fuse NISSAN NOTE 2016 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 3011 of 3641

![NISSAN NOTE 2016 Service Repair Manual SEC-154

< DTC/CIRCUIT DIAGNOSIS >[WITHOUT INTELLIGENT KEY SYSTEM]

POWER SUPPLY AND GROUND CIRCUIT

POWER SUPPLY AND GROUND CIRCUIT

BCM

BCM : Diagnosis ProcedureINFOID:0000000012542538

Regarding Wiring NISSAN NOTE 2016 Service Repair Manual SEC-154

< DTC/CIRCUIT DIAGNOSIS >[WITHOUT INTELLIGENT KEY SYSTEM]

POWER SUPPLY AND GROUND CIRCUIT

POWER SUPPLY AND GROUND CIRCUIT

BCM

BCM : Diagnosis ProcedureINFOID:0000000012542538

Regarding Wiring](/img/5/57363/w960_57363-3010.png)

SEC-154

< DTC/CIRCUIT DIAGNOSIS >[WITHOUT INTELLIGENT KEY SYSTEM]

POWER SUPPLY AND GROUND CIRCUIT

POWER SUPPLY AND GROUND CIRCUIT

BCM

BCM : Diagnosis ProcedureINFOID:0000000012542538

Regarding Wiring Diagram information, refer to

BCS-117, "Wiring Diagram".

1.CHECK FUSES AND FUSIBLE LINK

Check that the following fuses and fusible link are not blown.

Is the fuse blown?

YES >> Replace the blown fuse or fusible link after repairing the affected circuit.

NO >> GO TO 2.

2.CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM connectors.

3. Check voltage between BCM connector and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair harness or connector.

3.CHECK GROUND CIRCUIT

Check continuity between BCM connector and ground.

Is the inspection result normal?

YES >> Inspection End.

NO >> Repair harness or connector.

Terminal No. Signal nameFuses and fusible link No.

37 Battery power supply 8 (10A)

42 12 (10A)

50 G (40A)

11 Ignition switch ACC or ON 18 (10A)

38 Ignition switch ON or START 2 (10A)

BCMGround Ignition switch position

Connector Terminal

—OFF

ACC ON

M18 11

0 V

Battery voltage

Battery voltage

37

Battery voltage

38 0 V0 V

M19 42

Battery voltage Battery voltage

50

BCM GroundContinuity

Connector Terminal

M19 55—Yes

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3013 of 3641

![NISSAN NOTE 2016 Service Repair Manual SEC-156

< DTC/CIRCUIT DIAGNOSIS >[WITHOUT INTELLIGENT KEY SYSTEM]

VEHICLE SECURITY INDICATOR

4. Check continuity between BCM connector M18 terminal 23 and ground.

Is the inspection result normal?

YES NISSAN NOTE 2016 Service Repair Manual SEC-156

< DTC/CIRCUIT DIAGNOSIS >[WITHOUT INTELLIGENT KEY SYSTEM]

VEHICLE SECURITY INDICATOR

4. Check continuity between BCM connector M18 terminal 23 and ground.

Is the inspection result normal?

YES](/img/5/57363/w960_57363-3012.png)

SEC-156

< DTC/CIRCUIT DIAGNOSIS >[WITHOUT INTELLIGENT KEY SYSTEM]

VEHICLE SECURITY INDICATOR

4. Check continuity between BCM connector M18 terminal 23 and ground.

Is the inspection result normal?

YES >> Check the following:

• 10A fuse No. 8, located in fuse block (J/B)

• Harness for open or short between security indicator lamp and fuse.

NO >> Repair or replace harness.

Diagnosis Procedure (Type A)INFOID:0000000012430489

Regarding Wiring Diagram information, refer to SEC-132, "Wiring Diagram".

1.SECURITY INDICATOR LAMP ACTIVE TEST

With CONSULT

Check “THEFT IND”” in “Active Test” of “IMMU”.

