, perform ECM Terminals and Reference

Value inspection and make sure ECM functions properly.

Refer to EC-71, "

Reference Value".

• Handle mass air flow sensor carefully to avoid damage.

• Do not clean mass air flow senso r with any type of detergent.

• Do not disassemble electric th rottle control actuator.

• Even a slight leak in the air intake system can cause serious

incidents.

• Do not shock or jar the camsh aft position sensor (PHASE),

crankshaft position sensor (POS).

SEF289H

PBIA9222J

PBIB0090E

MEF040D

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1137 of 3641

![NISSAN NOTE 2016 Service Repair Manual EC-10

< PRECAUTION >[HR16DE]

PRECAUTIONS

•

After performing each TROUBLE DIAGNOSIS, perform DTC

CONFIRMATION PROCEDURE or Component Function

Check. The DTC should not be displayed in the DTC Confir NISSAN NOTE 2016 Service Repair Manual EC-10

< PRECAUTION >[HR16DE]

PRECAUTIONS

•

After performing each TROUBLE DIAGNOSIS, perform DTC

CONFIRMATION PROCEDURE or Component Function

Check. The DTC should not be displayed in the DTC Confir](/img/5/57363/w960_57363-1136.png)

EC-10

< PRECAUTION >[HR16DE]

PRECAUTIONS

•

After performing each TROUBLE DIAGNOSIS, perform DTC

CONFIRMATION PROCEDURE or Component Function

Check. The DTC should not be displayed in the DTC Confir-

mation Procedure if the repair is completed. The Component

Function Check should be a good result if the repair is com-

pleted.

• When measuring ECM signals with a circuit tester, never allow

the two tester probes to contact.

Accidental contact of probes will cause a short circuit and

damage the ECM power transistor.

• Do not operate fuel pump when there is no fuel in lines.

• Tighten fuel hose clamps to the specified torque.

• Do not depress accelerator pedal when starting.

• Immediately after starting, do not rev up engine unnecessar-

ily.

• Do not rev up engine just prior to shutdown.

SAT652J

SEF348N

SEF709Y

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1150 of 3641

![NISSAN NOTE 2016 Service Repair Manual COMPONENT PARTSEC-23

< SYSTEM DESCRIPTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Exhaust Valve Timing Control Solenoid ValveINFOID:0000000012431286

Exhaust valve timing control solenoi

d valve is NISSAN NOTE 2016 Service Repair Manual COMPONENT PARTSEC-23

< SYSTEM DESCRIPTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Exhaust Valve Timing Control Solenoid ValveINFOID:0000000012431286

Exhaust valve timing control solenoi

d valve is](/img/5/57363/w960_57363-1149.png)

COMPONENT PARTSEC-23

< SYSTEM DESCRIPTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Exhaust Valve Timing Control Solenoid ValveINFOID:0000000012431286

Exhaust valve timing control solenoi

d valve is activated by ON/OFF

pulse duty (ratio) signals from the ECM.

The exhaust valve timing control solenoid valve changes the oil

amount and direction of flow through exhaust valve timing control

unit or stops oil flow.

The longer pulse width retards valve angle.

The shorter pulse width advances valve angle.

When ON and OFF pulse widths become equal, the solenoid valve

stops oil pressure flow to fix the exhaust valve angle at the control

position.

Fuel InjectorINFOID:0000000012431287

The fuel injector is a small, precise solenoid valve. When the ECM

supplies a ground to the fuel injector circuit, the coil in the fuel injec-

tor is energized. The energized coil pulls the ball valve back and

allows fuel to flow through the fuel injector into the intake manifold.

The amount of fuel injected depends upon the injection pulse dura-

tion. Pulse duration is the length of time the fuel injector remains

open. The ECM controls the injection pulse duration based on

engine fuel needs.

Fuel PumpINFOID:0000000012431288

*: ECM determines the start signal status by the signals of engine speed and battery voltage.

The ECM activates the fuel pump for a few seconds after the ignition switch is turned ON to improve engine

start ability. If the ECM receives a engine speed signal from the crankshaft position sensor (POS) and cam-

shaft position sensor (PHASE), it knows that the engi ne is rotating, and causes the pump to operate. If the

engine speed signal is not received when the ignition s witch is ON, the engine stalls. The ECM stops pump

operation and prevents battery discharging, thereby improving safety. The EC M does not directly drive the fuel

pump. It controls the ON/OFF fuel pump rela y, which in turn controls the fuel pump.

JSBIA0652ZZ

JSBIA0742ZZ

SensorInput signal to ECMECM functionActuator

Crankshaft position sensor (POS)

Camshaft position sensor (PHASE) Engine speed*

Fuel pump controlFuel pump relay

↓

Fuel pump

Battery Battery voltage*

Condition Fuel pump operation

Ignition switch is turned to ON. Operates for 1 second.

Engine running and cranking Operates.

When engine is stopped Stops in 1.5 seconds.

Except as shown above Sto ps .

Revision: August 20152016 Versa Note

cardiagn.com