Without CONSULT

1. Disconnect BCM.

2. Check voltage between BCM harness connector M18 terminal 23 and ground.

Is the inspection result normal?

YES >> Security indicator lamp is OK.

NO >> GO TO 2.

2.SECURITY INDICATOR LAMP CHECK

Check security indicator lamp condition.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Replace combination meter. Refer to MWI-54, "

Removal and Installation".

3.CHECK HARNESS CONTINUITY

1. Turn ignition switch OFF.

2. Disconnect BCM and security indicator lamp connector.

3. Check continuity between BCM connector M18 term inal 23 and combination meter connector M82 termi-

nal 18.

4. Check continuity between BCM connector M18 terminal 23 and ground.

BCM Combination meter

Continuity

Connector TerminalConnector Terminal

M 182 3M 241 8 Y es

BCM GroundContinuity

Connector Terminal

M18 23 No

ConnectorTe r m i n a l s

ConditionVoltage (V)

(Approx.)

(+) (-)

M18 23Ground ON

0

OFF Battery voltage

BCM Combination meter

Continuity

Connector TerminalConnector Terminal

M 182 3M 821 8 Y es

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3014 of 3641

![NISSAN NOTE 2016 Service Repair Manual VEHICLE SECURITY INDICATORSEC-157

< DTC/CIRCUIT DIAGNOSIS > [WITHOUT INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

Is the inspection result normal?

YES >> Check the following: • 10A fuse NISSAN NOTE 2016 Service Repair Manual VEHICLE SECURITY INDICATORSEC-157

< DTC/CIRCUIT DIAGNOSIS > [WITHOUT INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

Is the inspection result normal?

YES >> Check the following: • 10A fuse](/img/5/57363/w960_57363-3013.png)

VEHICLE SECURITY INDICATORSEC-157

< DTC/CIRCUIT DIAGNOSIS > [WITHOUT INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

Is the inspection result normal?

YES >> Check the following: • 10A fuse No. 8, located in fuse block (J/B)

• Harness for open or short between security indicator lamp and fuse.

NO >> Repair or replace harness.

BCM

GroundContinuity

Connector Terminal

M18 23 No

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3114 of 3641

SRS AIR BAG WARNING LAMP DOES NOT TURN OFF

SRC-97

< SYMPTOM DIAGNOSIS >

C

D E

F

G

I

J

K L

M A

B

SRC

N

O P

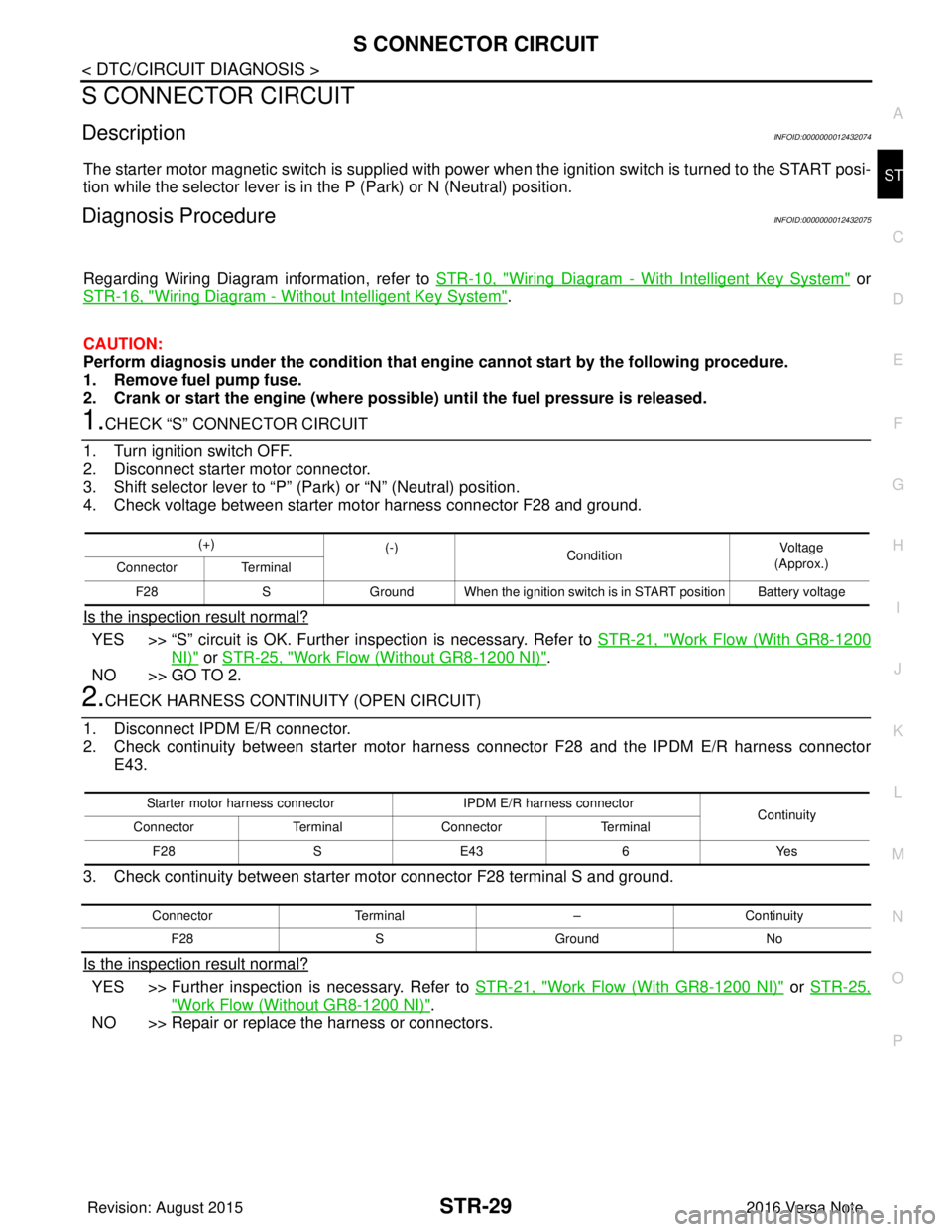

SYMPTOM DIAGNOSIS

SRS AIR BAG WARNING LAMP DOES NOT TURN OFF

Diagnosis ProcedureINFOID:0000000012430683

1.CHECK AIR BAG MODULE AND SEAT BELT PRE-TENSIONER

Check the deployment of air bag module.

Is air bag module deployed?

YES >> Replace the malfunctioning parts.

NO >> GO TO 2.

2.CHECK AIR BAG FUSE

Check 10 A fuse [No.7, located in fuse block (J/B)].

Is the inspection result normal?

YES >> GO TO 3.

NO >> Replace the fuse.

3.CHECK HARNESS CONNECTOR

Check the harness connector.

Is the inspection result normal?

YES >> GO TO 4.

NO >> Replace harness connectors.

4.CHECK WIRING HARNESS

Check the wiring harness externals.

Is the inspection result normal?

YES >> GO TO 5.

NO >> Replace wiring harness.

5.REPLACE AIR BAG DIAGNOSIS SENSOR UNIT

1. Replace air bag diagnosis sensor unit. Refer to SR-30, "

Removal and Installation".

2. Check air bag warning lamp operation.

Is the inspection result normal?

YES >> Inspection End.

NO >> GO TO 6.

6.REPLACE COMBINATION METER

1. Replace combination meter. Refer to MWI-54, "

Removal and Installation" (type A) or MWI-115, "Removal

and Installation" (type B).

2. Check air bag warning lamp operation.

Is the inspection result normal?

YES >> Inspection End.

NO >> GO TO 1.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3116 of 3641

SEAT BELT WARNING SYSTEMSRC-99

< SYMPTOM DIAGNOSIS >

C

DE

F

G

I

J

K L

M A

B

SRC

N

O P

SEAT BELT WARNING SYSTEM

Seat Belt Warning Syst em Does Not FunctionINFOID:0000000012430685

1.SEAT BELT WARNING LIGHT

Turn ignition switch ON.

Does the seat belt warning lamp come ON?

YES >> GO TO 2.

NO >> • Check 10A fuse [No. 8, loca ted in the fuse block (J/B)].

• Check seat belt buckle switch (driver seat).

• Check harness between combination meter and seat belt buckle switch (driver seat).

• Check combination meter. Refer to MWI-11, "

METER SYSTEM : Fail-safe" (type A) or MWI-62,

"METER SYSTEM : Fail-safe" (type B).

2.SEAT BELT BUCKLE (DRIVER SEAT)

Fasten the seat belt buckle (driver seat).

Does the seat belt warning lamp go OFF?

YES >> GO TO 3.

NO >> • Check seat belt buckle switch (driver seat). • Check harness between combination meter and seat belt buckle switch (driver seat).

3.OCCUPANT CLASSIFICATION SYSTEM

Have a helper sit in the passenger seat.

Does the seat belt warning lamp go ON?

YES >> GO TO 4.

NO >> • Check occupant classification system. Refer to SRC-11, "

OCCUPANT CLASSIFICATION SYS-

TEM : System Description".

• Check harness between occupant classification control unit and air bag diagnosis sensor unit.

4.SEAT BELT BUCKLE (PASSENGER SEAT)

Fasten the seat belt buckle (passenger seat).

Does the seat belt warning lamp go OFF?

YES >> System OK.

NO >> • Check seat belt buckle switch (passenger seat). • Check harness between seat belt buckle switch (passenger seat) and air bag diagnosis sensor

unit.

• Replace air bag diagnosis sensor unit. Refer to SR-30, "

Removal and Installation".

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3178 of 3641

STR-26

< BASIC INSPECTION >

DIAGNOSIS AND REPAIR WORKFLOW

2.CHECK THAT THE STARTER MOTOR STOPS

Check that the starter motor stops after starting the engine.

Does the starter motor stop?

YES >> Inspection End.

NO >> Replace starter motor. Refer to STR-31, "

Removal and Installation".

3.CHECK THAT THE ENGINE TURNS WHEN CRANKING

Check that the engine turns when cranking.

Does engine turn when cranking?

YES >> GO TO 4.

NO >> GO TO 5.

4.CHECK THE ENGINE SPEED WHEN CRANKING

Check that the engine speed is not low when cranking.

Does engine turn normally?

YES >> Check ignition/fuel system.

NO >> Check charge condition, corrosion and connection condition of the battery. Refer to PG-61, "

How

to Handle Battery".

5.CHECK STARTER MOTOR ACTIVATION

Check that the starter motor runs at cranking.

Does starter motor turn?

YES >> Replace starter motor. Refer to STR-31, "Removal and Installation".

NO >> GO TO 6.

6.CHECK POWER SUPPLY CIRCUIT

Check the following conditions:

• Fuse and fusible link

• Charge condition, corrosion and connection of the battery.

Are these inspection results normal?

YES >> GO TO 7.

NO >> Repair as needed.

7.CHECK STARTING SYSTEM WIRING

Check the following:

• “B” terminal circuit. Refer to STR-27, "

Diagnosis Procedure".

• “S” terminal circuit. Refer to STR-29, "

Diagnosis Procedure".

Are the inspection results normal?

YES >> Replace starter motor. Refer to STR-31, "Removal and Installation".

NO >> Repair as needed.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3179 of 3641

B TERMINAL CIRCUITSTR-27

< DTC/CIRCUIT DIAGNOSIS >

C

DE

F

G H

I

J

K L

M A

STR

NP

O

DTC/CIRCUIT DIAGNOSIS

B TERMINAL CIRCUIT

DescriptionINFOID:0000000012432072

Terminal “B” is constantly supplied with battery power.

Diagnosis ProcedureINFOID:0000000012432073

Regarding Wiring Diagram information, refer to

STR-10, "Wiring Diagram - With Intelligent Key System" or

STR-16, "

Wiring Diagram - Without Intelligent Key System".

CAUTION:

Perform diagnosis under the cond ition that the engine cannot start by the following procedure.

1. Remove fuel pump fuse.

2. Crank or start the engine (where possi ble) until the fuel pressure is released.

1.CHECK “B” TERMINAL CIRCUIT

1. Turn ignition switch OFF.

2. Check that starter motor B” terminal connection is clean and tight.

3. Check voltage between starter motor connector F27 and ground.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Check harness between battery and starter motor for open circuit.

2.CHECK BATTERY CABLE CONNECTION STATUS (VOLTAGE DROP TEST)

1. Shift selector lever to P (P ark) or N (Neutral) position.

2. Check voltage between battery positive terminal and starter motor B terminal.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Check harness between the battery and starter motor for continuity.

3.CHECK GROUND CIRCUIT STATUS (VOLTAGE DROP TEST)

1. Shift selector lever to P (P ark) or N (Neutral) position.

2. Check voltage between starter motor case and battery negative terminal.

Is the inspection result normal?

Te r m i n a l s

Voltage

(Approx.)

(+)

(-)

Starter motor “B” terminal Terminal

F27 BGround Battery voltage

Te r m i n a l s

ConditionVoltage

(Approx.)

(+) (-)

Starter motor “B“ terminal Terminal

Battery positive terminal F27 B When the ignition switch is in START position Less than 0.5V

Te r m i n a l s

ConditionVoltage

(Approx.)

(+) (-)

Starter motor case Battery negative terminal When the ignition switch is in

START position Less than 0.2V

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 3181 of 3641

S CONNECTOR CIRCUITSTR-29

< DTC/CIRCUIT DIAGNOSIS >

C

DE

F

G H

I

J

K L

M A

STR

NP

O

S CONNECTOR CIRCUIT

DescriptionINFOID:0000000012432074

The starter motor magnetic switch is supplied with power when the ignition switch is turned to the START posi-

tion while the selector lever is in the P (Park) or N (Neutral) position.

Diagnosis ProcedureINFOID:0000000012432075

Regarding Wiring Diagram information, refer to

STR-10, "Wiring Diagram - With Intelligent Key System" or

STR-16, "

Wiring Diagram - Without Intelligent Key System".

CAUTION:

Perform diagnosis under the cond ition that engine cannot start by the following procedure.

1. Remove fuel pump fuse.

2. Crank or start the engine (where possi ble) until the fuel pressure is released.

1.CHECK “S” CONNECTOR CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect starter motor connector.

3. Shift selector lever to “P” (Park) or “N” (Neutral) position.

4. Check voltage between starter motor harness connector F28 and ground.

Is the inspection result normal?

YES >> “S” circuit is OK. Further inspection is necessary. Refer to STR-21, "Work Flow (With GR8-1200

NI)" or STR-25, "Work Flow (Without GR8-1200 NI)".

NO >> GO TO 2.

2.CHECK HARNESS CONTINUI TY (OPEN CIRCUIT)

1. Disconnect IPDM E/R connector.

2. Check continuity between starter motor harnes s connector F28 and the IPDM E/R harness connector

E43.

3. Check continuity between starter motor connector F28 terminal S and ground.

Is the inspection result normal?

YES >> Further inspection is necessary. Refer to STR-21, "Work Flow (With GR8-1200 NI)" or STR-25,

"Work Flow (Without GR8-1200 NI)".

NO >> Repair or replace the harness or connectors.

(+) (-)

Condition Voltage

(Approx.)

Connector Terminal

F28 SGround When the ignition switch is in START position Battery voltage

Starter motor harness connector IPDM E/R harness connector

Continuity

Connector TerminalConnector Terminal

F28 SE43 6Yes

Connector Terminal –Continuity

F28 SGround No

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3202 of 3641

STC-18

< DTC/CIRCUIT DIAGNOSIS >

C1601 BATTERY POWER SUPPLY

DTC/CIRCUIT DIAGNOSIS

C1601 BATTERY POWER SUPPLY

DTC LogicINFOID:0000000012431953

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn ignition switch OFF and

wait at least 10 seconds before conducting the next test.

>> GO TO 2.

2.DTC REPRODUCTION PROCEDURE

With CONSULT

1. Turn the ignition switch OFF to ON.

2. Perform “Self Diagnostic Result” of “EPS”

Is DTC

“C1601” detected?

YES >> Proceed to diagnosis procedure. Refer to STC-18, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis ProcedureINFOID:0000000012431954

Regarding Wiring Diagram information, refer to STC-11, "Wiring Diagram".

1.CHECK EPS CONTROL UNIT GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect EPS control unit harness connector.

3. Check continuity between EPS contro l unit harness connector terminal and ground.

4. Connect EPS control unit harness connector.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair open circuit or short to ground or short to power in harness or connectors.

2.CHECK EPS CONTROL UNIT PO WER SUPPLY CIRCUIT (1)

1. Check voltage between EPS control unit harness connector terminal and ground.

DTC Display item Malfunction detected condition Possible cause

C1601 BATTERY VOLT When a power supply voltage to the EPS control unit

is maintained at 17.5 V or more or at less than 9V

continuously for five second or more. • Harness or connector

• EPS control unit

•Fuse

• Power supply system

•Battery

EPS control unit

—Con tin uit y

Connector Terminal

E23 18Ground Yes

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3203 of 3641

C1601 BATTERY POWER SUPPLYSTC-19

< DTC/CIRCUIT DIAGNOSIS >

C

DE

F

H I

J

K L

M A

B

STC

N

O P

2. Turn ignition switch ON. CAUTION:

Never start the engine.

3. Check voltage between EPS control unit harness connector and ground.

Is the inspection result normal?

YES >> GO TO 4.

NO >> GO TO 3.

3.CHECK EPS CONTROL UNIT POWER SUPPLY CIRCUIT (2)

1. Turn ignition switch OFF.

2. Check the 10A fuse No. 5.

3. Check the harness for open or short between EPS c ontrol unit harness connector M53 terminal 4 and the

10A fuse No. 5.

Is the inspection result normal?

YES >> Perform the trouble diagnosis for i gnition power supply circuit. Refer to PG-27, "Wiring Diagram

— Ignition Power Supply —".

NO >> Repair or replace malfunctioning component.

4.CHECK EPS CONTROL UNIT POWER SUPPLY CIRCUIT (3)

1. Turn ignition switch OFF.

2. Check voltage between EPS control unit harness connector terminal and ground.

3. Turn ignition switch ON. CAUTION:

Never start the engine.

4. Check voltage between EPS control unit harness connector and ground.

Is the inspection result normal?

YES >> GO TO 6.

NO >> GO TO 5.

5.CHECK EPS CONTROL UNIT POWER SUPPLY CIRCUIT (4)

1. Turn ignition switch OFF.

2. Check the 60A fusible link (J).

3. Check the harness for open or short between EPS c ontrol unit harness connector E23 terminal 17 and the

60A fusible link (J).

Is the inspection result normal?

YES >> Perform the trouble diagnosis fo r power supply circuit. Refer to PG-15, "Wiring Diagram — Bat-

tery Power Supply —".

EPS control unit

—Vol tag e

(Approx.)

Connector Terminal

M53 4Ground 0 V

EPS control unit

—Voltage

(Approx.)

Connector Terminal

M53 4GroundBattery voltage

EPS control unit

—Vo l ta g e

(Approx.)

Connector Terminal

E23 17GroundBattery voltage

EPS control unit —Vol tag e

(Approx.)

Connector Terminal

E23 17GroundBattery voltage

Revision: August 2015 2016 Versa Note

cardiagn.com